Method for producing fiber/particle boards

A technology of fiber particle board and production method, which is applied in the direction of household components, flat products, household appliances, etc., can solve the problems of adhesive layer aging, raw material cost increase, structure degumming, etc., achieve fine surface, save raw material and investment cost, and high The effect of mechanical property requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

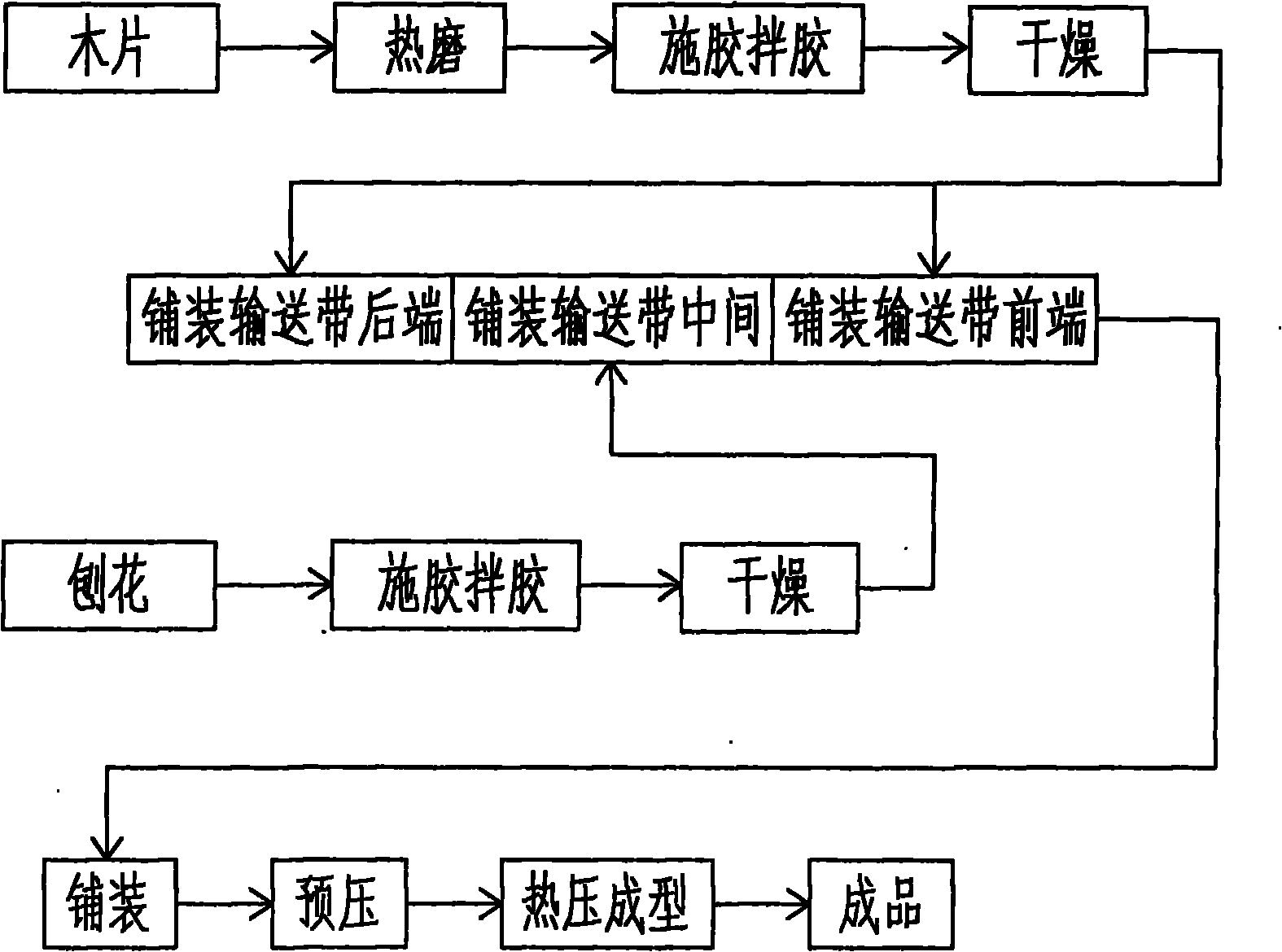

[0013] The specific implementation of the production method of the fiber particleboard of the present invention will be further described in detail below in conjunction with the accompanying drawings.

