Patents

Literature

59 results about "Millwork" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Millwork building materials are historically any woodmill-produced products for building construction. Stock profiled and patterned millwork building components fabricated by milling at a planing mill can usually be installed with minimal alteration. Today, millwork also encompasses items that are made using alternatives to wood, including synthetics, plastics, and wood-adhesive composites.

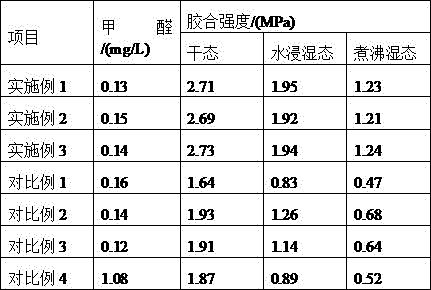

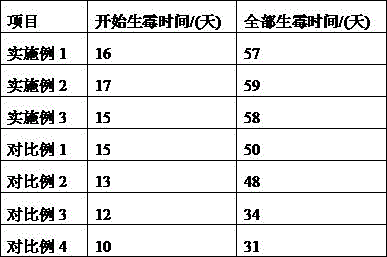

Woodwork environmentally-protective waterproof adhesive

InactiveCN106467716AAbundant raw materialsGood flexibilityNon-macromolecular adhesive additivesProtein adhesivesPolyvinyl alcoholPhenyl Ethers

The invention relates to the technical field of woodwork processing, and discloses a woodwork environmentally-protective waterproof adhesive. The woodwork environmentally-protective waterproof adhesive comprises the following raw materials: fish scale protein, konjac polysaccharide, seaweed powder, vinyl resin, itaconic acid, nano zinc oxide, dibutyl phthalate, tributyl phosphate, polyvinyl alcohol and polyoxyethylene nonyl phenyl ether. The environmentally-protective waterproof adhesive has the advantages of simple preparation, little application amount, safety and no toxicity, delicate fragrance and no peculiar smell, convenient usage, water resistance and durability, and can reach I-class waterproof requirement, the dry state bonding strength is 2.73 MPa; the fish scale is added for protein extraction, so that the waste is changed into valauables, the environment is protected, economic income of fish-farming peasant is increased, production cost of the adhesive is reduced, the deep processing approach of the fish scale is increased; konjak polysaccharide and seaweed powder are added, which are environmentally-protective and no toxic, can increase fragrance, increases bonding strength of the adhesive, so that the adhesive has the characteristics of water retention and water resistance, can be directly used while being opened, can keep the bonding strength, has abundant raw materials, and can increases the flexibility and processing performance of the woodwork after smearing and drying, and is antibacterial and antifungal.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

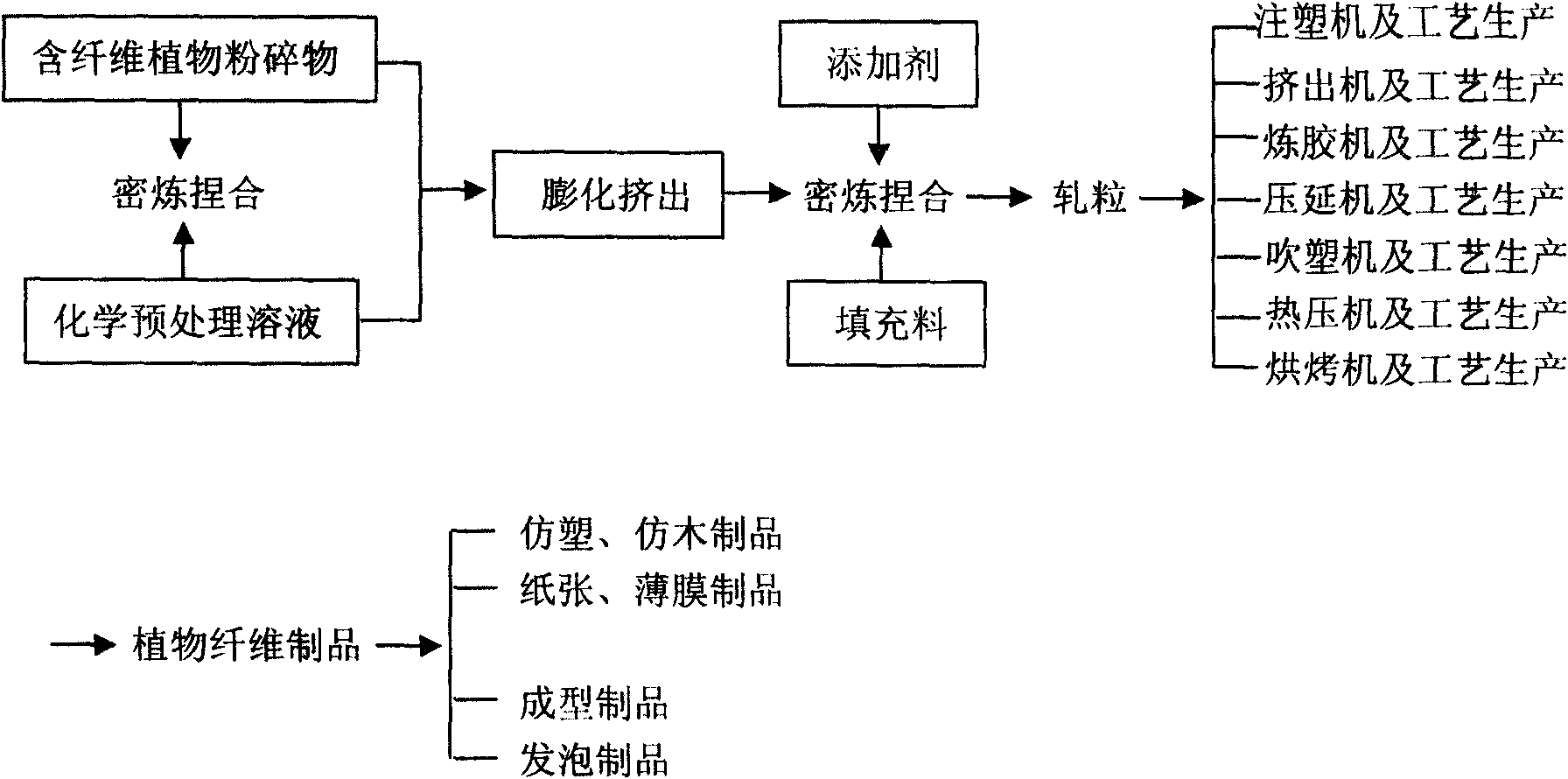

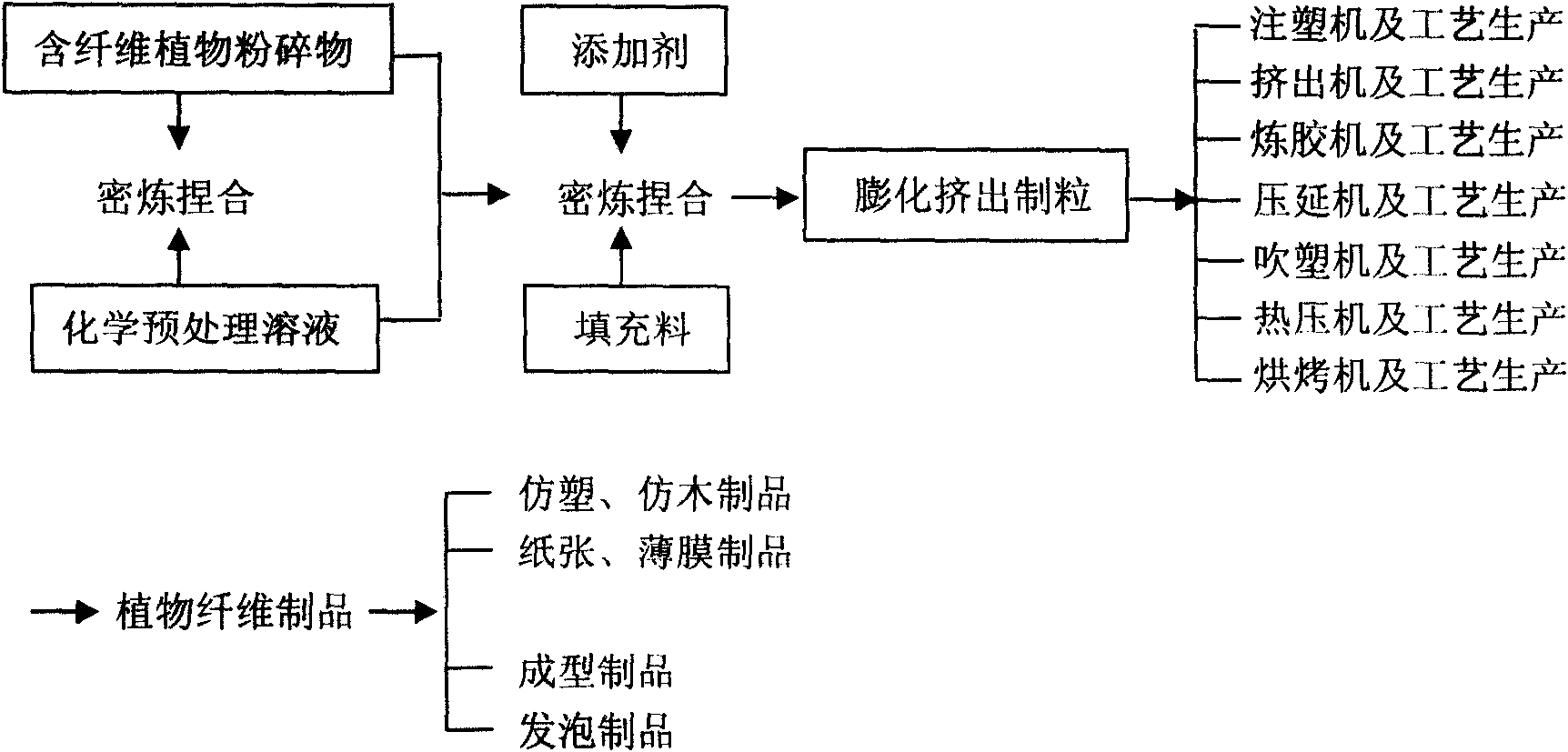

Manufacturing method of plant fibre products

The invention relates to a manufacturing method of plant fibre products, which comprises the steps: pulverized substances containing textile plants are poured into a banburying kneader and chemical pretreatment solution is added, so the fibre pretreatment chemical modification is realized simultaneously when mechanical physics modifying is realized; after entering into an expansion extruder for expansion modification, the pulverized substances are added with various additives and fillings, which are banburied and kneaded together, and the banburying kneading substance is rolled into particles by a particle rolling machine; or plant fibre subjected to banburying kneading chemical modification and various additives and fillings are directly and together banburied and kneaded and then are extruded and produced to form particles or extrusion sectional materials by the expansion extruder; the produced particles or sectional materials can be used for producing plant fibre products of various types and performances and plant fibre products of sheets, sectional materials, paper, membranes, and the like by utilizing the prior plastic injection machine, extruder, blow moulding machine, rubber refining machine, calander, hot press, and equipment and technology principles of microwave and infrared, steam drying, and the like so as to replace plastic, plastic foam, woodworks, paper and membranes.

Owner:朱秀刚

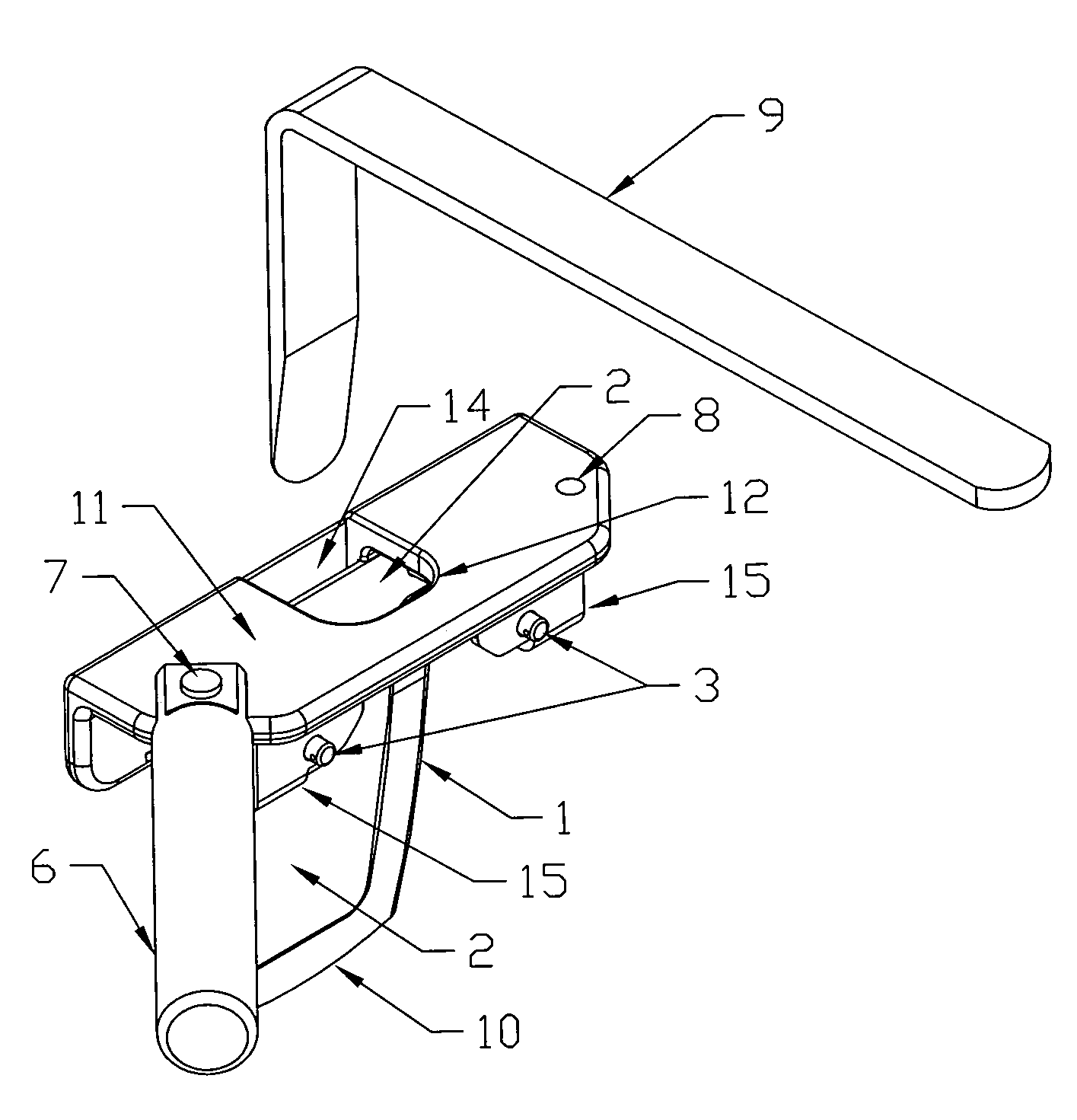

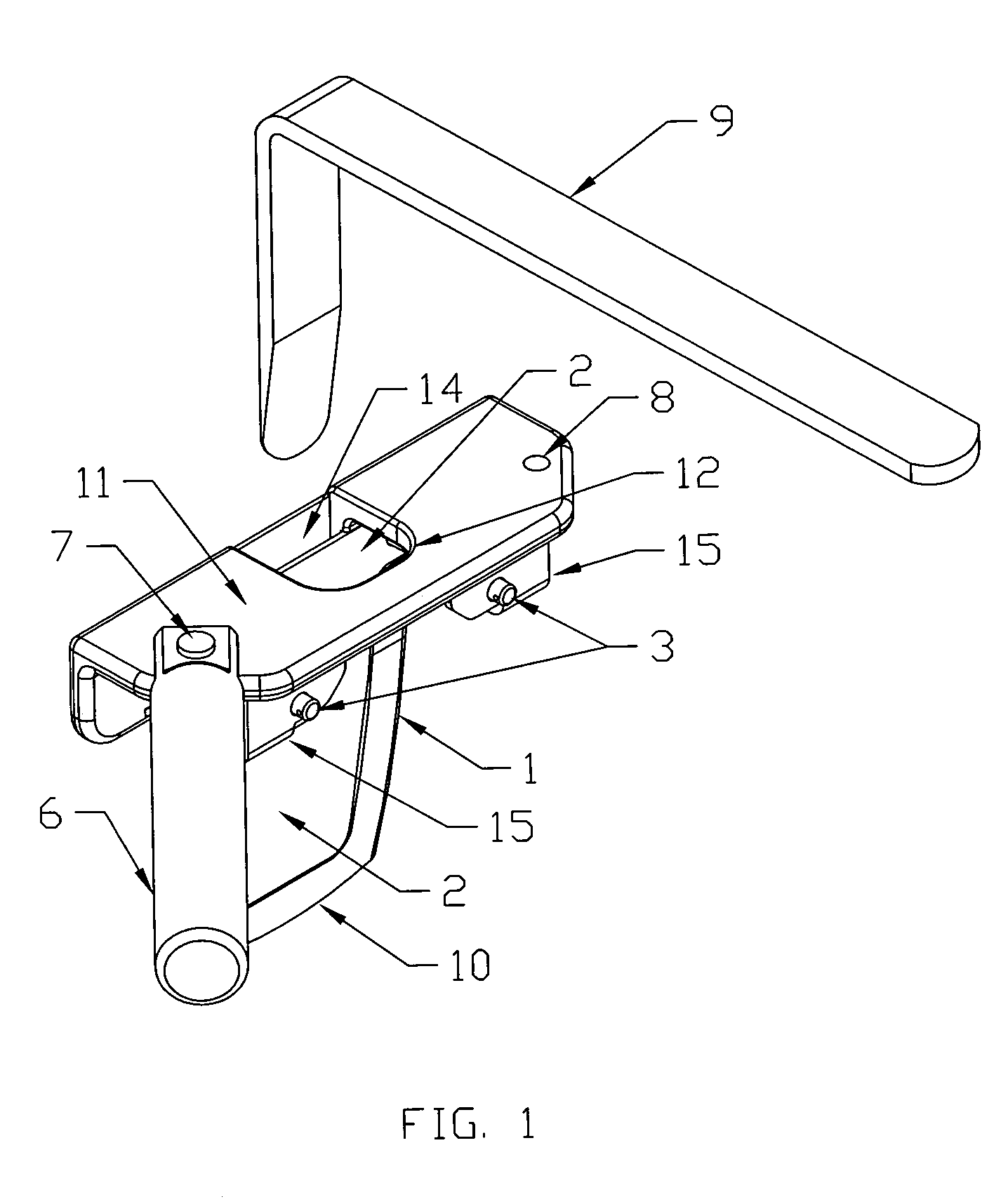

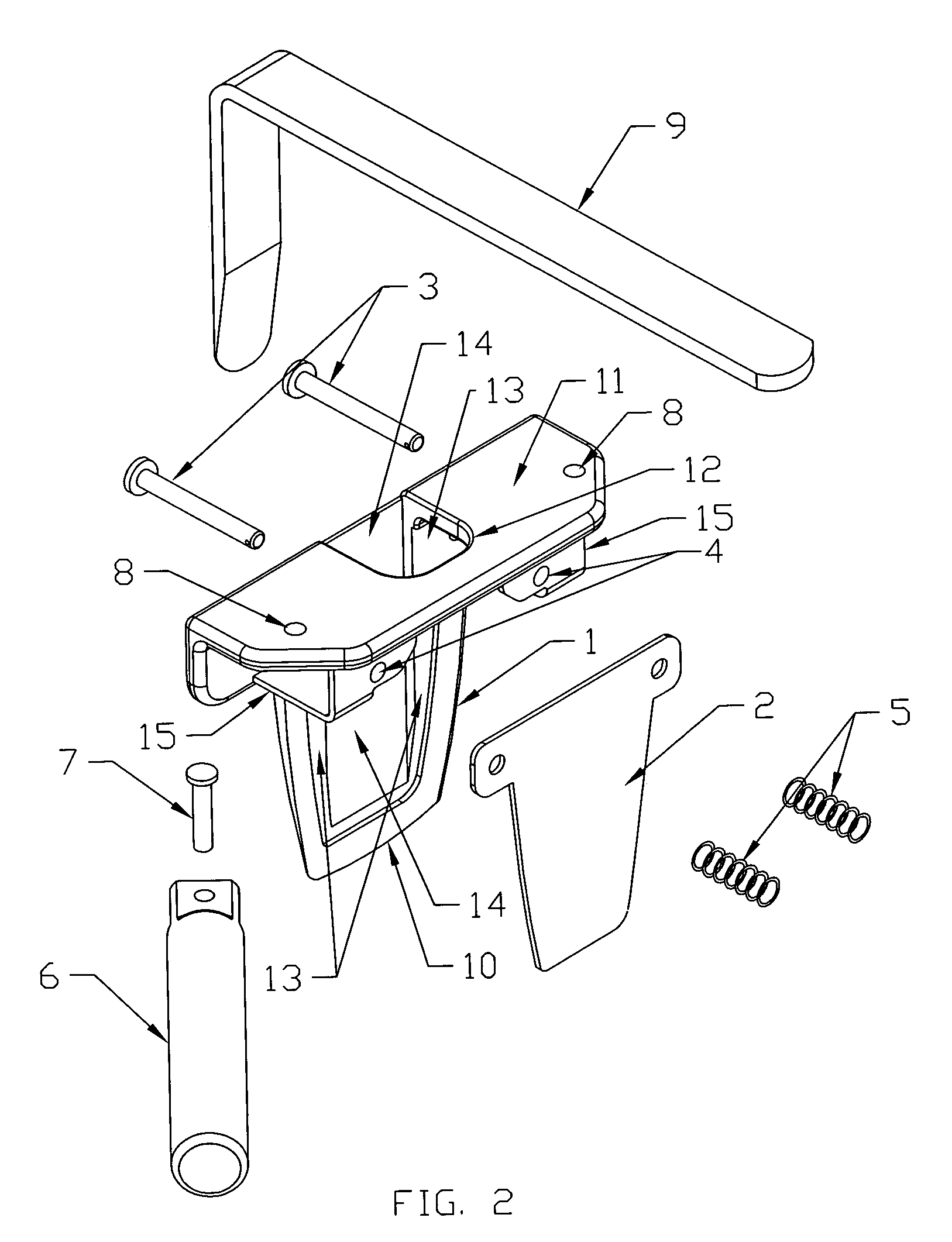

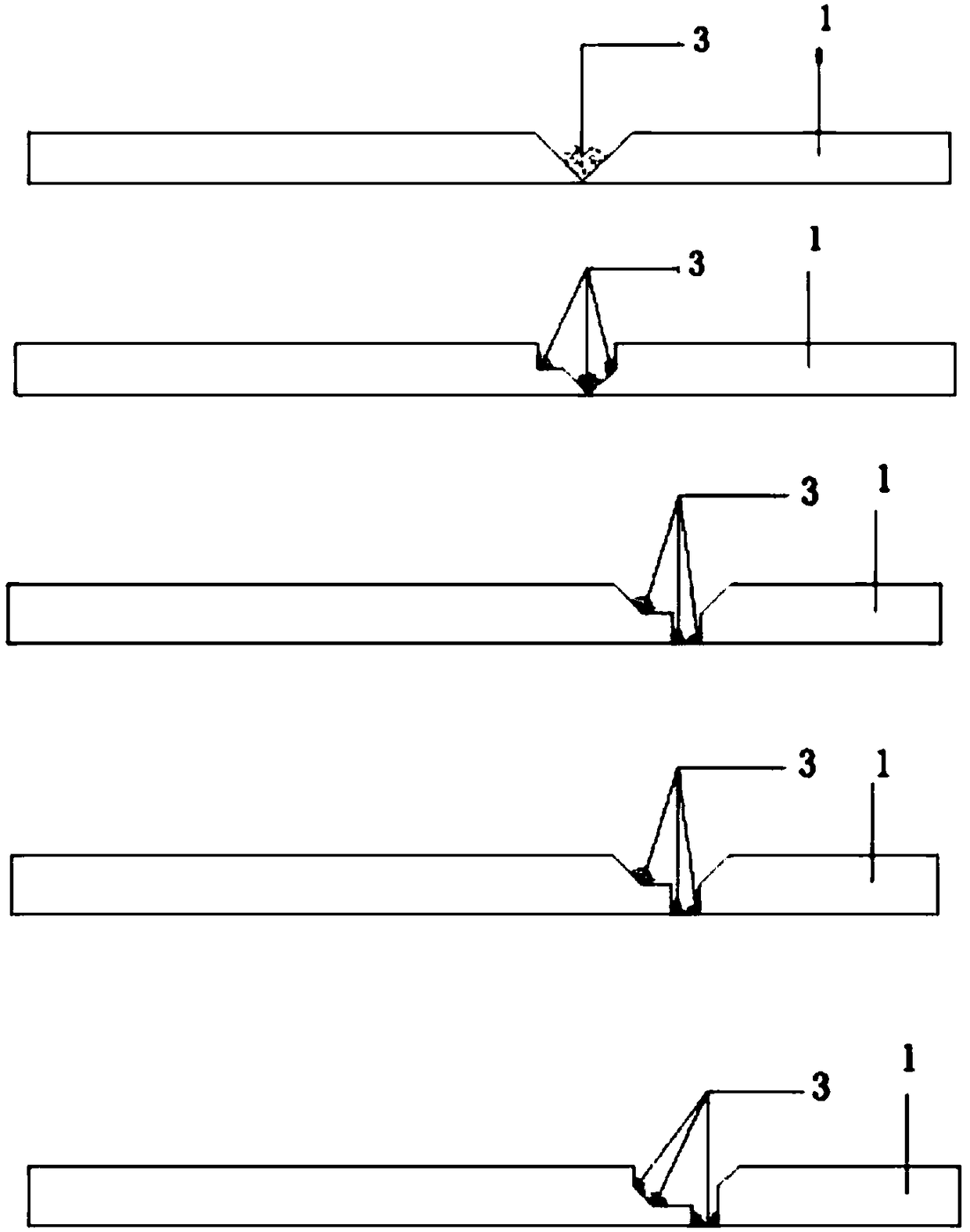

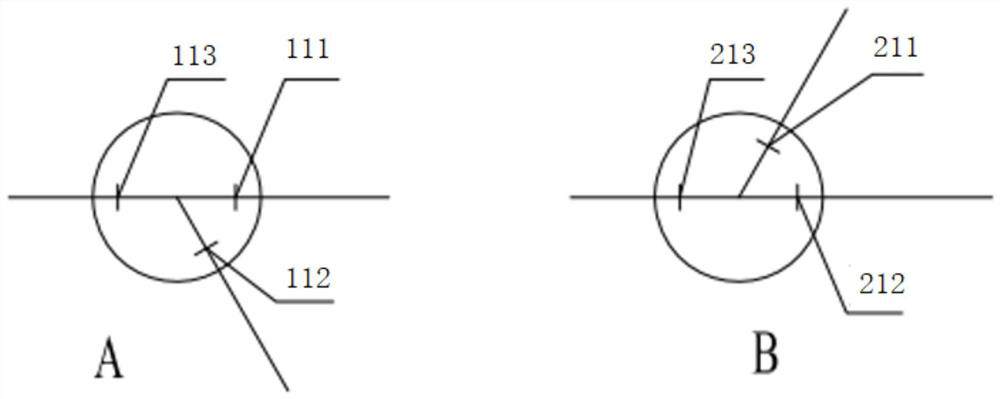

Woodwork removal device

InactiveUS6959473B1Easy to insertIncrease widthBuilding constructionsMetal working apparatusEngineeringMechanical engineering

