Patents

Literature

94results about How to "Shear stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

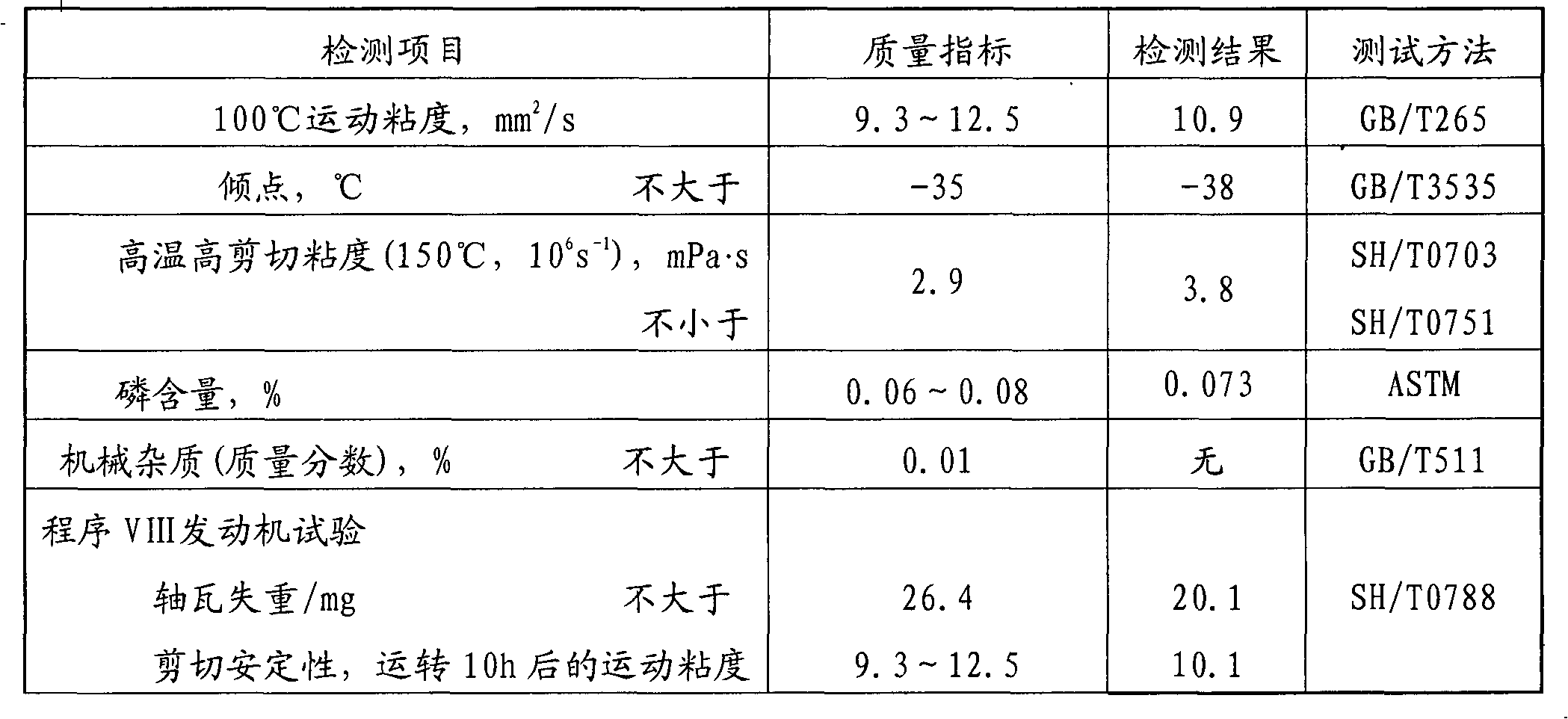

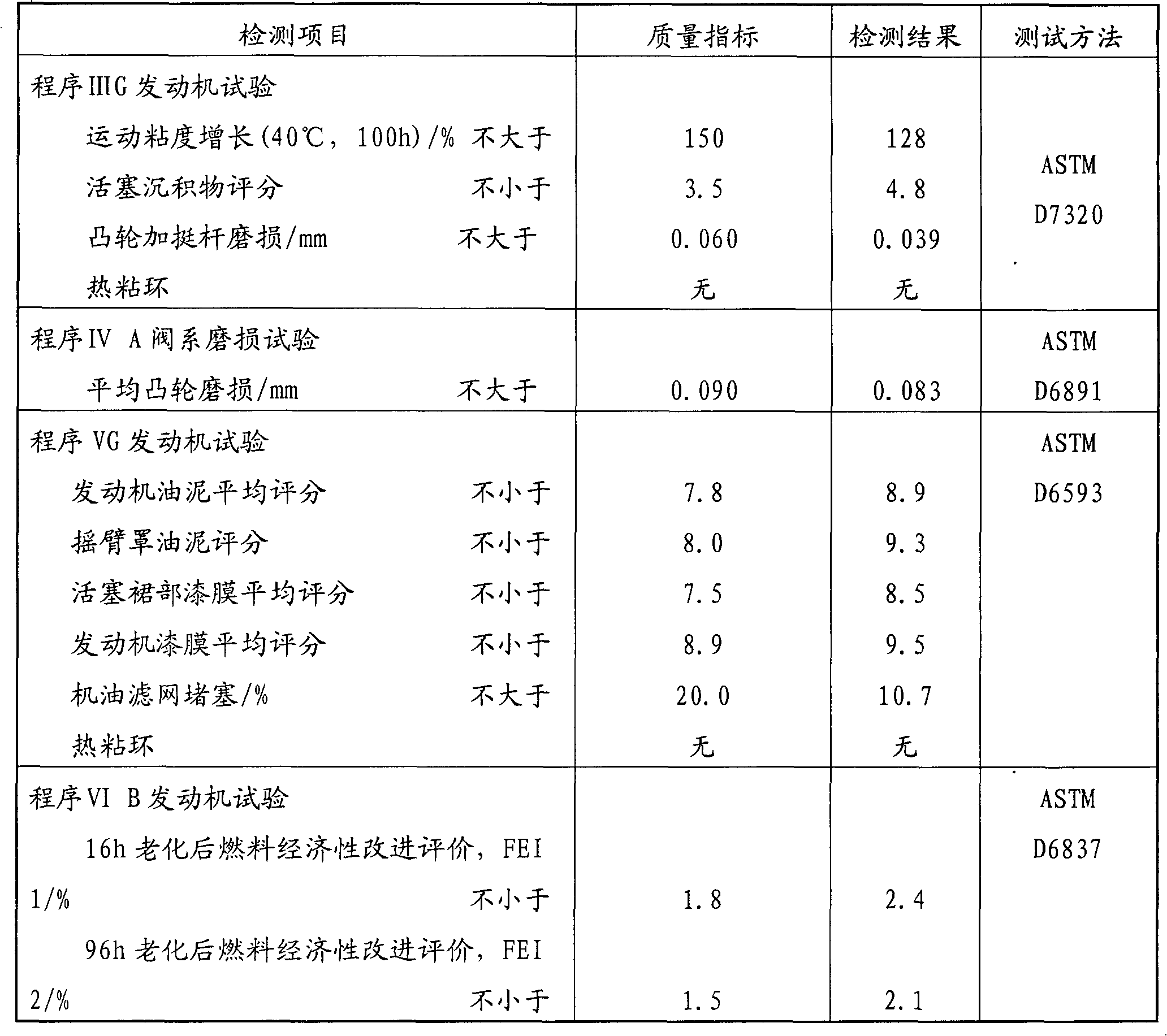

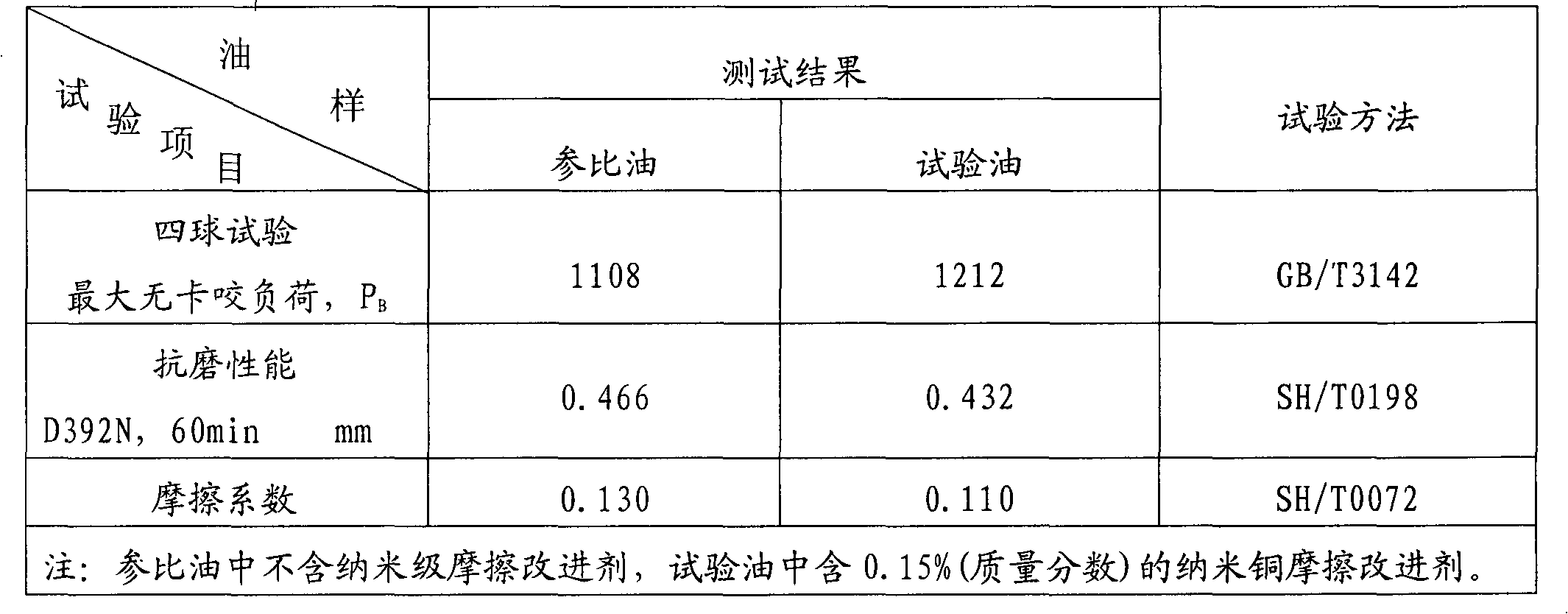

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

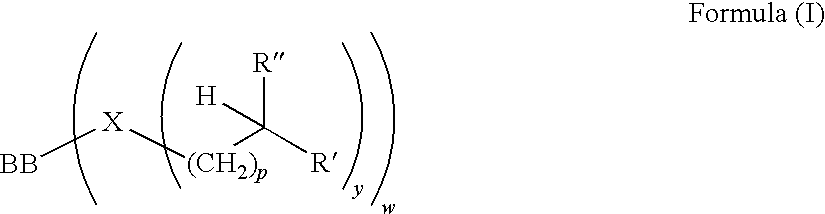

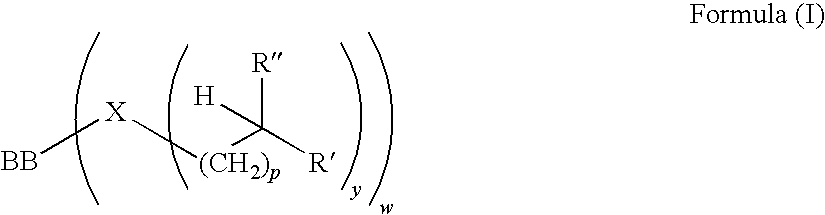

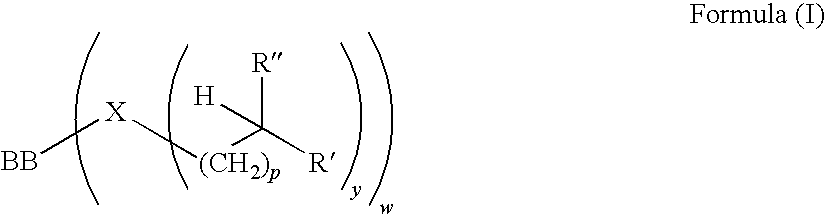

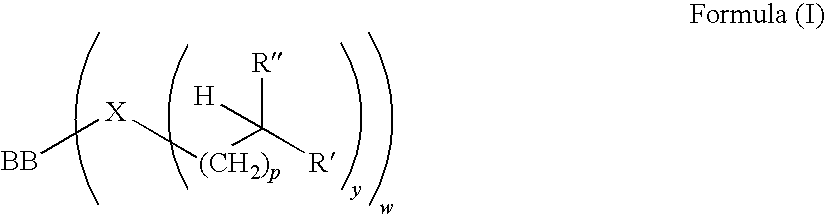

Novel Polymers and Methods of Controlling Viscosity

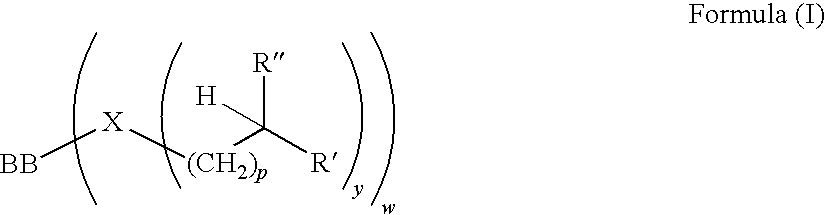

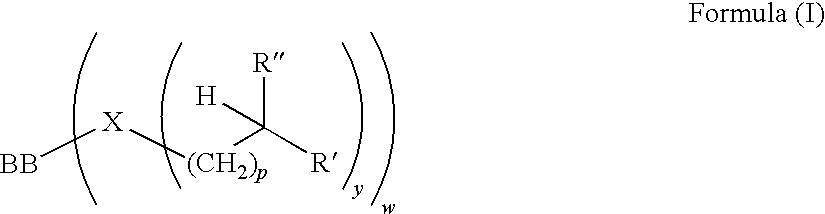

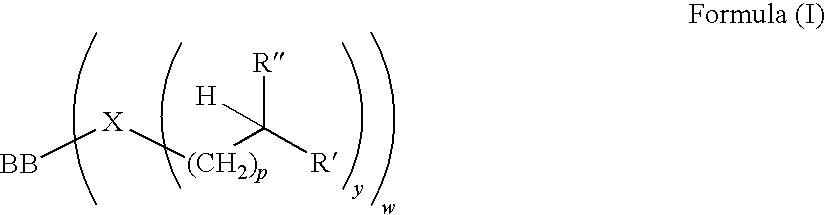

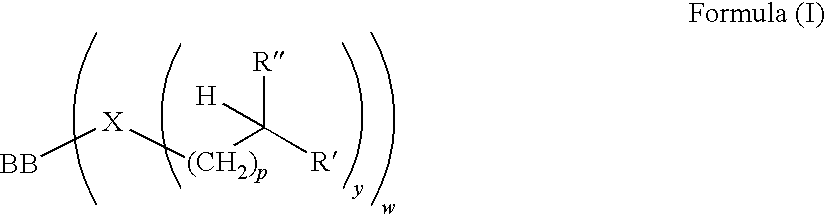

ActiveUS20090221461A1Acceptable/improved shear stabilityShear stableAdditivesFoam dispersion/preventionViscosity indexPendant group

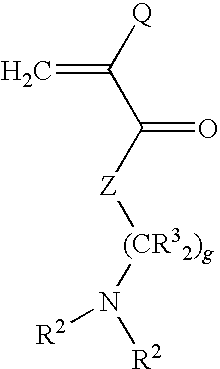

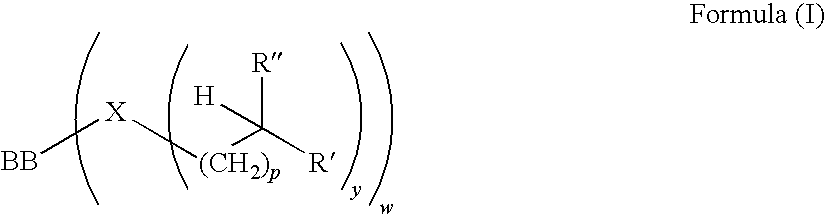

The present invention relates to a novel polymer with pendant groups. The invention further provides for a lubricating composition containing said polymer. The invention further provides a method and use of controlling viscosity index by supplying to an oil of lubricating viscosity the polymer with pendant groups.

