Room temperature solidified expansion type fire retardant coating and method for preparing the same

A fire retardant coating, room temperature curing technology, used in fire retardant coatings, epoxy resin coatings, coatings, etc., can solve the problem of chemical corrosion resistance, water resistance and solvent resistance, coating loss of fire resistance, film-forming material force Poor and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

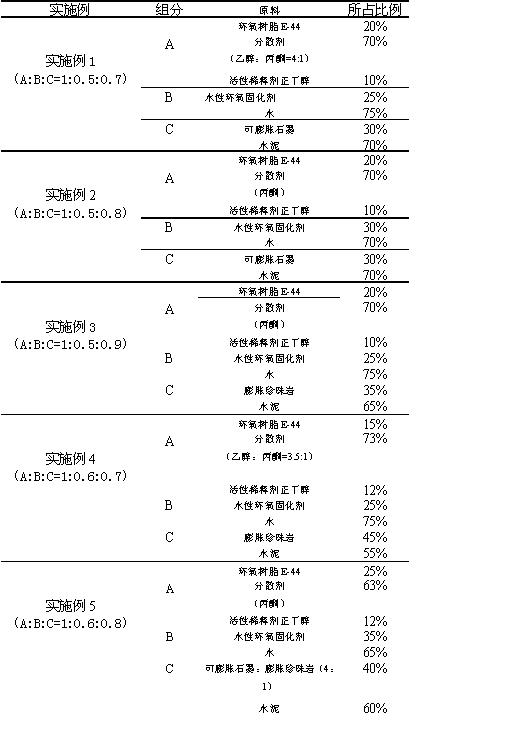

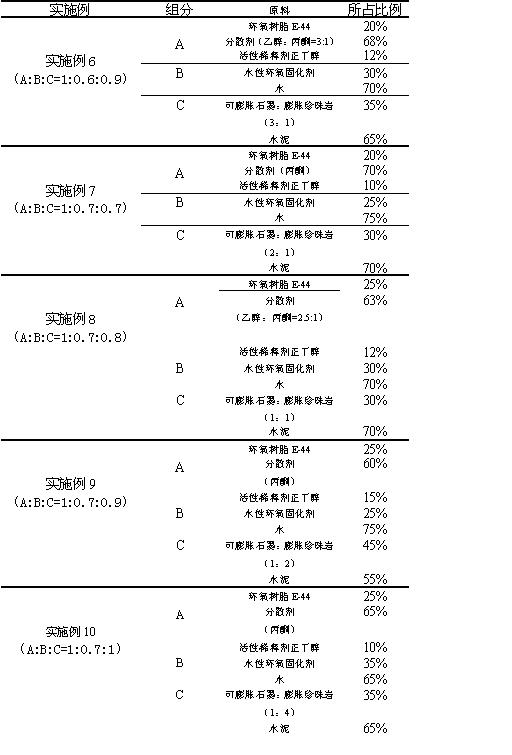

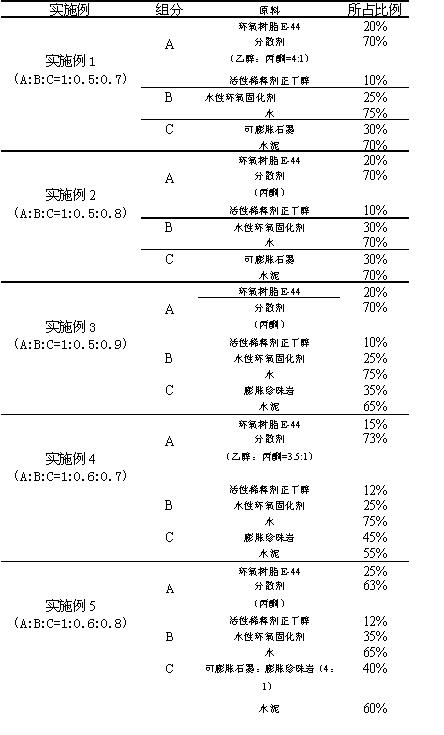

[0015] Example 1: Coating formulation such as figure 1 shown.

[0016] Preparation:

[0017] Add 20 parts of epoxy resin E-44 and 70 parts of a mixed dispersant of absolute ethanol and acetone into the container, stir mechanically for 5 minutes at room temperature, so that all the epoxy resin is dissolved in the dispersant, and then add 10 parts of n-butyl alcohol, and stir evenly to obtain the component A of the coating;

[0018] Take another container, add 25 parts of xy-200 water-based epoxy curing agent and 75 parts of water, stir mechanically for 5 minutes at room temperature, so that the water-based epoxy curing agent is completely dissolved in water to obtain coating component B;

[0019] Take 30 parts of expanded graphite and 70 parts of cement and mix them evenly to prepare component C of the coating

[0020] The components A, B, and C of the coating are mixed in a ratio of 1:0.5:0.7, and mechanically stirred evenly at normal temperature to prepare a new type of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com