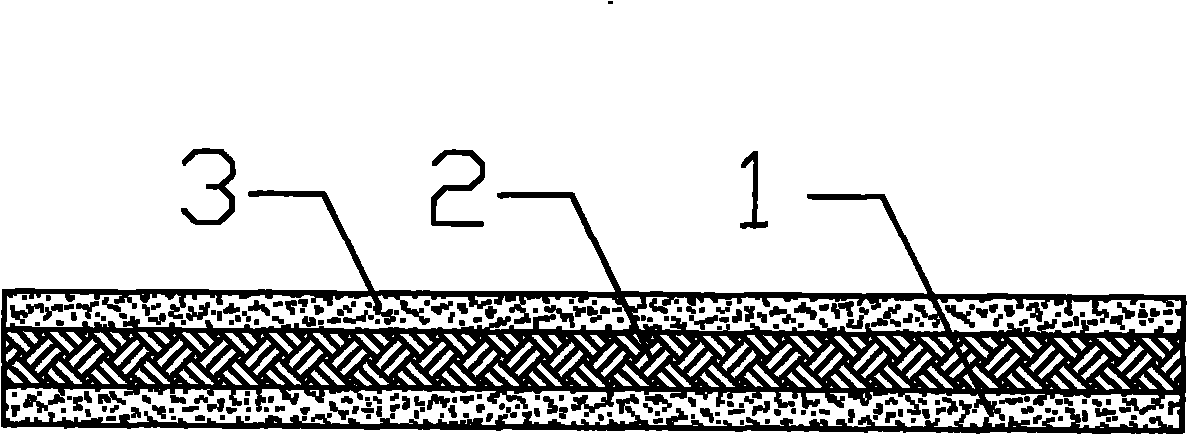

[0014] Such as figure 1 As shown, the existing fiber particleboard is mainly composed of three layers, which are respectively the lower surface fiberboard 1, the core layer particleboard 2, and the upper surface fiberboard 3. The layers are connected by adhesives. The fiber particleboard with this structure, Affected by the environment, it is easy to cause problems such as the aging of the adhesive layer and the degumming of the structure.

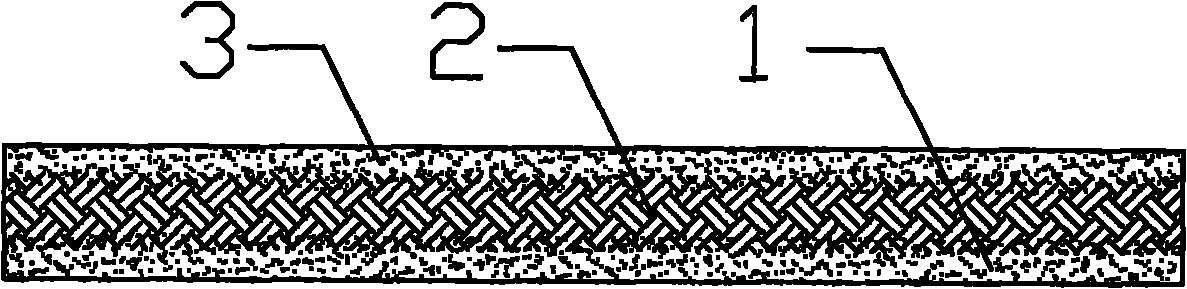

[0015] figure 2 Shown is the fiber particle board prepared by the production method of the present invention. In the composite board, the connection between the core layer particle 2 and the lower surface fiber 1 and the upper surface fiber 3 does not have an obvious dividing line, and the materials penetrate each other, and through layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com