Small double-sided lining machine for efficient school uniform production

A lining machine, a small technology, is applied in the direction of sewing tools, cleaning methods and utensils, and cleaning methods using tools, etc., which can solve the problem of inconvenient and fast pushing of the pressing plate to clean impurities, reduce the quality of the pressing lining, and easy adhesion of the pressing plate. Problems such as foreign matter and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

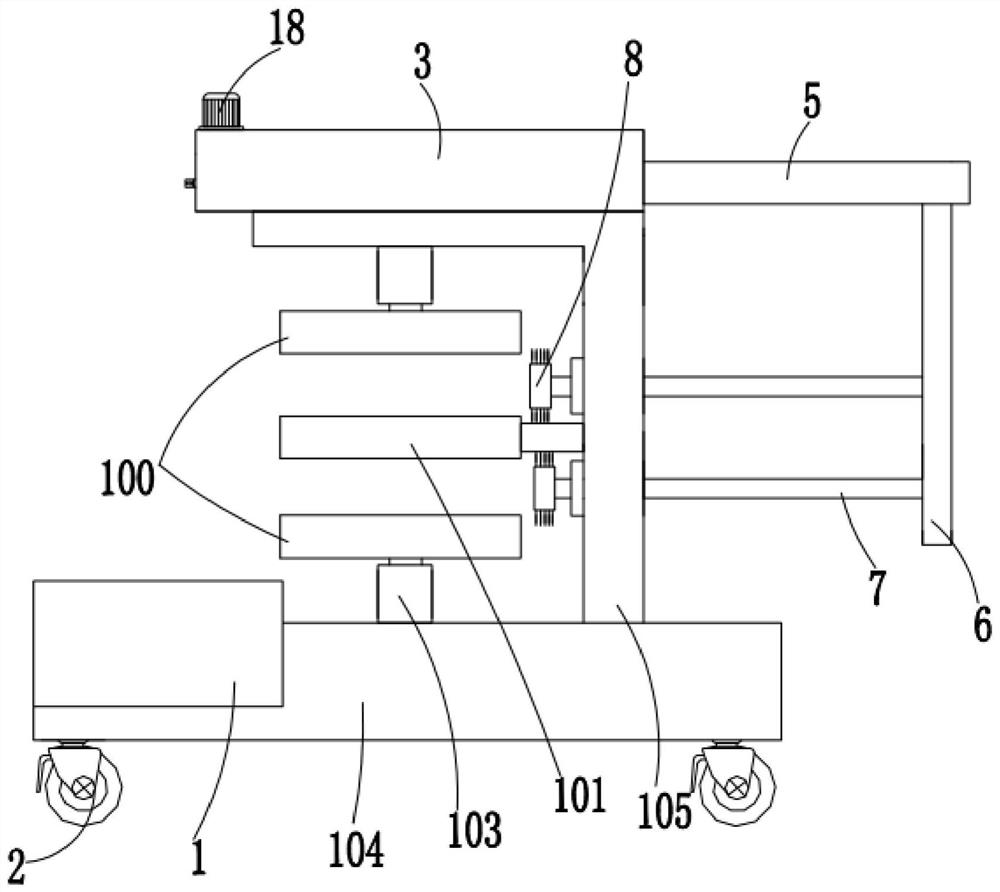

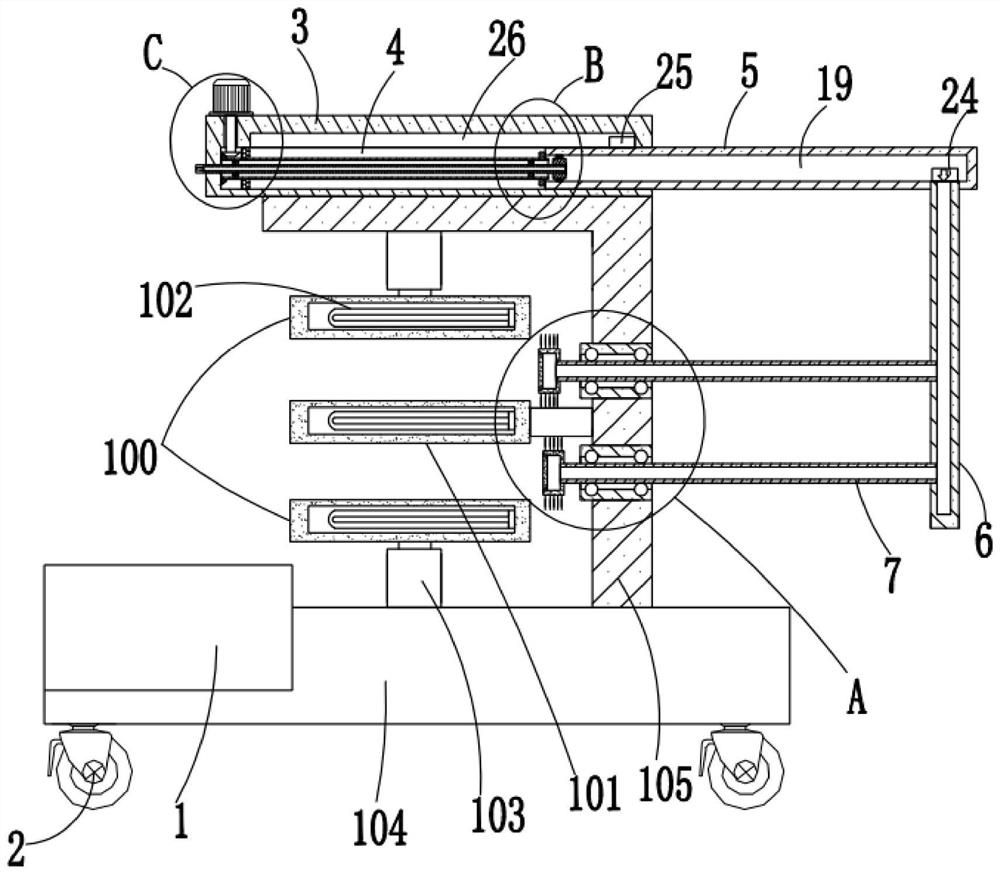

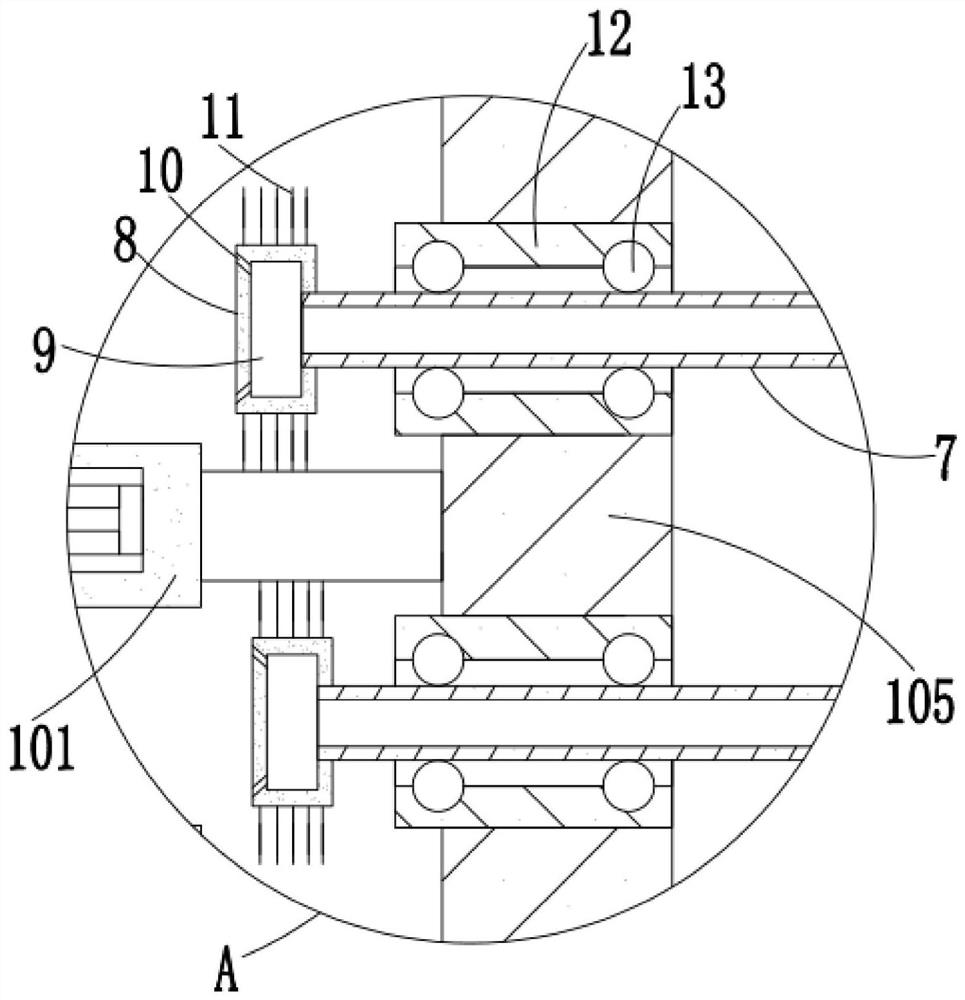

[0029] refer to Figure 1-6, this embodiment proposes an efficient small double-sided lining machine for school uniform production, including a small double-sided lining machine body, and the small double-sided lining machine body includes a base 104 and two first pressure plates arranged above the base 104 100 and the second pressure plate 101, the inside of the first pressure plate 100 and the second pressure plate 101 are fixedly installed with the heating pipe 102, the second pressure plate 101 is located between the two first pressure plates 100, and the top of the base 104 is fixedly installed with an L-shaped support. The seat 105, the top inner wall of the L-shaped support 105 and the top of the base 104 are all fixedly mounted with a cylinder 103, and the protruding end of the cylinder 103 is fixedly connected to the side of the corresponding first pressure plate 100 away from the second pressure plate 101, and the second pressure plate is fixedly connected. 101 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com