Owner:ANIBAS KEVIN J

Classification recovery utilization method for building garbage

InactiveCN104307840AImprove recycling efficiencyImprove classification efficiencyConstruction waste recoverySolid waste disposalParticulatesFineness modulus

The invention discloses a classification recovery utilization method for building garbage, and mainly solves the problem that conventional nontimely processing and utilization of building garbage bring adverse influence. The method comprises: (1) screening out sand particles with the fineness modulus less than 3.7 from the building material; (2) sorting out metal products, wood products and plastic products from the building material; (3) crushing the residual building material into particles with the fineness of 100 mm-200 mm; (4) repeating the step (1) and the step (2), crushing the residual particle material into particles with the particle size of 40 mm or less, and screening out sand particles with the fineness modulus less than 3.7; (5) sending the residual particles after screening into a baking oven for baking to dry; (6) putting the dried material into a cracking furnace for cracking; and (7) performing infrared heating on the cracked particles for charring, and separating out sand particles with the fineness modulus less than 3.7. The method has the advantages of high effective utilization rate, timely recovery processing, low processing cost and the like.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO WUDI COUNTY POWER SUPPLY CO

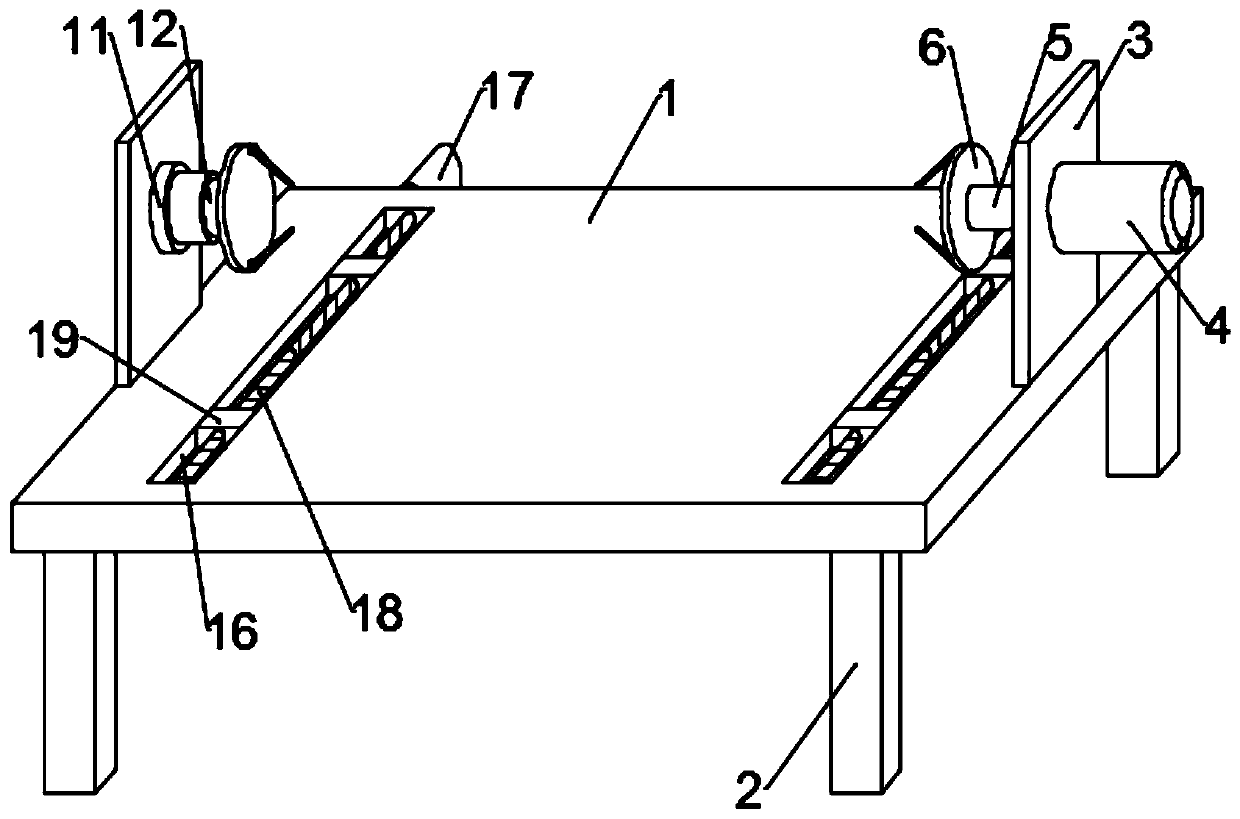

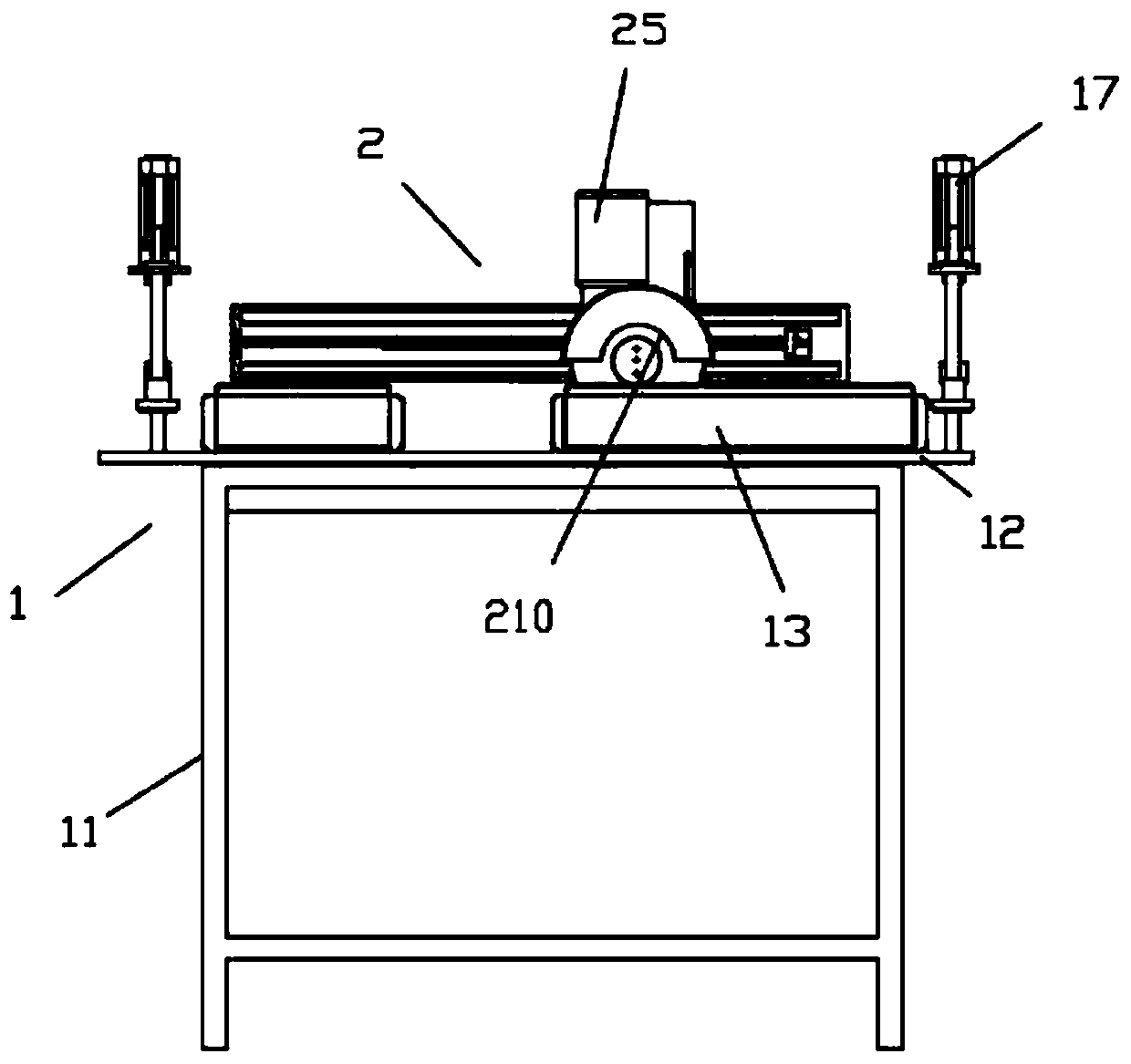

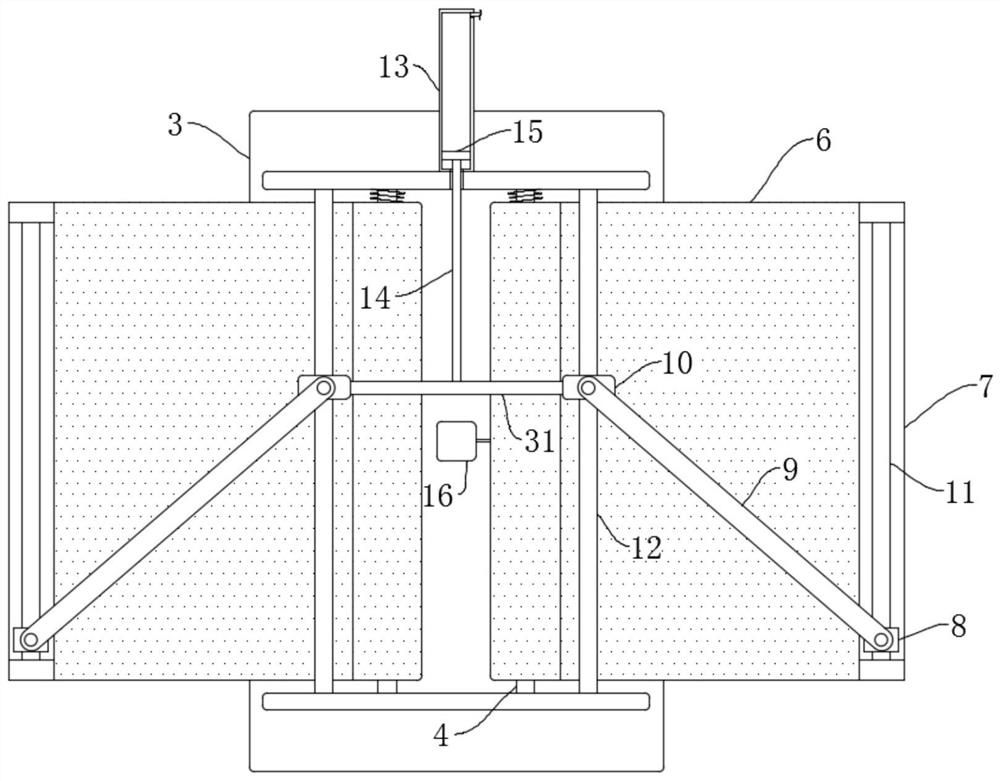

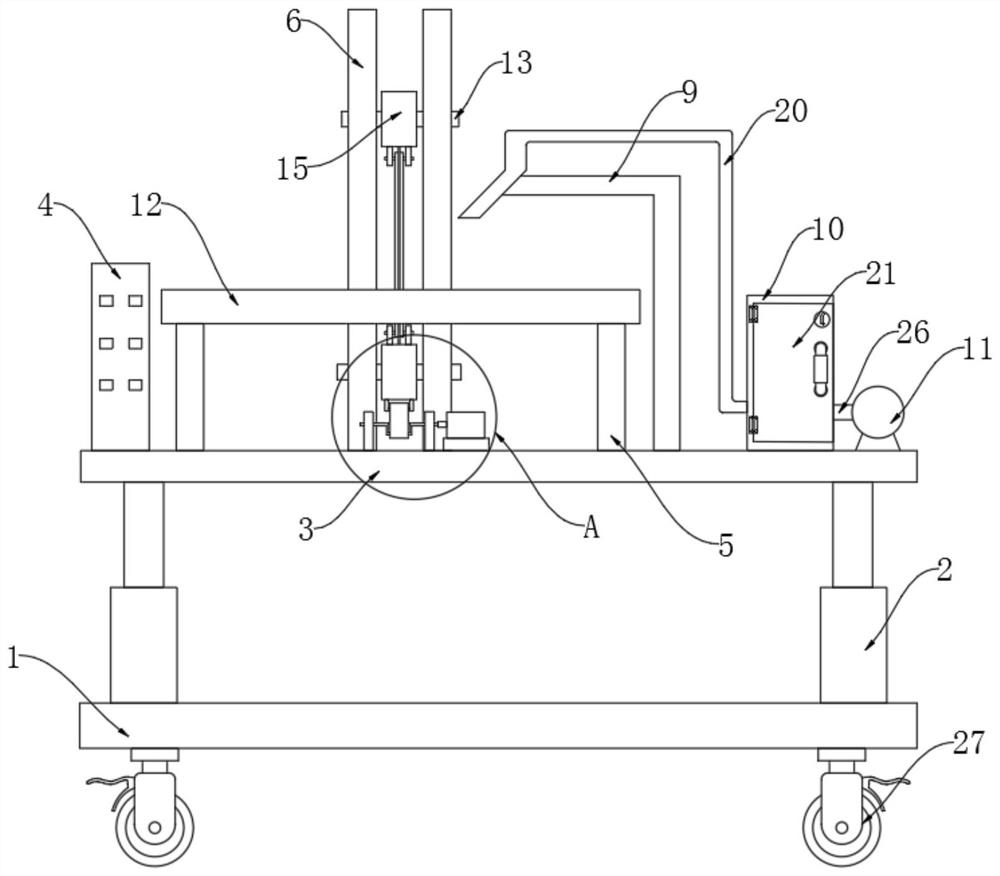

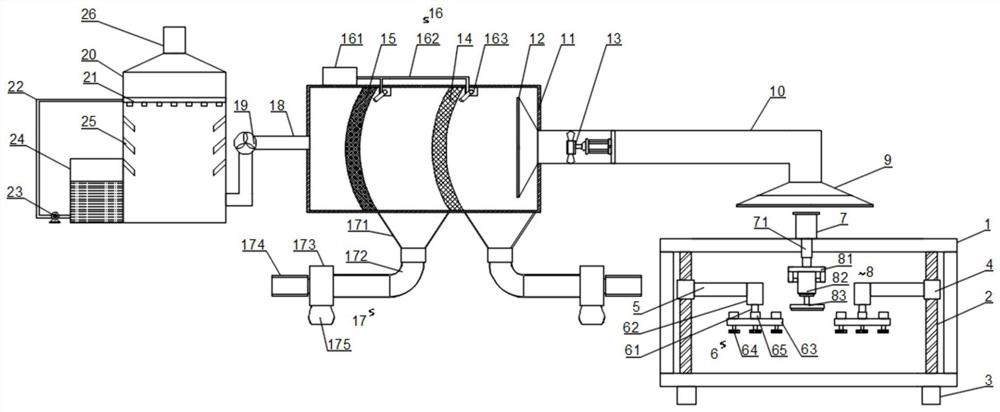

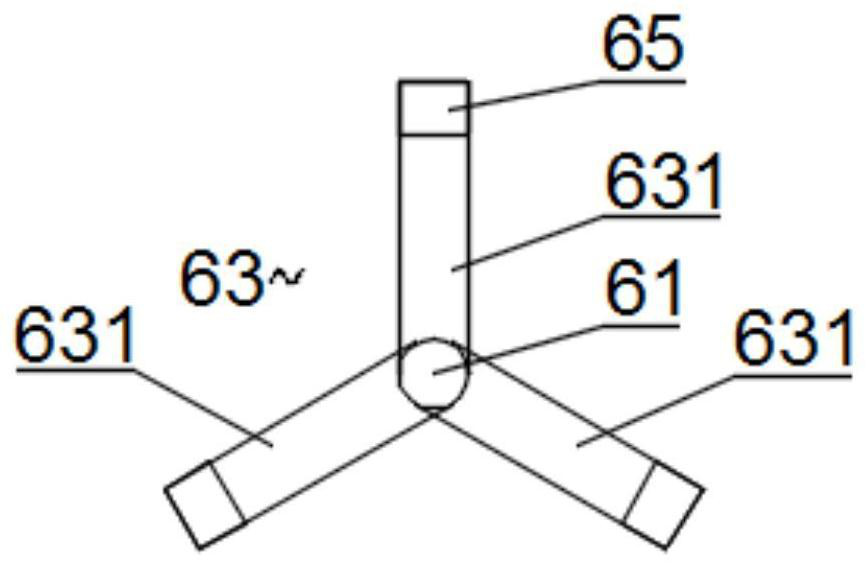

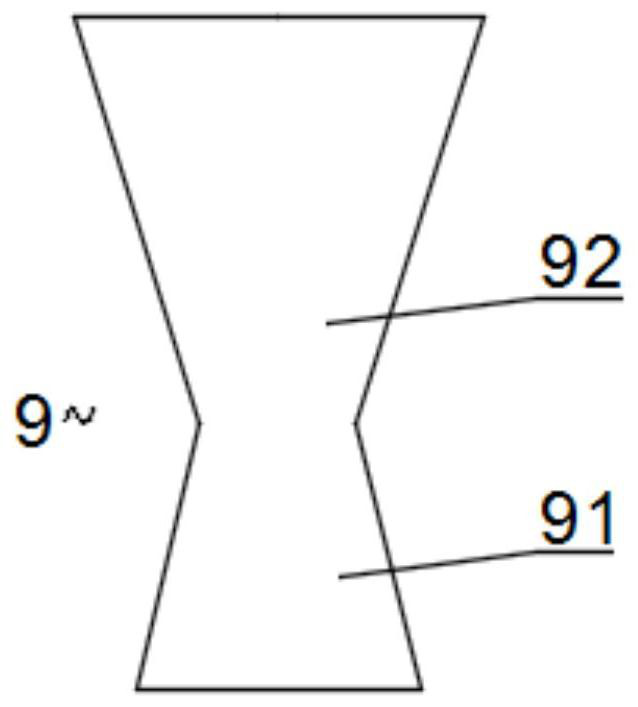

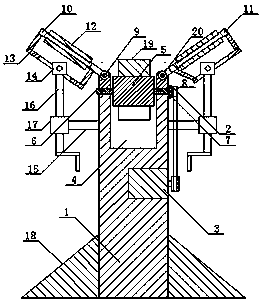

Grinding and spraying integrated device for woodware machining

InactiveCN111451878ATurn without hindranceSpray evenlyEdge grinding machinesSpray boothsWood machiningEngineering

The invention is applicable to the technical field of wood machining, and provides a grinding and spraying integrated device for woodware machining. The grinding and spraying integrated device comprises a worktable, supporting legs are fixed to the bottom of the worktable, supporting plates are fixed to the upper surface of the worktable in a bilateral symmetry manner, clamping assemblies are mounted on the inner sides of the two supporting plates, the clamping assembly on one side is connected with the supporting plate on one side through an active rotating assembly, the clamping assembly onthe other side is connected with the supporting plate on the other side through a passive rotating assembly, an empty groove is formed in the upper surface of the worktable, an adjustable grinding mechanism is mounted in the empty groove, a top plate is fixed to the tops of the two supporting plates, and a spraying mechanism is mounted on the bottom of the top plate. The problem that in the priorart, machining equipment is single in function can be solved, grinding and spraying processes during wood machining are combined, the step of carrying and transferring wood is reduced, and the wood machining efficiency is improved.

