Patents

Literature

43results about How to "Realize automatic pushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

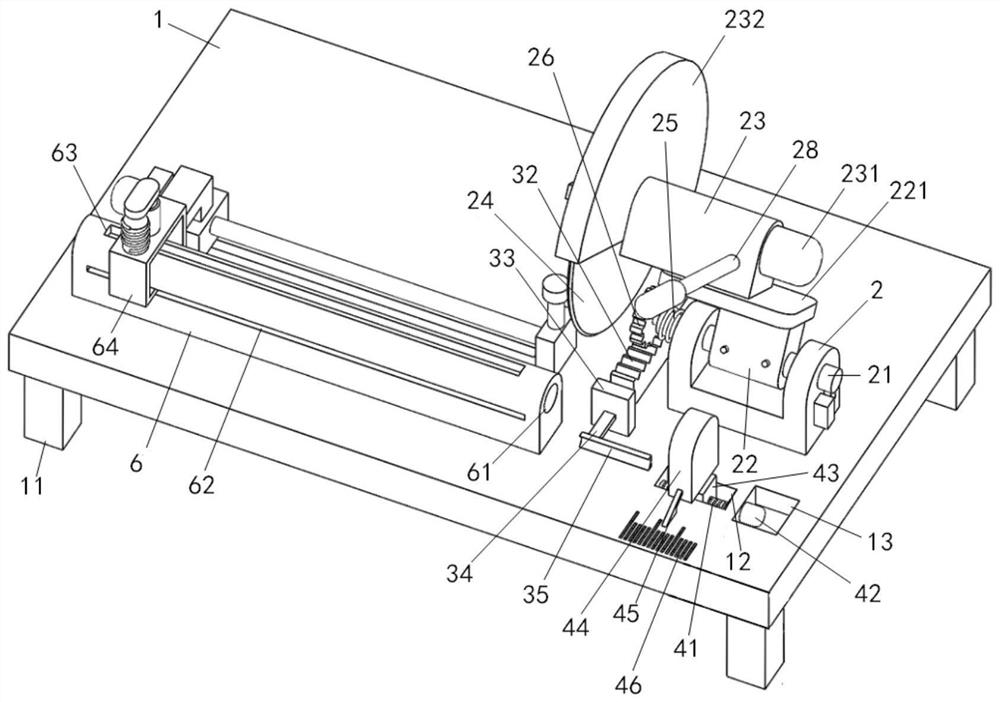

Silica gel product automatic cutting machine

ActiveCN111791276AAchieve intermittent exerciseQuick cutMetal working apparatusCircular discStructural engineering

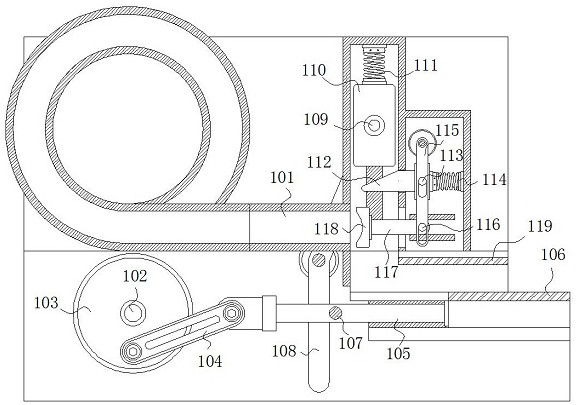

The invention relates to a cutting machine, in particular to a silica gel product automatic cutting machine. The technical problem to be solved is to provide the silica gel product automatic cutting machine which can rapidly cut a silica gel product, can realize precise cutting and high cutting efficiency, and can realize automatic discharging. The silica gel product automatic cutting machine comprises a cutting frame and an intermittent transmission mechanism; an intermittent driving is installed on the upper part of the cutting frame; and the intermittent transmission mechanism is installedon the cutting frame close to one side of the intermittent driving mechanism and is matched with the intermittent driving mechanism. Through matching between a fan-shaped gear and a toothed belt, intermittent motion of a discharging disc is realized; through matching between a circular disc and a lifting slide plate, a cutting tool is driven to move downwardly and conduct rapid cutting of the silica gel product; and through matching between a cylinder and a cylindrical column, the silica gel product is fixed so the cutting tool can realize more precise cutting of the silica gel product.

