Dish washer/dryer

A tableware washing and drying machine technology, which is applied to the parts of the tableware washing machine/rinsing and washing machine, etc., can solve the problems that the air volume cannot be discharged for cooling, and cannot eliminate the hot air feeling, etc., and achieves the effect of improving drying performance and reducing temperature and humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

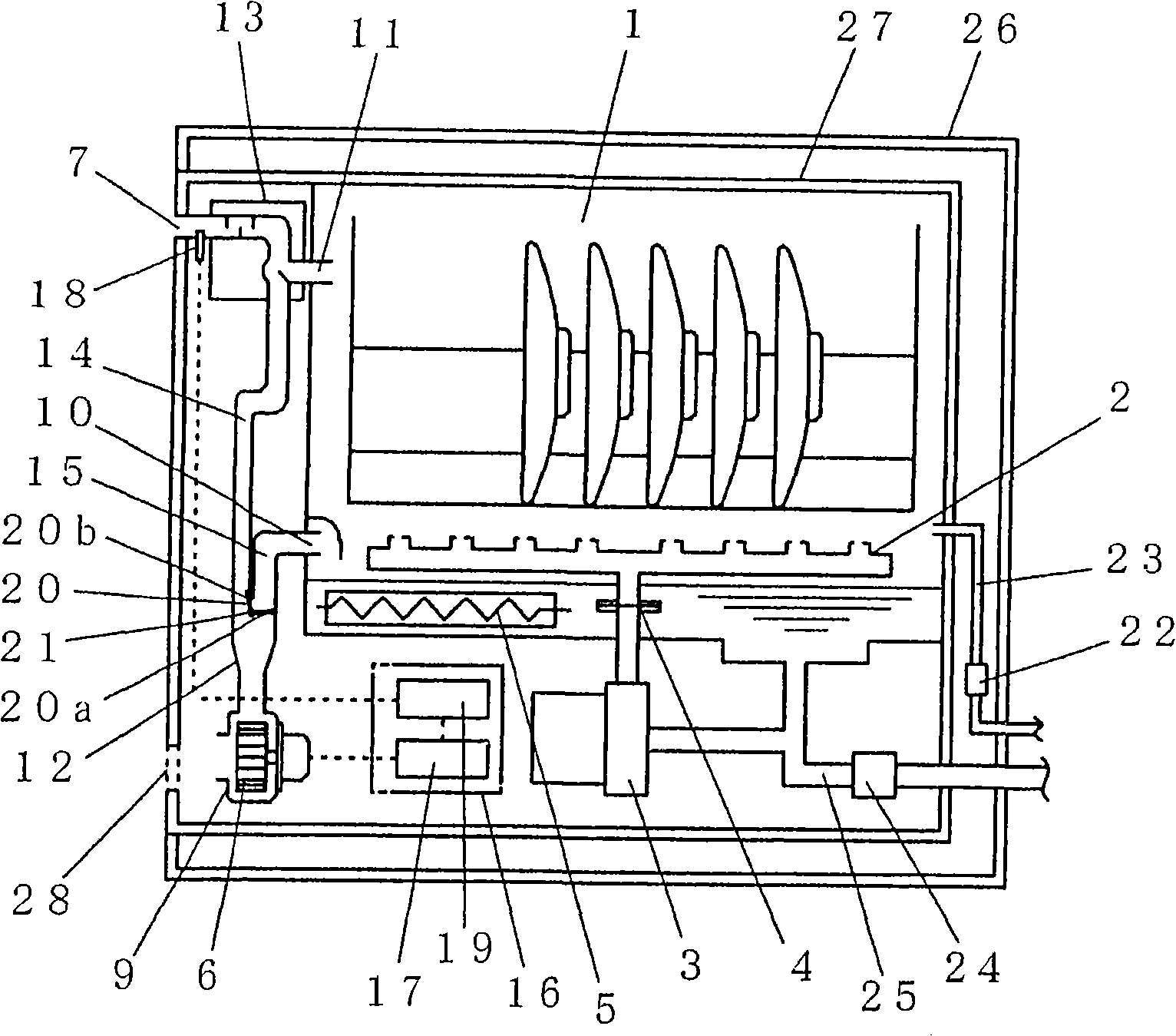

[0040] figure 1 It is a structural cross-sectional view of the dish washer and dryer according to the first embodiment of the present invention.

