Hybrid filler load type anti-aging agent, and preparation method and application thereof

A supported and antioxidant technology, applied in the field of hybrid filler supported antioxidants and their preparation, can solve the problems of easy migration and migration of ammonia antioxidants, and achieve the effects of excellent solvent resistance, not easy to migrate, and good anti-aging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

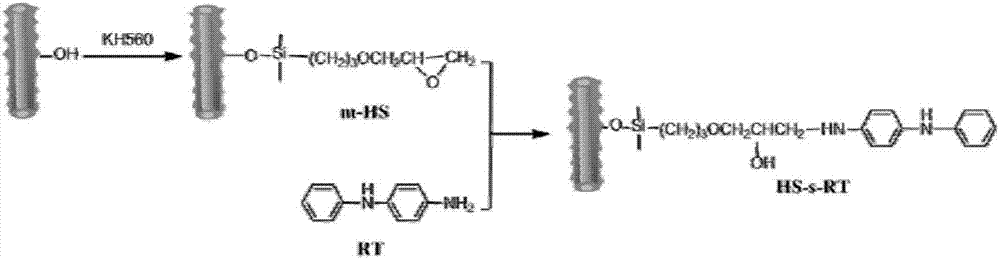

[0035] 10g HNTs-g-SiO 2 (HS) and 0.8g silane coupling agent γ-(2,3-glycidoxy)propyltrimethoxysilane were added to a 500mL three-necked flask, reacted at 70°C for 10 hours, cooled to room temperature, and The intermediate product (m-HS) was obtained after drying under low temperature. Then add 0.5g RT (N-phenyl-p-phenylenediamine), react at 50°C for 8h, and then dry at 60°C to obtain a loaded antioxidant, marked as HS-s-RT.