Owner:ZHONGSHAN WORLD MEDICAL INSTR

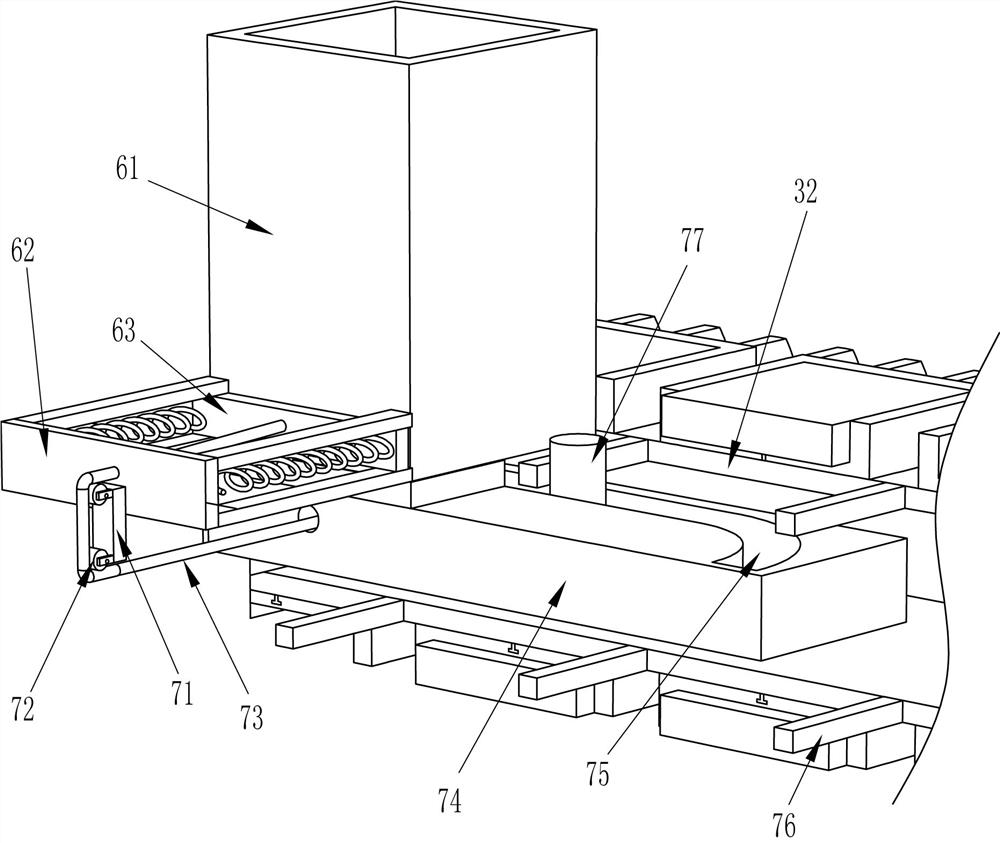

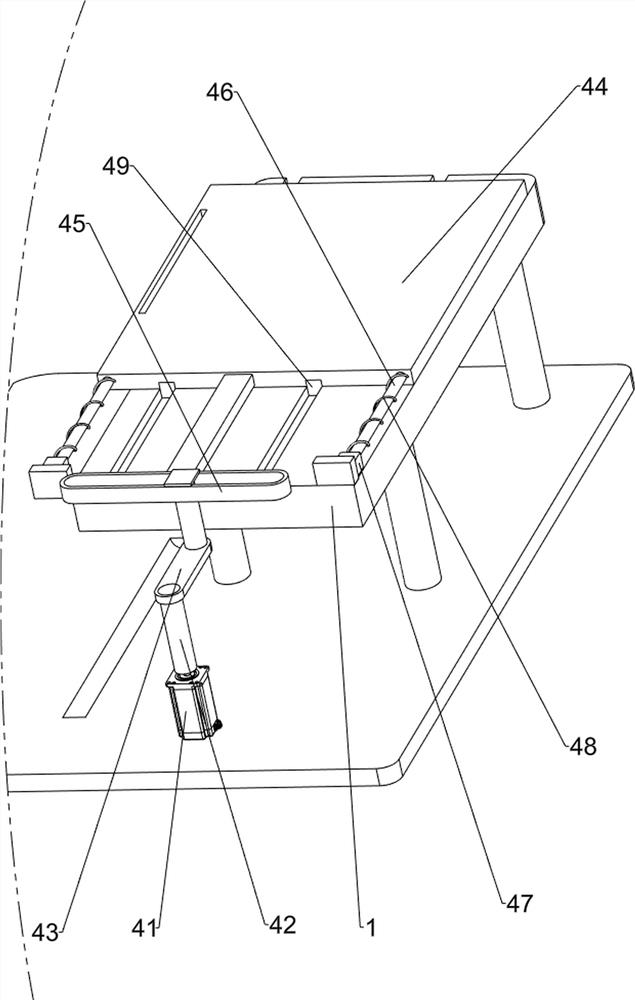

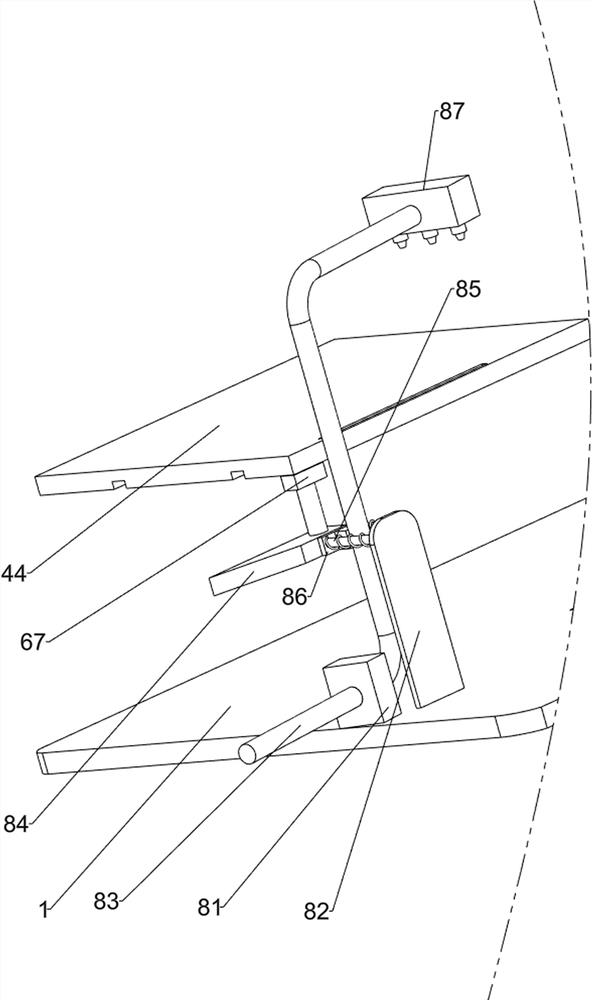

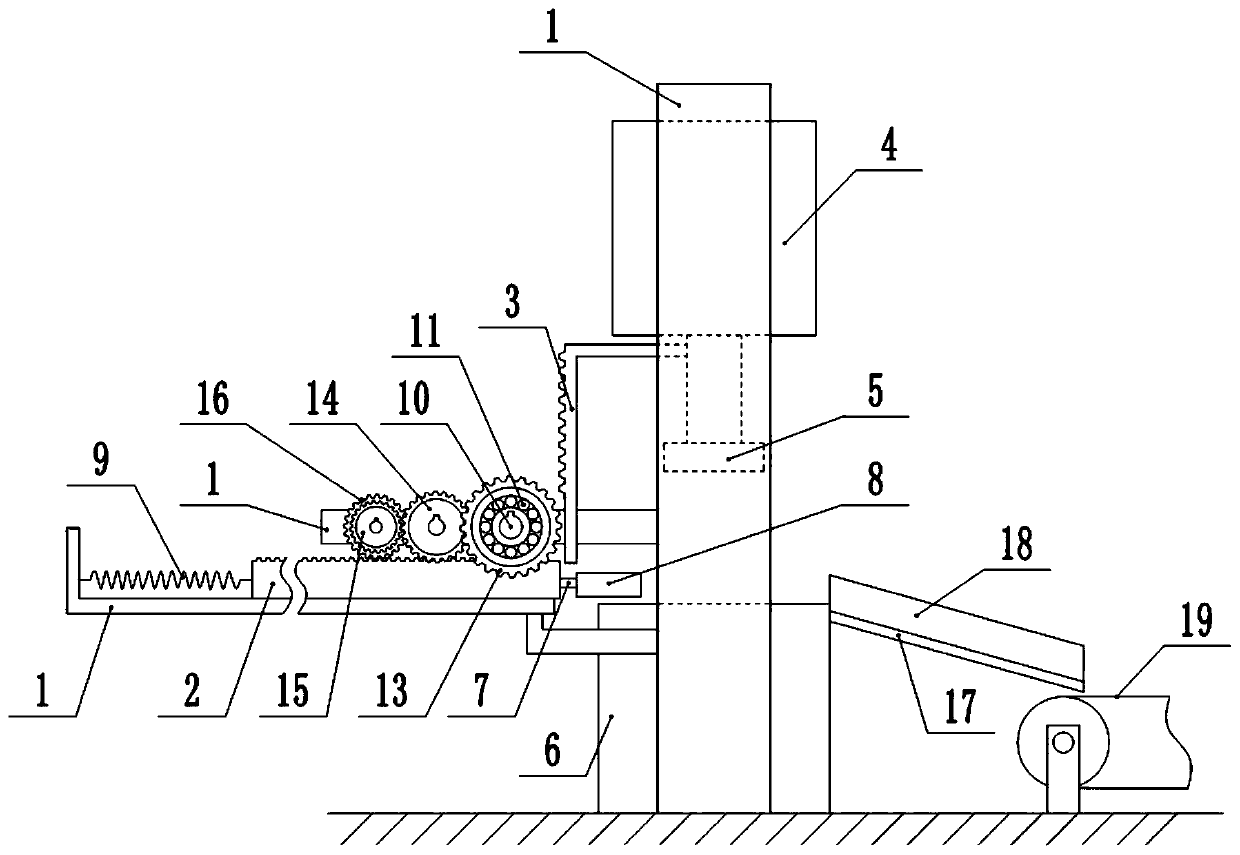

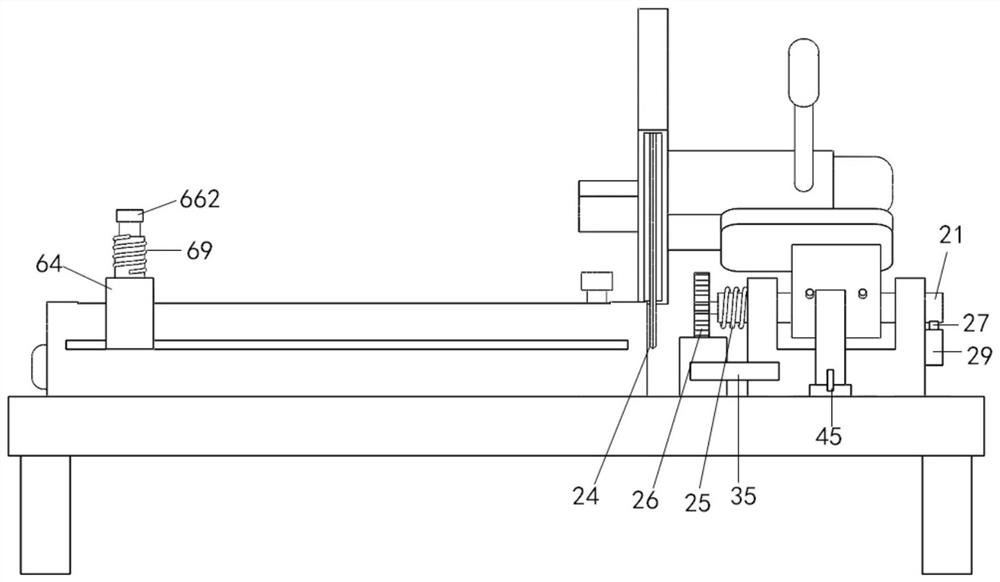

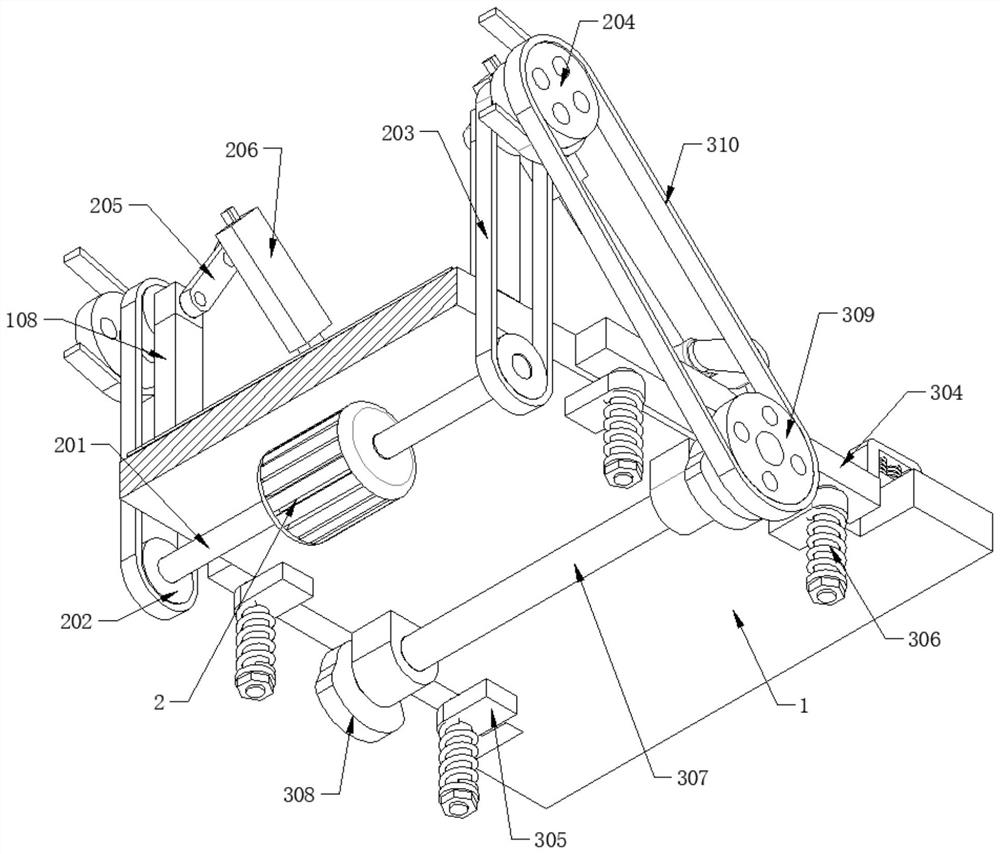

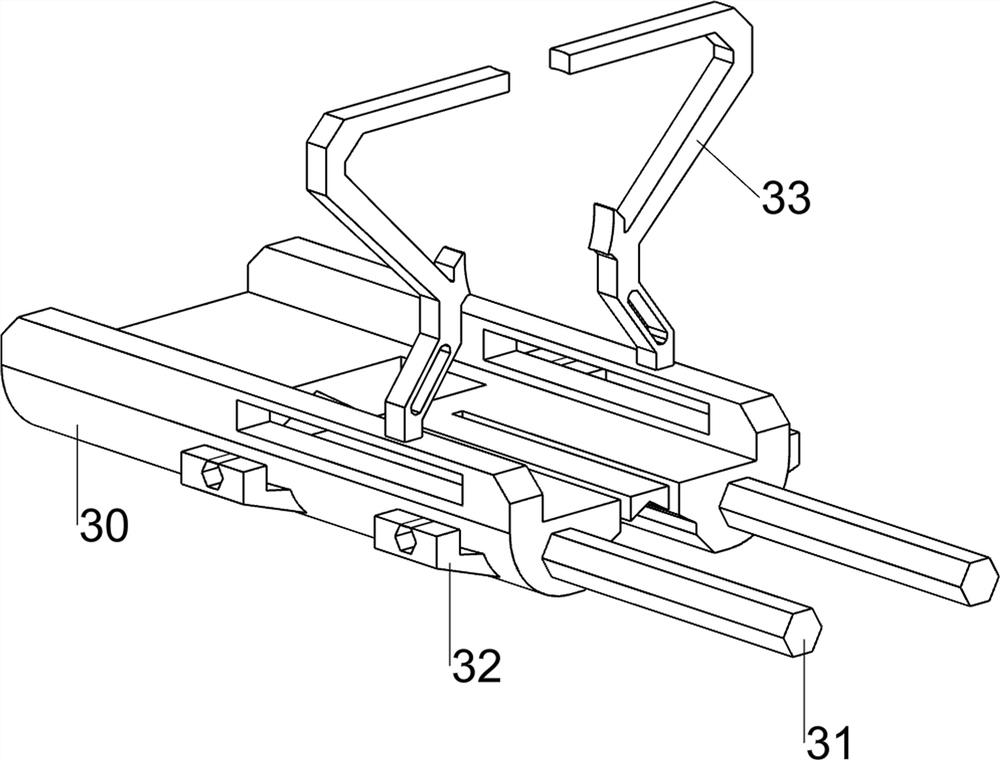

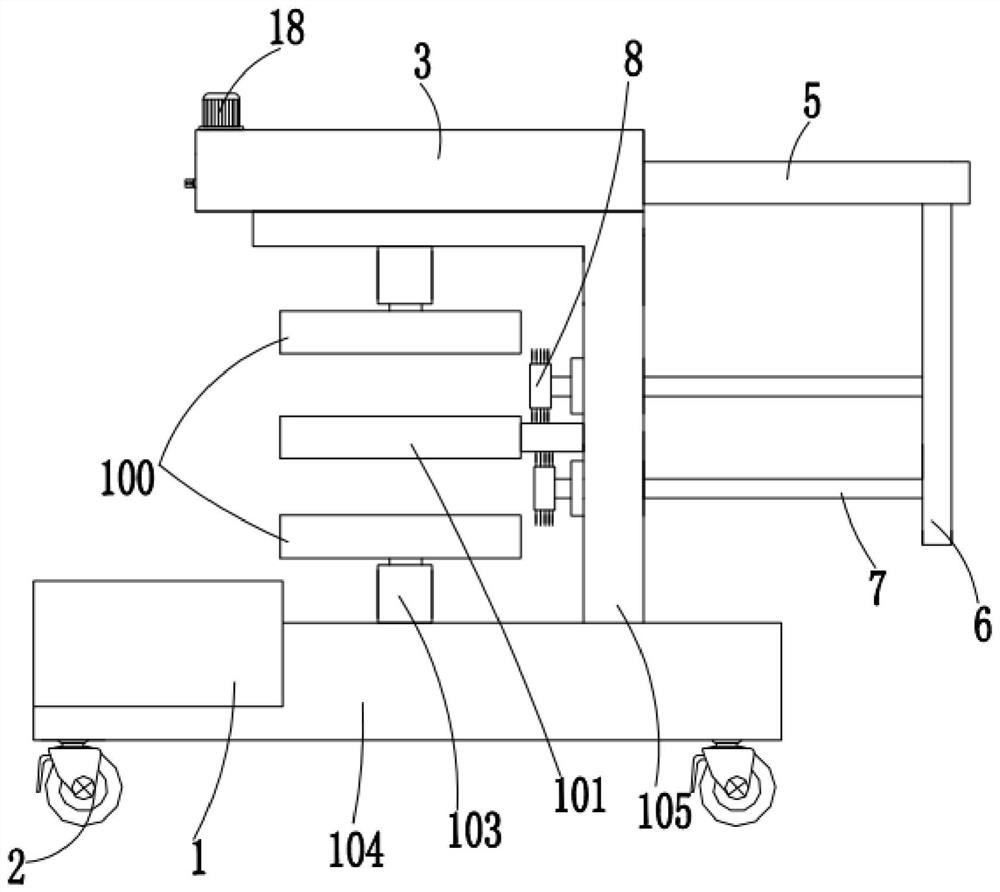

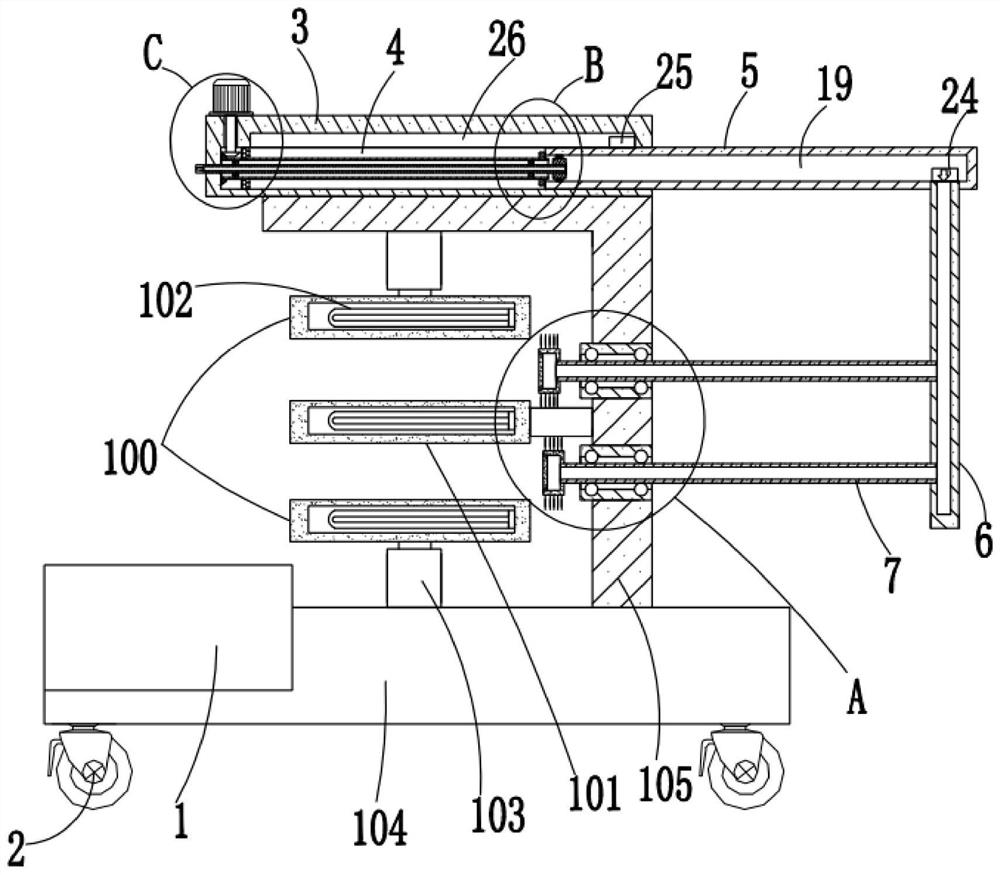

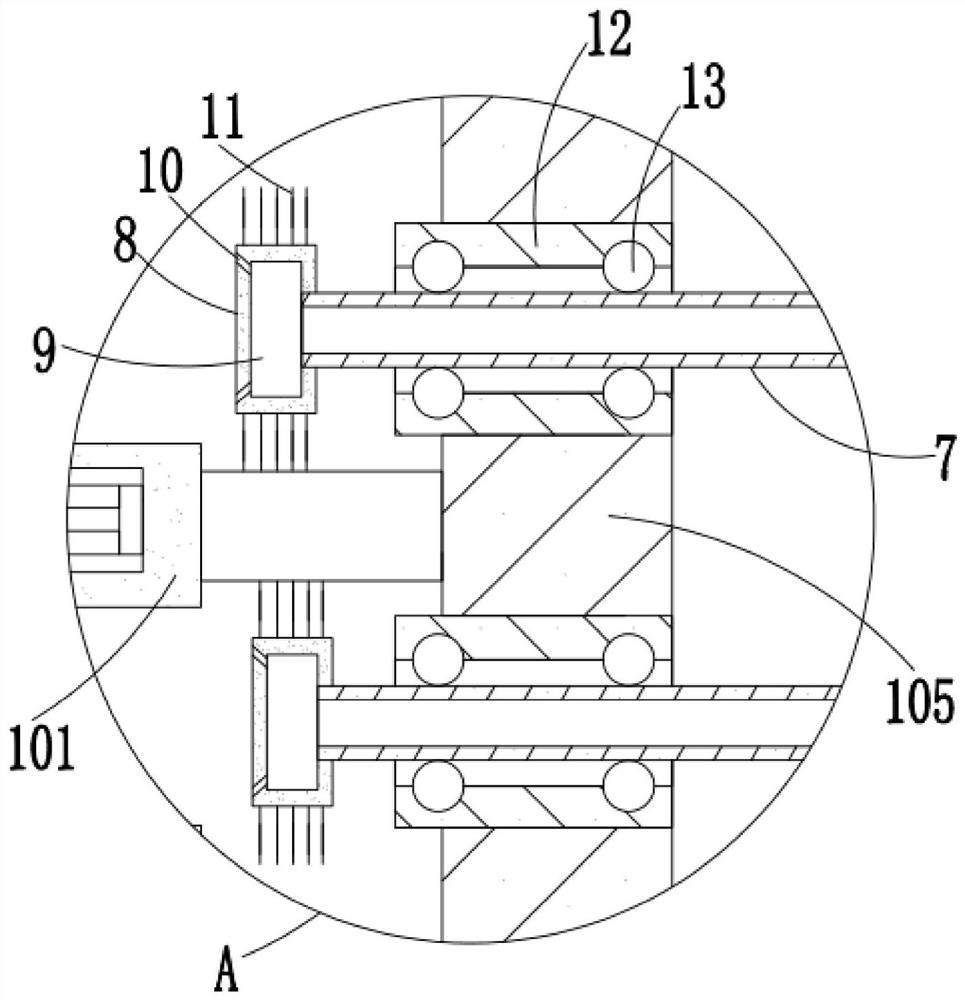

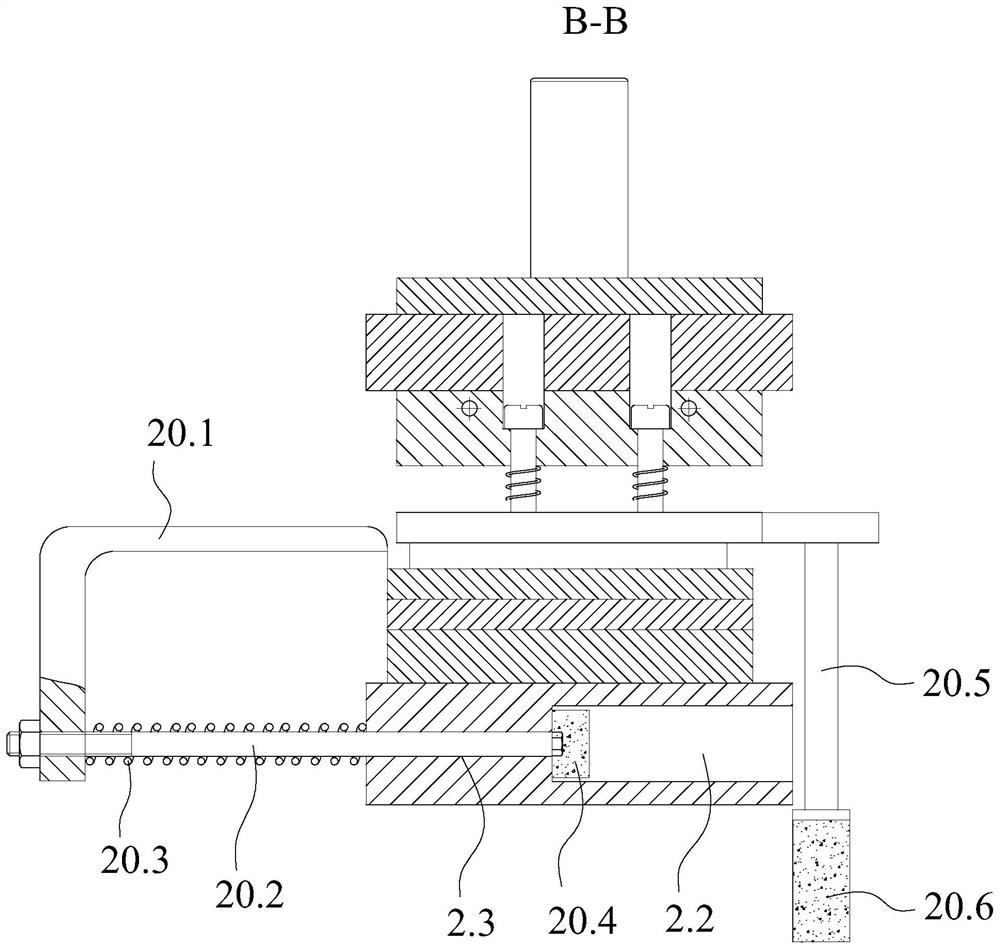

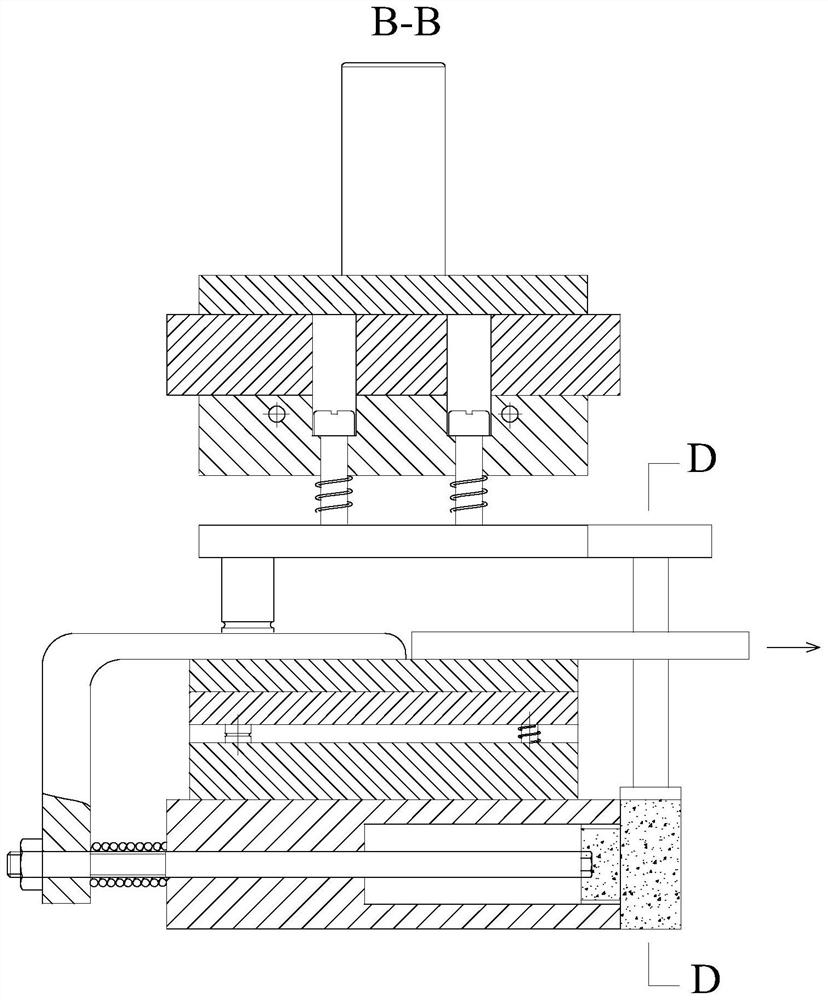

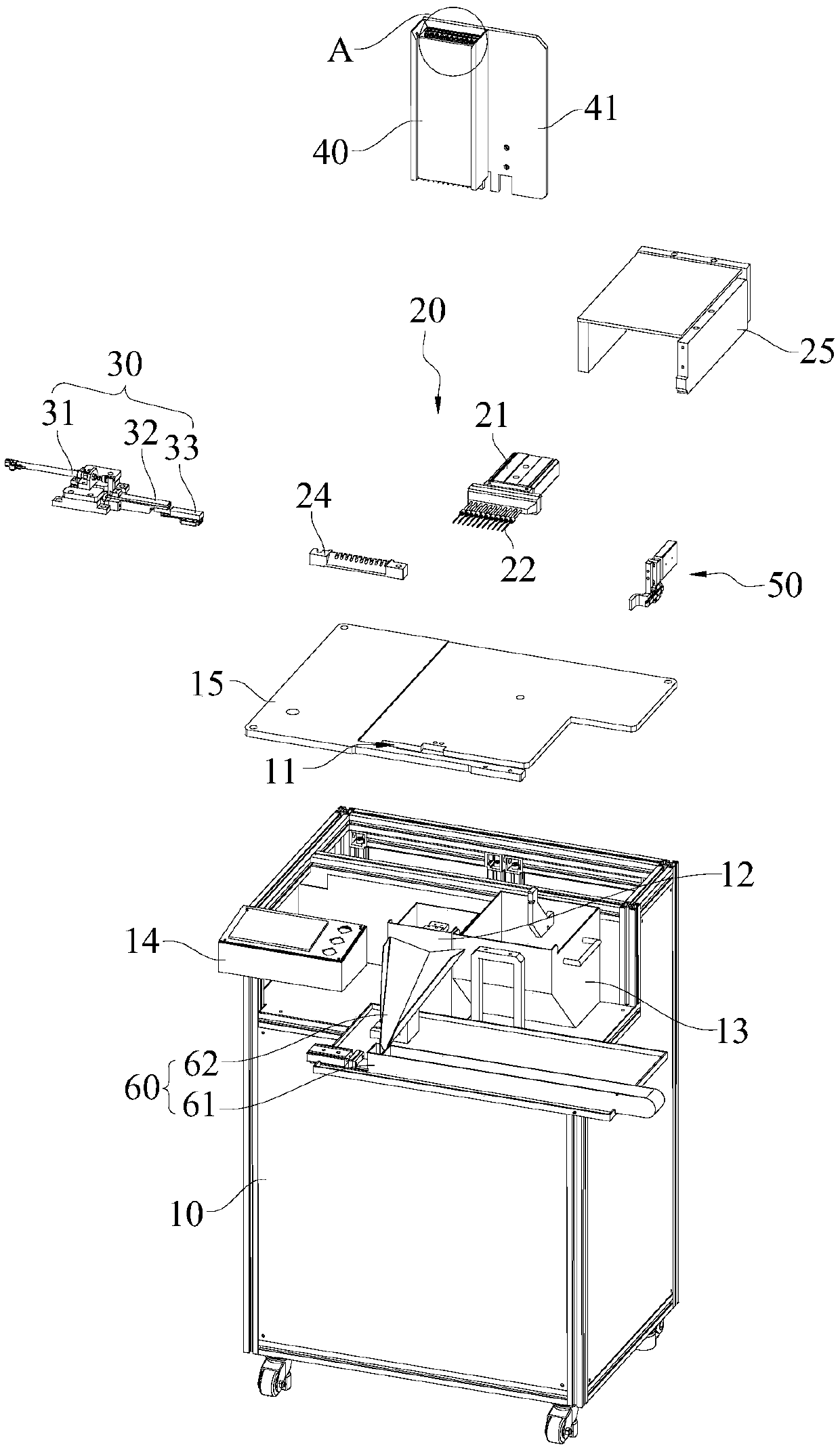

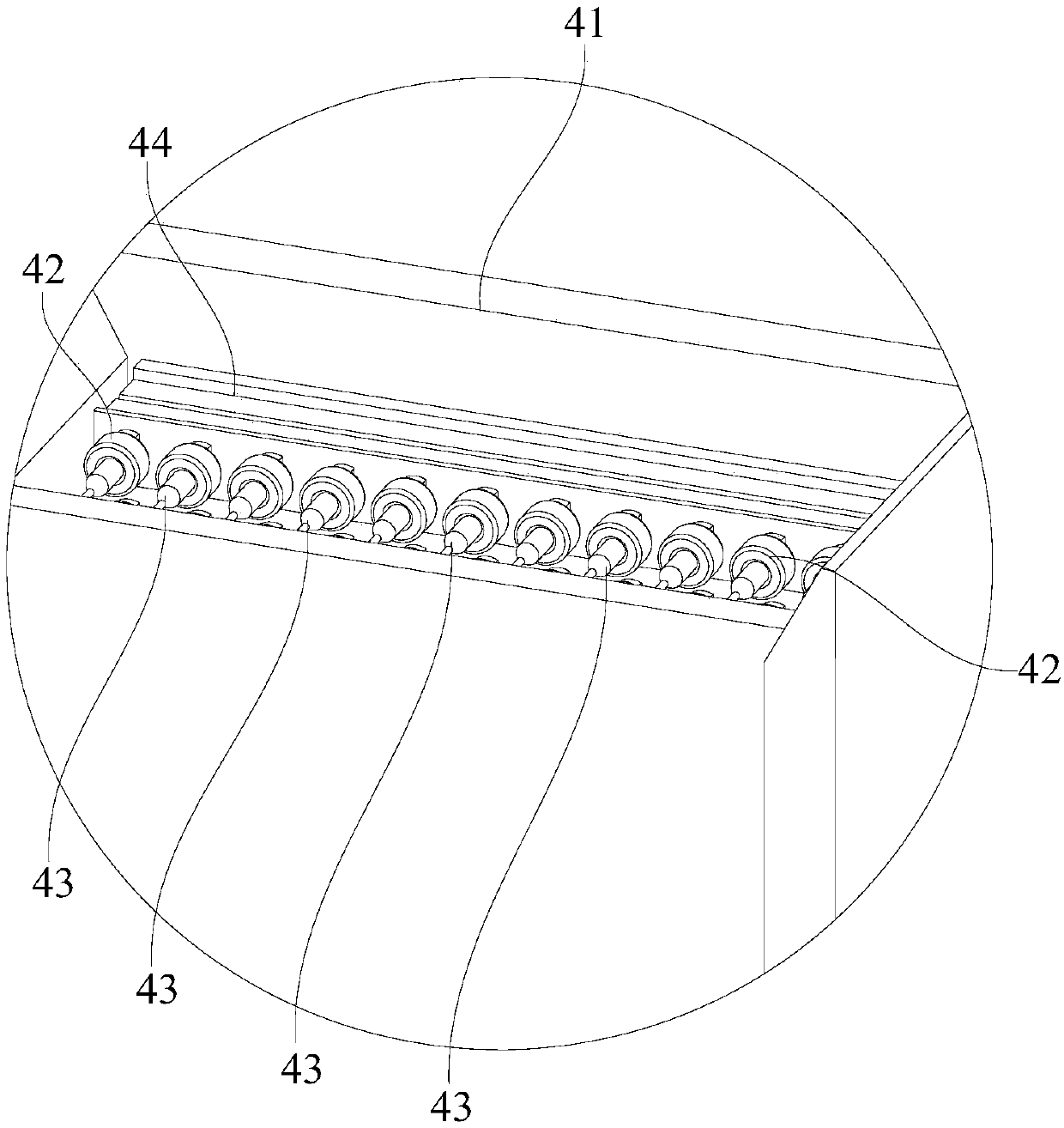

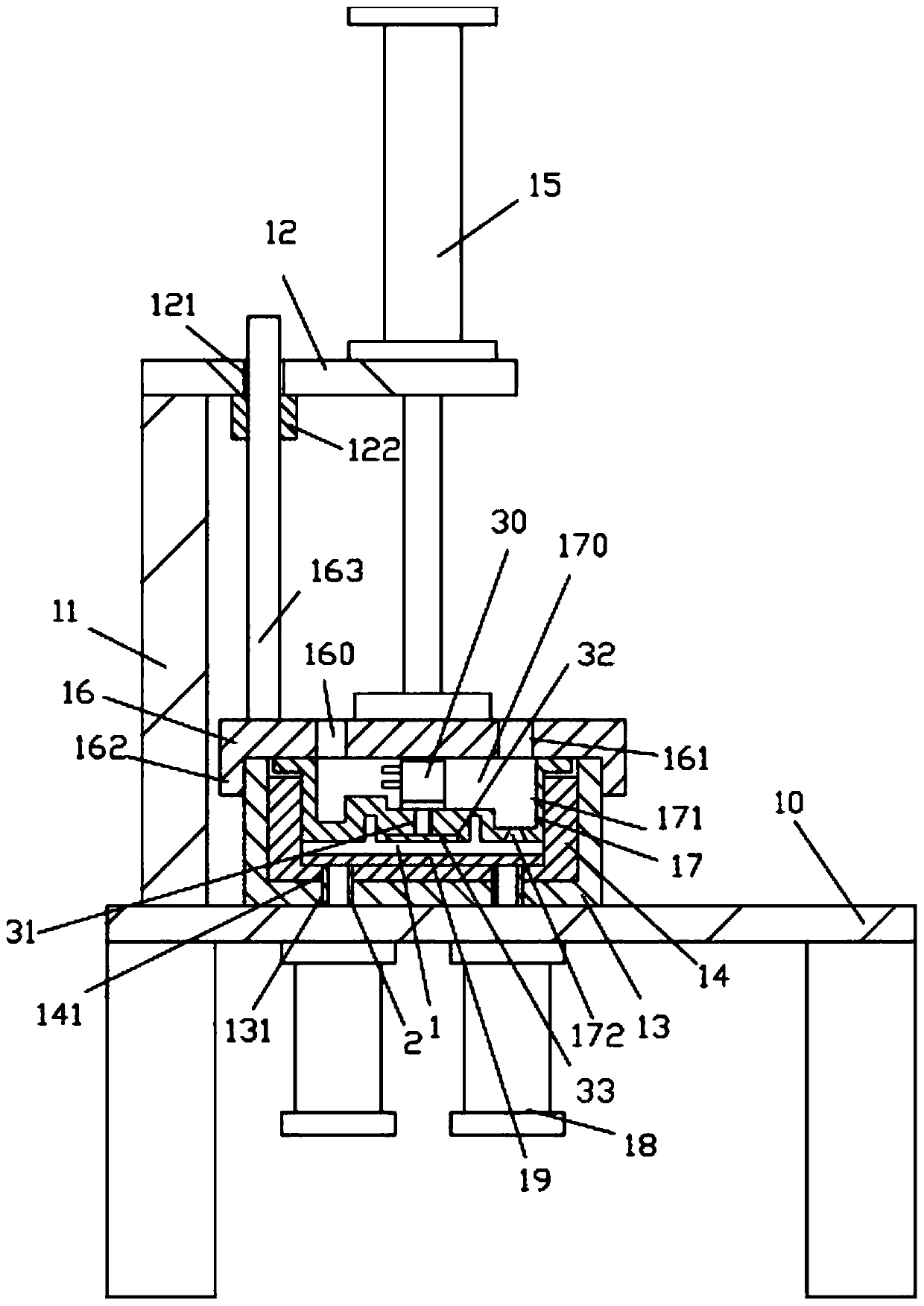

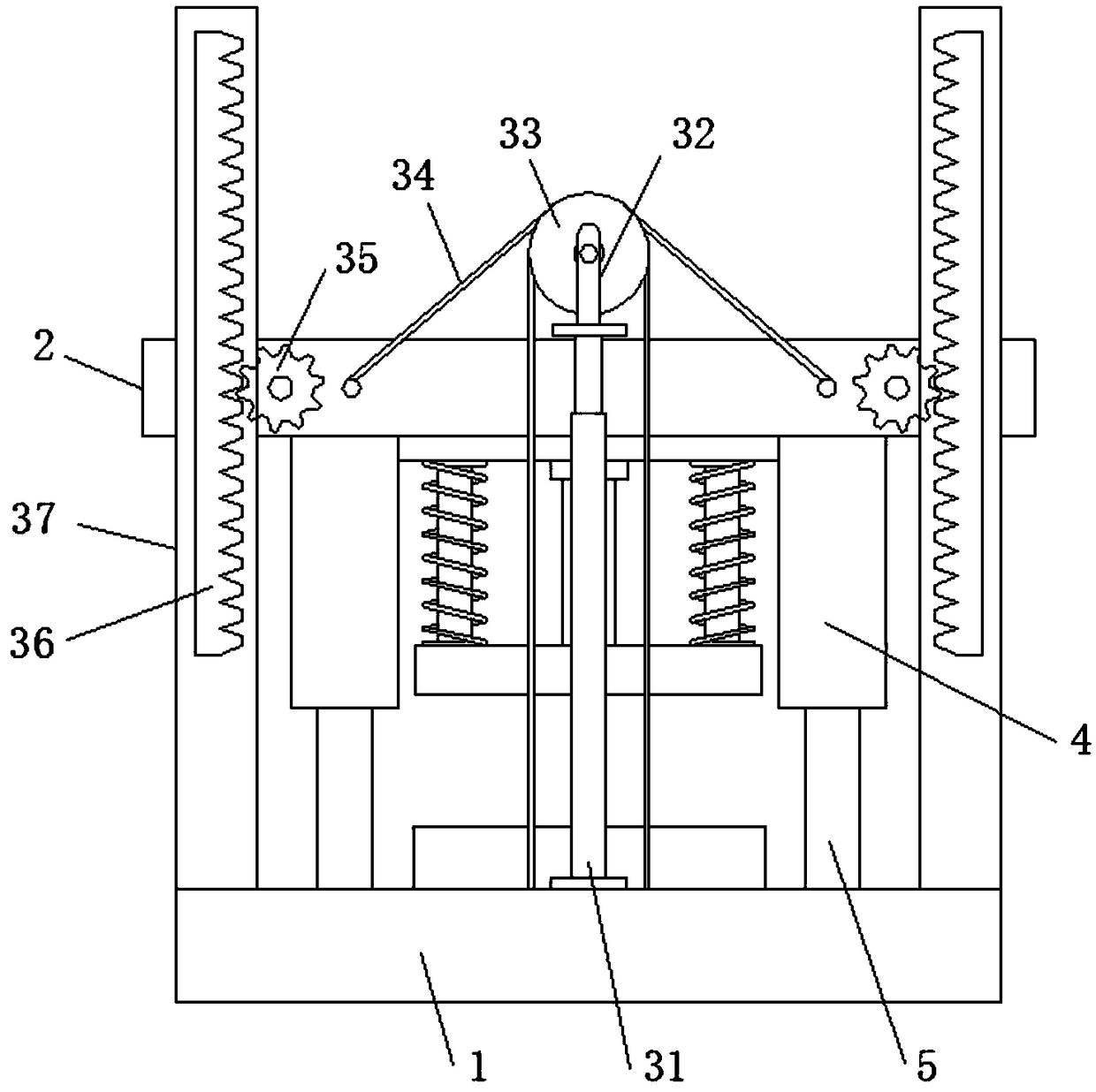

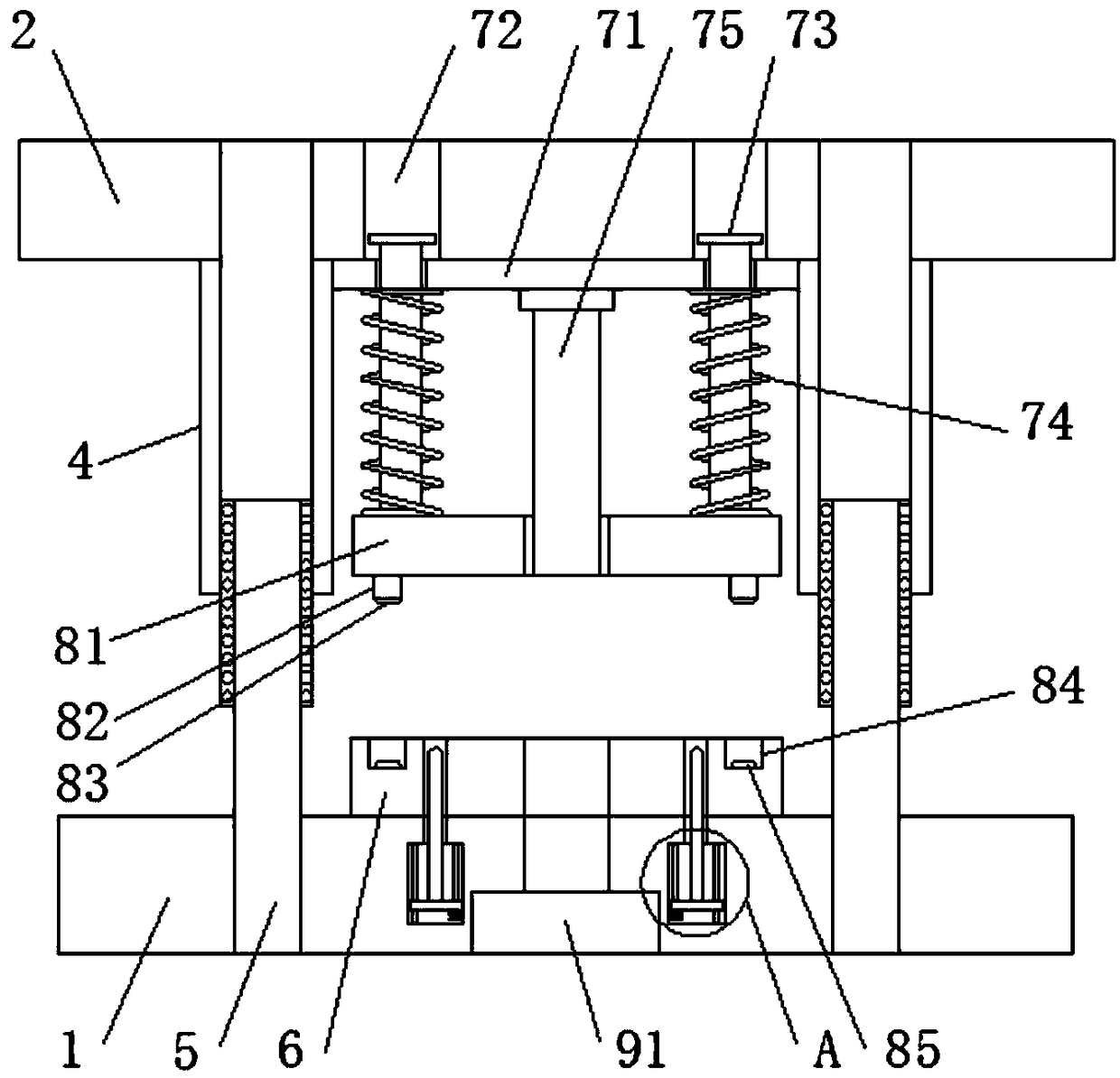

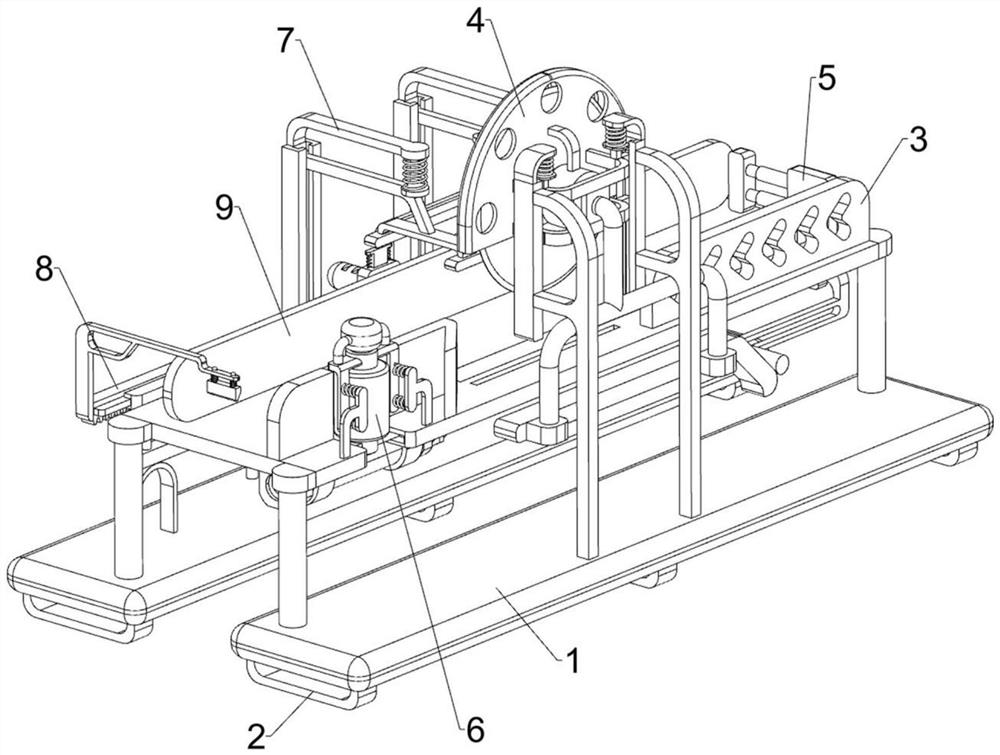

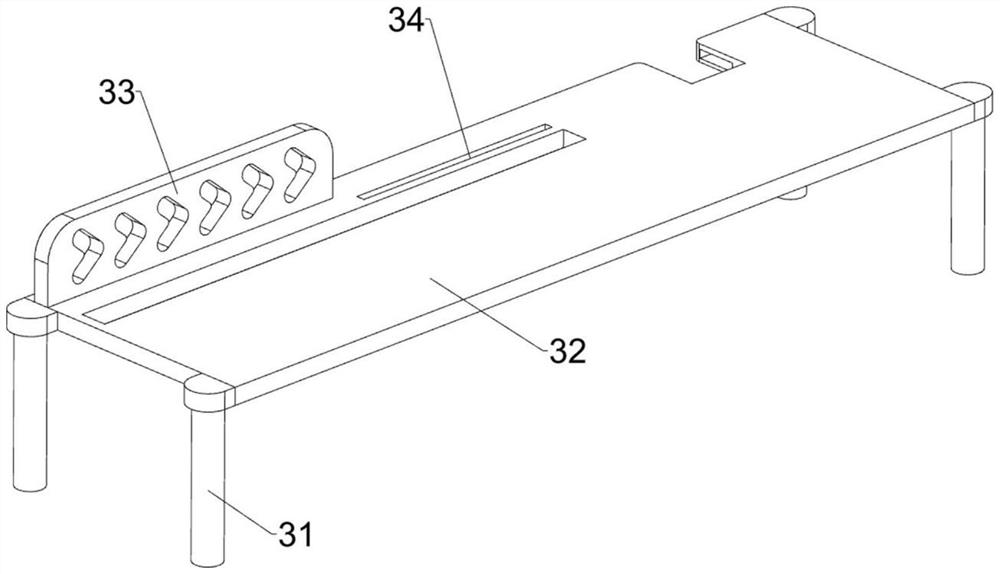

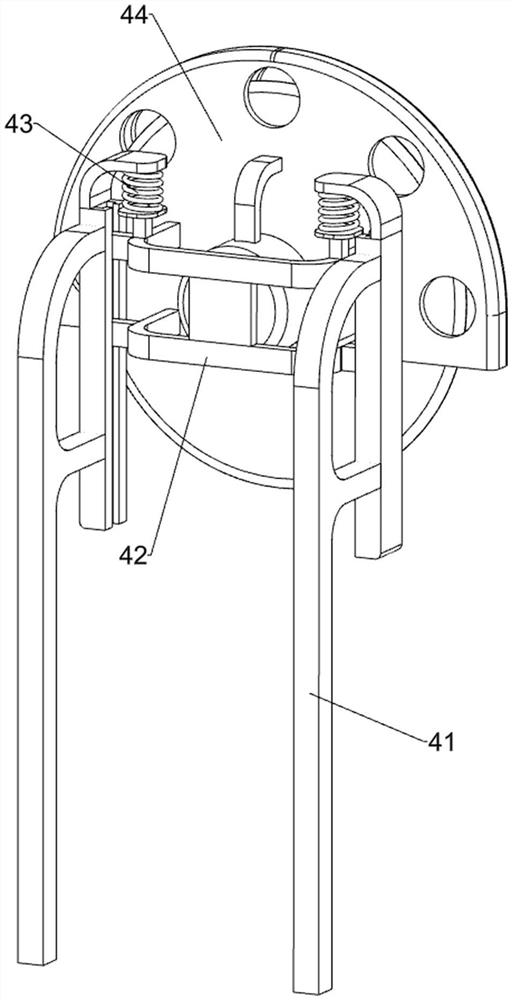

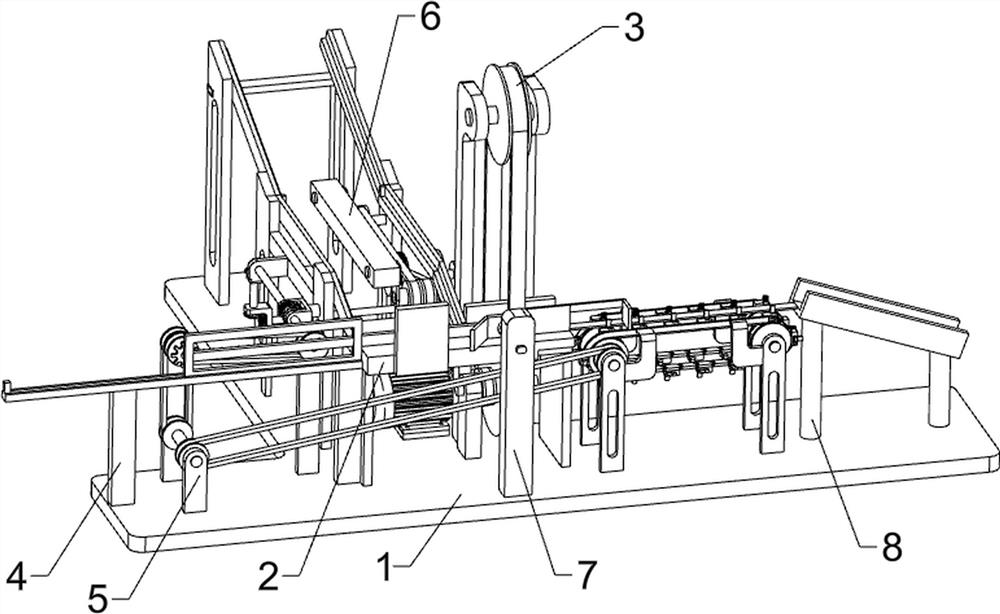

Rapid welding device for new-energy lithium battery pack

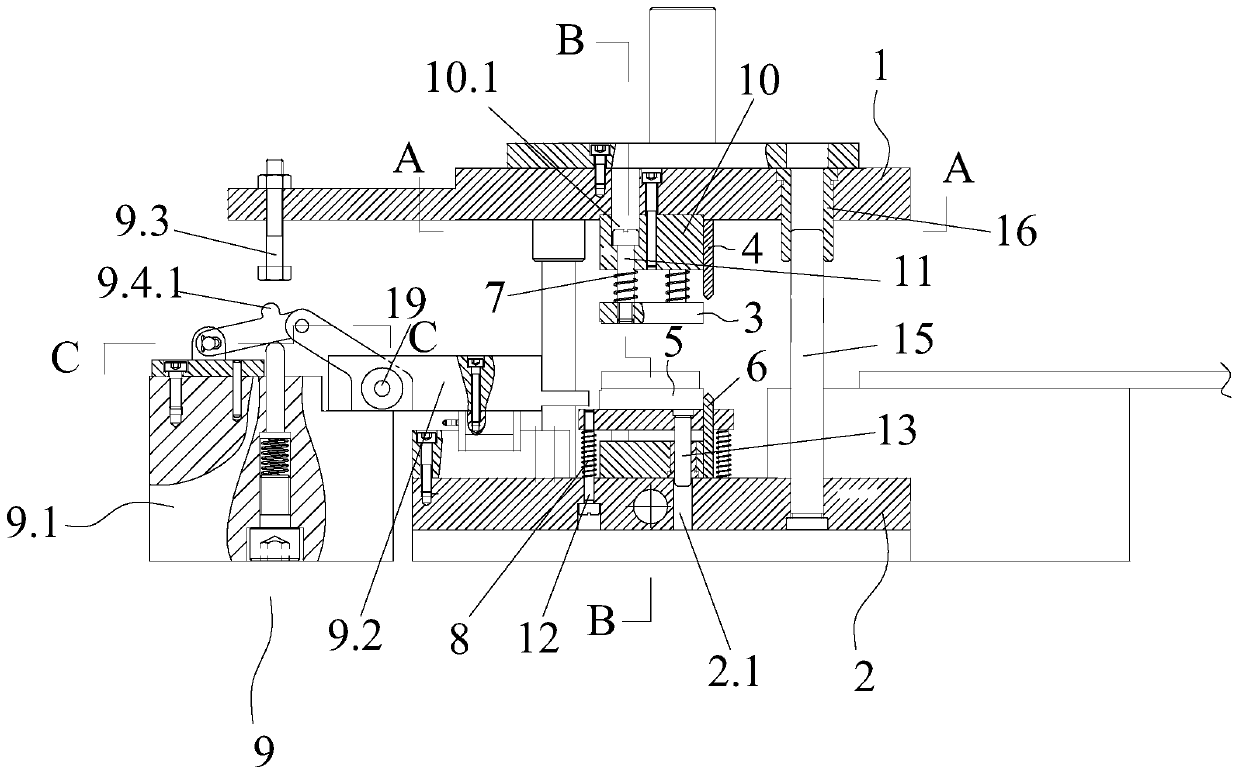

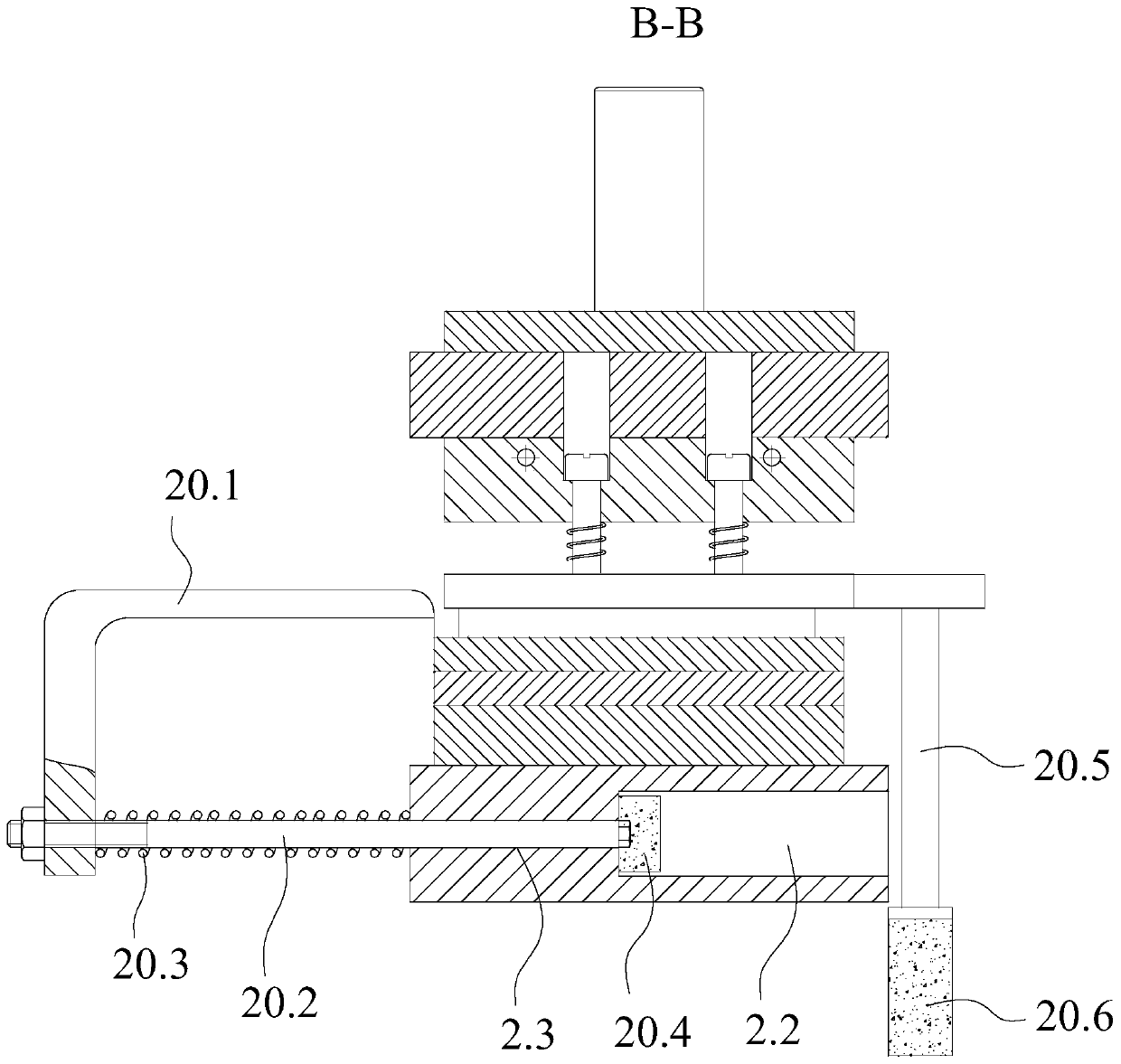

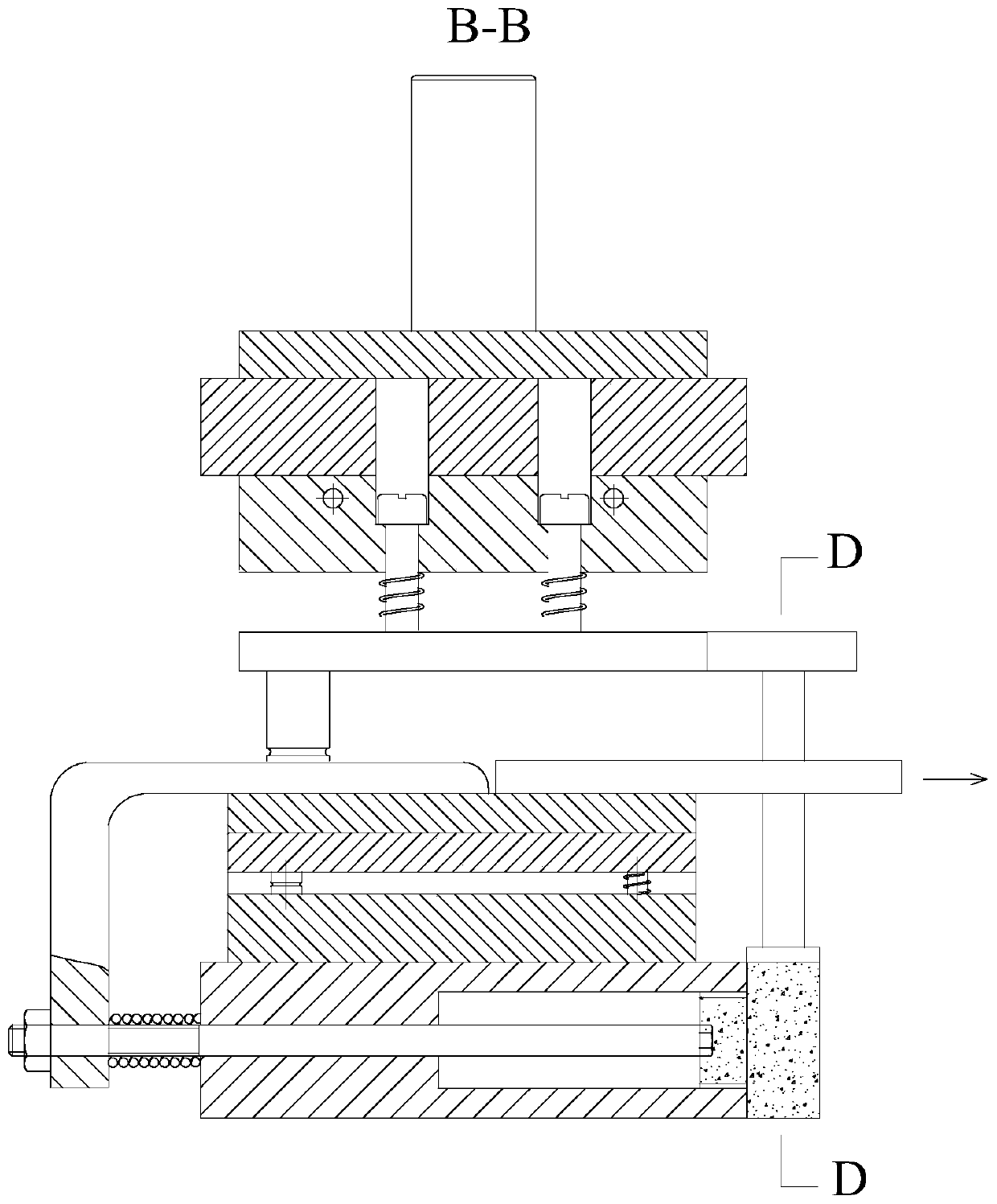

ActiveCN112388134ARealize the welding effectRealize automatic pushingWelding/soldering/cutting articlesMetal working apparatusElectrical batteryNew energy

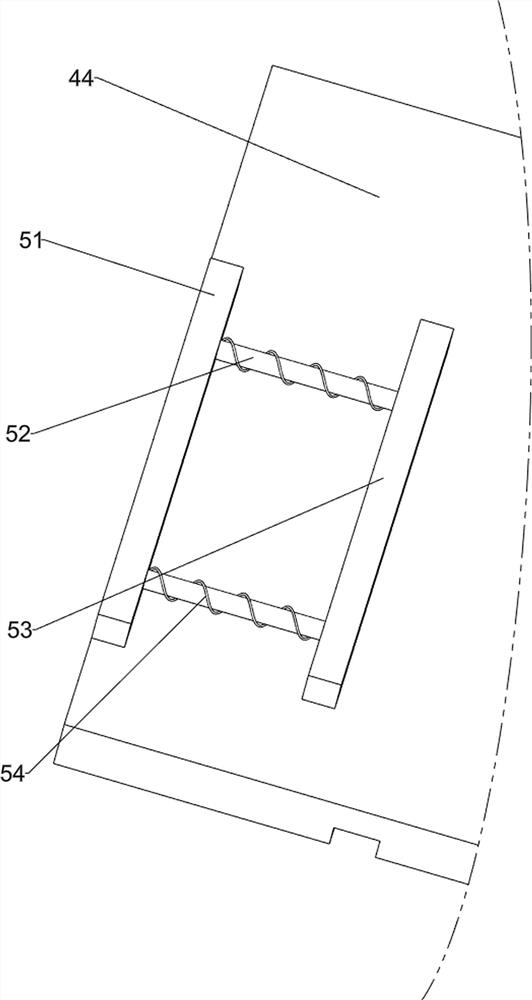

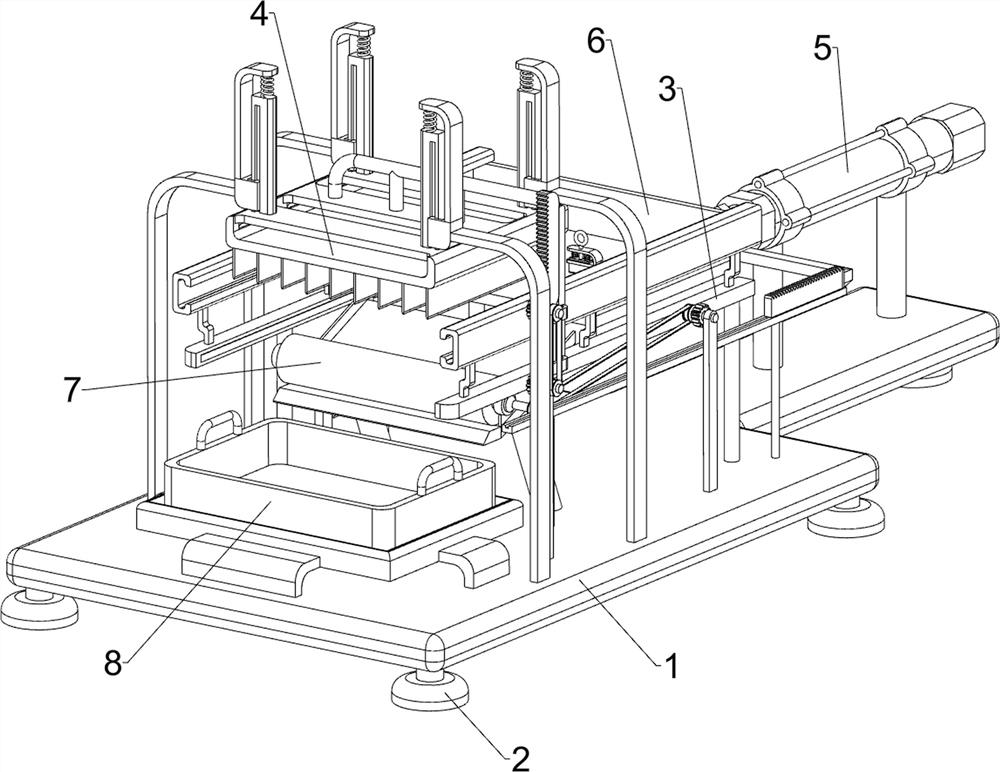