Owner:THE LUBRIZOL CORP

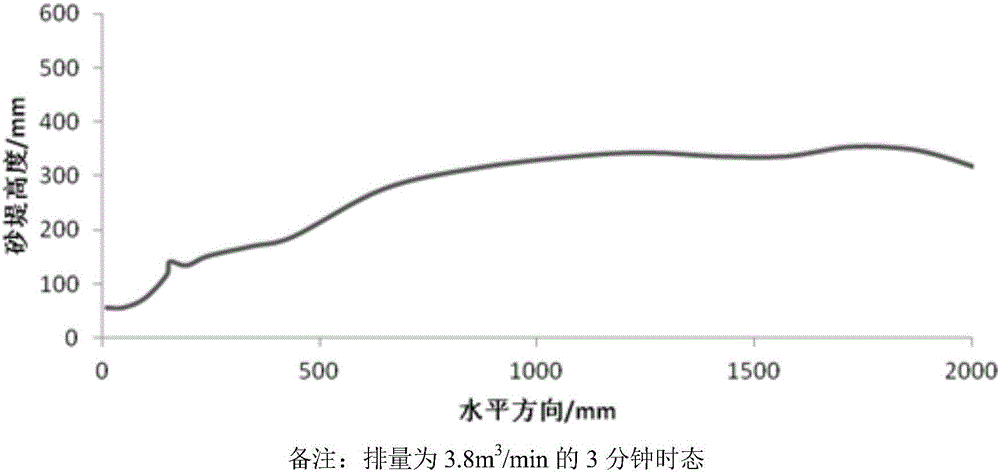

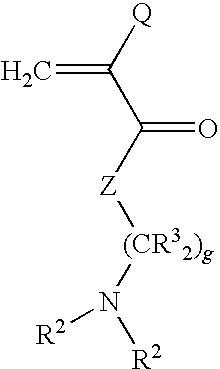

Preparation method for self-suspension propping agent in laboratory

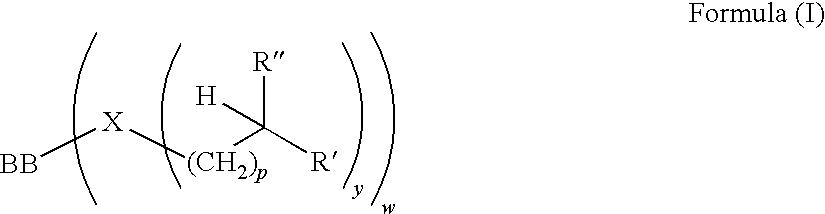

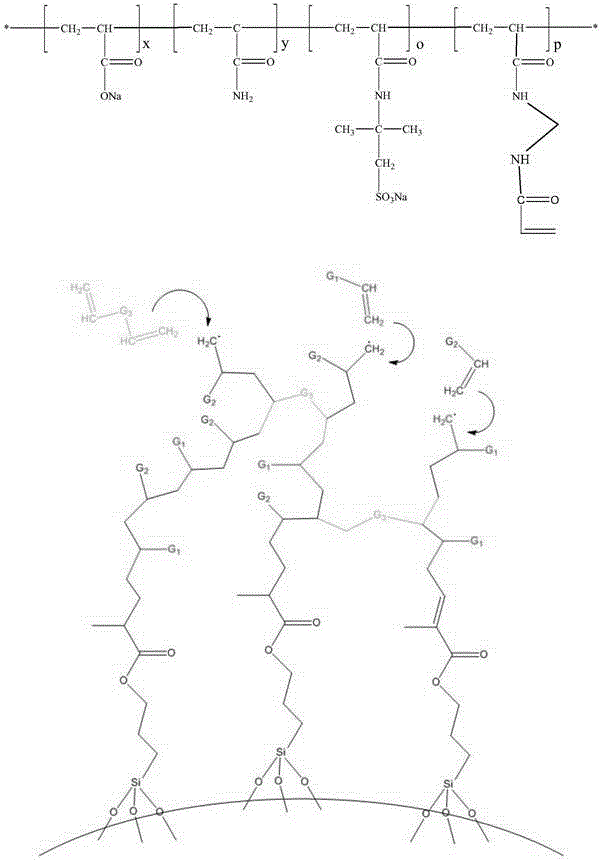

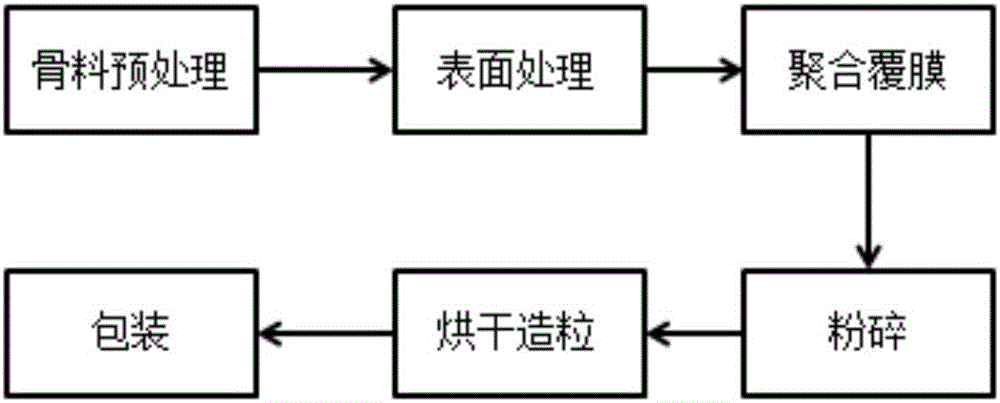

InactiveCN106634939AReduced fracturing costsShear stableFluid removalDrilling compositionFunctional monomerExpanded clay aggregate

The invention belongs to the technical field of yield increasing and fracturing of petroleum engineering and provides a method for preparing a self-suspension propping agent in a laboratory. The method comprises the following steps: taking quartz sand / ceramsite / propping agent as aggregates; pre-treating with an organic solvent and treating the surface with a coupling reagent; polymerizing and coating; and crushing, drying, pelletizing and then packaging. A coating polymerizing product (as shown in the figure) is acquired through the polybasic polymerization of the reactant and acrylamide / sodium acrylate / functional monomer / cross-linking agent. The expansion times of the prepared self-suspension propping agent is 3-12 times; the self-suspension propping agent can be completely hydrated within 1min-2min; the hydrated layer is stably expanded at 2 DEG C to 193 DEG C; the self-suspension propping agent swells once encountering with water, the volume density is reduced from 2.4g / cm3 to 1.3g / cm3 and the excellent self-suspension characteristic after the clean water system swelling is presented. The self-suspension propping agent prepared in the laboratory can realize the onsite mixing for hydraulic fracturing construction, the water for fracturing is greatly reduced, the labor cost is lowered and the application prospect is wide.

Owner:王展旭

Lubricating Composition Containing a Polymer and Antiwear Agents

ActiveUS20090312210A1Wear performanceShear stableAdditivesBase-materialsViscosity indexPendant group

Owner:THE LUBRIZOL CORP

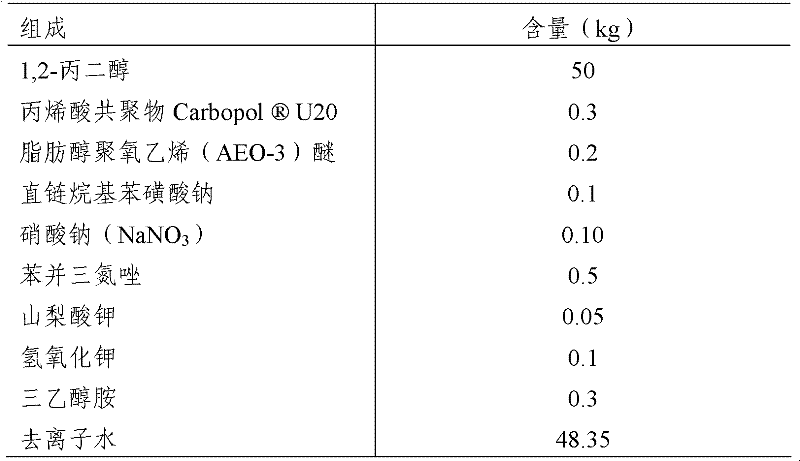

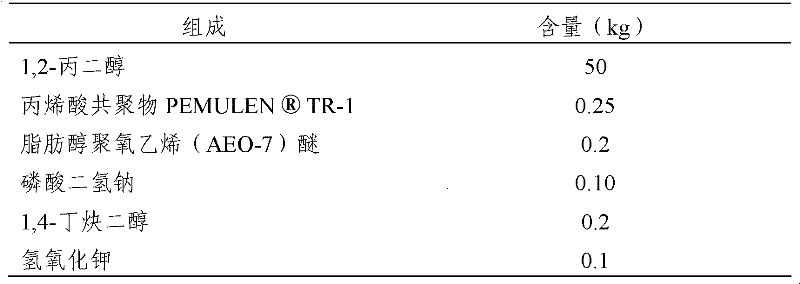

Novel airplane de-icing/anti-icing liquid and preparation method thereof

ActiveCN102329597ALong and short clearance efficiencyLong and short retention timeOther chemical processesAlcoholFrost

The invention relates to novel airplane de-icing / anti-icing liquid and a preparation method thereof. The de-icing / anti-icing liquid consists of de-ionized water and the following ingredients in percentage by weight: 30 to 80 percent of dibasic alcohol, 0.01 to 1.0 percent of thickening agents, 0.05 to 2 percent of surface active agents, 0.01 to 1 percent of corrosion inhibitors and 0.05 to 0.2 percent of antimicrobial agents, and the pH is 7.0 to 7.5. The airplane de-icing / anti-icing liquid is mainly used for clearing condensed settlings such as ice, snow, frost and the like formed on the airplane surface when an airplane stops on the ground, and new snow, ice or frost can be prevented from being formed on the airplane surface through the further accumulation.

Owner:北京雅迪力特航空新材料股份公司

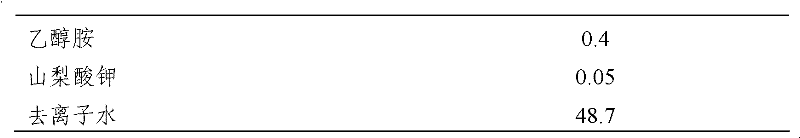

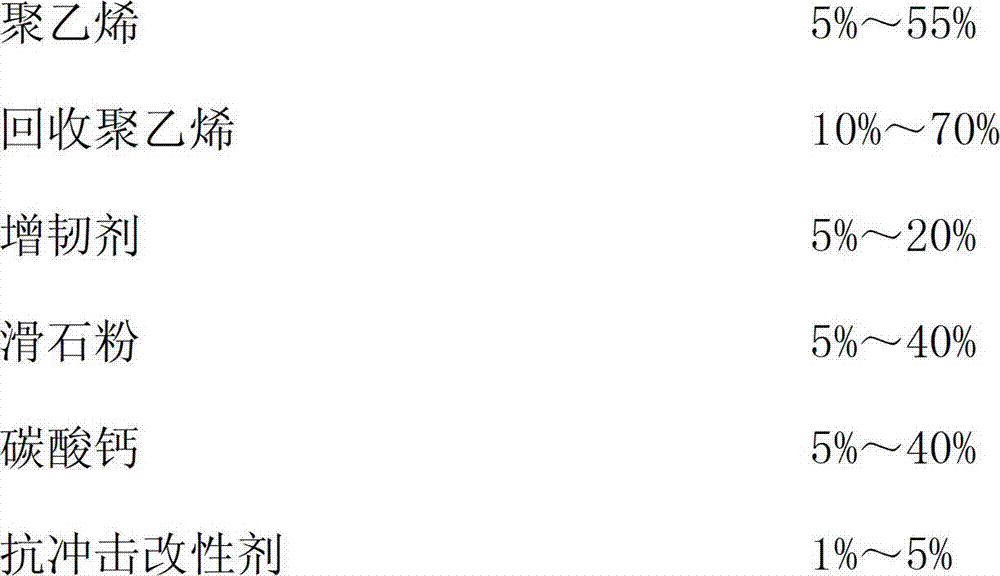

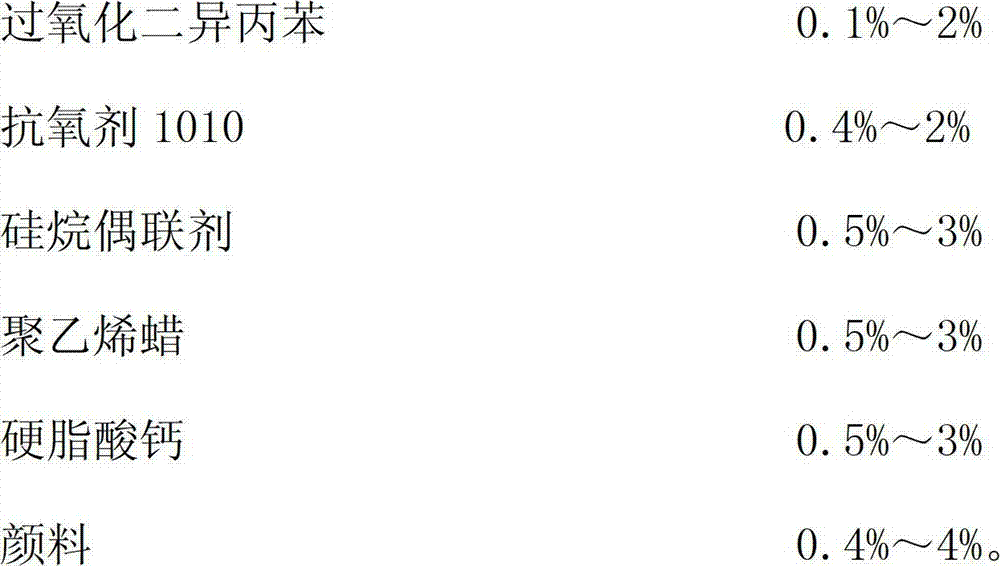

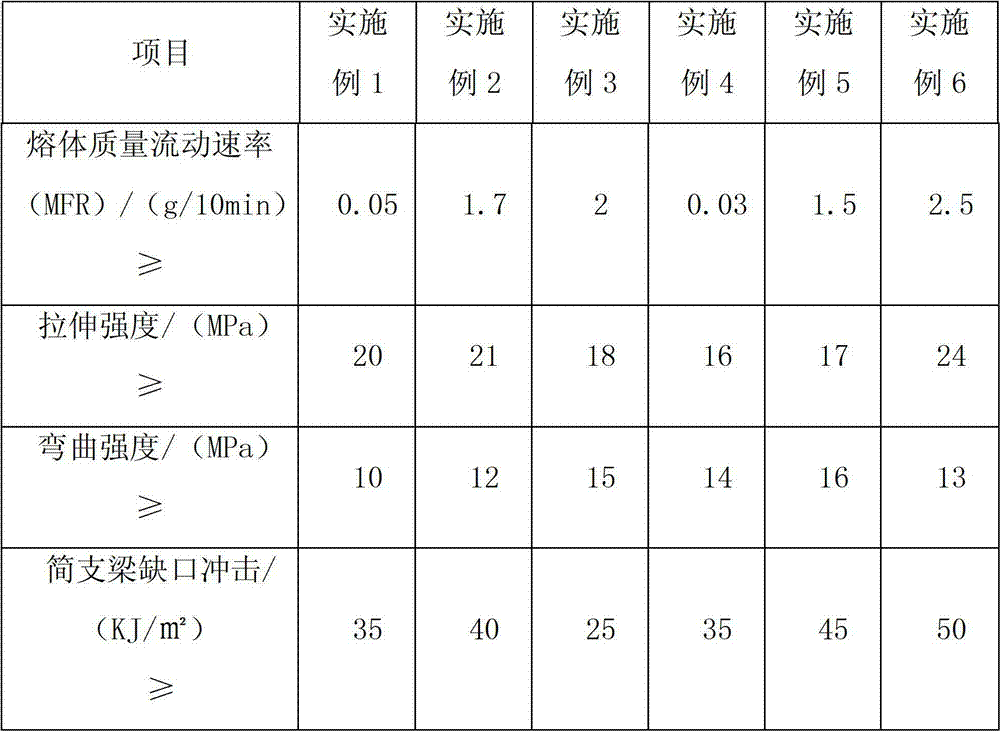

Special modified recycled polyethylene material for pipes and pipe fittings and preparation method of special modified recycled polyethylene material

The invention discloses a special modified recycled polyethylene material for pipes and pipe fittings and a preparation method of the special modified recycled polyethylene material, so that the problems of higher new polyethylene consumption and higher production cost of an existing special modified polyethylene material for pipes and pipe fittings are solved. The special modified recycled polyethylene material mainly comprises, by weight, 5%-55% of polyethylene, 10%-70% of recycled polyethylene, 5%-20% of toughening agents, 5%-40% of talcum powder, 5%-40% of calcium carbonate, 1%-5% of impact modifiers, 0.1%-2% of dicumyl peroxide, 0.4%-2% of antioxidants 1010, 0.5%-3% of silane coupling agents, 0.5%-3% of polyethylene wax, 0.5%-3% of calcium stearate and 0.4%-4% of pigment. Waste polyethylene is recycled and reused effectively, and the special modified recycled polyethylene material for the pipes and the pipe fittings and the preparation method have the advantages of resource saving, environmental protection, cost reduction and the like.

Owner:四川塑金科技有限公司

Special material for waste ABS (acrylonitrile butadiene styrene) plastic regenerated and modified automobile and preparation method of special material

The invention discloses a special material for a waste ABS plastic regenerated and modified automobile and a preparation method of the special material, and solves the problem that the recovery rate of a waste ABS plastic is lower, and resources are wasted in the prior art. The special material comprises the components in parts by weight as follows: 100 parts of a waste ABS broken material, 1-8 parts of ABS, 0.1-0.3 parts of EBS (ethylene bis stearamide), 0.1-0.2 parts of zinc stearate, 0.1-0.2 parts of calcium stearate, 0.1-0.2 parts of antioxidant 10100, 0.2-0.6 parts of antioxidant 168 and 0.1-0.4 parts of montan wax, wherein the waste ABS broken material is obtained by picking, breaking, cleaning, dehydrating, absorbing and drying the waste ABS plastic. The preparation method of the special material for the waste ABS plastic regenerated and modified automobile is further provided. The special material for the waste ABS plastic regenerated and modified automobile and the preparation method of the special material have the advantages that the waste ABS plastic can be recycled, resources are saved, the environment is protected, the cost is reduced, the preparation process is simplified, and the like.

Owner:四川塑金科技有限公司

Thermotropic supermolecule gel temporary-plugging deflection fracturing fluid

ActiveCN106190087ANo residual damageEasy to flow backDrilling compositionTemperature controlPolymer science

The invention discloses a thermotropic supermolecule gel temporary-plugging deflection fracturing fluid. The thermotropic supermolecule gel temporary-plugging deflection fracturing fluid is prepared from, by weight, 10% to 35% of cyclodextrin, 0.5% to 3.5% of lithium chloride, 1.3% to 15% of fatty alcohol, 0.3% to 10% of methylcellulose and the balance N,N-dimethyl formamide. The number of C atoms of the fatty alcohol is 10 to 18, and the weight-average molecular weight of the methylcellulose is 400 to 10,000. By means of the thermotropic supermolecule gel temporary-plugging deflection fracturing fluid, temperature-controlled gelling can be achieved, a user does not need to add other temporary-plugging agents, and formed gel is stable and resistant to shearing, and can be restored into the gel shape after being sheared; as the supermolecule gel temporary-plugging deflection fracturing fluid is composed of micromolecules, the re-arranging effect can be easily achieved after gel breaking, and residual damage to a reservoir can be avoided. The thermotropic supermolecule gel temporary-plugging deflection fracturing fluid is suitable for fracturing transforming of oil and gas fields, and has broad market prospects.

Owner:赵立强 +2

Recycled waste polystyrene plastic produced special modified material for household appliances, and preparation method thereof

The invention discloses a recycled waste polystyrene plastic produced special modified material for household appliances, and a preparation method thereof, and the material can be used for solving the problem that, in the existing technology, the recovery rate of polystyrene plastic of television shells is lower, and resource is wasted. The material is composed of the following components in parts by weight: 100 parts of waste polystyrene television shell broken material, 5-8 parts of SEBS, 0.1-0.3 parts of EBS, 0.1-0.5 parts of calcium stearate and 0.1-0.3 parts of zinc stearate, wherein the waste polystyrene television shell broken material is obtained by detaching the waste television, smashing the polystyrene broken material, rubbing, cleaning, rinsing, drying, and soaking in brine, screening, then, cleaning again, and drying. The invention also provides the preparation method of the recycled waste polystyrene plastic produced special modified material for the household appliances. The method can be used for effectively recycling the polystyrene plastic of the waste televisions, and has the advantages of saving resource, protecting environment, lowering the cost, simplifying the preparation process, and the like.

Owner:四川塑金科技有限公司

Core-shell particles

InactiveCN101090920AIncrease brightnessImproved mechanical load capacityCoatingsComposite materialRefractive index

The invention relates to core-shell particles, the core of which is essentially solid with an essentially monodisperse size distribution, with a difference between the refractive index of the core material and the shell material. The core is made from a material which either does not flow or does so at a temperature above the flow temperature of the shell material and the shell is connected to the core by means of an intermediate layer, characterised in that the shell is made from a copolymer with at least one C4-C8 alkylacrylate and at least one C4-C8 alkyl- or -alkylarylmethacrylate as monomer component.

Owner:ROHM CO LTD

Modified regeneration high impact polystyrene for tubes and pipe fittings and preparation method of high impact polystyrene

InactiveCN102775715ALow costImprove the economic efficiency of the enterpriseSilane couplingCalcium carbonate

The invention discloses modified regeneration high impact polystyrene for tubes and pipe fittings and a preparation method of the high impact polystyrene, which solve the problems of high cost and complex method of the conventional high impact polystyrene for the tubes and pipe fittings. The modified regeneration high impact polystyrene mainly comprises the following components by weight percentage: 10%-50% of high impact polystyrene, 15%-80% of recycled high impact polystyrene, 5%-20% of toughening agent, 5%-40% of calcium carbonate, 0.1%-1% of antioxygen 1010, 0.3%-1% of silane coupling agent and 0.4%-2% of pigment. The invention also provides the preparation method of the modified regeneration high impact polystyrene for the tubes and pipe fittings. The preparation method can be used for effectively recycling waste high impact polystyrene. The modified regeneration high impact polystyrene for the tubes and pipe fittings has the advantages that resources are saved, the environment is protected, the cost is lowered, the preparation process is simplified and the like.

