Common electrode of crimping type insulation power semiconductor module

A technology for power semiconductors and shared electrodes, which is applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as failure to find key points, damage to the crystal structure, and increased hardness, so as to reduce the cost of rework and repair Improve man-hours, yield, and reduce chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

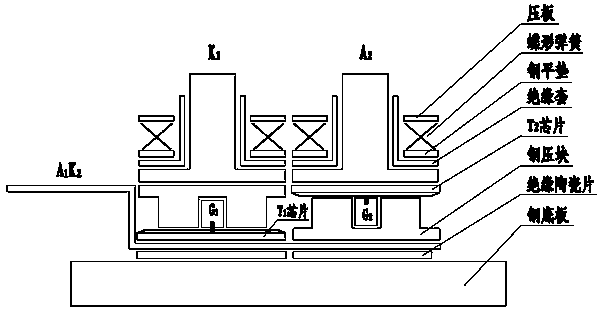

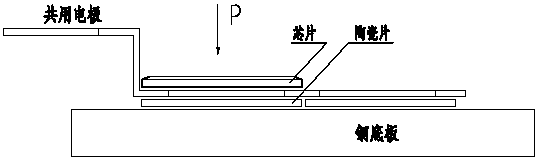

Embodiment Construction

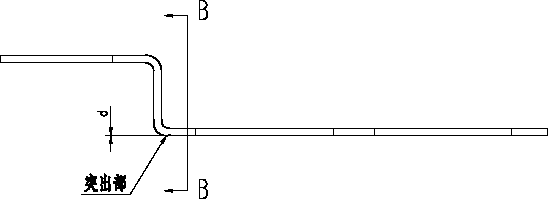

[0032] Image 6 , Figure 7 Among them, the common electrode has two bending parts, and the two ends of the upper bending part are correspondingly provided with a gap 1 to prevent the common electrode from forming an extrusion part during the bending and forming process; the outer wall of the upper bending part is provided with a gap connecting the two ends . The groove 2 for preventing the common electrode from forming a protrusion during the bending and forming process. The two ends of the lower bending part are correspondingly provided with notches 3 to prevent the common electrode from forming an extrusion part during the bending forming process; the outer wall of the lower bending part is provided with a gap connecting the two ends to prevent the common electrode from forming a protrusion during the bending forming process. Groove 4. In the present invention, by adding 4 gaps on both sides of the bend of the common electrode, and stamping or milling two grooves, the deb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com