Magnesium alloy continuous extrusion die

An extrusion die and magnesium alloy technology, applied in metal extrusion die and other directions, can solve the problems of reduced mechanical properties of magnesium alloys, easy cracking of the die, and many procedures, and achieves good elongation, high compressive strength, and high yield strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

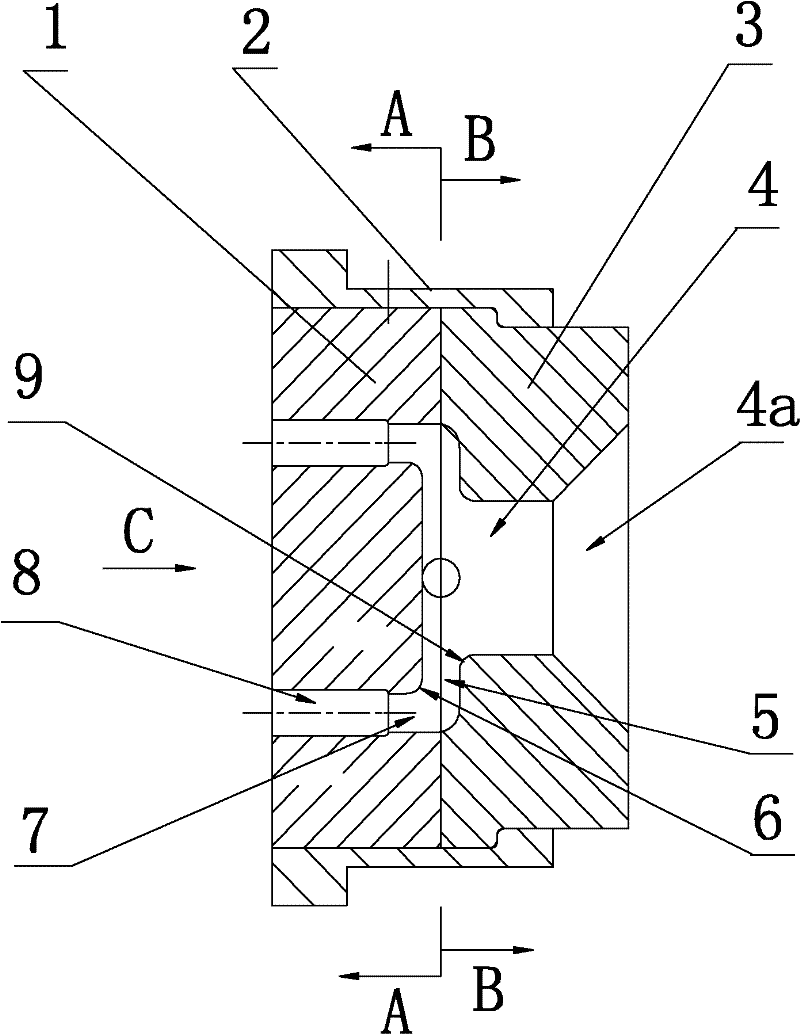

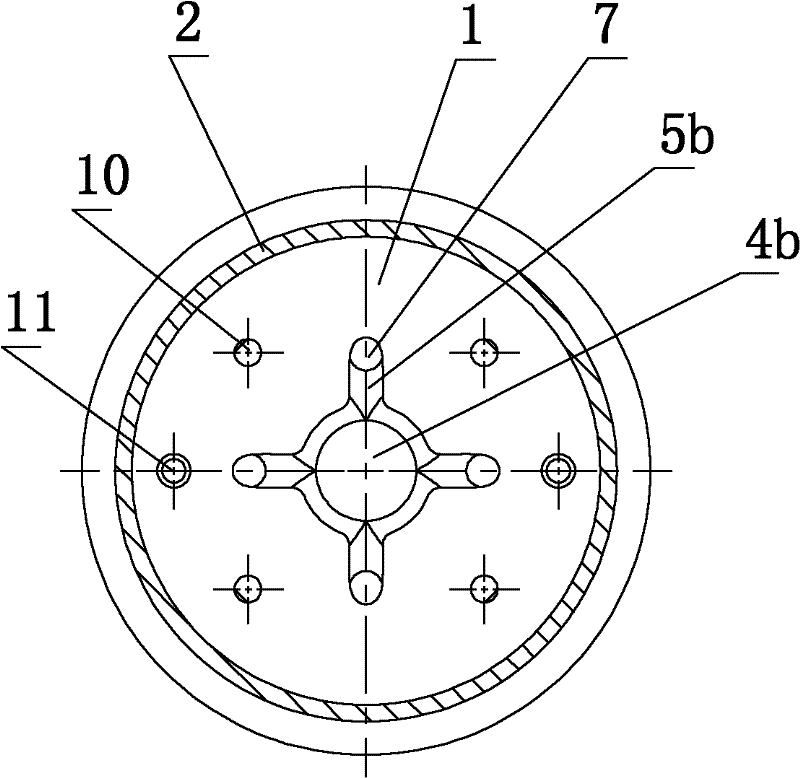

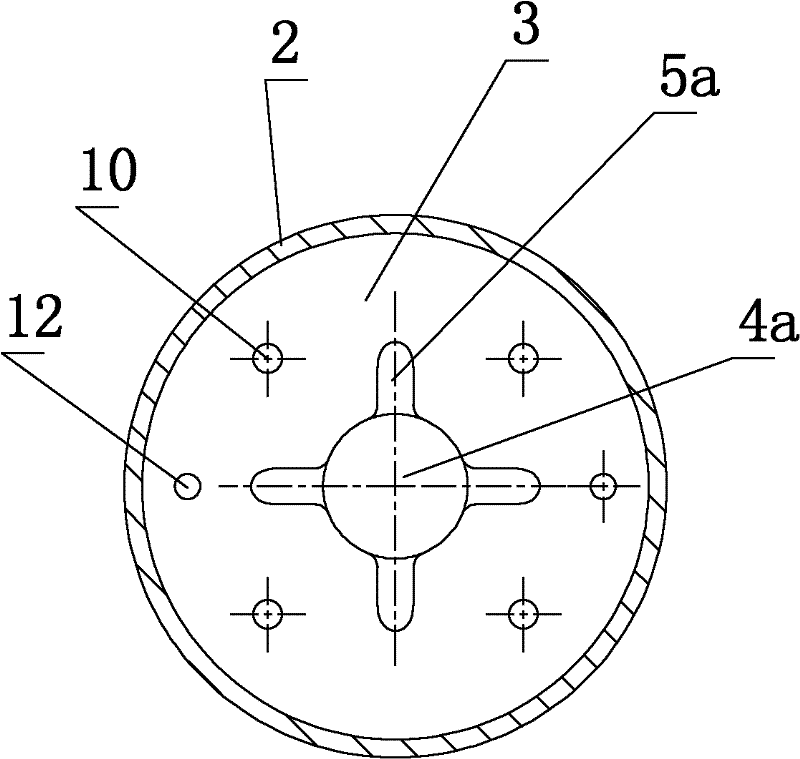

[0032] see Figure 1 to Figure 4 , the magnesium alloy continuous extrusion die of the present invention comprises a left half die 1 and a right half die 3, and the extrusion channel of the continuous extrusion die is composed of two parts respectively arranged on the left and right half dies; wherein, the right half die 3 A part of it includes a circular through hole 4a and a plurality of semicircular section grooves 5a, the circular through hole 4a axially penetrates the right half mold 3, and a plurality of semicircular section grooves 5a are arranged on the left end of the right half mold 3 for clamping surface, radially distributed on the circumference of the circular through hole 4a and communicated with the circular through hole, the axial direction of each semicircular cross-section groove 5a is perpendicular to the axial direction of the circular through hole 4a, and the axis of each semicircular cross-sectional groove 5a The right half-mold 3 circumference does not e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com