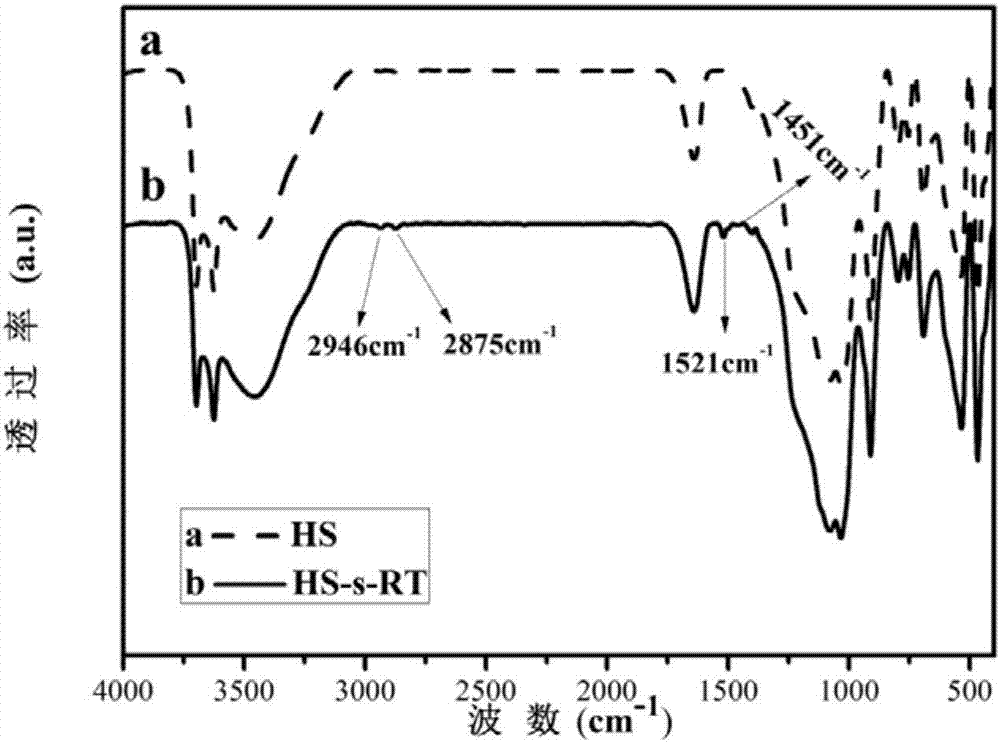

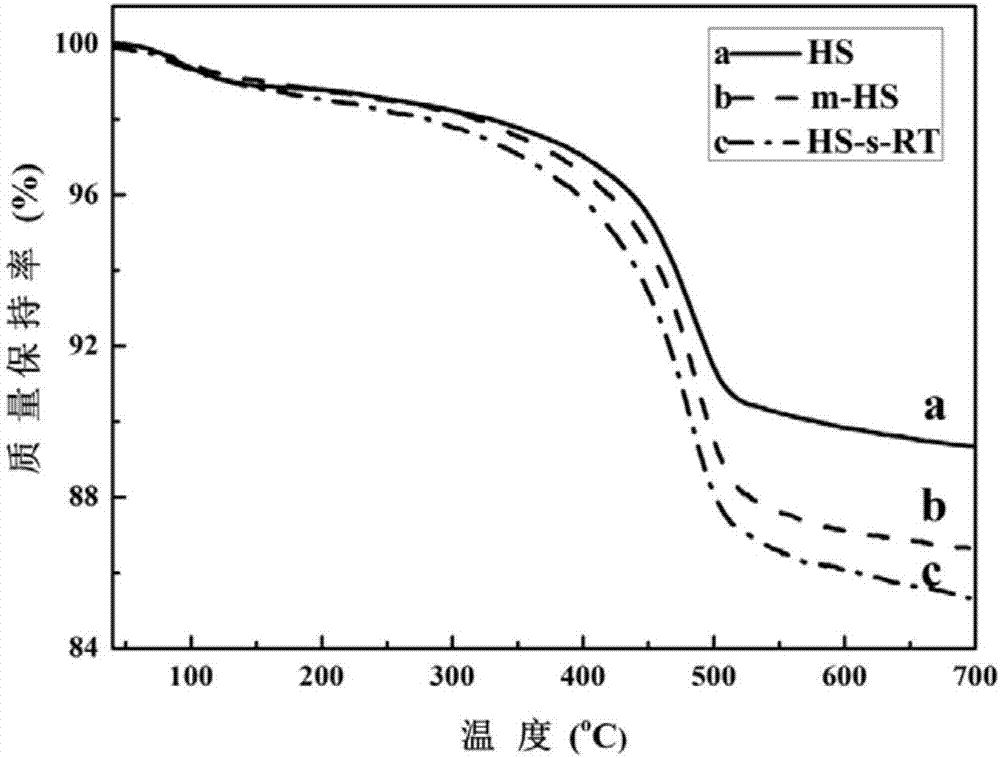

[0036] The infrared spectrum of the loaded anti-aging agent prepared in this embodiment after ethanol extraction is as follows: figure 2 As shown in curve b, at 2946cm -1 and 2875cm -1 is the stretching vibration absorption peak of methylene, and at 1521cm -1 There is a carbon skeleton C=C bending vibration absorption peak of the aromatic ring. The thermogravimetric analysis diagram of the synthetic product of this embodiment is as follows image 3 shown. Combining the infrared spectrum and thermogravimetric analysis, it can be seen that RT has bee...

Embodiment 2

[0038] 10g HNTs-g-SiO 2 (HS) and 1g of silane coupling agent γ-(2,3-glycidoxy)propyltrimethoxysilane were added to a 500mL three-neck flask, reacted at 80°C for 12 hours, cooled to room temperature, and dried at 70°C Then the intermediate product (m-HS) is obtained. Add 1g of RT (N-phenyl-p-phenylenediamine) to react at 60°C for 12h, and dry at 50°C to obtain a loaded antioxidant, marked as HS-s-RT.

[0039] Table 1 shows the basic formula for preparing styrene-butadiene rubber composites using γ-(2,3-glycidoxy)propyltrimethoxysilane as a loaded antioxidant HS-s-RT. The specific process of the preparation of styrene-butadiene rubber composite materials: according to the order of adding rubber (SBR), activator (ZnO+St), filler, accelerator, anti-aging agent and sulfur, they are mixed uniformly on a double-roller mill, and then mixed at 160 °C vulcanization to obtain styrene-butadiene rubber composites.

[0040] Table 1

[0041]

[0042] Units in Table 1 are parts by mass...

Embodiment 3

[0046] 10g HNTs-g-SiO 2 (HS) and 0.9g silane coupling agent γ-(2,3-glycidoxy)propyltrimethoxysilane were added to a 500mL three-necked flask, reacted at 90°C for 24 hours, cooled to room temperature, and The intermediate product (m-HS) was obtained after drying under low temperature. Then add 2g of RT (N-phenyl-p-phenylenediamine) and react at 70°C for 10h, then dry at 70°C to obtain a loaded antioxidant, marked as HS-s-RT.

[0047] Table 2

[0048]

[0049] According to the formula in Table 2, after adding the prepared anti-aging agent to styrene-butadiene rubber, the oxidation induction period was measured. Compared with SBR / m-HS / 4010NA, the oxidation induction period of SBR / HS-s-RT composite material was from 109.45min increased to 122.73min, and the aging resistance of the styrene-butadiene rubber composite was significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com