Owner:四川塑金科技有限公司

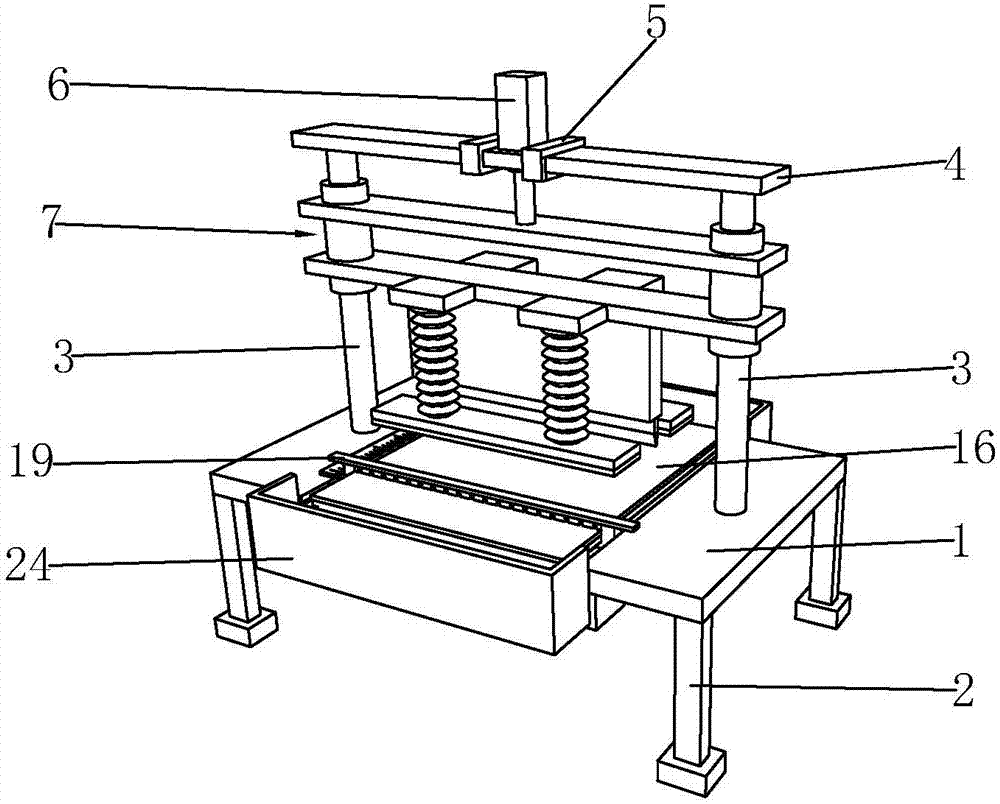

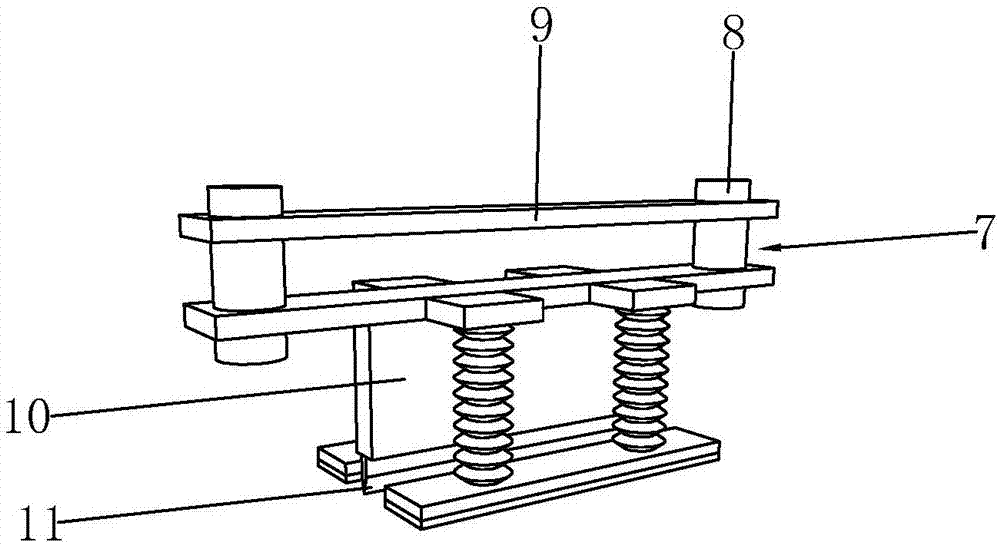

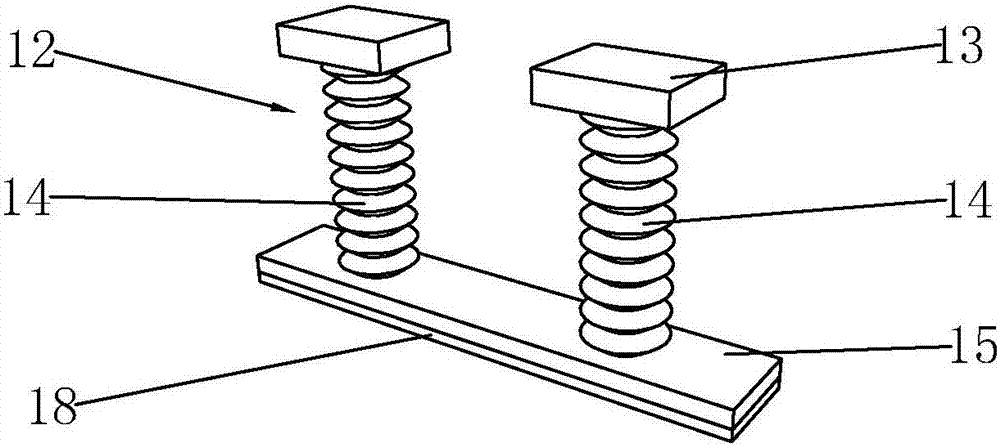

Trimming cutter for textile fabric

The invention discloses an edge cutting machine for textile fabrics, which comprises a working platform and supporting feet, the supporting feet are arranged on four corners of the bottom surface of the working platform, support rods are symmetrically distributed on the working platform, and the top of the supporting rods is provided with a fixed Clamps, there is a drive cylinder between the fixed clamps, a platen assembly is provided between the support rods, the drive cylinder is connected to the platen assembly, elastic pressure seats are provided on both sides of the platen assembly, blades are provided at the bottom of the platen assembly, and the working platform There is a backing plate on the top, the backing plate is located below the blade, a wiper is slidably connected to the working platform, and a strip brush is arranged on the bottom surface of the wiper, and the strip brush is in contact with the backing plate, and U-shaped frames are symmetrically distributed on the bottom surface of the working platform , A collection frame is arranged on the U-shaped frame, and the collection frame is in the shape of an upper opening. The invention has the advantages of compact structure, flexible connection, high working efficiency, good cutting effect, convenient cleaning of waste materials, and effectively keeping the working environment clean.

Owner:嵊州市靖洁纺织机械有限公司

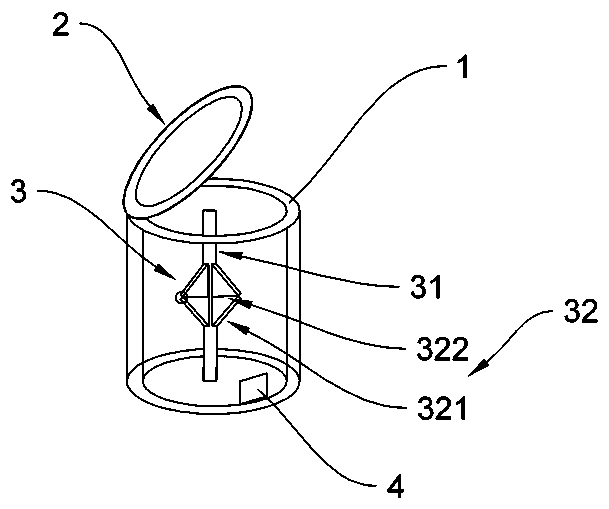

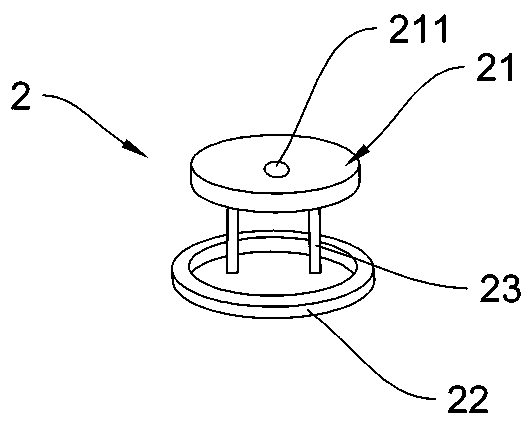

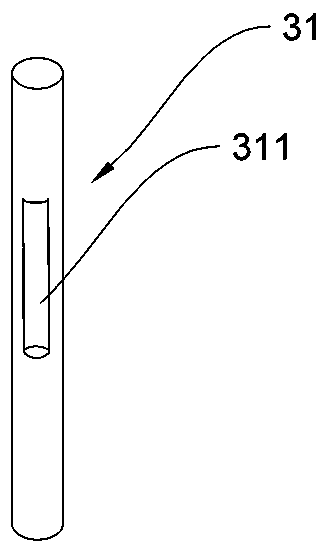

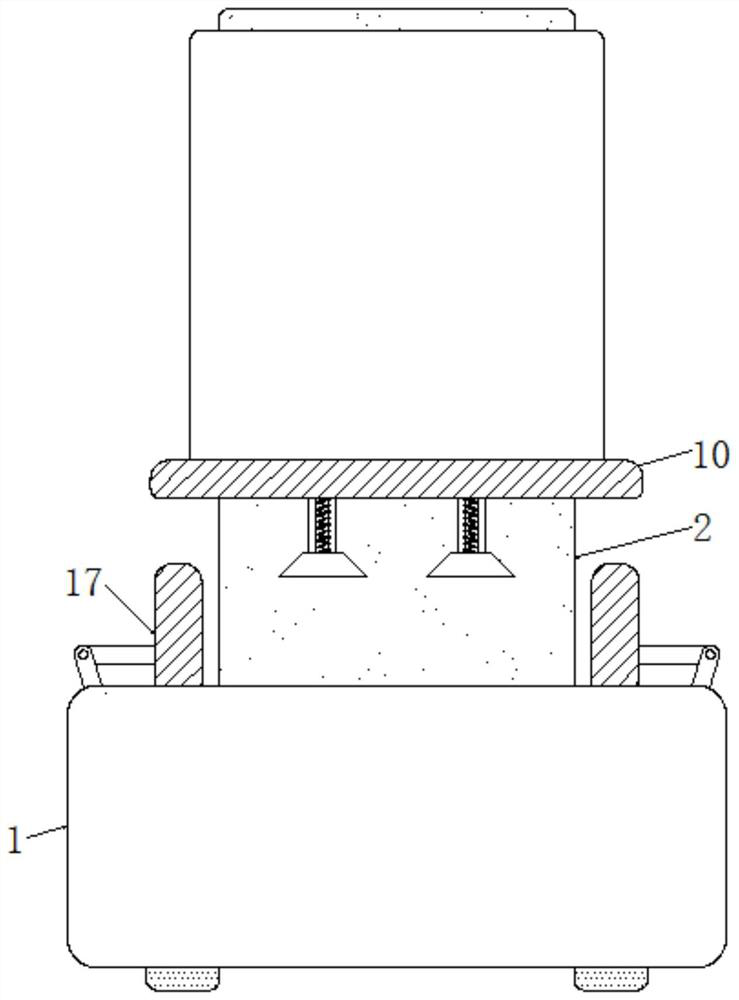

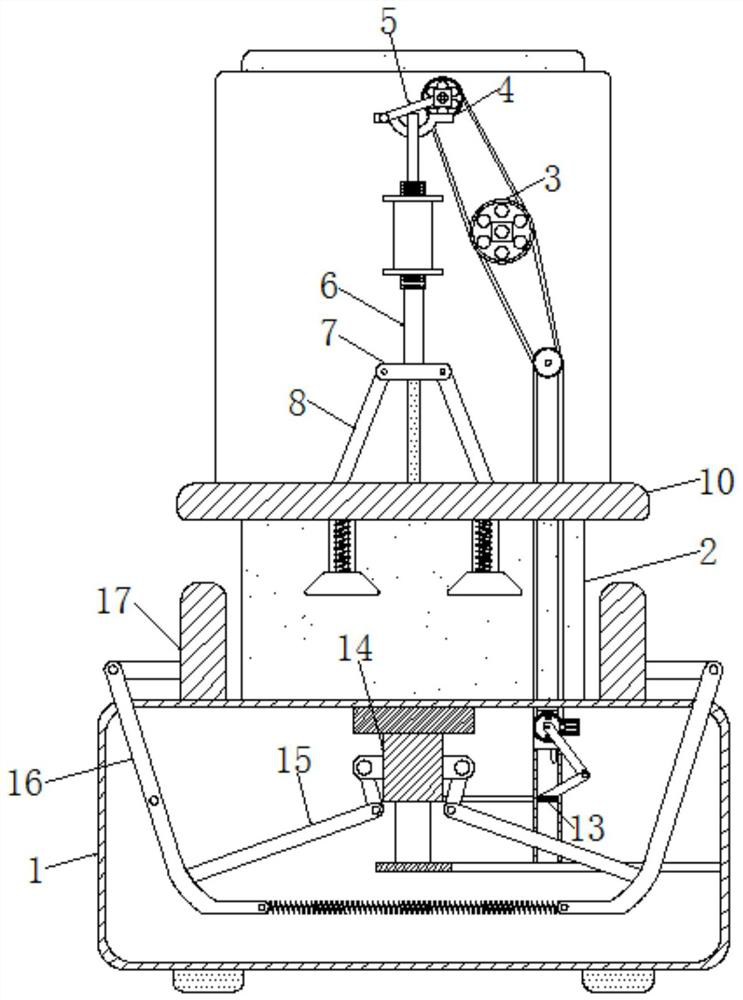

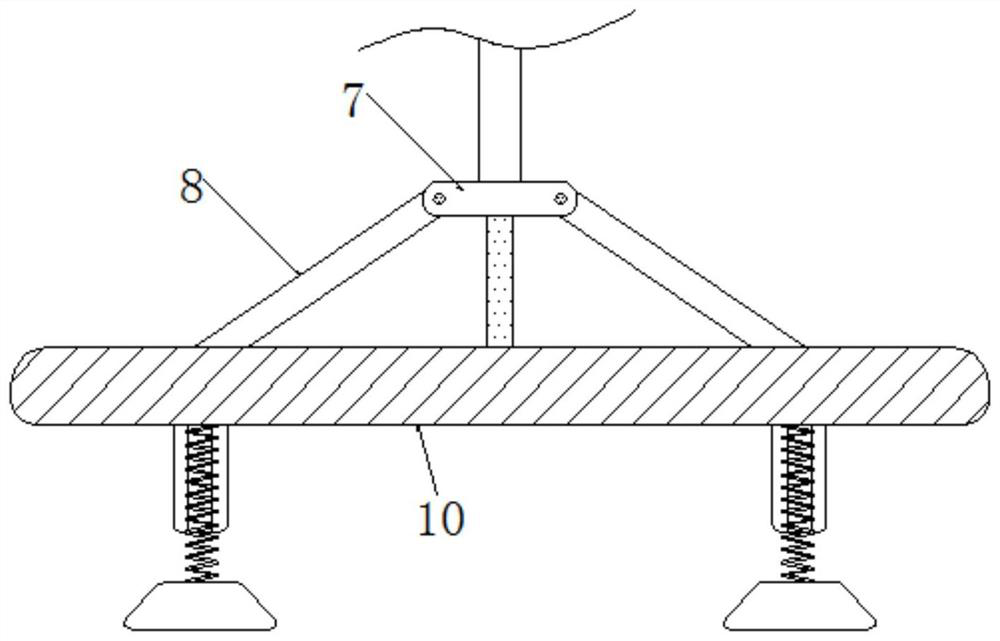

Coating stirring device

PendingCN109046082AIncrease the output speedStir wellRotary stirring mixersTransportation and packagingEngineeringDriven element

The invention provides a coating stirring device, and relates to the technical field of coatings. The coating stirring device comprises a barrel body and a stirring mechanism, wherein an opening-closing cover body is arranged on the top end of the barrel body; an extruding plate for draining liquid in the barrel body is arranged at the cover body; the stirring mechanism is arranged in the barrel body and comprises a driving main shaft, and one end of the driving main shaft penetrates through the bottom part of the barrel body and is connected to a driving element; the driving main shaft is provided with a first storing chamber for accommodating a foldable stirring element; the stirring element comprises telescopic stirring brackets, and telescoping parts for fixedly connecting the stirringbrackets to the driving main shaft in a stretching and closing manner; one end of each stirring bracket is fixedly connected to the end part of the first storing chamber, and the other end of each stirring bracket is movably connected to the corresponding telescoping part. According to the coating stirring device, the stirring element of the stirring mechanism can be stored in the first storing chamber in a folding manner, so that the blockage in feeding is avoided; the extruding plate speeds up discharging, and discharging residues are avoided; the stirring uniformity is ensured through theplurality of stirring brackets; and meanwhile, stable shearing force is formed, so that the materials can be uniformly mixed.

