Patents

Literature

198results about How to "Realize classified collection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beverage bottle recovering device

ActiveCN104443943AAchieving processing powerRealize the collectionRefuse receptaclesEngineeringProcessing cost

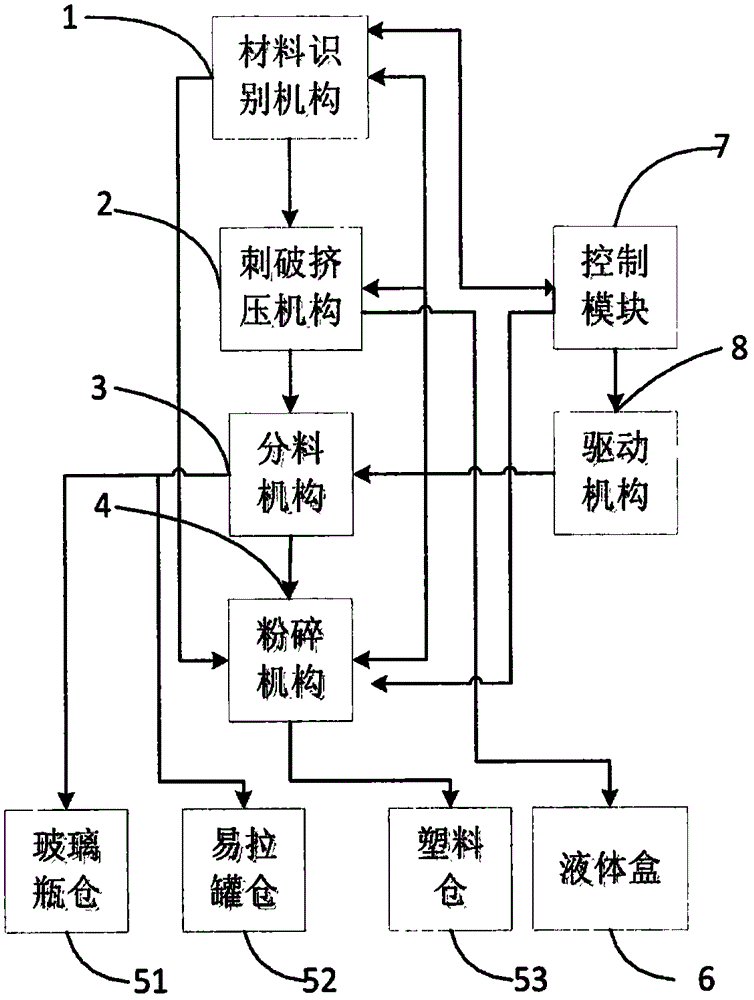

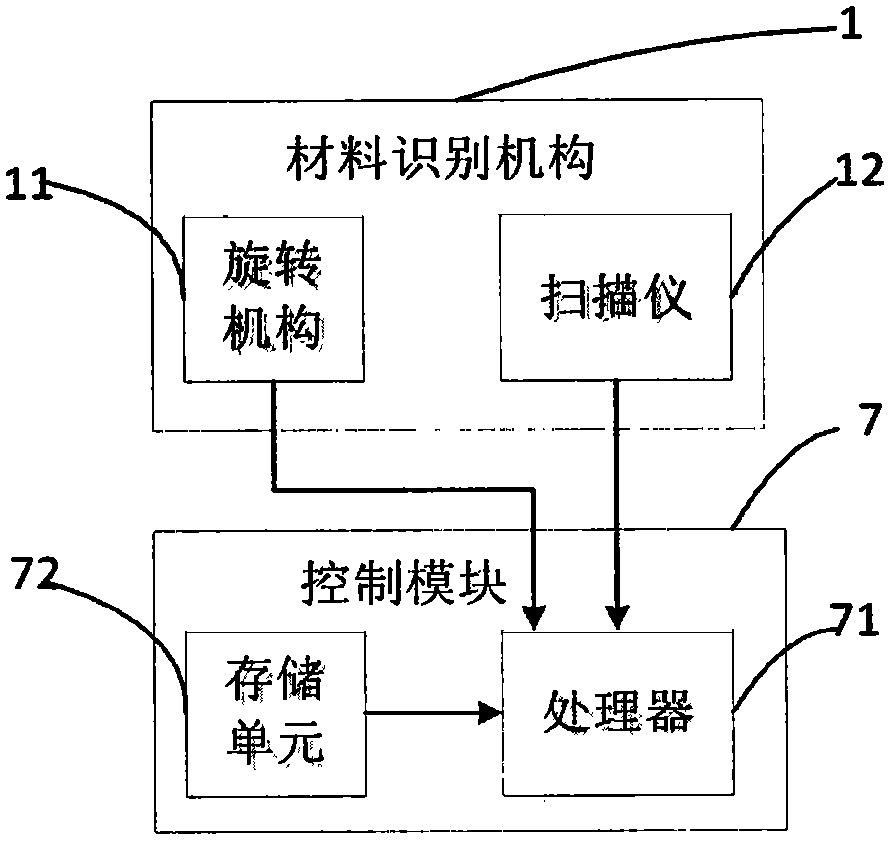

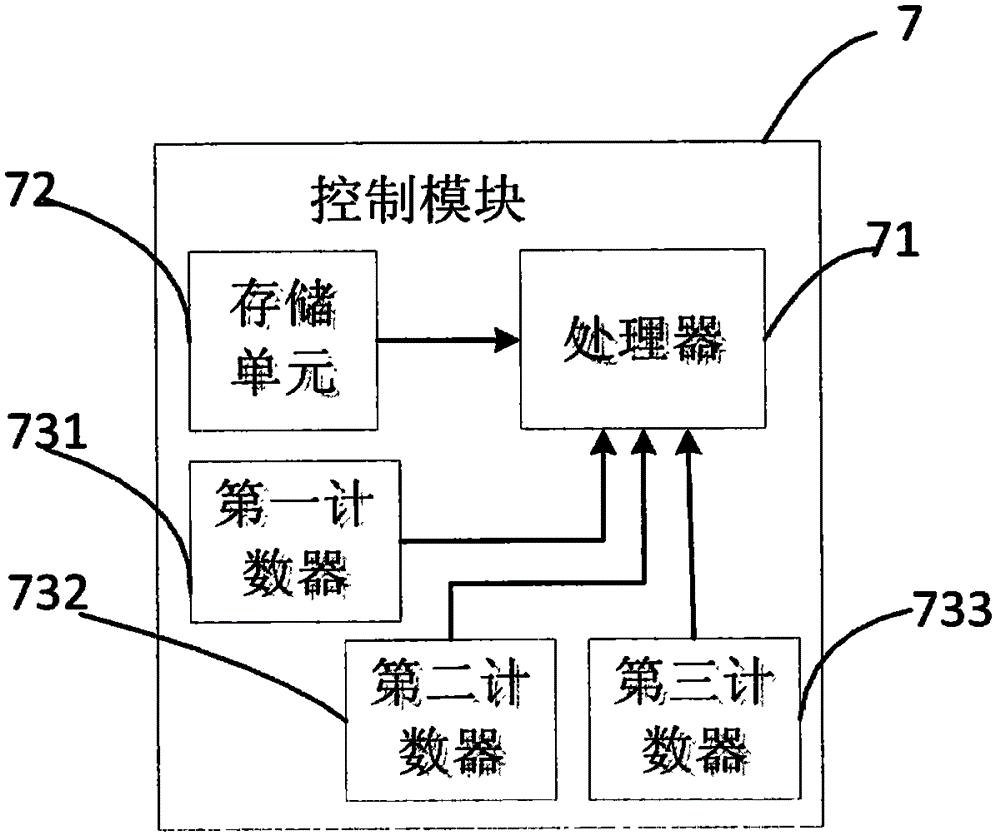

The invention discloses a beverage bottle recovering device which comprises a material recognizing mechanism, a puncturing and extruding mechanism, a material distributing mechanism, a crushing mechanism, a glass bottle bin, a ring-pull can bin, a plastic bin, a liquid box, a control module and a drive mechanism. The material recognizing mechanism is connected with the puncturing and extruding mechanism and the control module. The puncturing and extruding mechanism is connected with the material distributing mechanism and the crushing mechanism. The material distributing mechanism is connected with the glass bottle bin and the ring-pull can bin. The crushing mechanism is connected with the material distributing mechanism, the plastic bin and the control module. The liquid box is communicated with the puncturing and extruding mechanism through a liquid guide pipe. By the adoption of the beverage bottle recovering device, plastic bottles, ring-pull cans and glass bottles can be collected in a classified mode; meanwhile, the ring-pull cans can be pressed flat, the plastic bottles can be crushed, space occupied by materials is reduced, beverage bottles can be processed and collected in the classified mode, the number of the recovered materials is increased, and the processing cost is reduced.

Owner:深圳市利恩信息技术股份有限公司

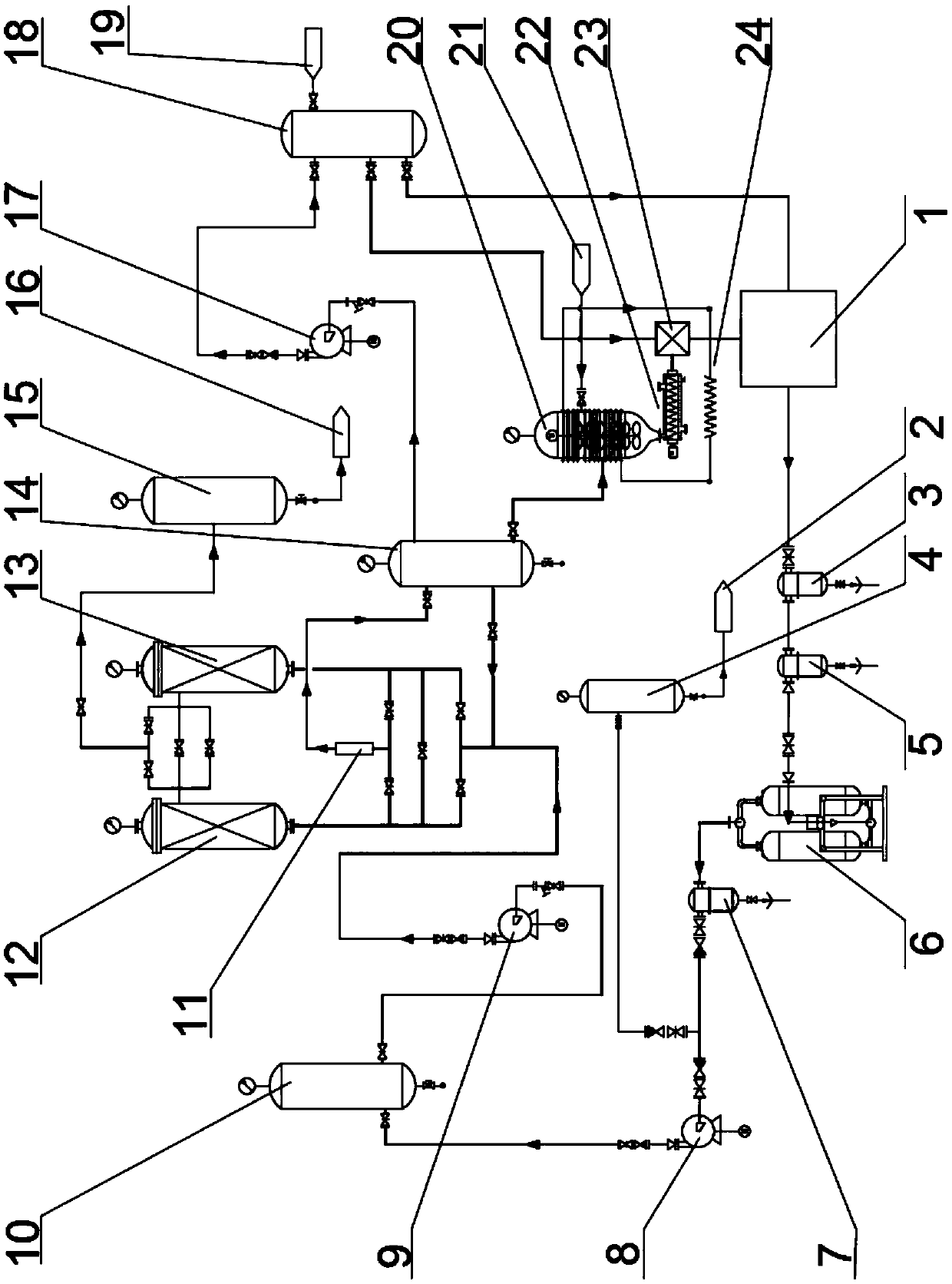

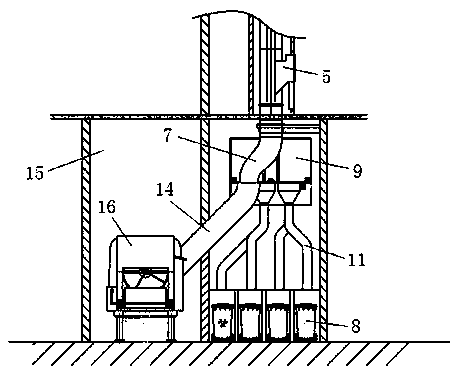

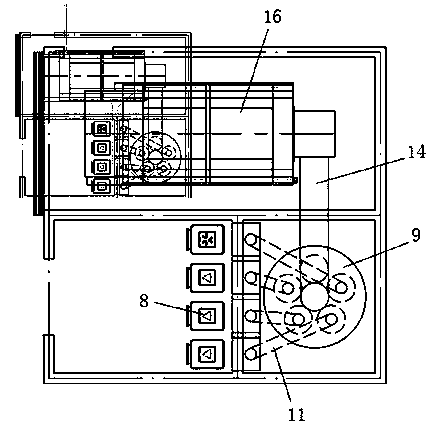

Cleaning waste gas pressure swing adsorption purification and recycling method and device for fusion reactor hot room

ActiveCN105513661AMinimize wasteAchieving classification of by-productsGas treatmentDispersed particle filtrationRadioactive gasCarbon dioxide

