Novel airplane de-icing/anti-icing liquid and preparation method thereof

A technology of anti-icing fluid and aircraft, applied in the field of aerospace, can solve the problems of thickener viscosity loss, polymer network structure damage, polymer chain damage, etc., achieve high shear thinning index, prolong retention time, improve The effect of anti-icing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: De-icing / anti-icing fluid

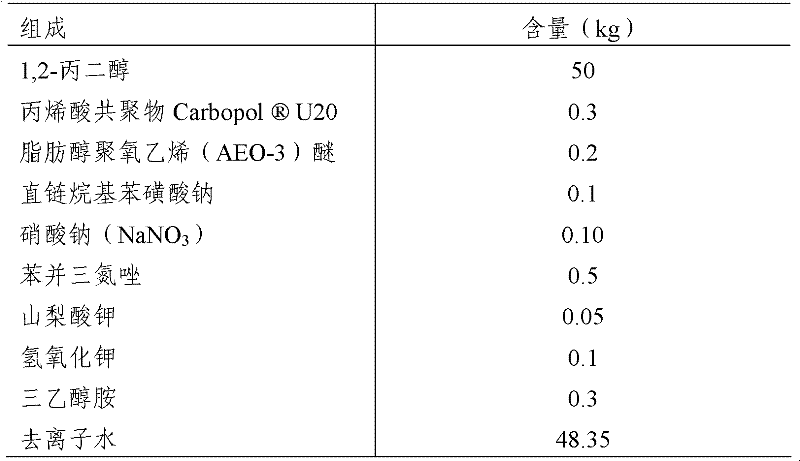

[0049] 1. Composition (weight: kg):

[0050]

[0051] 2. Preparation method

[0052] 1) acrylic acid copolymer Carbopol U20 is pre-swelled in deionized water, fully wetted, stirred evenly, and set aside;

[0053] 2) Add 1,2-propanediol, fatty alcohol polyoxyethylene (AEO-3) ether, sodium nitrate, and potassium sorbate in sequence to the solution in step 1) and stir well, and finally use pre-configured potassium hydroxide and three The pH regulator compounded with ethanolamine adjusts the pH of the solution to 7.0-7.5.

Embodiment 2

[0054] Example 2: De-icing / anti-icing fluid

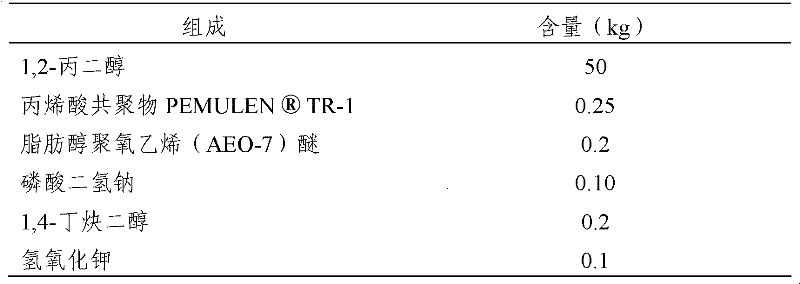

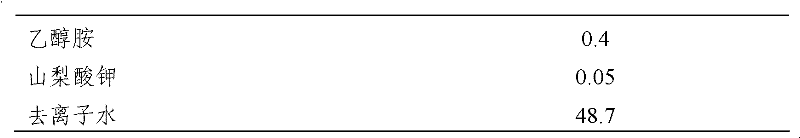

[0055] 1. Composition (weight: kg):

[0056]

[0057]

[0058] 2. Preparation method

[0059] 1) The acrylic copolymer PEMULEN TR-1 is pre-swelled in deionized water, fully wetted, stirred evenly, and set aside;

[0060] 2) Add 1,2-propanediol, fatty alcohol polyoxyethylene (AEO-7) ether, NaNO to the solution in step 1) sequentially 3 1. After the potassium sorbate is fully stirred, finally adjust the pH of the solution to 7.0-7.5 with a pre-configured pH regulator compounded of potassium hydroxide and ethanolamine.

Embodiment 3

[0061] Example 3: De-icing / anti-icing fluid

[0062] 1. Composition (weight: kg):

[0063]

[0064] 2. Preparation method

[0065] 1) Thickener acrylic copolymer PEMULEN TR-2 is pre-swelled in deionized water, fully wetted, stirred evenly, and set aside;

[0066] 2) Add 1,2-propanediol, fatty alcohol polyoxyethylene (AEO-9) ether, NaNO to the solution in step 1) sequentially 3 1. After the potassium sorbate is fully stirred, finally adjust the pH of the solution to 7.0-7.5 with a pre-configured pH regulator compounded of KOH and diethanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com