Owner:长兴撒哈拉新材料有限公司

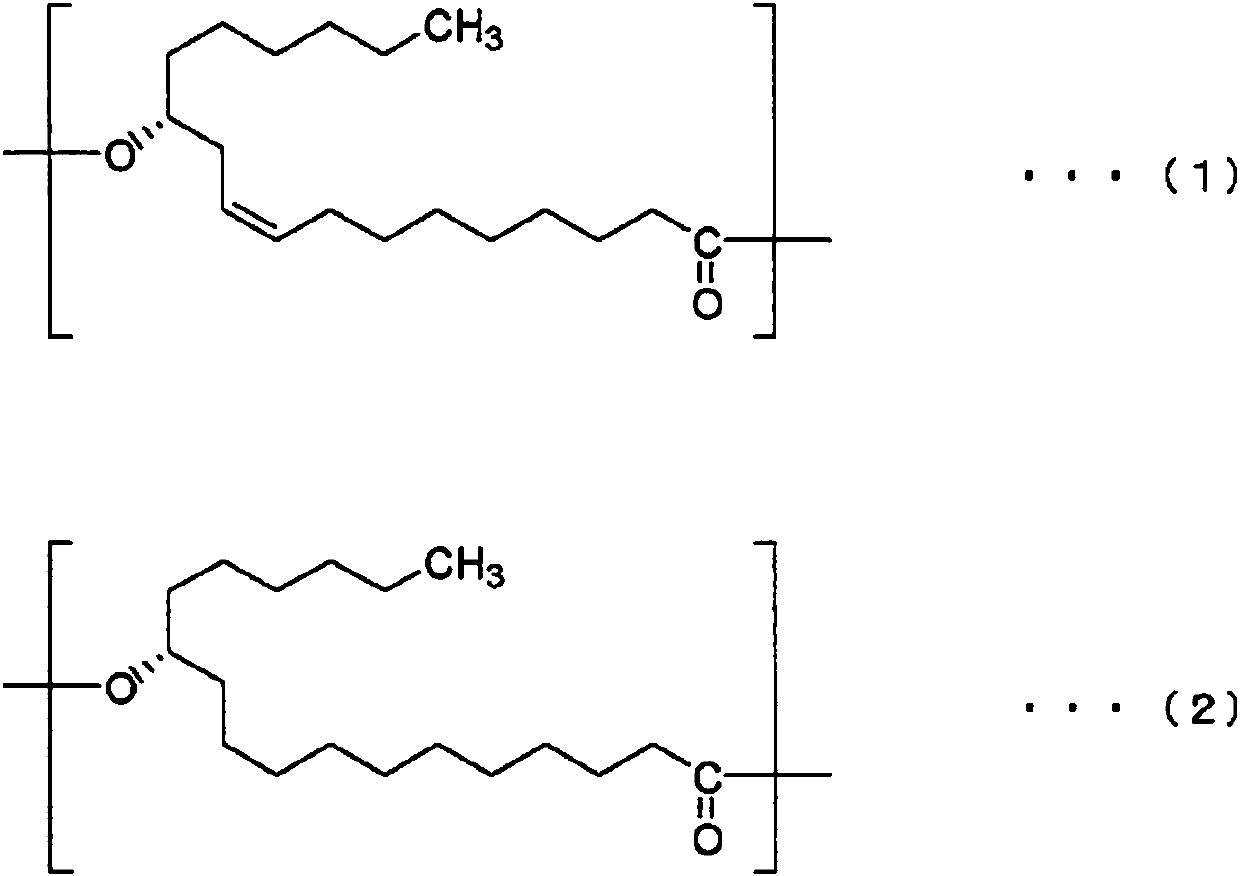

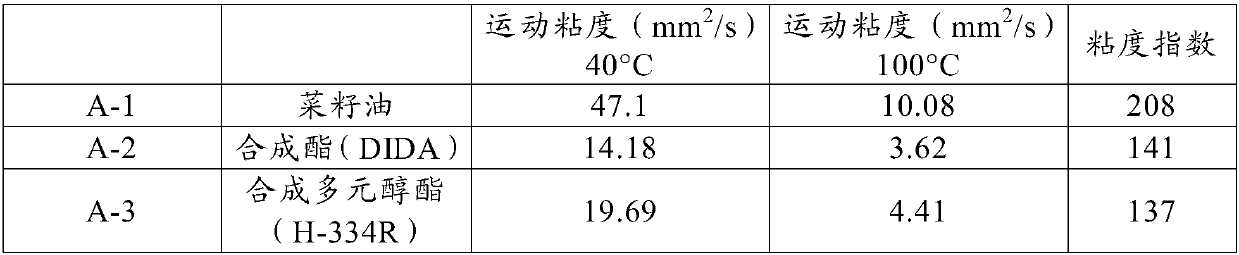

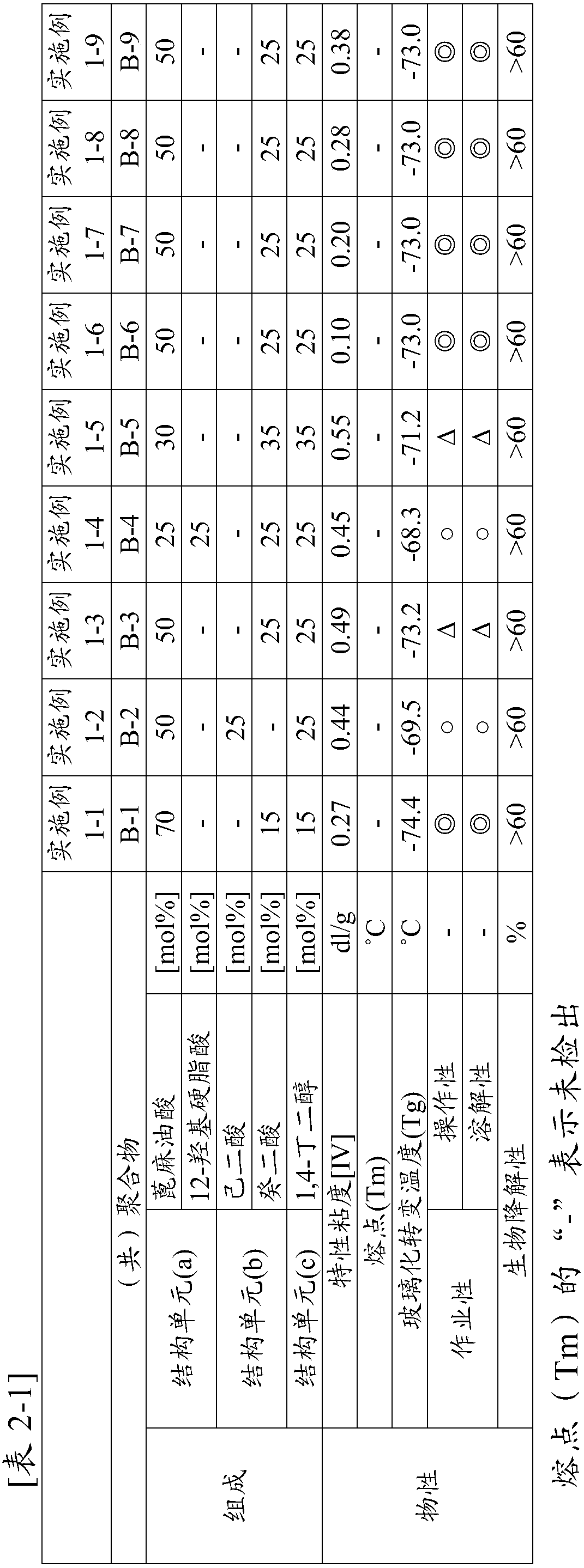

Copolymer and lubricating oil composition

InactiveCN107922603AImprove workabilityPromote degradationAdditivesBase-materialsHeat resistanceCarboxylic acid