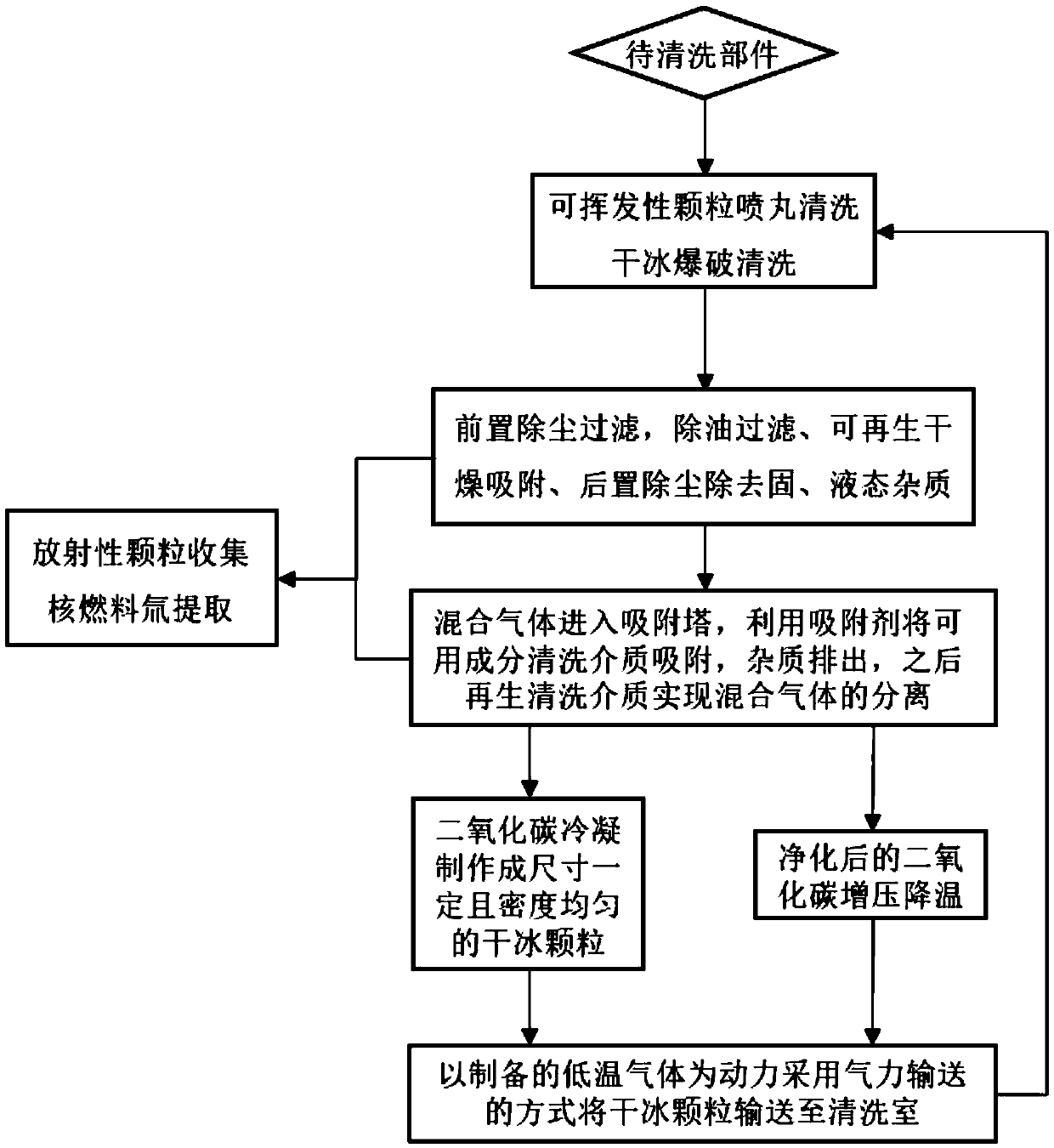

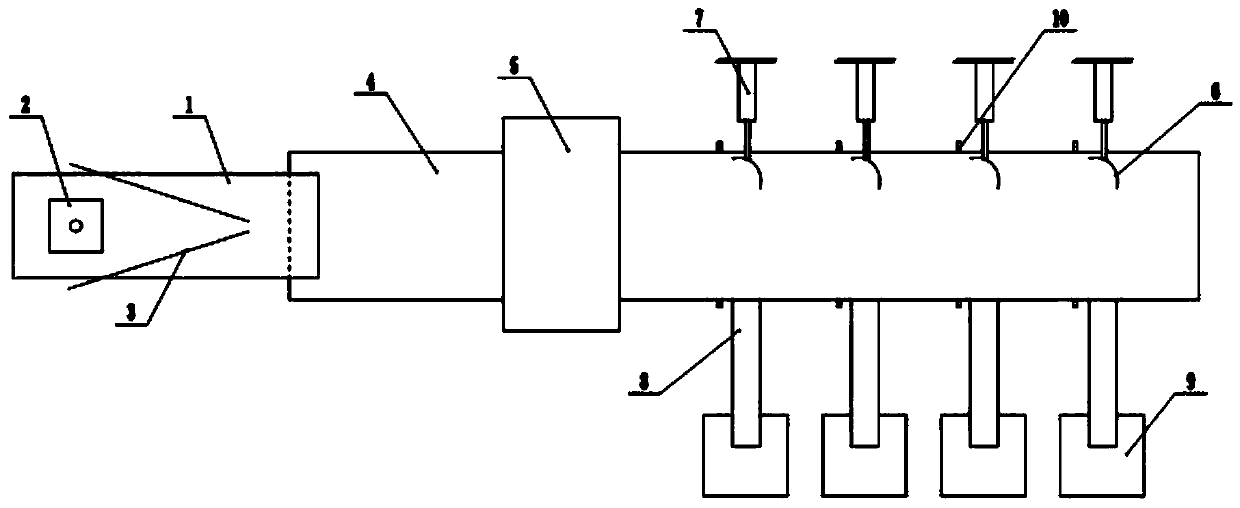

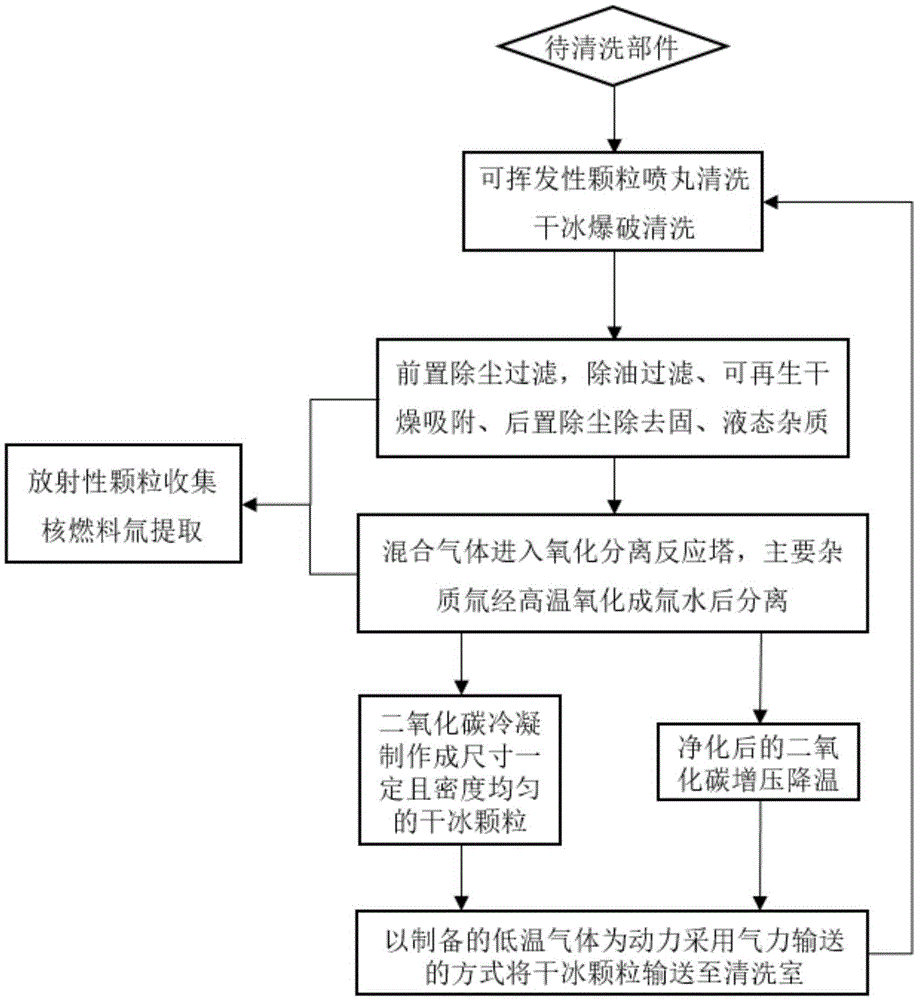

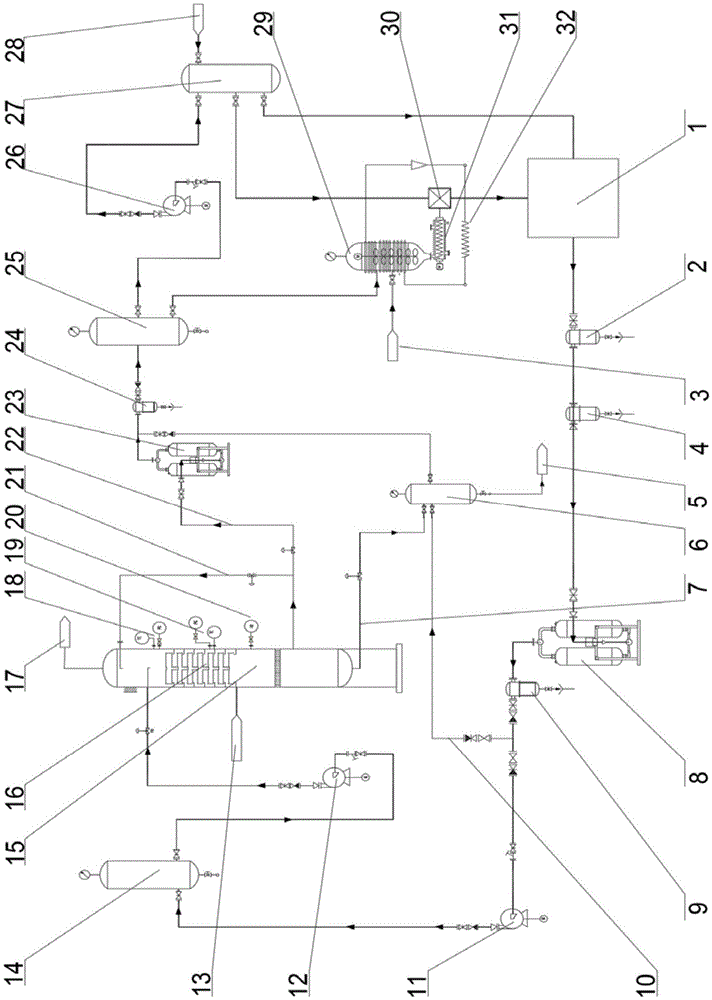

The invention relates to a cleaning waste gas pressure swing adsorption purification and recycling method and device for a fusion reactor hot room. The method includes the technological process of cleaning and contaminating, solid and liquid impurity filtration and purification, cleaning medium adsorption separation and regeneration, low-temperature power gas preparation, volatilizable particle regeneration and volatilizable particle remote-distance pneumatic transport. Fusion reactor hot room cleaning waste gas containing radioactive particles and radioactive gas is processed in a low-risk mode through a multiple filtration and pressure swing adsorption method, and separation, classified collection and recycling of radioactive particles, radioactive gas tritium and a cleaning medium carbon dioxide gas are achieved. The purity of regenerated products is high, no external heat source heating is needed, the gas temperature change range is small, the device is more economical and saves more energy, the service life of adsorbent is long, the device maintenance is easy and convenient, automatic production can be completely achieved, and the method and the device are suitable for the hot room environment remotely controlled and operated.

