Grinding and spraying integrated device for woodware machining

A technology for wood products and equipment, which is applied in the field of integrated grinding and spraying equipment for wood product processing, which can solve the problems that grinding and painting can not be combined, and the processing equipment has a single function, so as to achieve the effect of uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

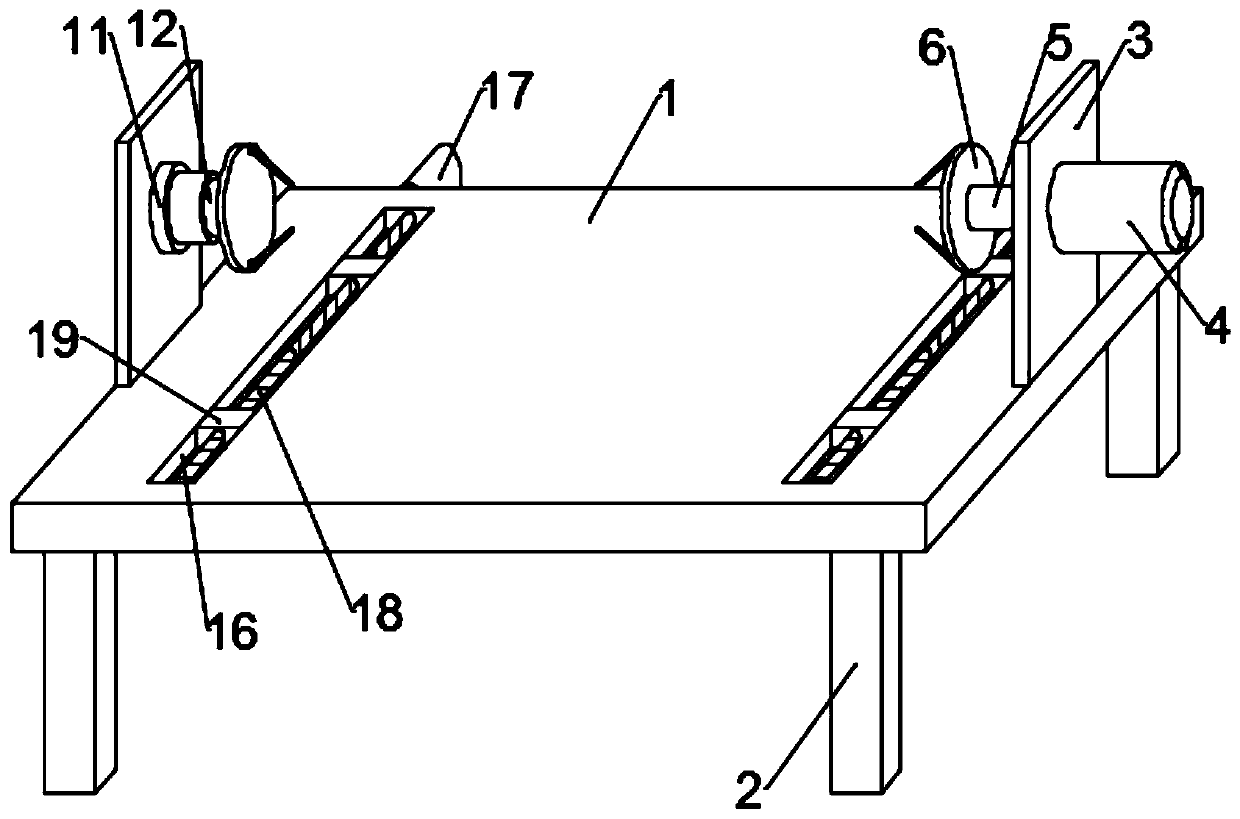

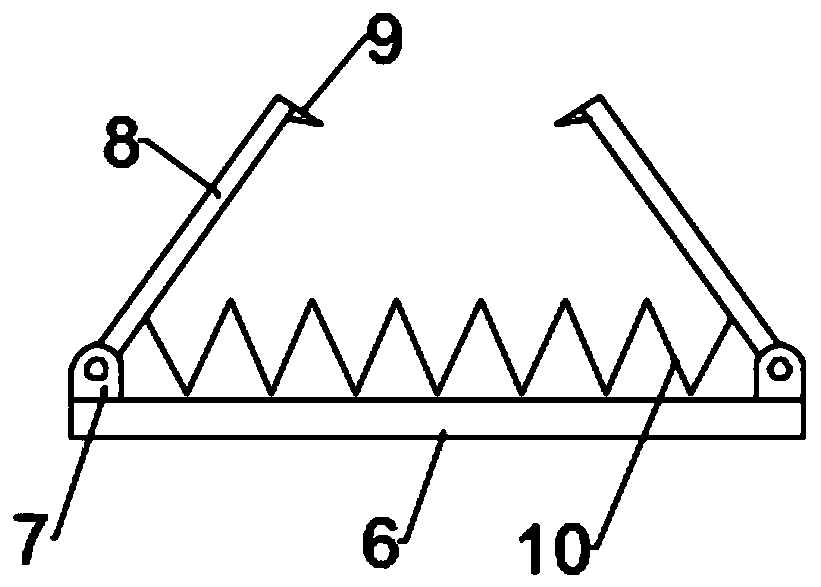

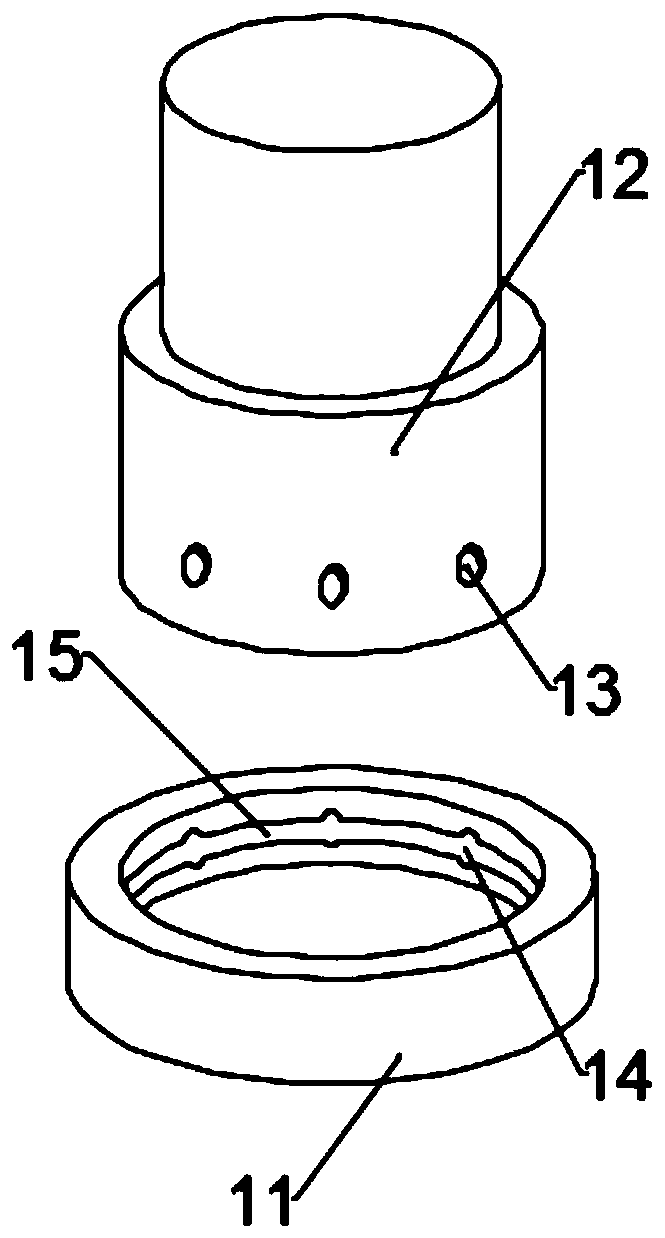

[0035] like Figure 1~5 As shown, the embodiment of the present invention provides an integrated grinding and spraying equipment for processing wood products, the integrated spraying equipment includes a workbench 1, the bottom of the workbench 1 is fixed with support legs 2, and the workbench 1 The upper surface of the upper surface is left and right symmetrically fixed with supporting plates 3, and the inner sides of the two supporting plates 3 are equipped with clamping components; one side of the clamping component is connected with one side of the supporting plate 3 through an active rotating component, and the other side of the clamping component is passed through a passive The rotating assembly is connected with the support plate 3 on the other side; an empty slot 16 is opened on the upper surface of the workbench 1, and an adjustable grinding mechanism is installed inside the empty slot 16; a top plate 22 is fixed on the top of the two support plates 3 , the bottom of ...

Embodiment 2

[0049] like Image 6 As shown, in another embodiment provided by the present invention, the front side and the rear side of the inside of the top plate 22 are provided with a cavity, the bottom of the cavity is provided with a door slot, and the inside of the cavity is equipped with an automatic Sliding door mechanism; the automatic sliding door mechanism includes a rolling door 24, the rolling door 24 is sheathed and fixed on the fixed rod 23, the fixed rod 23 is rotatably installed in the cavity, and one end of the rolling door 24 is connected with a pull Rope 28, the other end of the stay rope 28 passes through the door slot and is connected to the winding roller 27, the winding roller 27 is fixed on the third rotating shaft 26, and the third rotating shaft 26 is connected to the outer wall of the support plate 3 The third motor 25 on the drive is connected.

[0050] Before the wood needs to be painted, start the third motor 25, the third motor 25 drives the winding roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com