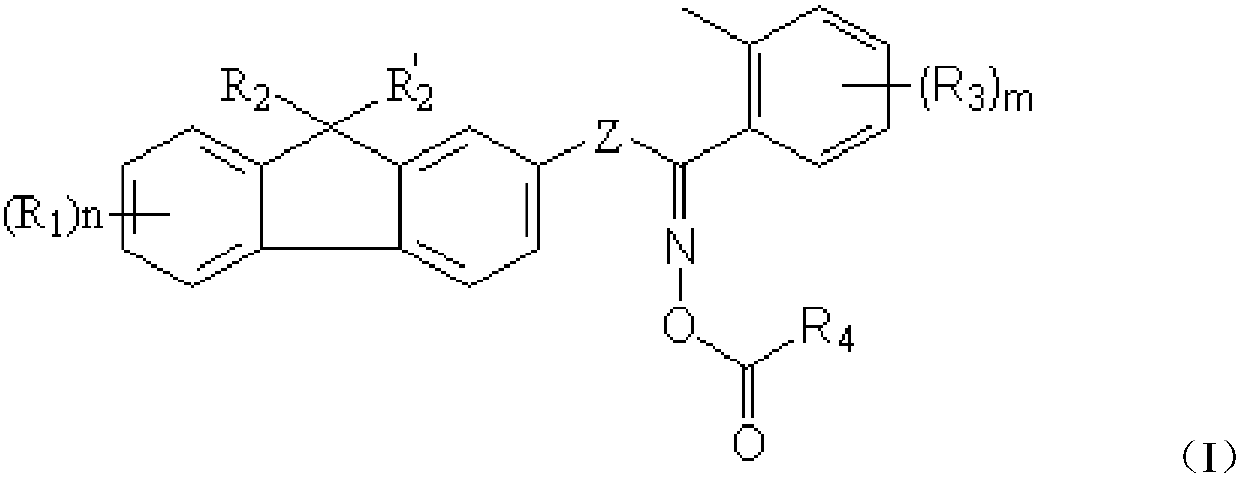

Fluoro-containing fluorene oxime ester photoinitiator, photocurable composition containing the same, and application thereof

A technology of photoinitiator and ester, which is applied in the field of organic synthesis, can solve the problems of poor surface dryness and easy migration, and achieve the effects of high initiation efficiency, good surface dryness, and good surface curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