Owner:UNIV OF SCI & TECH OF CHINA

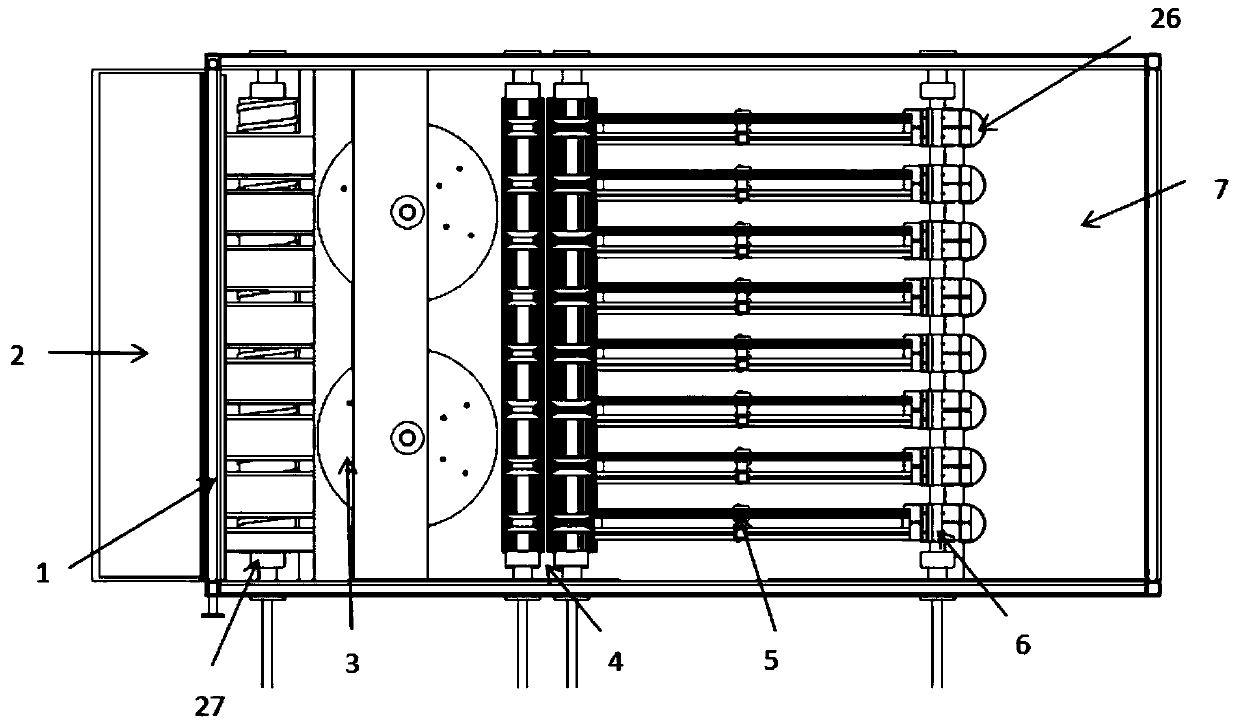

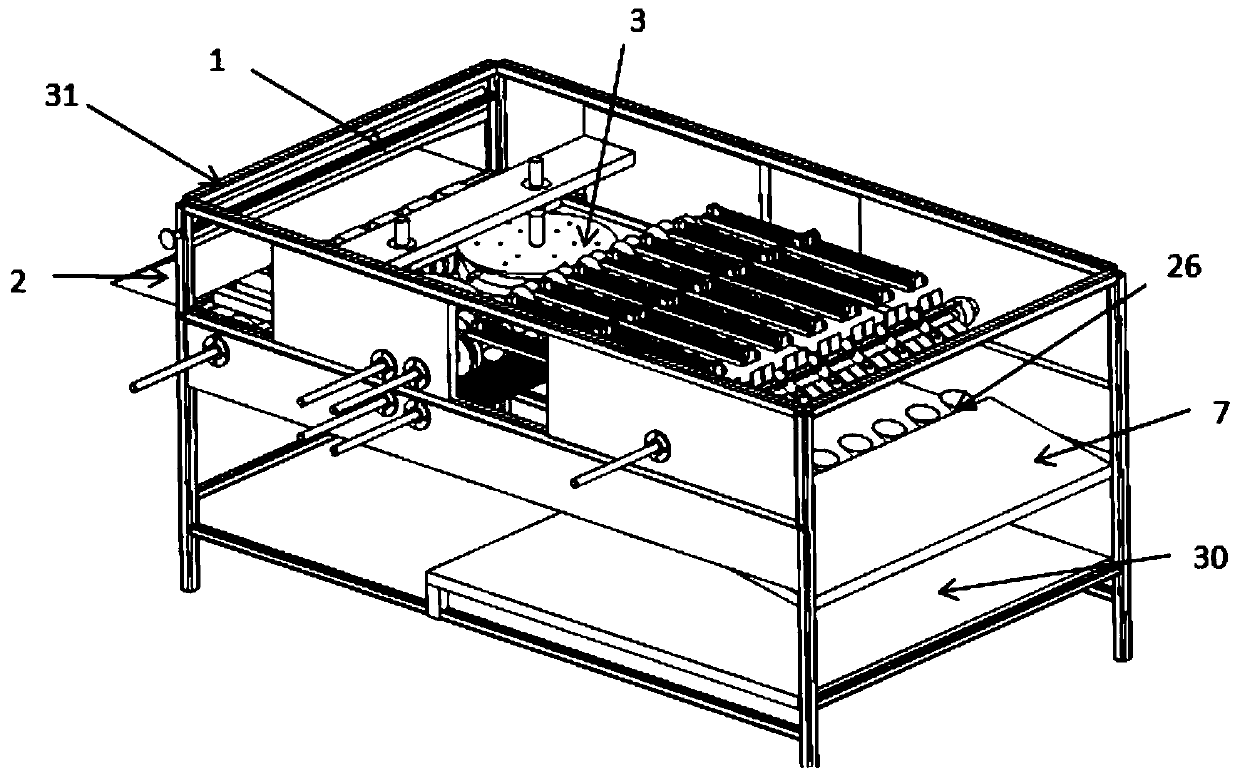

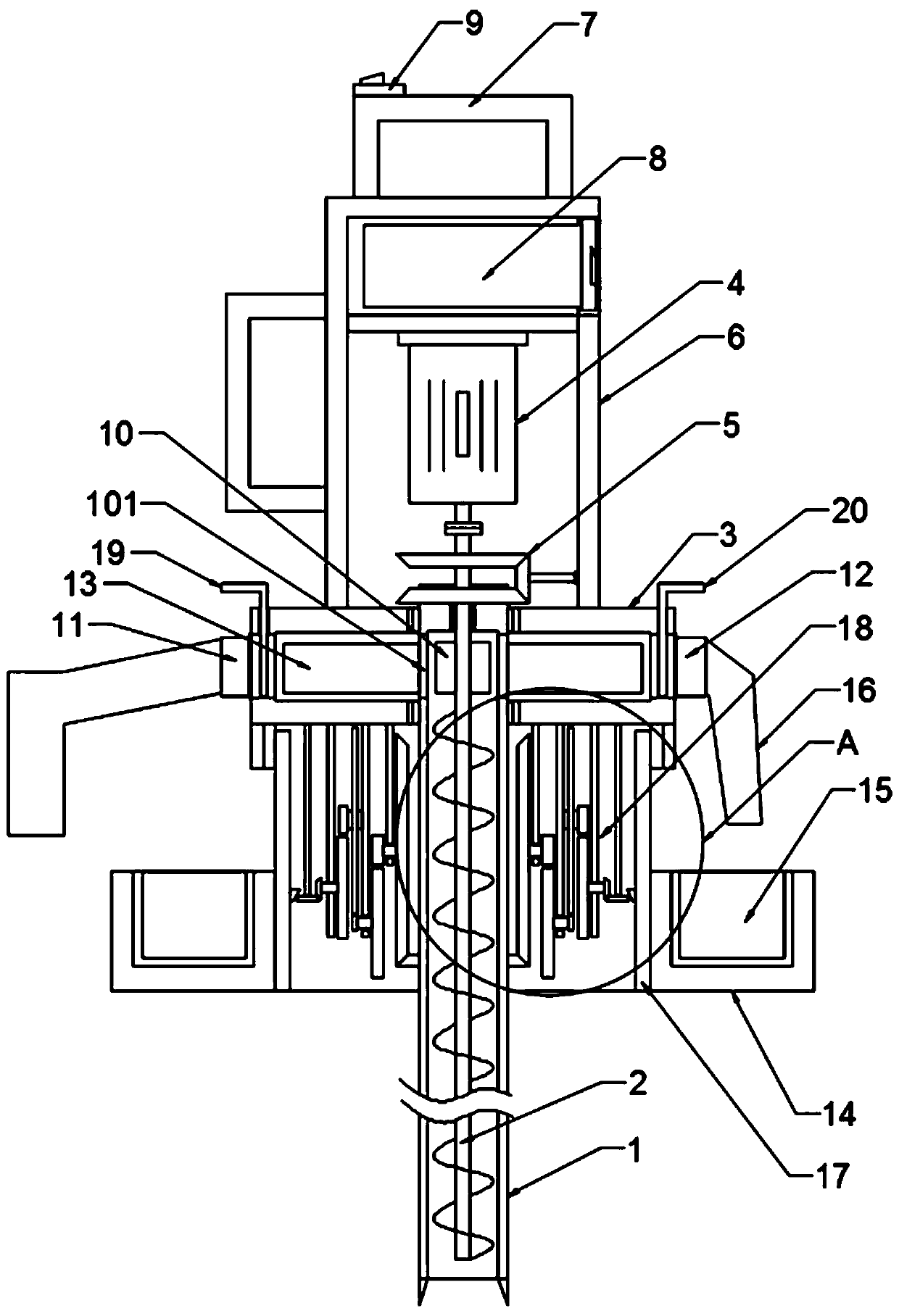

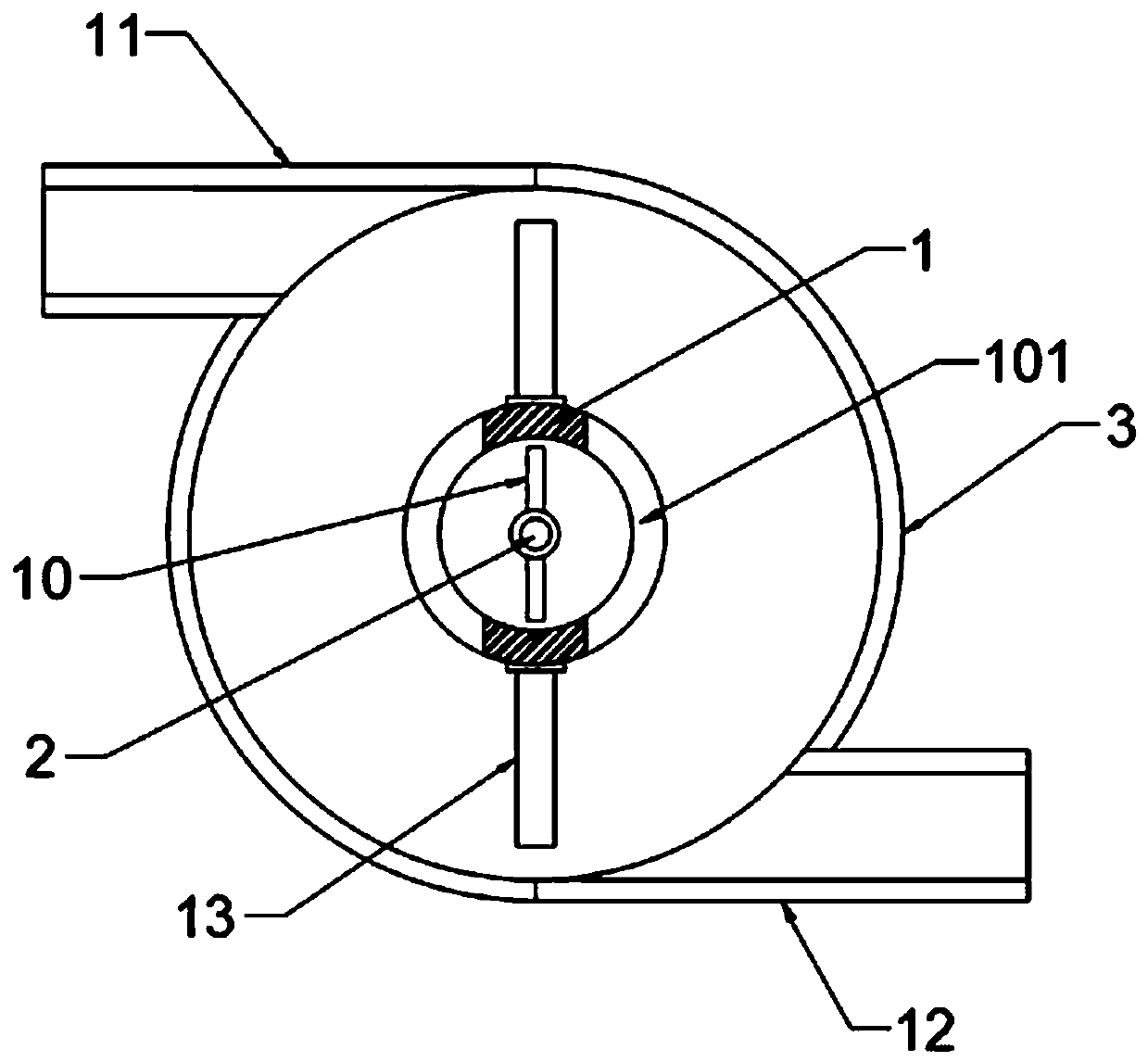

Environmental-friendly recovery processing equipment for polyethylene PE plastic bottles

ActiveCN108724527AImprove work efficiencyReduce labor costsPlastic recyclingSeparation processEngineering

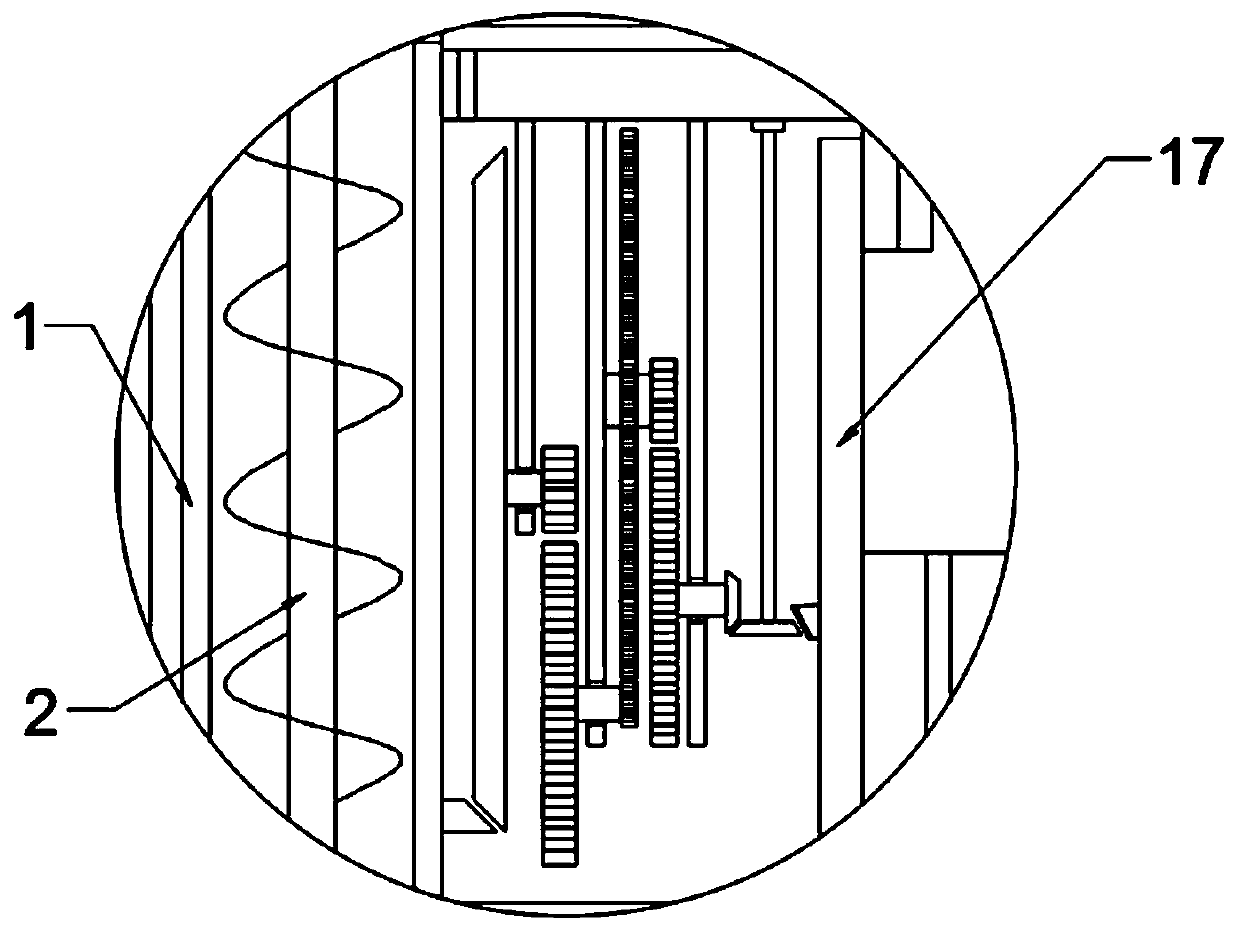

The invention relates to environmental-friendly recovery processing equipment for polyethylene PE plastic bottles. The environmental-friendly recovery processing equipment comprises a bottom plate, amounting rack, a conveyor, a bottle cap removal device and a label removal device, wherein the mounting rack is arranged on the bottom plate, a round hole and a sliding chute are formed in the mounting rack, and a conveyor is arranged in the round hole; the bottle cap removal device is arranged at the upper end of the conveyor, the label removal device is arranged at the right end of the conveyor,and the bottle cap removal device and the label removal device are both arranged at the lower end of the mounting rack; and the conveyor comprises a discharging barrel, a conveying mechanism and a collecting box, the bottle cap removal device comprises rotating mechanism and a fixing mechanism, and the label removal device comprises a dividing mechanism and a collecting mechanism. The environmental-friendly recovery processing equipment can solve the problems of high labor cost, low working efficiency, existence of safety risks, high labor intensity, etc. in the existing separation process ofa label, a bottle cap and a bottle body of a plastic bottle, and can realize the function of automatically separating the label and the bottle cap of the plastic bottle.

