Environment-friendly fireproof coating and preparation method thereof

A fire-retardant coating and environmental protection technology, applied in fire-resistant coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of cumbersome methods, easy to fall off, weak coating adhesion, etc., to achieve low thermal conductivity, good thermal insulation, Good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

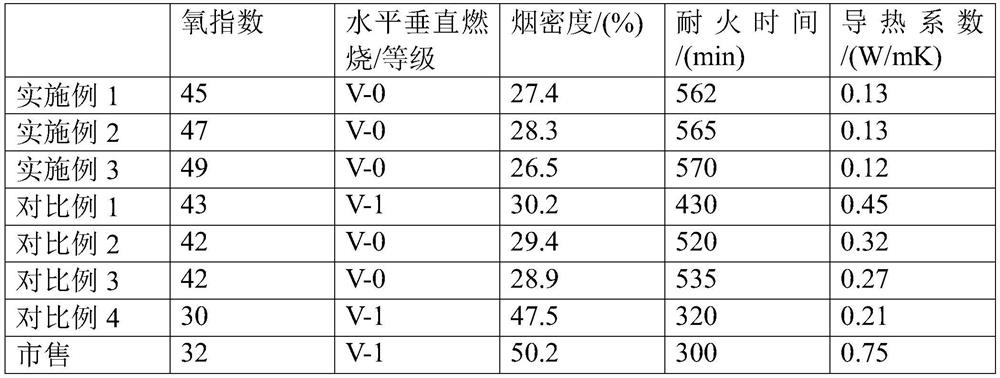

Examples

Embodiment 1

[0041] Raw material composition (parts by weight): 70 parts of intercalation phase change energy storage material modified core-shell emulsion, 5 parts of low molecular weight epoxy resin, 3 parts of phenolic fiber, 1 part of triphenyl phosphate, 1 part of pigment yellow 2GLT, o-phthalic 0.5 part of dioctyl diformate, 0.5 part of polyurethane, 0.1 part of liquid silicone rubber, 0.1 part of sodium diamyl succinate sulfonate, and 0.1 part of polyethylene glycol 200.

[0042] In this embodiment, the core-shell emulsion modified by the intercalation phase change energy storage material is bentonite-urea intercalation compound modified acrylate core-shell emulsion;

[0043] The low molecular weight epoxy resin in this embodiment is a low molecular weight bisphenol F epoxy resin, and the average molecular weight is less than 700.

[0044] The preparation method of bentonite-urea intercalation compound modified acrylate core-shell emulsion is as follows:

[0045] S1. Preparation of...

Embodiment 2

[0059] Raw material composition (parts by weight): 120 parts of intercalation phase change energy storage material modified core-shell emulsion, 10 parts of low molecular weight epoxy resin, 10 parts of phenolic fiber, 3 parts of chlorobridge anhydride, 2 parts of antimony white powder, chlorinated biphenyl 1 part, 2 parts of attapulgite, 1 part of polysulfide rubber, 0.5 part of polyglycerol ester, 2 parts of ethylene bis stearamide.

[0060] In this embodiment, the core-shell emulsion modified by the intercalation phase change energy storage material is bentonite-urea intercalation compound modified acrylate core-shell emulsion;

[0061] The low molecular weight epoxy resin in this embodiment is a low molecular weight bisphenol F epoxy resin, and the average molecular weight is less than 700.

[0062] The preparation method of bentonite-urea intercalation compound modified acrylate core-shell emulsion is as follows:

[0063] S1. Preparation of bentonite-urea intercalation c...

Embodiment 3

[0077] Raw material composition (parts by weight): 100 parts of intercalation phase change energy storage material modified core-shell emulsion, 7 parts of low molecular weight epoxy resin, 6 parts of phenolic fiber, 2 parts of triphenyl phosphate, 1.5 parts of rutile titanium dioxide, 0.7 parts of dibutyl phthalate, 1.5 parts of styrene-butadiene rubber, 0.5 parts of ABS resin, 0.3 parts of polyacrylamide, 1.2 parts of polyethylene glycol 400.

[0078] In this embodiment, the core-shell emulsion modified by the intercalation phase change energy storage material is bentonite-urea intercalation compound modified acrylate core-shell emulsion;

[0079] The low molecular weight epoxy resin in this embodiment is a low molecular weight bisphenol F epoxy resin, and the average molecular weight is less than 700.

[0080] The preparation method of bentonite-urea intercalation compound modified acrylate core-shell emulsion is as follows:

[0081] S1. Preparation of bentonite-urea inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com