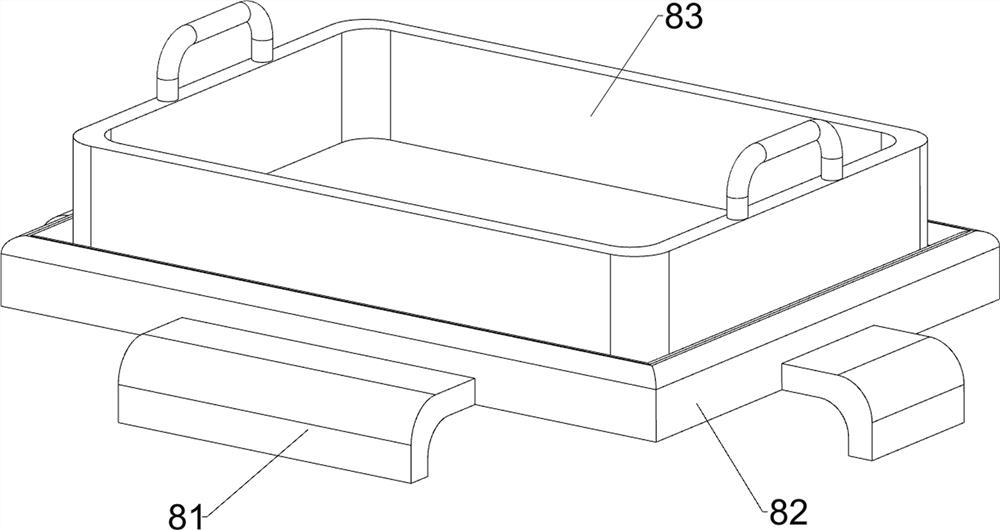

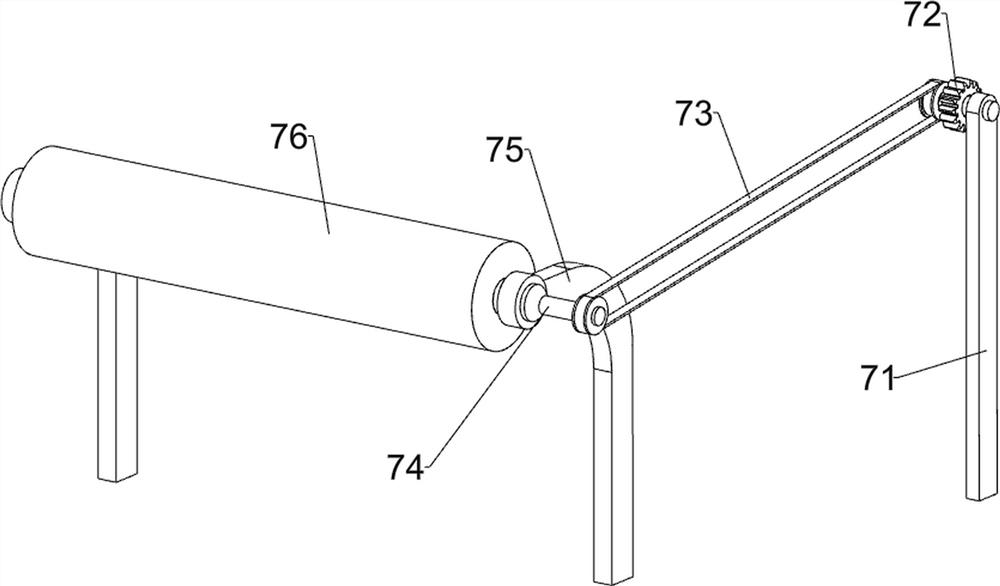

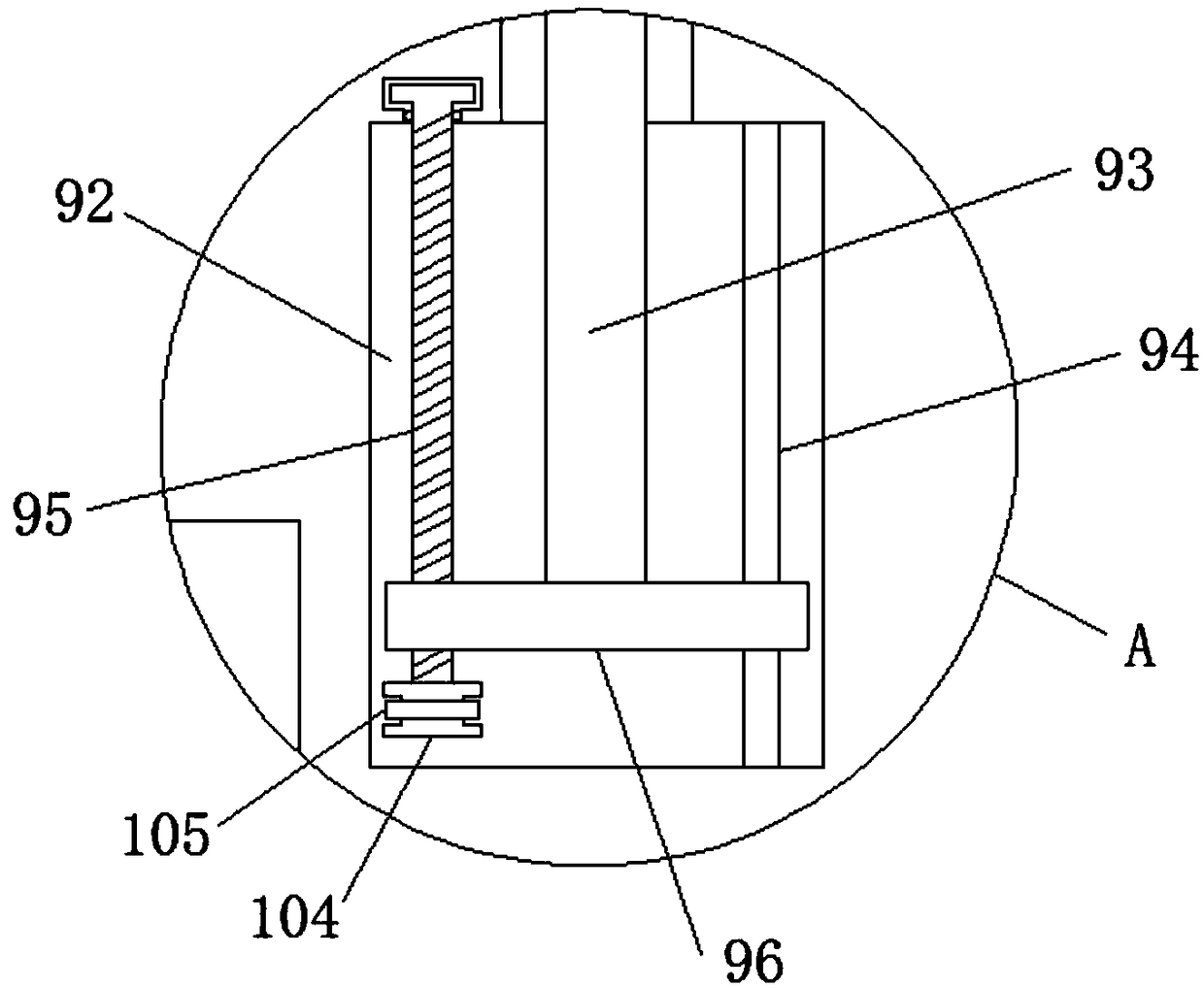

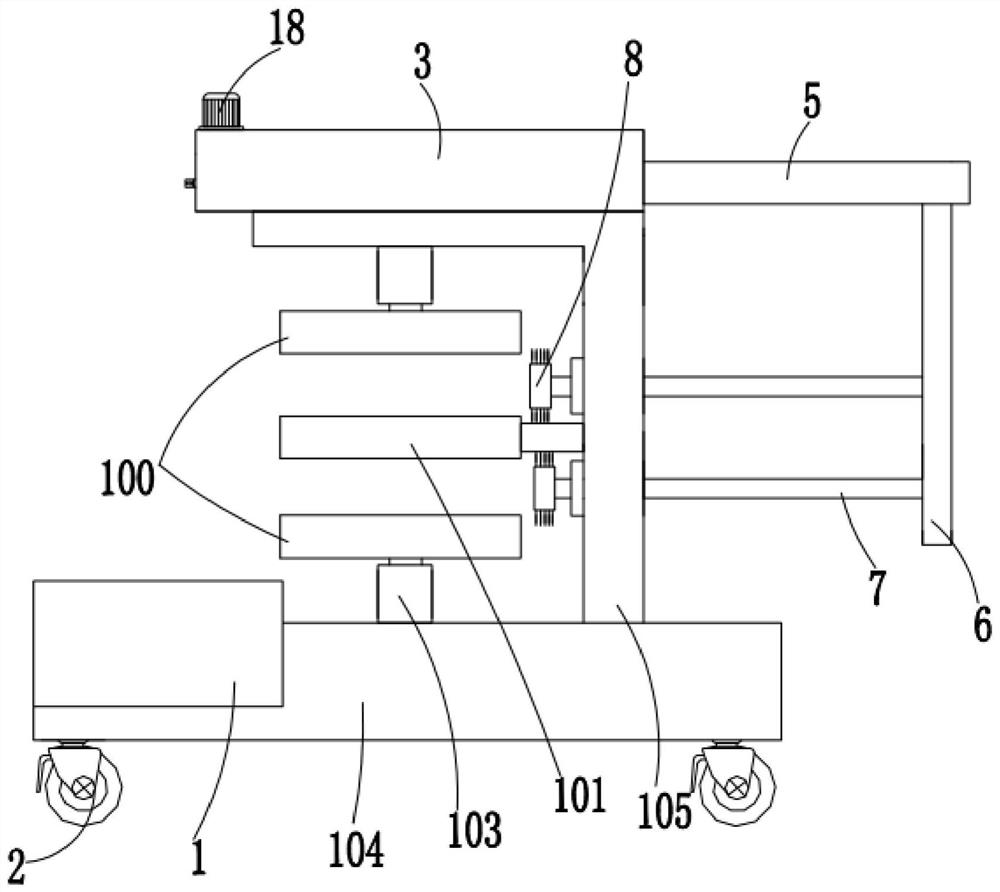

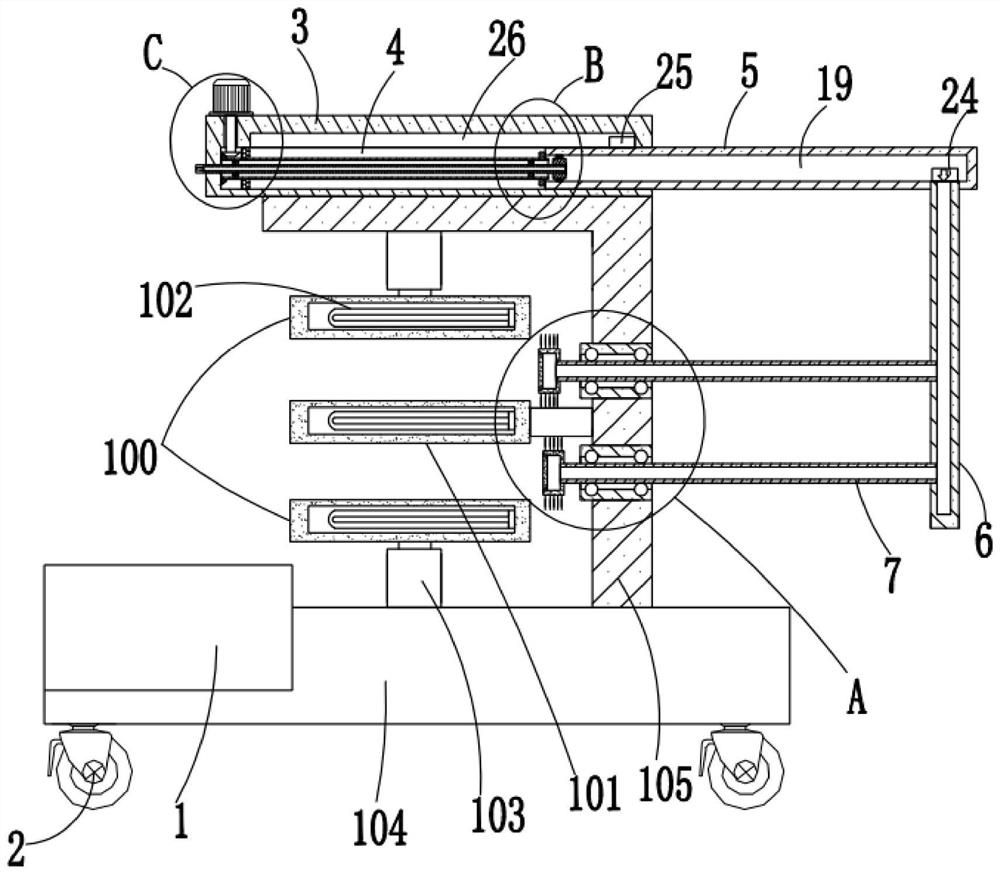

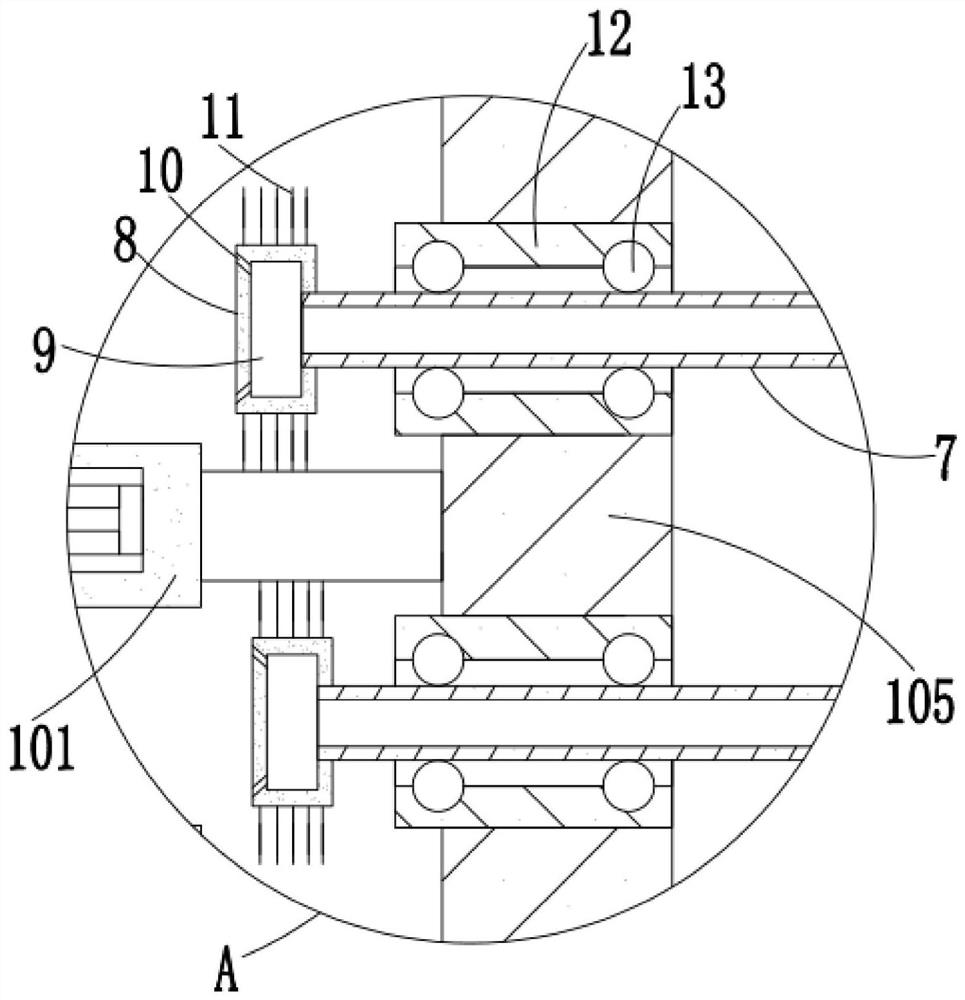

The invention relates to a welding device, in particular to a rapid welding device for a new-energy lithium battery pack, and aims to solve the technical problem about how to provide the quick weldingdevice which is used for the new-energy lithium battery pack, can realize automatic feeding and welding and is time-saving and labor-saving. The rapid welding device for the new-energy lithium battery pack comprises a base, a mounting plate, an electric welding mechanism and a pushing mechanism; the mounting plate is arranged on one side of the base; the electric welding mechanism is arranged onone side of the base; and the pushing mechanism is arranged on one side of the base. Through cooperation of the electric welding mechanism and the pushing mechanism, the effects of automatic pushing and battery welding can be achieved, and the working efficiency of people can be improved; and through cooperation of a limiting mechanism and a lifting mechanism, when a battery is welded, the batterycan be positioned and clamped, automatic welding can be conducted, and manual operation is not needed.