Owner:连云港海润包装有限公司

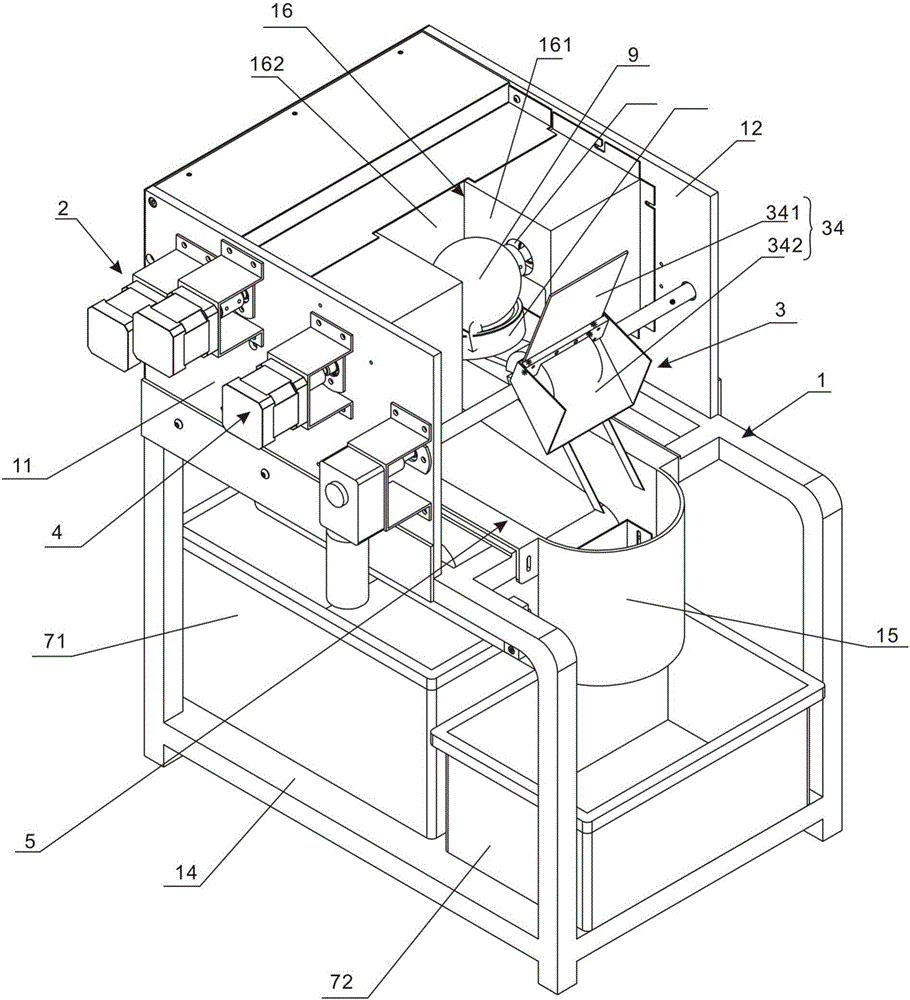

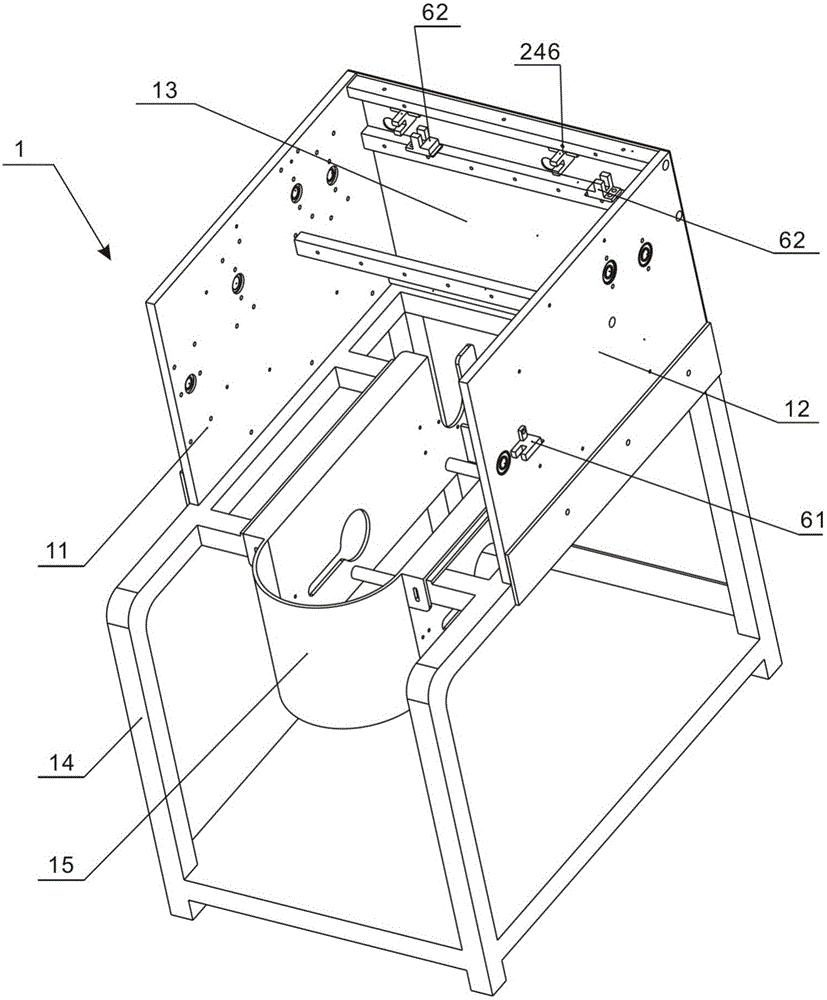

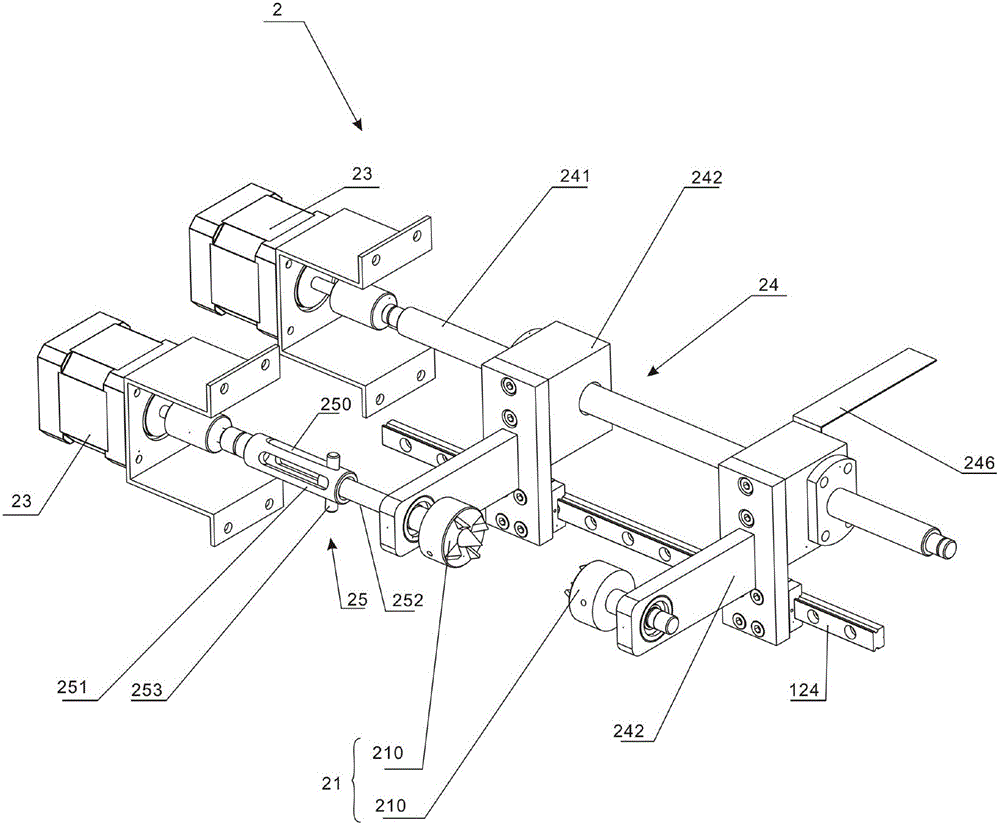

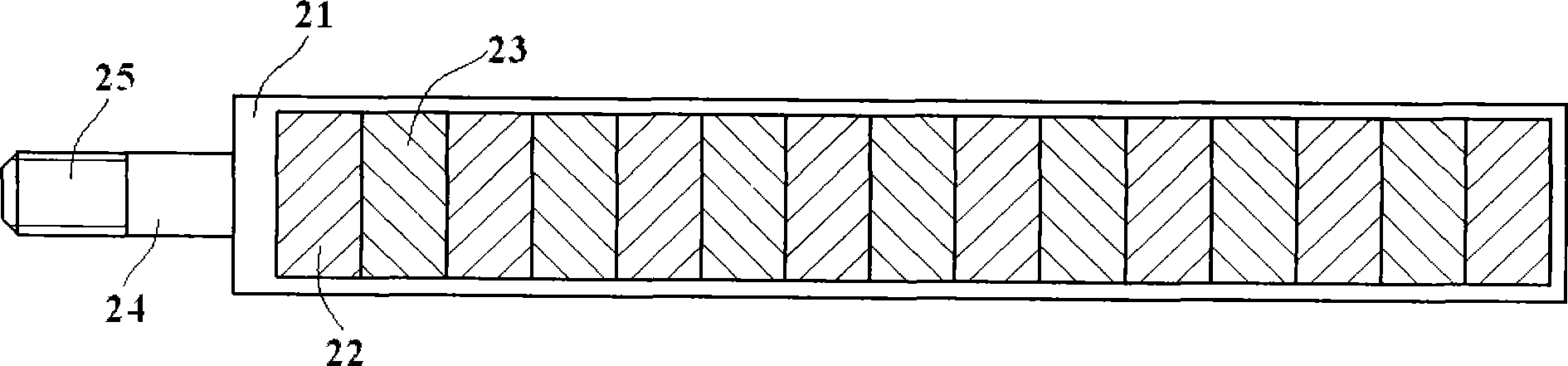

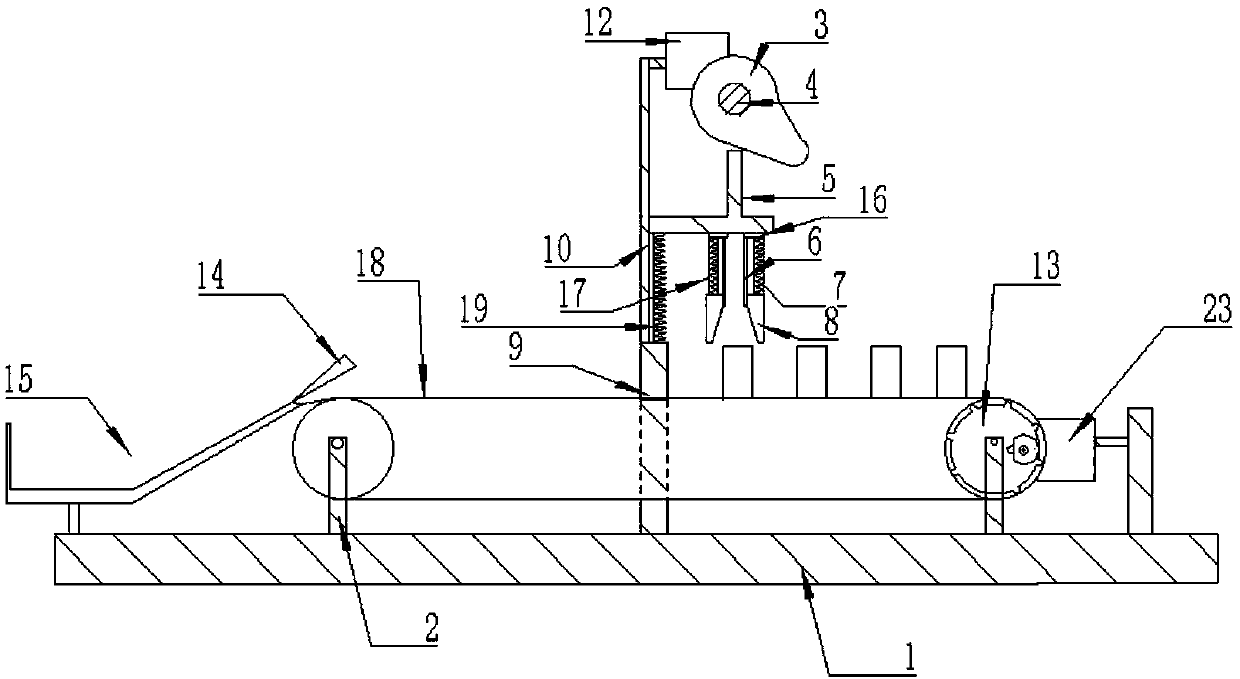

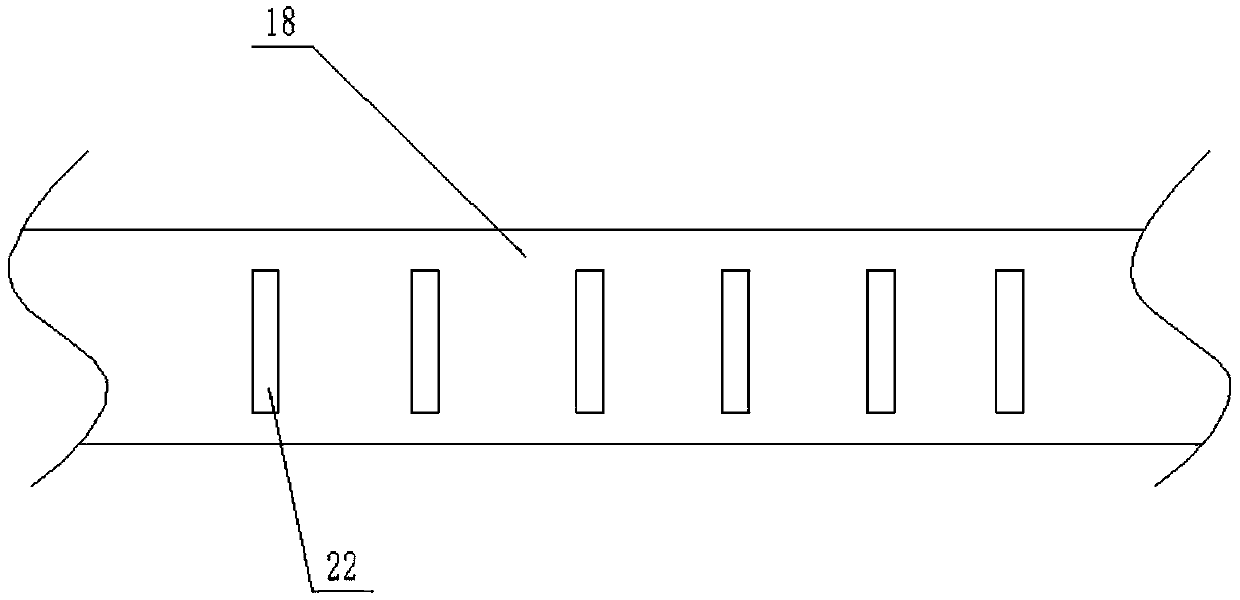

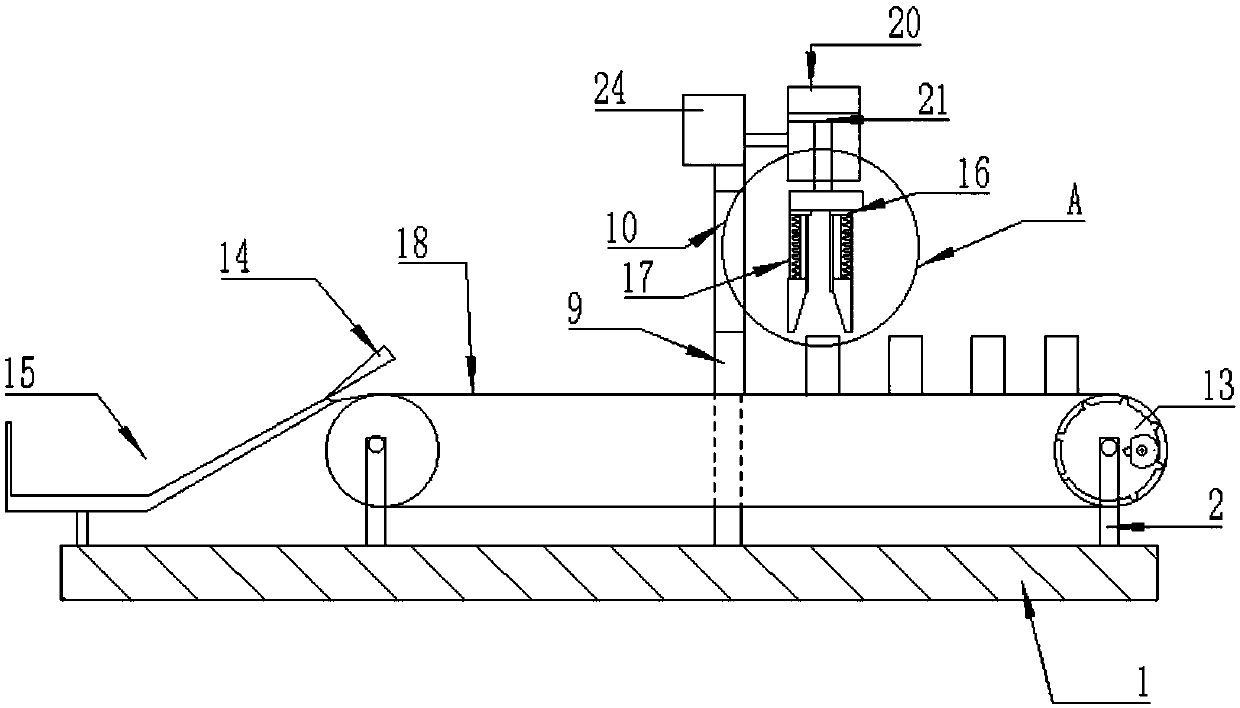

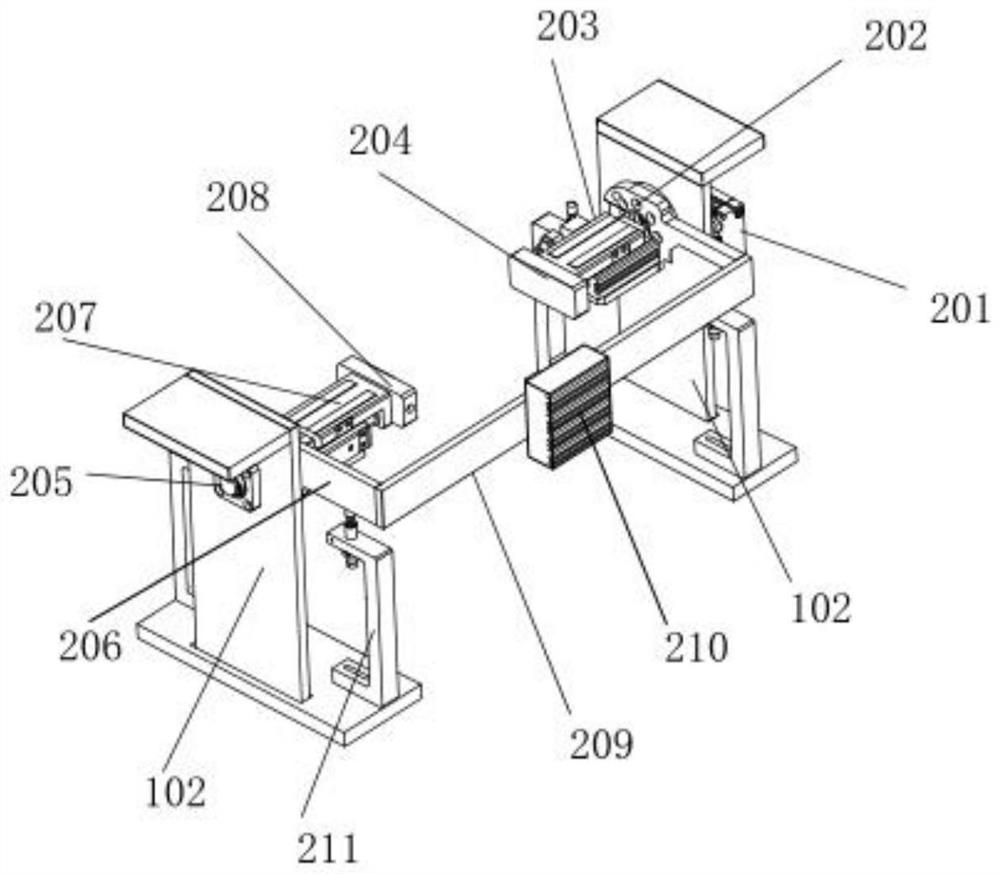

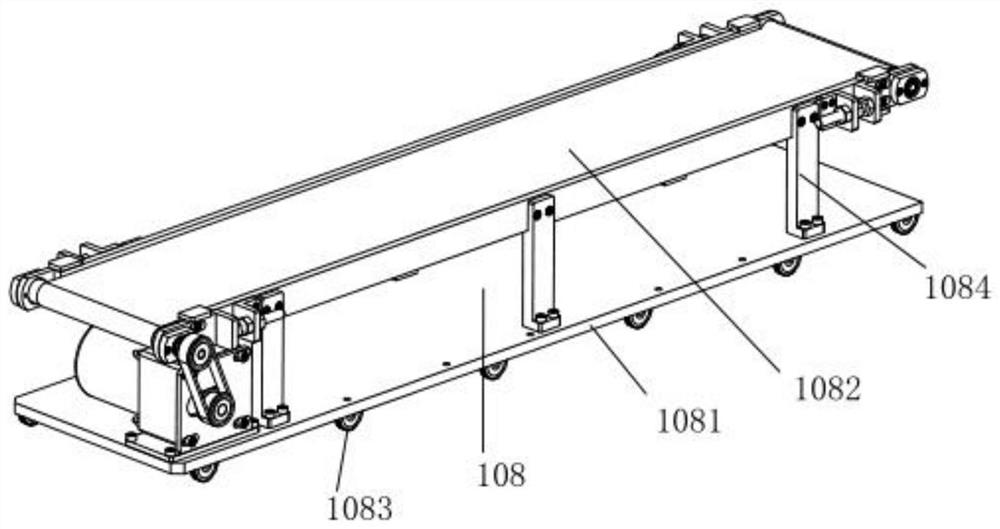

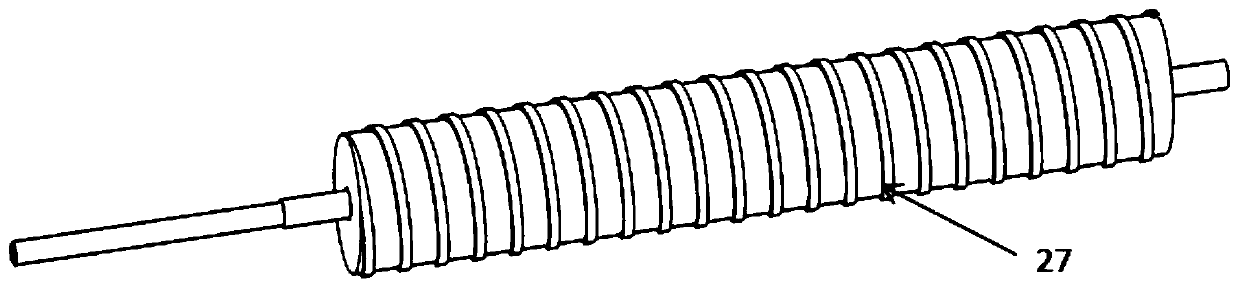

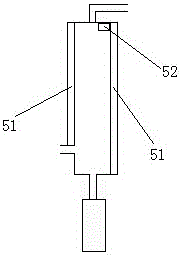

Automatic peeling machine

InactiveCN105768125AGuaranteed to fall intoRealize classified collectionVegetable peelingElectric machineryKnife blades

The invention discloses an automatic peeling machine. The automatic peeling machine consists of a body frame, a clamping and rotating unit, a positioning and end removing unit, a peeling unit and a separating and conveying unit; the positioning and end removing unit comprises an end removing motor, a rotating shaft, a positioning plate, a peel guiding assembly and an end cutting knife assembly; the end cutting knife assembly components include two end cutting blades; the positioning plate, peel guiding assembly and end cutting knife assembly rotate successively under the drive of the rotating shaft to the clamping and rotating unit. The separating and conveying unit comprises a conveying motor and a conveying belt, and the conveying belt is in a tilter arrangement. The positioning plate is used to place melons and fruits, the rotation of the rotating shaft can enable the peel guiding assembly to be cooperated with the melons and fruits to ensure fallings of fruit peels on the conveyor belt, and the end cutting knife assembly is used to cut the ends of the melons and fruits down to enable the fruit peels and the fruit flesh to be separated completely; the conveyor belt is in the tilter arrangement and can convey the fruit peels and ends to a fruit peel collection box, and the slope of the conveying belt is used to enable the fruit flesh to automatically slip into a fruit flesh collection box to effectively realize the classification and collection of the fruit flesh and the fruit peels and ends. The automatic peeling machine increases work efficiency.

