Paint spraying circulation line

A circulating line and paint spray booth technology, applied in the paint spray booth, spraying device, etc., can solve the problems of long length of paint spray line and occupation of production workshop area, so as to reduce area occupancy rate, reduce air pollution, and improve drying operation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

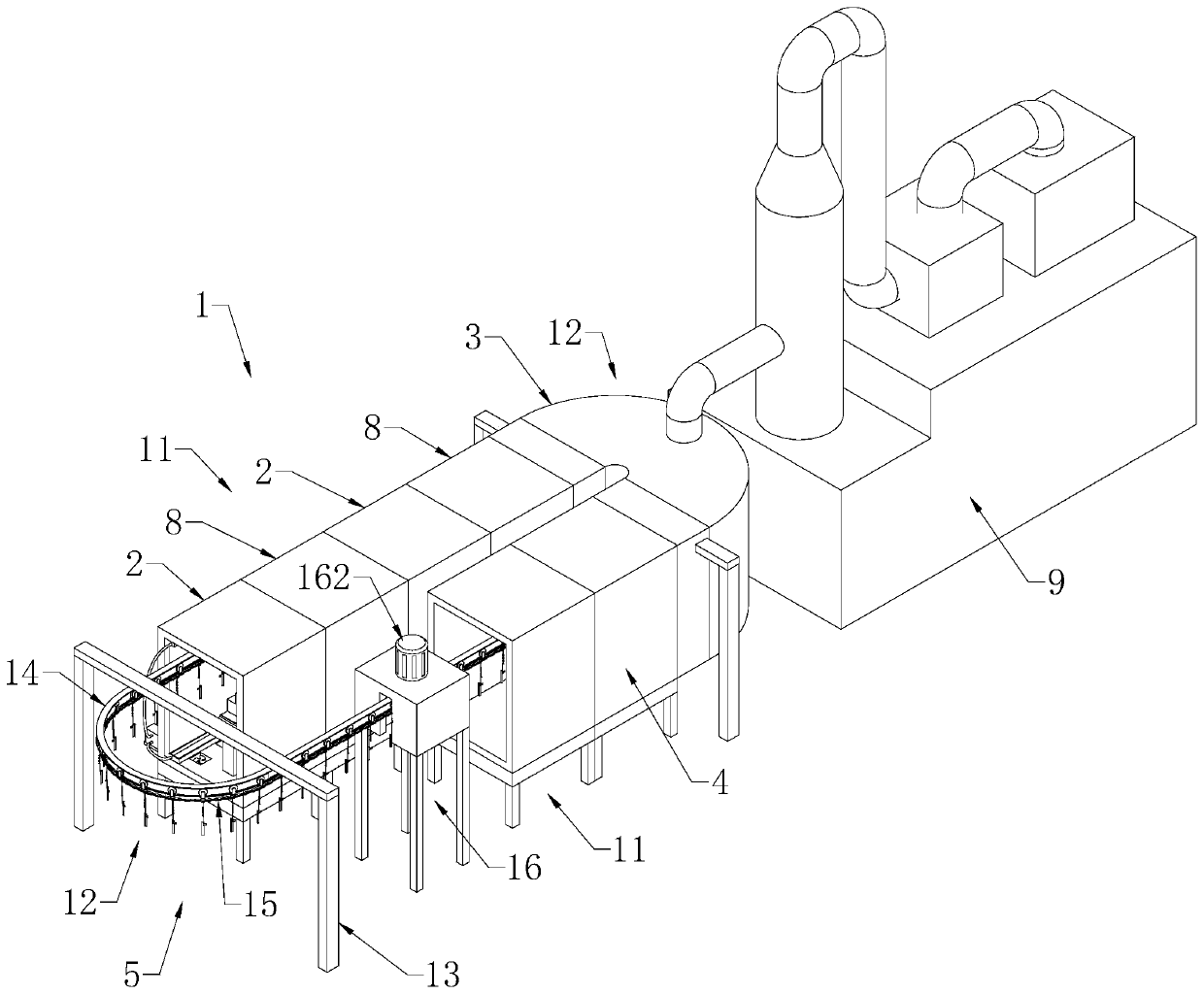

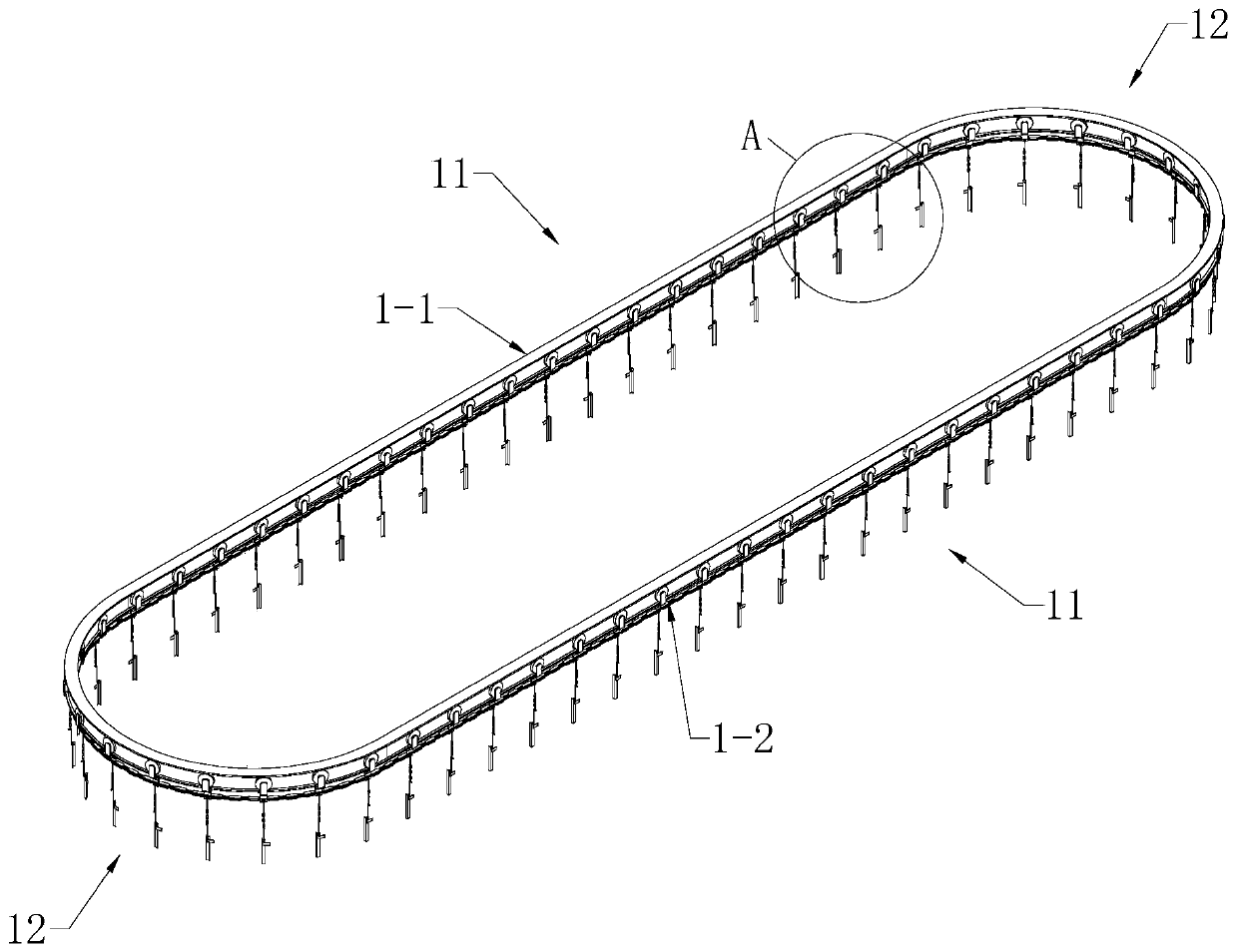