Owner:高翠荣

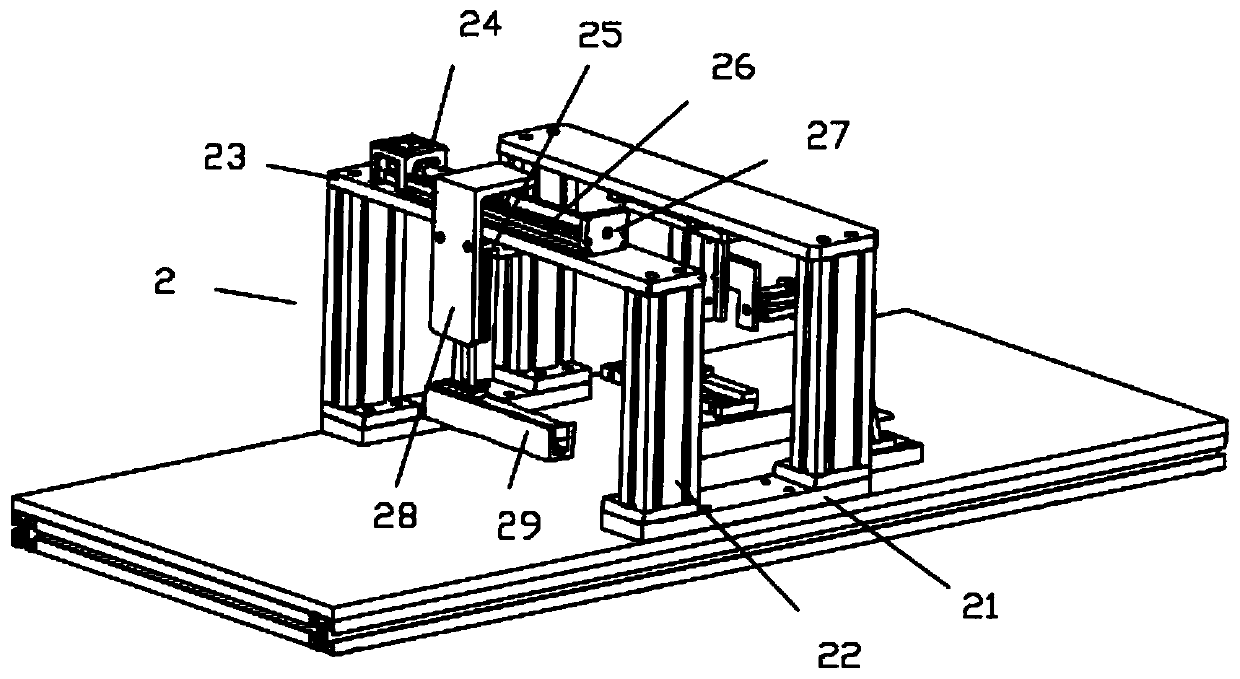

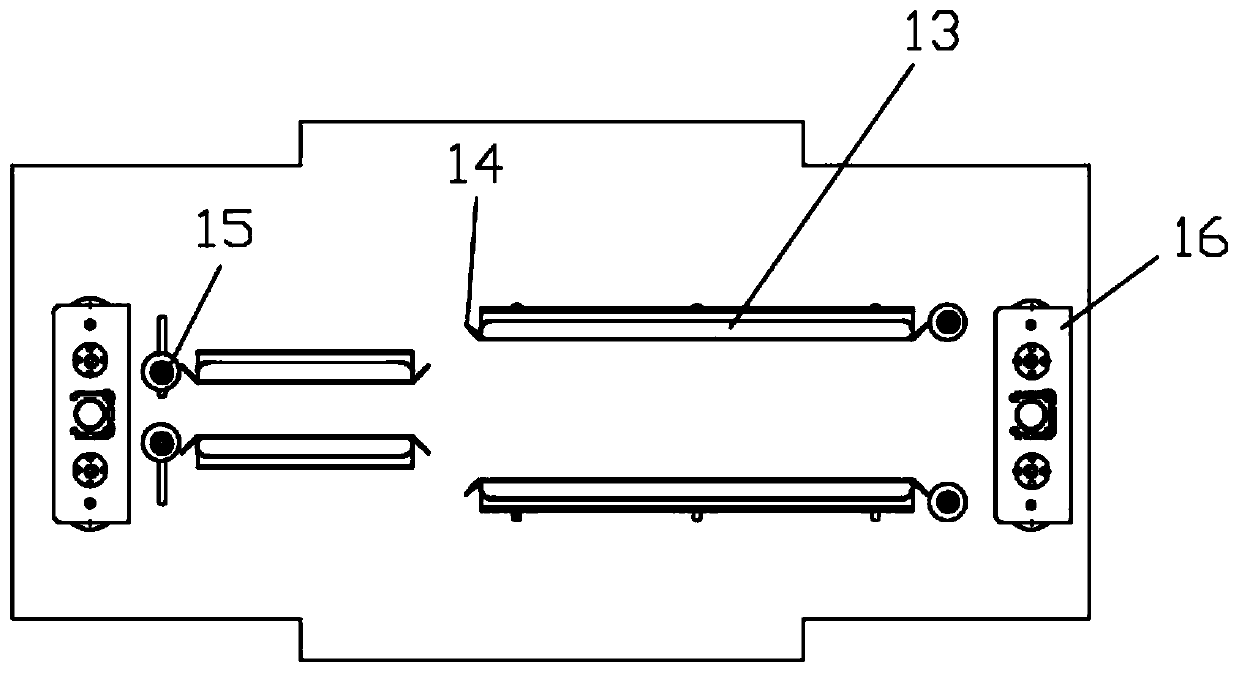

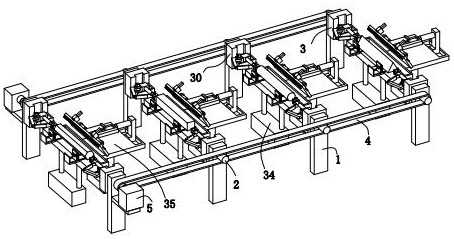

Woodware grinding equipment and working method thereof

InactiveCN111590427AEasy to move aroundImprove grinding efficiencyEdge grinding machinesGrinding carriagesGrindingMillwork

The invention discloses woodware grinding equipment. The woodware grinding equipment comprises a supporting mechanism, a grinding mechanism and a sweeping mechanism. The supporting mechanism comprisesa bottom plate, a cushion plate, a connecting block, a first motor, a supporting frame, a sliding block, a first threaded rod, fixing rods, sliding rails, a movable plate and sliding grooves. The grinding mechanism comprises fixing plates, first vertical frames, first connecting plates, a second motor, a clamping plate, a second threaded rod, a limiting plate, an L-type fixing frame and a grinding plate. The sweeping mechanism comprises second vertical frames, second connecting plates, an air cylinder, a guide column and a sweeping head. The invention further discloses a working method of thewoodware grinding equipment. Woodware is ground and swept through the grinding mechanism and the sweeping mechanism, the woodware is moved to make contact with a grinding plate to be ground, the grinding efficiency can be improved, and through the arrangement of the sweeping mechanism, burrs generated after the woodware is ground can be swept away.

Owner:安徽持家汉家居工艺品有限公司

Machining technology for pecan artware

InactiveCN104960371AImprove yieldQuality improvementSpecial ornamental structuresWood working apparatusMachining processWood plank

The invention discloses a machining technology for pecan artware. The machining technology comprises the first step of pecan selecting, the second step of plate sawing, the third step of soaking, the fourth step of boiling, the fifth step of drying, the sixth step of air drying, the seventh step of carving a processed plank with the artware according to a drawing, and the eighth step of manufacturing the finished artware and packaging the finished artware into a warehouse, wherein in the third step of soaking, after the plank is saw, the plank is soaked with clean water immediately, during soaking, the water needs to be higher than the complete plank, and the soaking time is 16-19 days; in the fourth step of boiling, after soaking is finished, one-time boiled water boiling is carried out on the plank immediately, a cement pool serves as a boiling pool, the length and the width of the pool are two meters, and the boiled plank is aired for 2-3 hours. The pecan product processed through the technology method is high in yield and good in quality, and benefits can be increased for manufacturers.

Owner:柳州启智信息科技有限公司

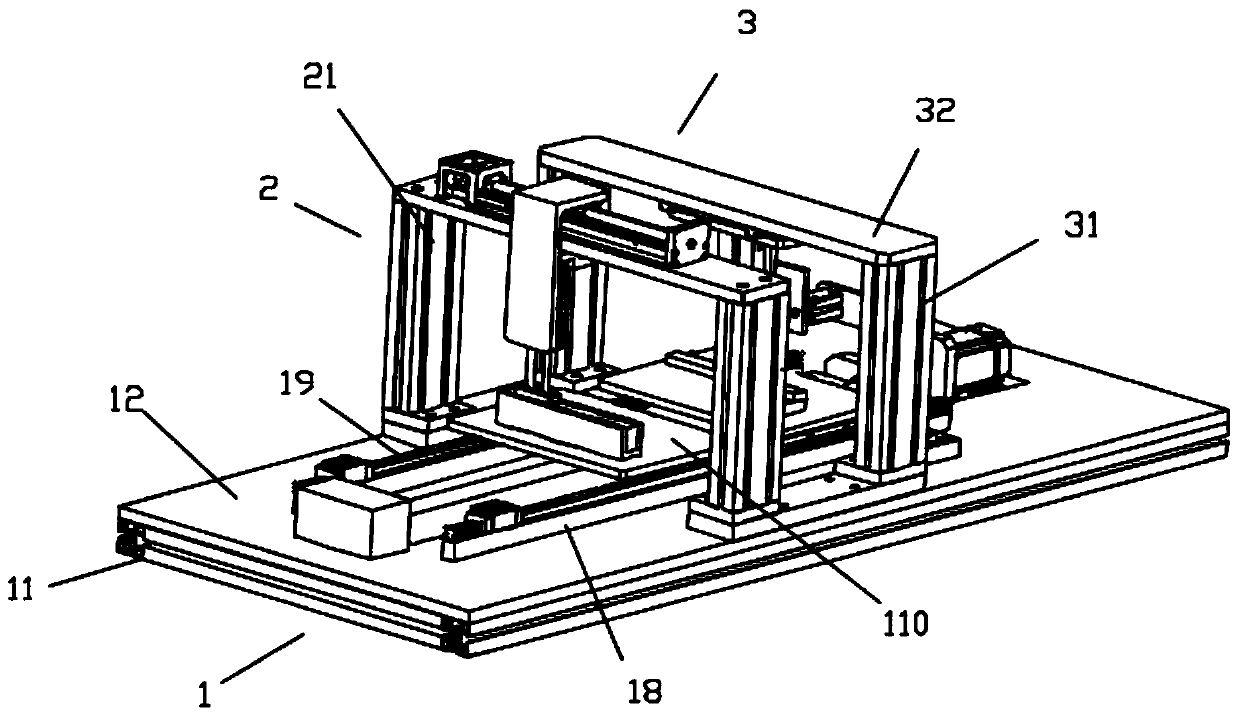

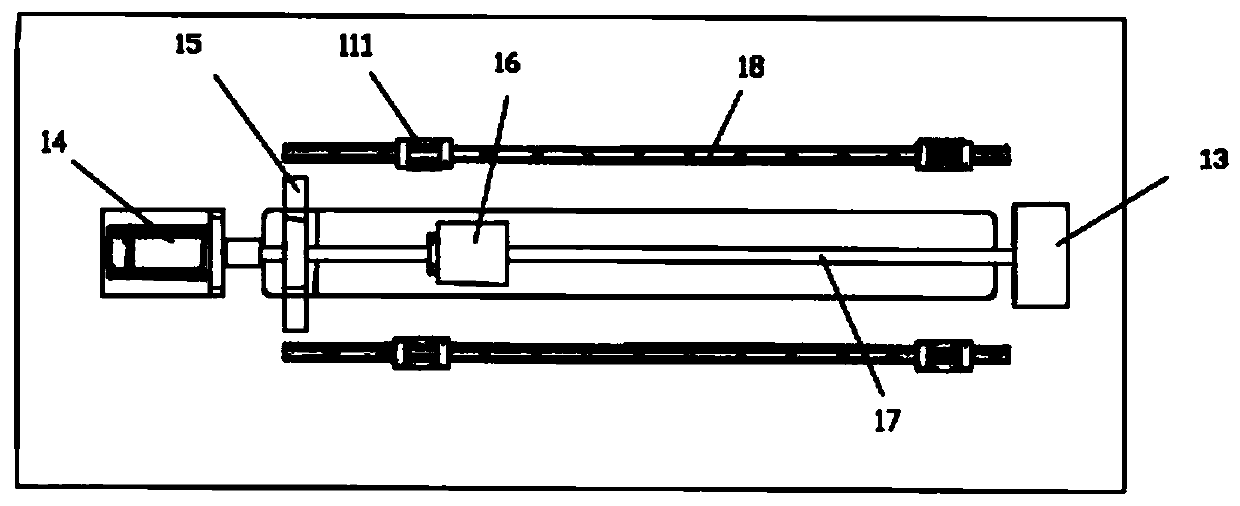

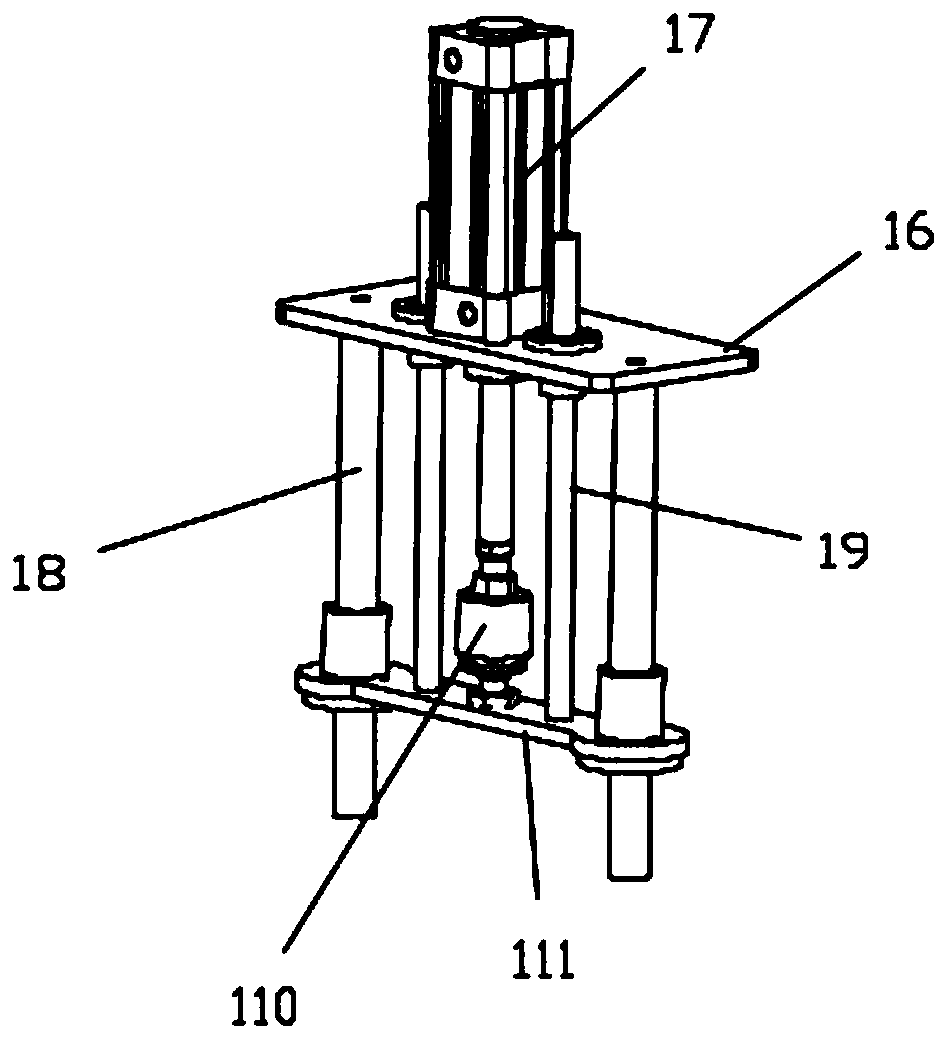

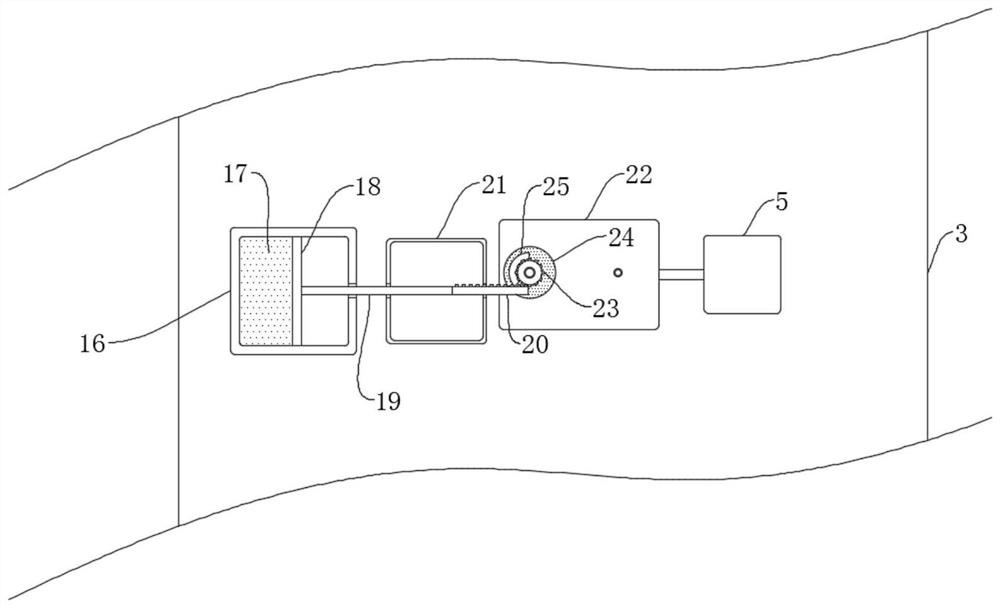

Adjustable tool for woodware machining and working method thereof

InactiveCN111571725AFree position adjustmentGripping devicesClamping devicesElectric machineryReducer

The invention discloses an adjustable tool for woodware machining. The adjustable tool comprises a fixing mechanism and a tool mechanism. The tool mechanism is mounted above a fixing mechanism. The bottom end of the tool mechanism is fixed to the upper surface of the fixing mechanism. The fixing mechanism comprises a support frame, a cushion plate, splash boards, material discharging plates, vertical pulleys, support plates, air cylinders, first support rods, guide rods, extending-and-contracting rods and pressing plates. The tool mechanism comprises second support rods, a horizontal cross beam, sliding rails, a moving plate, a first motor, a reducer, a threaded cross bar, a sliding block, a groove, a cutting tool, limiting plates and a second motor. The invention further discloses a working method of the adjustable tool for woodware machining. The working method comprises the steps that firstly, squeezing fixation is conducted on woodware through the fixing mechanism; and then, the tool mechanism moves to cut the woodware. The position of the cutting tool can be freely adjusted, so that different positions of the woodware are machined.