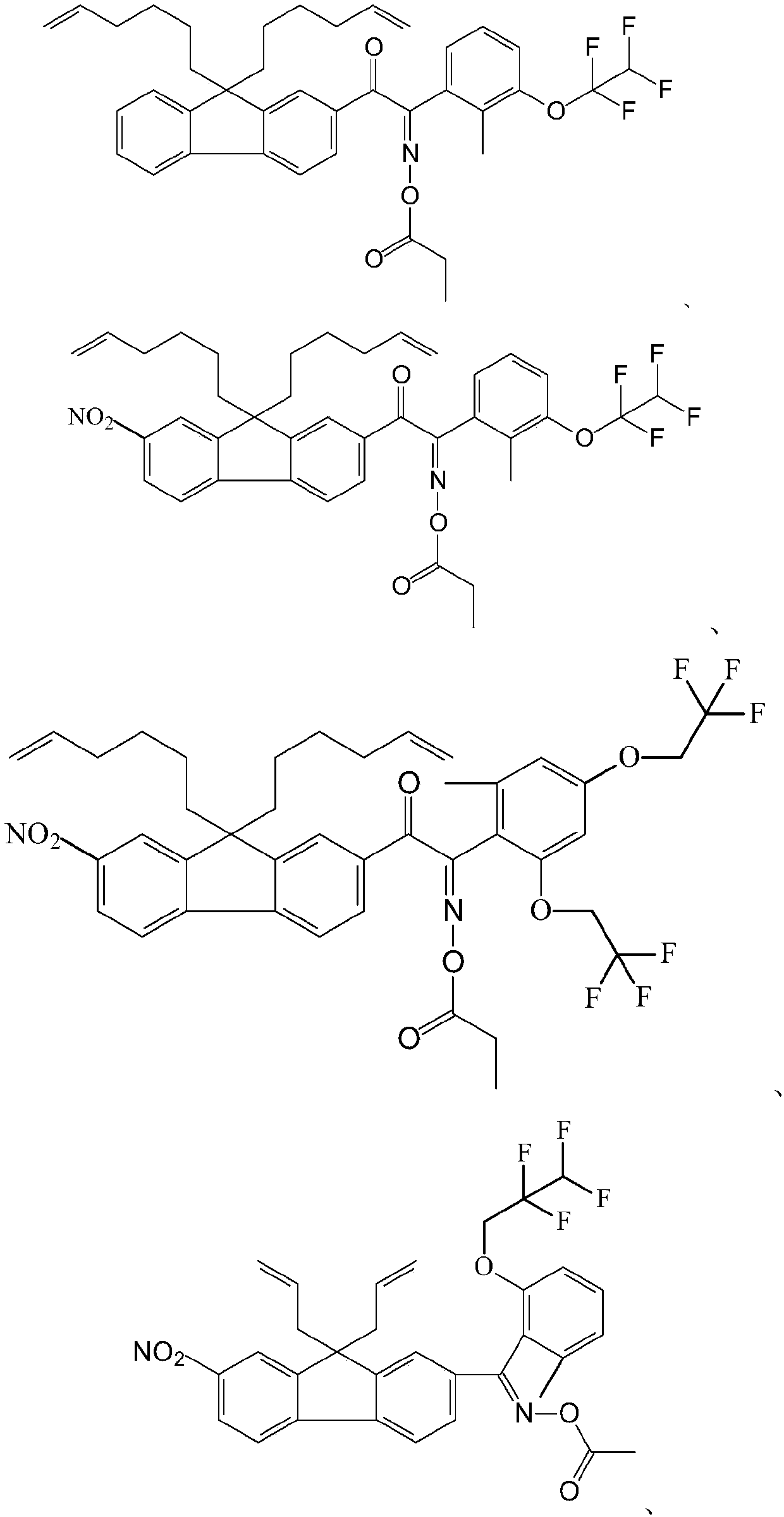

Examples

preparation example Construction

[0039] According to another aspect of the present invention, the present invention also provides the preparation method of the fluorine-containing fluorene oxime ester photoinitiator shown in above-mentioned general formula (I), comprises the following steps:

[0040] (1) Preparation of intermediate a

[0041] Under the catalysis of aluminum trichloride or zinc chloride, raw material a and raw material b undergo Friedel-Crafts acylation reaction in an organic solvent to obtain intermediate a; the synthetic route is as follows:

[0042]

[0043] A is empty or methylene.

[0044] (2) Preparation of intermediate b

[0045] When intermediate a is subjected to oximation reaction under the action of hydroxylamine hydrochloride and sodium acetate, A is empty, and intermediate b is generated. The synthetic route is as follows:

[0046]

[0047] When intermediate a is oximated with nitrite or nitrite in the presence of concentrated hydrochloric acid at normal temperature, A is ...