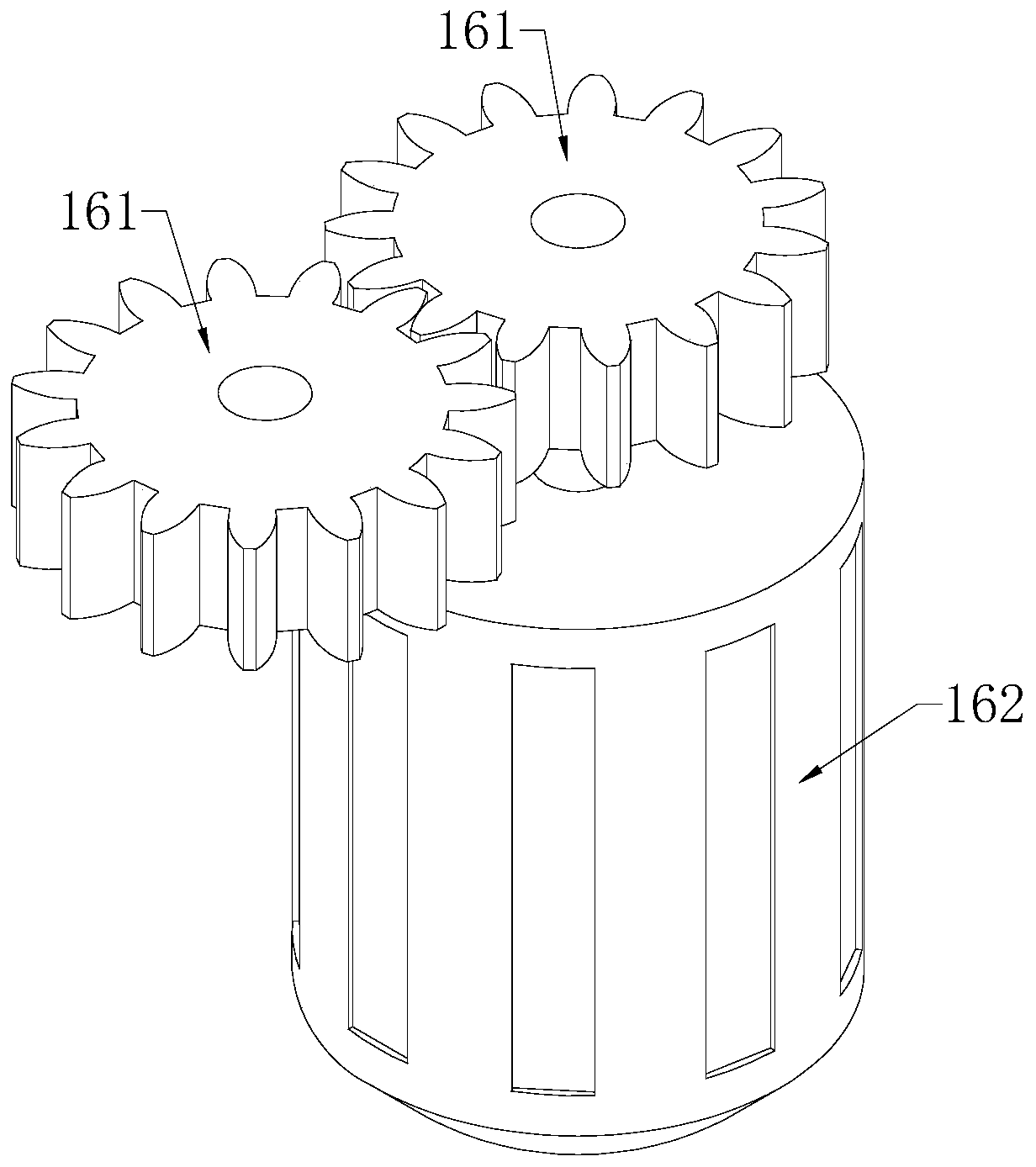

[0040] Such as figure 1 As shown, a painting circulation line includes a conveying line body 1, and the conveying line body 1 includes two straight line segments 11 and two arc line segments 12, the two straight line segments 11 are arranged in parallel, and the two arc line segments 12 are respectively connected to two Both ends of the straight line segment 11, and the two straight line segments 11 and the two arc line segments 12 together form a circular line body structure. Along the conveying direction of the conveying line body 1, a paint spraying room 2, a transitional drying room 3, a drying room 4, and a loading and unloading station 5 are successively built. The transitional drying chamber 3 and the loading and unloading station 5 are located on the two arc segments 12 of the conveying line body 1 . Loading and unloading workers or loading and unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com