Owner:MITSUI CHEM INC

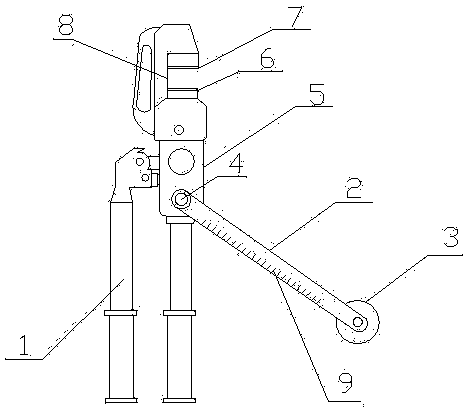

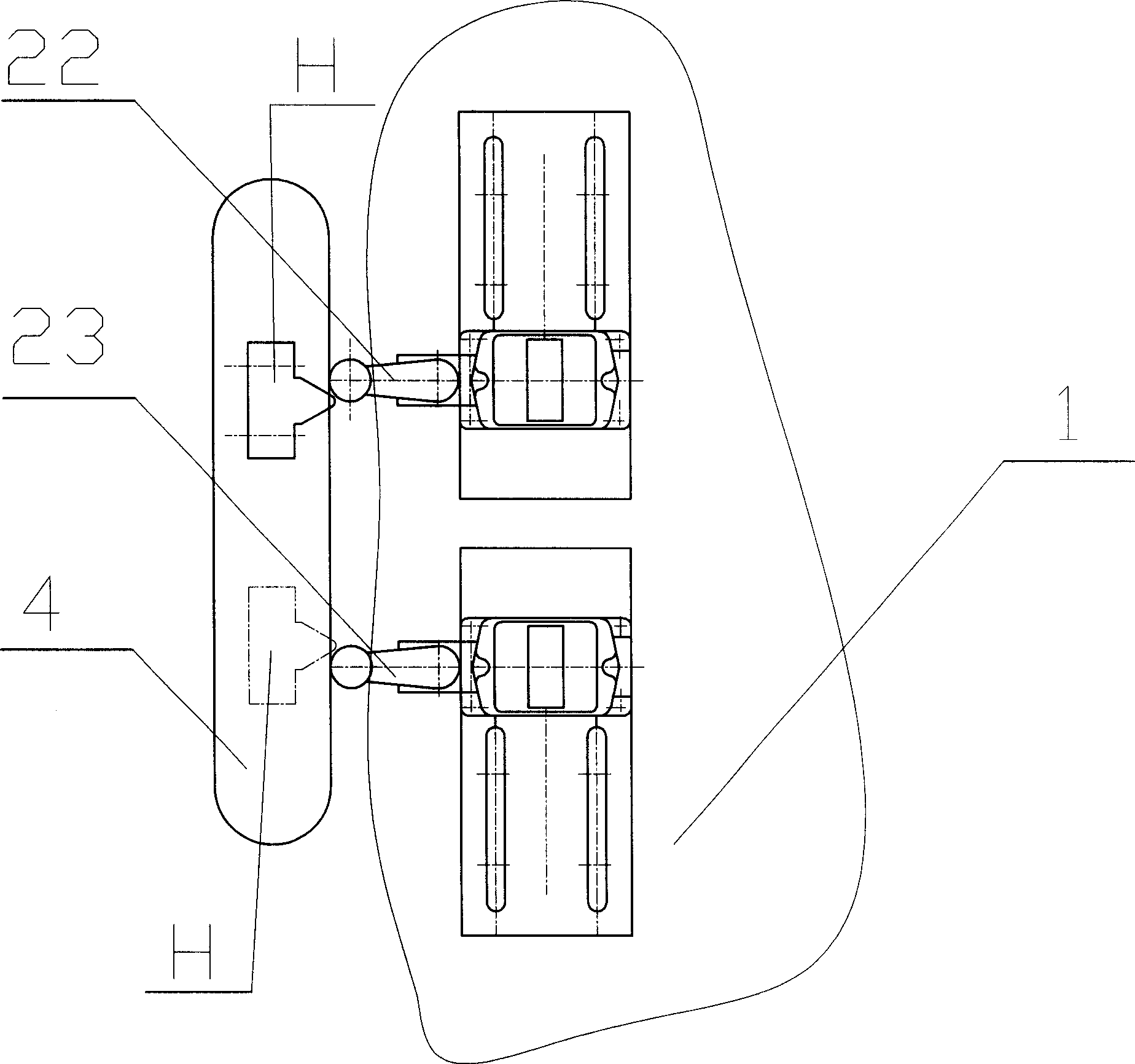

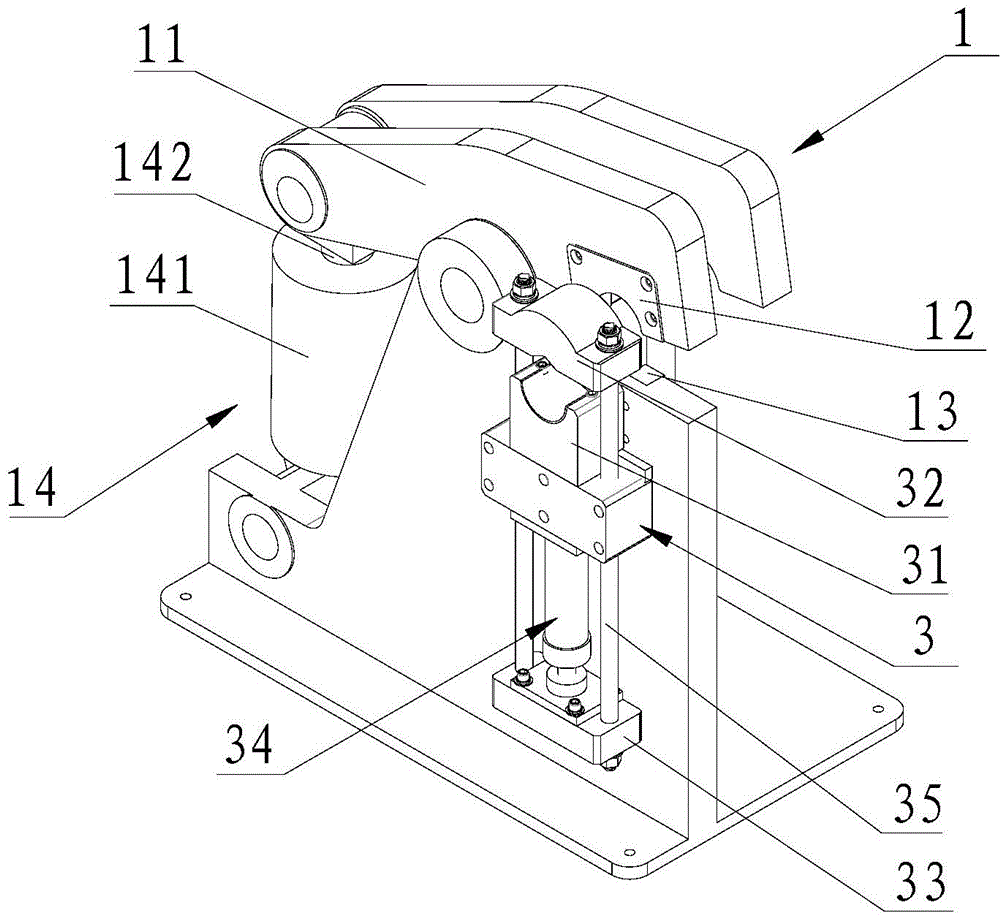

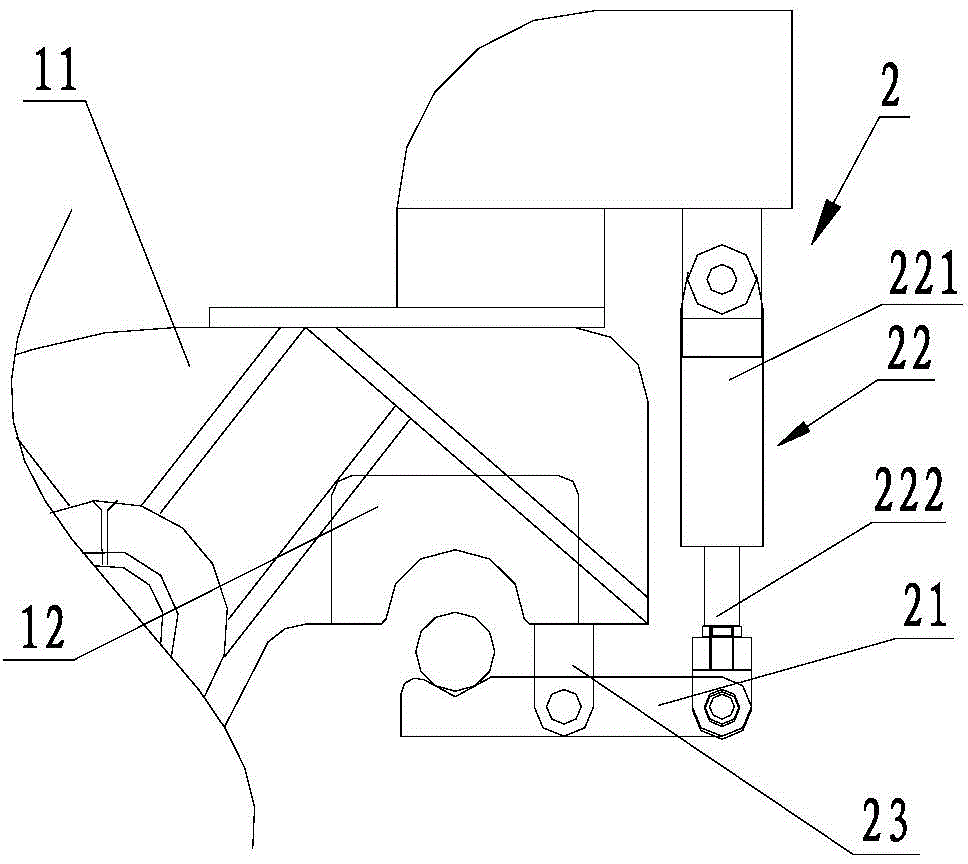

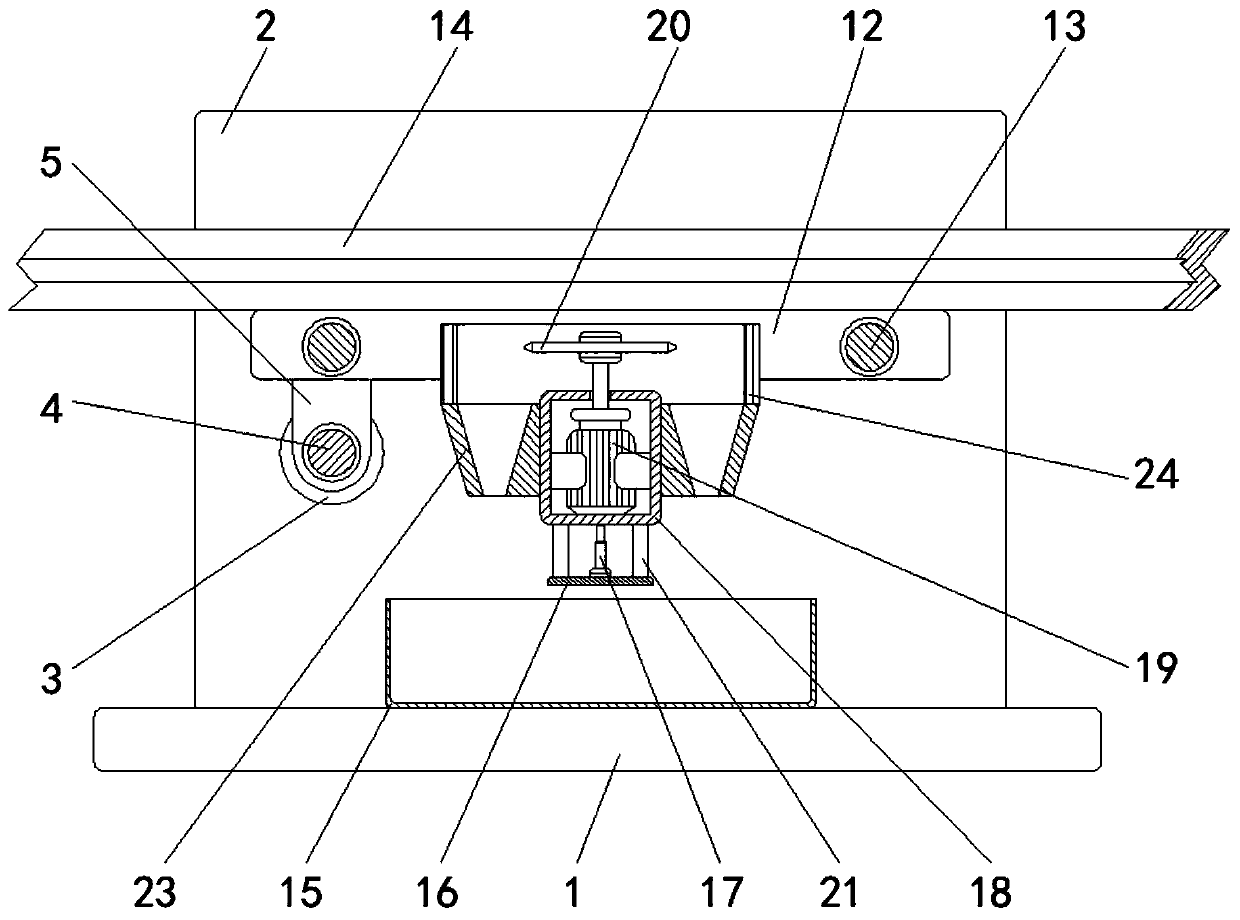

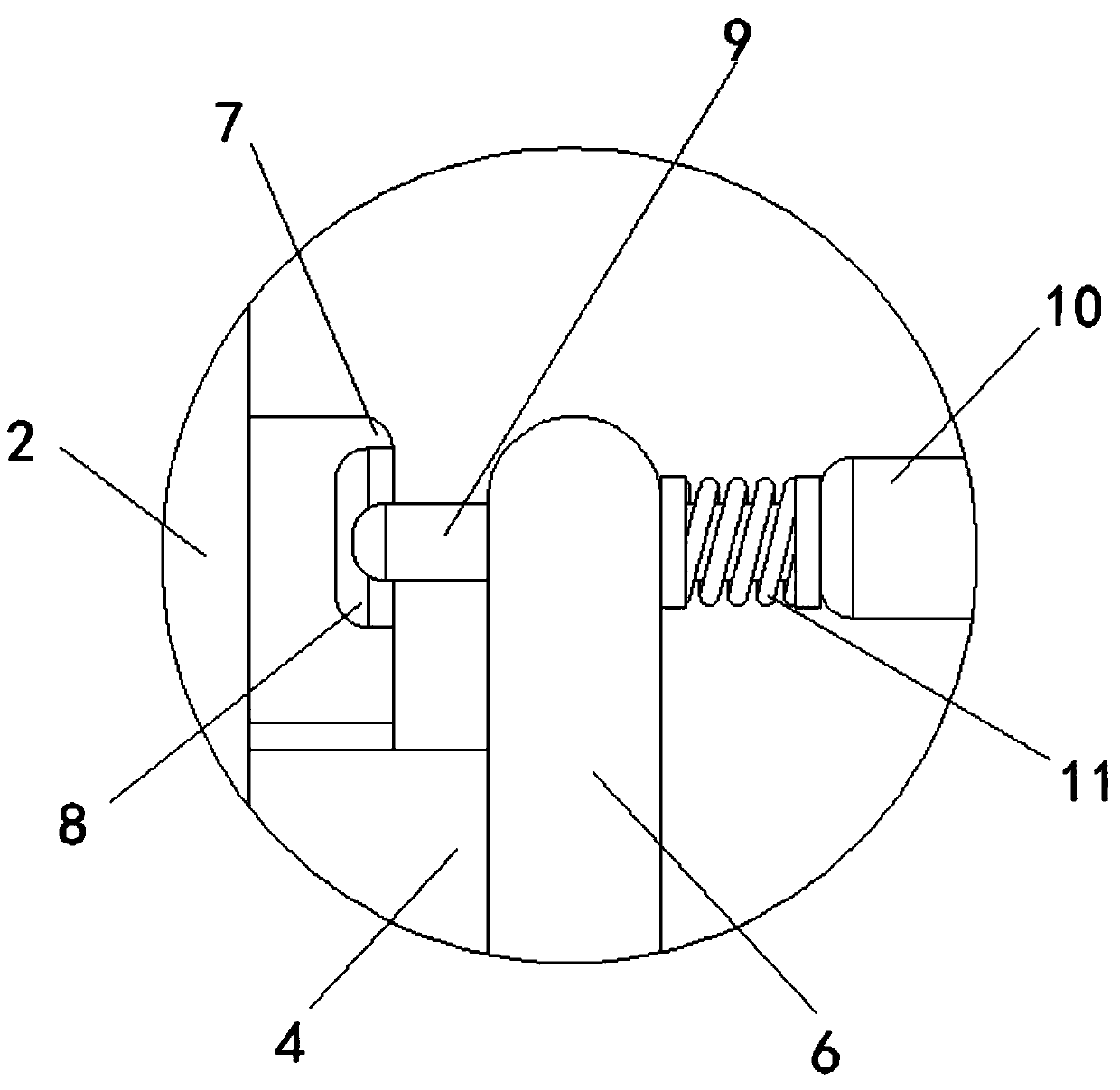

Hydraulic shearing pliers

InactiveCN103357947APlay a supporting roleShear stablePortable handheld shearing machinesHydraulic cylinderStructural engineering

The invention discloses a pair of hydraulic shearing pliers which comprises hydraulic handles, a hydraulic cylinder, a piston rod, a jaw, an upper die plate and a lower die plate, wherein the two hydraulic handles are both connected with the hydraulic cylinder, the upper die plate and the lower die plate are mounted in the jaw, two shearing teeth are respectively arranged on the upper die plate and the lower die plate, and supporting rods are arranged on the hydraulic cylinder. In the hydraulic shearing pliers, the two supporting rods are arranged on the hydraulic cylinder, the positions of the supporting rods and the hydraulic cylinder are adjusted through tightening a button, when in shearing, the hydraulic shearing pliers are adjusted to the upper end of the hydraulic cylinder to play a role of supporting in shearing, so that the shearing is more stable, and when the pair of hydraulic shearing pliers is not in use, the hydraulic shearing pliers are moved by rollers at the lower ends of the supporting rods, and the traditional transportation is replaced, so that the manpower and the physical resources are saved greatly, the structure is simple, and the use is convenient.

Owner:TAICANG OURUI INTELLIGENT ENG

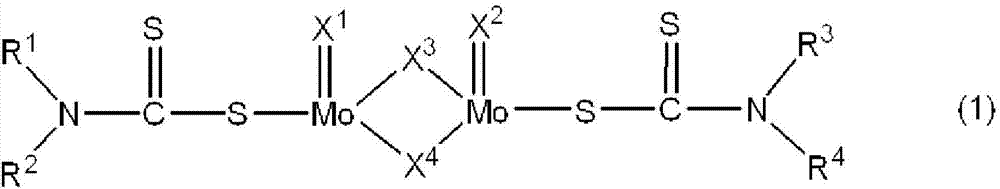

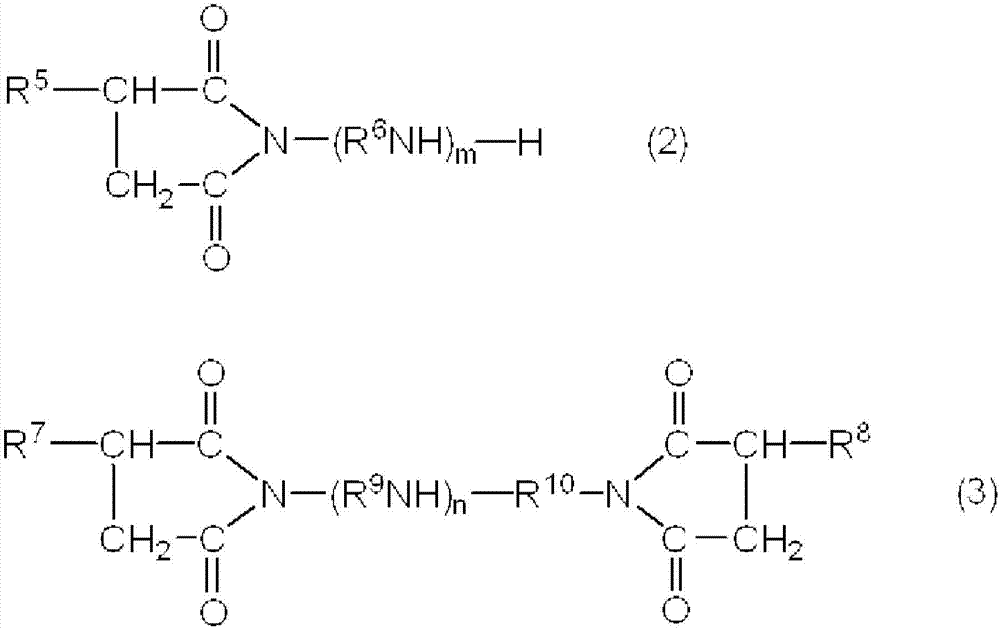

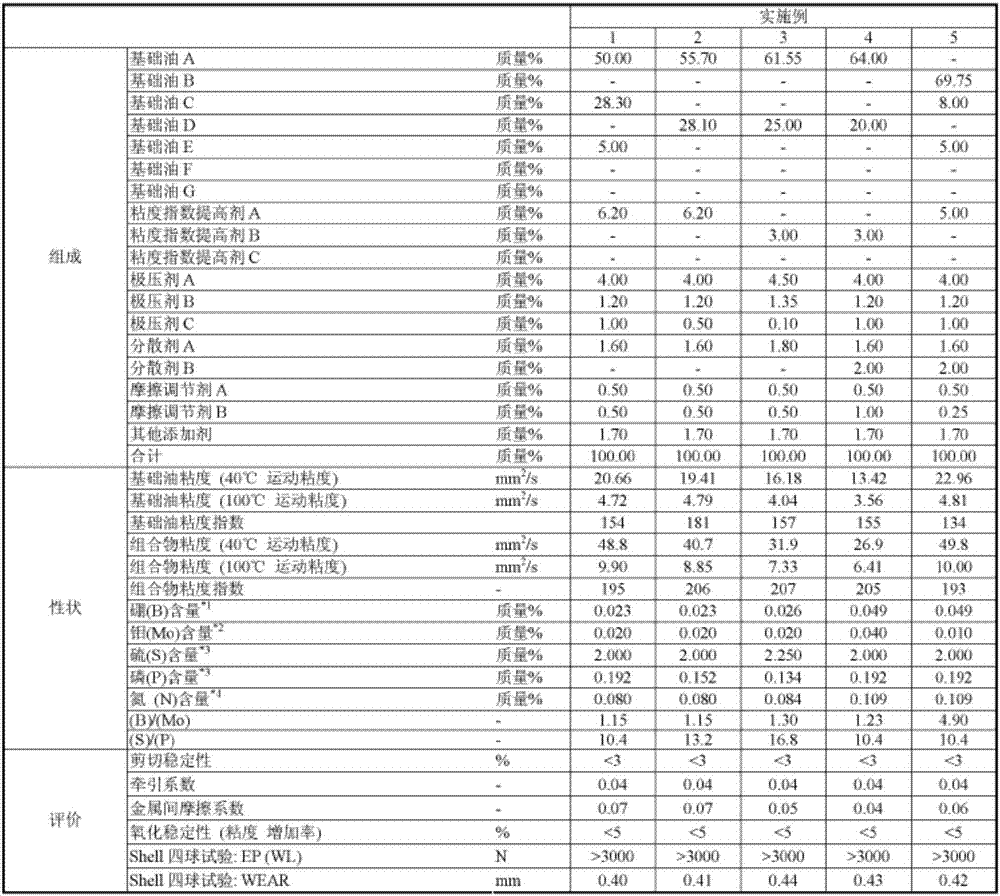

Lubricant composition

ActiveCN107532106AImprove economyTaking extreme pressure into accountAdditivesBase-materialsMass ratioSulfur

Provided is a lubricant composition which has achieved a good balance between fuel consumption saving and extreme-pressure properties, while having shear stability, oxidation stability and wear resistance. Specifically, provided is a lubricant composition which is characterized by containing a base oil, a viscosity index improver, a molybdenum-based friction modifier, a boron-containing dispersant, and a sulfur / phosphorus-based extreme-pressure additive or at least two extreme-pressure additives selected from among a sulfur-based extreme-pressure additive, a phosphorus-based extreme-pressure additive and a sulfur / phosphorus-based extreme-pressure additive, and which is also characterized in that: the base oil is composed only of a synthetic oil; the base oil has a kinematic viscosity of from 3 mm2 / s to 10 mm2 / s (inclusive) at 100 DEG; the viscosity index improver is a resin having a number average molecular weight (Mn) of from 1,000 to 10,000 (inclusive); the mass ratio of the boron atoms (B) contained in the boron-containing dispersant to the molybdenum atoms (Mo) contained in the molybdenum-based friction modifier, namely (B) / (Mo) is from 1 to 5 (inclusive); and the mass ratio ofthe sulfur atoms (S) contained in the extreme-pressure additive(s) to the phosphorus atoms (P) contained in the extreme-pressure additive(s), namely (S) / (P) is from 10 to 20 (inclusive).

Owner:IDEMITSU KOSAN CO LTD

Lubricating composition containing a polymer and antiwear agents

Owner:THE LUBRIZOL CORP

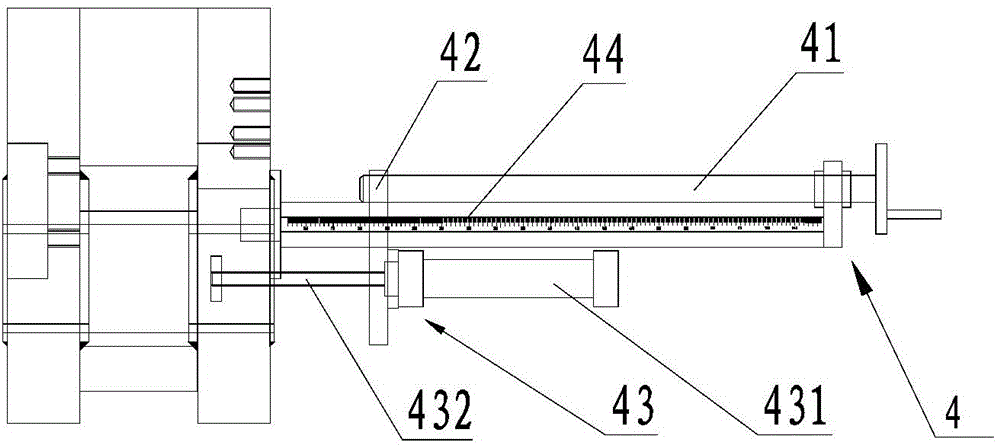

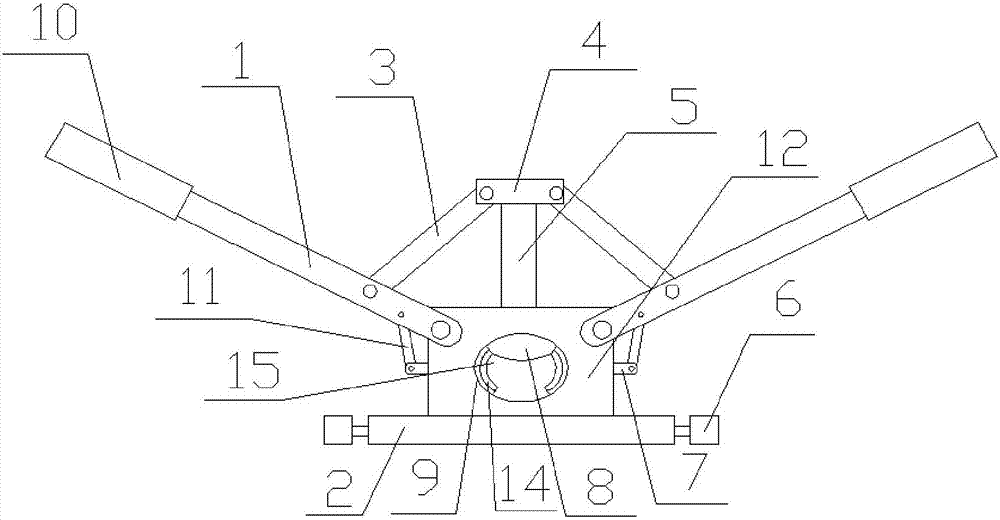

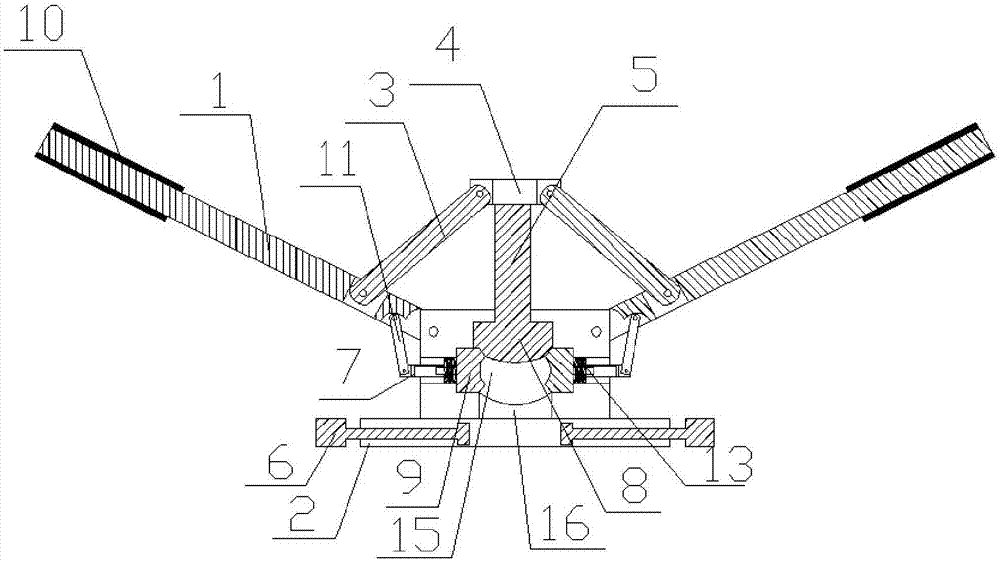

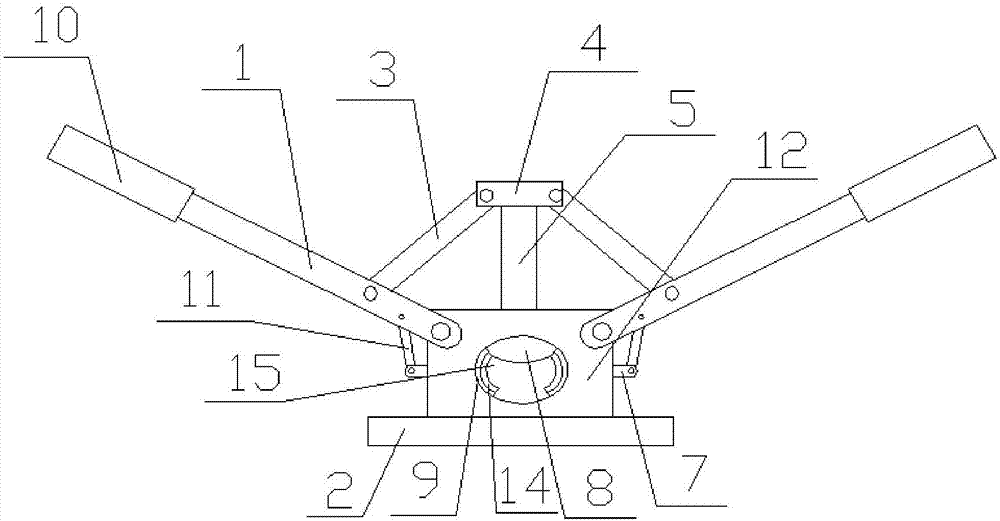

Scissor of sampling sheet metal

InactiveCN1916589AEasy to operateIncrease productivityWithdrawing sample devicesHinge angleEngineering

