Wet moulding sand used for iron casting high density molding and preparation method of wet moulding sand

A high-density, cast-iron technology, applied in casting molding equipment, molds, cores, etc., can solve the problems of high price, poor comprehensive performance, affecting the quality of castings, etc., to achieve low manufacturing costs, improve fluidity, and ensure comprehensive Effects of performance and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

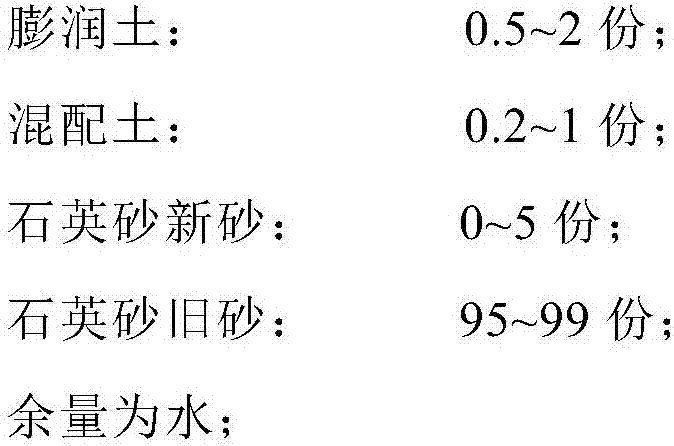

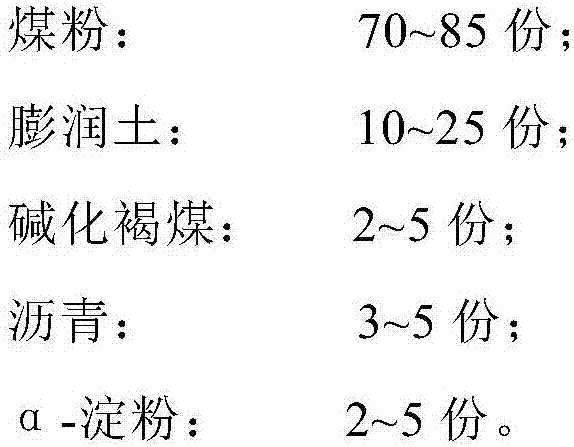

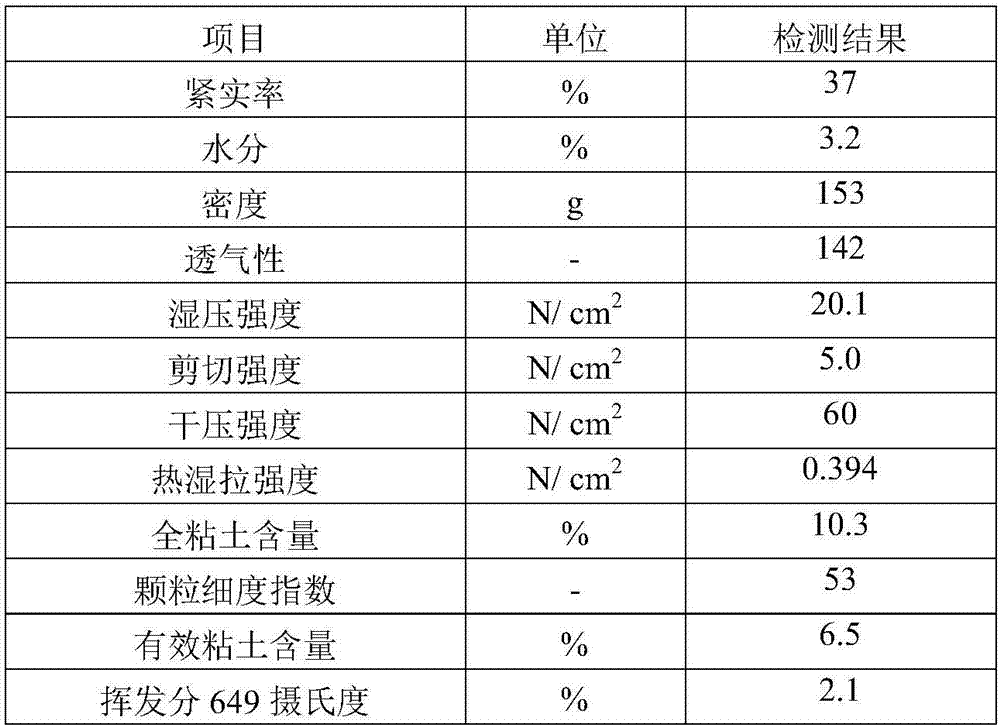

[0026] This embodiment relates to a green sand for high-density molding of iron castings, which is made of the following raw materials in parts by weight: bentonite 0.5-2, mixed soil 0.2-1 (the mixed soil is composed of high-efficiency coal powder 70-85, bentonite 10-25, alkalized lignite 2-5, asphalt 3-5, alpha starch 2-5), quartz sand new sand 0-5, quartz sand old sand 95-99, water balance.

[0027] A method for preparing green sand for high-density molding, comprising the following steps:

[0028] (1) The old sand of quartz sand has been treated by screening, magnetic separation, water replenishment, cooling, and sand awakening to ensure that the water content of the old sand is kept at 60-70% of the water content of the molding sand before mixing, preferably at 1.5-2.5%, such as molding sand The moisture requirement is 3.2%, and the moisture content of the old sand is stable at 1.92-2.24%. The sand temperature of the old sand is not higher than room temperature by 15°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com