Owner:汇通胜(广州)科技有限公司

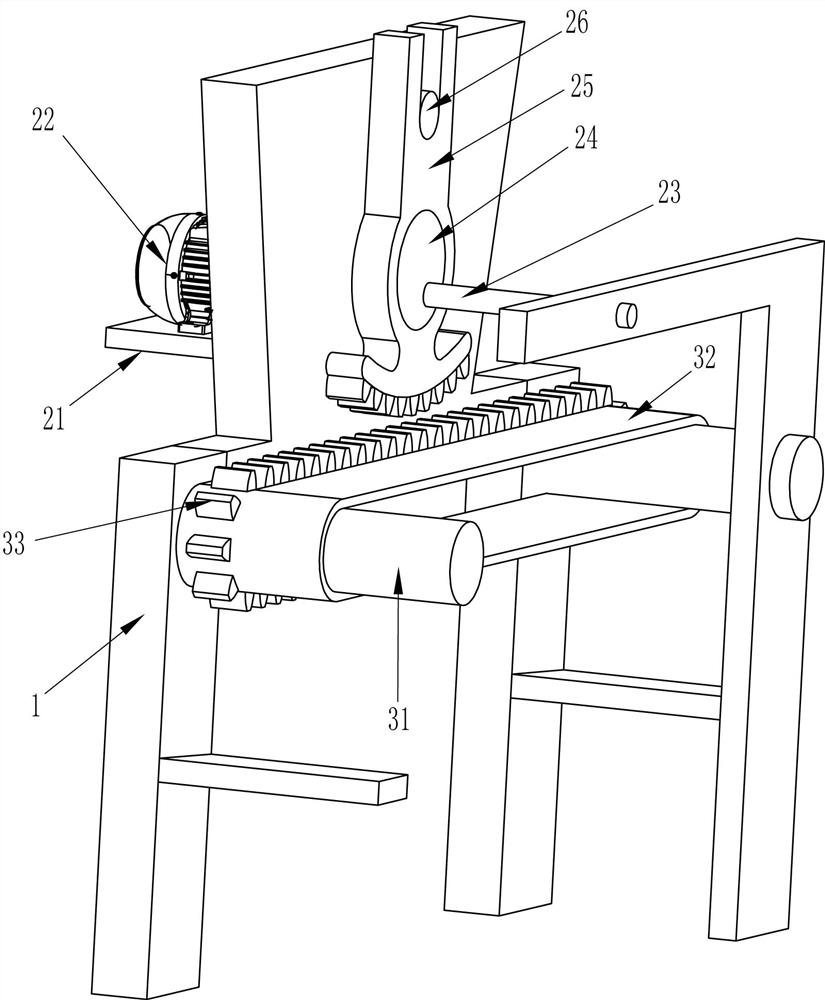

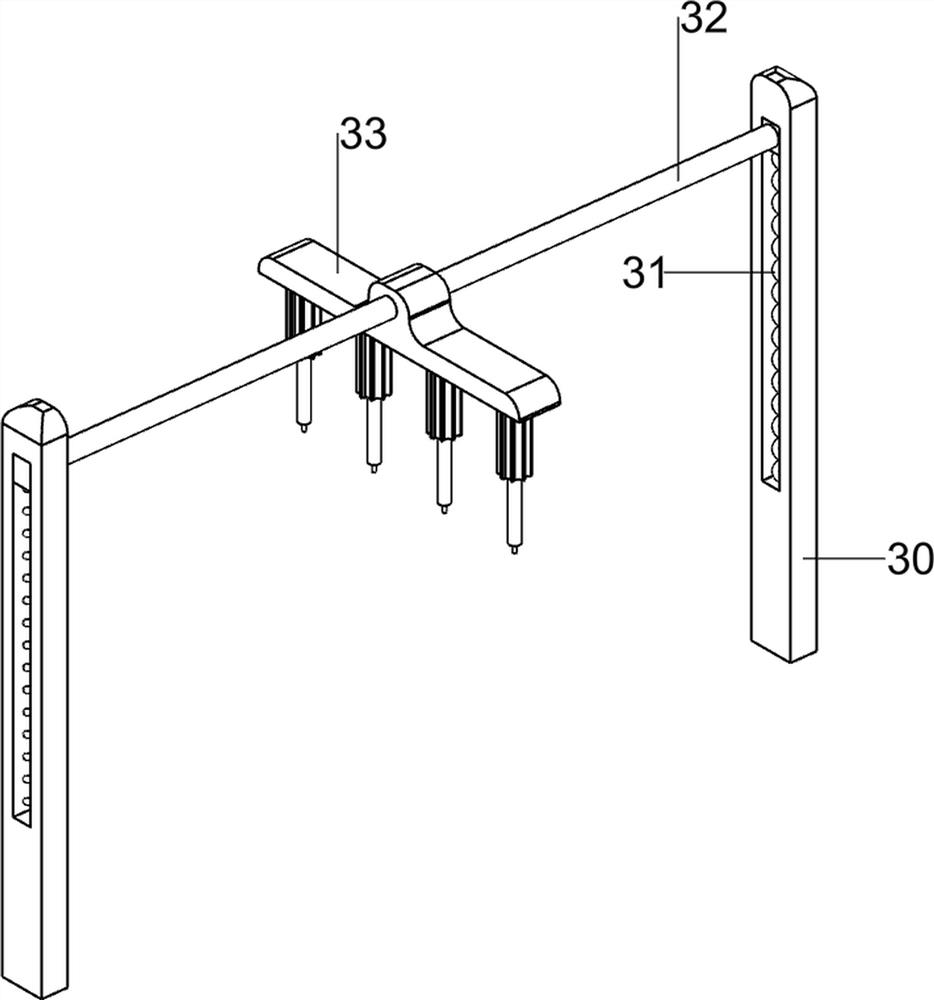

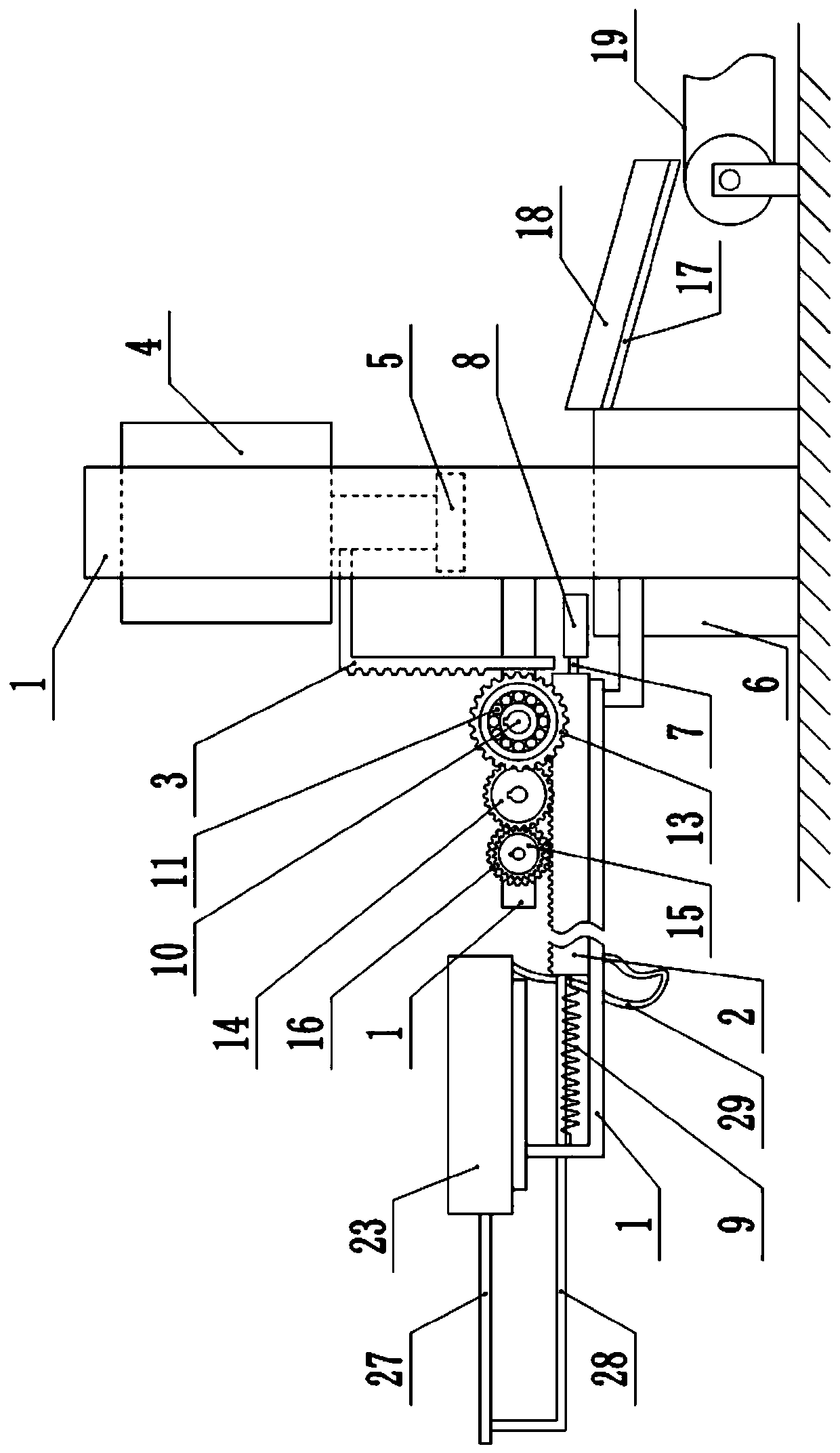

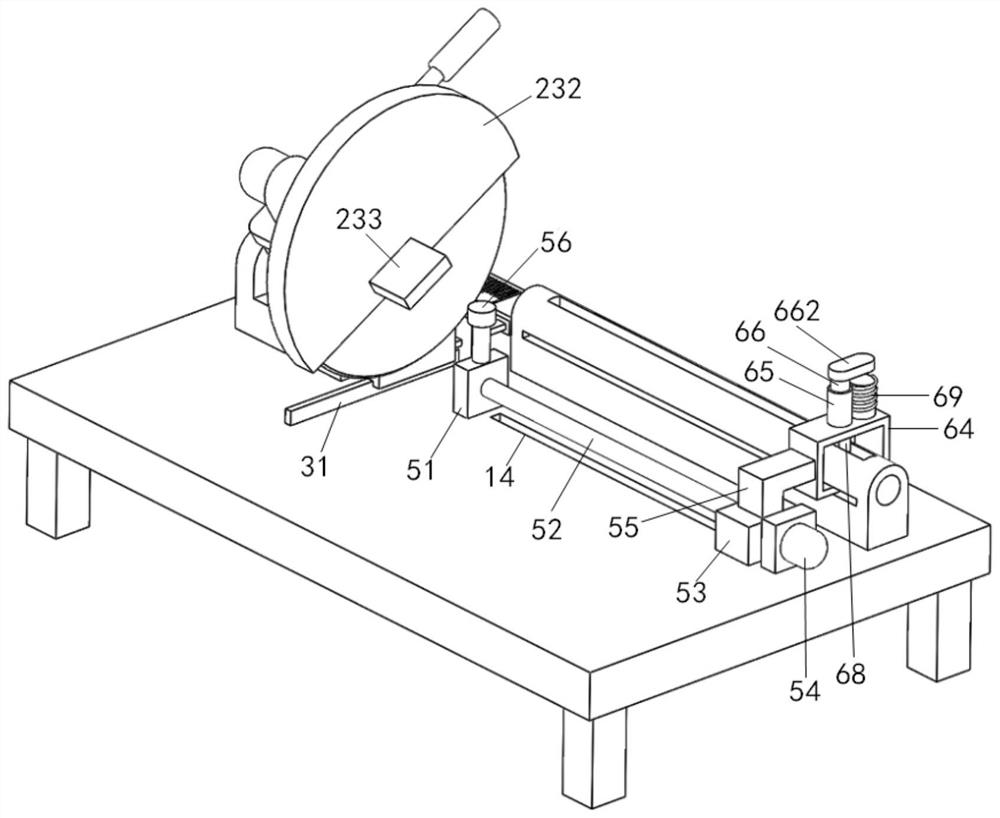

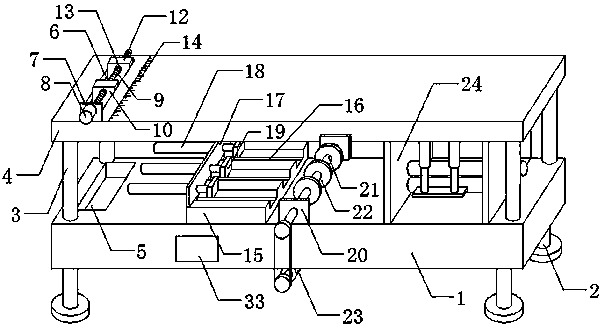

Uniform segmented cutting equipment for logs for building materials

InactiveCN112207909AUnified specificationsRealize automatic pushingProfiling/shaping machinesBark-zones/chip/dust/waste removalConstruction engineeringMechanical engineering

The invention relates to segmented cutting equipment, in particular to uniform segmented cutting equipment for logs for building materials. The technical purpose to be achieved is to provide the uniform segmented cutting equipment for the logs for the building materials, wherein automatic fixing, pushing and cutting of the logs can be achieved. According to the technical scheme, the uniform segmented cutting equipment for the logs for the building materials comprises a base and a cutting mechanism, wherein the base is connected with the cutting mechanism; a blocking mechanism, wherein the baseis connected with the blocking mechanism, and the cutting mechanism is located on the side of the material blocking mechanism; a pushing mechanism, wherein the base is connected with the pushing mechanism; and an ejecting mechanism connected to the pushing mechanism. By means of the cooperation of the cutting mechanism, the blocking mechanism, the pushing mechanism and the ejecting mechanism, manual log cutting can be replaced, automatic pushing, blocking and cutting can be achieved, human involvement is not needed in the whole process, the working efficiency of people is improved, and the cut logs can be uniform in specification.

Owner:何顺

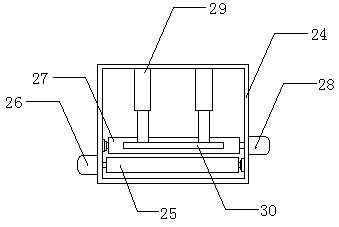

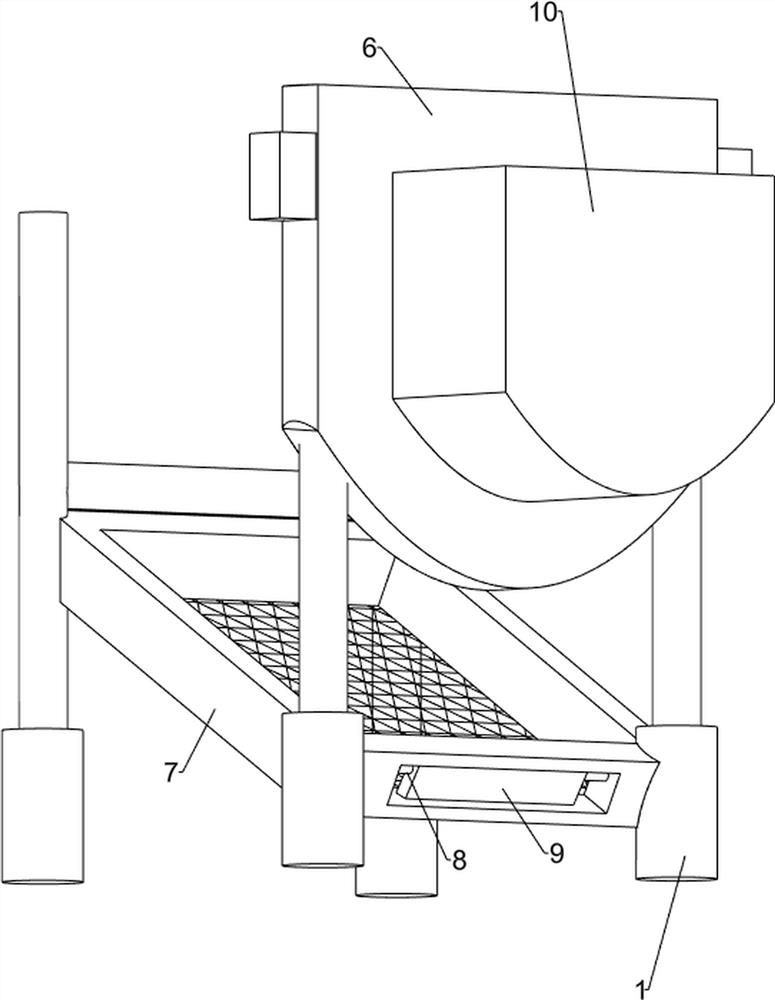

Chinese herbal medicine pressing and shredding device for traditional Chinese medicine

ActiveCN112518830ATo achieve shredded effectRealize automatic pushingMetal working apparatusProcess engineeringMechanical engineering

The invention relates to a shredding device, in particular to a Chinese herbal medicine pressing and shredding device for traditional Chinese medicine. The Chinese herbal medicine pressing and shredding device for the traditional Chinese medicine can achieve large-scale production and is high in efficiency. According to the technical scheme, the Chinese herbal medicine pressing and shredding device for the traditional Chinese medicine comprises a bottom plate, supporting feet, a placing mechanism and a shredding mechanism. The supporting feet are arranged at the five sides of the bottom of thebottom plate; the placing mechanism is arranged on the bottom plate; and the shredding mechanism is arranged on the bottom plate. Through cooperation of a driving mechanism, the placing mechanism andthe shredding mechanism, the effects of automatically pushing materials and shredding the Chinese herbal medicines can be achieved, and manual operation is not needed.

Owner:张循格

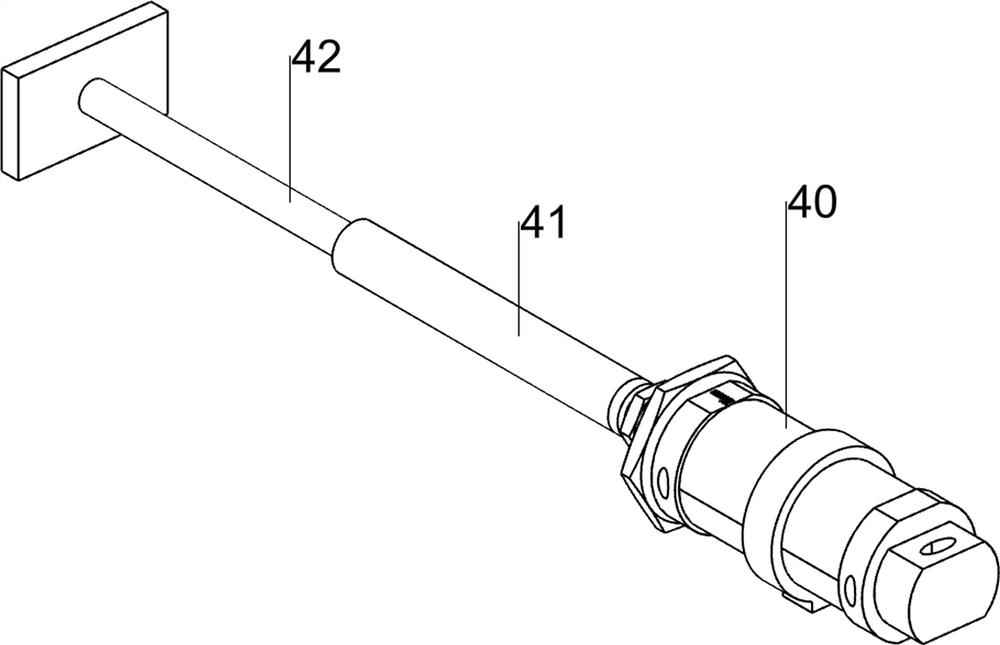

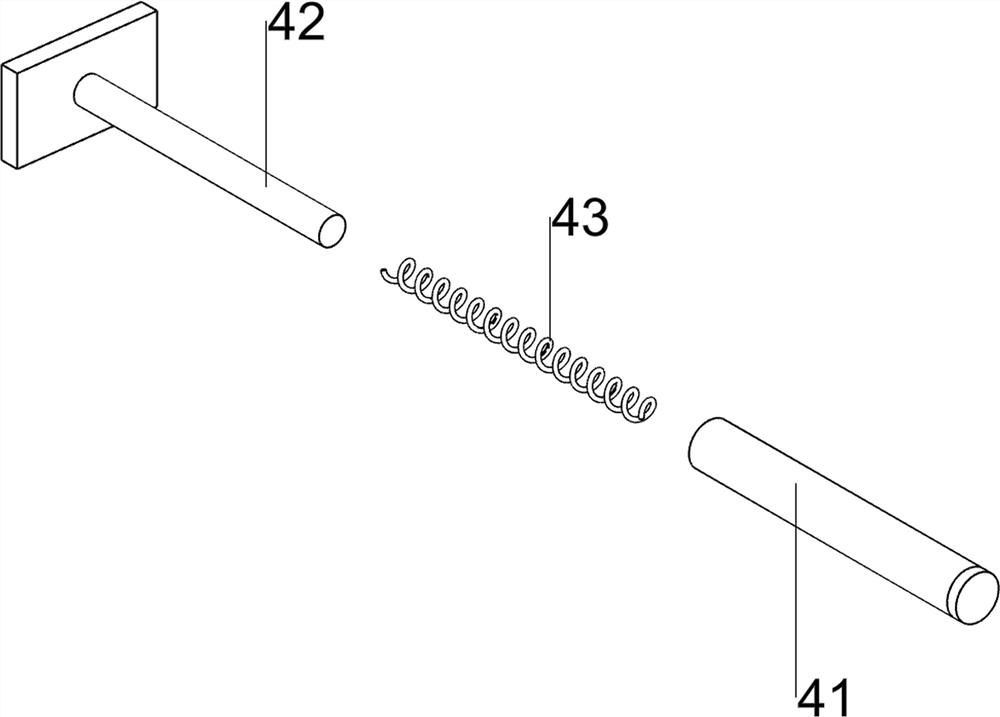

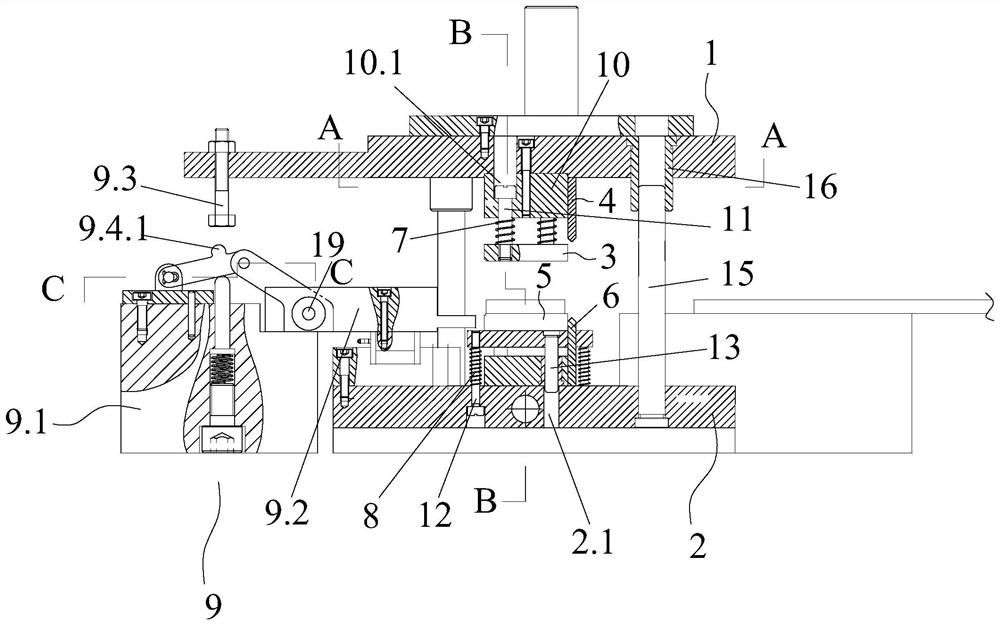

Strip nail blanking device

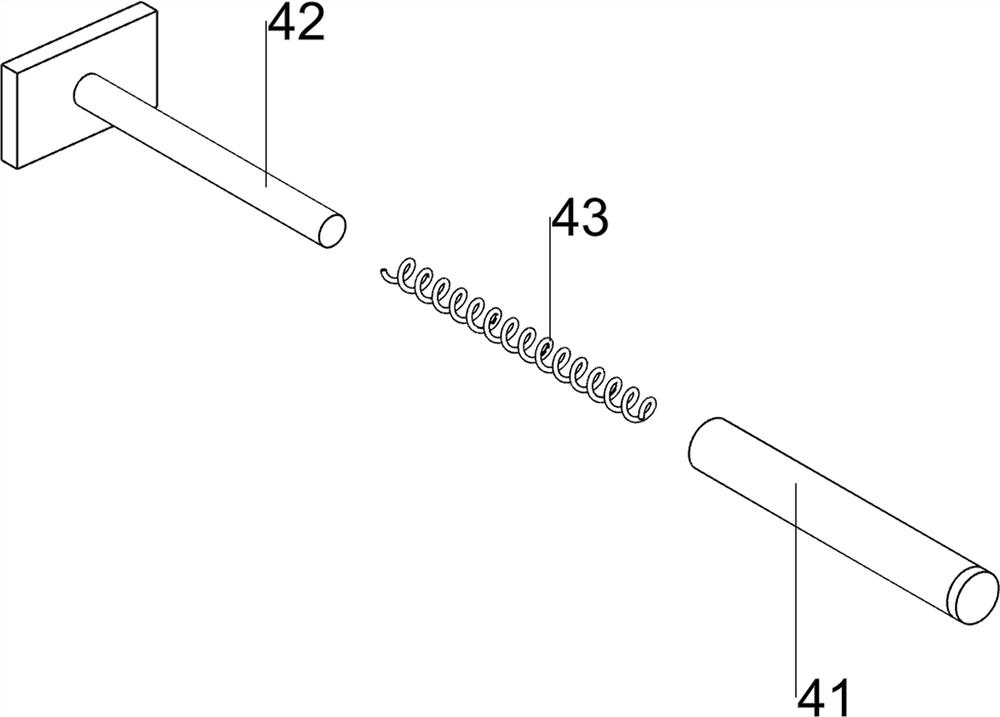

ActiveCN111069484ARealize automatic pushingImprove work efficiencyPinsNailsSuction forceStructural engineering

The invention discloses a strip nail blanking device comprising an upper die plate and a lower die plate. The upper die plate is provided with an upper blade. The lower die plate is provided with a lower blade. During die assembly, the upper blade and the lower blade simultaneously cut the two end faces of a strip nail material. The strip nail blanking device further comprises a material pushing mechanism. The material pushing mechanism comprises an L-shaped pushing plate, a pull rod and a reset spring. One end of the pull rod is connected with the L-shaped pushing plate, and the other end ofthe pull rod is arranged in the lower die plate in a sliding manner. The end, arranged in the lower die plate, of the pull rod is connected with a first magnet. The reset spring is arranged outside the pull rod in a sleeving manner. The lower end face of the end, close to the containing cavity, of an upper pressing plate is provided with a second magnet. During die opening, the first magnet is close to the second magnet, and the magnetic attraction force drives the L-shaped pushing plate to push the strip nail to horizontally move; and during conducting die assembly again, the first magnet andthe second magnet are separated, and under the action of the reset spring, the L-shaped push plate resets. The strip nail blanking device can automatically push the strip nail obtained after blankingto a next station, manual intervention in carrying is not needed, and the work efficiency is improved.