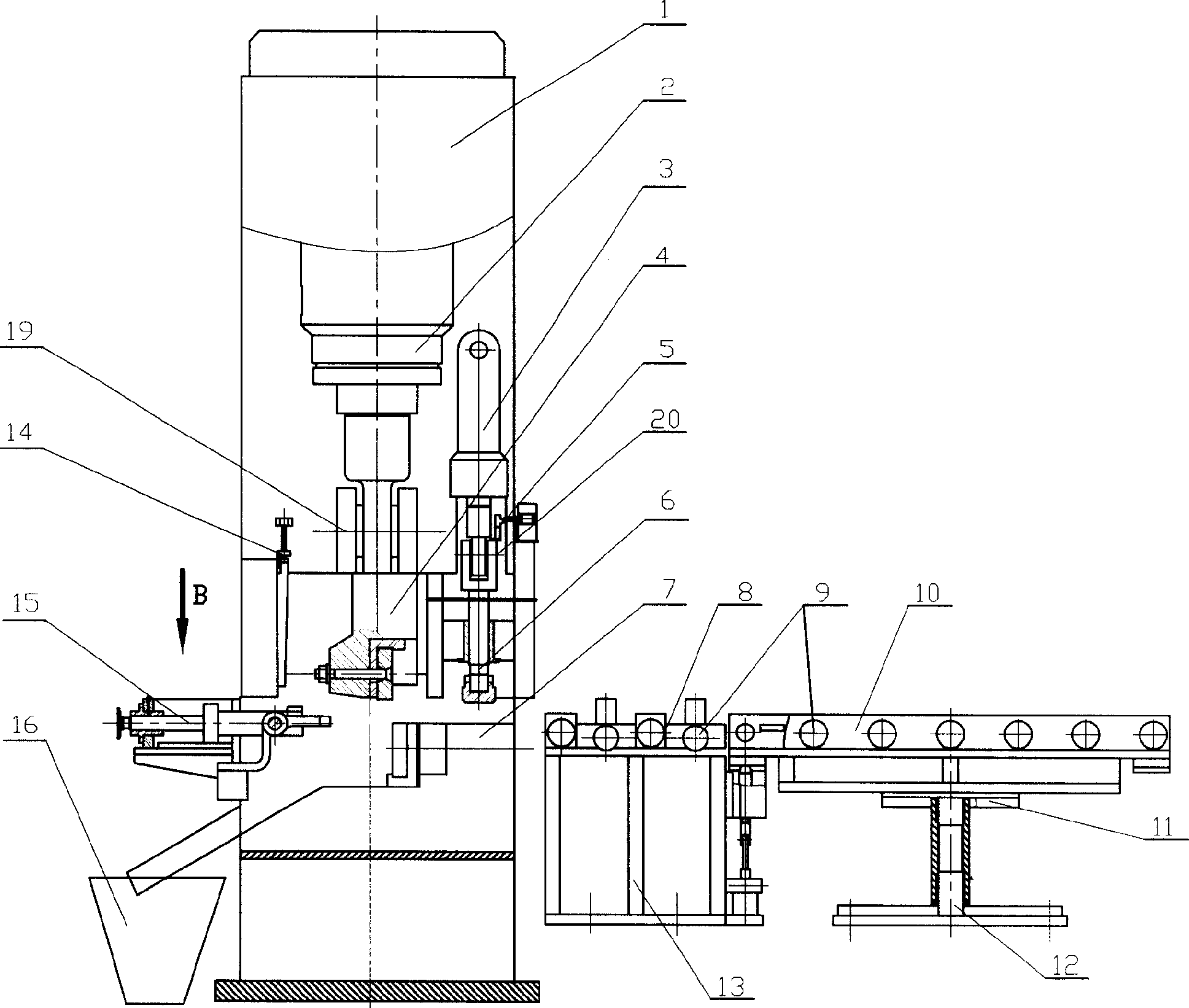

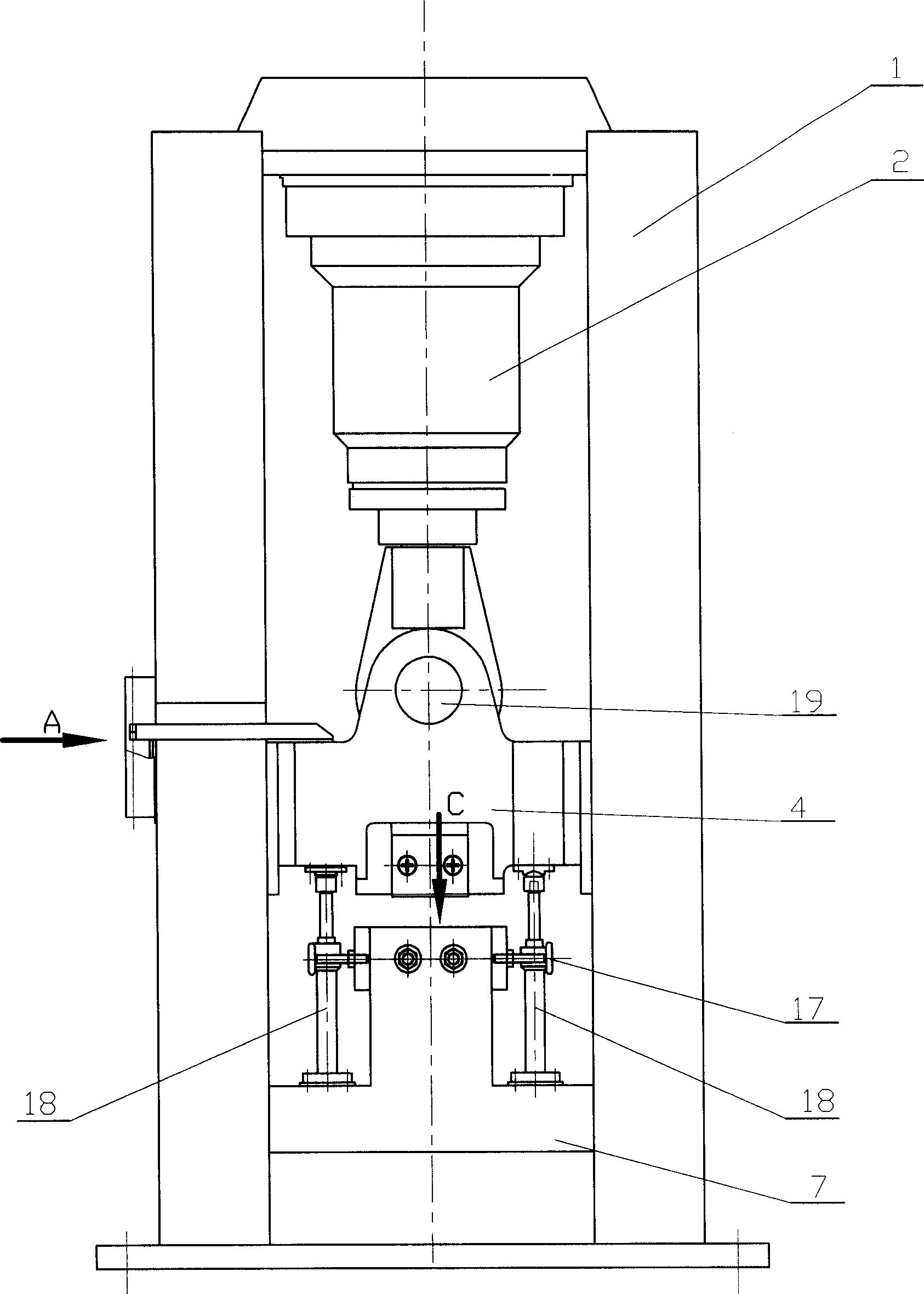

A sampling scissors of metal slab is prepared as setting master hydraulic cylinder for driving top shearing blade on top of body frame through hinge and setting bottom shearing blade corresponding to position of top shearing blade on bottom of body frame, setting metal slab material pressing unit in front of top and bottom shearing blades, setting size-setting mechanism and gap regulation mechanism of top and bottom shearing blades at back of top and bottom shearing blades, setting metal slab material conveying unit with rollers in front of body frame.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

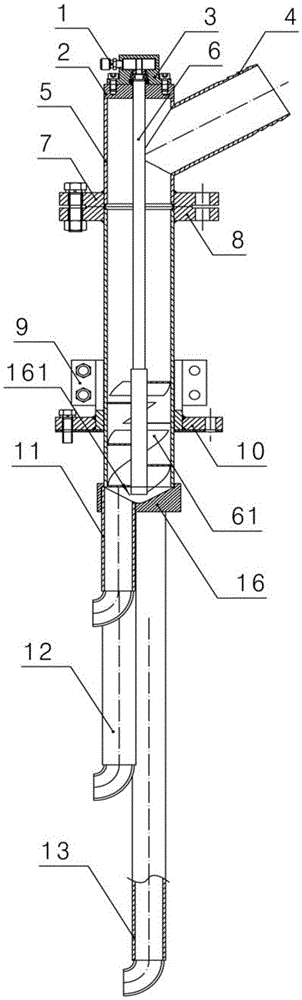

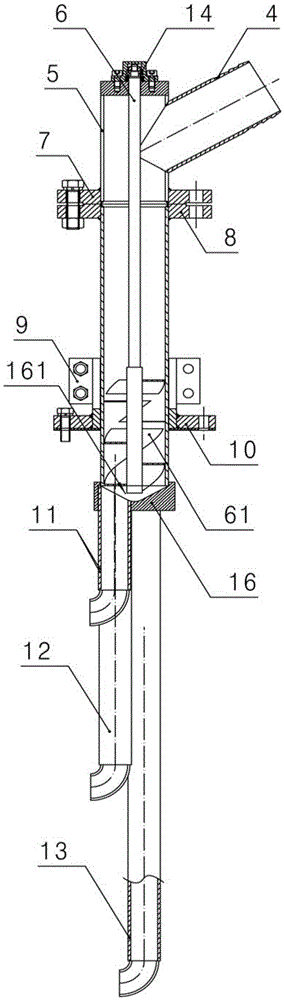

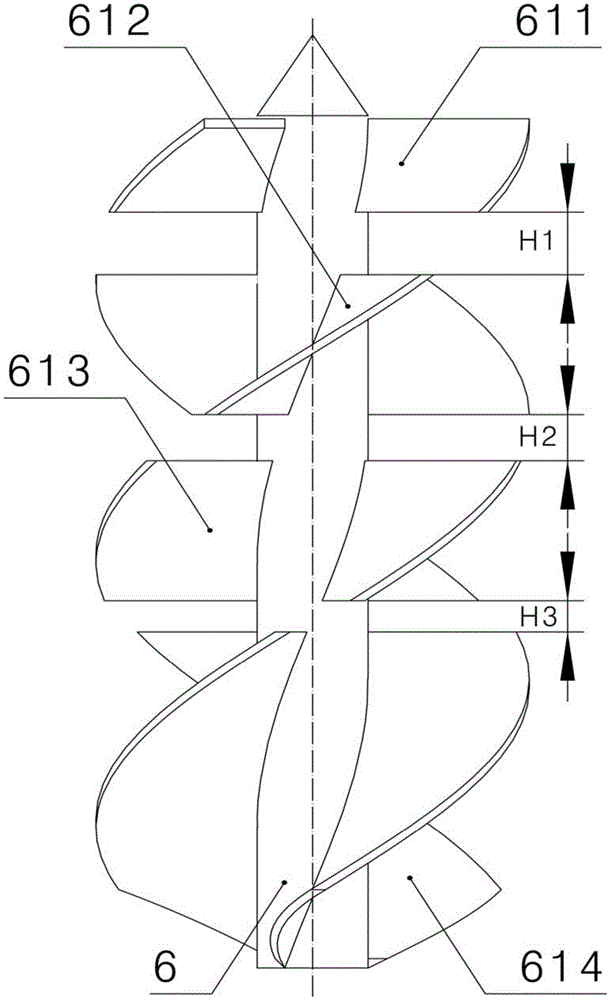

Feeding device for vertical centrifugal machine

ActiveCN105583088AEasy to disassembleUniform flowCentrifugesGrain treatmentsEngineeringMechanical engineering

The invention discloses a feeding device for a vertical centrifugal machine. By the adoption of the feeding device for the vertical centrifugal machine, materials can be made uniform. The feeding device for the vertical centrifugal machine comprises a feeding pipe. A feeding port is formed in the upper portion of the feeding pipe. A blanking plate is arranged at the bottom end of the feeding pipe. The blanking plate is provided with at least one blanking pipe and blanking through holes communicating with all the blanking pipes in a one-to-one correspondence mode. A blanking port is formed in the bottom end of each blanking pipe. A rotary shaft is rotatably arranged in the feeding pipe in the axial direction. At least one stirring and breaking knife set is arranged on the portion, below the feeding port, of the rotary shaft. Each stirring and breaking knife set comprises at least three stirring and breaking blades which are arranged from top to bottom. Cutting edges are arranged on the upper edge and the lateral edges of each stirring and breaking blade correspondingly. A gap is reserved between every two adjacent stirring and breaking blades and becomes smaller gradually from top to bottom. The centrifugal machine additionally provided with the feeding device is particularly suitable for separating materials prone to caking.

Owner:JIANGSU HUADA CENTRIFUGE

Polymers and methods of controlling viscosity

ActiveUS8343900B2Shear stableAcceptable/improved viscosity index controlAdditivesFoam dispersion/preventionPolymer scienceViscosity index

The present invention relates to a novel polymer with pendant groups. The invention further provides for a lubricating composition containing said polymer. The invention further provides a method and use of controlling viscosity index by supplying to an oil of lubricating viscosity the polymer with pendant groups.

Owner:THE LUBRIZOL CORP

Flattening and clamping paper stabilizing table for printing

InactiveCN111660662AAvoid wrinklesReduce waste paper rateRotary pressesPrinting press partsIndustrial engineeringPaper sheet

The invention relates to the technical field of printing, and discloses a flattening and clamping paper stabilizing table for printing. The paper stabilizing table comprises a base. According to the paper stabilizing table, a fixing plate is supported and stabilized by using the base, through cooperative use of a vertical rod, a first sleeve rod, a first connecting rod, a first sliding block and atransverse plate, paper is flattened during paper shearing, and the first sliding block is used for pressing the upper portion of the paper, so that wrinkles are avoided during paper shearing, and the waste paper rate of the paper is reduced; through cooperative use of a second sleeve rod, a second connecting rod, a third connecting rod and a clamping plate, clamping is conducted during paper cutting, loosening caused by shaking during shearing of a plurality of pieces of paper is avoided, and the paper shearing is more stable; and through cooperative use of a first rotating disc, a third rotating disc, a fourth rotating disc and a second sliding block, two steps of paper clamping and paper flattening are linked, so that the linkage of the whole paper stabilizing table is improved, and the operation is simpler.

Owner:陈爱丽

Bar shearing device

InactiveCN104308257AGood cross section flatnessSave materialShearing machinesShearing machine accessoriesKnife bladesBar stock

Owner:高超 +1

Wire harness cutting-off device

The invention discloses a wire harness cutting-off device and relates to the field of automobile wire harnesses. The wire harness cutting-off device comprises two handles, a base and a shearing platform; the shearing platform is arranged on the base with a cuboid structure; the two handles are symmetrically arranged at two sides of the shearing platform and are hinged with the shearing platform; a through hole is formed in the top of the shearing platform; a pressure column is sleeved by the through hole; a blade is arranged inside the shearing platform and is connected with the bottom of the pressure column; the top of the pressure column is provided with a connecting platform; a supporting rod I is hinged between the connecting platform and each handle; notches are formed in two sides of the shearing platform and are internally sleeved with push rods on which clamping pieces are arranged; a supporting rod II is hinged between each push rod and each handle; a shearing port is formed in the middle of the shearing platform; and both the blade and the clamping pieces are arranged in the shearing port. By using the cutting-off device, a wire harness can be fixed, so that the phenomenon that the efficiency is affected due to the slip off of the wire harness during cutting is avoided.

