A roasting method of k326 variety based on the quality of fresh tobacco leaves

A roasting method and technology of fresh tobacco leaves, applied in the field of flue-cured tobacco roasting, can solve the problems of increasing the proportion of variegated tobacco, low enthusiasm of K326, easy to hang ash, etc., to overcome the fear of difficulties, shorten the roasting time, and improve the roasting efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

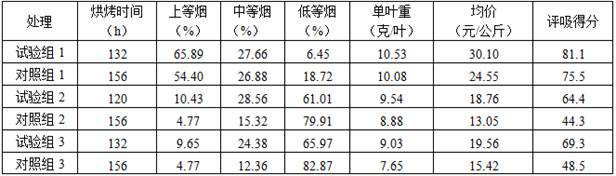

Examples

Embodiment 1

[0053] A method for roasting K326 varieties based on the quality of fresh tobacco leaves, comprising the following steps:

[0054] 1) Harvesting of fresh tobacco leaves: Harvest mature tobacco leaves of K326 variety in Jiuxi Town, Jiangchuan District, Yuxi City; the maturity of harvesting is light yellow leaf color, main veins are all white and shiny, branch veins turn white, leaf tips and leaf margins roll down, leaves The surface is wrinkled, with mature spots, and most of the hairs fall off; the tobacco leaves mentioned are the leaves in the middle of the tobacco plant;

[0055] 2) Determination of quality indicators of fresh tobacco leaves: the harvested K326 variety tobacco leaves were tested for quality indicators of fresh tobacco leaves, and the following indicators were obtained: the area of fresh tobacco leaves was 1.56 m 2 , the SPAD value is 24.38, and the starch content is 25.80%; Further measurement, the fresh weight of single leaf is 95.34 g, and the dry weight...

Embodiment 2

[0062] A method for roasting K326 varieties based on the quality of fresh tobacco leaves, comprising the following steps:

[0063] 1) Harvesting of fresh tobacco leaves: Harvest mature tobacco leaves of K326 variety in Jiuxi Town, Jiangchuan District, Yuxi City; the maturity of harvesting is light yellow leaf color, main veins are all white and shiny, branch veins turn white, leaf tips and leaf margins roll down, leaves The surface is wrinkled, with mature spots, and most of the hairs fall off; the tobacco leaves mentioned are the leaves in the middle of the tobacco plant;

[0064] 2) Determination of quality indicators of fresh tobacco leaves: The quality indicators of fresh tobacco leaves were measured for the harvested K326 variety tobacco leaves, and the following indicators were obtained: the area of fresh tobacco leaves was 1.08m 2 , the SPAD value is 20.7, and the starch content is 15.67%; Further measurement, the fresh weight of single leaf is 64.53 g, and the dry we...

Embodiment 3

[0071] A method for roasting K326 varieties based on the quality of fresh tobacco leaves, comprising the following steps:

[0072] 1) Harvesting of fresh tobacco leaves: Harvest mature tobacco leaves of K326 variety in Jiuxi Town, Jiangchuan District, Yuxi City; the maturity of harvesting is light yellow leaf color, main veins are all white and shiny, branch veins turn white, leaf tips and leaf margins roll down, leaves The surface is wrinkled, with mature spots, and most of the hairs fall off; the tobacco leaves mentioned are the leaves in the middle of the tobacco plant;

[0073]2) Determination of quality indicators of fresh tobacco leaves: The quality indicators of fresh tobacco leaves were measured for the harvested K326 variety tobacco leaves, and the following indicators were obtained: the area of fresh tobacco leaves was 1.70 m 2 , SPAD value is 36.8, and starch content is 46.34%; Further measure, single leaf fresh weight is 104.63 g, and single leaf dry weight is 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com