Grinding and dust collecting device for wooden cabinet production

A technology for dust collection devices and cabinets, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., which can solve the problems of low grinding efficiency, waste of resources, and inability to realize classified processing, etc., and achieves good dust removal effect and improved Effects of adsorption force, improvement of grinding area and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

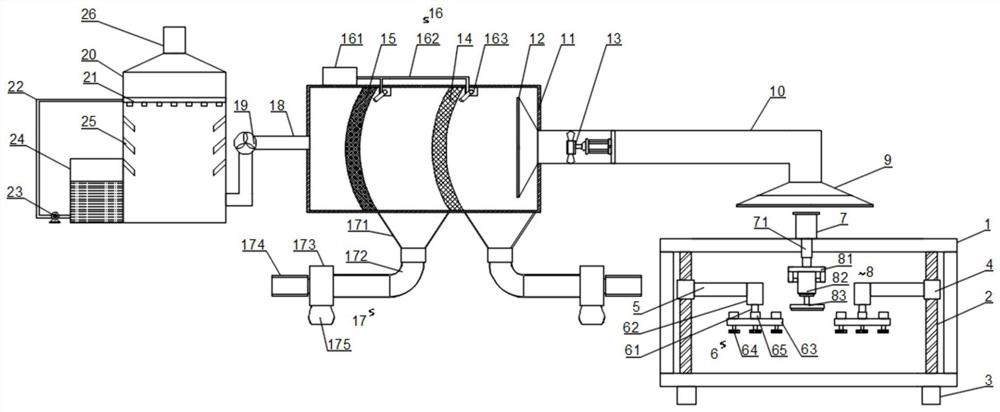

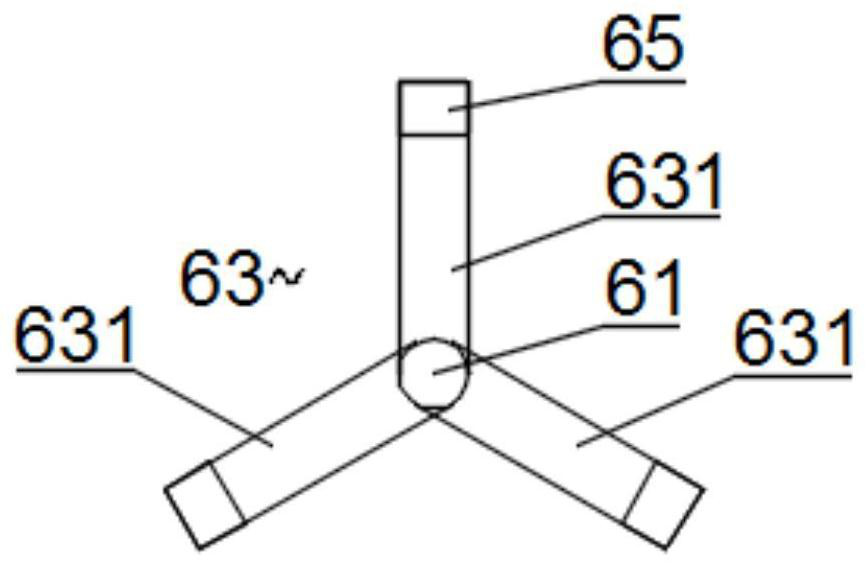

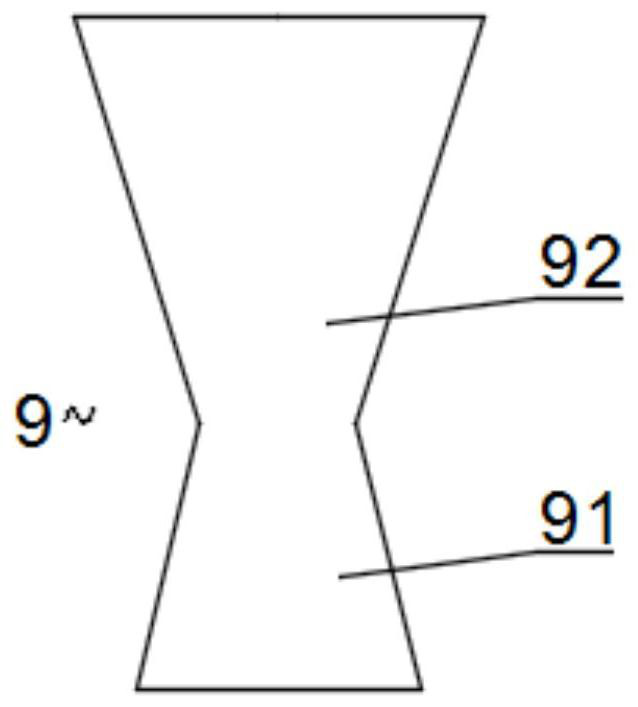

[0027] like Figure 1~3 As shown, a kind of grinding and dust suction device for the production of wooden cabinets according to the present invention includes a grinding frame 1, a first grinding mechanism 6, a second grinding mechanism 8, a dust collection cover 9, a dust discharge pipe 10, a second grinding mechanism A dust removal box 11, an air blowing mechanism 16, a negative pressure dust suction mechanism 17, a second dust removal box 20, the screw rod 2 is installed between the top inner wall and the bottom inner wall of the both sides of the grinding frame 1, the The screw rod 2 is driven by the drive motor 3, the screw rod 2 is connected with a moving block 4 in a threaded manner, one side of the moving block 4 is connected with one end of the moving rod 5, and the other end of the moving rod 5 is connected with a The first grinding mechanism 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com