Owner:WUHU QIAOYUN & YOUXING ELECTRICAL IND CO LTD

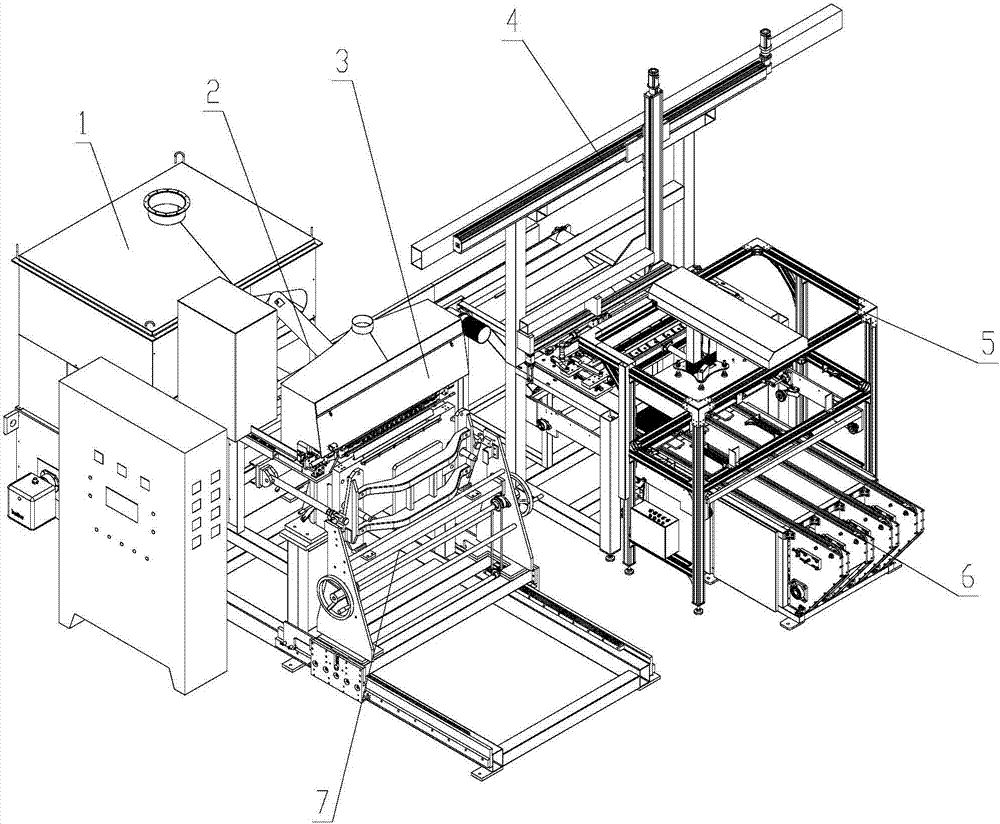

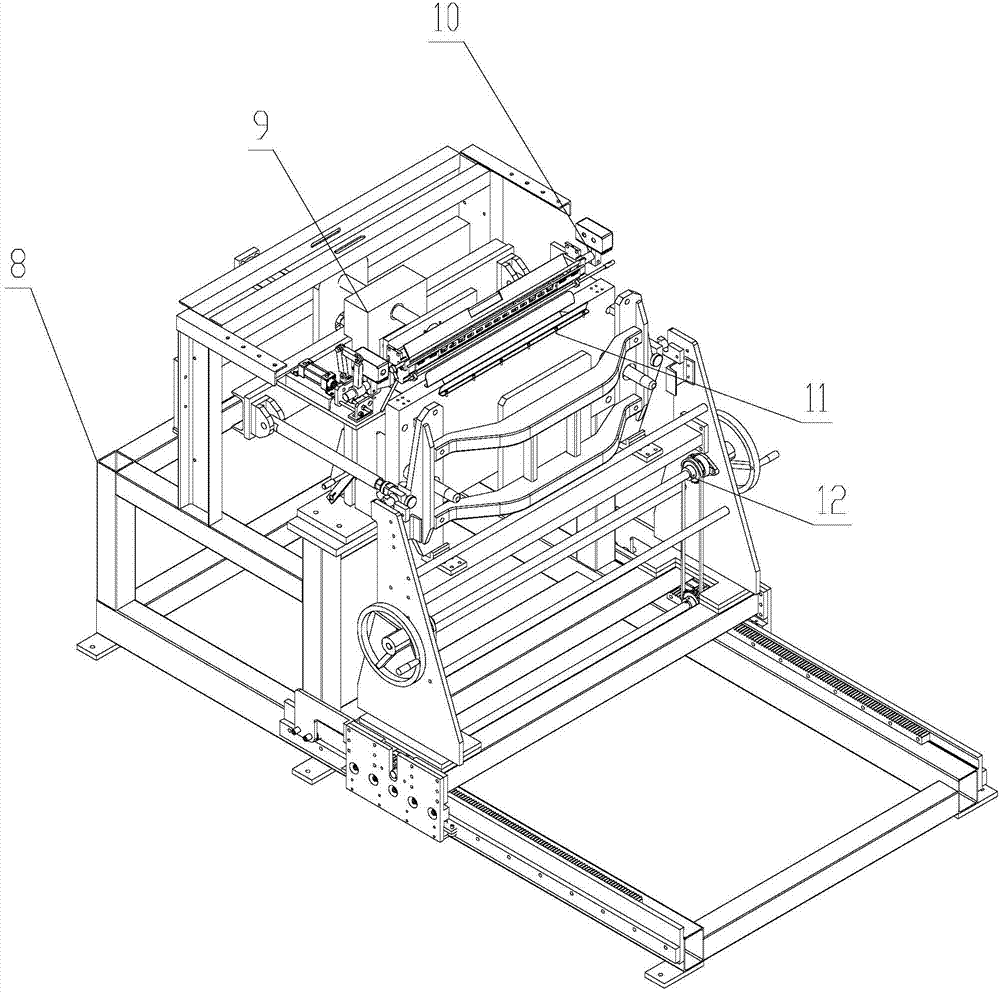

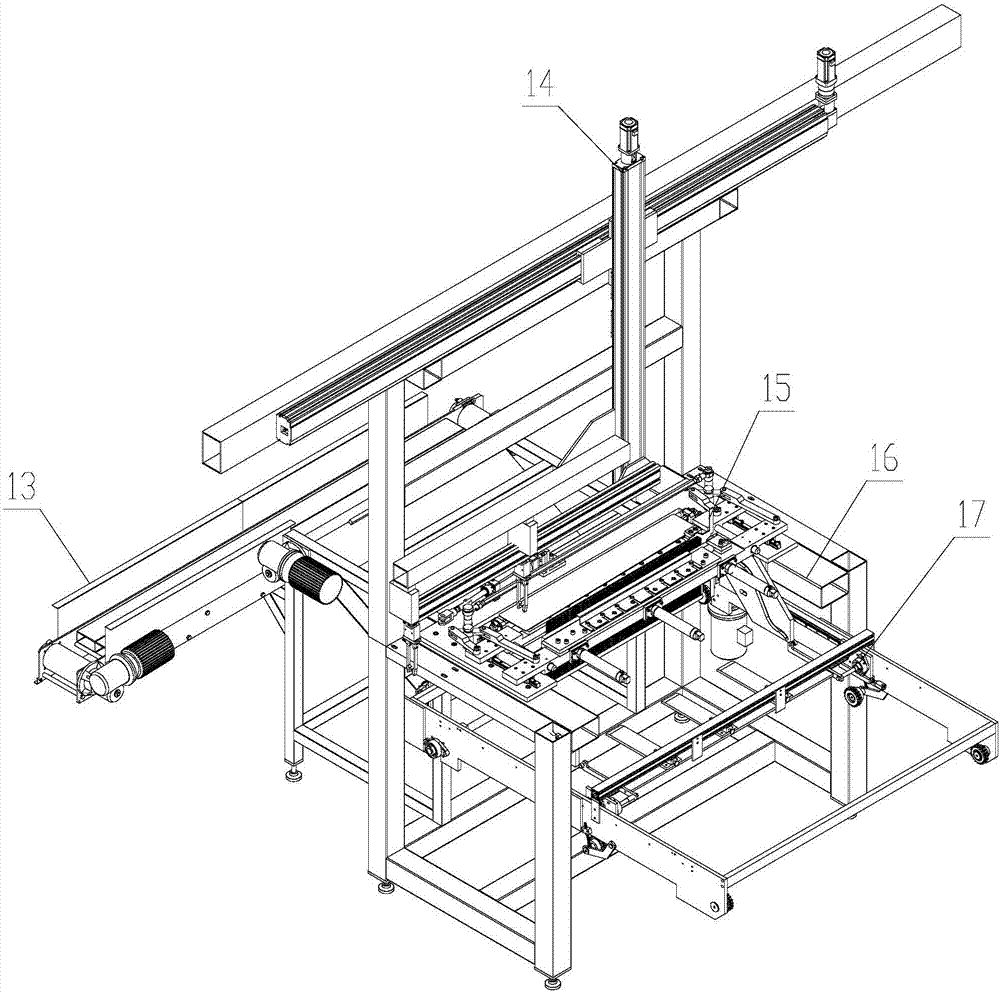

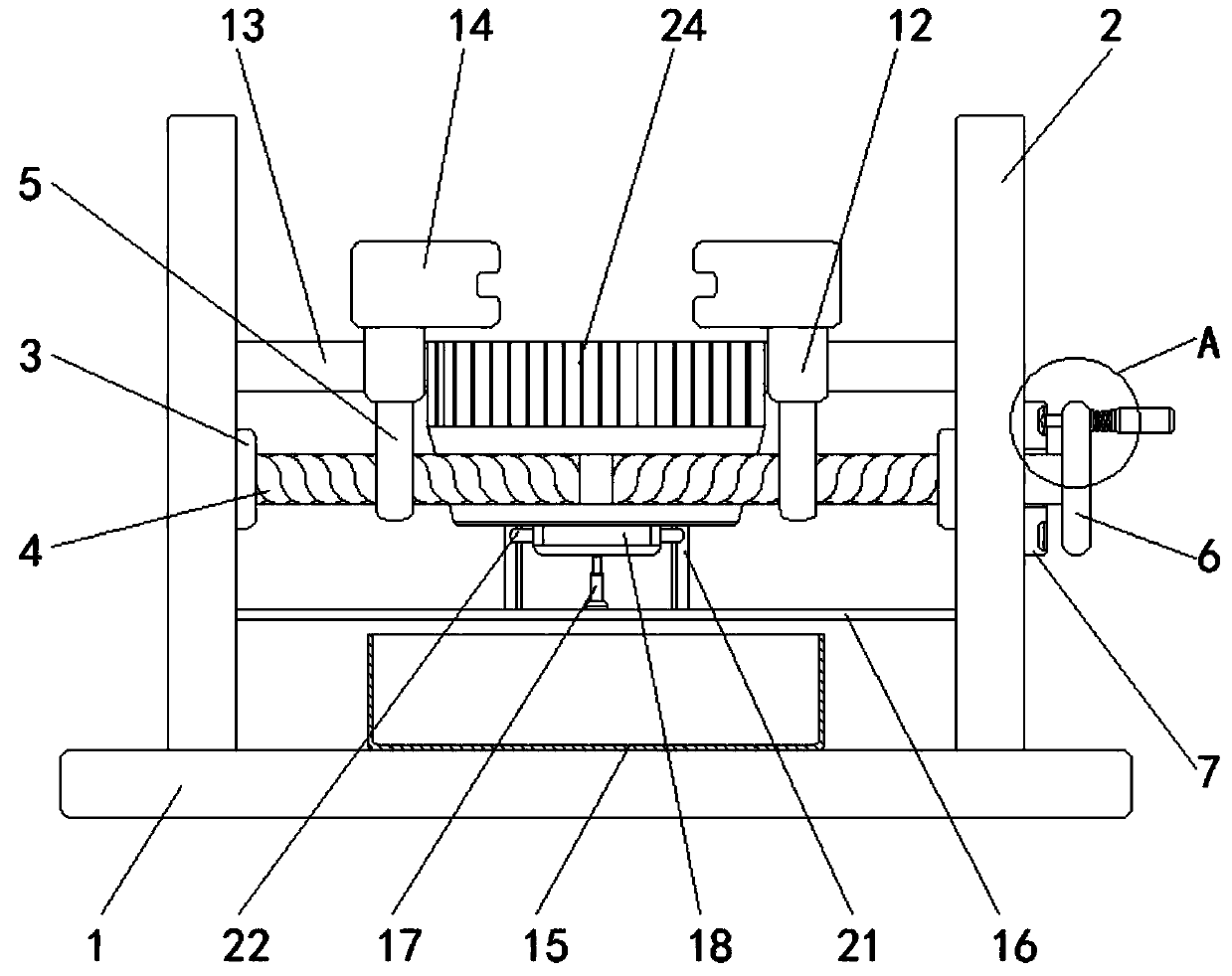

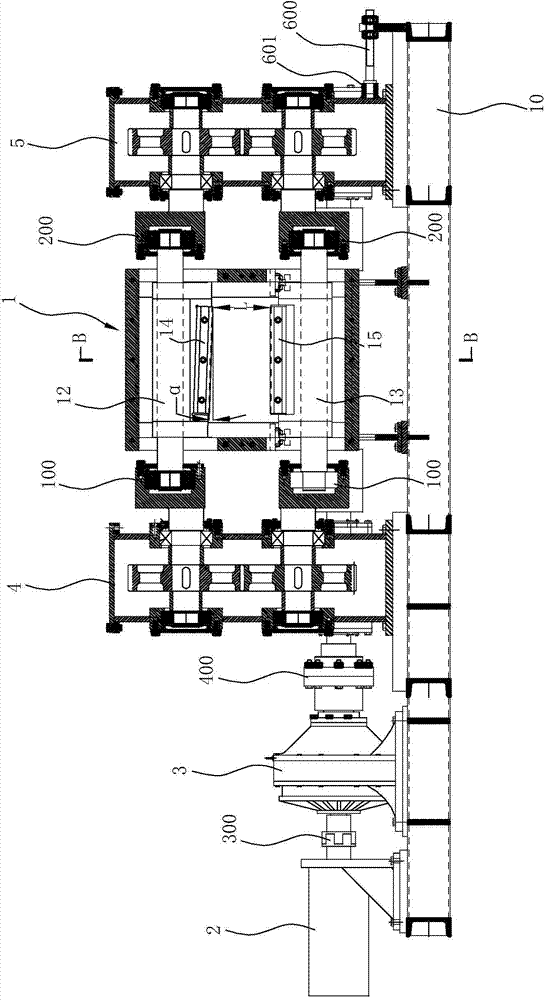

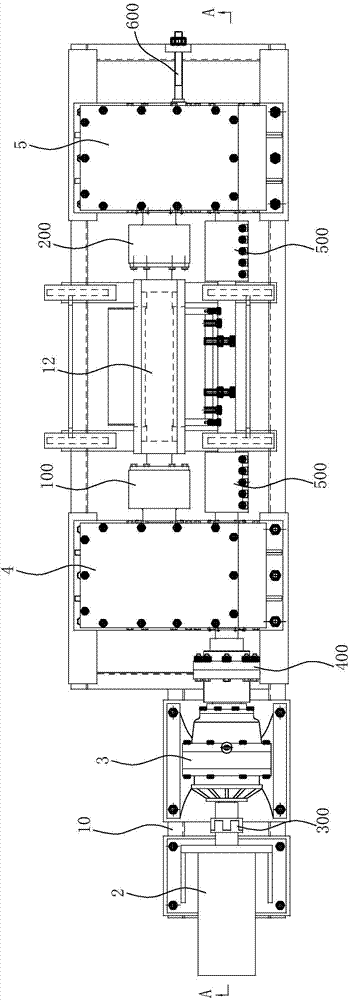

Storage battery large-plate grid casting equipment

ActiveCN107046134AQuality improvementReduce distortionElectrode carriers/collectorsGrid deformationManipulator

The invention discloses storage battery large-plate grid casting equipment. The storage battery large-plate grid casting equipment comprises a casting plate and a casting plate auxiliary machine; a casting plate host is used for casting and moulding a battery plate grid; the casting plate auxiliary machine comprises a vertical shearing mechanism used for shearing a casting head of the vertically placed plate grid, a plate grid turning device used for driving the sheared plate grid from a vertical state to a horizontal state by overturning, and a truss manipulator assembly which is crossed between the casting plate host and the vertical shearing mechanism and used for casting and moulding the casting plate host and vertically hoisting the plate grid mould by the casting plate host to the vertical shearing mechanism. The equipment can reduce the machinery damage at each link during plate grid manufacture as possible, and plate grid deformation can be controlled.

Owner:中国船舶重工集团衡远科技有限公司

Adjustable pin shearing machine for electronic component production

The invention relates to the technical field of electronic component production equipment, and discloses an adjustable pin shearing machine for electronic component production. The adjustable pin shearing machine comprises a base plate, the top of the base plate is fixedly provided with two side plates, the opposite sides of the side plates are fixedly provided with bearing clamps, a screw rod which penetrates through each side plate and extends to the inside of each bearing clamp is movably arranged on the right side of each side plate, the outer wall of the screw rod is sleeved with a connecting block, a hand wheel is fixedly arranged on the right side of the screw rod, and a limiting disc is fixedly arranged on the right side of each side plate and positioned on the periphery of each screw rod. According to the adjustable pin shearing machine for electronic component production, by starting an electric push rod to stretch and retract, the electric push rod drives a motor and a cutting knife to lift through a case, so that the cutting height of the cutting knife is adjusted, and the effect of simple and convenient adjustment is achieved, so that the adjustable pin shearing machine is suitable for shearing various electronic components of different types, thereby improving the practicability of the adjustable pin shearing machine.

Owner:西安智强科技有限公司

Special material for waste ABS (acrylonitrile butadiene styrene) plastic regenerated and modified automobile and preparation method of special material

The invention discloses a special material for a waste ABS plastic regenerated and modified automobile and a preparation method of the special material, and solves the problem that the recovery rate of a waste ABS plastic is lower, and resources are wasted in the prior art. The special material comprises the components in parts by weight as follows: 100 parts of a waste ABS broken material, 1-8 parts of ABS, 0.1-0.3 parts of EBS (ethylene bis stearamide), 0.1-0.2 parts of zinc stearate, 0.1-0.2 parts of calcium stearate, 0.1-0.2 parts of antioxidant 10100, 0.2-0.6 parts of antioxidant 168 and 0.1-0.4 parts of montan wax, wherein the waste ABS broken material is obtained by picking, breaking, cleaning, dehydrating, absorbing and drying the waste ABS plastic. The preparation method of the special material for the waste ABS plastic regenerated and modified automobile is further provided. The special material for the waste ABS plastic regenerated and modified automobile and the preparation method of the special material have the advantages that the waste ABS plastic can be recycled, resources are saved, the environment is protected, the cost is reduced, the preparation process is simplified, and the like.

Owner:四川塑金科技有限公司

Special material for regenerating and modifying heel by recycling ABS plastic housing of household appliance and preparation method of special material

The invention discloses a special material for regenerating and modifying a heel by recycling an ABS (Acrylonitrile Butadiene Styrene) plastic housing of a household appliance and a preparation method of the special material in order to solve the problem that a resource is wasted due to the fact that an ABS plastic housing of a household appliance is not recycled in the prior art. The special material comprises the following components in parts by weight: 100 parts of broken material of the ABS plastic housing of the household appliance, 5-20 parts of ABS, 0.1-1 part of calcium stearate, 0.1-1 part of EBS (Ethylene Bis Stearamide) and 0.1-0.5 parts of toner, wherein the broken material of the ABS plastic housing of the household appliance is obtained by breaking, cleaning, rinsing and drying the recycled ABS plastic housing of the household appliance and sucking a label of the recycled ABS plastic housing. The invention further provides the preparation method of the special material for regenerating and modifying the heel by recycling the ABS plastic housing of the household appliance. The special material and the preparation method can effectively recycle the ABS plastic housing of the household appliance, and have the advantages of resource saving, environmental protection, cost reduction, preparation process simplification and the like.