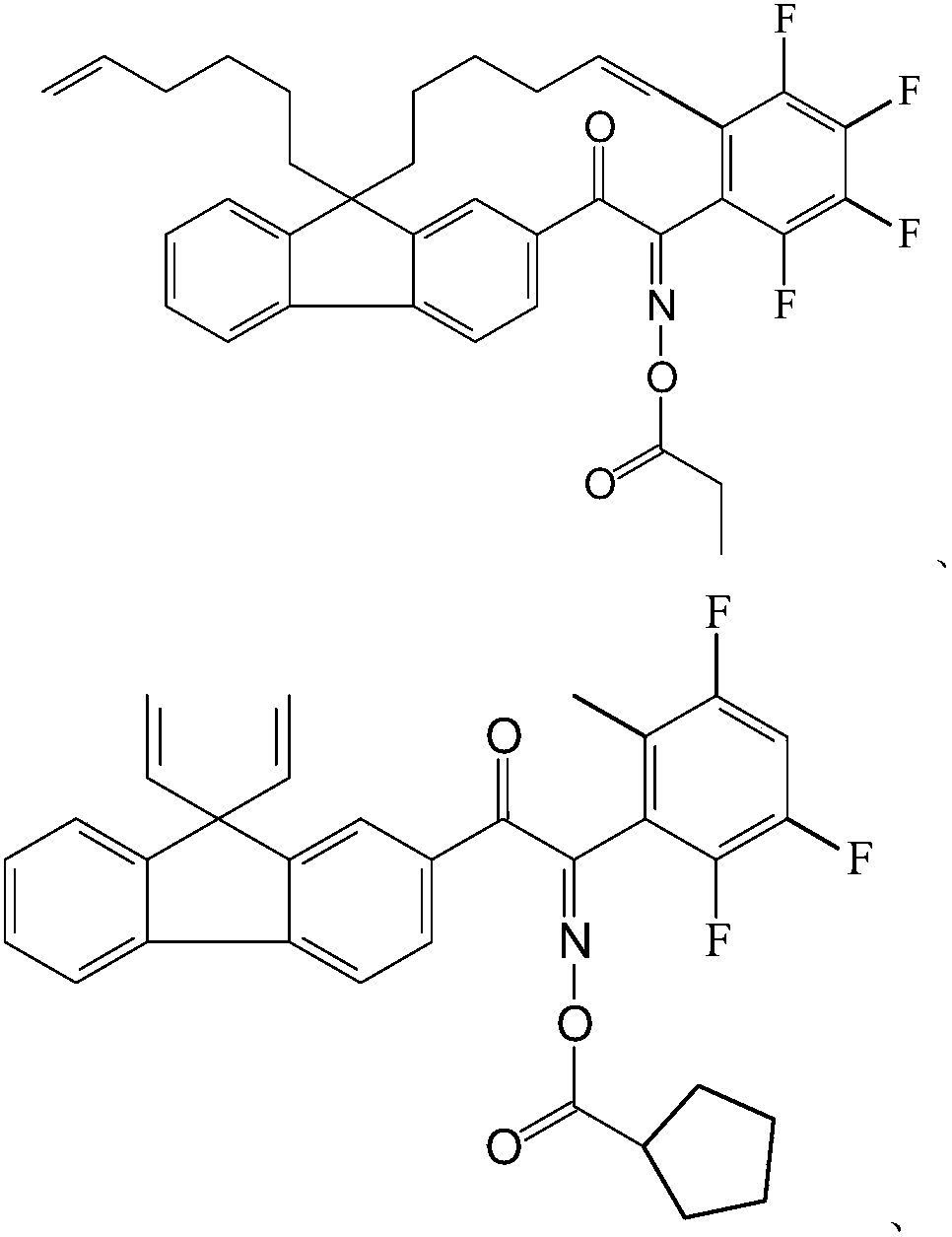

Embodiment 1

[0064] (1) Synthesis of Intermediate 1a

[0065] Add 66.1 g of intermediate 1a, 27.0 g of aluminum trichloride, and 100 mL of dichloromethane into a 500 mL four-necked flask, and lower the temperature of the raw materials in the four-necked flask to 0° C. using an ice-water bath. Then, under stirring, a mixed solution of 57.0 g of raw material 1b and 50 mL of dichloromethane was added dropwise to the above raw material, while controlling the temperature of the reaction system below 10° C., and the dropwise addition was completed within 2 hours. After the dropwise addition, continue to stir for 2h, and follow the liquid phase to complete the reaction. Then the above reaction system is slowly poured into the dilute hydrochloric acid made of 400g ice water and 50mL concentrated hydrochloric acid (37%), stir while adding, then pour it into a separatory funnel, separate the lower dichloromethane layer, and use Continue to wash the aqueous layer with 50 mL of dichloromethane, and c...

Embodiment 2

[0080] (1) Synthesis of Intermediate 2a

[0081] Add 72.5 g of intermediate 2a, 27.0 g of aluminum trichloride, and 100 mL of dichloromethane into a 500 mL four-necked flask, and use an ice-water bath to lower the temperature of the raw materials in the four-necked flask to 0°C. Then, under stirring, a mixed solution of 54.5 g of raw material 2b and 50 mL of dichloromethane was added dropwise to the above raw material, while the temperature of the reaction system was controlled below 10° C., and the dropwise addition was completed within 2 hours. After the dropwise addition, continue to stir for 2h, and follow the liquid phase to complete the reaction. Then the above reaction system is slowly poured into the dilute hydrochloric acid made of 400g ice water and 50mL concentrated hydrochloric acid (37%), stir while adding, then pour it into a separatory funnel, separate the lower dichloromethane layer, and use Continue to wash the water layer with 50 mL of dichloromethane, combi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com