Owner:安徽持家汉家居工艺品有限公司

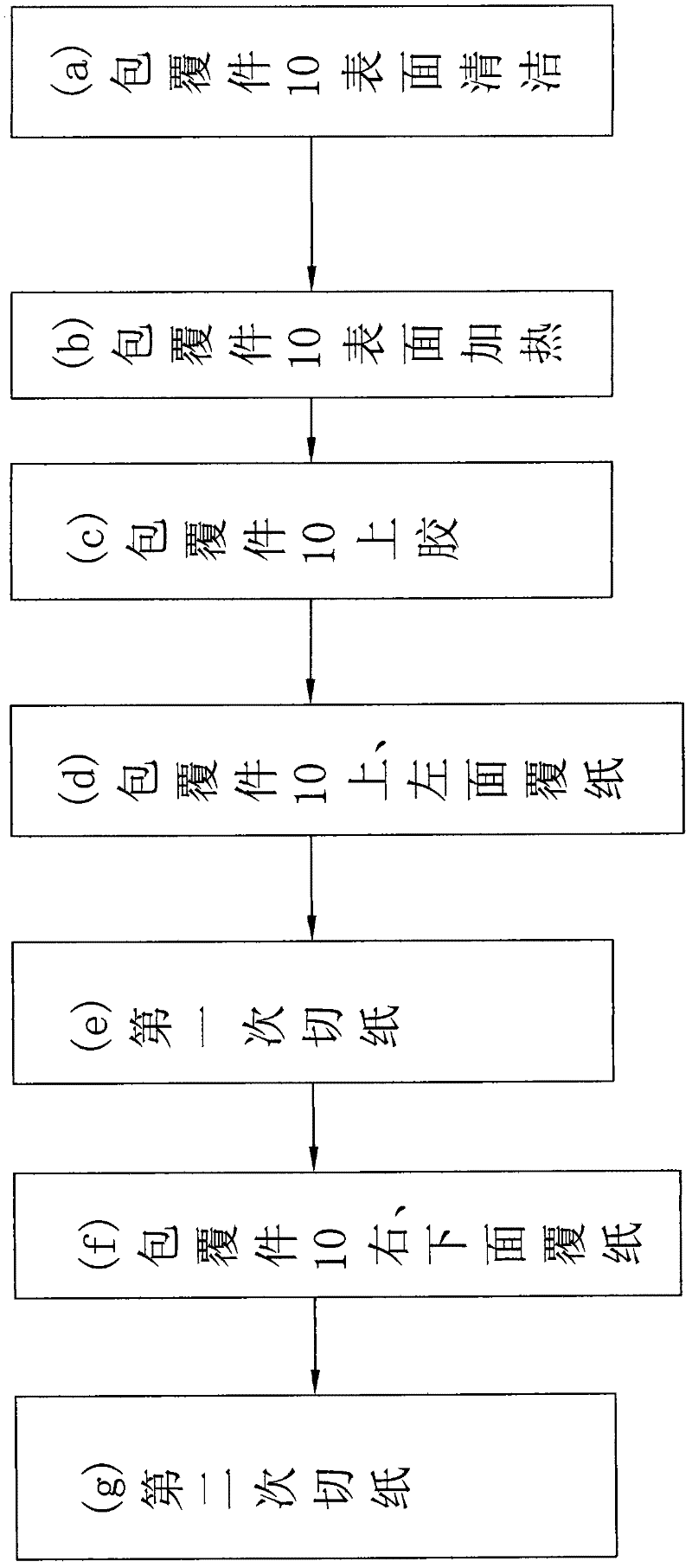

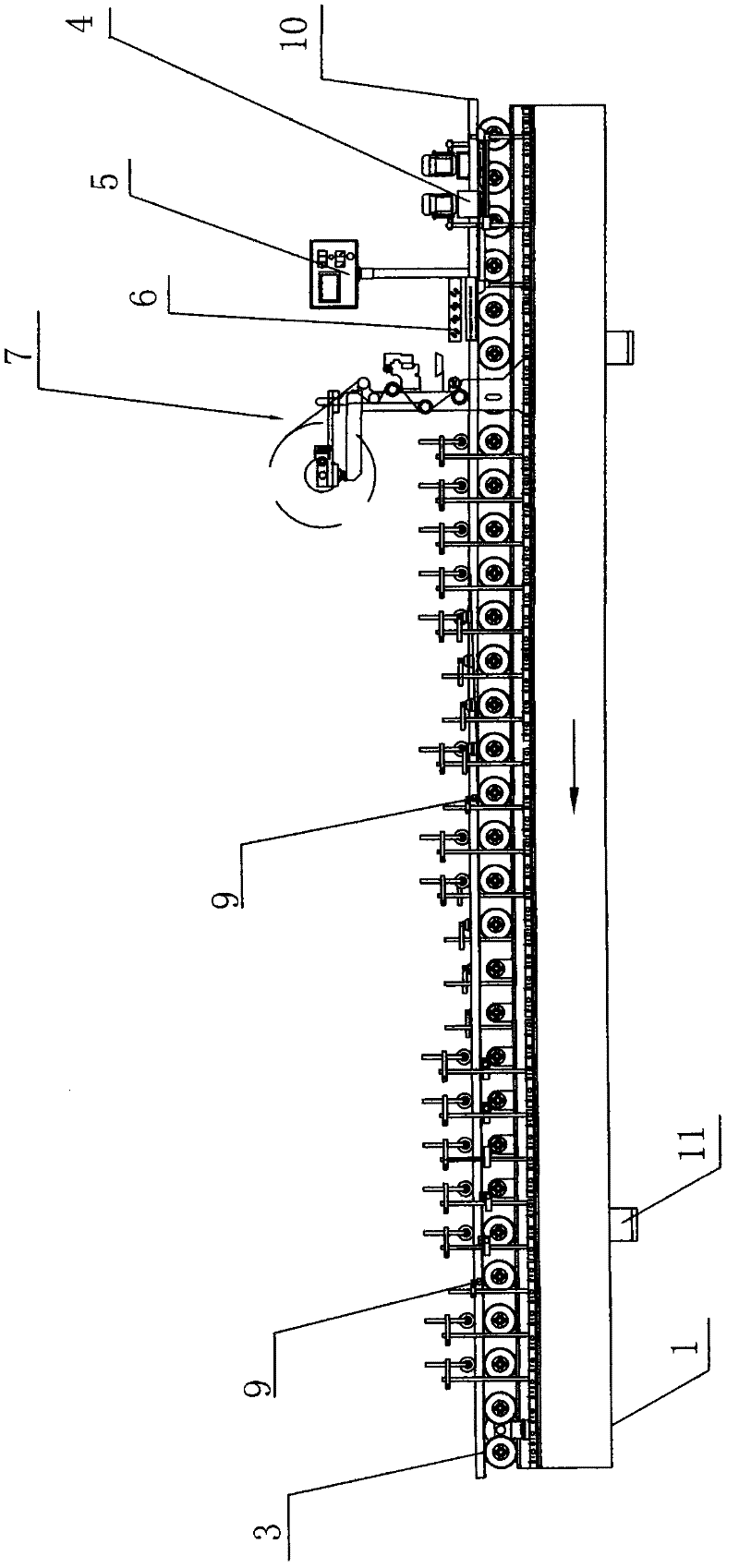

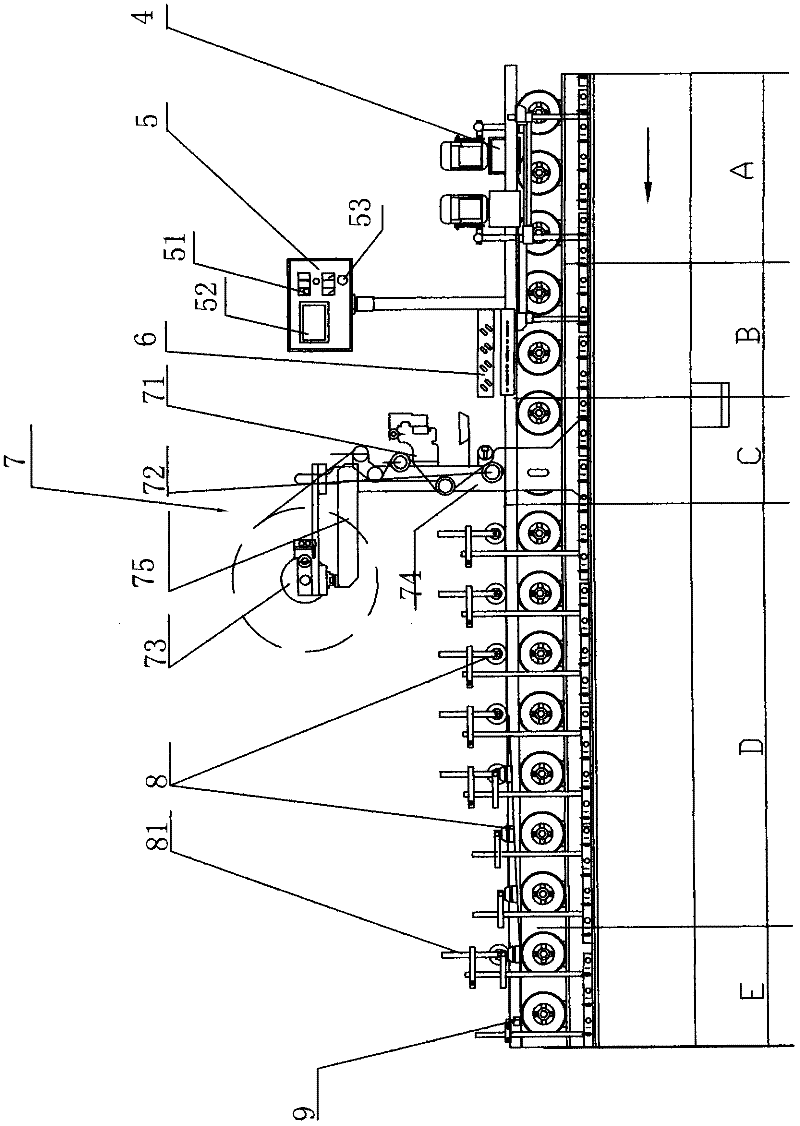

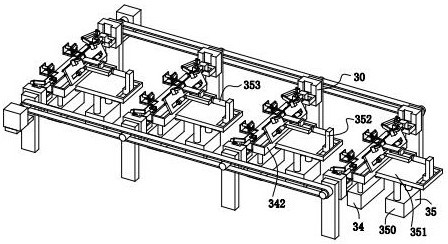

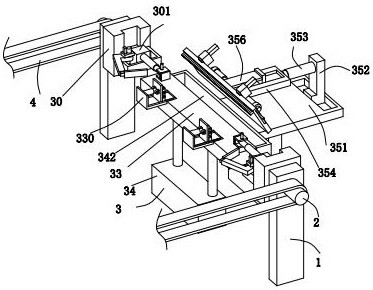

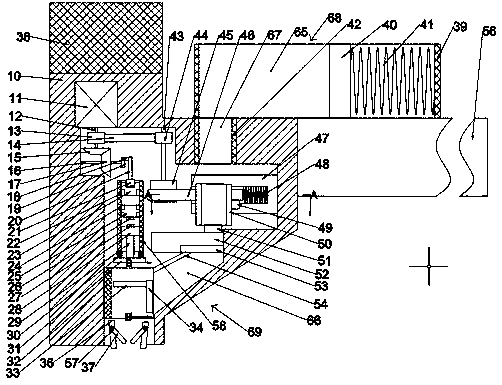

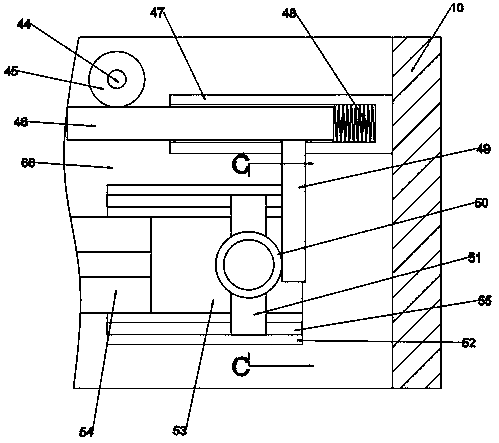

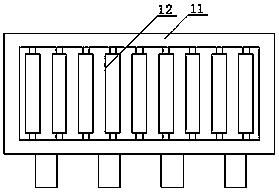

Processing method for square woodwork with coating as well as processing equipment thereof and product

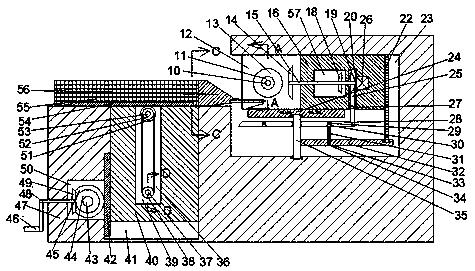

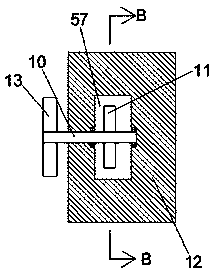

ActiveCN102528894ANice appearanceFeel smoothWood working apparatusDomestic articlesSurface cleaningPulp and paper industry

A processing method for square woodwork with coating as well as processing equipment thereof and a product belong to the technical field of woodwork processing methods, equipment and products. The coating processing procedure comprises the followings: cleaning the surface of a coated piece, heating the surface, gluing, covering an upper surface and a left surface with paper, cutting paper for the first time, covering the right surface and the lower surface with paper, and cutting paper for the second time; and in the steps of cutting paper for the first time and cutting paper for the second time, a square woodwork covering machine is adopted. The square woodwork covering machine comprises a frame, a transmission device, 20 or more than 20 driving rollers, as well as a cleaning device, a control panel, an infrared heating lamp, a coating paper rolling system, a paper guiding roller and two coating paper cutting device which are sequentially arranged on a coated piece transportation station. A square woodwork product with a coated layer is characterized in that a butted state is shown at the connector of the coated layer. The square woodwork product has the advantages that the paper connector of the product is enabled to be under a butted state, the coated products are enabled to be less susceptible to upturn, stripping, breakage failure and flaking off, and to be scouring resisting and wet resisting, and the product quality is improved.

Owner:宁波捷丰现代家俱有限公司

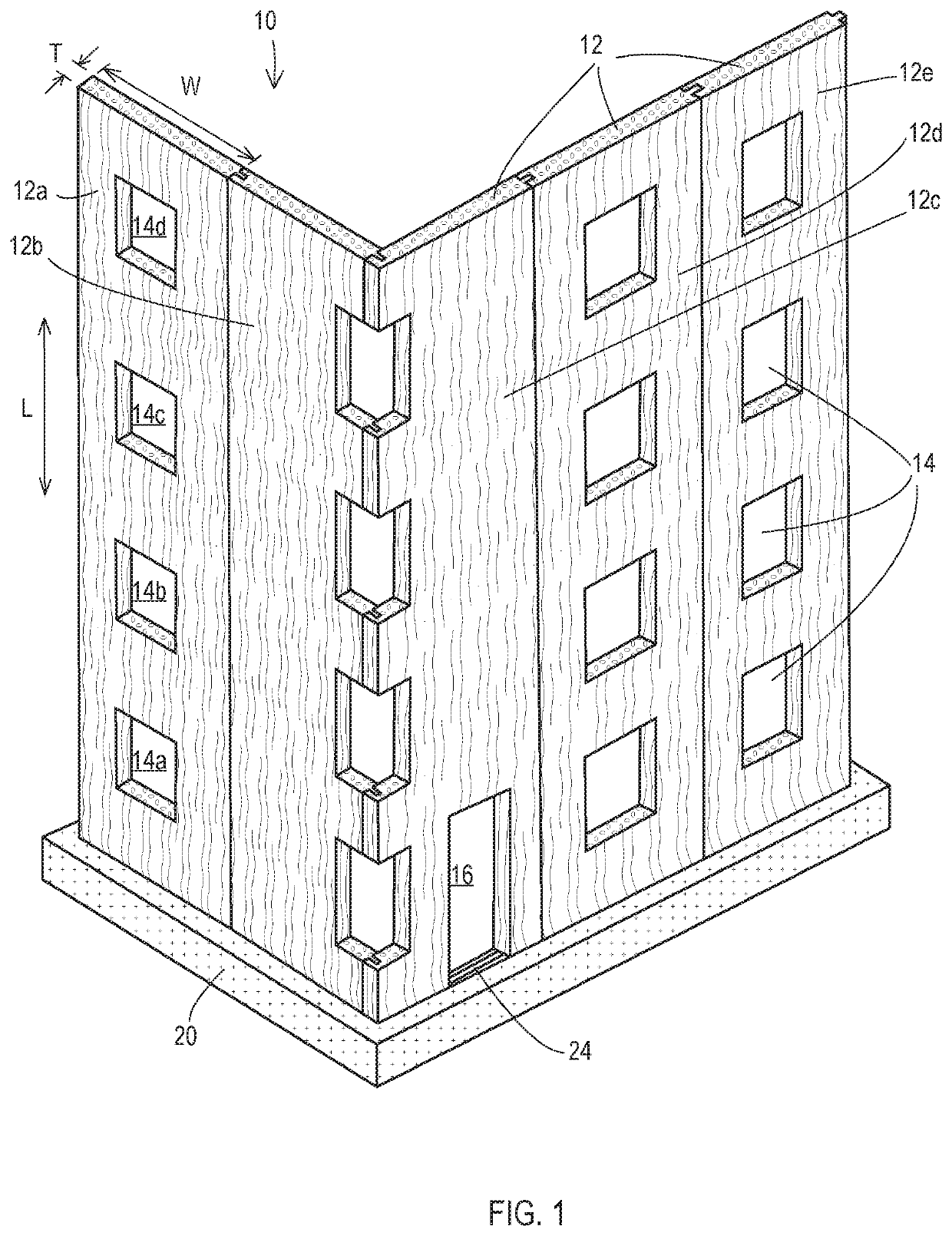

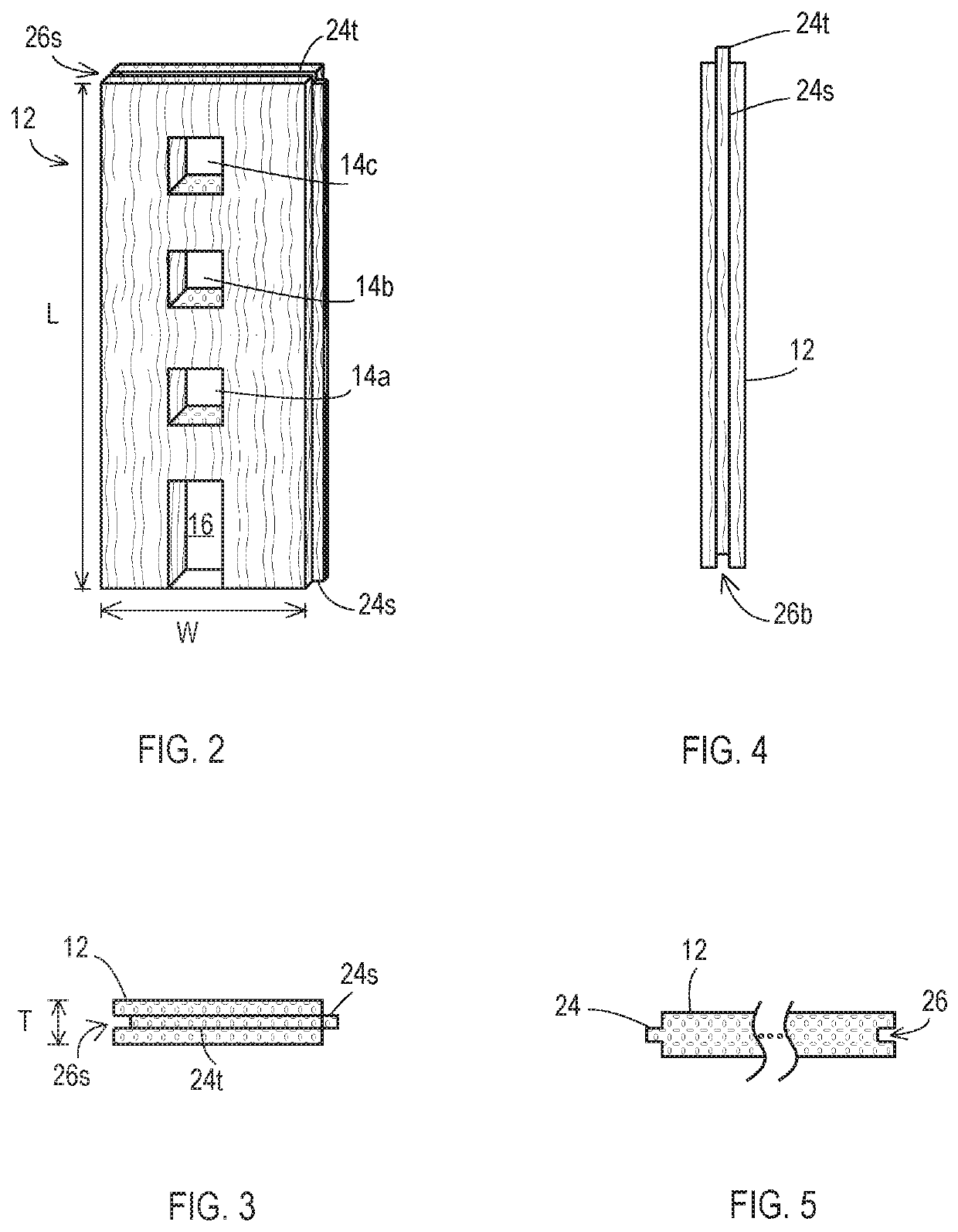

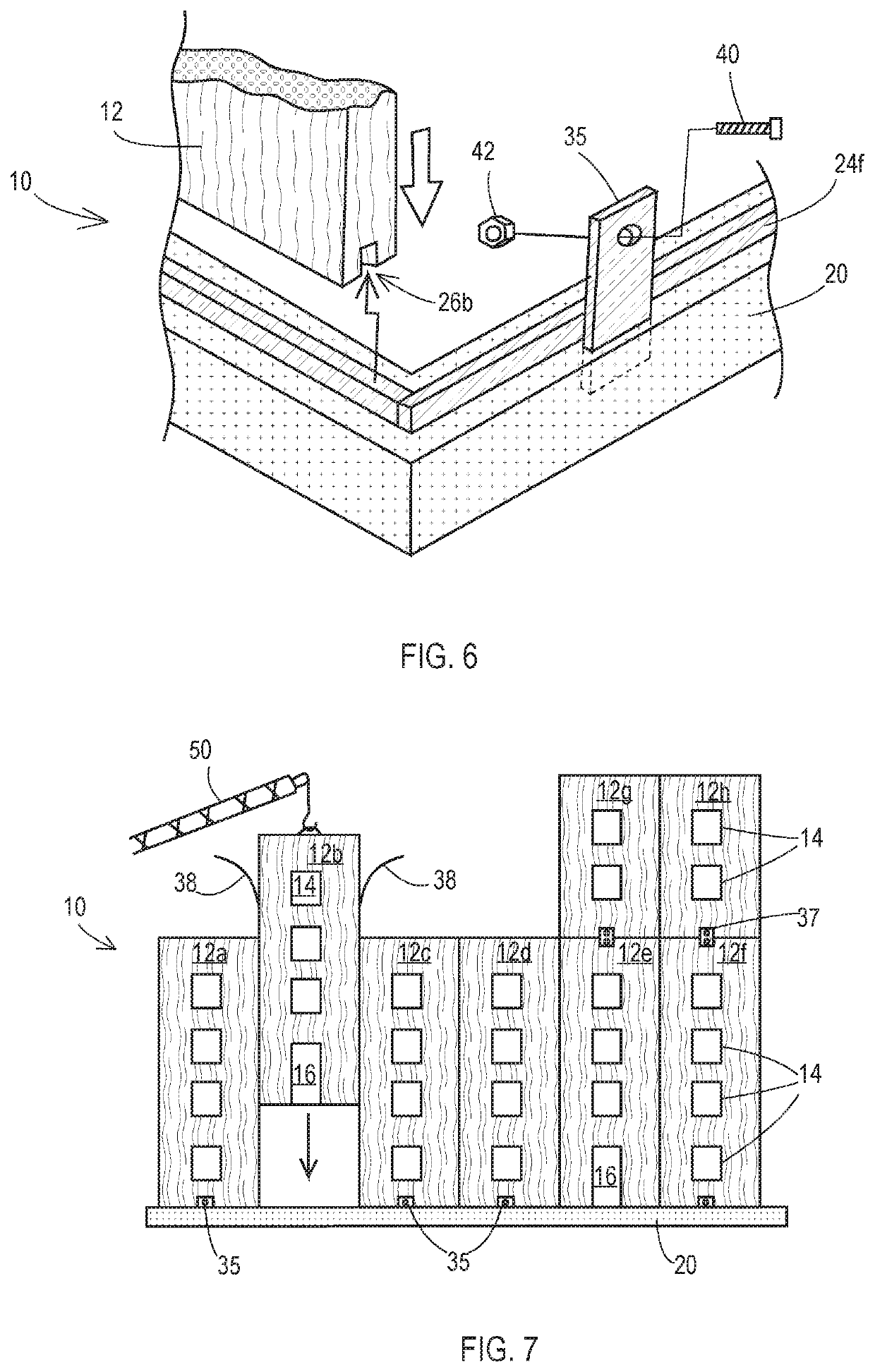

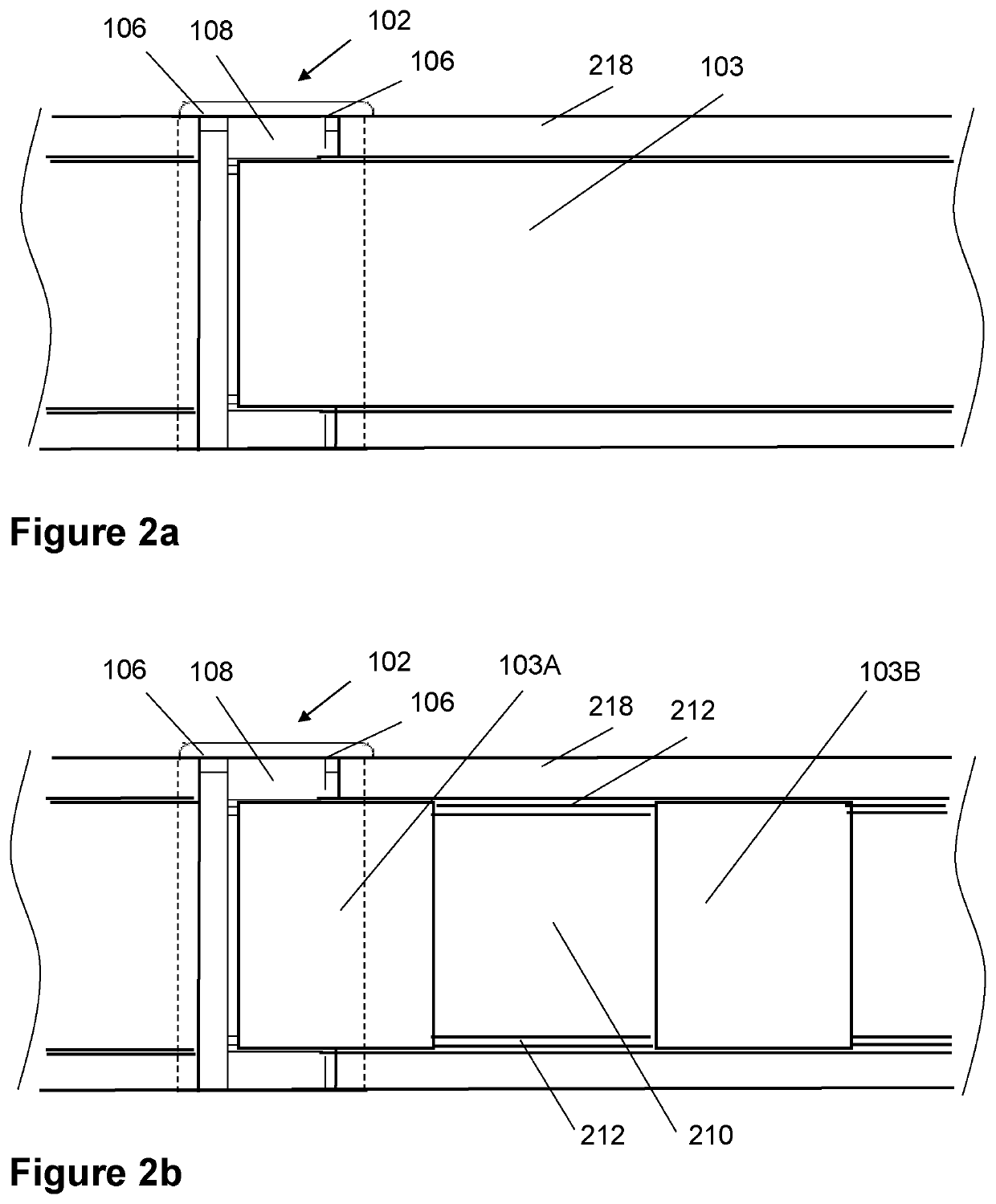

Multi-story building construction using long strand timber panels

InactiveUS20200181905A1Cost-effective fabricationIncreased load-bearing capacityConstruction materialWallsArchitectural engineeringJoist

Products and methods for constructing mass timber structures in multi-story configurations using long strand timber (LST) engineered wood products. Structural LST panels of predetermined dimensions are fabricated using LST manufacturing methods, typically involving steam pressing a billet of scrimber material that includes treatment materials and bonding material. The long strands of the material used in the panels are oriented vertically for improved load bearing capacity. The panels are sized for shipment to a job site. Prior to shipment, a plurality of panels are pre-processed by cutting openings for windows, doors, tongues, and grooves at a fabrication plant. At the job site, the LST panels are quickly assembled into a building shell (i.e. full exterior walls). Floor and roof joists are then attached using conventional wood fastening devices, and interior build out can commence very quickly after initial construction of the exterior walls.

Owner:TIMTEK

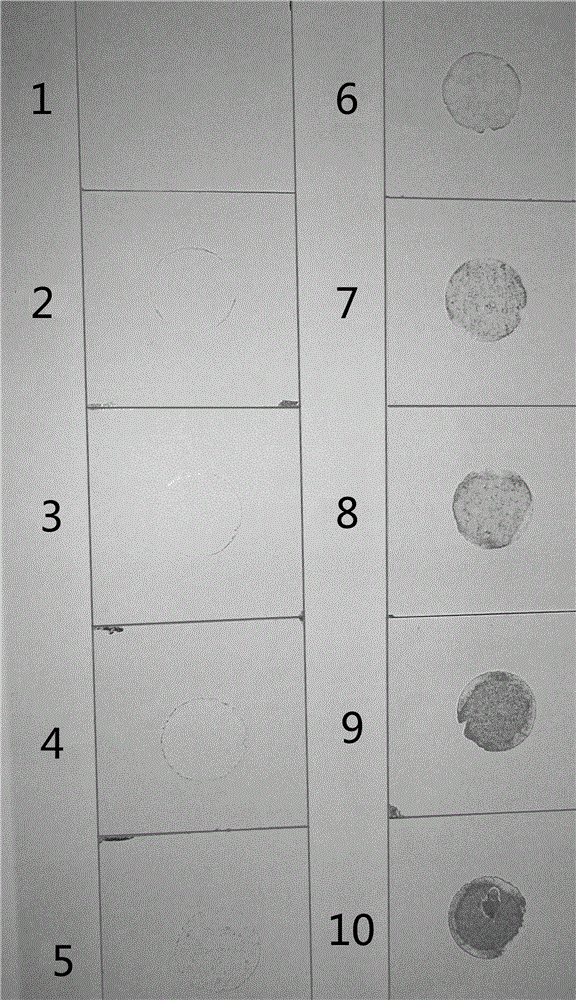

Method used for detecting resin curing degree of sticky membrane paper laminated woodwork surfaces

ActiveCN103336006AEasy to operateDistinctiveMaterial analysis by observing effect on chemical indicatorPolymer scienceMelamine formaldehyde resin

The invention belongs to the field of processing technologies of interior decorative plates, and relates to a detecting method of resin curing degree, and especially relates to a method used for detecting resin curing degree of sticky membrane paper laminated woodwork surfaces. The detecting method of the invention comprises steps of preparing an inorganic acid solution of an indicator, preparing a resin curing degree standard table for comparison, and comparing by using three points comparative method. According to the method used for detecting resin curing degree of sticky membrane paper laminated woodwork surfaces, curing degree of the resin surfaces are determined based on the reaction degree of melamine formaldehyde resin and the inorganic acid; and the indicator is used for color indication which is relatively visualized. The higher the melamine formaldehyde resin curing degree is, the lower is the reaction degree of the melamine formaldehyde resin and the inorganic acid. The detecting method of the invention is used in production lines with a fast speed, convenience and utility, and is capable of increasing production efficiency significantly.

