Painting circulating line used for civil air defense door

A technology of civil air defense doors and circulation lines, which is applied in the direction of spray paint booths, spraying devices, etc., can solve the problems of low work efficiency of civil air defense doors, achieve the effects of improving drying operation efficiency, efficient drying operations, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

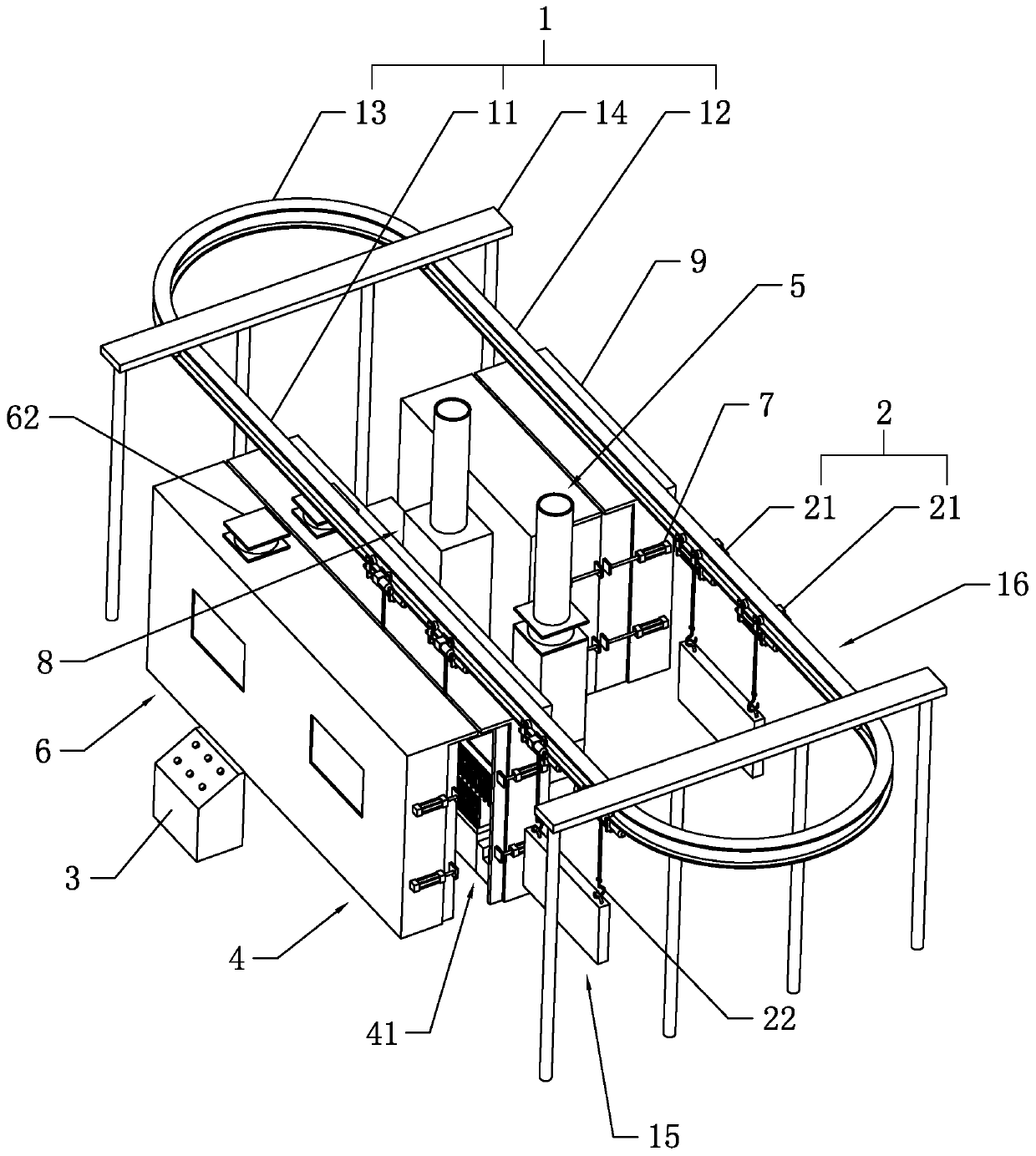

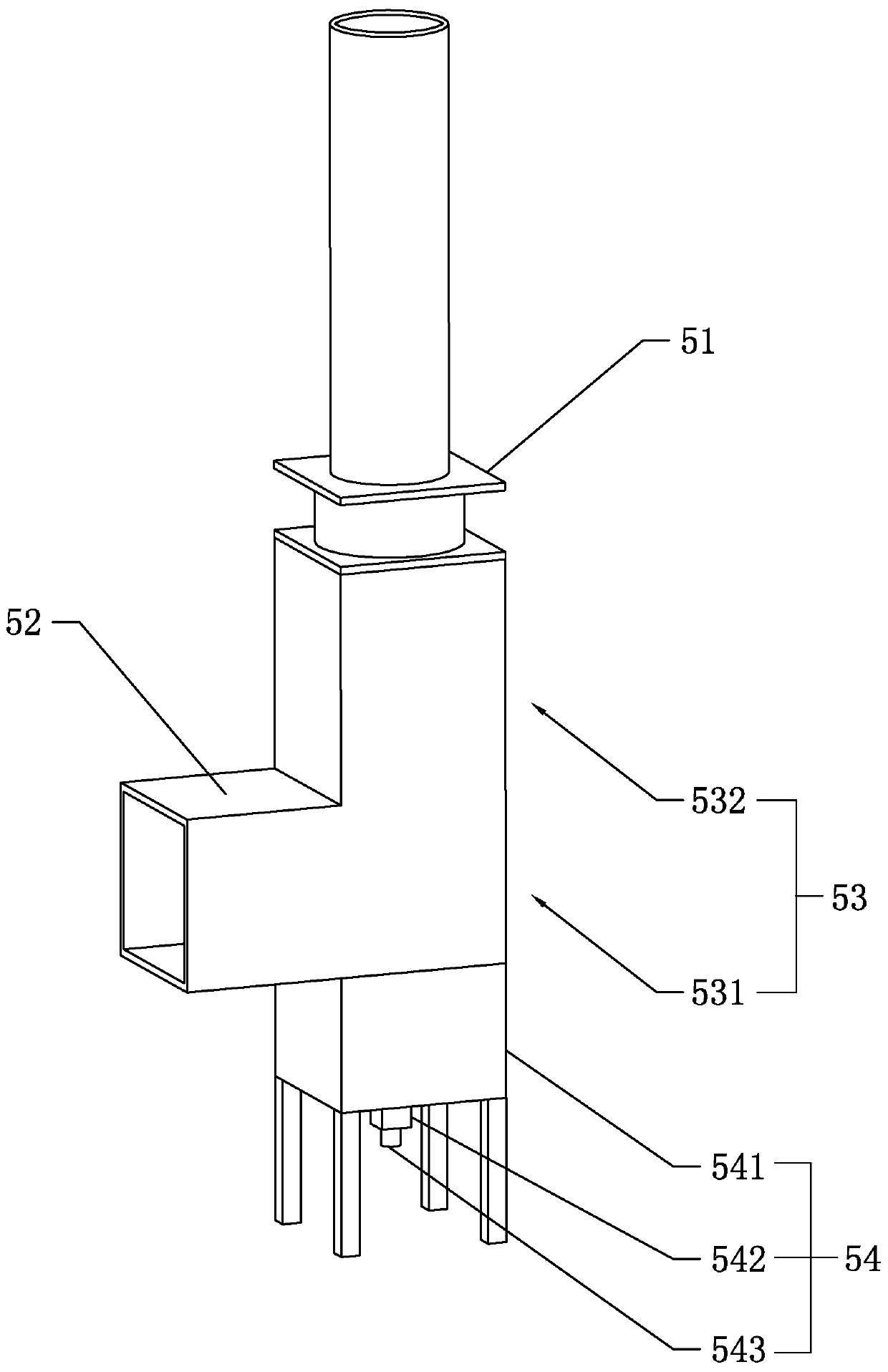