Owner:萍乡市鸿安五金制品有限公司

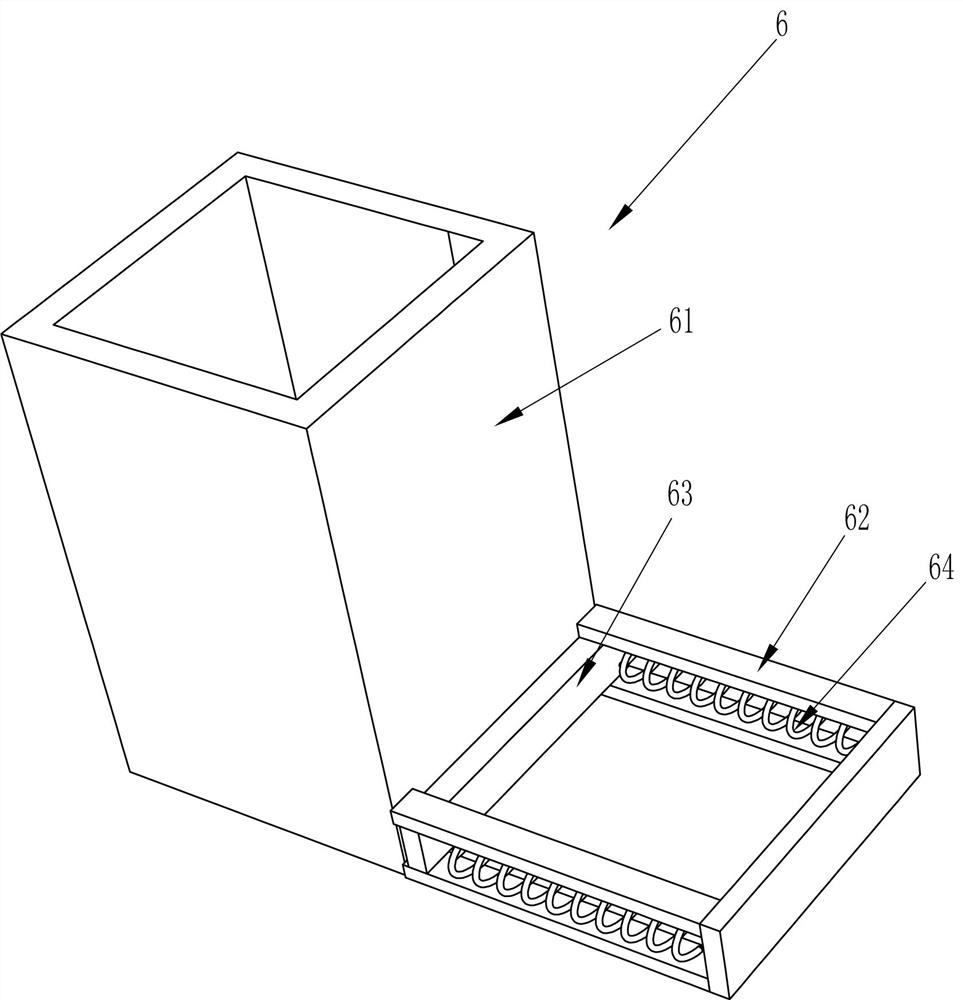

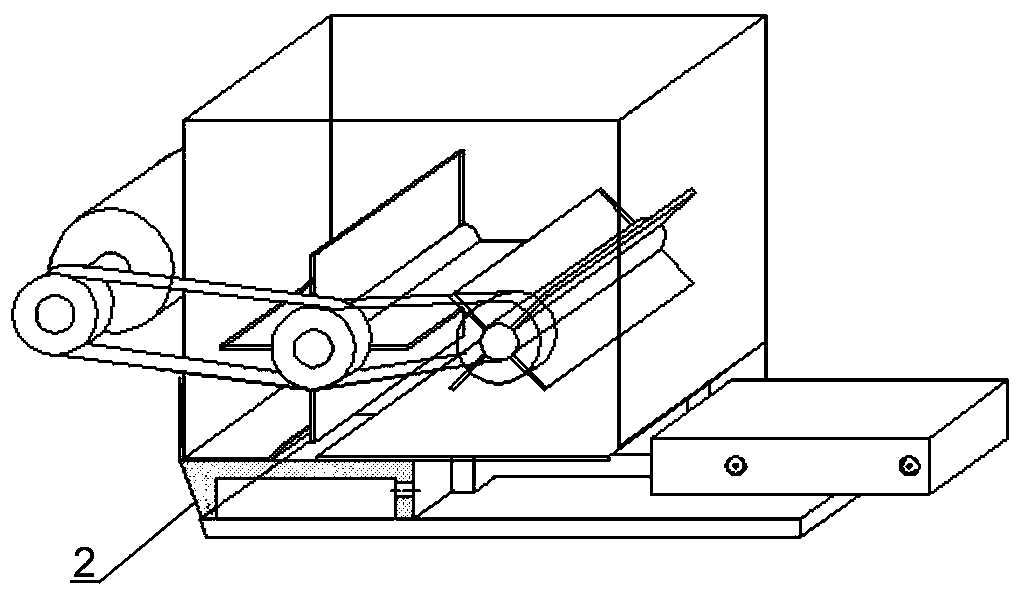

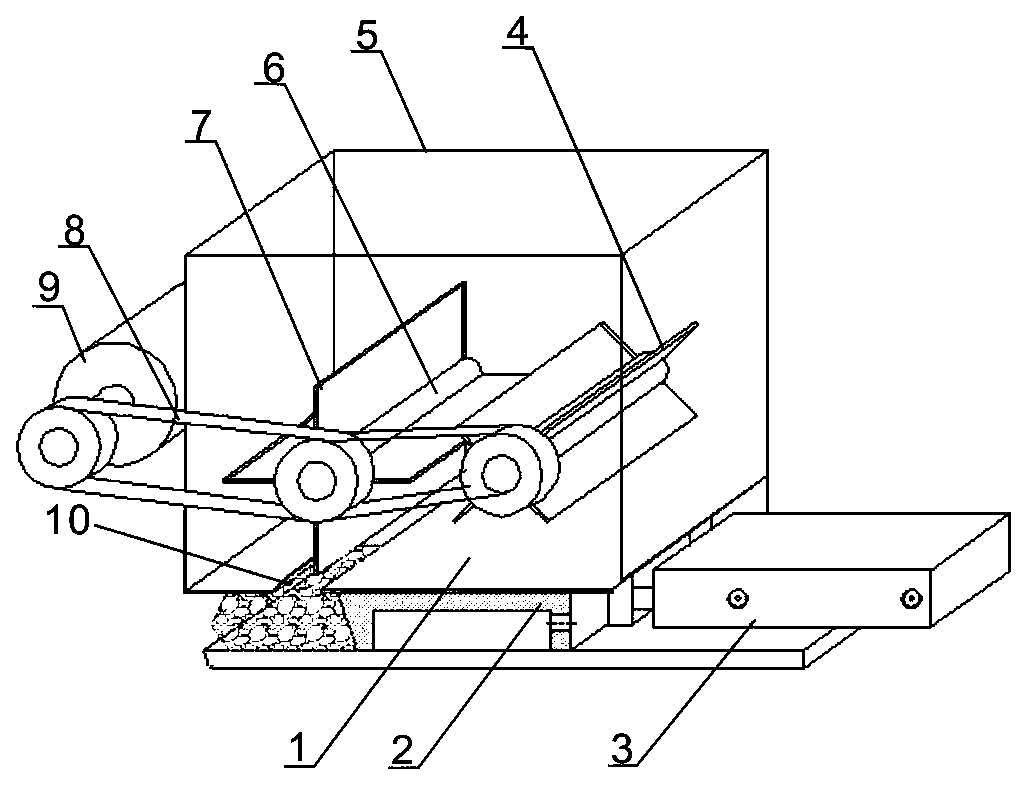

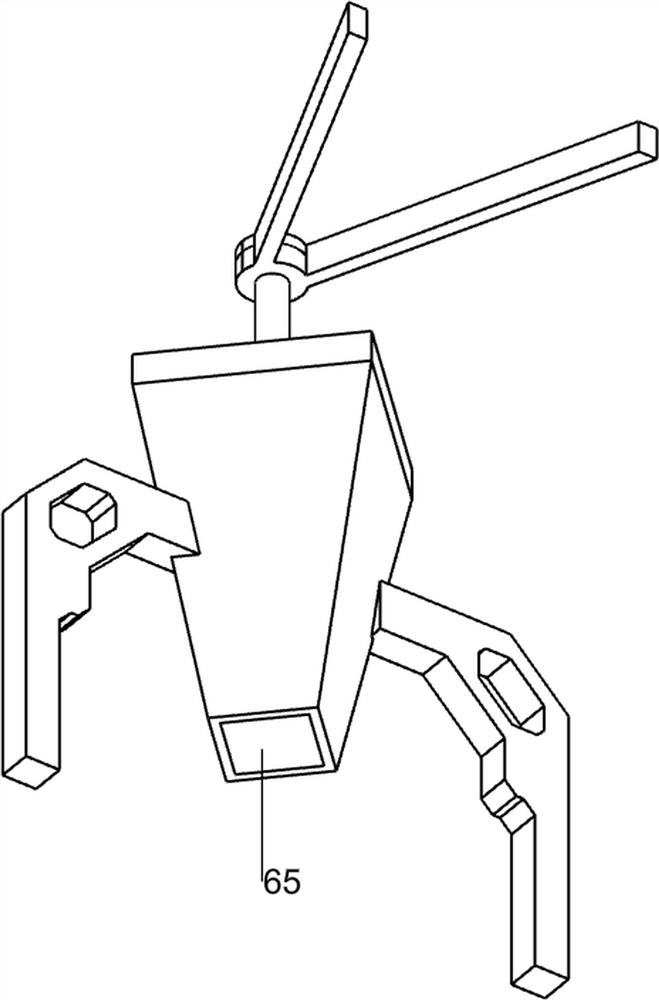

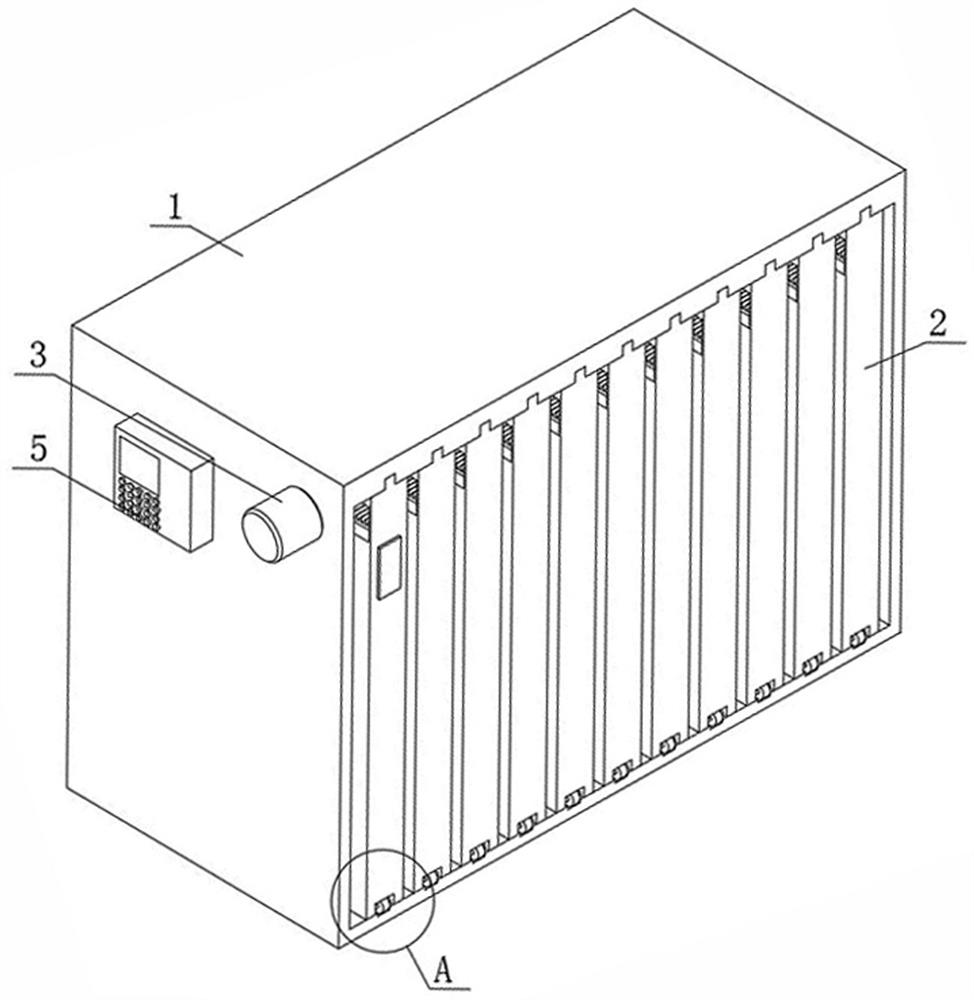

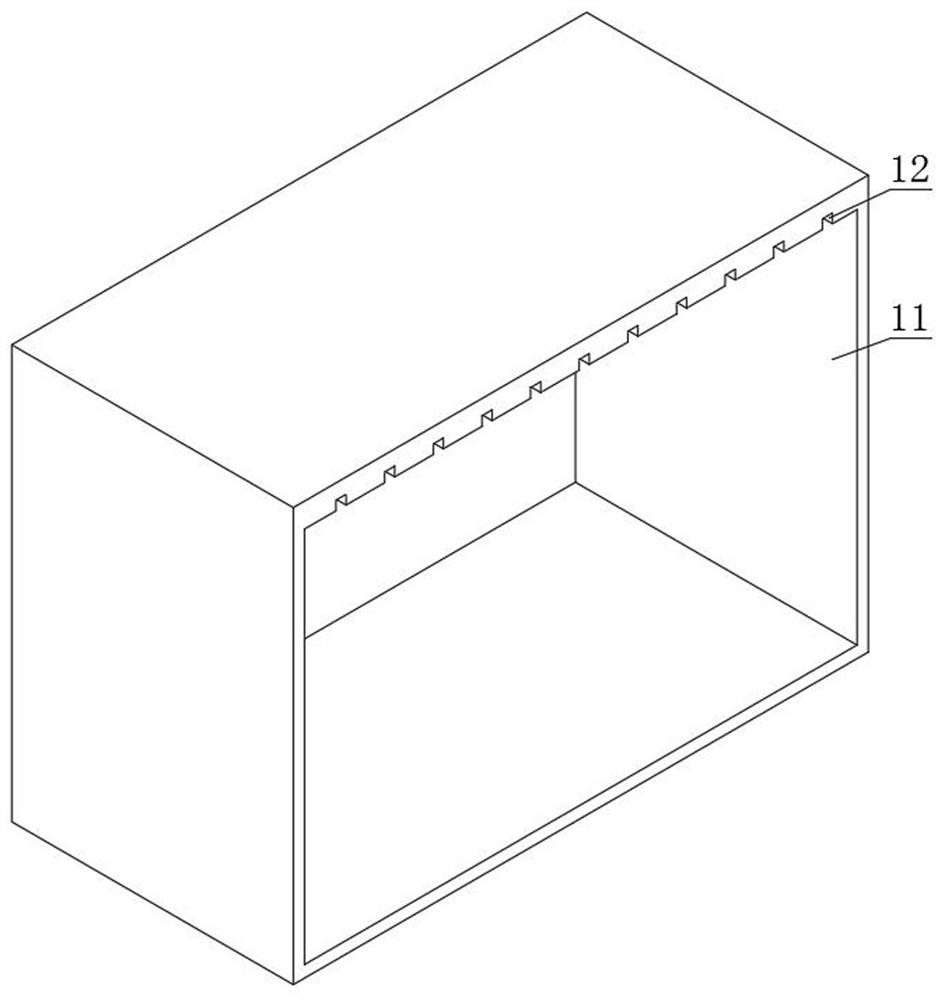

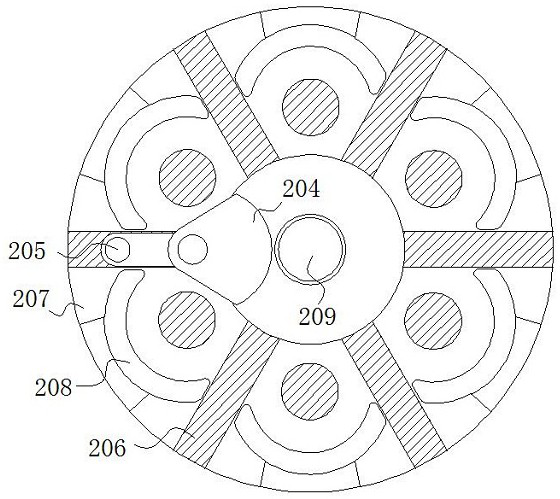

Quantitative control system for granular or fiber-like material discharging

The invention discloses a quantitative control system for granular or fiber-like material discharging. The quantitative control system comprises a stock bin, a driving mechanism, a motor and a material poking wheel; the stock bin is of a hollow structure of which the upper end is open, the interior of the stock bin is provided with a material leakage plate, and an inner cavity of the stock bin isdivided into an upper space and a lower space which are independent from each other; the material leakage plate is provided with a material leakage gap, and the material poking wheel located above thematerial leakage gap is arranged in the stock bin; the outer side of the stock bin is provided with the motor, and the motor is in transmission connection with the material poking wheel through a belt; the stock bin is internally provided with a sliding bin door located at the bottom of the material leakage plate, and the sliding bin door is connected with the driving mechanism capable of drivingthe sliding bin door to slide left and right; and the left side wall of the stock bin is provided with a material outlet communicating with the interior of the stock bin, and the material outlet corresponds to the sliding bin door.

Owner:LUOYANG SHENJIA KILN

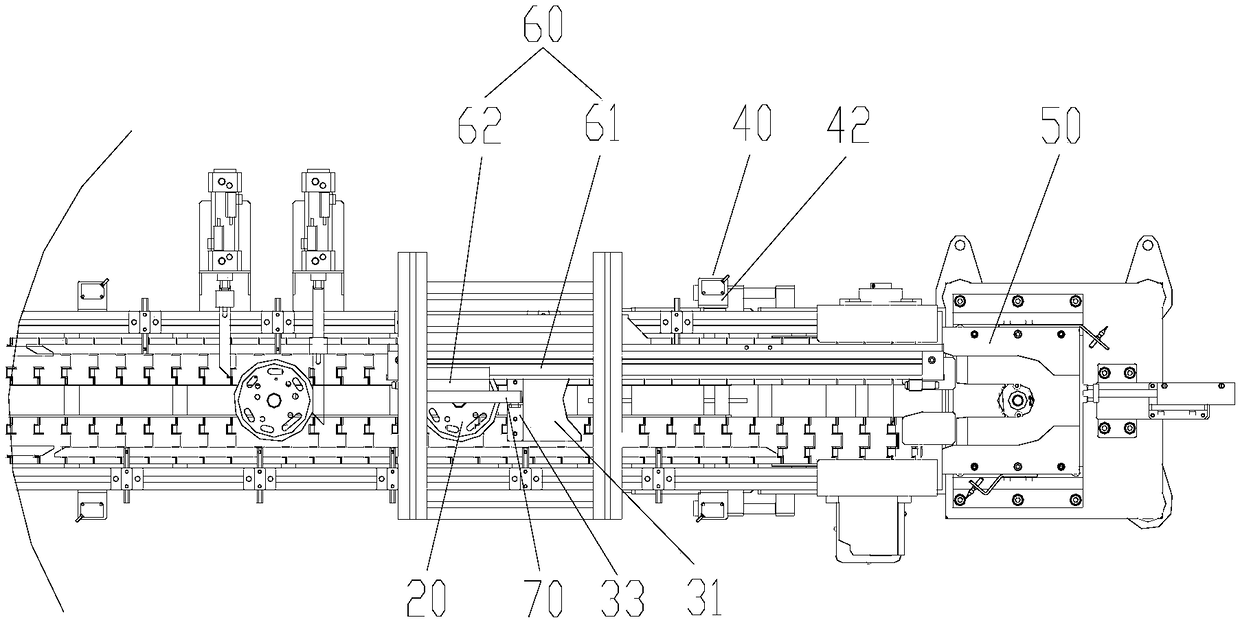

Shearing sending system

ActiveCN104555284AHigh degree of automationReduce labor intensityConveyorsAutomatic controlControl system

The invention discloses a shearing sending system. The system comprises a pushing unit, a storage frame, a feeding unit and an automatic control system. The pushing unit is used for pushing plates to a plate shearer, and the storage frame is used for storing plates. The feeding unit comprises a rail frame, a sliding trolley and a suction unit. The rail frame is erected above the pushing unit, the sliding trolley is arranged on the rail frame movably, and the suction unit is arranged below the sliding trolley and capable of being driven by the sliding trolley to transport the storage frame to a delivery frame. The automatic control system is used for controlling the pushing unit, the storage frame, the sliding trolley and the suction unit synchronously. By means of the system, automatic pushing and circulation operations are achieved during sending of plates to the plate shearer, the shearing sending and whole plate shearing process automatic degree is improved, the work efficiency is improved, and the worker labor intensity is reduced greatly.

Owner:中集车辆(江门市)有限公司

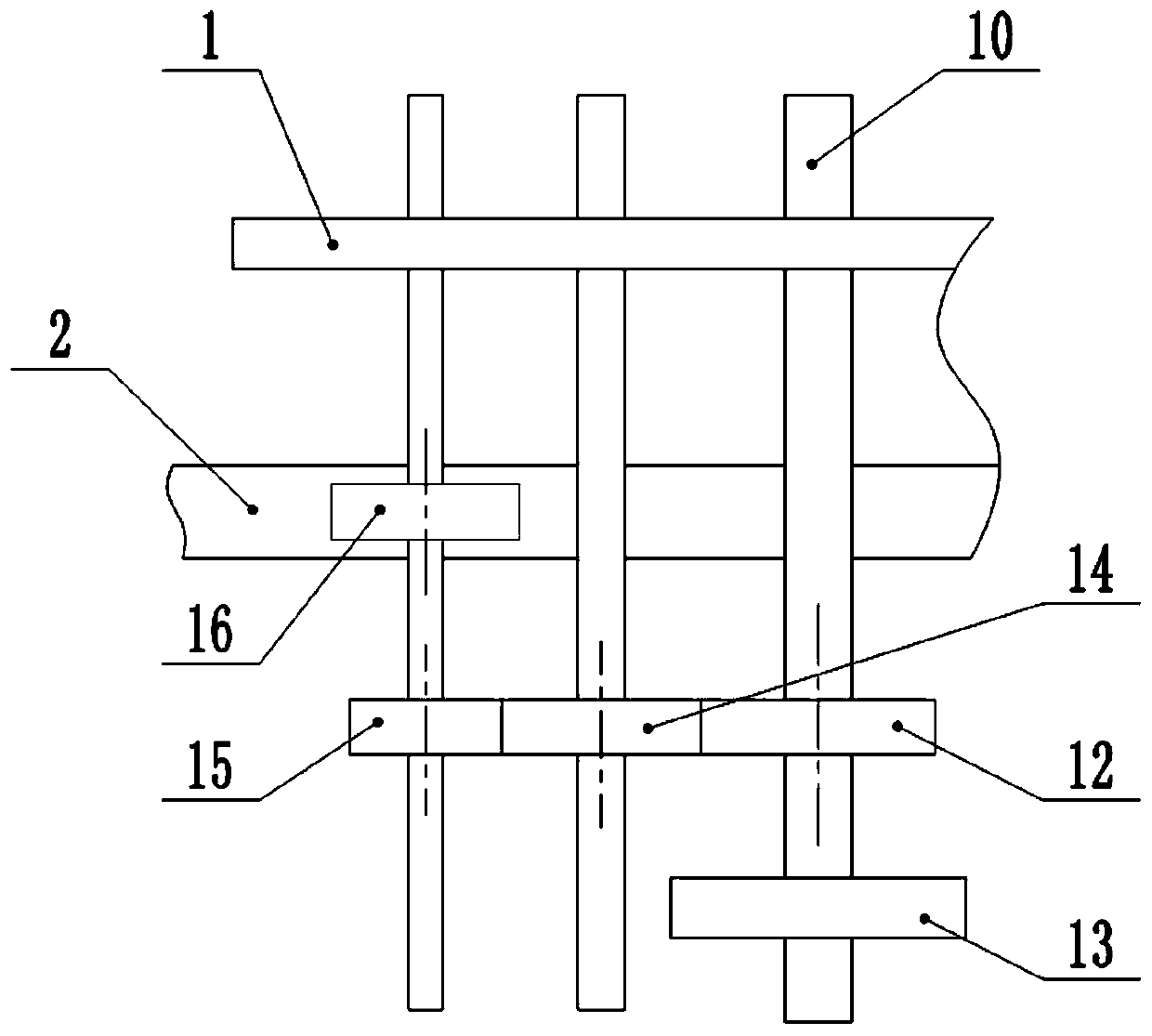

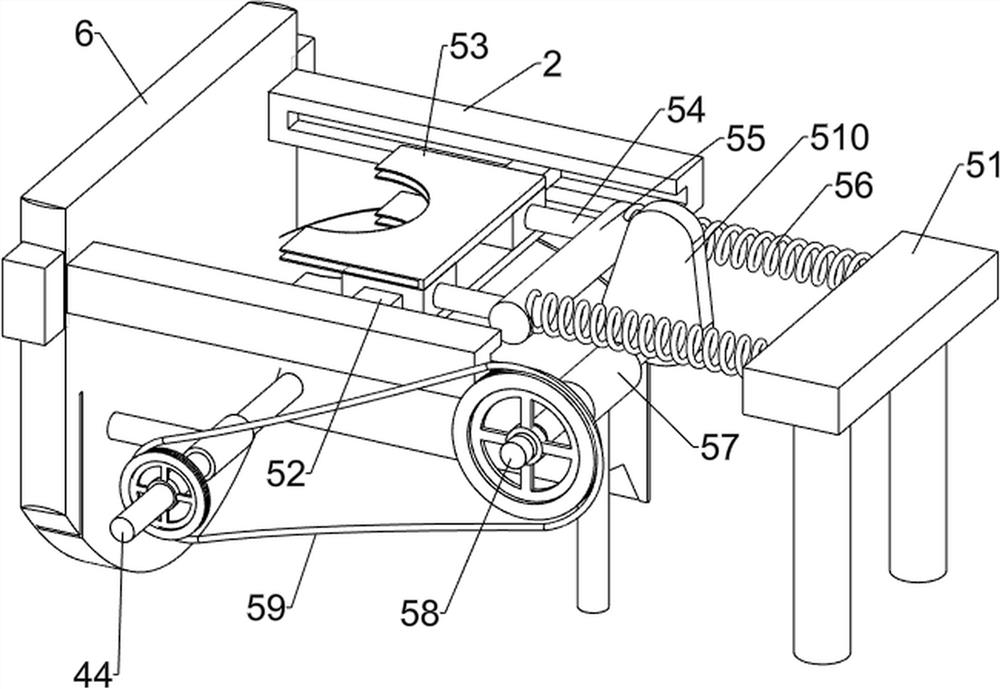

Automatic material pushing device

ActiveCN111215570AIncrease elasticityReduce laborForging/hammering/pressing machinesGear wheelEngineering

The invention relates to the technical field of accessory machining, and particularly discloses an automatic material pushing device. The automatic material pushing device comprises a frame, a first rack and a second rack, wherein the first rack is horizontally and slidably connected to the frame, a push rod is arranged at one end of the first rack, the push rod is fixedly connected with a push plate, the push plate is positioned above a stamping table, an elastic piece is fixedly connected to the other end of the first rack, and the elastic piece is fixedly connected with the frame; the top end of the second rack is fixedly connected with the output end of a stamping machine, the frame is rotatably connected with a horizontally arranged rotating shaft, the rotating shaft is coaxially andfixedly connected with a one-way bearing and a driving gear, and the outer peripheral wall of the one-way bearing is fixedly connected with an outer gear ring capable of being engaged with the secondrack; and the driving gear is engaged with a primary driven gear, the primary driven gear is engaged with a secondary driven gear, and the secondary driven gear is coaxially and fixedly connected witha driving gear engaged with the first rack. According to the automatic material pushing device, the stamping machine is used as a power source to realize automatic material pushing, so that the laboramount of workers is reduced, and the working efficiency is improved.