Owner:圣象实业(江苏)有限公司

Special molding process of finished lacquered wood veneer, lacquer and preparation method

ActiveCN108437105AHigh hardnessImprove toughnessOther plywood/veneer working apparatusFireproof paintsWood veneerLacquer

The invention relates to the technical field of automatic special molding of finished lacquered wood veneers, in particular to a special molding process of a finished lacquered wood veneer, lacquer used in the brushing process, and a preparation method, and solves a series of problems of manual blanking, chamfering, gluing, cementing, corner combining, molding, wood grinding, trimming, primer brushing, polishing, padding, finish paint brushing and packaging, low efficiency, low efficacy, high pollution, high energy consumption, high cost, and no functions of self-cleaning, sterilizing and resisting abrasion.

Owner:西安德木轩家具有限公司

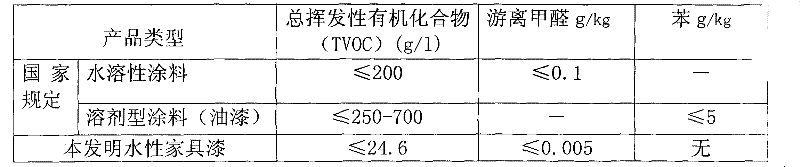

Aqueous transparent low luster furniture paint and its preparation method

The invention relates to a paint used for furniture manufacture, building decoration and building material, especially relates to an aqueous paint, and provides an aqueous transparent low luster furniture paint and its preparation method, the aqueous transparent low luster furniture paint can be used for office furniture, adult and children suit-room, woodwork and the like. The aqueous transparent low luster furniture paint and its preparation method break an traditional formula, the food level raw materials are employed except an ethene modified acrylic acid emulsion, the raw materials enable no toxicity and environmental protection, and can be applied to direct construction, the aqueous transparent low luster furniture paint has beautiful appearance, is capable of mitigating the labor intensity of workers, and will not influence the body health of the workers. The secondary product has various advantages of the current furniture paints. In addition, the aqueous transparent low luster furniture paint takes water as a primary solvent, thereby the non-renewable resource is reduced, the invention belongs to energy saving and environment-friendly type product.

Owner:李远登

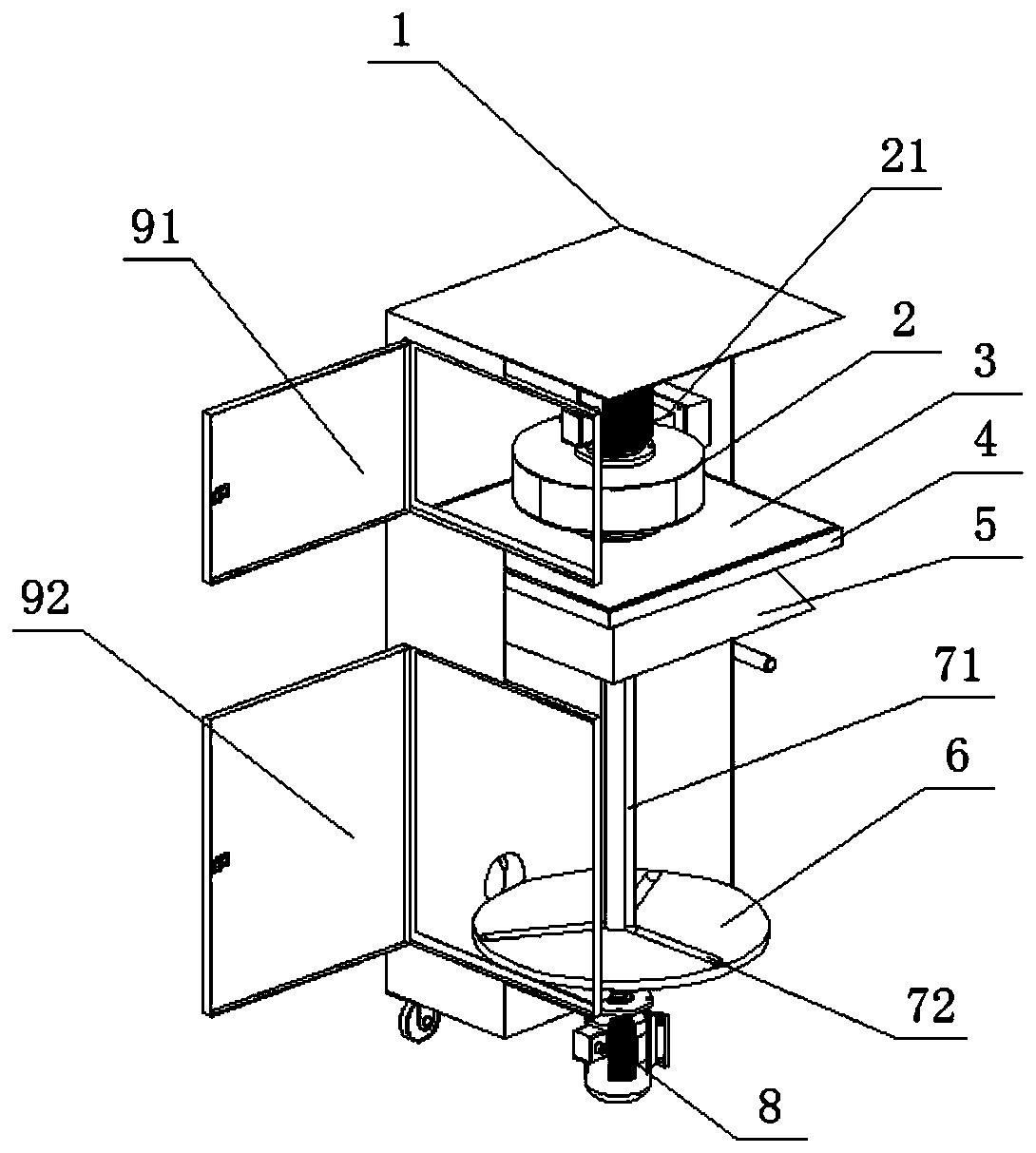

Log treatment process for wood processing

InactiveCN111015869AQuality improvementReasonable designWood working apparatusMaterials preparationIndustrial engineering

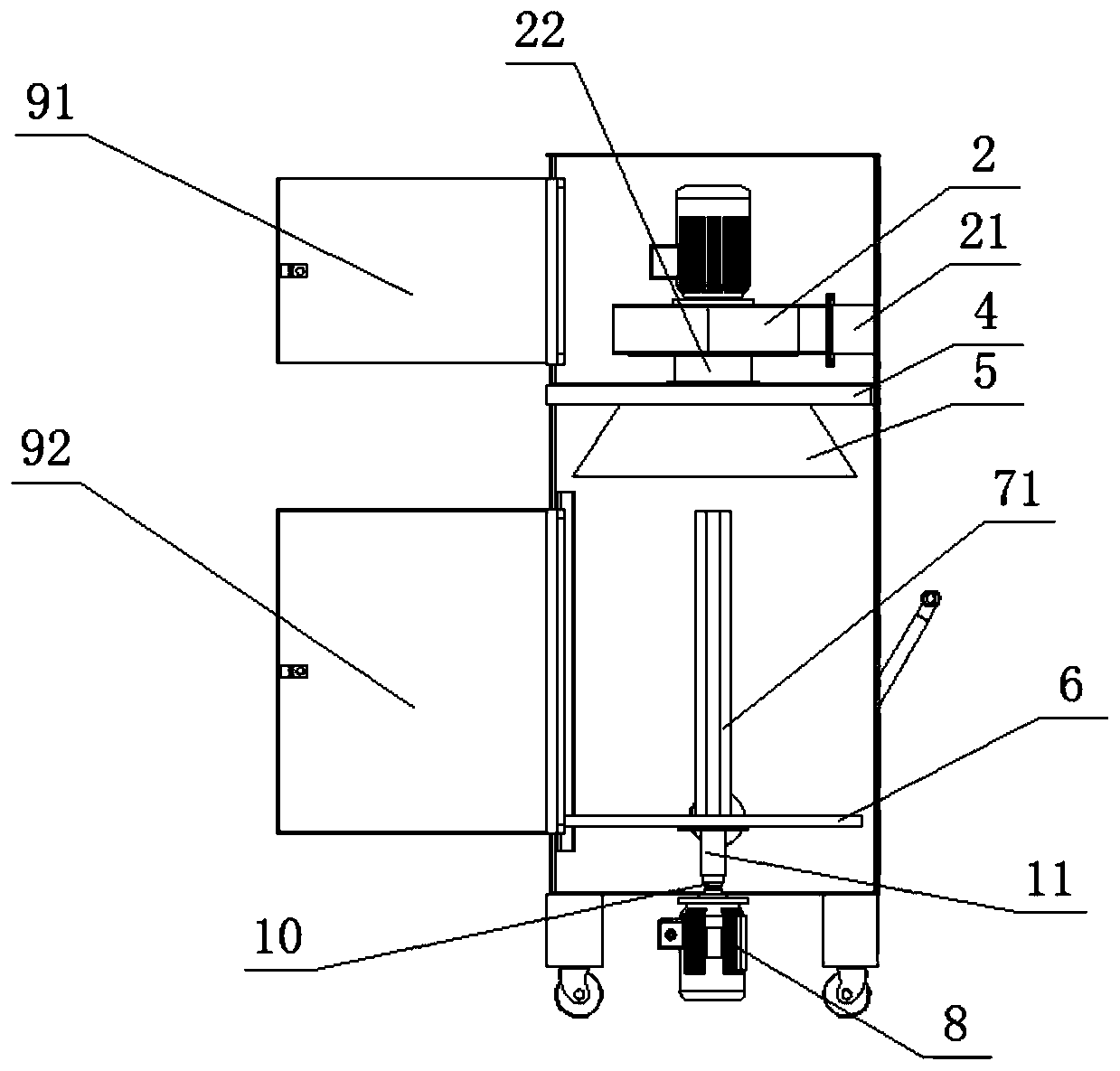

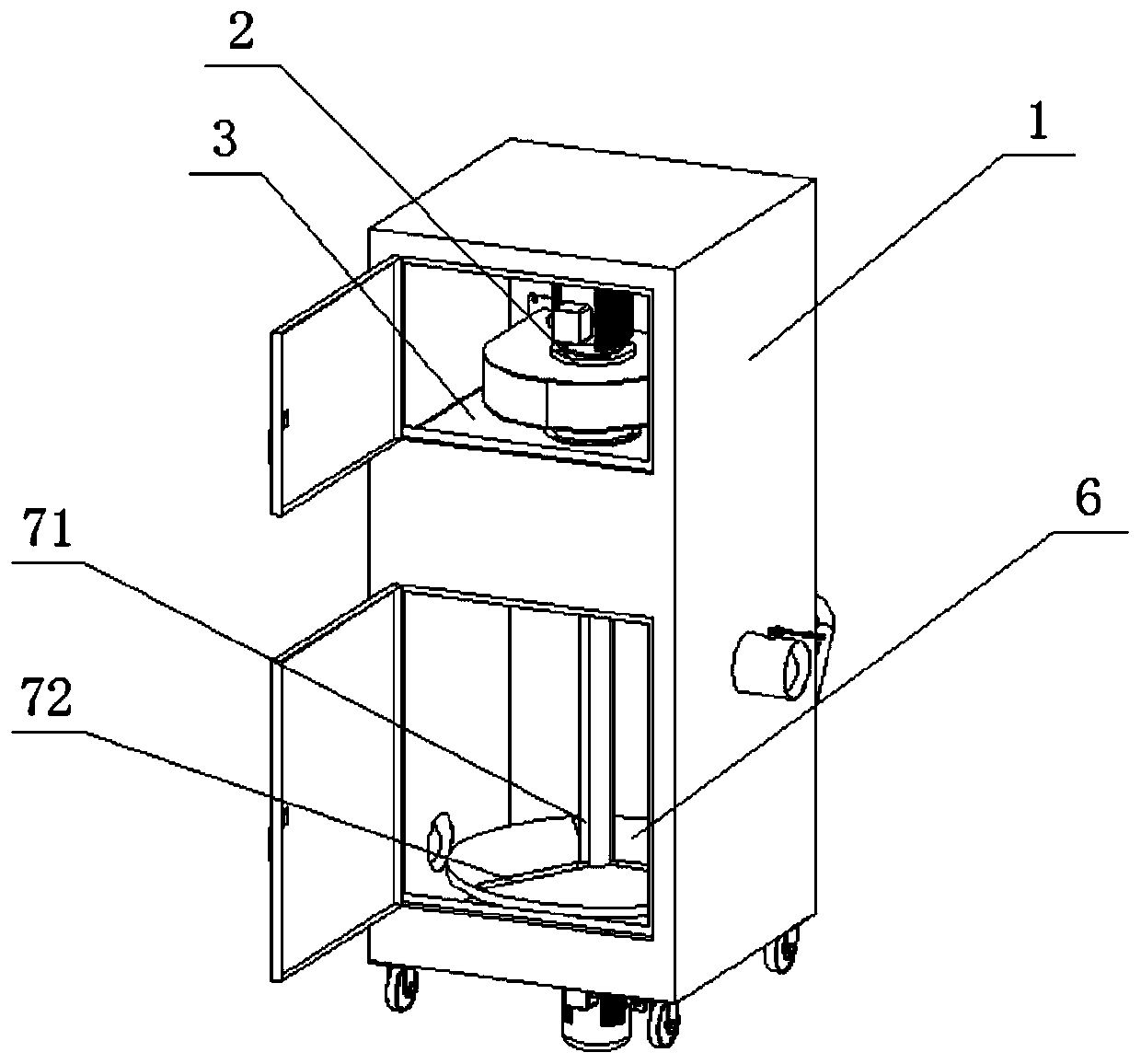

The invention discloses a log treatment process for wood processing. The log treatment process comprises the following steps: A, material preparation; B, component processing; C, assembling; and D, surface coating of a wooden product, wherein a drying device comprises a drying box body, a mounting plate arranged at the middle upper part of the drying box body, a high-pressure fan arranged on the mounting plate, an air guide cover arranged on the lower end face of the mounting plate, a rotary disc arranged at the lower end of the drying box body, a limiting assembly arranged on the rotary disc,a connecting rotary shaft arranged on the lower end face of the rotary disc, and a driving assembly used for driving the connecting rotary shaft; the rotary disc is used for placing raw logs. According to the log treatment process for wood processing, the high-pressure fan can be used for conveniently air-drying the raw logs, the driving assembly can conveniently drive the rotary disc to rotate,then changing is performed and the raw logs are dried in all directions, and thus the log treatment quality is effectively improved.

Owner:湖州联科粘合剂有限公司

Grinding device for drilling machine cutter

ActiveCN111085904AReduce the risk factorCompact structureGrinding drivesDrilling toolsEngineeringDrilling machines

The invention discloses a grinding device for a drilling machine cutter. The grinding device comprises a shell, wherein a translation cavity is formed in the outer shell, a supporting block is slidably mounted in the right end wall of the translation cavity, a first rack is fixedly mounted on the left side of the supporting block, a rotating cavity is formed in the left side of the first rack, a moving assembly is arranged in the rotating cavity, a fixing block is slidably mounted above the supporting block, the right end of the fixing block is slidably provided with a clamping block, and theright side of the translation cavity is provided with a right transmission cavity. According to the grinding device, the structure is compact, the cutter is ground more safely, the danger coefficientof an operator can be reduced, the device can be used in a small-size millwork plant, the device can be used for grinding the inclined plane of the cutter through a conical grinding block, a circulargrinding block can grind the edge of the cutter, and a clamping assembly can clamp and grind various cutters with different diameters.

Owner:涡阳县新源泡沫夹心板有限公司

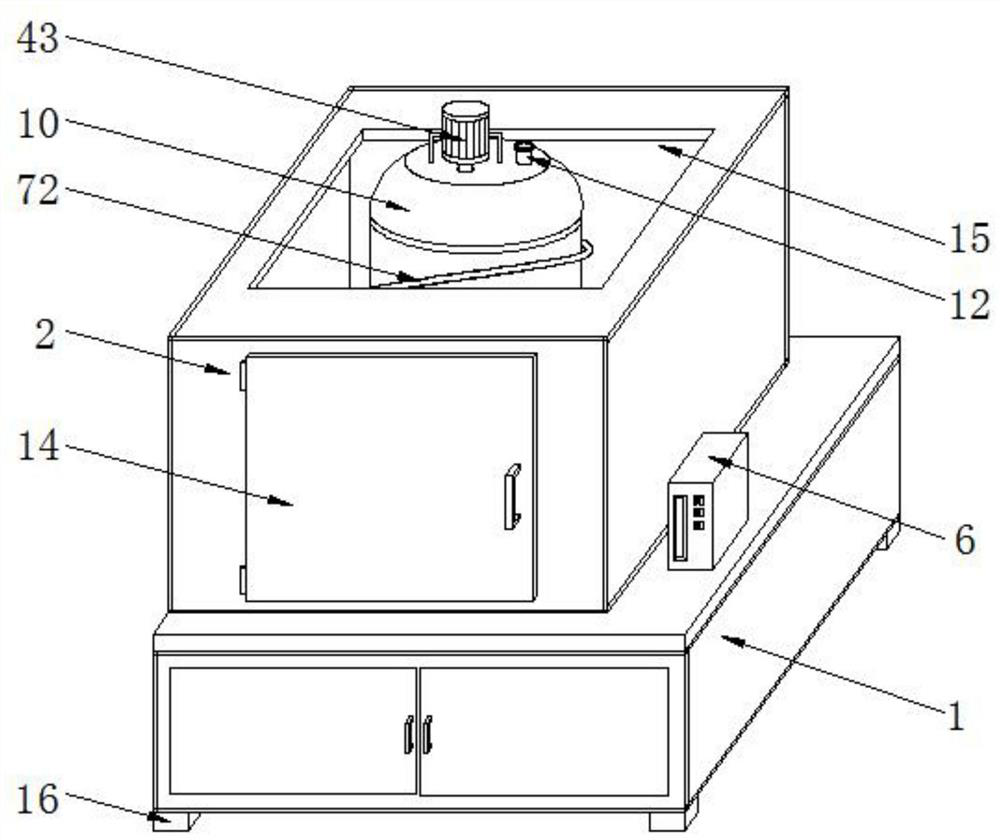

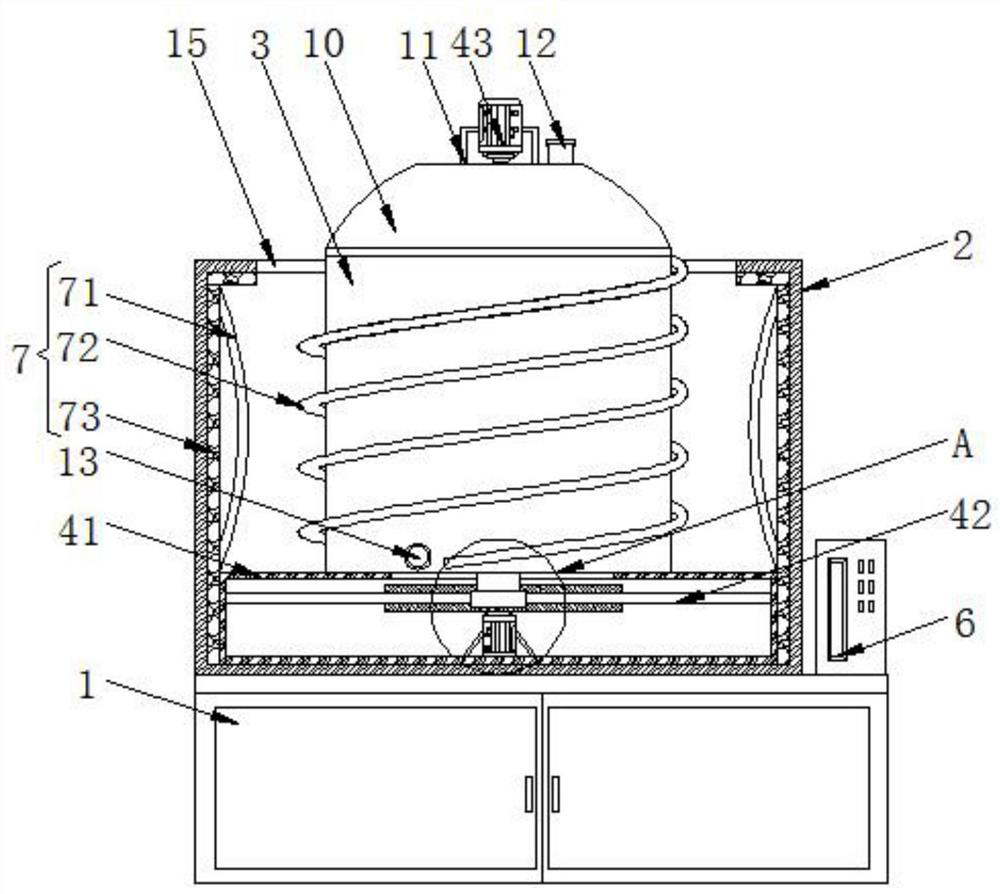

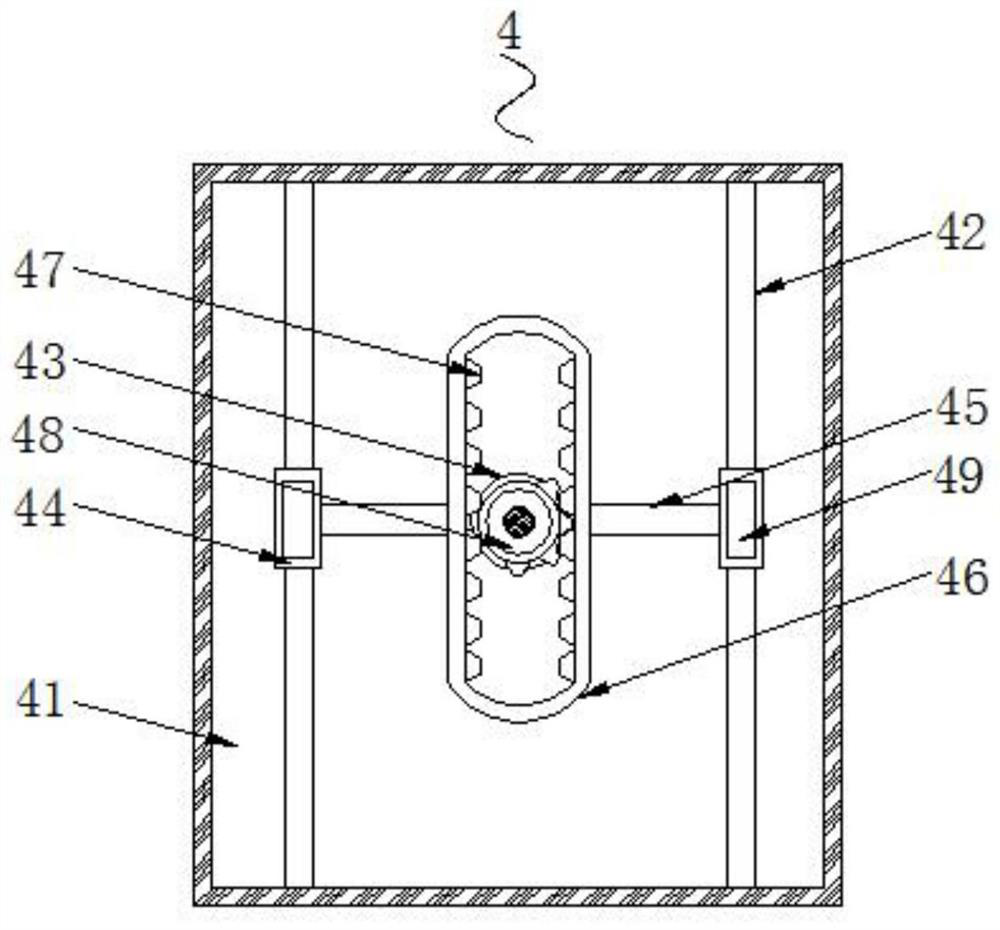

Heat preservation furnace for metal aluminum machining

InactiveCN112304088AFast heatingImprove heating efficiencyCharge manipulationCrucible furnacesGlass fiberMetallic aluminum

The invention discloses a heat preservation furnace for metal aluminum machining, and relates to the technical field of heat preservation furnaces. The heat preservation furnace comprises a workbench,a shell and a furnace body, wherein the shell and the furnace body are fixed on the left side of the top of the workbench; the bottom of the inner wall of the shell is fixedly connected with a translation mechanism; a cleaning mechanism is arranged in the furnace body; the right side of the top of the workbench is fixedly connected with an electromagnetic controller; the furnace body comprises anaerogel felt layer and a glass fiber cotton plate layer; the bottom of the aerogel felt layer is bonded with the top of the glass fiber cotton plate layer through a bonding agent; and a heating mechanism is arranged in the shell. According to the heat preservation furnace for the metal aluminum machining, the heating mode of combusting wood products is replaced by the electromagnetic heating mode, the heating speed is higher, the heating efficiency is improved, the energy consumption is less, repeated manual addition of raw materials for combustion is not needed, the use is more convenient, meanwhile, and heat reflection plates are arranged to reflect the emitted heat to the furnace body again, so that the heating efficiency is improved.