Owner:深圳市通达智能制造有限公司

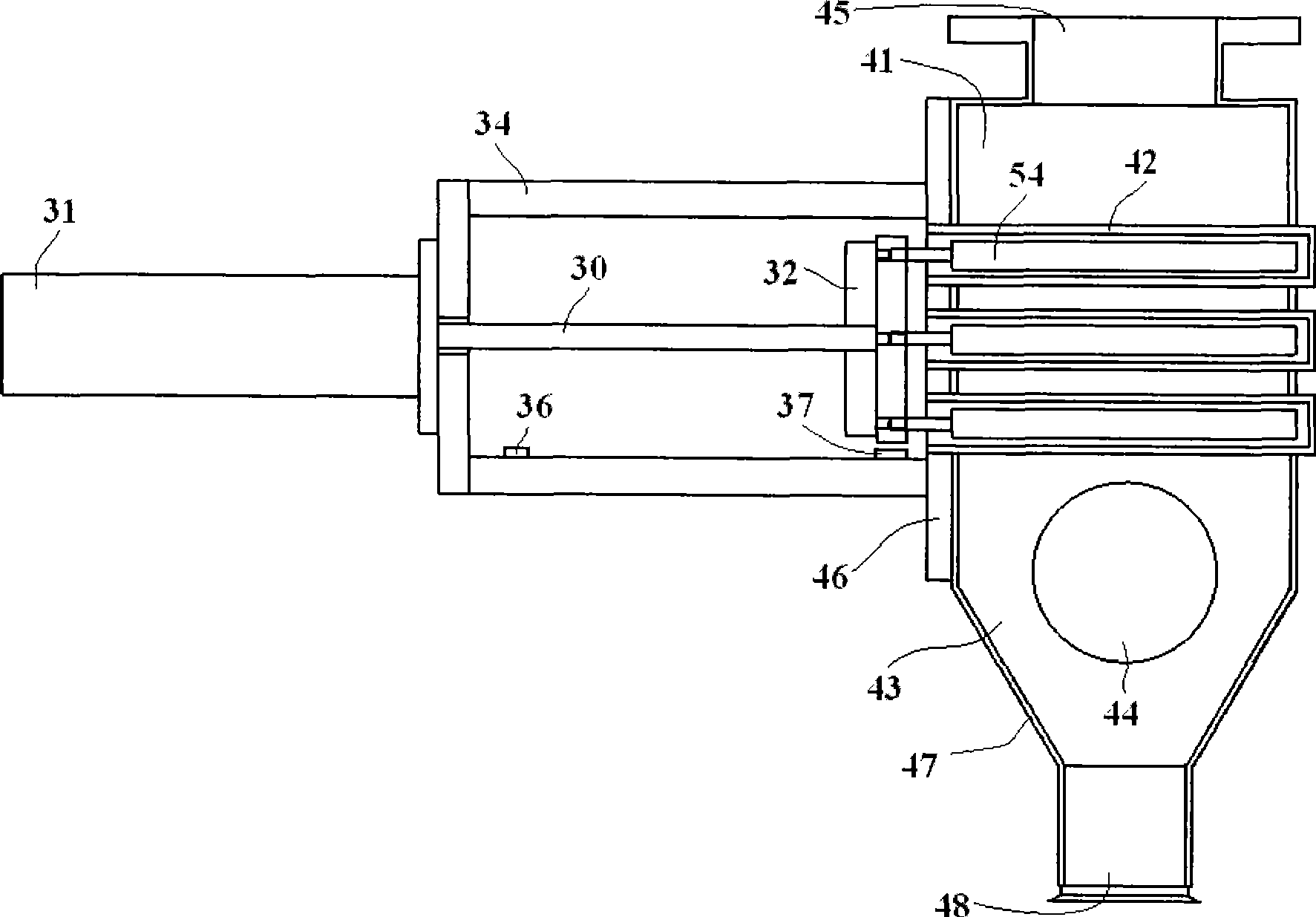

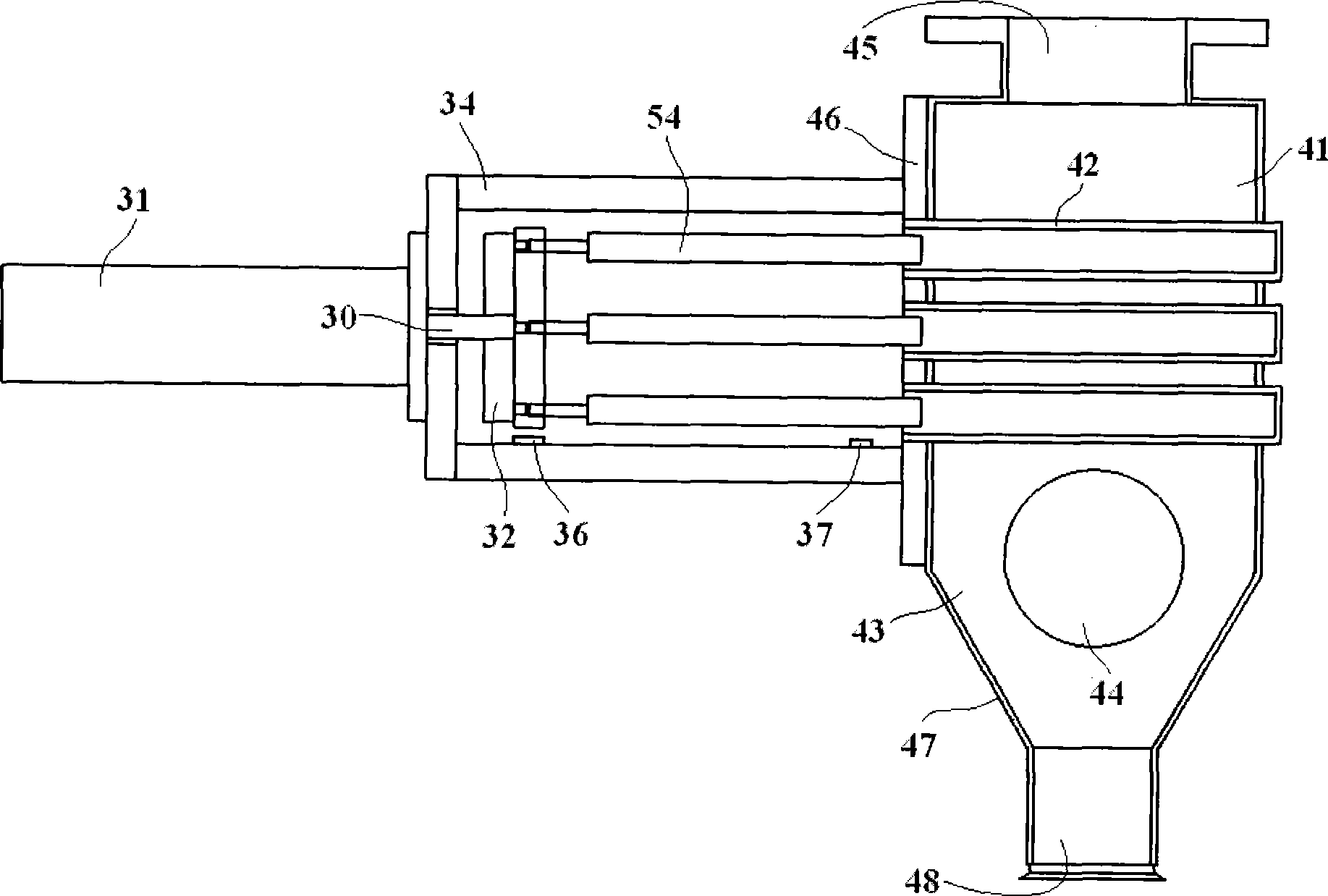

Magnetic dust-cleaning equipment

ActiveCN101376122AExtended service lifeRealize automatic collectionCombination devicesAuxillary pretreatmentControl systemElectrical control

A magnetic dust remover is characterized in that the dust remover comprises at least two sets of dust-collecting devices, and each set of the dust-collecting device is composed of a housing, a group of magnetic force sticks of a permanent magnet, a driving device for the magnetic force sticks, an electric control system, and a sound wave vibrator and / or an air hammer, wherein the housing is provided with a group of cylinders spanning the inner cavity of the housing between a to-be-treated air inlet and a treated air outlet, and both two ends of each cylinder are hermetically bonded with the side wall of a work room; each magnetic force stick is corresponding to each cylinder; the driving device for the magnetic force sticks drives the magnetic force sticks of the permanent magnet to insert into or remove out of magnetic force stick isolation sleeves; the electric control system opens a set of the dust-collecting device and closes the other dust-collecting device simultaneously; and the sound wave vibrator and / or the air hammer acts on the housings of the dust-collecting devices in a dust-removing state. By using the magnetic dust remover, the service life of filter materials is prolonged, the automatic collection is realized through on-line work of the dust-collecting devices, and the separate collection of ultra fines can be realized.

Owner:NINGBO KONIT IND +1

Method for preparing molybdenum nickel alloy by directly reducing and smelting molybdenum nickel ore

The invention relates to a method for preparing molybdenum nickel alloy by directly reducing and smelting molybdenum nickel ore. The method comprises the following steps: grinding the molybdenum nickel ore into molybdenum nickel ore powder with the average particle size of less than or equal to 0.18 mm; adding a slag forming agent and a reducing agent with the average particle size of less than or equal to 0.18 mm into the molybdenum nickel ore powder to obtain furnace charge; mixing the furnace charge uniformly and pelletizing to obtain pellet; heating the pellet to 1,600 to 1,800 DEG C; smelting; and collecting liquid alloy, slag, smoke dust and furnace gas respectively, wherein the liquid alloy is crude molybdenum nickel alloy; the direct yield of the molybdenum and the nickel is 96 percent and 94 percent respectively; the molybdenum content of the smoke dust is less than 0.2 percent and the nickel content of the smoke dust is less than 0.2 percent; and the SO2 concentration of thefurnace gas is less than or equal to 400 mg / m<3>. The process method is simple and reasonable, and convenient to operate; the molybdenum nickel ore is not subjected to oxidizing roasting de-sulfuration; and the crude molybdenum nickel alloy is prepared by directly reducing and smelting the molybdenum nickel ore and by using the carbon of the molybdenum nickel ore as a reducing agent, so that indirect smelting is changed into direct smelting. The prepared molybdenum nickel alloy is low in sulfur content and phosphorus content, environment friendly and low in production cost; and the method is suitable for extraction of the molybdenum nickel ore.

Owner:CENT SOUTH UNIV +2

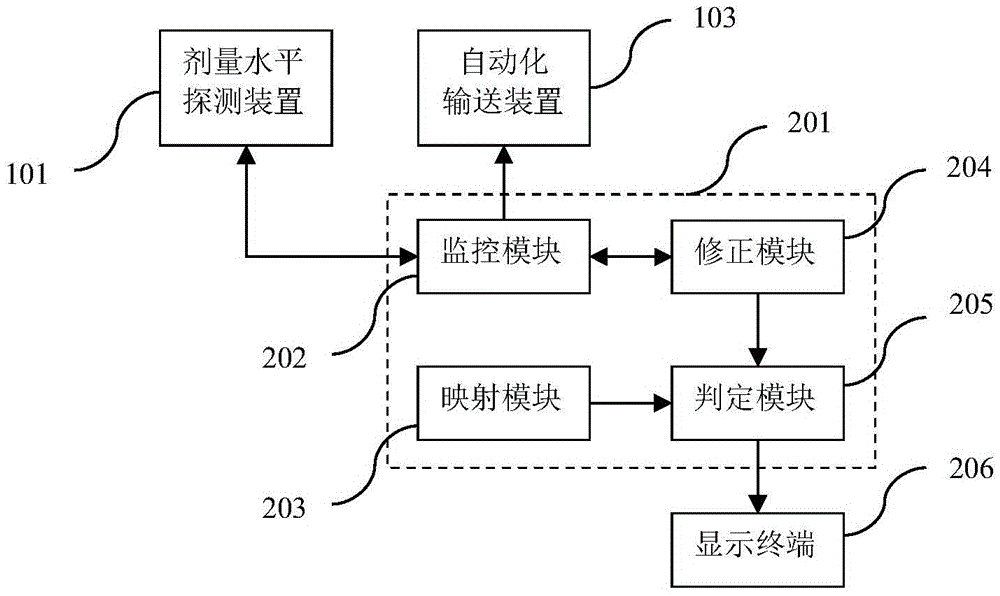

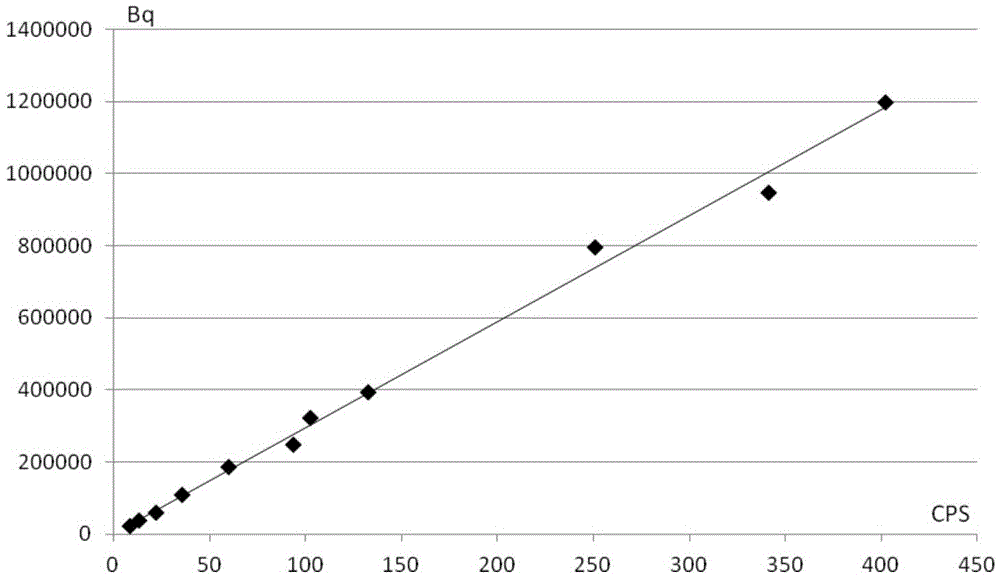

Radioactive solid waste detecting and classifying method and system

ActiveCN105665310AEasy to handleGood control effectX-ray spectral distribution measurementDosimetersEngineeringWaste treatment

The invention belongs to the technical field of solid waste treatment, and discloses a radioactive solid waste detecting and classifying method. The method comprises the steps of: measuring a surface dose level, a pollution nuclide type and a radioactive specific activity of a radioactive solid waste sample; obtaining a fitting curve of the dose level and the radioactive specific activity, building a function relation of the two, and determining a dose limiting value range of the radioactive solid waste in a different-pollution-grade state; measuring a dose level of the radioactive solid waste; and comparing the dose level of the radioactive solid waste with the dose limiting value range thereof in the different-pollution-grade state, judging the pollution grade of the radioactive solid waste, and classifying and collecting the radioactive solid waste. The method compares the dose level of the radioactive solid waste with the dose level limiting value range through building the relation between the radioactive solid waste pollution grade and the dose level limiting value range, so that the pollution grade can be quickly judged, the classification and the collection are realized, and the treatment and management capacity of the radioactive solid waste is greatly promoted.

Owner:深圳市利美泰克自控设备有限公司

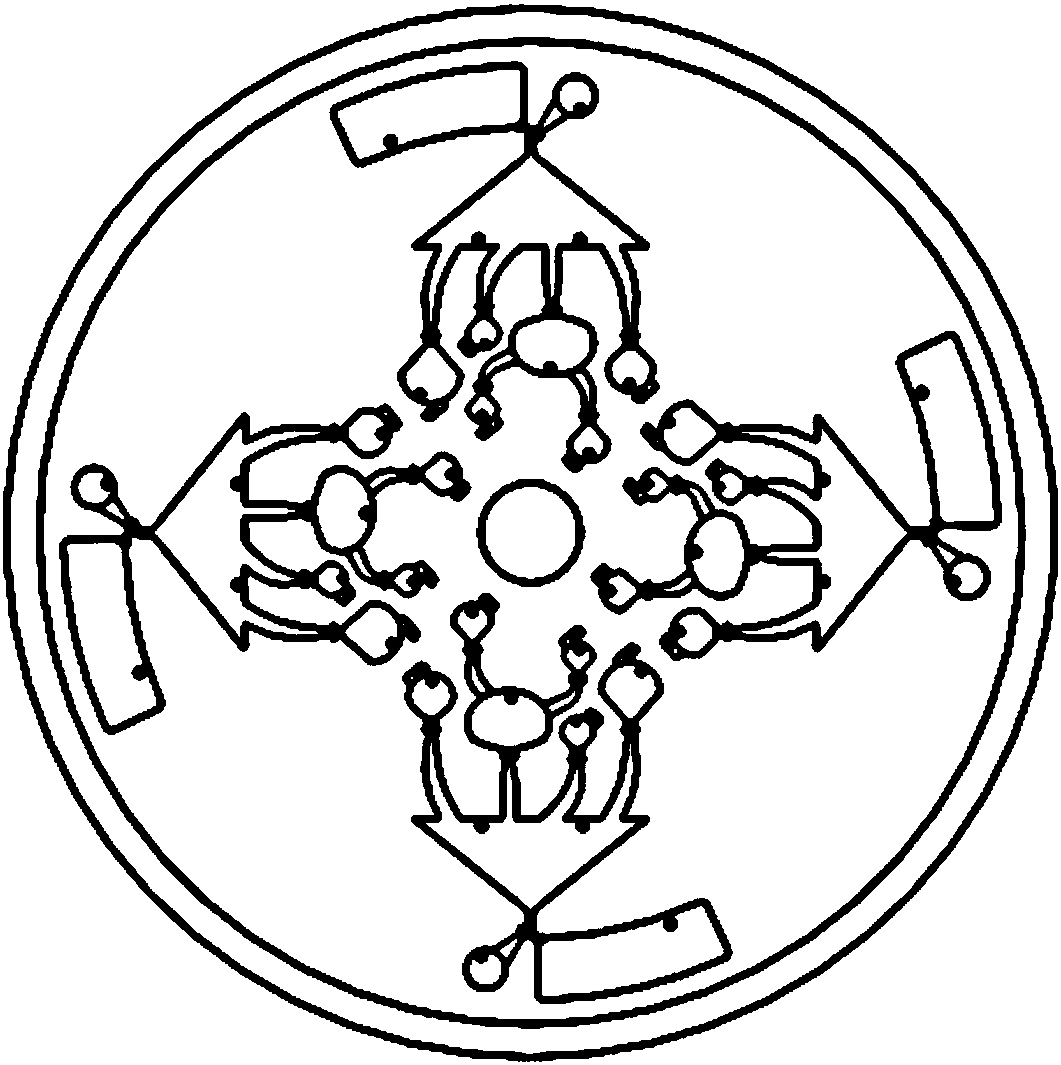

Centrifugal force micro fluidic chip used for nucleic acid extraction

InactiveCN108424850AReduce energy consumptionFlexible control of automatic introductionBioreactor/fermenter combinationsBiological substance pretreatmentsElutionCentrifugal micro-fluidic biochip

The invention provides a centrifugal force micro fluidic chip used for nucleic acid extraction, and a nucleic acid extraction method using the centrifugal force micro fluidic chip. The centrifugal force micro fluidic chip is composed of PDMS formed via integration of wirelessly controlled paraffin valves and other micro valves (preferable capillary micro valves) and corresponding circuits, and iscapable of realizing sample extraction integrated process including sample introduction, impurity washing, nucleic acid adsorption, and elution. Efficiency is high, speed is fast, and resource is saved.