Owner:重庆市桂生机械制造有限公司

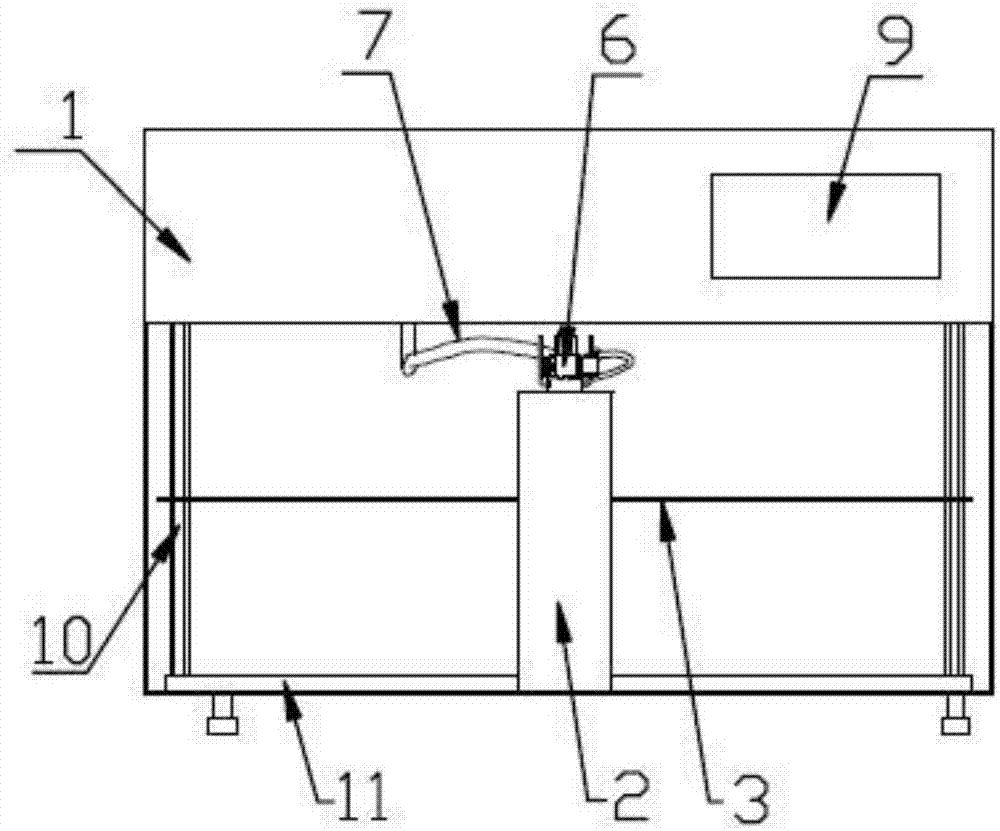

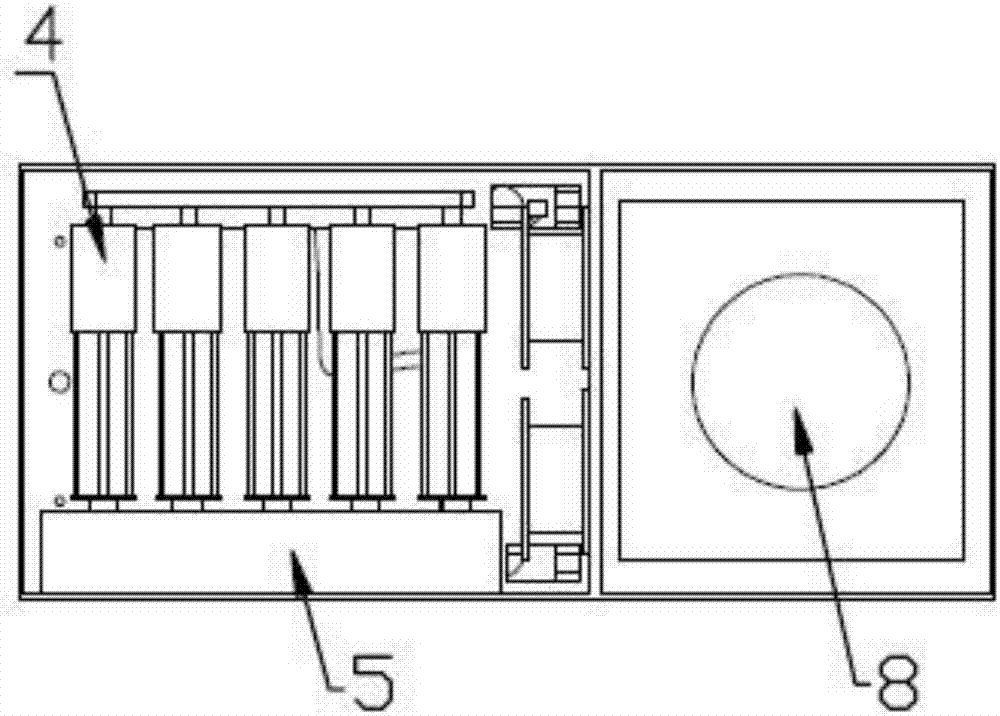

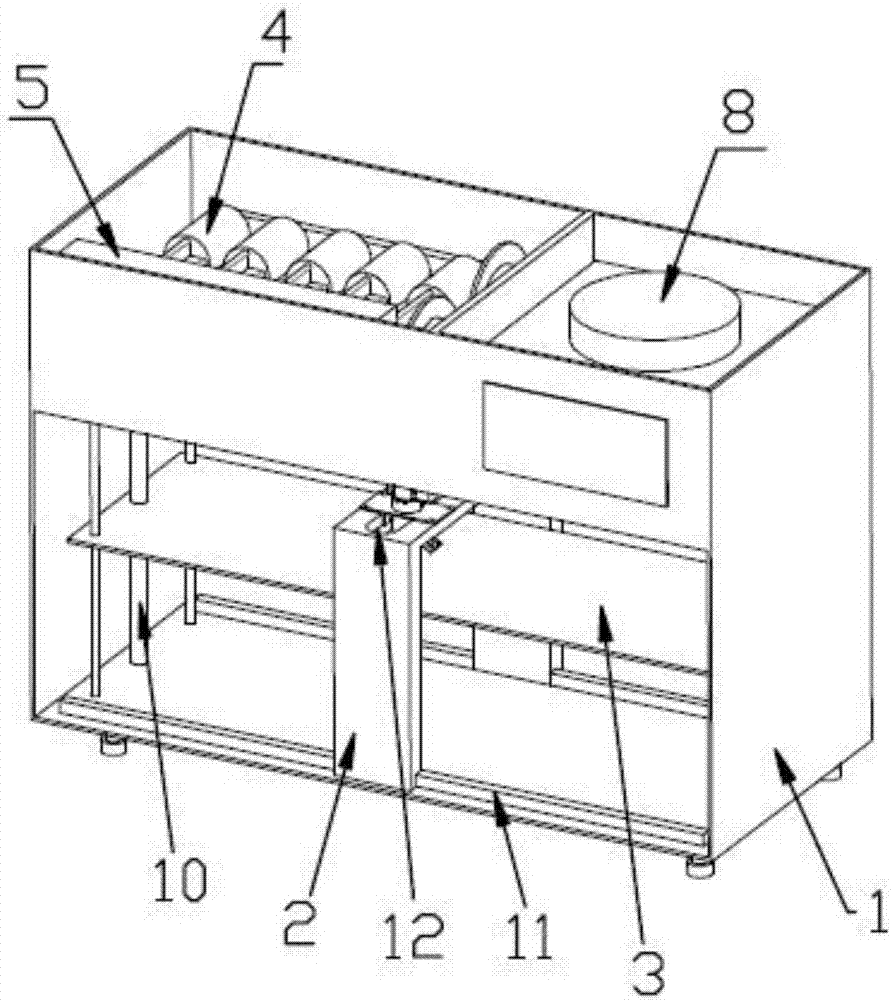

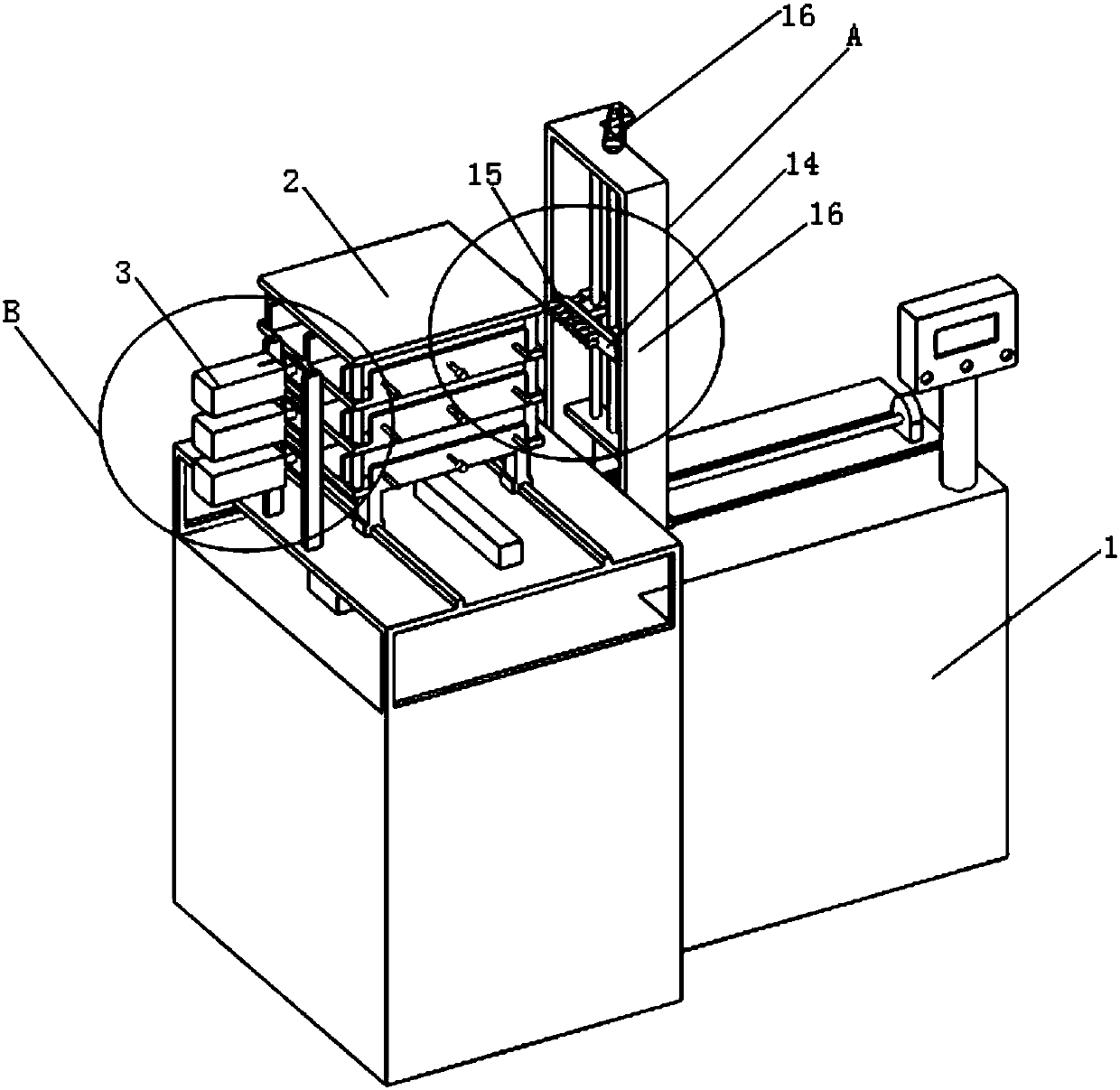

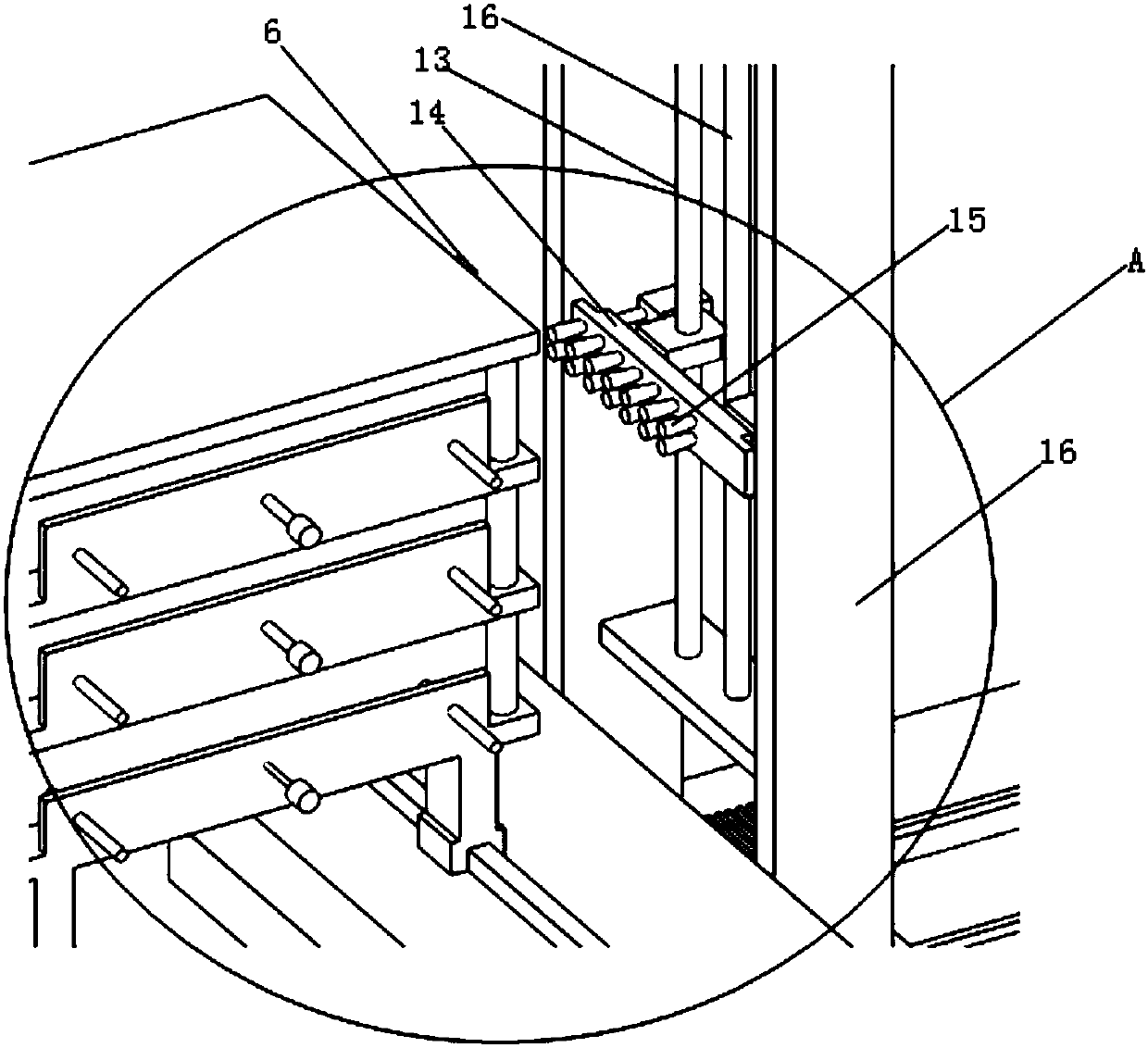

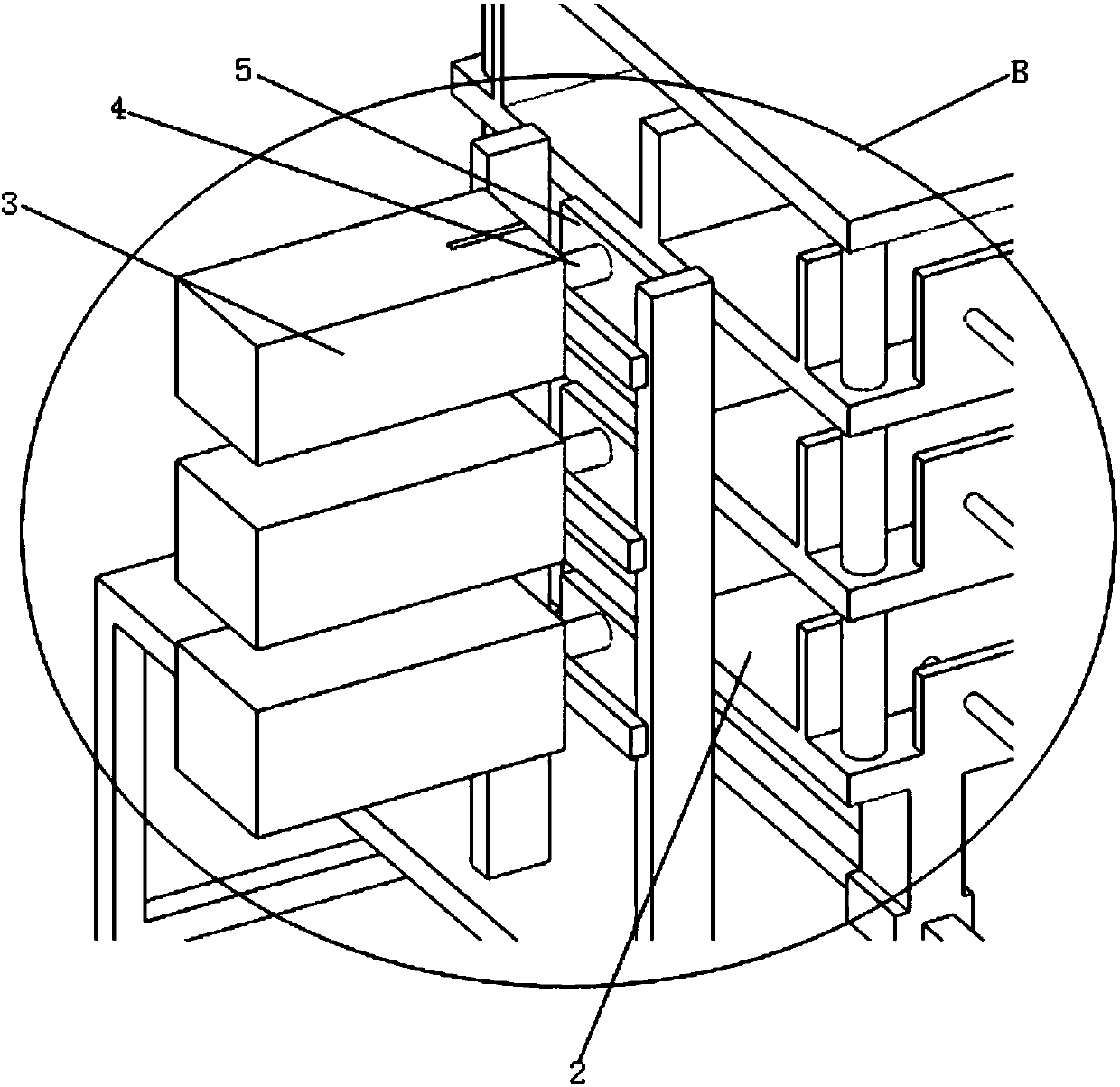

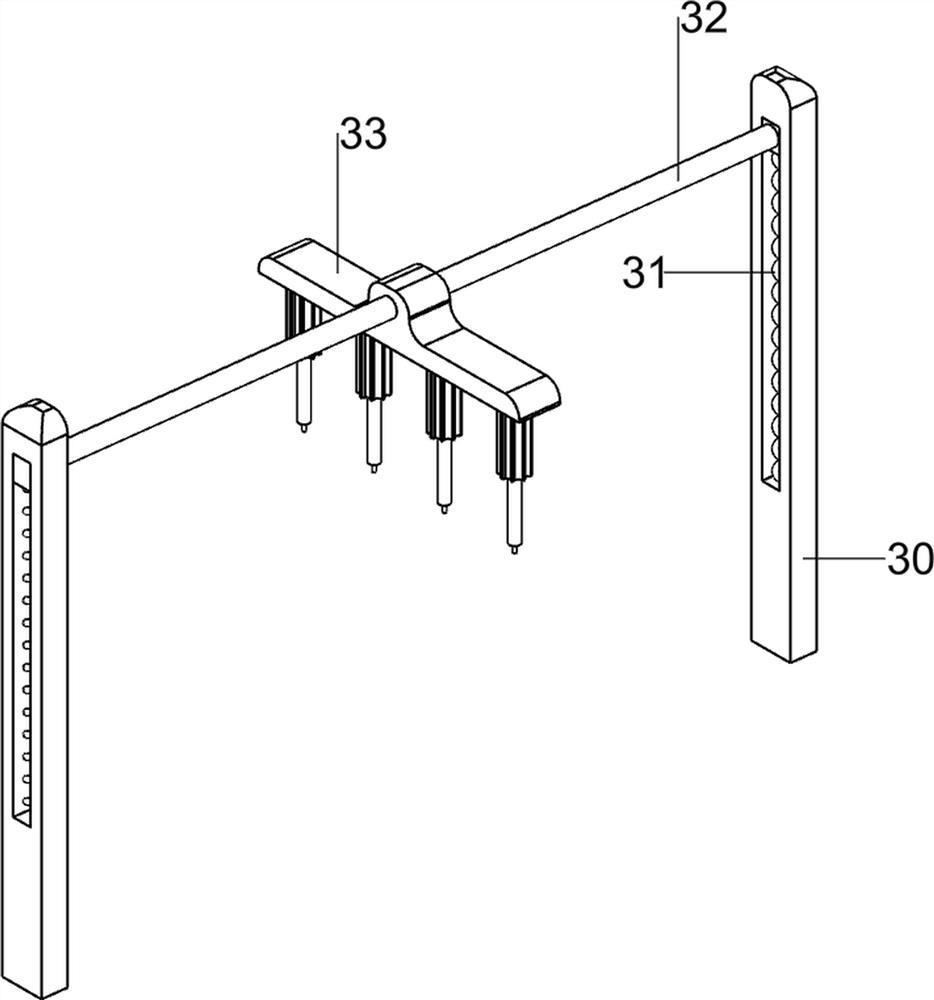

Oil sludge 3D printer

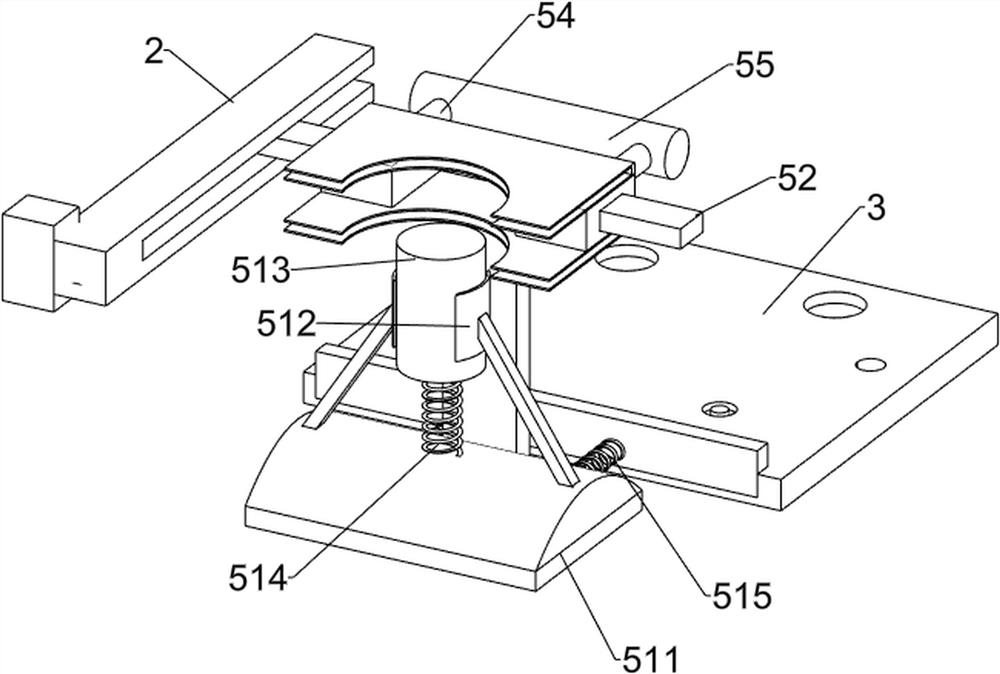

PendingCN107187031AAccurate temperature controlRealize automatic pushingCeramic shaping apparatusAdditive manufacturing with liquidsElectric machineryProcess engineering

The invention discloses an oil sludge 3D printer. The oil sludge 3D printer is characterized by comprising a box, a portal frame, a working table, an oil sludge barrel, a motor driving material system, a printing head, a tube, a waste purifying system and an industrial personal computer, wherein two parallel X-axis guide tracks are arranged at the bottom of the box; two vertical Z-axis guide tracks are arranged at two ends of the box; the portal frame is arranged on the X-axis guide tracks; two ends of the working table are connected with the Z-axis guide tracks; the oil sludge barrel is arranged on the upper part of the box; the motor driving material system is arranged on the upper part of the box; the other end of the oil sludge barrel is connected with the tube; the printing head is arranged on the top of the portable frame; and the oil sludge barrel is connected with the printing head through the tube. According to the oil sludge 3D printer, oil sludge is used as a raw material; by a 3D printing mode, the oil sludge raw material is directly printed into a mold required by a designer; manufacturing of models or parts can be finished by simple aftertreatment; the working efficiency is improved effectively; the expenditure is reduced; and the labor cost is also reduced.

Owner:浙江富瑞新材料有限公司

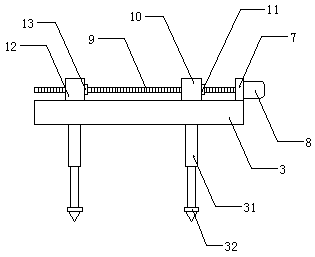

Stainless steel round tube cutting machine capable of achieving automatic feeding and discharging

InactiveCN111958039ARealize automatic pushingHigh degree of automationTube shearing machinesShearing machine accessoriesRotation - actionElectric machinery

The invention discloses a stainless steel round tube cutting machine capable of achieving automatic feeding and discharging. The stainless steel round tube cutting machine comprises a machining base plate and support feet. The top face of the machining base plate is provided with a cutting hinge seat. An inclined connecting block is arranged in the cutting hinge seat in a rotary manner and provided with a cutting blade. A discharging rack is arranged below the cutting blade. When a rotating central shaft of the inclined connecting block rotates, the discharging rack moves. A feeding seat is arranged at one side of the cutting blade and provided with a sliding bracket. Each time when the cutting blade resets after cutting, the sliding bracket moves by a fixed distance. The stainless steel round tube cutting machine has the beneficial effects that the stainless steel round tube cutting machine is provided with the feeding seat; the sliding bracket on the feeding seat can push stainless steel tubes to achieve automatic feeding through rotation of a motor; a material pushing rack is arranged at one side below the cutting blade, wherein the material pushing rack can move forwards and backwards; by means of the rotating action of the cutting machine, the material pushing rack moves forwards and backwards, and thus, automatic material pushing is achieved after cutting; and the stainless steel round tube cutting machine is high in automation degree, and safety performance and machining efficiency are greatly improved.

Owner:叶天然

Plate shearing equipment for new energy automobile part production and using method

ActiveCN113102817ARealize automatic pushingAdjustable distanceShearing machinesMetal working apparatusNew energyDrive shaft

The invention discloses plate shearing equipment for new energy automobile part production and a using method, and belongs to the technical field of automobile part machining. The plate shearing equipment for new energy automobile part production comprises a mounting table and supporting legs, wherein the supporting legs are connected to the bottom wall of the mounting table, the side wall of the mounting table is connected with a first material receiving plate, the inner walls of the supporting legs are connected with a second material receiving plate and a material collecting box, a material pushing mechanism comprises a double-end motor, a connecting rod assembly and a pressing assembly, and the top of the mounting table is connected with a supporting plate; the connecting rod assembly is arranged at the top of the supporting plate, the double-end motor is connected to the bottom wall of the mounting table, the output ends of the two ends of the double-end motor are connected with first transmission shafts, one ends, away from the double-end motor, of the first transmission shafts are connected with first belt wheels, the outer walls of the first belt wheels are connected with first belts, and the first belts are connected to the input end of the connecting rod assembly. According to the plate shearing equipment for new energy automobile part production, long steel plates can be automatically fed and sheared, the size is convenient to adjust, the shearing process is stable, and deviation is not prone to occurring.

Owner:KAZUO PENGDA CASTING

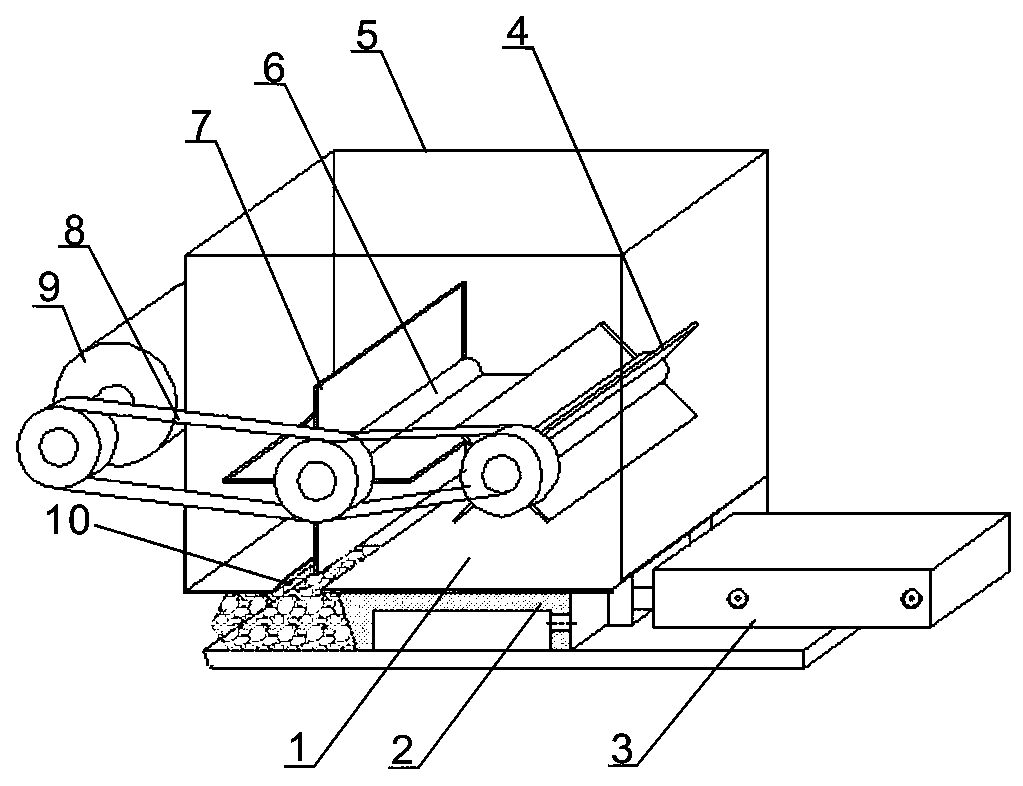

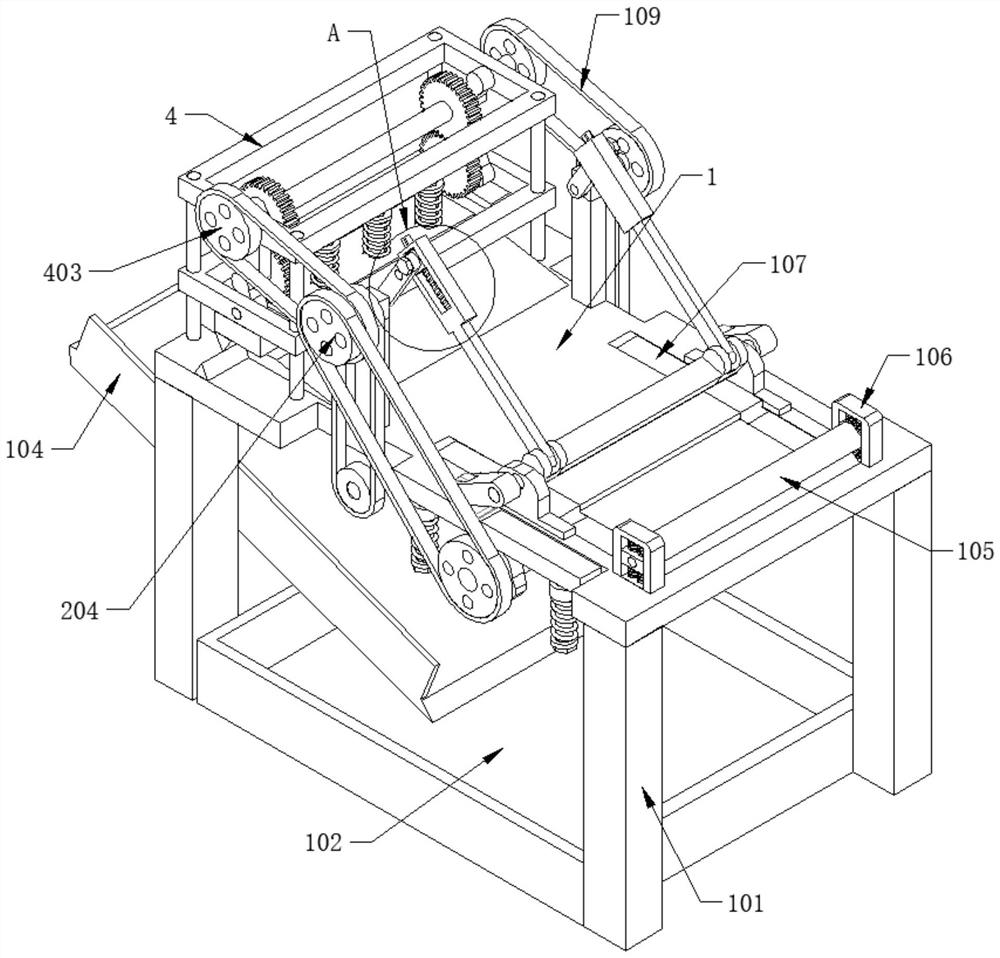

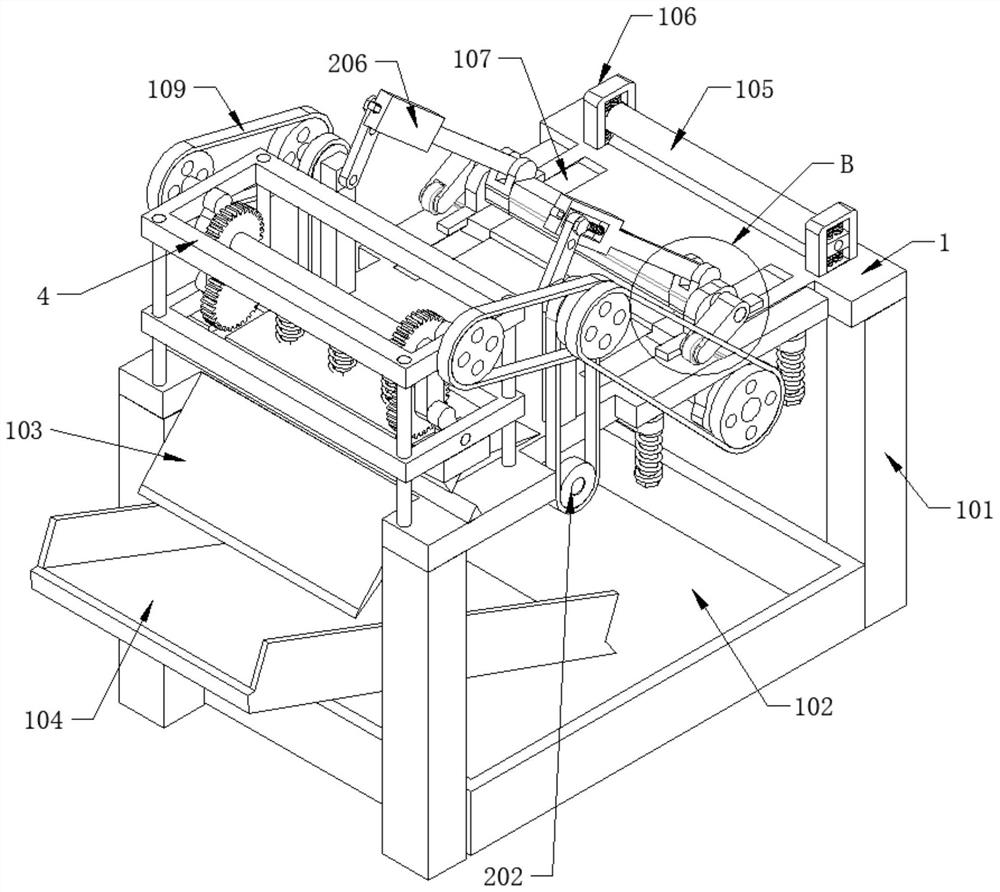

Reed shaping machine and using method thereof

InactiveCN108818799AAchieve shapingReduce labor intensityWood compressionCane mechanical workingDrive shaftEngineering

The invention discloses a reed shaping machine and a using method thereof. The reed shaping machine comprises a workbench. The bottom end of the workbench is fixedly provided with four support legs. One end of the top of the workbench is provided with a placing groove. The top end of the workbench is fixedly connected with the bottom end of a top plate through the four support rods. The top end ofthe top plate is provided with a groove. The interior of the groove is provided with a cutting mechanism. The middle of the top end of the workbench is provided with a support base. The top end of the support base is provided with a plurality of reed rod placing grooves. One end of the support base is provided with a material pushing mechanism. The reed shaping machine and the using method thereof are capable of, through a transmission shaft of an installed step motor, driving a screw rod to be rotated, thereby driving a first moving block and a second moving block to be slid in the groove, through an installed scale line, conveniently and accurately adjusting a position between two cutting knives, and conveniently cutting two heads of the reed.

