A continuous fiber reinforced thermoplastic resin composite sheet and its application

A technology for enhancing thermoplastic and thermoplastic resins, applied in the direction of synthetic resin layered products, laminated, layered products, etc., can solve the problem of reducing the weight of automobiles, and achieve the effect of reducing weight, high strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

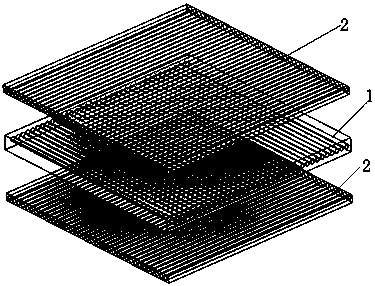

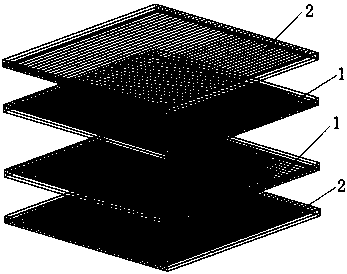

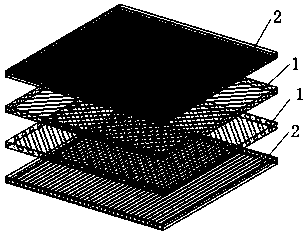

[0023] Embodiment 1: as figure 1 As shown, a continuous fiber-reinforced thermoplastic resin composite sheet includes a middle layer 1, and a surface layer 2 compounded on the upper and lower surfaces of the middle layer 1, and a total of three layers of unidirectional continuous fiber reinforcement The thermoplastic resin prepreg is laid according to [90° / 0° / 90°] or [0° / 90° / 0°] layup method. The three layers of unidirectional continuous fiber-reinforced thermoplastic resin prepreg sheets are all the same alkali-free glass fiber reinforced polypropylene sheet, the content of glass fiber is 70wt%, the thickness of the middle layer 1 is 0.3mm, and the thickness of the two-side layer 2 is is 0.15mm, and the surface density of the middle layer 1 is 480g / m 2 , the areal density of both sides layer 2 is 240g / m 2 . In the composite sheet produced according to this plan, the mass ratio of the fibers parallel to the fiber length direction of the surface layer to the fibers perpendic...

Embodiment 2

[0024] Embodiment 2: the thickness of the middle layer 1 is 0.27mm, the thickness of the two-side layer 2 is 0.15mm, and the surface density of the middle layer 1 is 432g / m 2 , the areal density of both sides layer 2 is 240g / m 2, the rest are the same as in Example 1, the mass ratio of the fibers parallel to the fiber length direction of the surface layer to the fibers perpendicular to the fiber length direction of the surface layer in the composite sheet produced according to this scheme is 0.9:1, and the composite sheet is in the 0° direction The tensile strength on the surface is 405MPa and the tensile modulus is 19GPa; the tensile strength on the 90° direction is 325MPa and the tensile modulus is 16 GPa. The size of the composite sheet is 800mm×600mm, the thickness is 0.57mm, and the weight is 437g.

Embodiment 3

[0025] Embodiment 3: the thickness of the middle layer 1 is 0.33mm, the thickness of the two-side layer 2 is 0.15mm, and the surface density of the middle layer 1 is 500g / m 2 , the areal density of both sides layer 2 is 240g / m 2 , the rest are the same as in Example 1, the mass ratio of the fibers parallel to the fiber length direction of the surface layer to the fibers perpendicular to the fiber length direction of the surface layer in the composite sheet produced according to this scheme is 1.1:1, and the composite sheet is in the 0° direction The tensile strength on the surface is 415MPa, and the tensile modulus is 18GPa; the tensile strength on the 90° direction is 338MPa, and the tensile modulus is 15GPa. The size of the composite sheet is 800mm×600mm, the thickness is 0.63mm, and the weight is 480g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com