A cut-to-length device for household textile thin cloth production

A fixed-length cutting and weaving technology, which is applied in the cutting of textile materials, textiles and papermaking, etc. It can solve the problem that it is impossible to quickly complete the cutting of multiple thin cloth strips, and it is impossible to cut thin cloth strips at the same time, which affects the smooth cutting of thin cloth, etc. problem, to achieve the effect of convenient cutting process, simple and convenient cutting operation, and small cutting error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

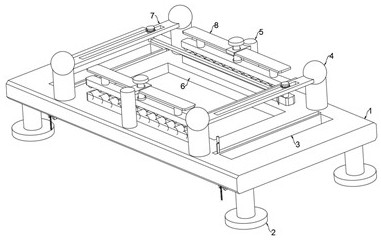

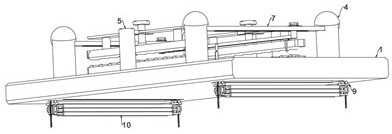

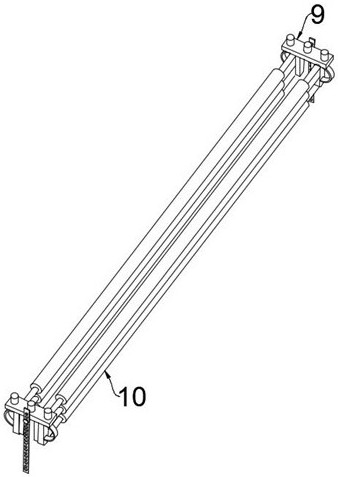

[0032] refer to Figure 1-4 , a fixed-length shearing device for home textile thin cloth production, including a processing table 1 fixedly installed on a plurality of support columns 2, two strip-shaped openings 3 are opened on the processing table 1, and the lower part of the processing table 1 passes through multiple A compression spring 12 is fixedly installed with a plurality of moving plates 9, and each moving plate 9 is fitted with two sliding plates 11 through the cooperation of the spacer groove and the spacer block;

[0033] The above points worth noting are as follows:

[0034] 1. The thin cloth to be cut is placed on the upper part of the processing table 1, and the two ends of the thin cloth are respectively passed through the two strip openings 3 and pulled into the bottom of the processing table 1, and the thin cloth to be cut can be cut. The part stays in processing table 1, makes the two ends of thin cloth be positioned at the bottom of processing table 1, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com