Owner:NANJING UNIV +1

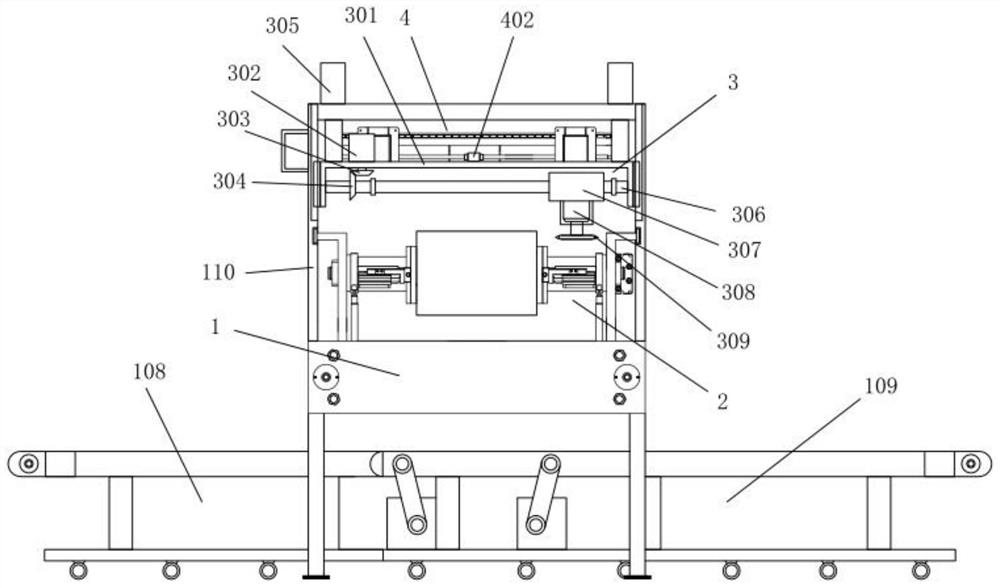

Dried bean curd surface cutting machine

ActiveCN109605437AAvoid uneven cuttingEasy to fixCheese manufactureMetal working apparatusEngineeringCam

The invention belongs to the field of dried bean curd processing and particularly discloses a dried bean curd surface cutting machine used for cutting off the two opposite surfaces of each dried beancurd. The dried bean curd surface cutting machine comprises a base, a vertical frame, supporting rods, a conveying unit, a cutting unit and a collecting unit, the vertical frame and the supporting rods are fixed to the base, the conveying unit comprises a conveying belt and a first intermittent conveying mechanism for driving the conveying belt to move, the conveying belt and the first intermittent conveying mechanism are both mounted on the supporting rods, the cutting unit comprises a cam, a transmission part, two cutting knives, a first elastic reset part, guiding modules and two second elastic reset parts, the two cutting knives are both mounted on the transmission part, each guiding module is mounted on the outer side of the corresponding cutting knife, and a horn-shaped clamping opening is defined between the two guiding modules. After the dried bean curd surface cutting machine is adopted, through the horn-shaped clamping opening, the cutting thickness of dried bean curds can beaccurately controlled when the surfaces of the dried bean curds are cut by the cutting machine, and the dried bean curds are collected more advantageously after cutting.