Owner:徐涛

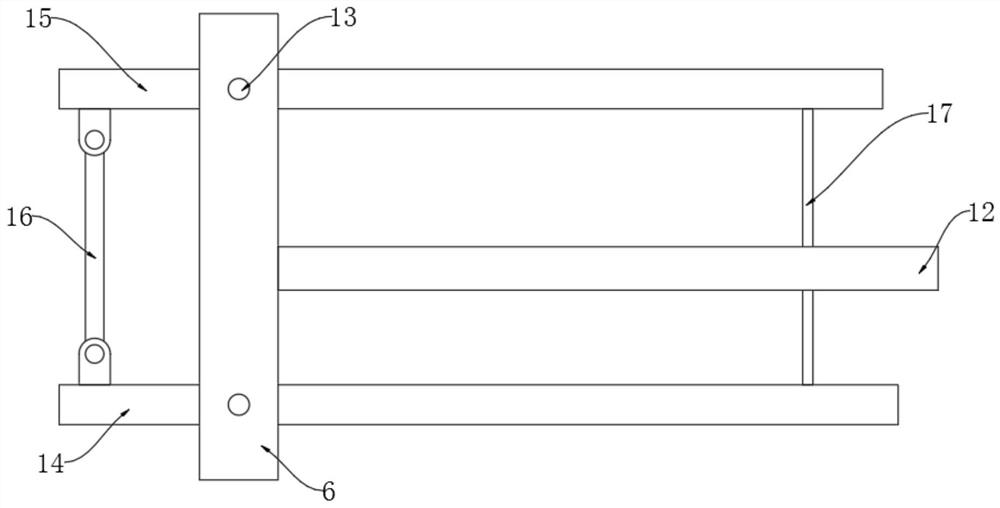

Woodware airing frame convenient for keeping rain out

PendingCN112556347APrevent rainReduce work intensityDrying chambers/containersDrying solid materialsStructural engineeringAtmospheric sciences

The invention discloses a woodware airing frame convenient for keeping rain out. The frame comprises two vertical plates arranged on the ground, wherein the upper ends of the two vertical plates are jointly and fixedly connected with a top plate, the opposite side walls of the two vertical plates are jointly and fixedly connected with multiple bearing plates, the opposite side walls of the two vertical plates are jointly and rotationally connected with two rotating shafts, the side walls of the two rotating shafts are elastically connected with the side wall of the vertical plate through clockwork springs, and rain cloth is wound around the side walls of the two rotating shafts. The woodware airing frame convenient for keeping rain out can prevent woodware on the bearing plates from beingwetted by rain and thereby protecting the woodware, workers do not need to take the woodware down when it is raining, the work intensity of people is reduced, the rain cloth can be put away when it isnot raining to air the woodware again, no manual control is needed, manpower consumption is greatly reduced, the airing cost of the woodware is reduced, the rain cloth can be dried quicker after being folded, and rainwater attached to the rain cloth is prevented from flowing onto the bearing plates.

Owner:万爱龙

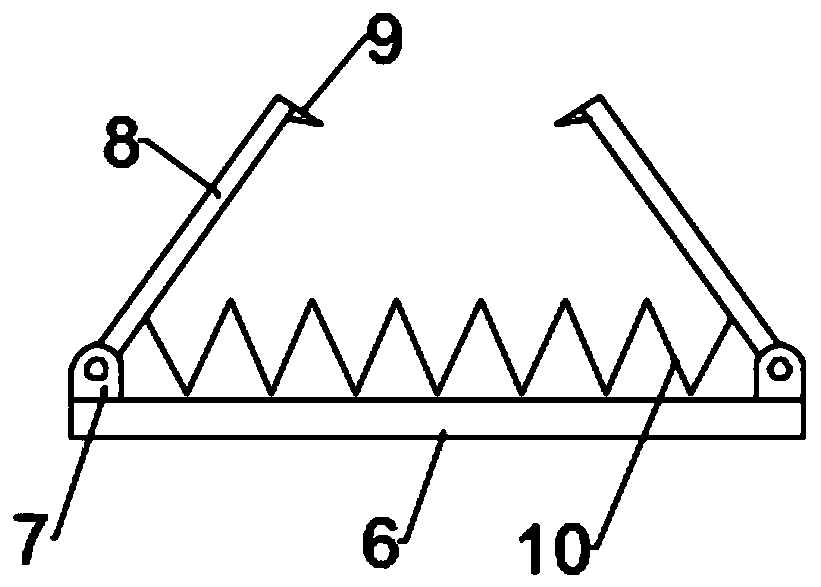

Wood building block outer end face polishing device

ActiveCN114505743AImprove sanding effectImprove clamping effectSolid waste managementGrinding drivesPolishingArchitectural engineering

The invention relates to the field of wooden product surface treatment, in particular to a wooden building block outer end face polishing device which comprises two sets of landing frames, a conveying shaft, a polishing part, a conveying belt and a motor. The main polishing plate can be completely attached to the end faces of the wooden building blocks, the polishing effect of the end faces of the wooden building blocks is effectively improved, on the basis, the overall application range of the polishing device is expanded, and the polishing device can be suitable for polishing the end faces of the wooden building blocks in various shapes; and meanwhile, the function of synchronously cleaning the polished end faces of the wooden building blocks is achieved, a lateral polishing plate and a main polishing plate are each of an assembled splicing type structure, the lateral polishing plate and the main polishing plate can be conveniently and regularly disassembled and cleaned through the structures, and the situation that the polishing effect is affected due to the fact that a large amount of wood chips are attached to the surfaces of the lateral polishing plate and the main polishing plate is avoided.

Owner:徐州贝塔文化传播有限公司

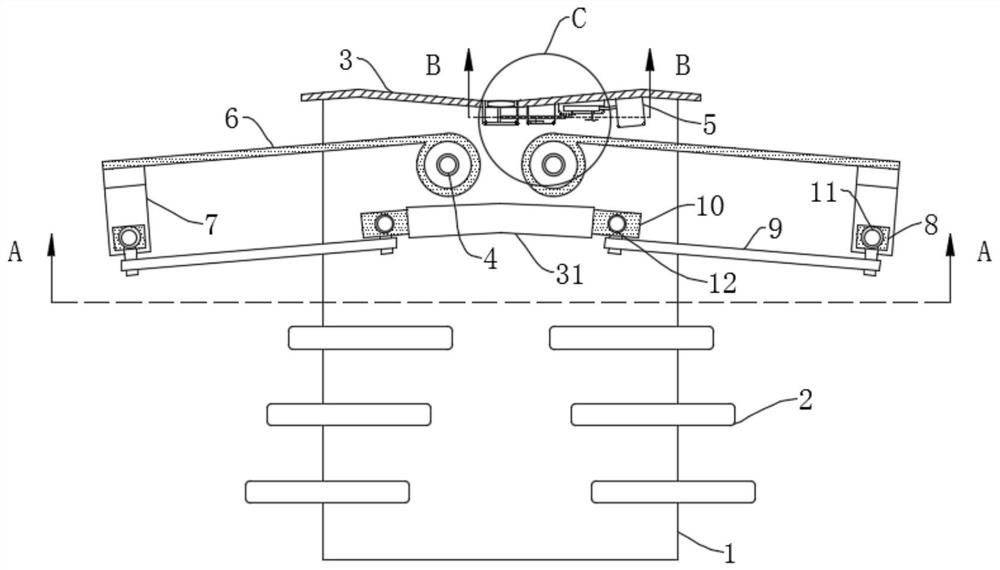

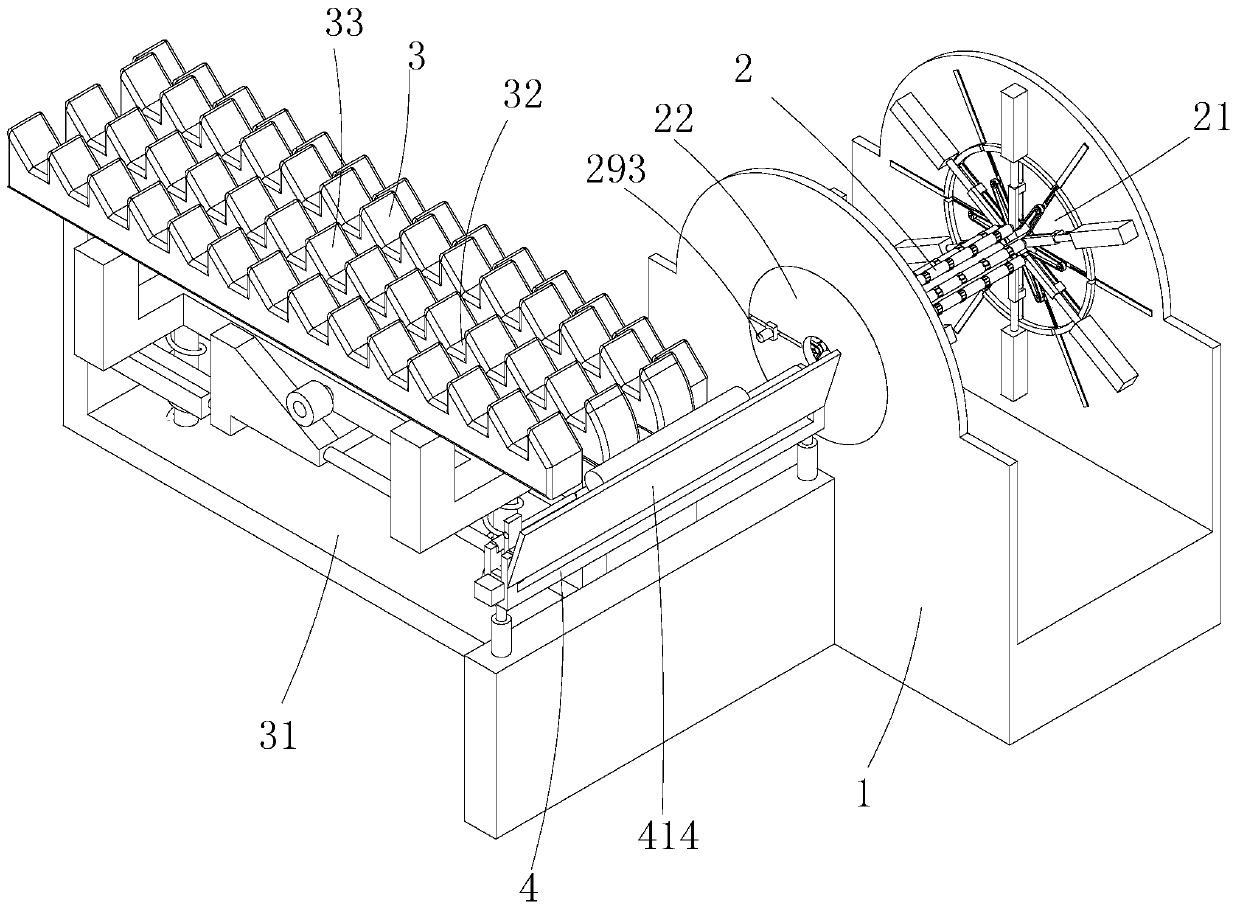

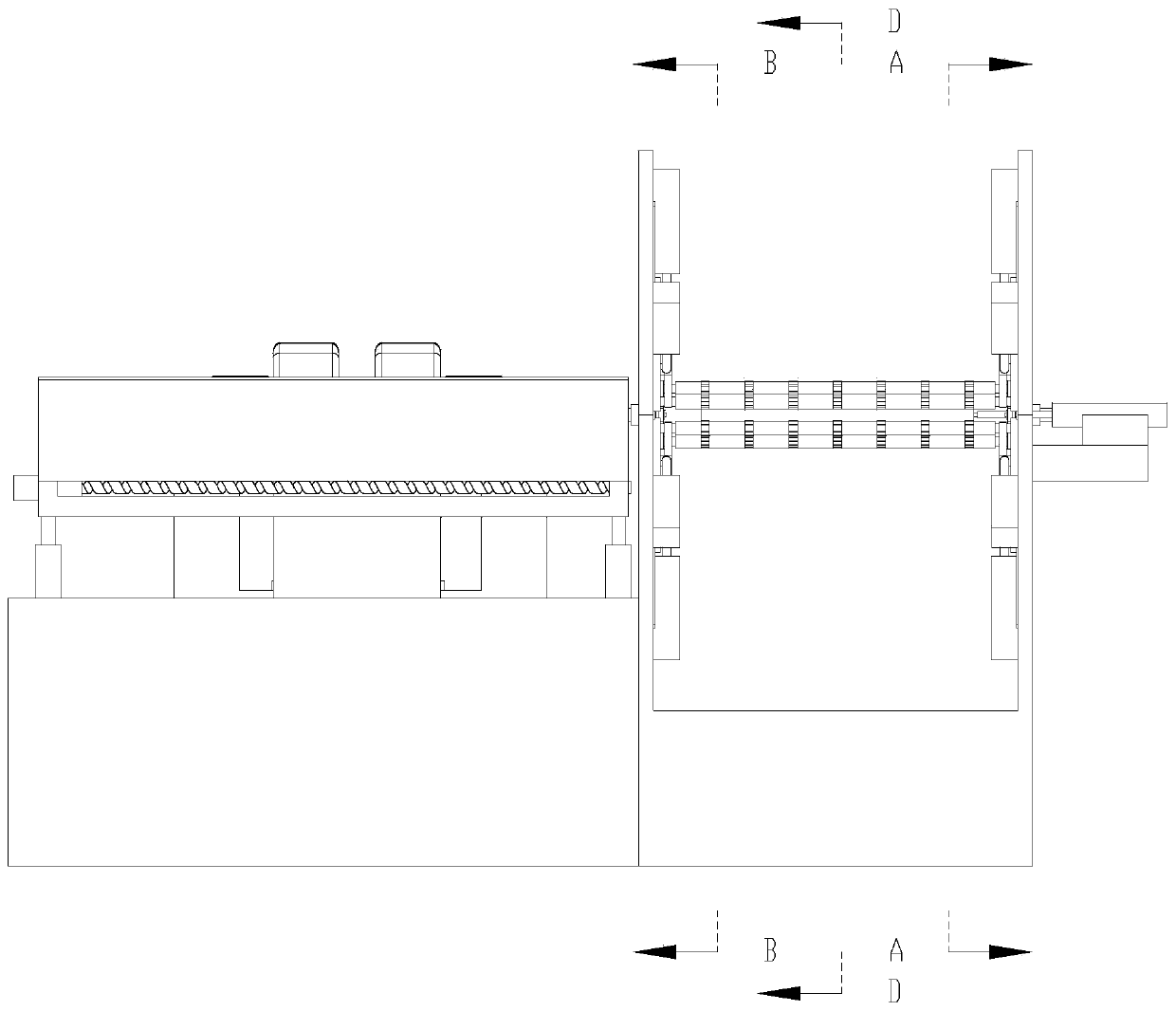

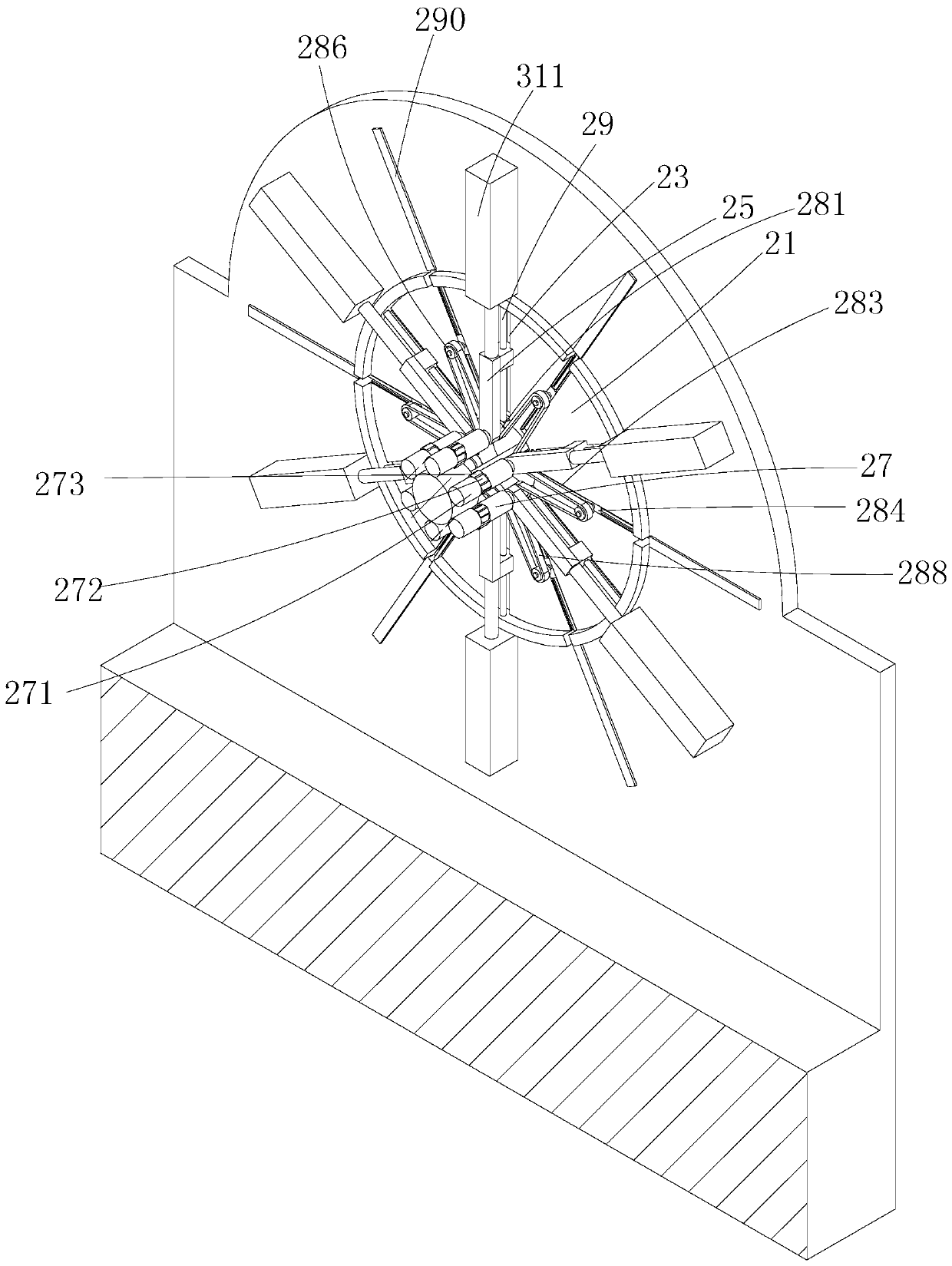

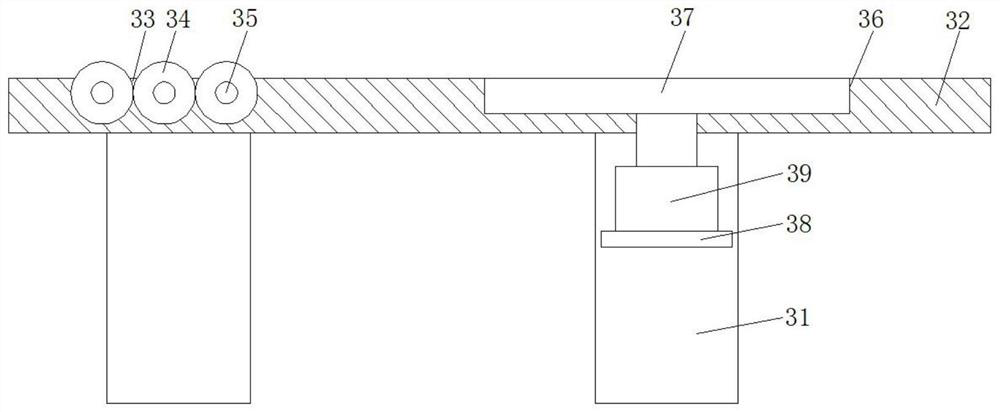

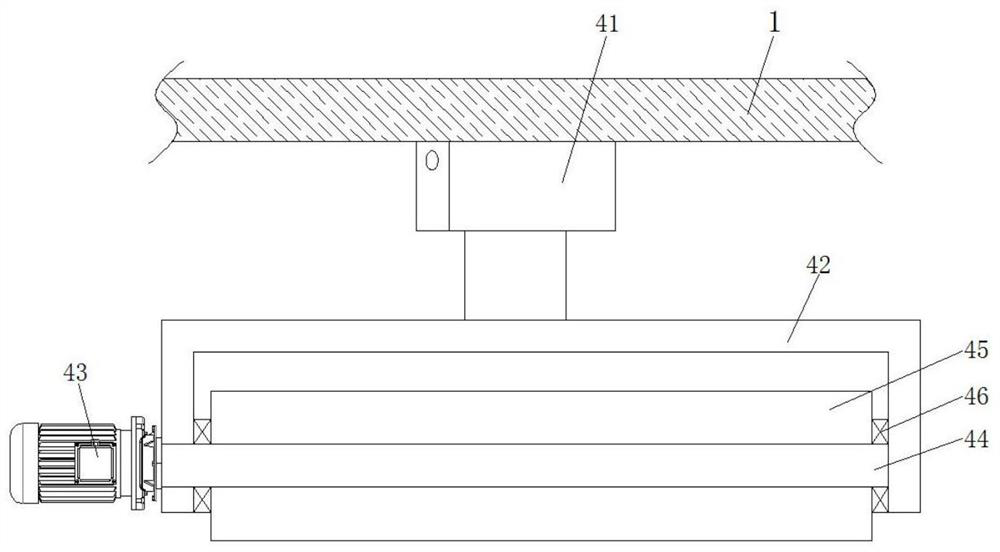

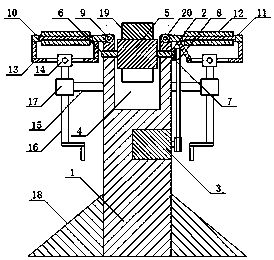

Wood product machining equipment

ActiveCN111571750ARotary cutting holdGuaranteed to move normallyRounding machinesVeneer manufactureHydraulic cylinderMachine

The invention discloses wood product machining equipment. The wood product machining equipment comprises a machine body, a transmission device arranged on the machine body and used for rotating logs,a conveying device used for conveying the logs and pushing devices arranged at the two ends of the transmission device, wherein the transmission device comprises a first base, a second base, a plurality of first sliding grooves annularly distributed in the first base at equal intervals, a plurality of second sliding grooves annularly distributed in the second base at equal intervals, a plurality of first sliding bases movably arranged on the plurality of first sliding grooves respectively, a plurality of second sliding bases movably arranged on the plurality of second sliding grooves respectively, a plurality of driving rollers with the two ends rotationally arranged on the plurality of first sliding bases and the plurality of second sliding bases correspondingly, a driving assembly for driving the plurality of driving rollers to rotate in the same direction, a plurality of first hydraulic cylinders for driving the plurality of first sliding bases to move and a plurality of second hydraulic cylinders for driving the second sliding bases to move. According to the wood product machining equipment, waste of the logs can be greatly reduced, and the rotating efficiency of the logs and the surface quality of veneers obtained after rotary cutting are ensured.