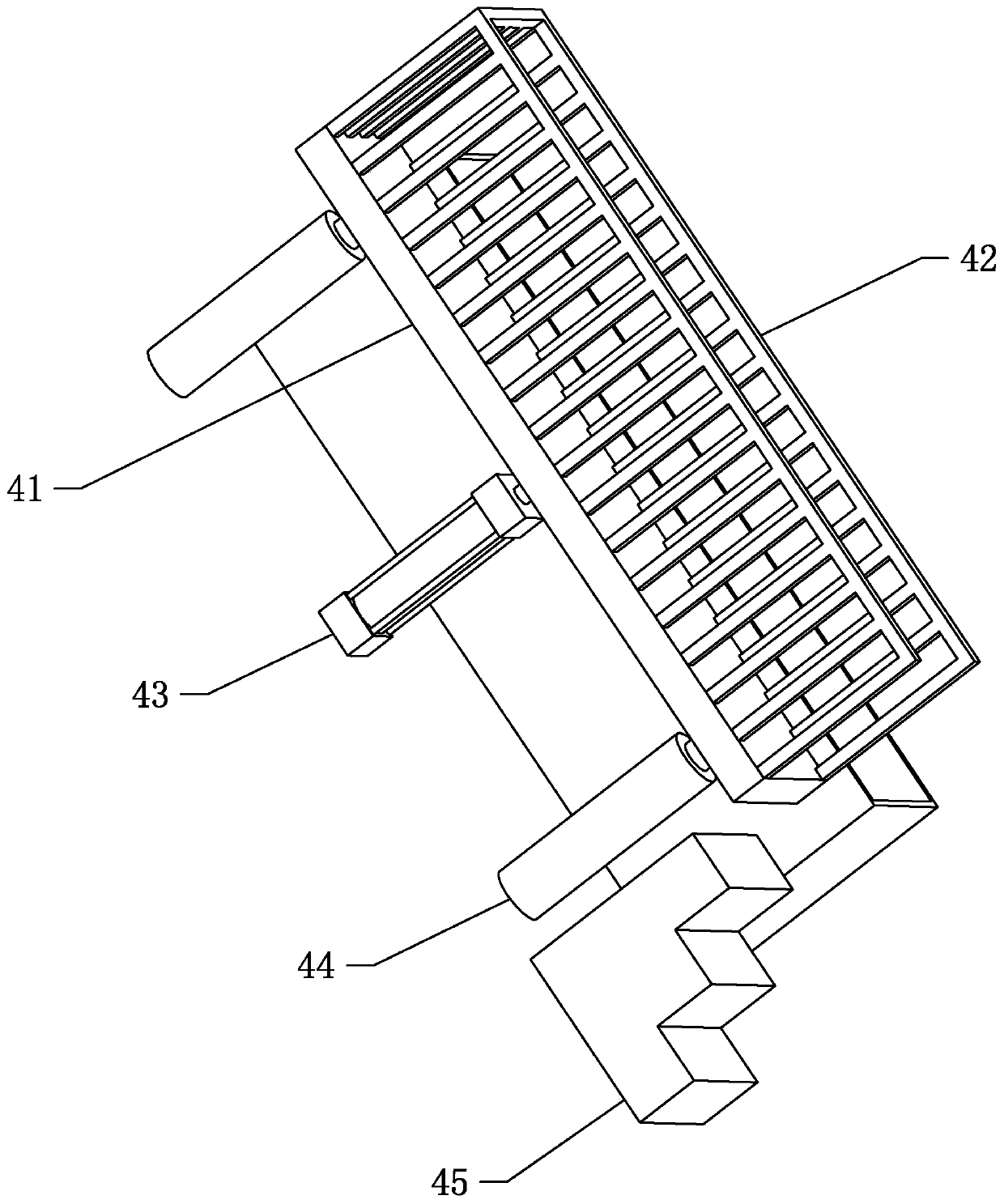

[0039] like figure 1As shown, a painting circulation line for civil air defense doors includes a conveying loop 1, and the conveying loop 1 includes a feeding line body 11, a return line body 12 and two loop line bodies 13, and the feed line body 11 and the return line body 12 are arranged in parallel, and two circular wire bodies 13 are respectively fixedly connected with the two ends of the feeding wire body 11 and the feeding wire body 12 to form the structure of the circulating wire body 13 . Along the conveying direction of the conveying loop line 1, there are paint spraying room 4, primary drying room 6, drying room 9, loading station 15 and unloading station 16, and the painting room 4 and drying room 9 are located at the feeding On the line body 11 and the return line body 12, and the initial drying chamber 6 is located at one end of the paint sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com