Owner:四川塑金科技有限公司

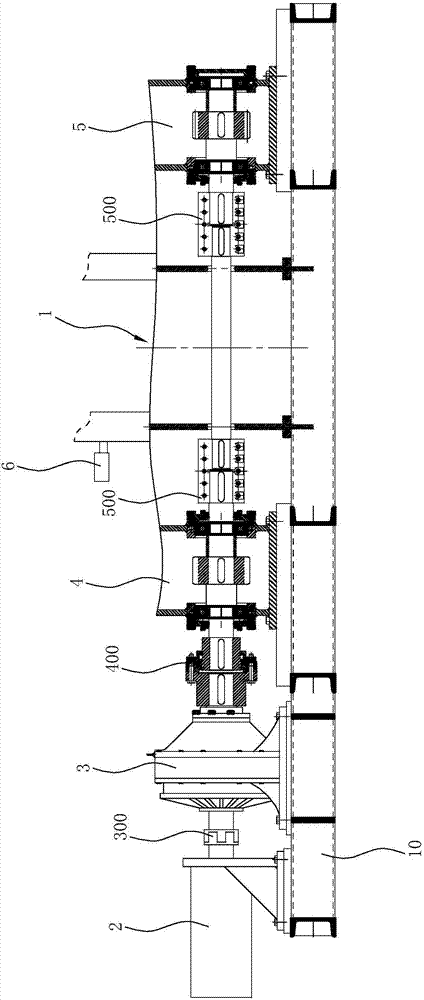

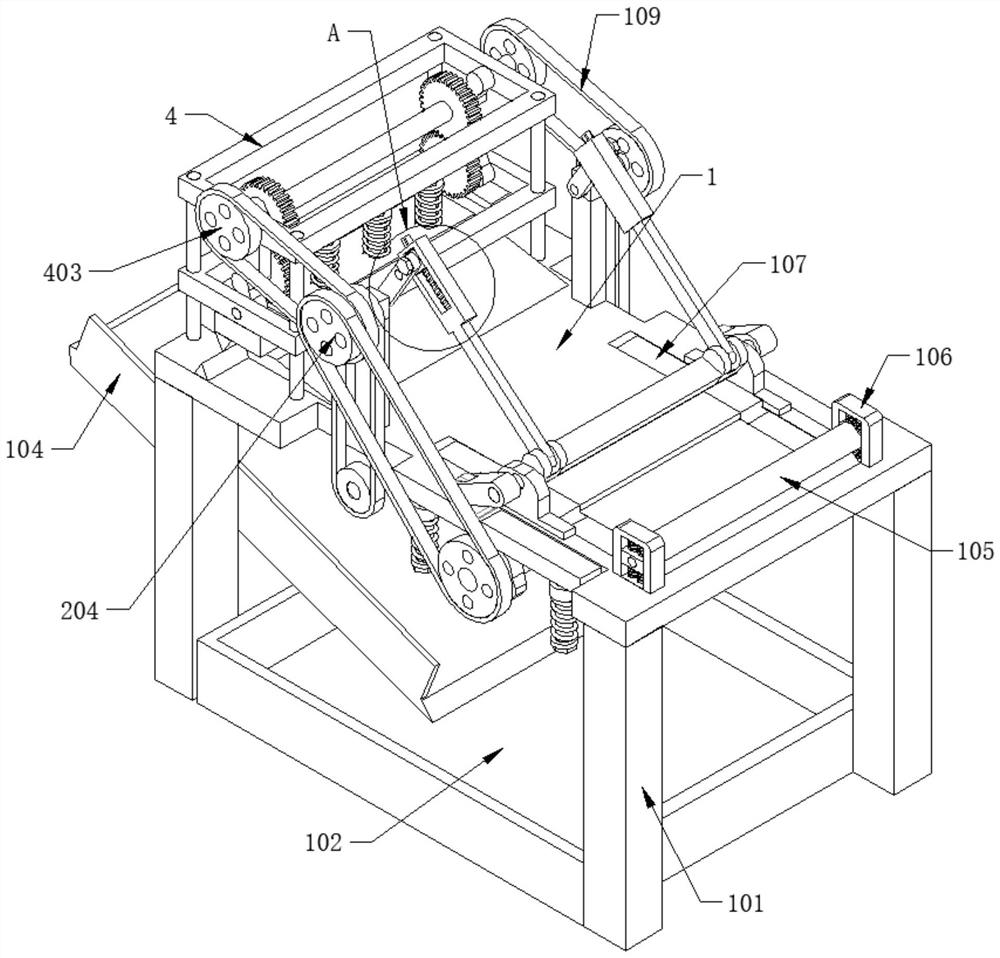

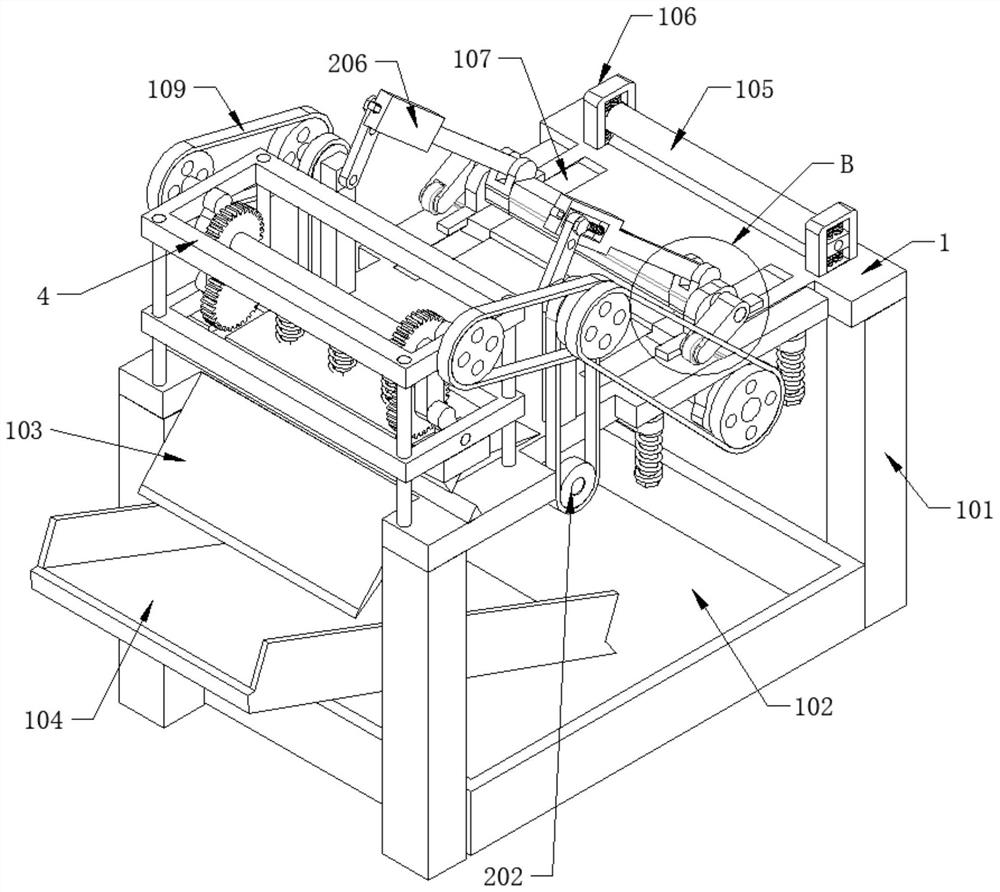

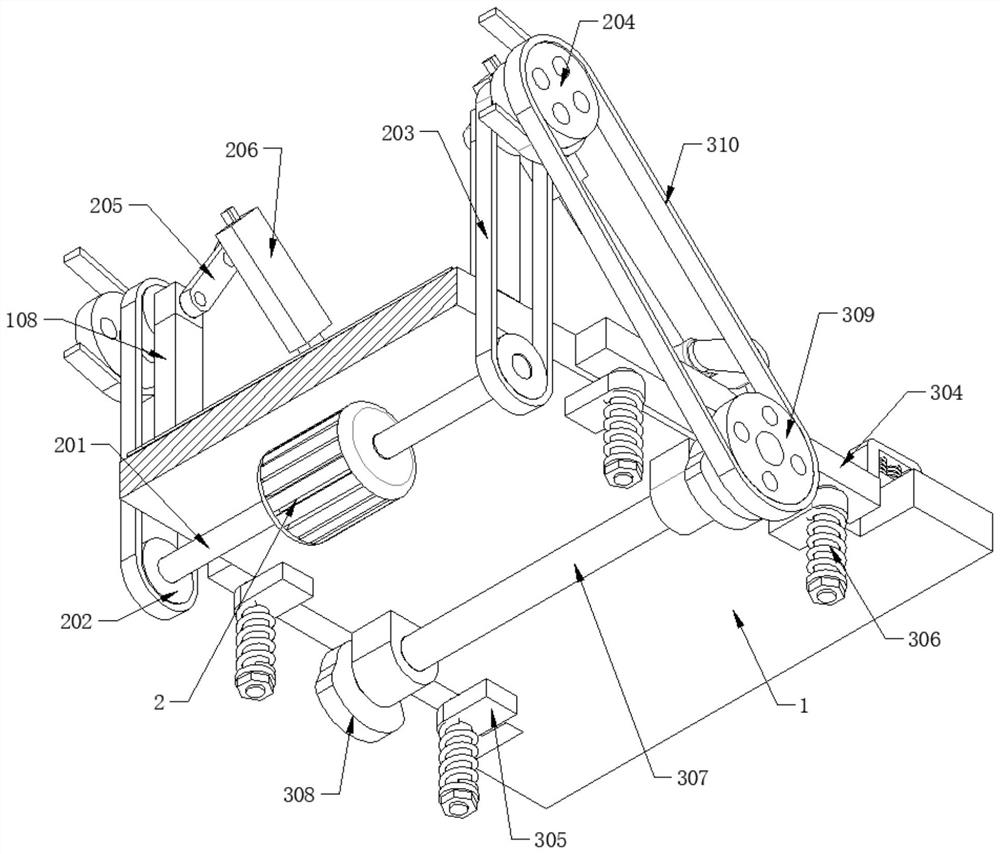

Rolling-cut transverse shearing device

ActiveCN104741683AShear stableImprove accuracyShearing machinesShearing machine accessoriesTransverse shearDriving mode

The invention relates to a rolling-cut transverse shearing device which comprises a vertical shearing mechanism and a drive assembly connected with the vertical shearing mechanism in a driving mode. The vertical shearing mechanism comprises a support, an upper transmission roller, a lower transmission roller, an upper shearing blade arranged on the upper transmission roller, and a lower shearing blade arranged on the lower transmission roller. The upper transmission roller and the lower transmission roller are arranged on the upper part and the lower part of the support respectively. The lower shearing blade is horizontally arranged on the top of the lower transmission roller. The upper shearing blade is arranged at the bottom of the upper transmission roller. The included angle between the blade edge of the upper shearing blade and the axis of the upper transmission roller ranges from 1.5 degrees to 3 degrees. A measurement roller which can measure the conveying speed and the length of a plate strip and provided with an encoder is arranged on the portion, close to the feed end, of the vertical shearing mechanism. The cutting depths of the upper shearing blade and the lower shearing blade can be consistent, it is ensured that the maximum shearing force value can reach 20 T, the accuracy of the size of a notch of the plate strip is improved, the upper shearing blade does not horizontally slide, abrasion to the shearing blades can be effectively reduced, the service life of the shearing blades can be prolonged, bending deformation on the fracture surface of the plate strip can be avoided, and the shearing quality can be improved.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Plate shearing equipment for new energy automobile part production and using method

ActiveCN113102817ARealize automatic pushingAdjustable distanceShearing machinesMetal working apparatusNew energyDrive shaft

The invention discloses plate shearing equipment for new energy automobile part production and a using method, and belongs to the technical field of automobile part machining. The plate shearing equipment for new energy automobile part production comprises a mounting table and supporting legs, wherein the supporting legs are connected to the bottom wall of the mounting table, the side wall of the mounting table is connected with a first material receiving plate, the inner walls of the supporting legs are connected with a second material receiving plate and a material collecting box, a material pushing mechanism comprises a double-end motor, a connecting rod assembly and a pressing assembly, and the top of the mounting table is connected with a supporting plate; the connecting rod assembly is arranged at the top of the supporting plate, the double-end motor is connected to the bottom wall of the mounting table, the output ends of the two ends of the double-end motor are connected with first transmission shafts, one ends, away from the double-end motor, of the first transmission shafts are connected with first belt wheels, the outer walls of the first belt wheels are connected with first belts, and the first belts are connected to the input end of the connecting rod assembly. According to the plate shearing equipment for new energy automobile part production, long steel plates can be automatically fed and sheared, the size is convenient to adjust, the shearing process is stable, and deviation is not prone to occurring.

Owner:KAZUO PENGDA CASTING

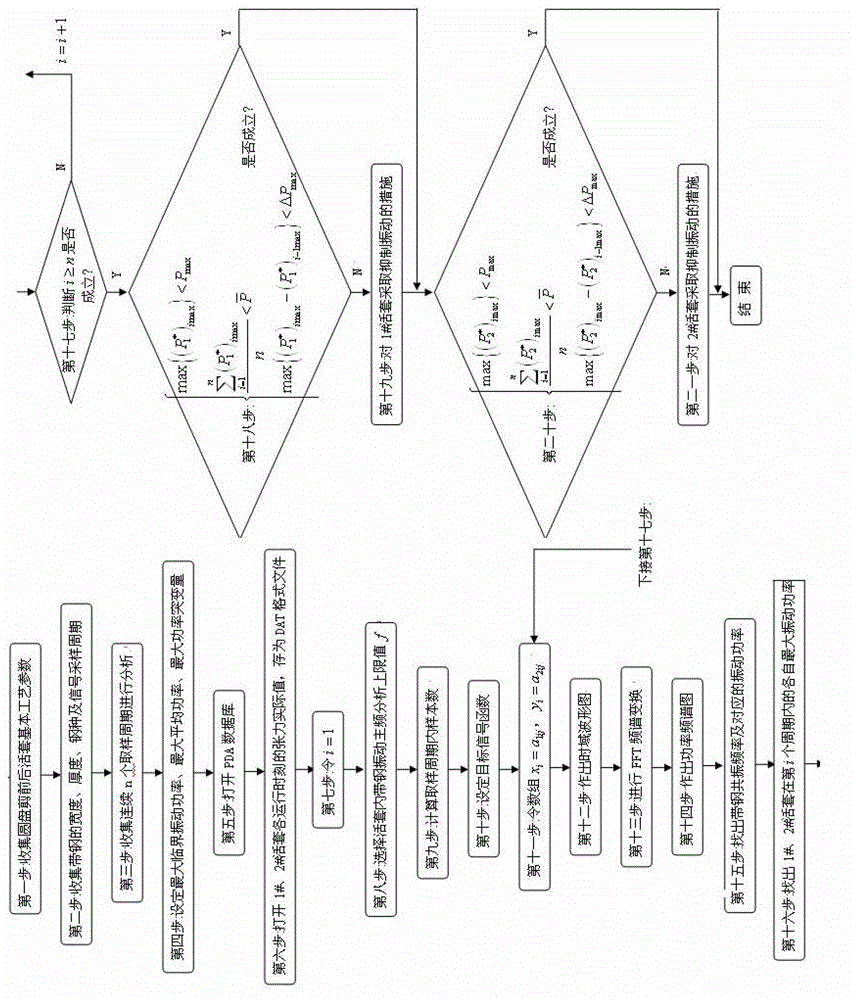

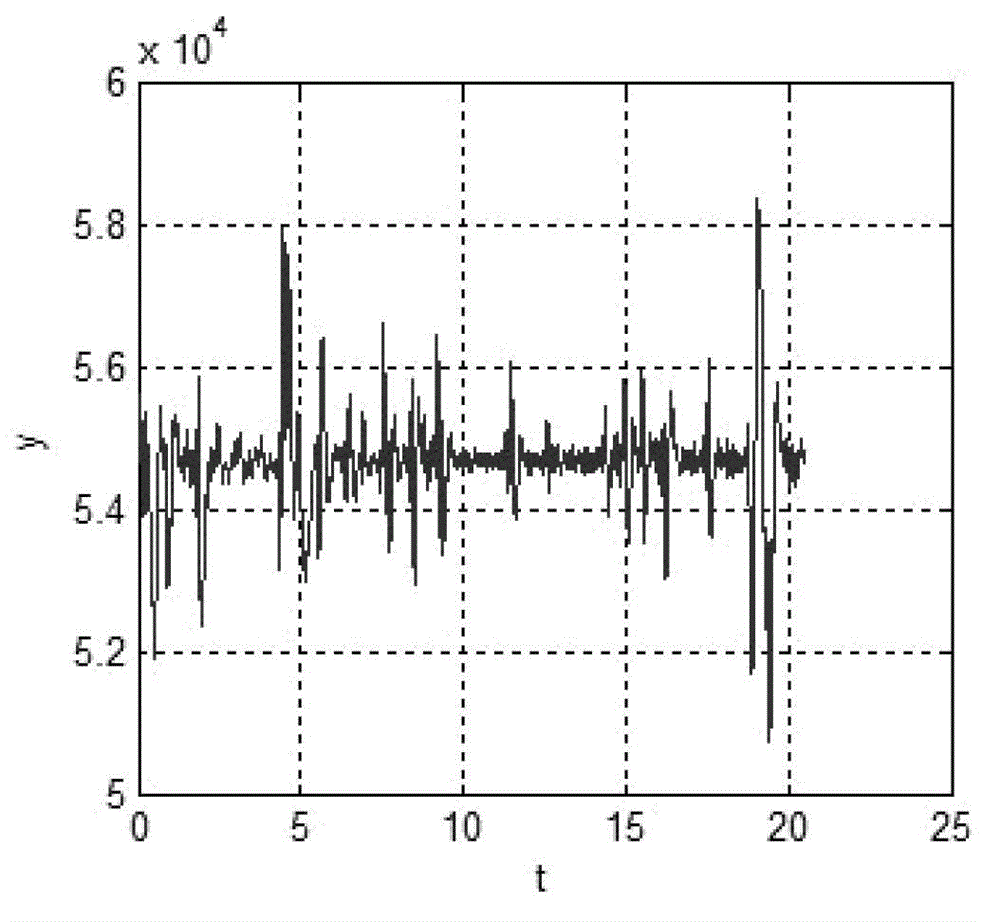

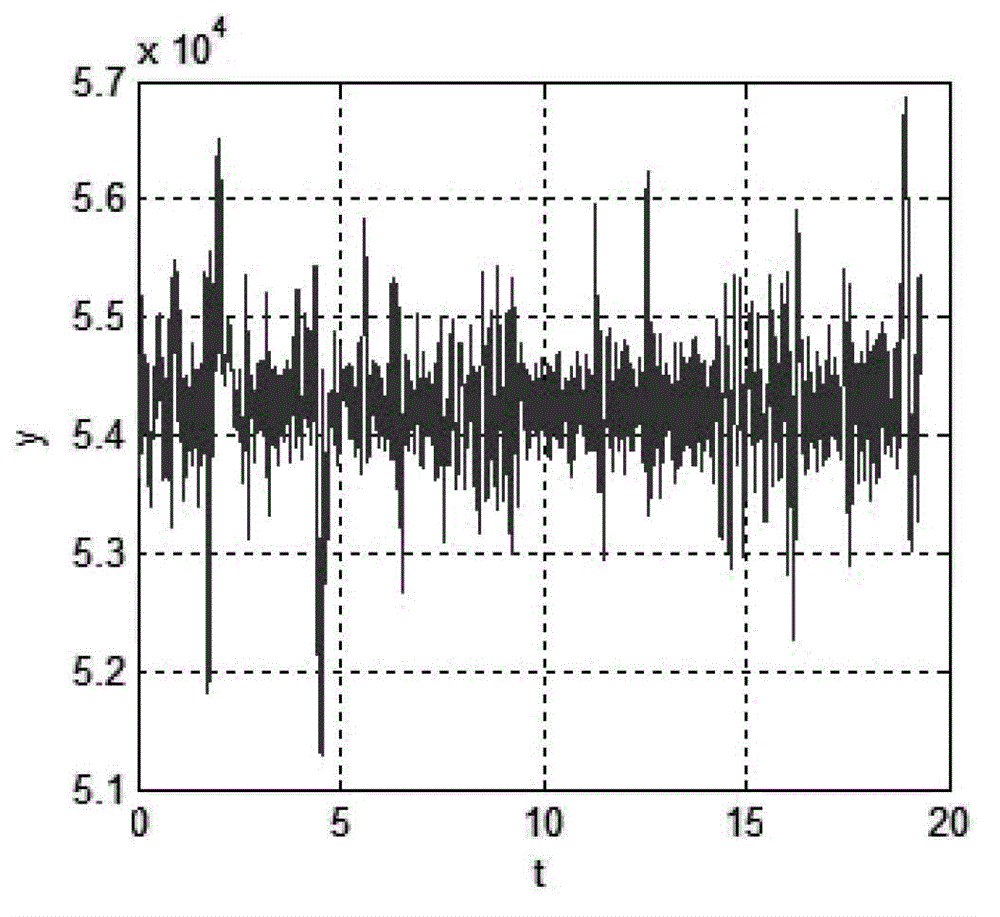

Method for online detecting harmful vibration of strip steel in shearing process of disc shear

ActiveCN103934286AStable Shear and RunShear stableMeasuring devicesMetal rolling arrangementsCollection systemSpecific speed

The invention discloses a method for online detecting the harmful vibration of strip steel in the shearing process of a disc shear. The method comprises the steps that an existing tension real-time collection system of a disc shear area is utilized, the vibration frequency and vibration amplitude of the strip steel are analyzed online and quantitatively according to the real-time tension data of the disc shear in the shearing process when the strip steel of the specific specification and steel type is sheared under specific tension and at specific speed, corresponding vibration restraining measures are adopted according to the data analysis result starting with speed adjustment, and the stable operation and shearing of the strip steel are guaranteed.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com