Owner:湖南省志平食品有限公司

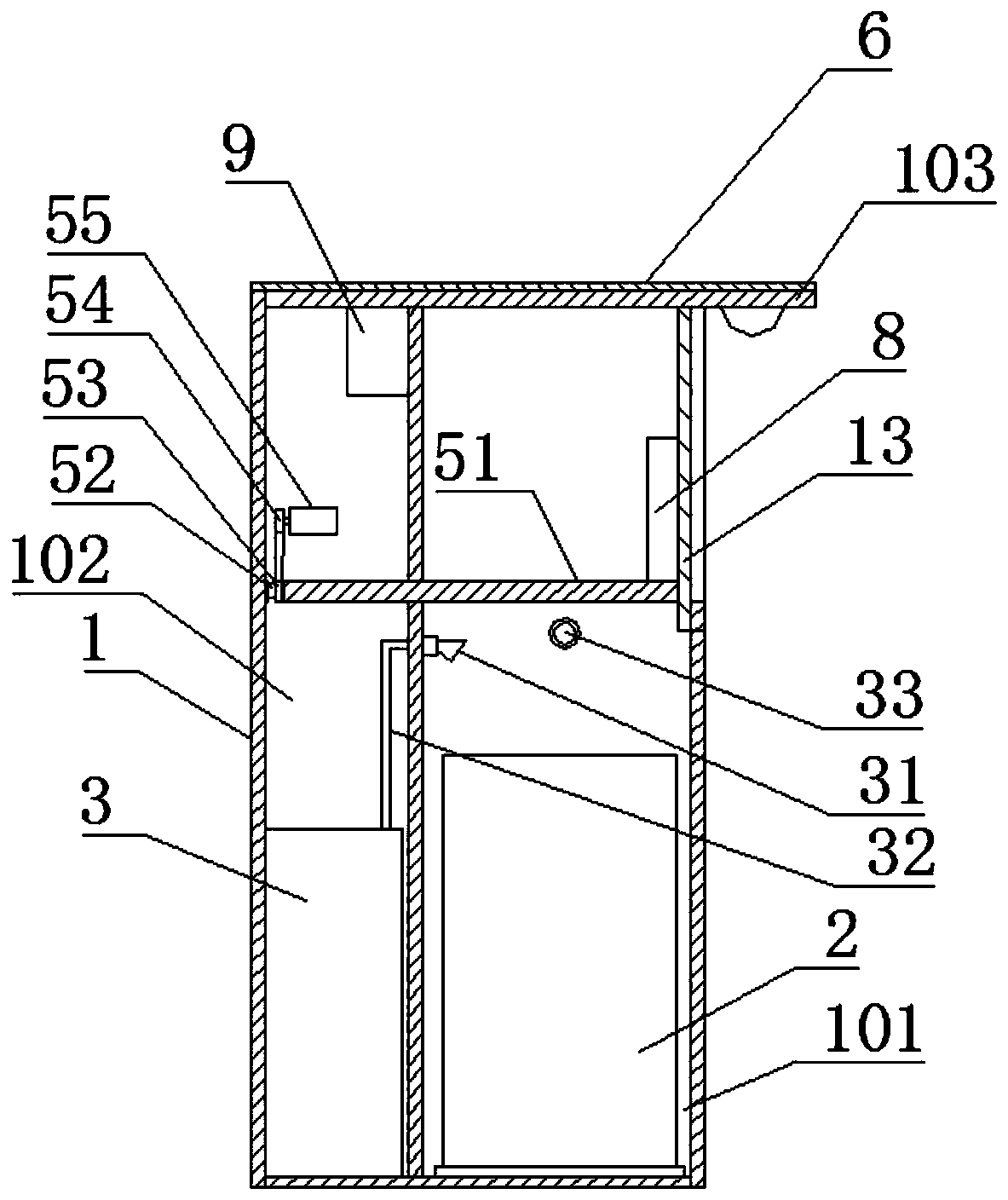

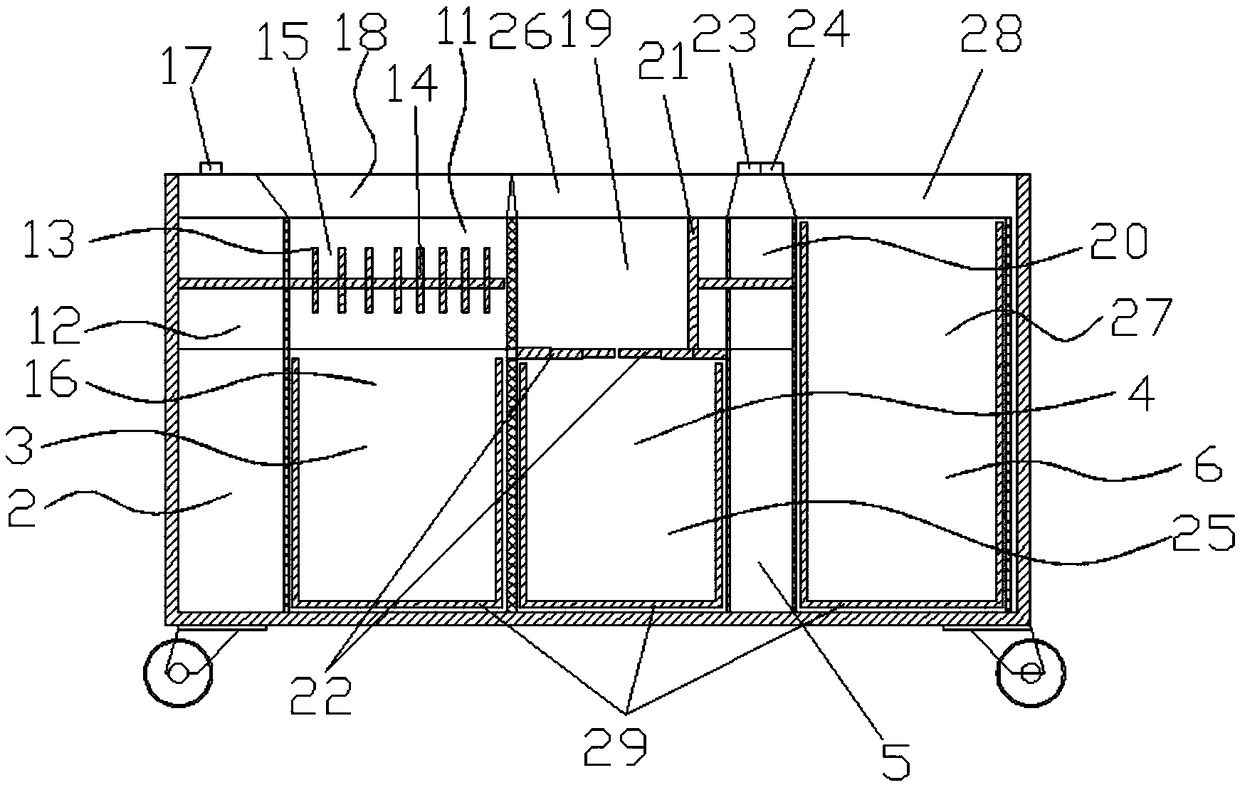

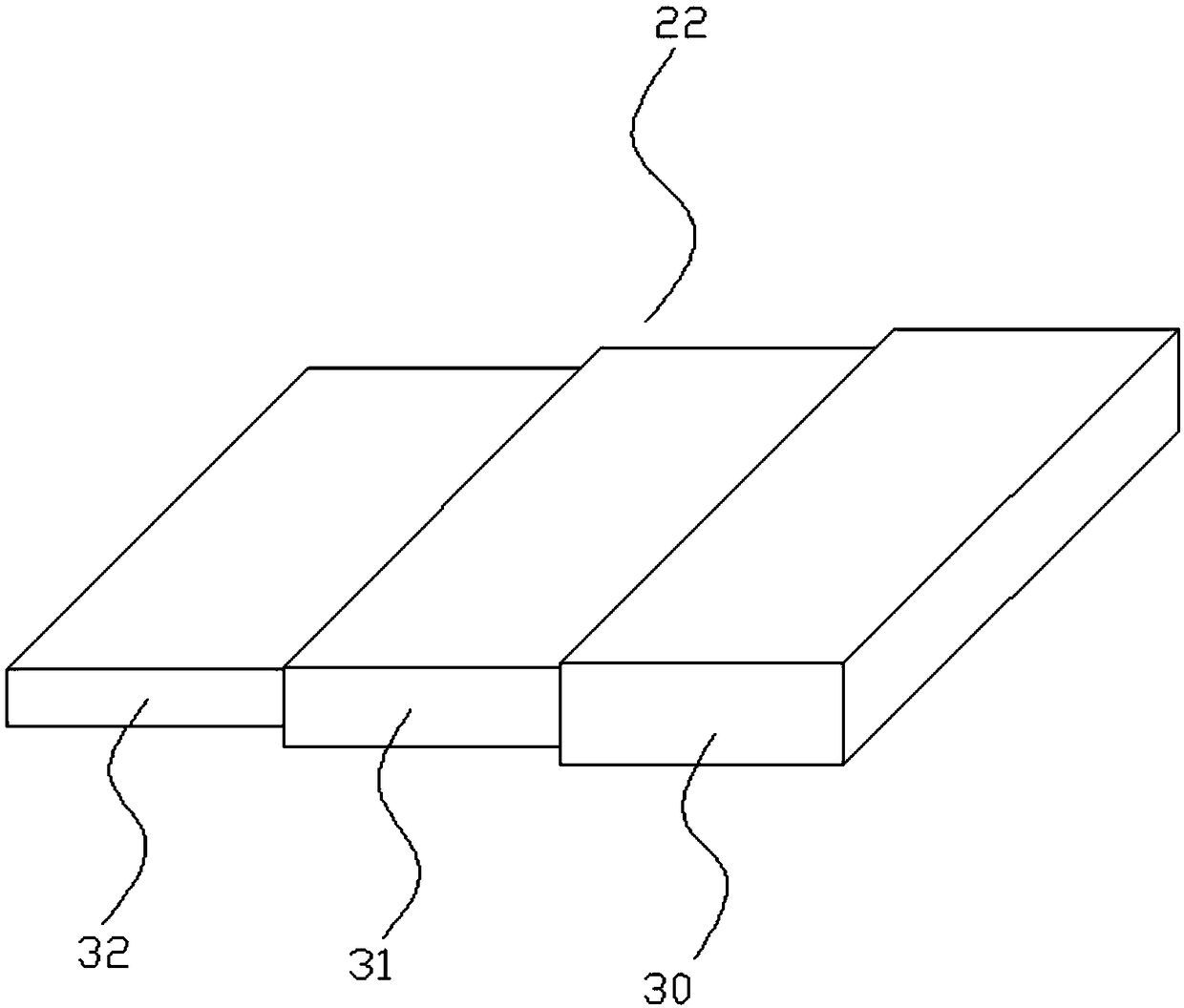

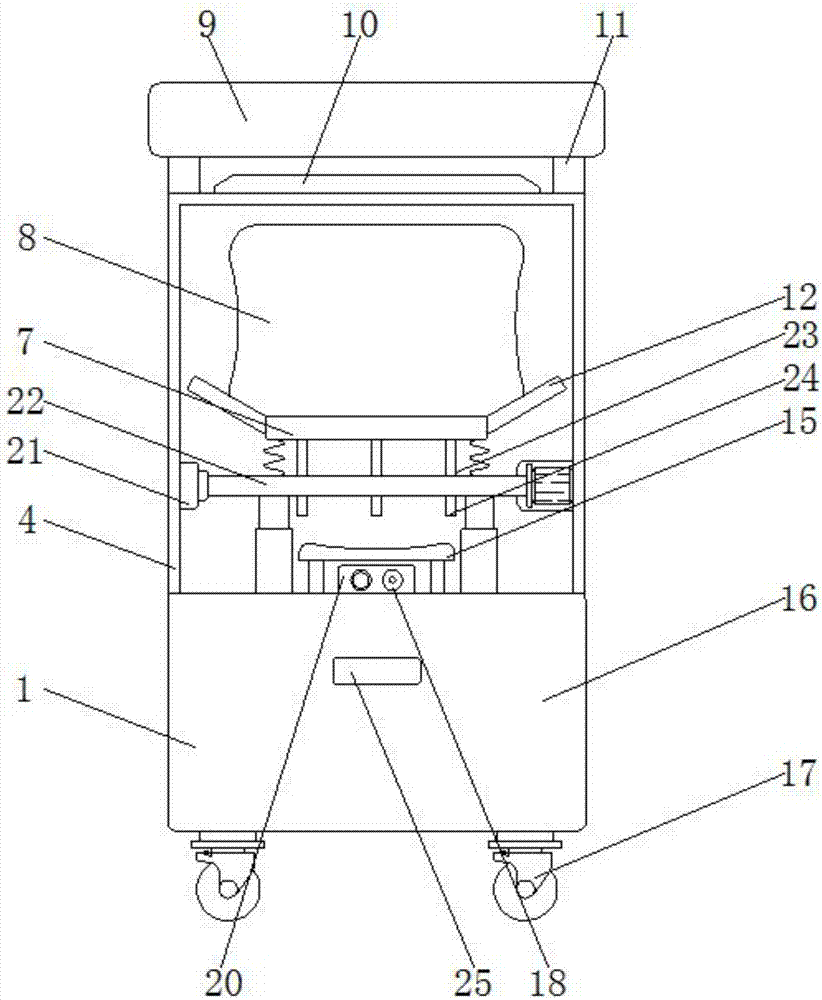

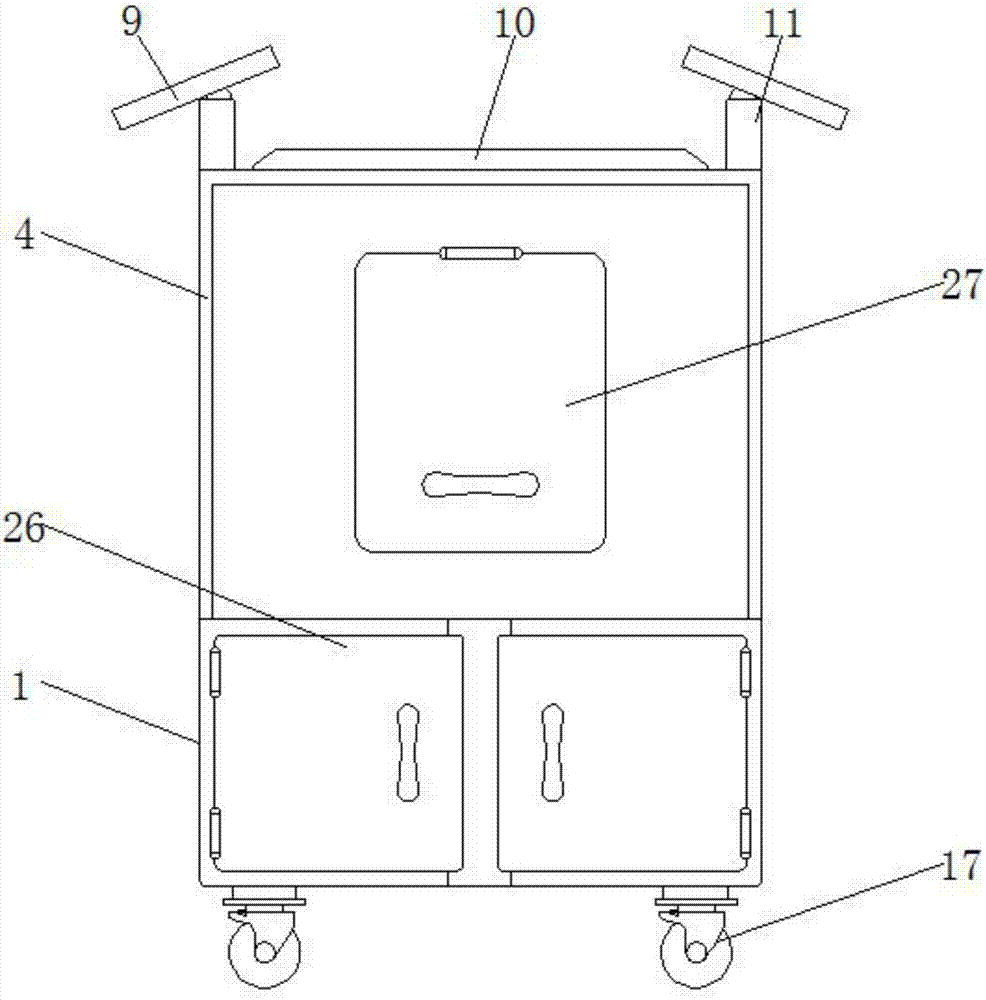

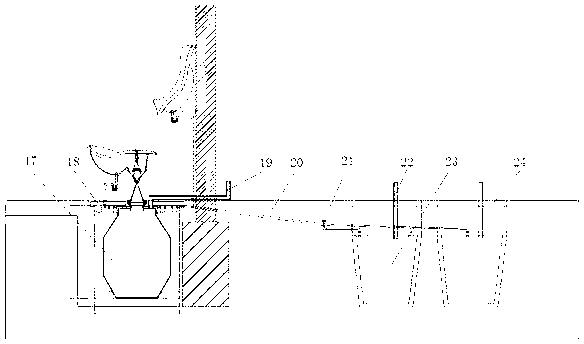

Waste lead-acid storage battery separation and collection device and use method thereof

ActiveCN113172076ARealize classified collectionLow costSolid waste disposalWaste accumulators reclaimingStructural engineeringMechanical engineering

The invention discloses a waste lead-acid storage battery separation and collection device and a use method thereof. The waste lead-acid storage battery separation and collection device comprises a collecting rack, the collecting rack is of a quadrilateral frame-shaped structure, guide cavities are formed in the two sides of the collecting rack, and a supporting rack is arranged through the guide cavities in the two sides of the collecting rack, the supporting rack is located above the collecting rack, an inverted U-shaped cover plate is fixedly arranged on the top surface of the collecting rack, a shearing frame and a drilling frame are arranged in the U-shaped cover plate, and the shearing frame and the drilling frame are located above the collecting rack. According to the waste lead-acid storage battery separation and collection device and the use method thereof, the collecting rack is arranged to be of the quadrilateral frame-shaped structure, and a liquid guide groove, a battery panel group groove and a shell groove are sequentially formed in the collecting rack in the longitudinal direction, so that the whole waste lead-acid storage battery separation and collection device is made to be compact in structure, high in integration degree and flexible and multipurpose.

Owner:太和县大华能源科技有限公司

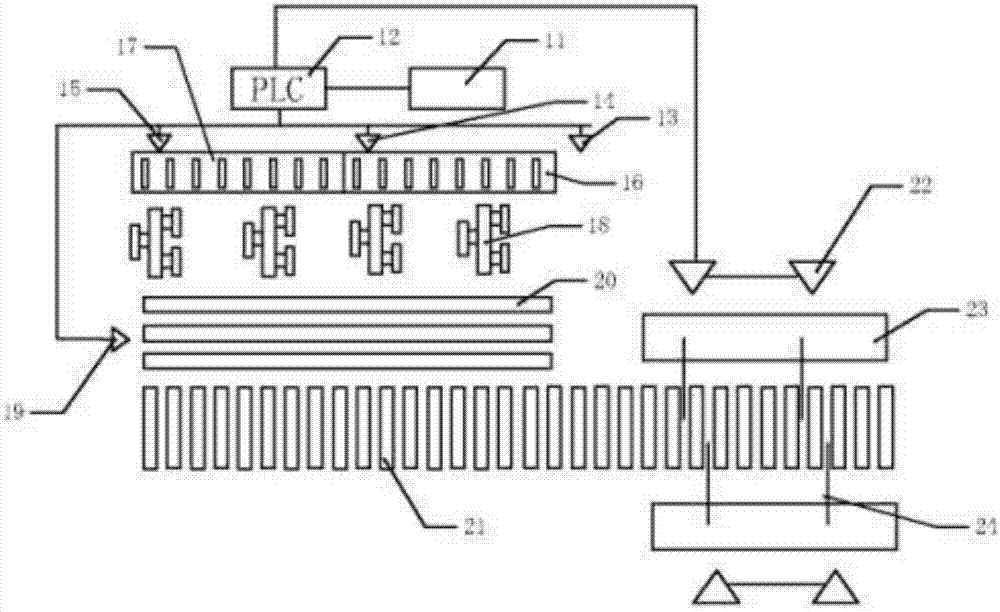