Owner:浙江景宁华寅工艺品有限公司

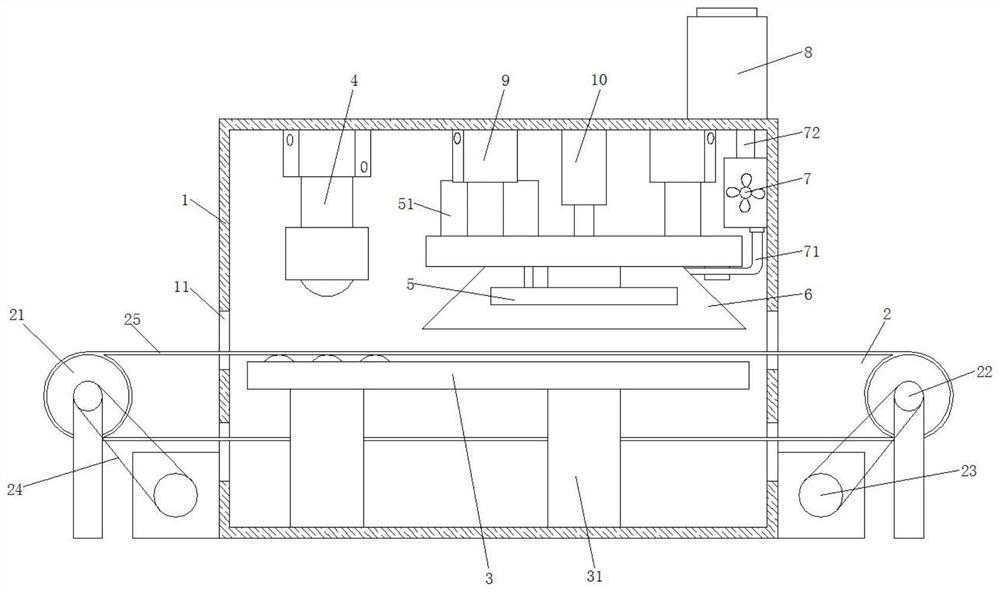

Hot press for woodware and working principle thereof

ActiveCN112092116AImprove product qualityGuaranteed flatnessGas treatmentPlywood pressesTransfer mechanismConveyor belt

The invention discloses a hot press for woodware and a working principle thereof and relates to the technical field of woodware processing equipment. The hot press for woodware comprises a work box, atransfer mechanism, a supporting mechanism, a leveling mechanism, a hot press mechanism, a protecting hood, an induced draft fan and an ai purification pipe. The work box is arranged as a hollow boxbody structure, and meanwhile, a conveyor belt in the transfer mechanism passes through externally from the work box. A workpiece is conveyed into the work box through the conveyor belt, the levelingmechanism is arranged at the front end of the hot press mechanism, a leveling air cylinder is started to move a leveling roller to the upper surface of the workpiece when the hot press mechanism carries out hot pressing on the woodware workpiece, and the workpiece is leveled in the transfer process, so that the contact levelness of a panel is ensured, a condition that air exists at a connection oftwo panels is avoided, a normal hot pressing operation is ensured, and the production quality of the woodware is improved. Meanwhile, exhuast gas is purified in the air purification pipe, so that influence of the exhaust gas on the environment is reduced effectively, and the device is more environmental-friendly.

Owner:和县薛氏木制品制造有限公司

Processing technology for improving anti-corrosion protection effect of carbonization layer on surface of wooden craft

InactiveCN112356200AImprove protectionImprove toughnessPressure impregnationWood charring/burningCarbon fibersAcrylonitrile

The invention discloses a processing technology for improving the anti-corrosion protection effect of a carbonization layer on the surface of a wooden craft, and relates to the technical field of wooden product processing, and the specific technology is as follows: 1) performing surface carbonization treatment on the wooden craft; 2) preparing composite carbon fibers from molybdenum oxide powder,pre-oxidized polyacrylonitrile fibers and sulfur powder; 3) performing modification treatment on the composite carbon fibers; and (4) carrying out dipping treatment on the surface carbonized wood craft by utilizing the modified composite carbon fiber dispersion liquid by adopting a vacuum pressure dipping process. According to the invention, the modified composite carbon fibers permeate into the surface carbonization layer of the wooden craft, a wood fiber pipe wall is used as a loading matrix, intercalation layers among nanosheets on the surfaces of the modified composite carbon fibers are connected in series, and a continuous carbon fiber network structure is formed in the carbonization layer, so that the toughness of the carbonization layer is improved, the carbonization layer is not liable to break, and the protection effect of the carbonization layer on the wooden craft is improved.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

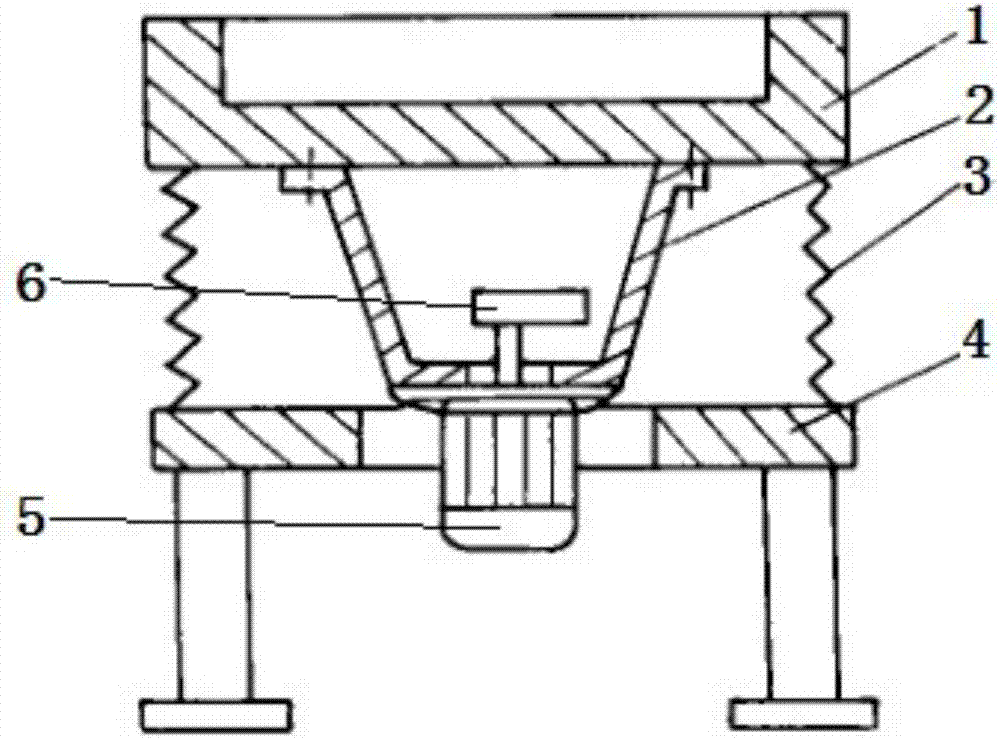

Woodware fine grinding device

PendingCN106903594AImprove work efficiencyMechanizationEdge grinding machinesPolishing machinesEngineeringMaterials science

The invention discloses a woodware fine grinding device. The woodware fine grinding device comprises a grinding basin internally containing a grinding material, a supporting spring for supporting the grinding basin and an eccentric vibration structure for providing vibration for the grinding basin; and the eccentric vibration structure is connected with a supporting disc arranged below a grinding disc. Wee woodware surface fine grinding process mechanization is achieved, and the wee woodware grinding working efficiency is improved.

Owner:YULIN UNIV

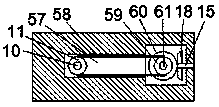

Wire cutting machine for woodwork engraving

InactiveCN112497356AImprove the protective effectEasy to collect and processDispersed particle filtrationTransportation and packagingHydraulic cylinderWire cutting

The invention discloses a wire cutting machine for woodwork engraving. The wire cutting machine comprises a bottom plate, hydraulic cylinders are fixedly connected to the upper surface of the bottom plate, a mounting plate is fixedly connected to the telescopic end of the hydraulic cylinder, a control table, supporting legs, supporting plates, supporting blocks, a motor, an L-shaped plate, a woodchip collecting box and an exhaust fan are fixedly connected to the upper surface of the mounting plate, a working plate is fixedly connected to the top ends of the supporting legs, and the number ofthe supporting plates is two. According to the wire cutting machine for woodwork engraving, through the arrangement of a dust suction pipe, the exhaust fan and an exhaust pipe, wood chips generated during cutting can be sucked out conveniently, through the arrangement of a wood chip filtering box and a wood chip filtering plate, the exhaust fan is protected conveniently, through the arrangement offixing bolts, limiting blocks and the wood chip filtering box, the wood chip filtering plate is replaced conveniently, and through the arrangement of a movable door, collection treatment of the woodchips is facilitated, the wire cutting machine has the function of collecting the wood chips, and the body health of workers is protected.

Owner:德清领千木业有限公司

Grinding and dust collecting device for wooden cabinet production

PendingCN113458924ALarge grinding areaImprove grinding efficiencyGrinding carriagesGrinding drivesDust controlProcess engineering

The invention relates to a grinding and dust collecting device for wooden cabinet production, in particular to the technical field of wooden product production equipment. The device comprises a grinding rack, a first grinding mechanism, a second grinding mechanism, a dust collection cover, a dust chimney, a first dust removal box, a blow mechanism, a negative pressure dust suction mechanism and a second dust removal box, wherein a diffuser is formed in one end of the first dust removal box; a first air outlet opening is formed in the other end of the first dust removal box; an induced draft fan is installed in the dust chimney; a first dust removal net and a second dust removal net are sequentially arranged in the first dust removal box from one end to the other end; the first air outlet opening is connected with one end of the induced draft fan through a pipeline; the other end of the induced draft fan is connected with one side of the lower portion of the second dust removal box through a pipeline; a spraying pipe is arranged in the second dust removal box; and cyclone guide plates are arranged on the inner walls of the two sides of the second dust removal box below the spraying pipe. According to the device, the grinding efficiency is improved, classified treatment of dust and wood chips is achieved, and waste of resources is reduced.

Owner:福建广昌和木业有限公司

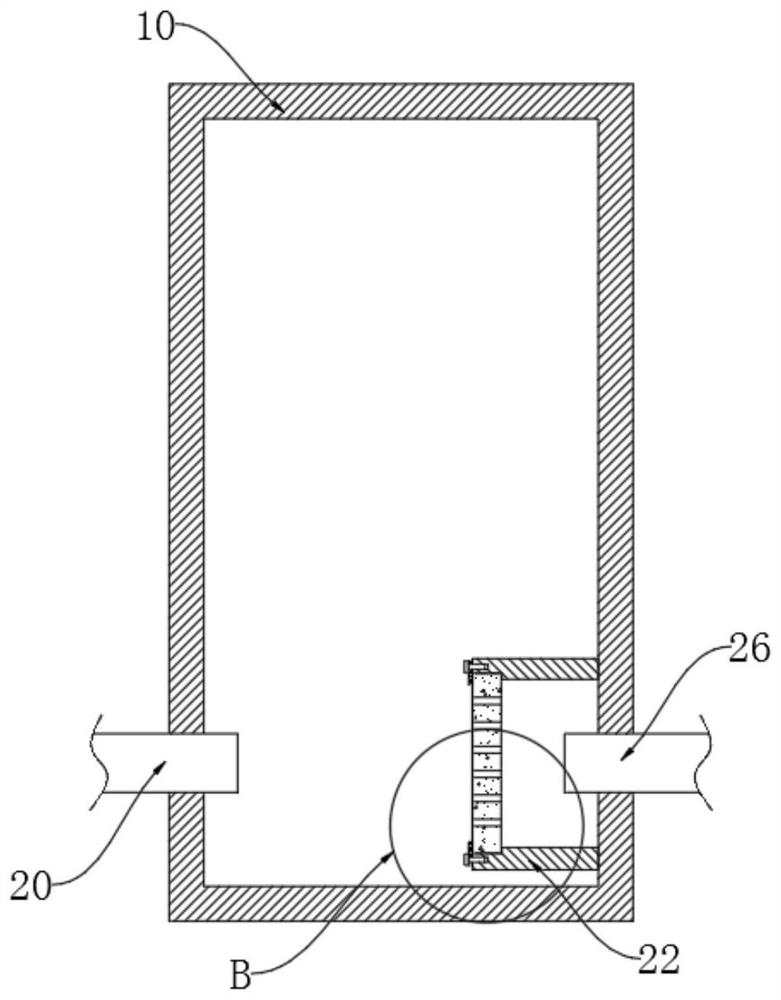

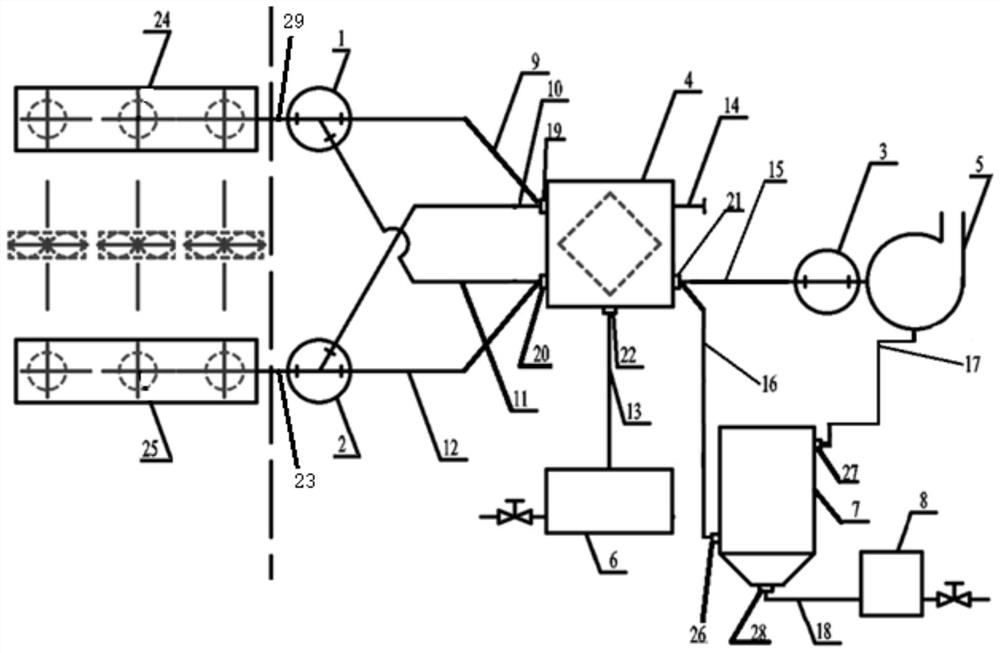

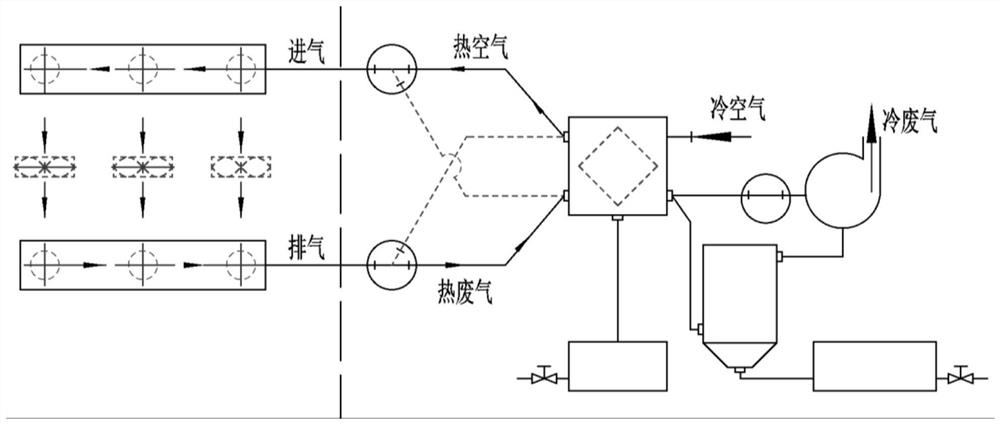

Device for wood drying chamber heat energy recovery and VOC treatment

PendingCN113008015ASimple structureEasy to operateGas treatmentWater contaminantsSolid woodExhaust fumes

The invention discloses a device for wood drying chamber heat energy recovery and VOC treatment. The device for wood drying chamber heat energy recovery and VOC treatment comprises an air inlet and outlet assembly, a heat exchange assembly, a VOC purification assembly and a discharge power assembly, wherein the air inlet and outlet assembly is connected with an air inlet and outlet of a drying chamber and the heat exchange assembly, the VOC purification assembly is connected with the heat exchange assembly and the discharge power assembly, and the heat exchange assembly is connected with the discharge power assembly. According to the device for wood drying chamber heat energy recovery and VOC treatment, the problem that an existing drying chamber is difficult to continuously exhaust moisture and gas under the working condition that a fan rotates at any direction is solved, the heat energy utilization rate in the wood drying process is greatly improved on the premise of guaranteeing the wood drying uniformity, grading treatment is carried out on VOC in waste gas generated in the drying process, and the device for wood drying chamber heat energy recovery and VOC treatment has the advantages of being simple in structure, low in cost, simple in operation method, small in installation difficulty and high in adaptability, can be used in a newly-built drying chamber, and can also be used for conducting energy-saving transformation on the existing drying chamber; the device can be widely applied to wood product manufacturing industries such as solid wood drying, wood product and artificial board processing and the like.

Owner:BEIJING FORESTRY UNIVERSITY

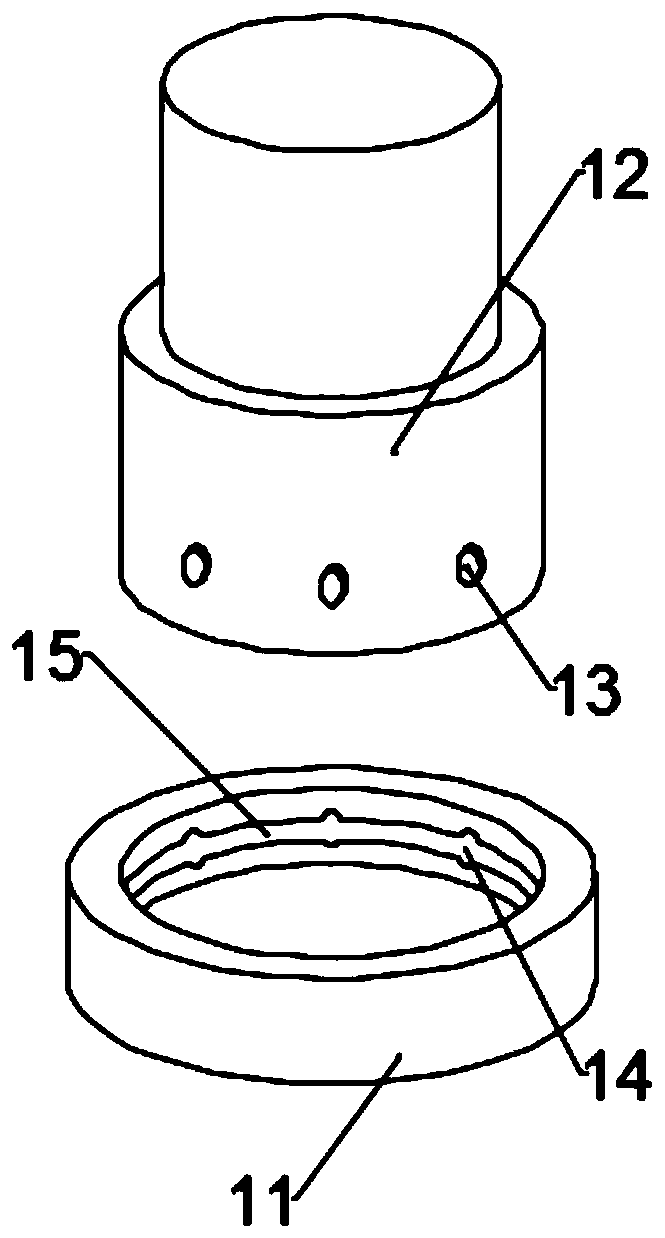

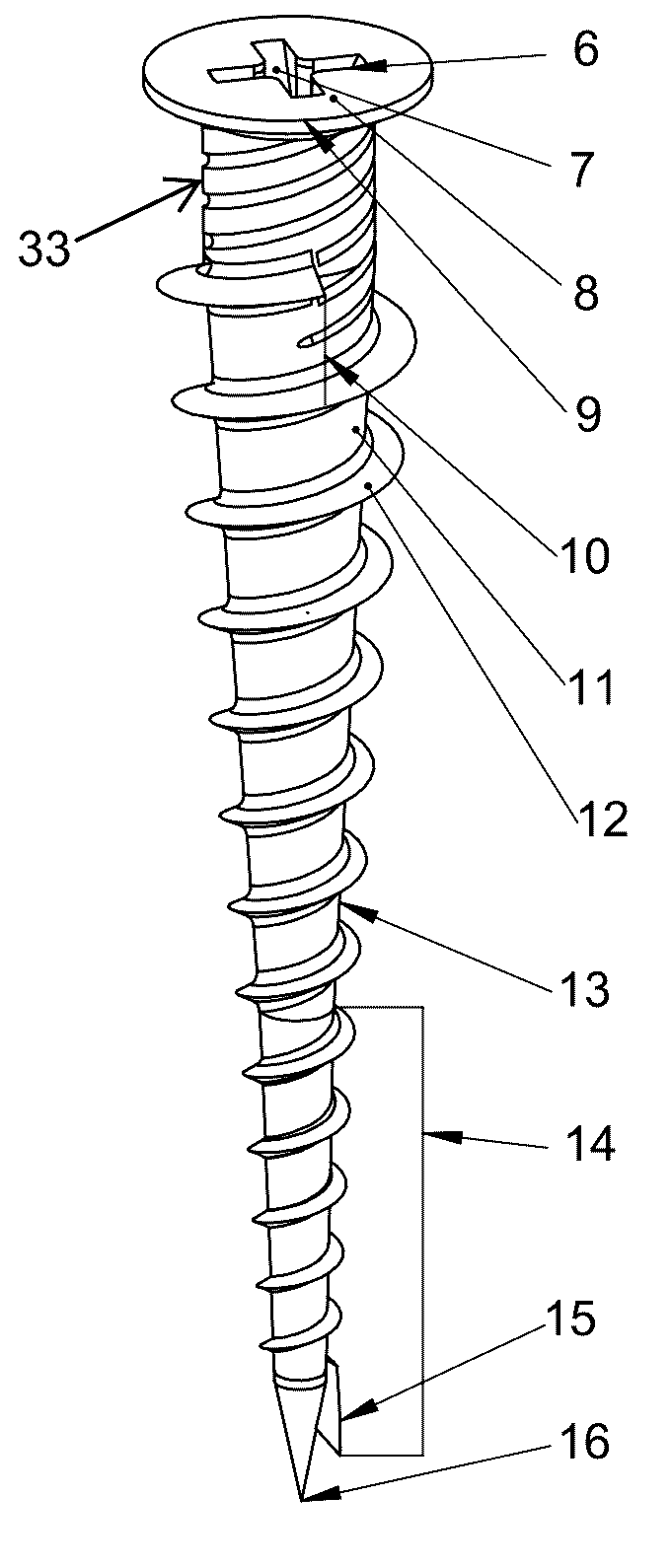

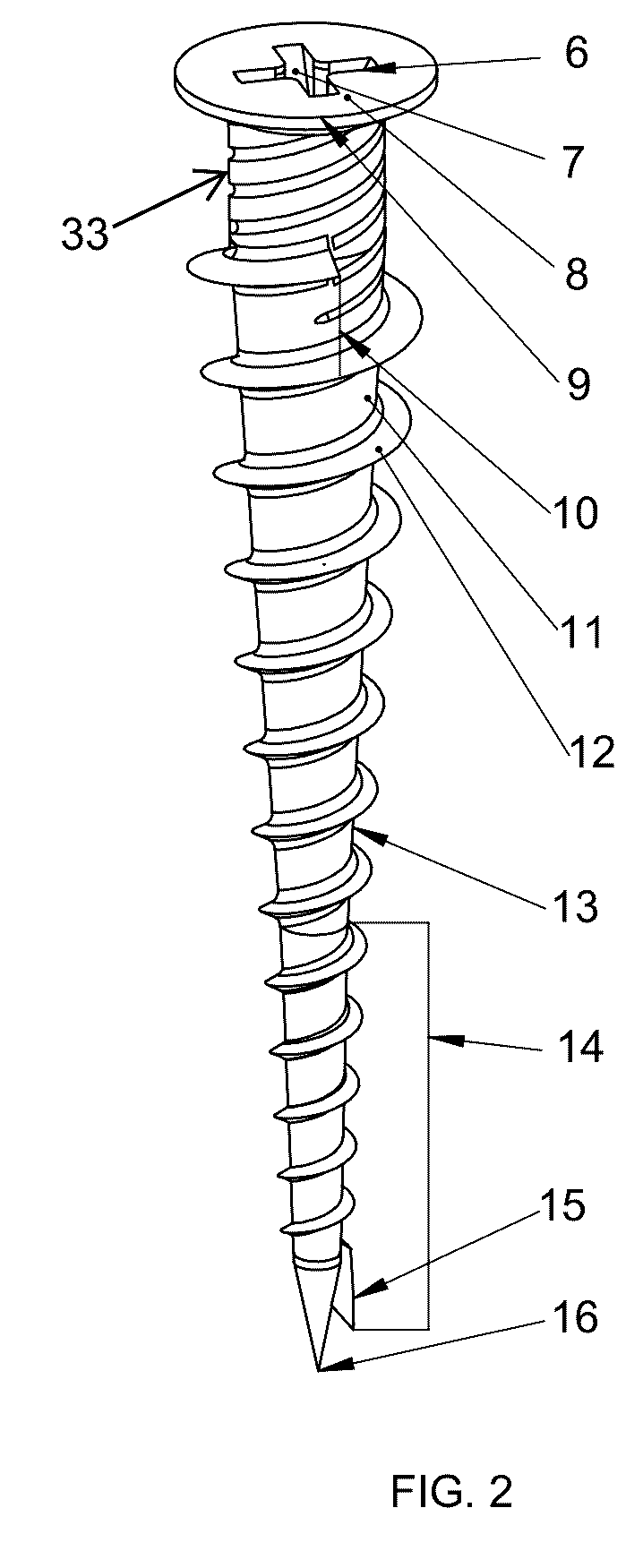

Steel stud anchor

A metal anchoring fastener fastens millwork onto walls constructed with wall cladding fastened to steel studs. The load typical of a loaded cabinet is borne by the steel stud anchors owing to the mate between the profile of the steel stud anchor and the layers of millwork and wall cladding and steel stud that said anchor penetrates. The pitch of the thread adorning the profile of the steel stud anchor progresses non-linearly along the length of said shaft, the shaft is generally non-linear in profile, and the thread profile is non-uniform along the length of said shaft. The anchor can also support a secondary screw concentrically penetrating the void at the center of the anchor, in order to hang loads from a wall, with or without millwork. Predrilling of the holes can enable installation of these zinc anchors.