Owner:东营职业学院

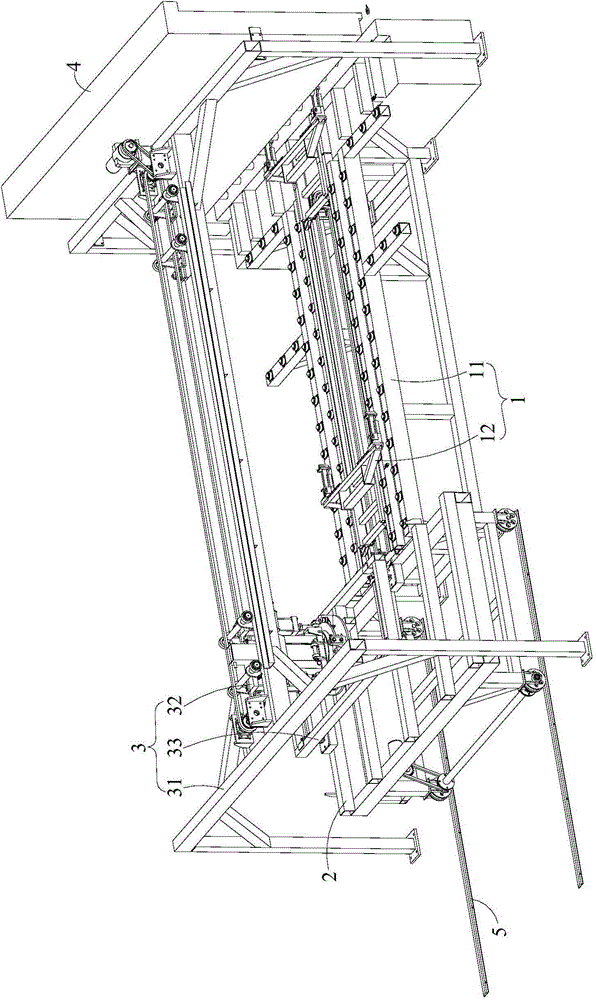

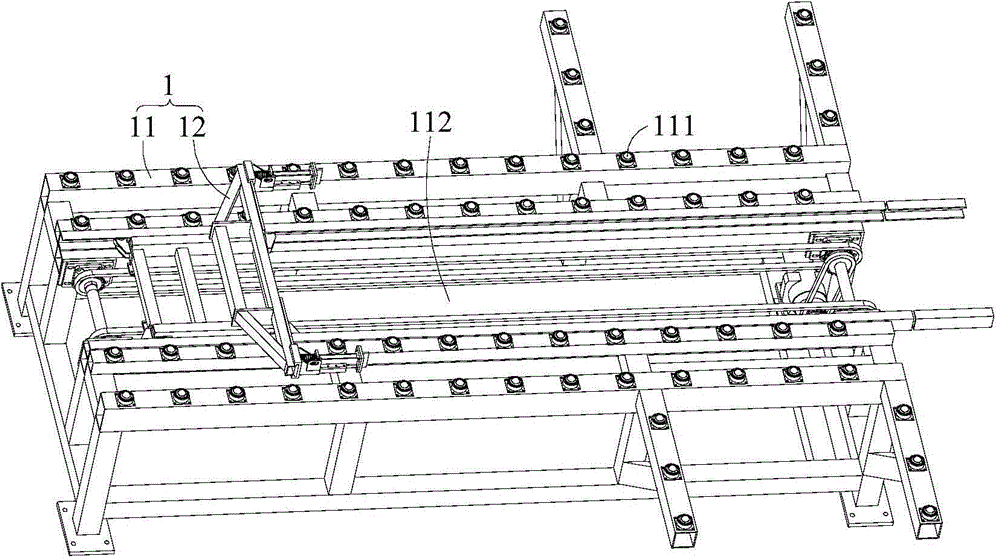

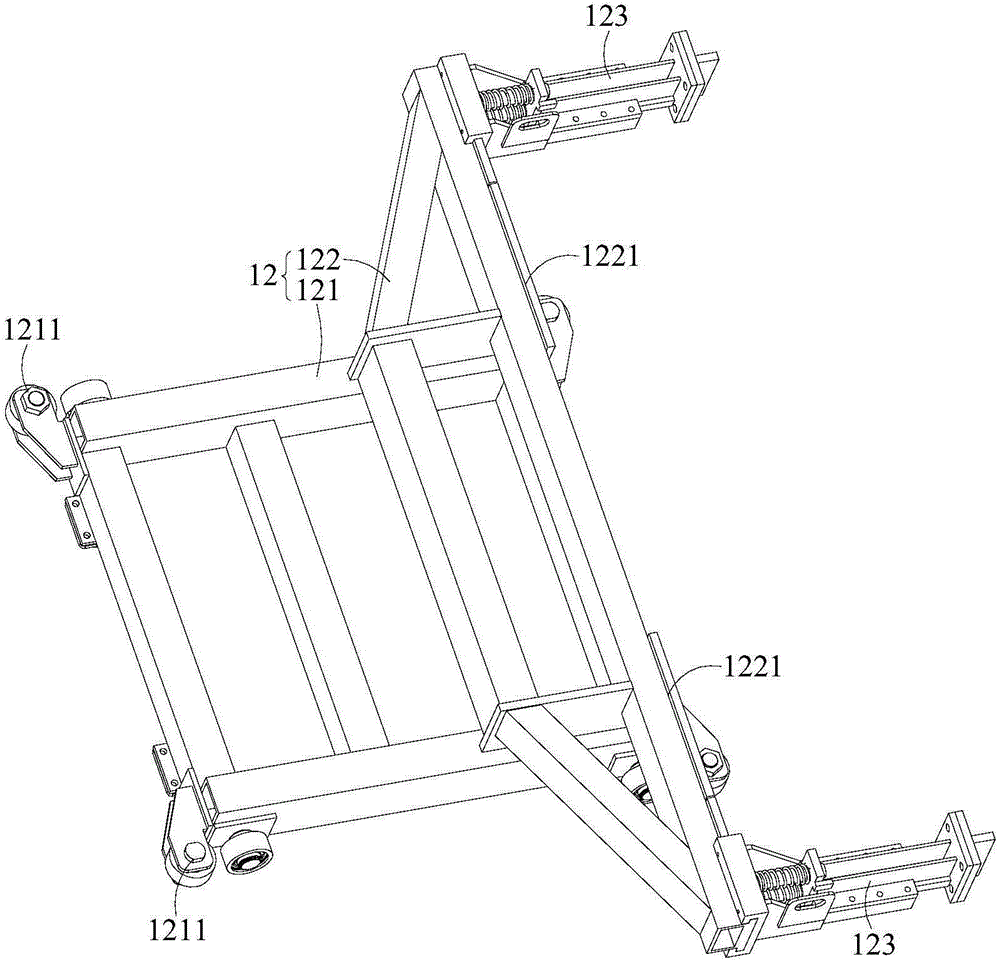

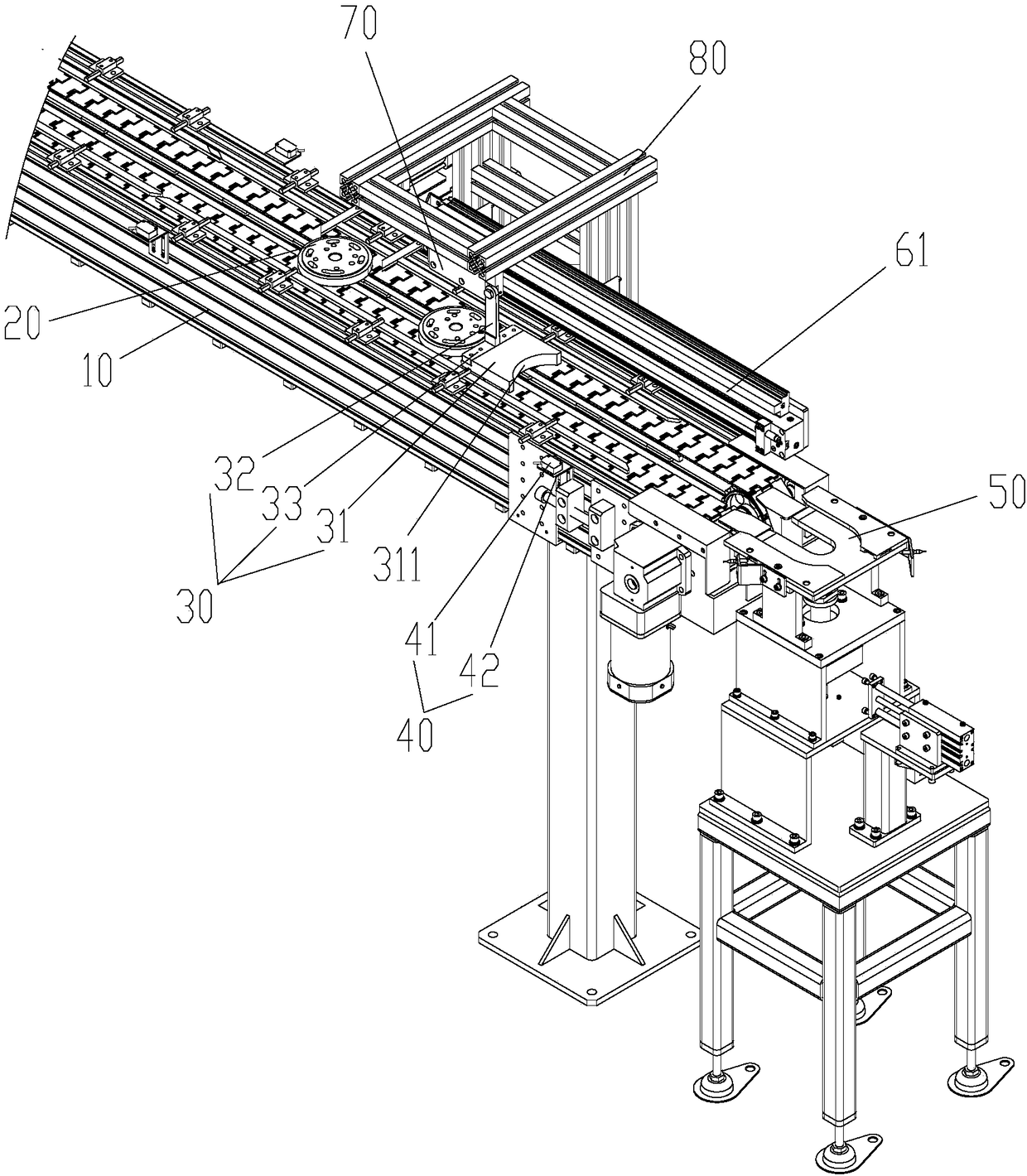

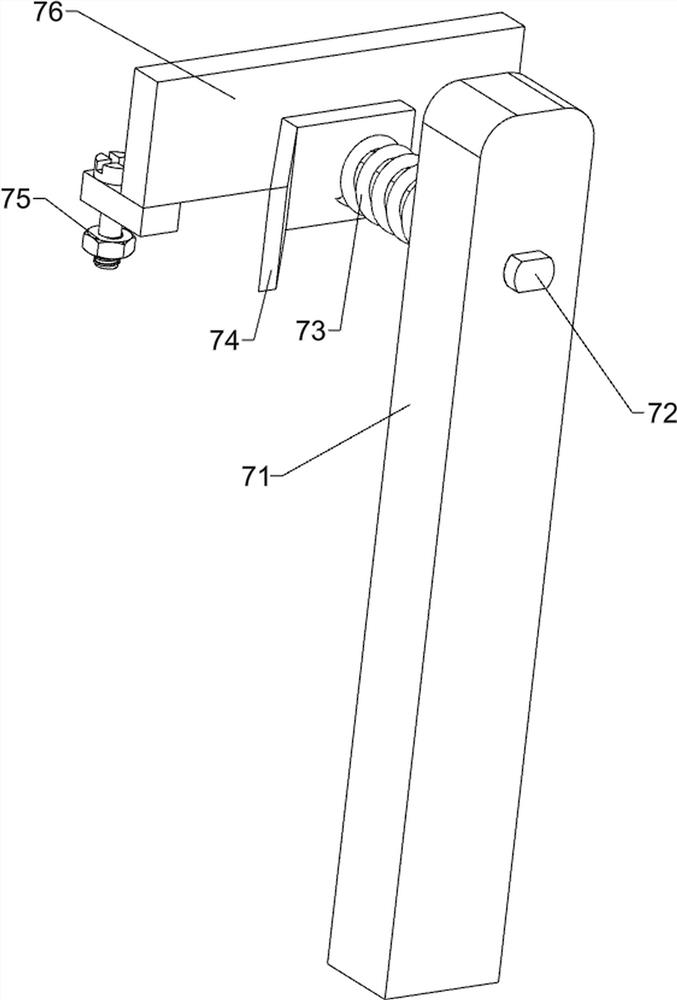

Flange pushing mechanism and flange machining line with same

InactiveCN108341246ARealize automatic pushingImprove processing efficiencyConveyorsControl devices for conveyorsMachiningFlange

The invention provides a flange pushing mechanism and a flange machining line with the same. The flange pushing mechanism is used for pushing flange components on a flange conveying line to a supporting table, and comprises a pushing portion, the pushing portion is arranged above the flange conveying line and movable in the conveying direction of the flange conveying line so as to make the flangecomponents between the pushing portion and a supporting table move to the supporting table, and the pushing portion is adjustable in position in the vertical direction so that the flange components onthe upstream of the pushing portion can pass through the bottom of the pushing portion. The flange pushing mechanism solves the problem that a flange machining line cannot achieve automatic pushing of flanges in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Agricultural garlic bulb separation device

PendingCN112589857ARealize automatic pushingQuick cutSievingScreeningAgricultural engineeringAllium sativum

The invention relates to a separation device, in particular to an agricultural garlic bulb separation device, and provides an agricultural garlic bulb separation device capable of achieving quick cutting, separation and collection. The agricultural garlic bulb separation device comprises supporting columns, a mounting plate, a cutting device, a pushing device and a baffle. A transverse plate is arranged between the tops of each set of supporting columns on the same side. The mounting plate is arranged in the middles of the sides, away from the transverse plates, of two of the supporting columns. The cutting device is arranged on the mounting plate. The pushing device is arranged between the two transverse plates. The baffle is arranged on the two supporting columns far away from the mounting plate. Through cooperation of the cutting device and the pushing device, automatic pushing and quick cutting of garlic can be achieved, manpower and working time are saved, and the garlic cutting efficiency is improved.

Owner:盘青云

Glass container clearing equipment for medical treatment

ActiveCN112692016ARealize automatic pushingRealize the effect of cleaning liquid under intervalGlass recyclingHollow article cleaningEngineeringMechanical engineering

The invention relates to clearing equipment, in particular to glass container clearing equipment for medical treatment. The technical problem to be solved is to provide the glass container clearing equipment for medical treatment which can realize automatic cleaning and is simple to operate. The glass container clearing equipment for medical treatment disclosed by the invention comprises bottom plates, support plates, a placement assembly and a pushing mechanism, wherein the bottom plates are arranged at the bottoms of the support plates; the placement assembly is arranged between the support plates; and the pushing mechanism is arranged on the placement assembly. Through cooperation between the placement assembly and the pushing mechanism, automatic pushing of materials can be realized, and then the cleaning effect of the glass container is realized.

Owner:河南艾迪康医学检验实验室有限公司

Efficient small-sized double-sided lining pressing machine for school uniform production

ActiveCN112869272AAchieve cleanupRealize automatic pushingCleaning using toolsCleaning using gasesBristleWorking environment

The invention discloses an efficient small-sized double-sided lining press for school uniform production, which comprises a small-sized double-sided lining press body, the small-sized double-sided lining press body comprises a base, a first pressing plate and a second pressing plate, the first pressing plate and the second pressing plate are arranged above the base, and heating pipes are fixedly mounted in the first pressing plate and the second pressing plate. The second pressing plate is located between the two first pressing plates, an L-shaped support is fixedly installed on the top of the base, and air cylinders are fixedly installed on the inner wall of the top of the L-shaped support and the top of the base. The machine is reasonable in design and convenient to use, a school uniform can be pushed out quickly after lining pressing, a plurality of soft bristles can be driven automatically to clean impurities of a first pressing plate and a second pressing plate during material pushing, attached tiny dust can be blown off automatically during impurity cleaning, material pushing, impurity cleaning and dust blowing can be achieved through single drive, and the lining pressing working environment is improved, so that the continuous lining pressing quality is improved, time and labor are saved, and the use requirement is met.

Owner:重庆弘博士服饰集团有限公司

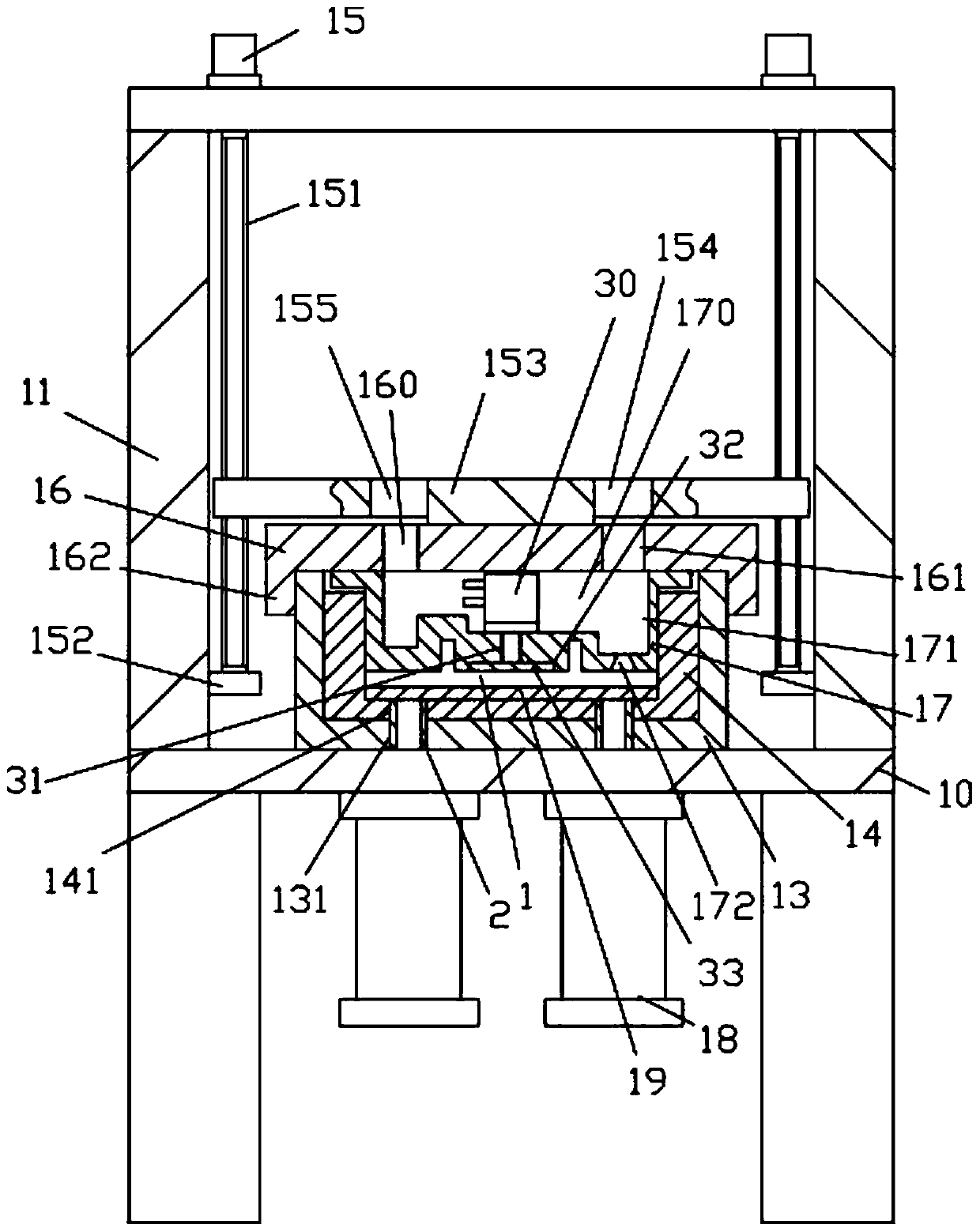

Motor driving type self-casting mechanism provided with upper and lower die releasing mechanisms

InactiveCN109759569AEasy to push out and unloadReduce the overall heightMould handling equipmentsMolten metal conveying equipmentsMotor driveEngineering

The invention discloses a motor driving type self-casting mechanism provided with upper and lower die releasing mechanisms. The motor driving type self-casting mechanism provided with the upper and lower die releasing mechanisms comprises a rack, wherein an upper supporting frame is fixed to the top surface of a top plate of the rack; servo motors are fixed to the top surfaces of the left side andthe right side of the top plate of the upper supporting frame; two vertical screws are positioned at the two sides of the top plate of the rack; the bottom ends of the vertical screws are hinged totwo lower connecting plates through bearings; and the lower connecting plates are fixed to the lower sidewalls of side supporting plates of the upper supporting frame. According to the motor driving type self-casting mechanism provided with the upper and lower die releasing mechanisms, the mechanism is driven through the servo motors; a compressing plate and a lower fixing housing are automaticallypressed against each other to enable fitting and fixing of an upper casting die and a lower casting die to be achieved; the upper casting die is not manually mounted and dismounted; due to the drivingof the servo motors, the height of the whole mechanism is greatly reduced, some factory houses or processing sites with limited height can perform processing conveniently, and the convenience is ensured; and meanwhile, materials can be automatically pushed through a lower pushing oil cylinder and an upper pushing oil cylinder, and thus a casted finishedproduct in a casting chamber can be pushed out and discharged.

Owner:郑青松

A nail punching device

The invention discloses a nail row blanking device, which comprises an upper template and a lower template. The upper template is provided with an upper blade, and the lower template is provided with a lower blade. When the mold is closed, the upper and lower blades simultaneously cut the two ends of the nail row cut; also includes a pusher mechanism, the pusher mechanism includes an L-shaped push plate, a pull rod and a return spring, one end of the pull rod is connected with the L-shaped push plate, the other end slides and is arranged in the lower template, and the end in the lower template is connected with the second One magnet, the return spring is set on the outside of the pull rod; the lower end surface of the upper pressing plate close to the end of the accommodating cavity is provided with a second magnet; when the mold is opened, the first magnet and the second magnet are close, and the magnetic attraction drives the L-shaped push plate to push The nail moves horizontally, and when the mold is closed again, the first magnet and the second magnet are separated, and the L-shaped push plate is reset under the action of the return spring. A nail row punching device disclosed by the invention can automatically push the punched out row nails to the next station without manual intervention and transportation, thereby improving work efficiency.

Owner:萍乡市鸿安五金制品有限公司

Material pushing device

PendingCN109573569ARealize automatic pushingImprove reclaiming efficiencyConveyor partsEngineeringPiston rod

The invention belongs to the technical field of automatic equipment, and particularly relates to a material pushing device. The material pushing device comprises a rack, a material pushing mechanism and a die pushing mechanism, wherein the material pushing mechanism comprises a driving part and a plurality of material pushing rods; the driving part is mounted on the rack; each material pushing rodis mounted at the driving end of the driving part and is used for pushing out an outside bar to be pushed from an outer material box; the die pushing mechanism comprises a die pushing cylinder and atransverse pushing block; the die pushing cylinder is mounted on the rack; the transverse pushing block is mounted on a piston rod of the die pushing cylinder and is used for pushing the outer material box far away from a material pushing station after each material pushing rod finishes material pushing; each bar is pushed out through the corresponding material pushing rod, and an empty box without the bars is pushed away from the material pushing station corresponding to each material pushing rod through the transverse pushing block, and thus a space is supplied to the next material box, andthe operation is circularly carried out. With the adoption of the material pushing device, needle shaped or bar shaped parts can be automatically pushed, so that the picking efficiency of fine needleshaped or bar shaped parts can be obviously improved, and the error rate in the picking process is decreased.

Owner:SHENZHEN JINZHOU PRECISION TECH

Self-casting mechanism with upper demolding mechanism and lower demolding mechanism

InactiveCN109773168AEasy to push out and unloadNo need for manual installation and disassemblyMould handling equipmentsMolten metal conveying equipmentsEngineeringCasting mold

The invention discloses a self-casting mechanism with an upper demolding mechanism and a lower demolding mechanism. The self-casting mechanism comprises a frame. A vertical support plate is fixed on the left top surface of a top plate of the frame. An upper fixing plate is fixedly arranged on the top surface of the vertical support plate. A lower fixing shell is fixed on the portion, under the upper fixing plate, of the top surface of the top plate of the frame. A lower casting mold is mounted in the lower fixing shell. An upper pressing oil cylinder is fixed on the top surface of the upper fixing plate. A push rod of the upper pressing oil cylinder penetrates through the bottom surface of the upper fixing plate and is fixedly provided with a pressing plate. An upper casting mold is fixedly arranged on the middle part of the bottom surface of the pressing plate. A mounting groove is formed in the middle of the top surface of the upper casting mold. An upper material pushing oil cylinder is fixedly arranged on the top surface of the middle part of the mounting groove. According to the self-casting mechanism, the upper casting mold and the lower casting mold are matched and fixed through the automatic pressing of the pressing plate and the lower fixing shell, the upper casting mold does not need to be manually mounted and disassembled, and meanwhile the automatic material pushingcan be realized through the operation of a material pushing oil cylinder and the upper material pushing oil cylinder.

Owner:郑青松

Collection book searching device

The invention discloses a library collection book searching device, belongs to the technical field of file management, and aims to solve the problems that the existing literature shelving arrangement position is not very accurate, only the corresponding category shelving arrangement position can be found approximately, and the book searching is very difficult according to the number, so that the query is difficult, and a large amount of time is wasted. The books cannot be adjusted according to needs in the process of exhibiting the books, so that the books are inconvenient to take; existing books are not easy to take out due to the fact that the books are arranged too tightly. According to the library collection book searching device, when the moving motor drives the rotating rod and the gear to rotate, the gear is matched with the tooth groove to drive the pressing plate and the storage frame to move forwards, so that the storage frame is automatically pulled out, books are conveniently inquired and taken, the automatic efficiency is improved, the use convenience of the storage frame is guaranteed, and therefore automatic pushing is achieved; the books can be pushed out of the clamping plates, so that the inconvenience of manual extraction is reduced, the inquired books can be independently taken out, the inquiry speed and convenience are effectively improved, and the inquiry efficiency is improved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

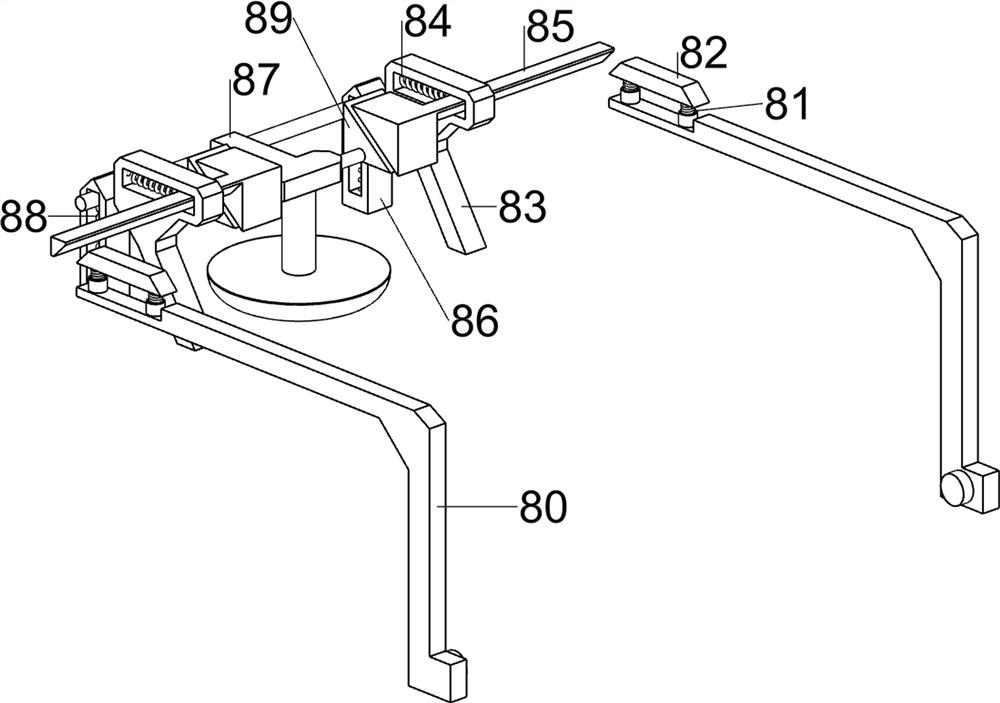

A stamping die for automatic material pushing of auto parts

ActiveCN107570600BImprove smoothnessDamage reliefShaping toolsEjection devicesHydraulic cylinderEngineering

The invention discloses a stamping die used for the automatic pushing of automobile accessories. The stamping die comprises a bottom plate and a top plate which are arranged in parallel and further comprises a stable lifting mechanism arranged between the bottom plate and the top plate, a buffering mechanism arranged at the bottom of the top plate and an automatic pushing mechanism arranged in thebottom plate, wherein the stable lifting mechanism comprises two groups of hydraulic cylinders and locating plates, which are vertically mounted at the top of the bottom plate, and the two groups ofhydraulic cylinders and locating plates are located at the two sides of the top plate; a U-shaped carrier is mounted on piston rods at the tops of the hydraulic cylinders, and a pulley is mounted in the U-shaped carrier in a rotating manner; two groups of steel ropes are wound on the pulley, one ends of the steel ropes are correspondingly connected to the two sides of the top of the bottom plate,and the other ends of the steel ropes are correspondingly connected to the two sides of the top plate; and gears are further mounted at both sides of the top plate in a rotating manner, and the sides,close to the top plate, of the locating plates are both provided with racks. The stamping die is reasonable in design and high in stamping precision, protects the automobile accessories from damage,achieves the automatic pushing purpose, increases the stamping efficiency of the automobile accessories, and improves the machining quality.

Owner:NINGBO TUGUAN PRECISION MOLD

Small double-sided lining machine for efficient school uniform production

ActiveCN112869272BAchieve cleanupRealize automatic pushingCleaning using toolsCleaning using gasesBristleWorking environment

The invention discloses an efficient small double-sided lining machine for school uniform production. And the second pressure plate, the inside of the first pressure plate and the second pressure plate are fixedly installed with heating pipes, the second pressure plate is located between the two first pressure plates, the top of the base is fixedly installed with an L-shaped support, the L-shaped support The top inner wall of the base and the top of the base are fixedly installed with cylinders. The invention has reasonable design and convenient use, is convenient for quickly pushing out the school uniform after pressing the lining, is convenient for automatically driving a plurality of soft bristles to clean the impurities on the first pressing plate and the second pressing plate when the material is pushed, and is convenient for automatic dipping when cleaning impurities. The attached tiny dust can be blown off, which can push the material, clean up impurities and blow dust with a single drive, improve the working environment of the lining, thereby improving the quality of the continuous lining, saving time and effort, and meeting the needs of use.