[0041] Such as figure 1 As shown in , the tableware washing and drying machine of this embodiment is provided with a washing tank 1 for accommodating tableware and other objects to be cleaned. Below the washing tank 1, a washing device 4 and a heating device 5 for heating the washing water to increase its temperature are provided. . The cleaning device 4 is provided with a cleaning nozzle 2 for spraying cleaning water onto the object to be cleaned and circulating the cleaning water, and a cleaning pump 3 for pressurizing the cleaning water. In addition, the dish washing and drying machine of the present embodiment is also provided with a drying device 9 for discharging the moisture in the washing tank 1 to make the inside of the washing tank 1 dry. A blower 6 which is referred to as "outside air" for short, and an exhaust port ...

Embodiment approach 2

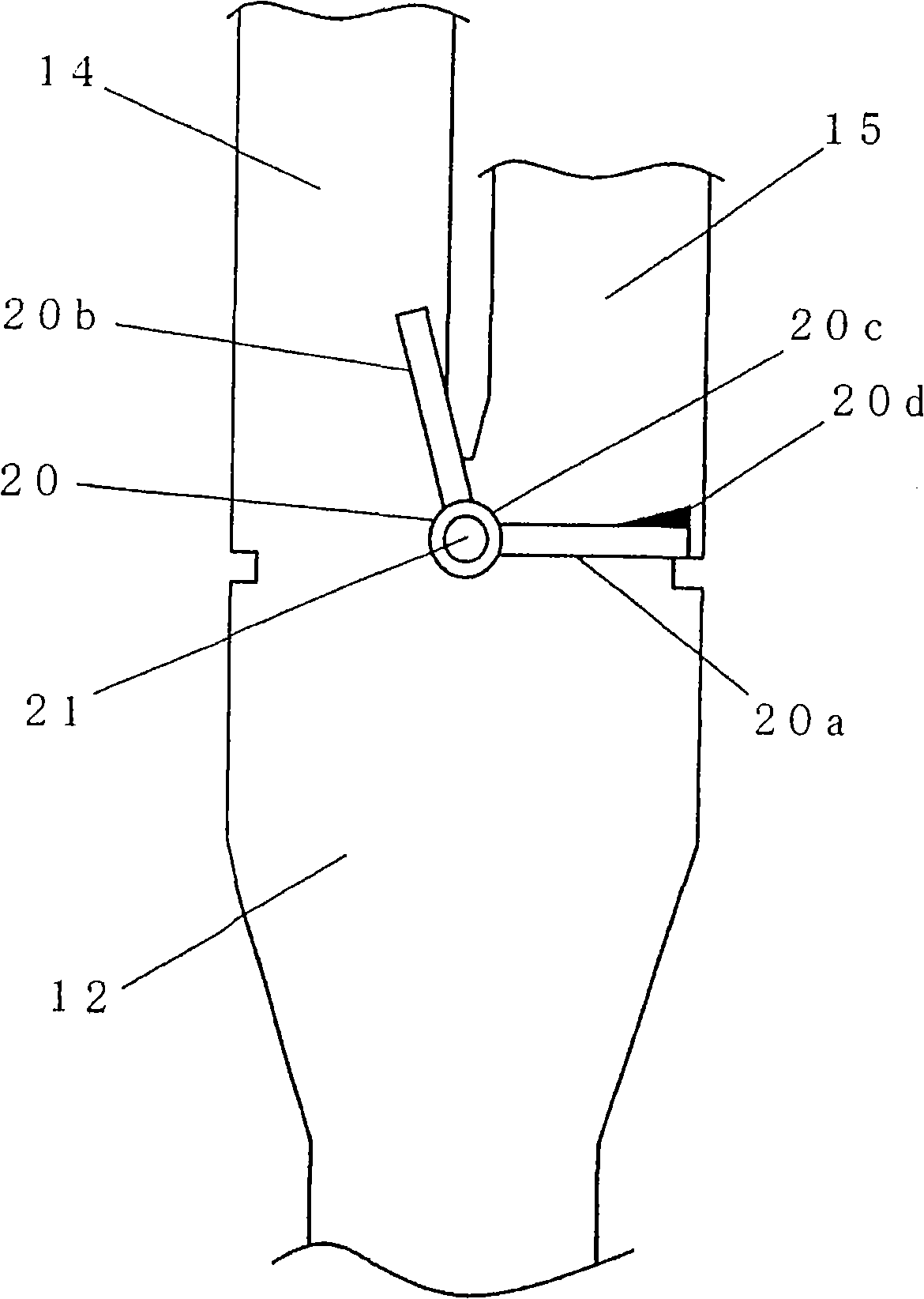

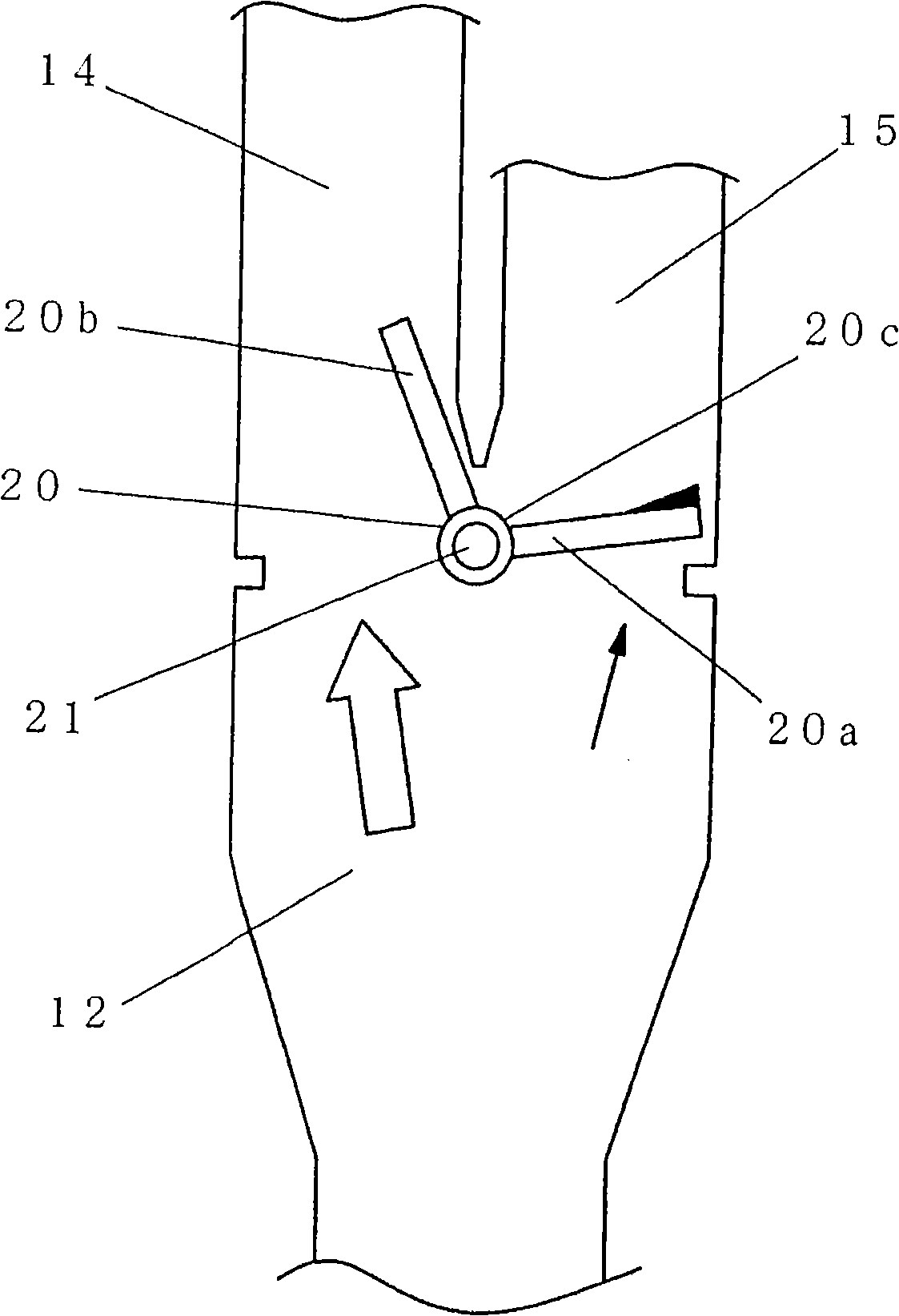

[0089] Figure 7 It is a schematic diagram of the damper structure in the second embodiment of the present invention.

[0090] Figure 7 neutralize Figure 1 to Figure 6 The same components or the same functional blocks in the illustrated embodiment 1 are marked with the same symbols, their repeated descriptions are omitted, and only the differences are focused on for description.

[0091] Figure 7The damper 20 shown in is provided with a posture setting device 32 that can change the coupling posture of the cleaning tank damper 20a and the external air damper 20b, so that the coupling angle α between the cleaning tank damper 20a and the external air damper 20b can be changed. , the relative position between each other can change.

[0092] In order to change the coupling posture according to the temperature of the washing tank 1, the posture setting device 32 uses a shape memory body 33 whose shape can be changed according to the temperature. The support shaft 21 of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com