Owner:CALL FRLIN JIRI +1

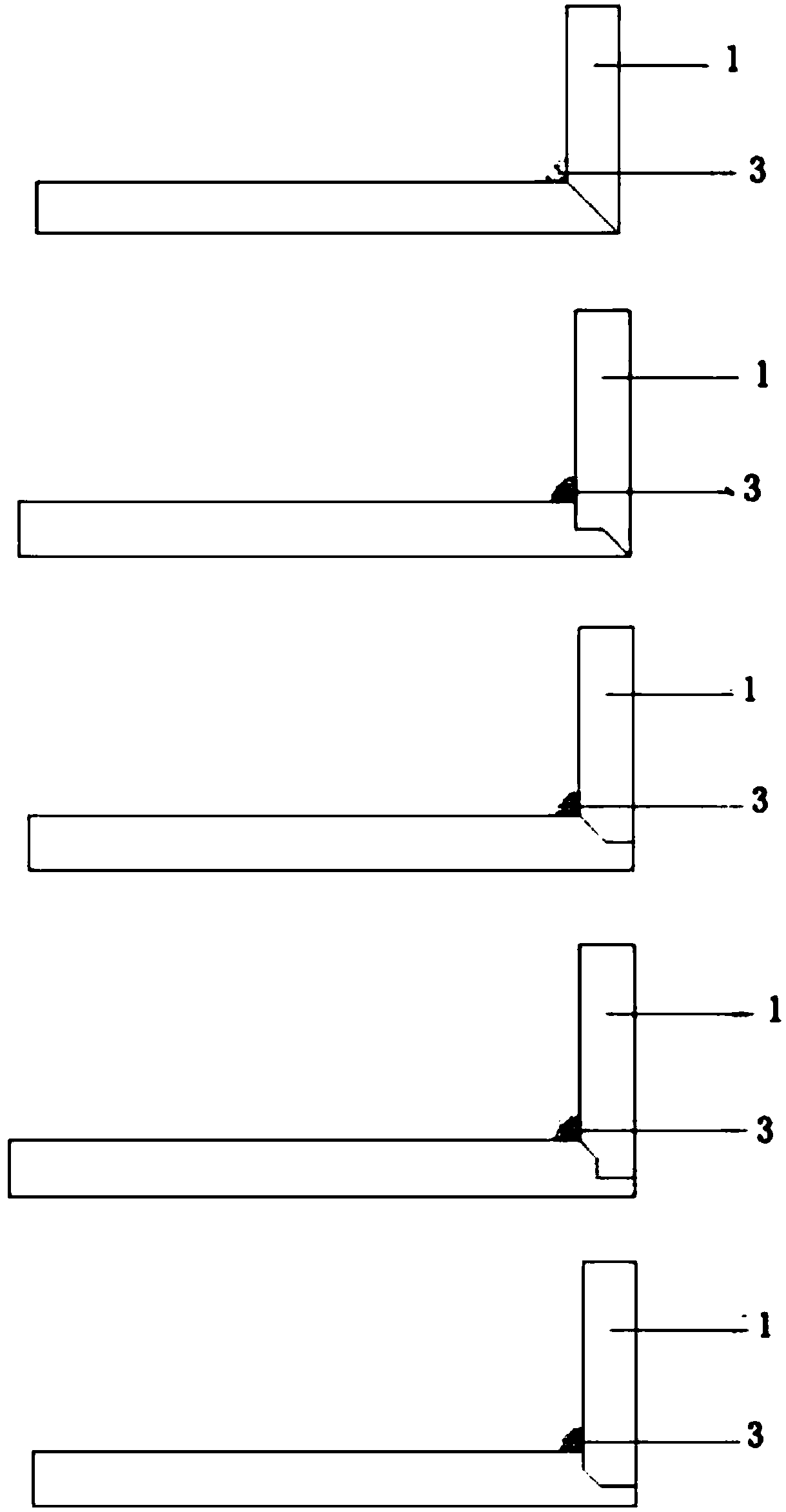

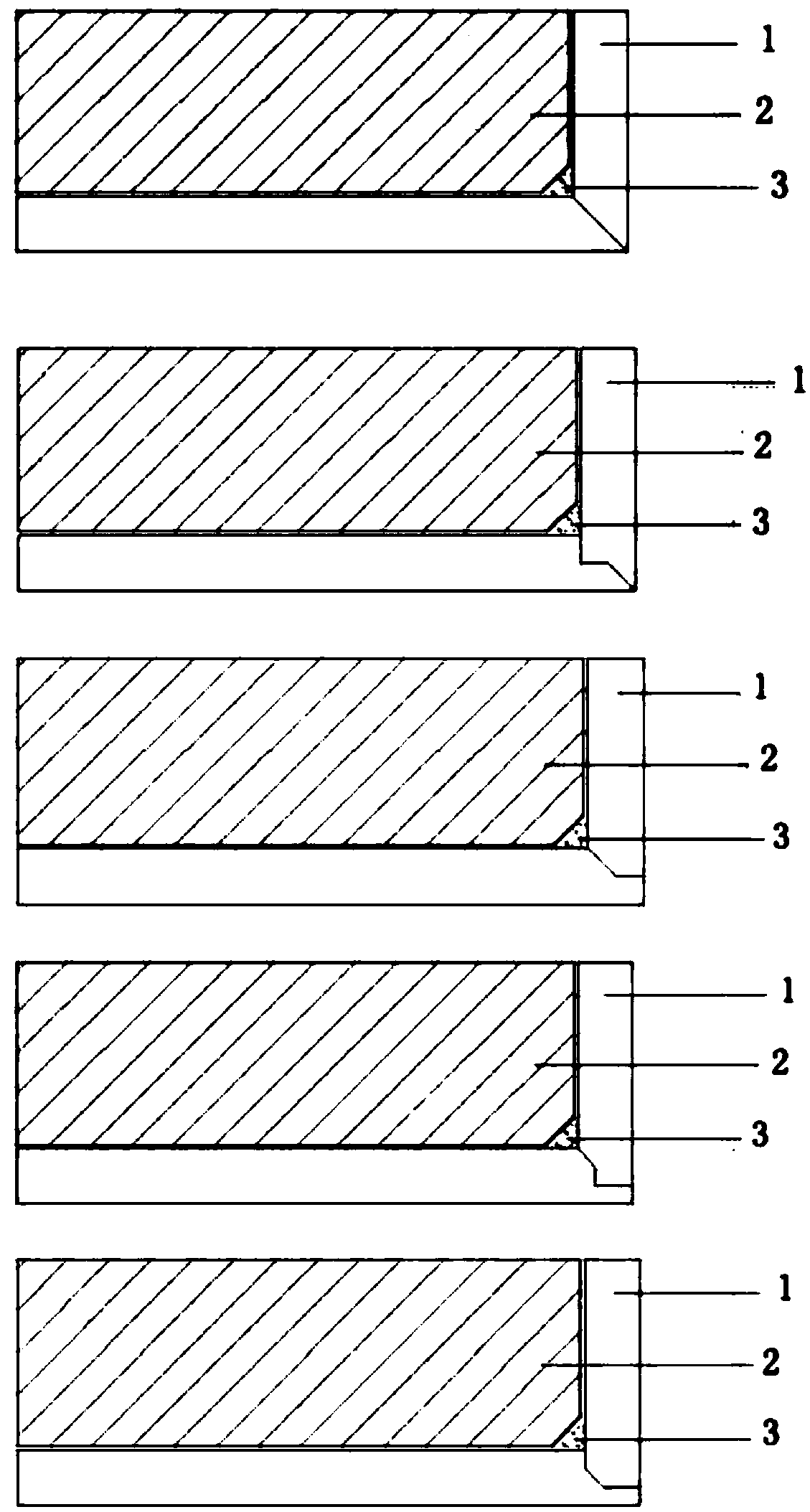

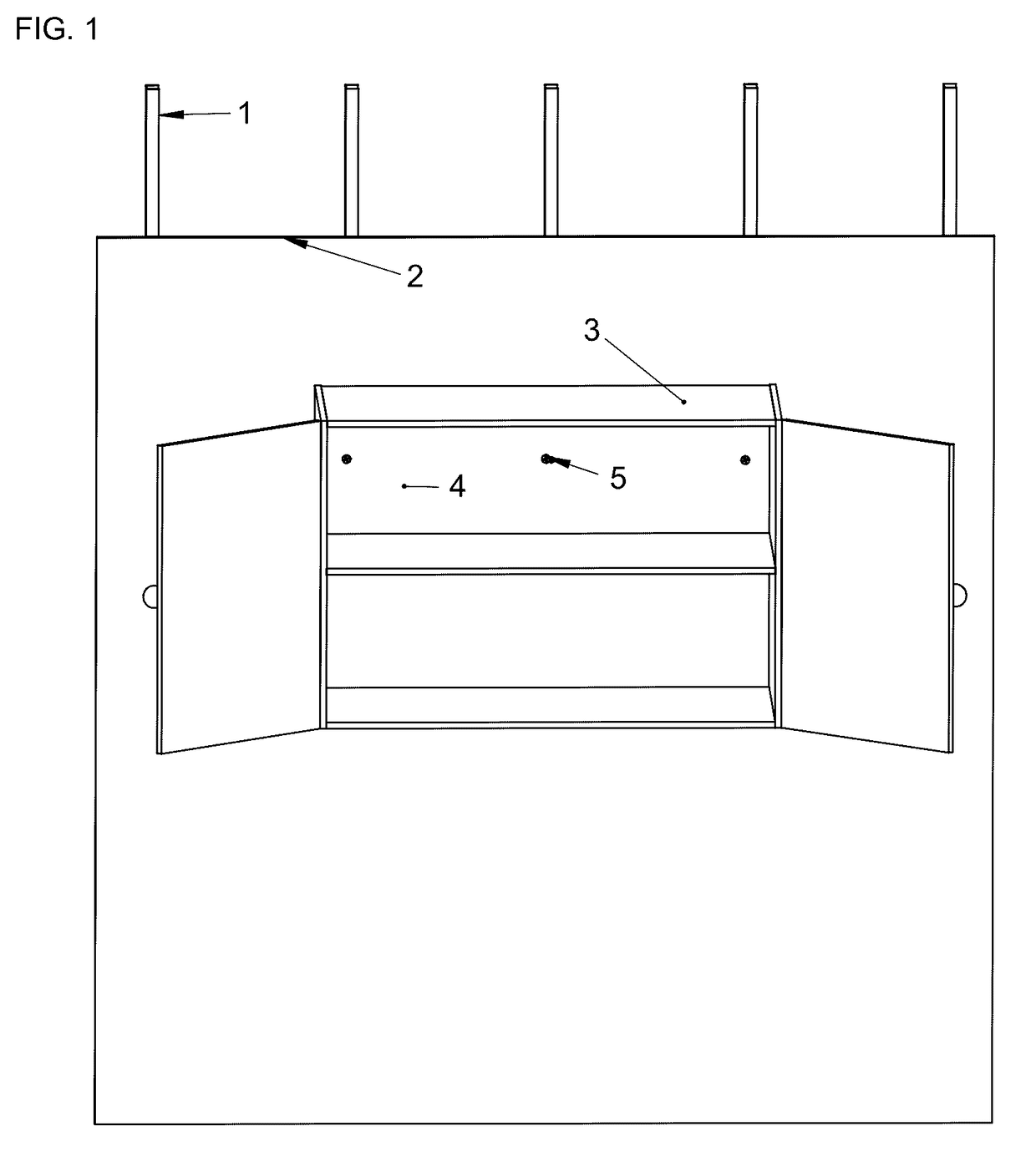

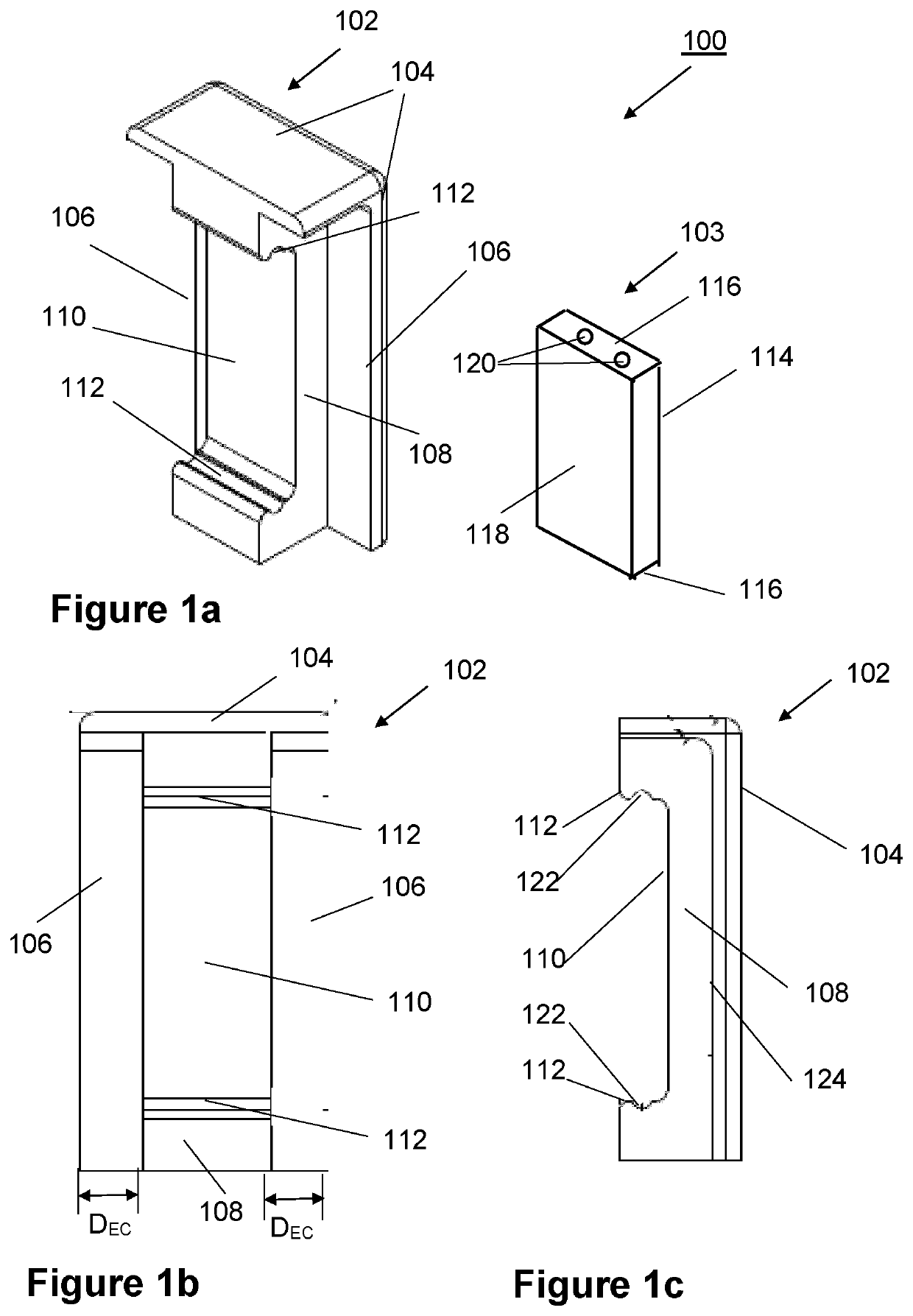

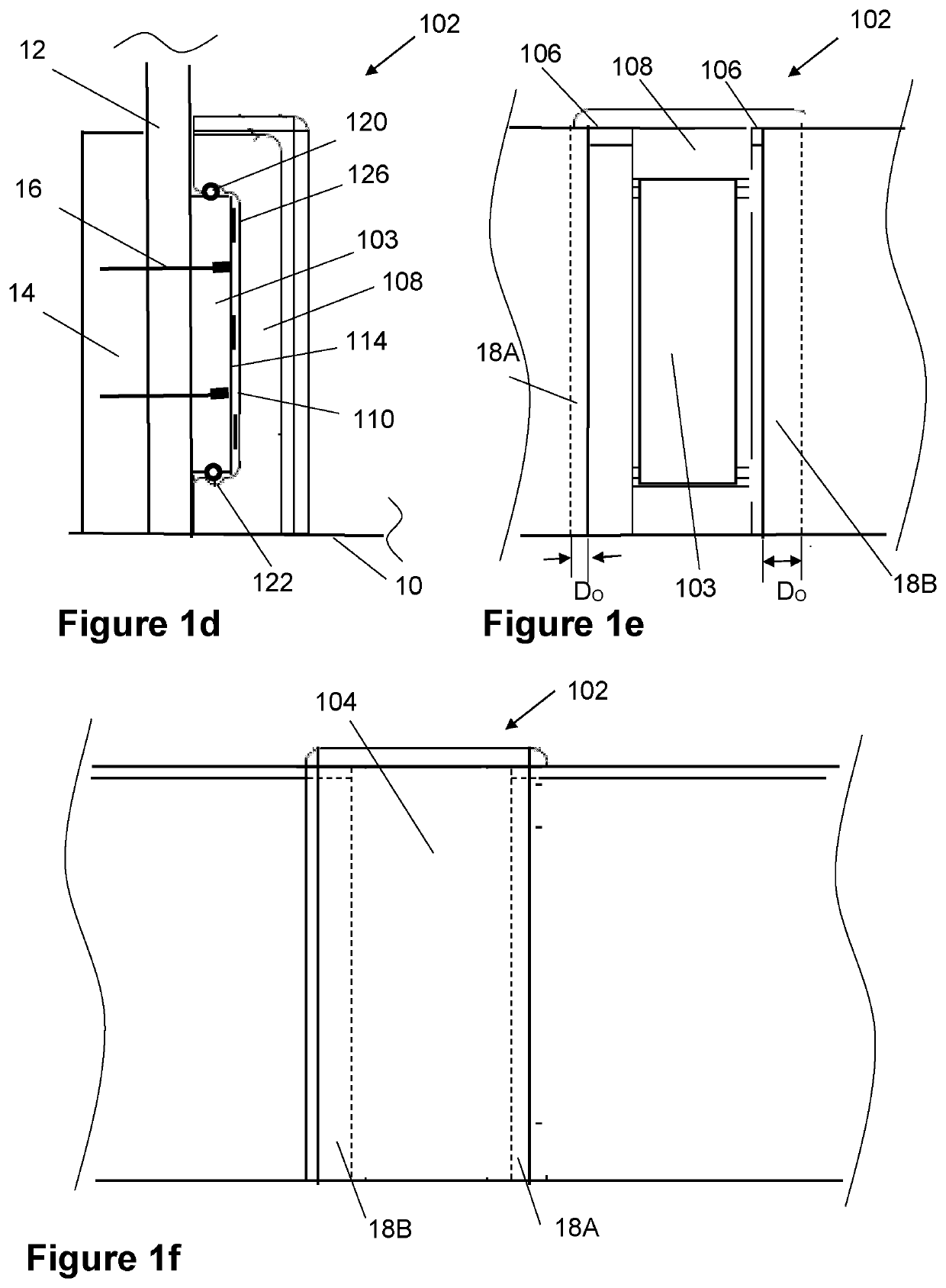

Prefinished and prefabricated corner for single step attachment in millwork applications

A finishing trim piece end cover system for concealing an end portion of at least a finishing trim piece, comprising at least a mounting element having an inner surface, inner side surfaces, and an outer surface. The outer surface of the mounting element is configured to be secured to a building structure. A finishing trim piece end cover element comprises at least an outer surface, at least an inner trim piece end covering portion, and at least an inner mounting portion. The inner surface and inner side surfaces of the at least an inner mounting portion are configured to receive the inner surface and inner side surfaces of the at least a mounting element, respectively, installable on the at least a mounting element. The mounting element and the end portion of the at least a finishing trim piece are substantially concealed by the finishing trim piece end cover element.

Owner:WILLIAMS TERRY +1

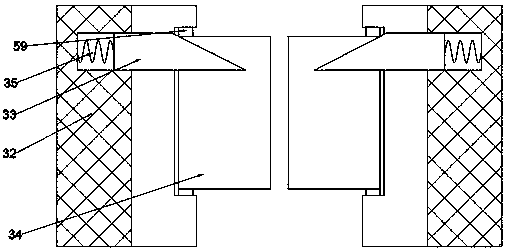

Automatic impact driving device for nails

InactiveCN110733001AAccurate tappingGuaranteed to be verticalStapling toolsDispensing apparatusElectric machineryEngineering

The invention discloses an automatic impact driving device for nails. The automatic impact driving device comprises a machine body, the machine body 10 is internally provided with a nail hammer cavity66, and the lower side of the nail hammer cavity 66 communicates with the outside; the nail hammer cavity 66 is internally provided with a nail hammer device 69 for hitting the nails; the nail hammerdevice 69 comprises a main motor 11 fixedly installed on the upper side wall of the nail hammer cavity 66, the lower side of the main motor 11 is in power connection with a motor shaft 12, and the motor shaft 12 is fixedly provided with a first belt wheel 13; and the upper side wall of the nail hammer cavity 66 is rotationally connected with a first wheel shaft 43, and the first wheel shaft 43 isfixedly provided with a first auxiliary wheel 44. According to the automatic impact driving device for the nails, the nails can be quickly and automatically driven on the premise that the safety is ensured, the machining efficiency of woodwork is improved, and the time is saved.

Owner:浦江县平柜电子科技有限公司

Log conveying device

InactiveCN107662789ASimple structureReasonable designConveyorsPackagingDrive wheelElectric machinery

The invention discloses a log conveying device, and belongs to the field of woodware machining. The log conveying device comprises a cuboid frame, a transmission chain and a driving motor, a longitudinal groove is formed in the top of the cuboid frame of the log conveying device, two or more rotary rolls are evenly arranged in the groove, and shaft rods at the two ends of the rotary rolls are mounted on the side walls of the groove through bearings. One or more axial blades are fixedly mounted on the periphery of each rotary roll, a transmission wheel is arranged on an extending part of the shaft rod at one end of each rotary roll, the transmission wheels are connected through the transmission chain, and a driving wheel is arranged on the extending part of one shaft rod and is in transmission connection with the driving motor fixed to the cuboid frame. The left side of the cuboid frame is in matched connection with a left frame, the right side of the cuboid frame is in matched connection with a right frame, and roll wheels are mounted in the left frame and the right frame. The log conveying device is simple in structure, reasonable in design, convenient to use, especially suitablefor short-distance carrying of logs, low in energy consumption, high in continuity and high in safety, the labor intensity is reduced, and the work efficiency is improved.

Owner:湖州跃盛农业科技有限公司

Antique building wood carving manufacturing and coloring process

InactiveCN111775605AImprove practicalityIncrease diversityOrnamental structuresWood treatment detailsIndustrial engineeringCarving

The invention relates to an antique building wood carving manufacturing and coloring process and relates to the technical field of wood carving manufacturing. The technical problem is that existing buildings are largely decorated with woodwork to highlight the sense of age and the quality of the buildings, but carving needs to be performed on the surfaces of ordinary woodwork and needs to take anengraver a lot of time, and time and labor are consumed. The process comprises the following steps that S1, wood in a vertical shape and of a certain size is selected; S2, the selected wood is dried;S3, bark of the wood is removed; S4, patterns need to be formed on the wood in a carving manner are input into programming software, a carving device is used for performing rough carving on the wood,a rough blank is formed, and then sleeking is performed on the tough blank, so that a fine blank is made; S5, the fine blank is subjected to fungi-proofing and insect-resisting treatment by means of adry storage method; and S6, the treated fine blank is subjected to scraped finishing treatment, and then an unpainted and unbleached wood carving is obtained. The antique building wood carving manufacturing and coloring process has the effects that the woodwork carving efficiency is improved, and manpower consumption is reduced.

Owner:江苏科宇古典园林建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com