Owner:重庆弘博士服饰集团有限公司

A kind of aluminum ingot trimming and grinding equipment for metal processing

ActiveCN112643346BTo achieve the effect of trimmingRealize automatic pushingEdge grinding machinesFeeding apparatusMetal machiningIngot

Owner:山东利信新材料有限公司

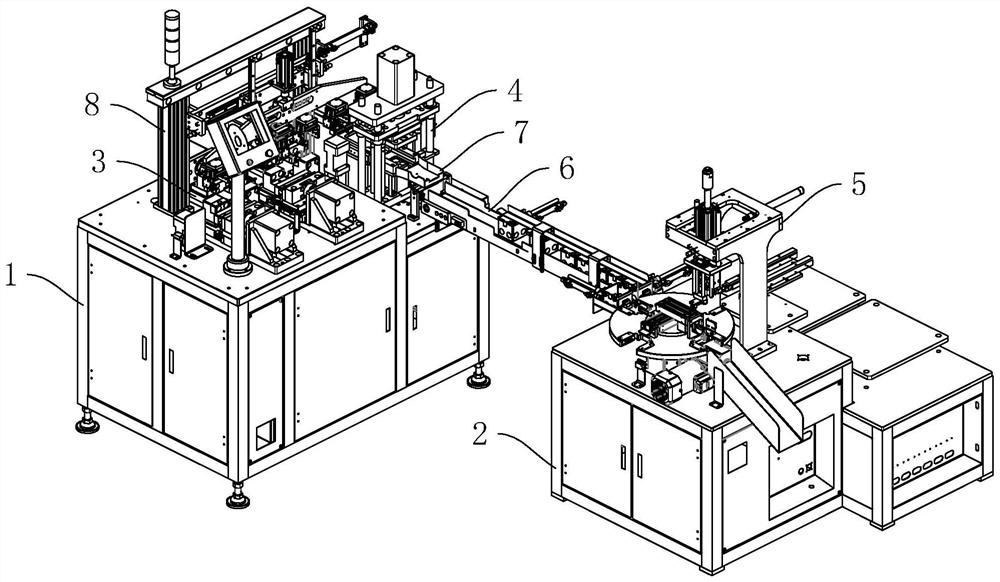

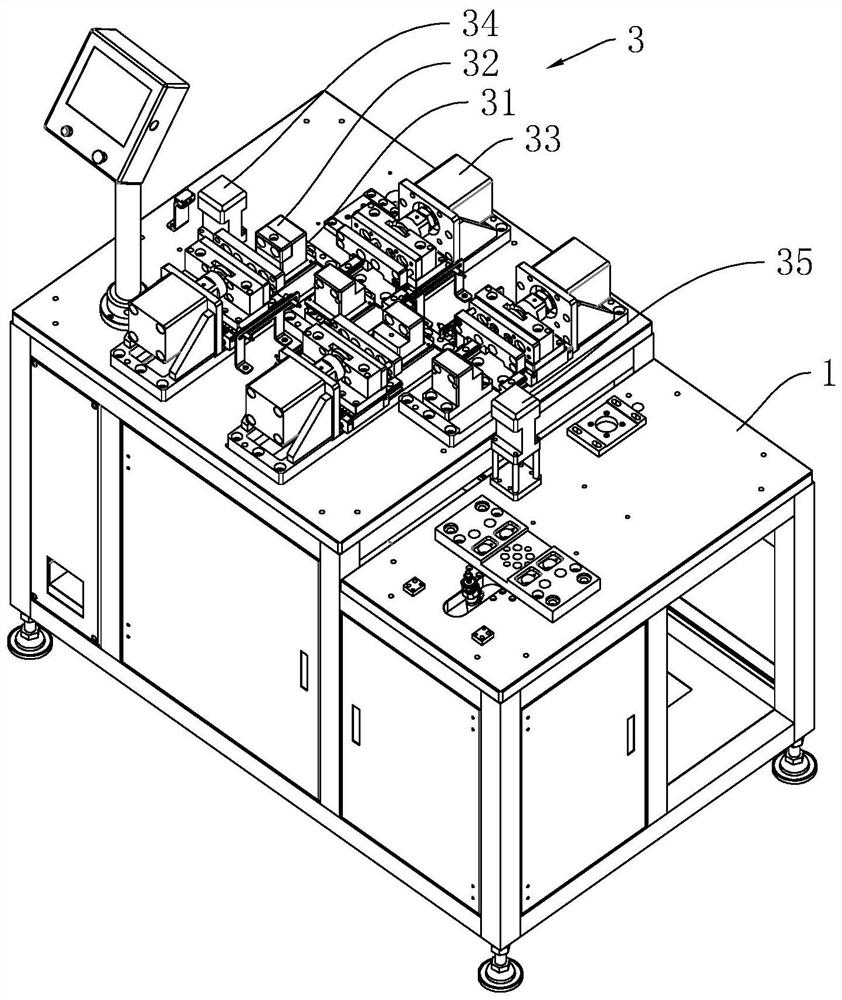

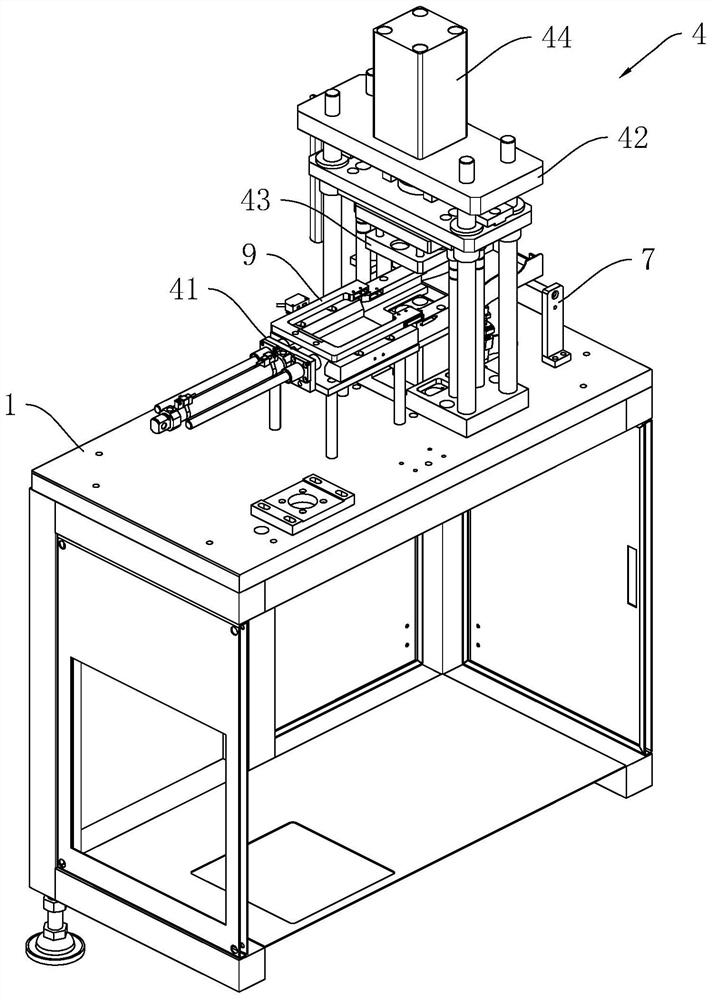

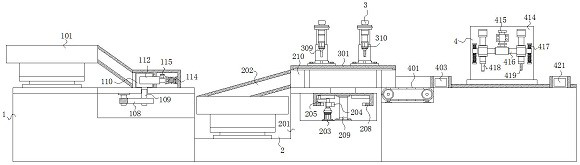

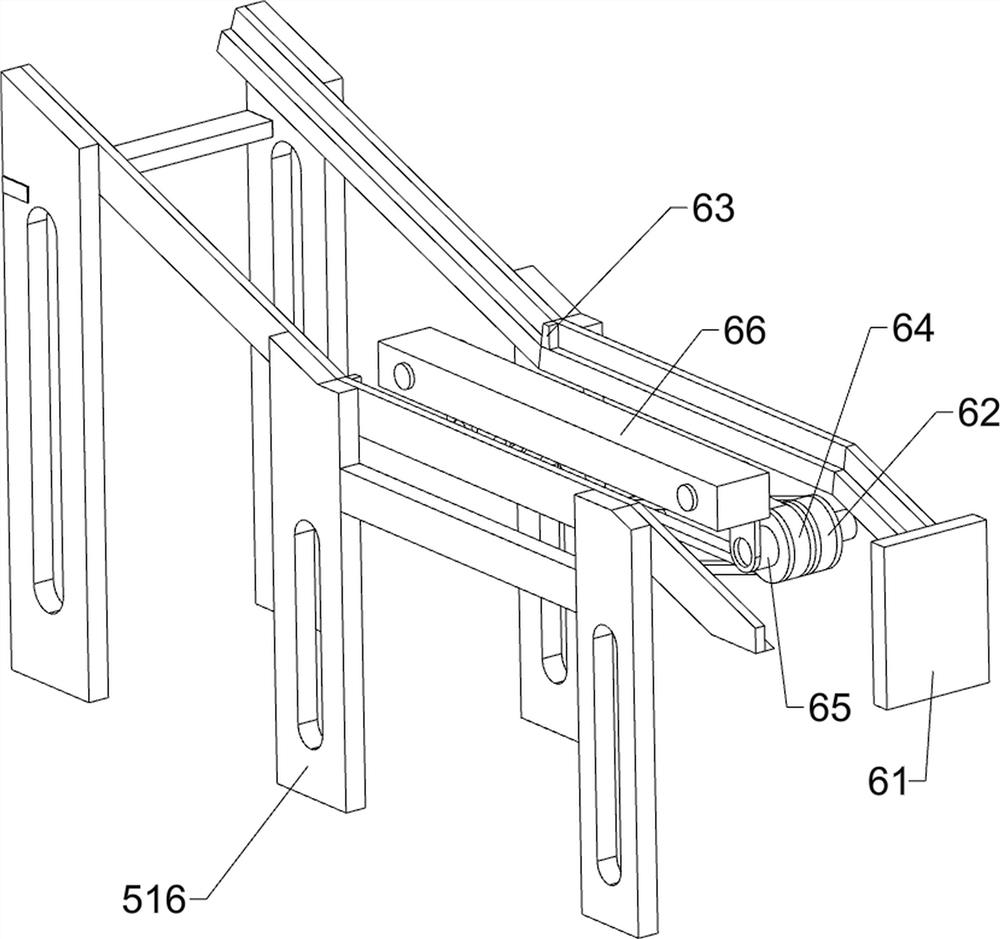

A kind of automatic production equipment for pre-embedded junction box

ActiveCN111890047BImplement automatic assemblyIncrease productivityMetal-working feeding devicesOther manufacturing equipments/toolsPunchingJunction box

The present application discloses an automatic production equipment for pre-embedded junction boxes, which includes a base and a support base. The base is sequentially provided with a first punching station and a second punching station. The hole stations are respectively used to punch holes around and at the bottom of the junction box; an assembly station is provided on the support base, and the assembly station is used to install and fix the fixing piece, and the second punching station and the assembly station are provided with The transmission slide rail is provided with an overturn mechanism for driving the junction box overturning at one end of the transmission slide rail close to the second punching station, and relates to the field of junction box production. The application has the following advantages and effects: by setting highly automated and high-continuity production equipment, the continuous punching operation around and at the bottom of the junction box and the automatic assembly of the fixing piece are realized to ensure the continuity of the production process, thereby improving the quality of the junction box. Productivity.

Owner:台州恒锐智能科技有限公司

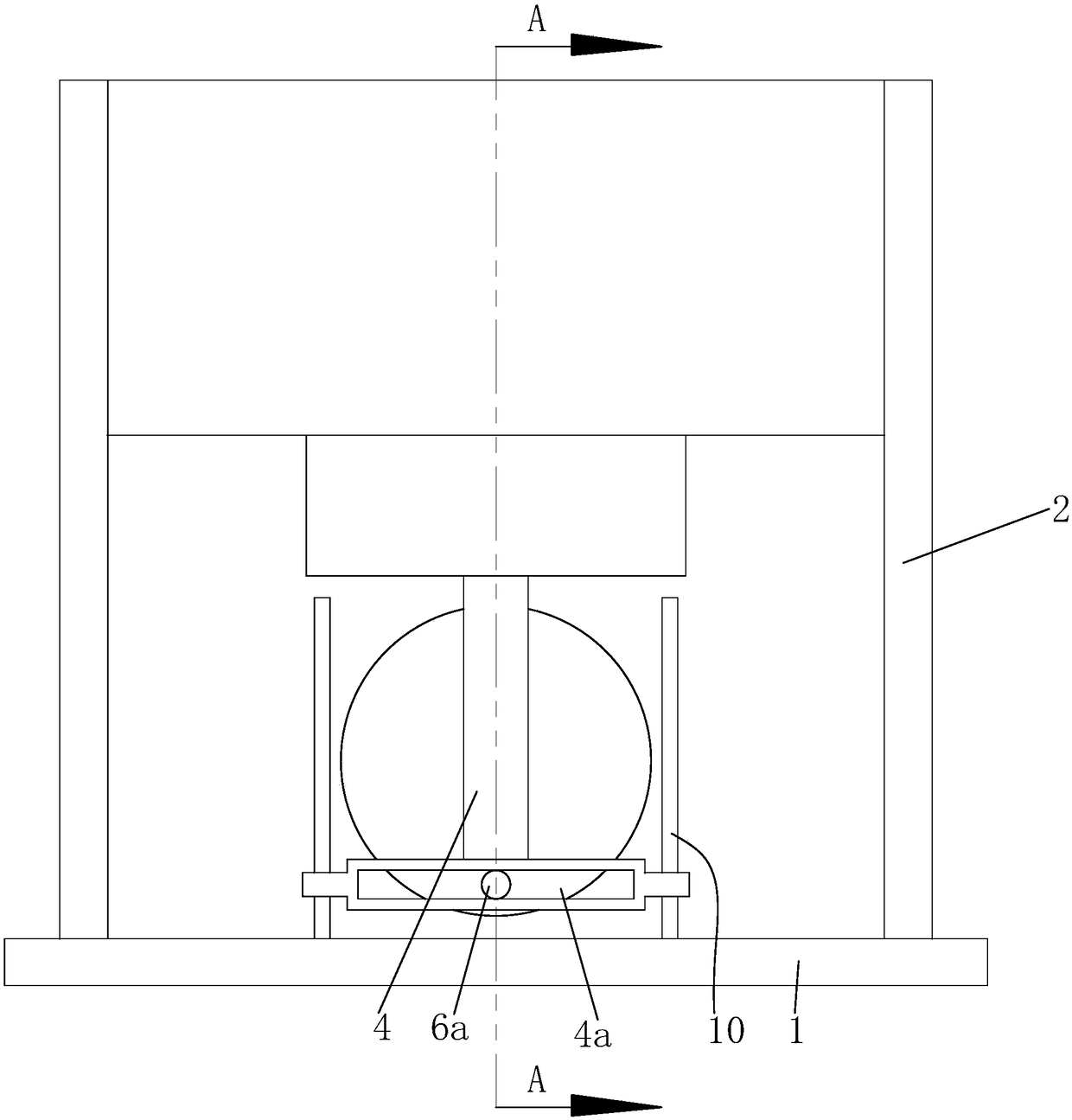

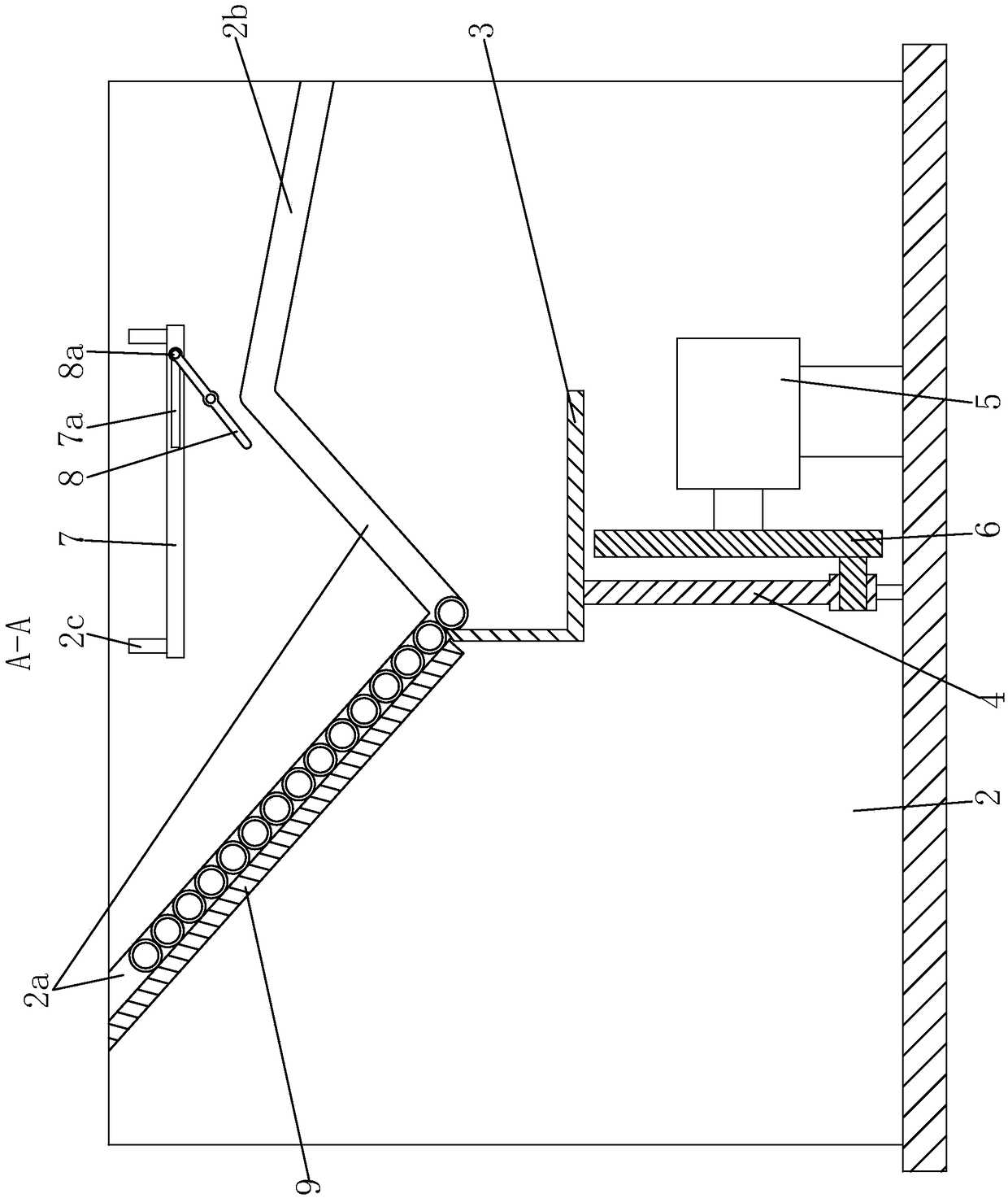

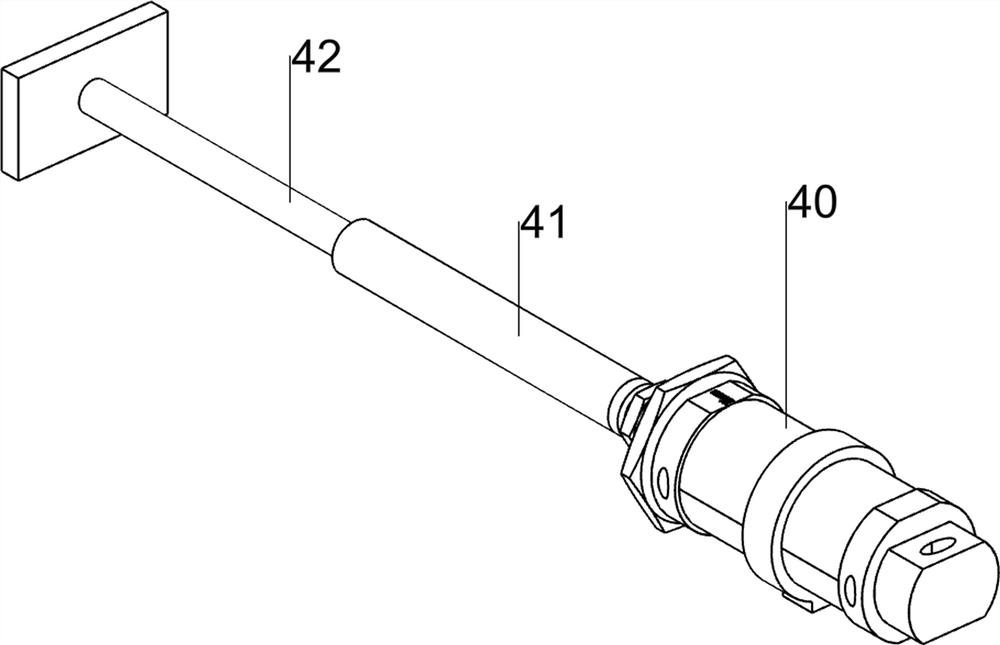

External pipe automatic supply device for heating aluminum pipe machining

InactiveCN109132480AHigh degree of automationRealize automatic pushingConveyor partsAutomatic controlExtrusion

The invention relates to an external pipe automatic supply device for heating aluminum pipe machining. The external pipe automatic supply device for heating aluminum pipe machining comprises a bottomplate and two side plate frames welded to the bottom plate, wherein a V-shaped feeding groove is formed in the back of each side plate frame, and discharging grooves communicating with the feeding groovesare formed in the fronts of the side plate frames. An L-shaped lifting plate is arranged at the lower position between the two feeding grooves, a connecting frame is welded to the lower end of thelifting plate, a dividing groove is formed in the connecting frame, a motor is arranged on the bottom plate, the motor is connected with a large circular disk, and the eccentric position of the largecircular disk is provided with a bulge block being matched with the dividing groove in a sliding mode. The external pipe automatic supply device for heating aluminum pipe machining has a high degreeof automation, automatically lifting an external pipe is realized by controlling a reciprocating lifting mode of the lifting plate, meanwhile, automatically controlling the rotation of a pushing rod to realize the automatic push-extrusion of the external pipe is realized, and the effect of automatic supply of the external pipe of a heating aluminum pipe is achieved.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

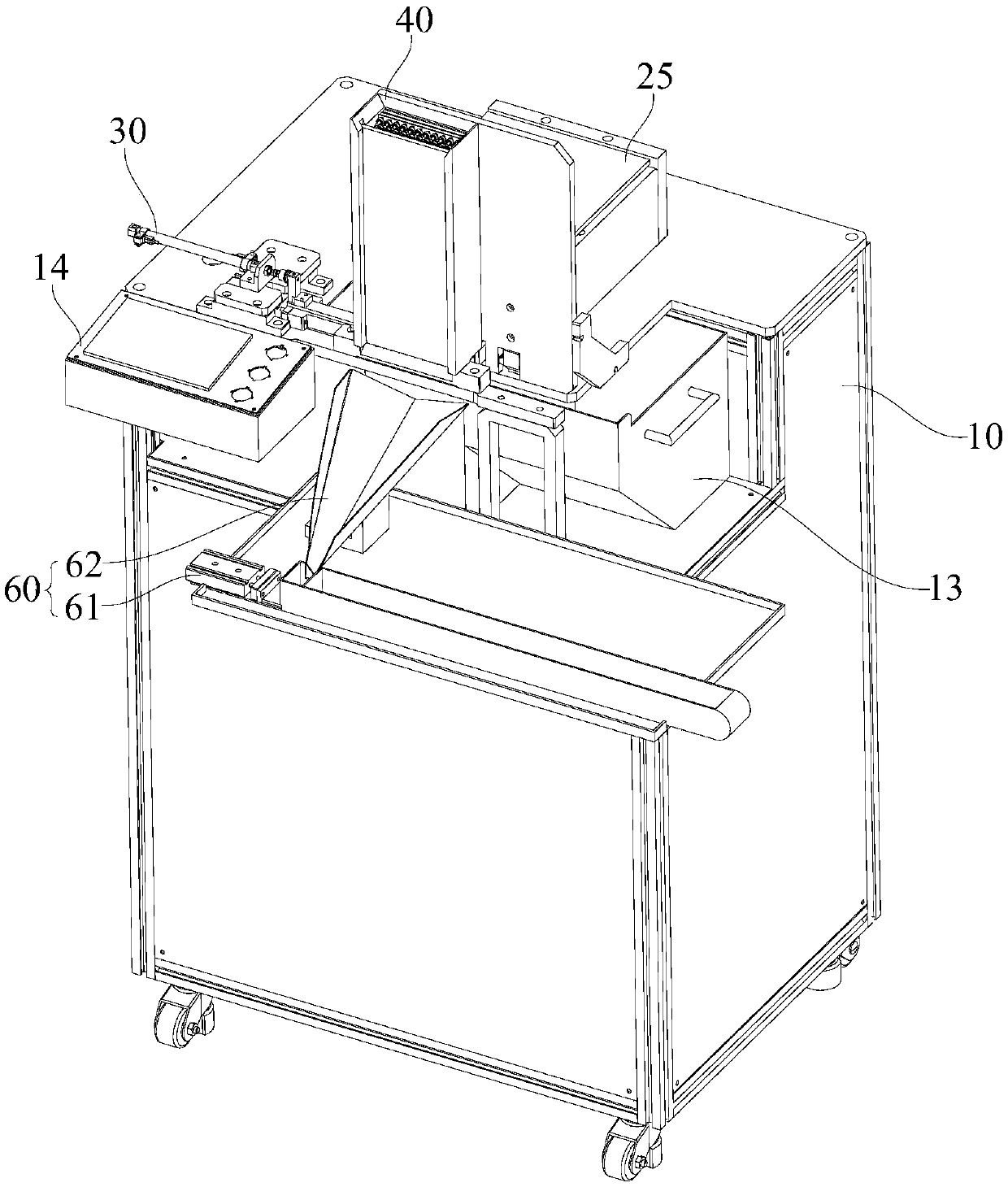

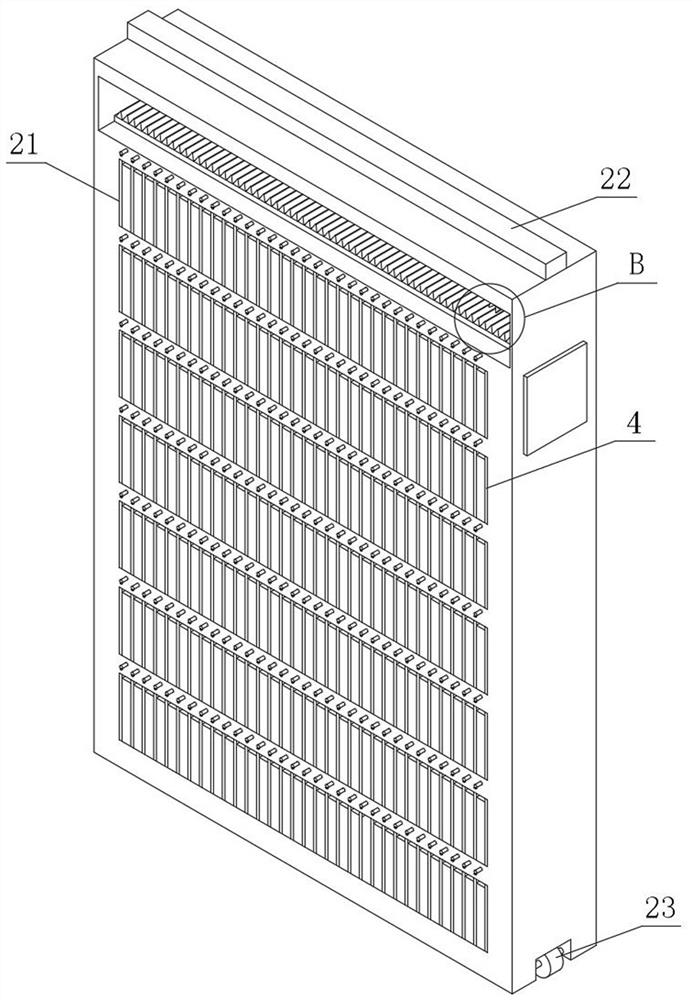

Automatic fin feeding device of fin evaporator

PendingCN110523868ARealize automatic pushingMetal-working feeding devicesHeat exchange apparatusEngineeringAutomatic testing

The invention relates to the field of fin evaporator production equipment, more specifically, relates to an automatic fin feeding device of a fin evaporator. The device comprises a rack and a storagebox arranged on the rack, a cylinder is arranged at the rear side of the storage box and is connected to a push rod, and a push plate is arranged on the push rod and is arranged in the storage box; afin limiting barrier strip is arranged at the front side of the storage box, a first linear guide rail and a second linear guide rail are arranged on the rack at the lower side of the storage box, anda fin arranging mold is arranged on the first linear guide rail; a fin arranging limiting plate is arranged on the second linear guide rail, a first lead screw motor is connected with the fin arranging mold, a second lead screw motor is connected with the fin arranging limiting plate, and a fin inserting device is mounted on the side surface of the storage box. Through the control of a PLC system, the cylinder drives the push rod to push the fins automatically, and the fin inserting device sucks the fins through a sucker to insert the fins in the fin arranging mold, so that the automatic finfeeding device has the advantages of being efficient and accurate.

Owner:HEFEI TAITONG REFRIGERATION TECH CO LTD

Special-shaped nut machining equipment capable of detecting internal and external threads

PendingCN113547054ARealize automatic pushingEasy to rubThread cutting feeding devicesThread cutting machinesSlide plateRolling sliding

The invention disclose special-shaped nut machining equipment capable of detecting internal and external threads. The equipment comprises a thread rolling mechanism, a feeding mechanism, a tapping mechanism and a detection mechanism, the feeding mechanism is installed on the right side of the thread rolling mechanism, the tapping mechanism is fixed to the upper portion of the feeding mechanism, the detection mechanism is installed on the right side of the tapping mechanism, a conveying belt is fixed to the upper left end of the detection mechanism, a first material pushing air cylinder is arranged behind the right end of the conveying belt, and a first material pushing plate is fixed to the front end of the first material pushing air cylinder. The special-shaped nut machining equipment capable of detecting the internal and external threads is compared with existing common special-shaped nut machining equipment, a material pushing rotating plate and a thread rolling limiting plate are arranged, through the arrangement of the material pushing rotating plate, when a thread rolling sliding plate is retracted, a material pushing rotating plate can rotate around a center through a sliding plate push rod, therefore a material pushing plate limiting rod is driven through a groove in the upper end to enable a thread rolling material pushing plate to move, and automatic material pushing operation on parts is achieved.

Owner:成都市惠迈锐智能装备科技有限公司

A fast welding device for a new energy lithium battery pack

ActiveCN112388134BRealize the welding effectRealize automatic pushingWelding/soldering/cutting articlesMetal working apparatusElectrical batteryNew energy

The invention relates to a welding device, in particular to a rapid welding device for a new energy lithium battery pack. The technical problem is: to provide a fast welding device for a new energy lithium battery pack that can automatically load and weld, and save time and effort. A rapid welding device for such a new energy lithium battery pack is provided, including a base and a mounting plate, the mounting plate is provided on one side of the base; an electric welding mechanism is provided on one side of the base; a pushing mechanism is provided on one side of the base Pushing mechanism. Through the cooperation between the electric welding mechanism and the pushing mechanism, the effect of automatic pushing and welding of the battery can be realized, which can improve people's work efficiency. Through the cooperation between the limit mechanism and the lifting mechanism, when the battery is welded, The battery can be positioned and clamped, and the welding can be performed automatically without manual operation.

Owner:汇通胜(广州)科技有限公司

Cutting equipment for square timber board cutting used for wooden product production

InactiveCN112621903ARealize automatic unloadingEasy to cutFeeding devicesGripping devicesIndustrial engineeringMillwork

The invention relates to board cutting equipment, in particular to cutting equipment for square timber board cutting used for wooden product production. The technical problem to be solved is to provide the cutting equipment for square timber board cutting used for wooden product production, and the cutting equipment is short in cutting time, high in efficiency, small in cutting error rate and capable of reducing potential safety hazards. According to the technical scheme, the cutting equipment for square timber board cutting used for wooden product production comprises a cutting mechanism a cutting platform and a material pushing mechanism; the cutting mechanism is arranged on one part of a bottom plate; the cutting platform is arranged on the bottom plate; and the material pushing mechanism is arranged at one part of the bottom plate, and the material pushing mechanism is connected with the cutting platform. Through cooperation of the cutting mechanism and the material pushing mechanism, automatic material pushing can be achieved, accidents of people in the material pushing process are avoided, and meanwhile easy cutting can be carried out on square wood; and through the action of a feeding mechanism, automatic feeding can be achieved, the feeding time is saved, and the feeding efficiency is improved.

Owner:周骏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com