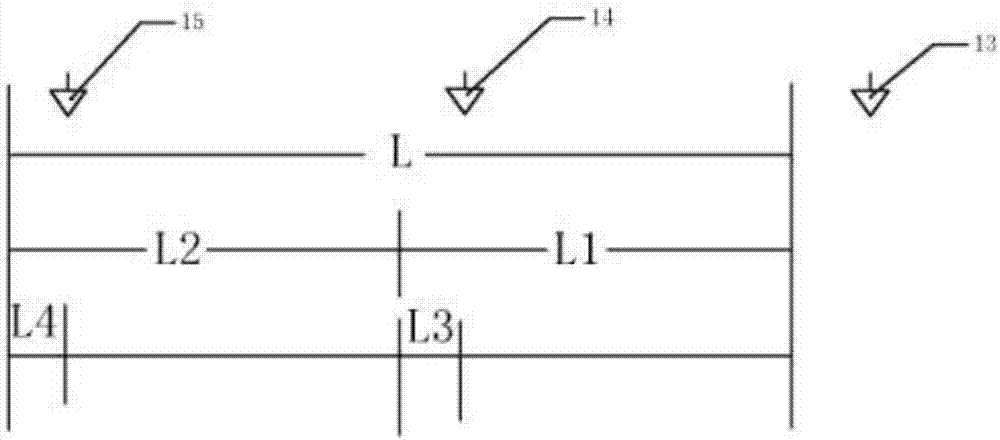

Cooling table charging automatic control device and method

InactiveCN106862286AMaster the length in real timeReasonable use of cooling resourcesCooling bedsMetal working apparatusAutomatic controlControl system

The invention belongs to the technical field of steel rolling machine tool equipment, and relates to a cooling table charging automatic control device and method. A cooling table upper steel roller bed is evenly divided into a first cooling table upper steel roller bed body and a second cooling table upper steel roller bed body. The distance between a first hot metal detector and the head end is equal to the distance between a second hot metal detector and the boundary of the first cooling table upper steel roller bed body and the second cooling table upper steel roller bed body, and is equal to the distance between a third hot metal detector and the tail end of the second cooling table upper steel roller bed body as well. The first hot metal detector, the second hot metal detector and the third hot metal detector are in signal connection with a PLC control system. The PLC control system is connected with an industrial personal computer through wires. An MES system is connected with the industrial personal computer. The PLC control system is connected with a cooling table detection proximity switch through a wire. A pair of finished product collection troughs are arranged on the outer side of a cooling table discharging roller bed. Cool metal detectors are arranged on the outer sides of the finished product collection troughs. The problem that part of zone of a cooling table is not fully utilized when steel plates are distributed in a single row is solved.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

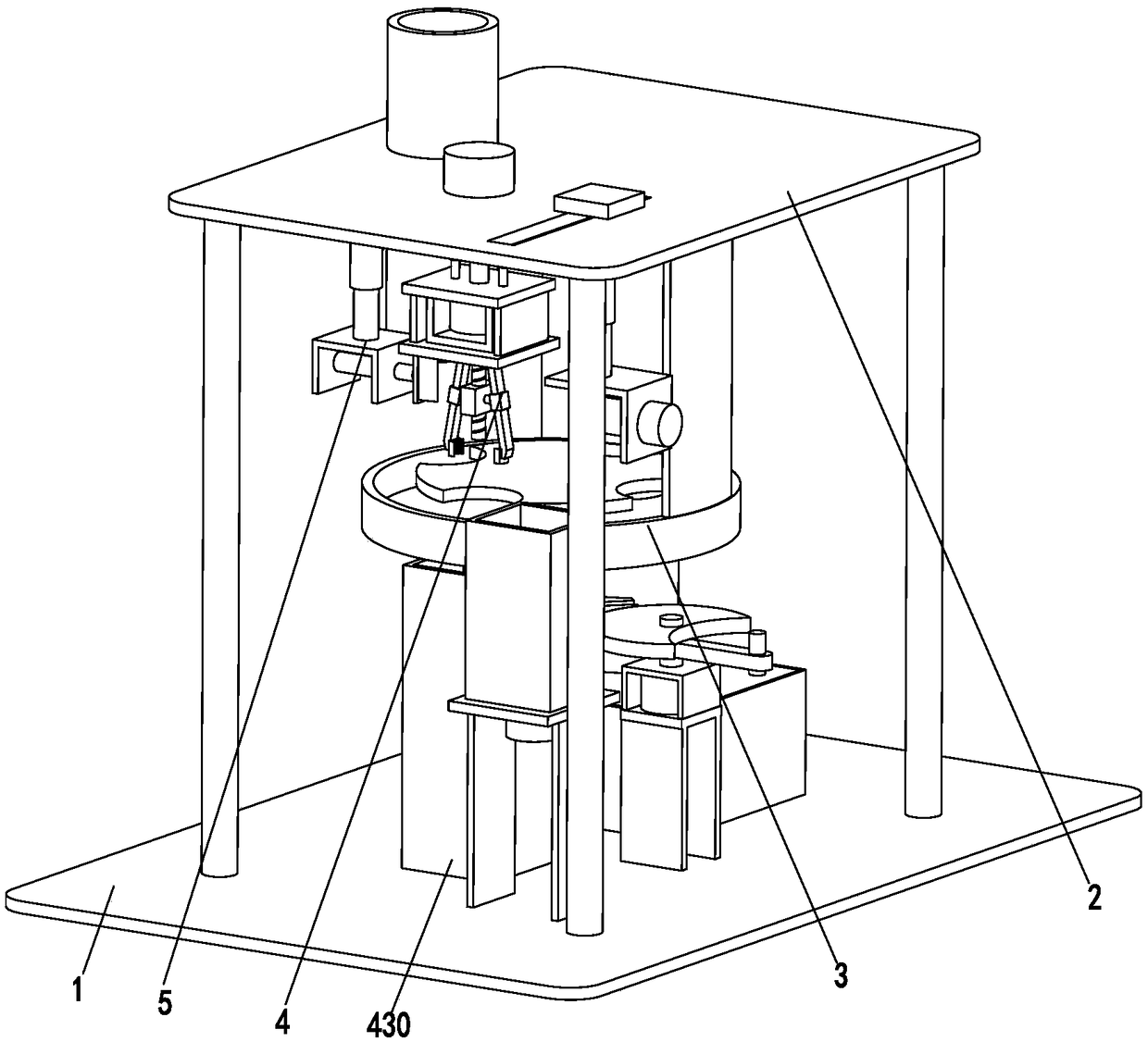

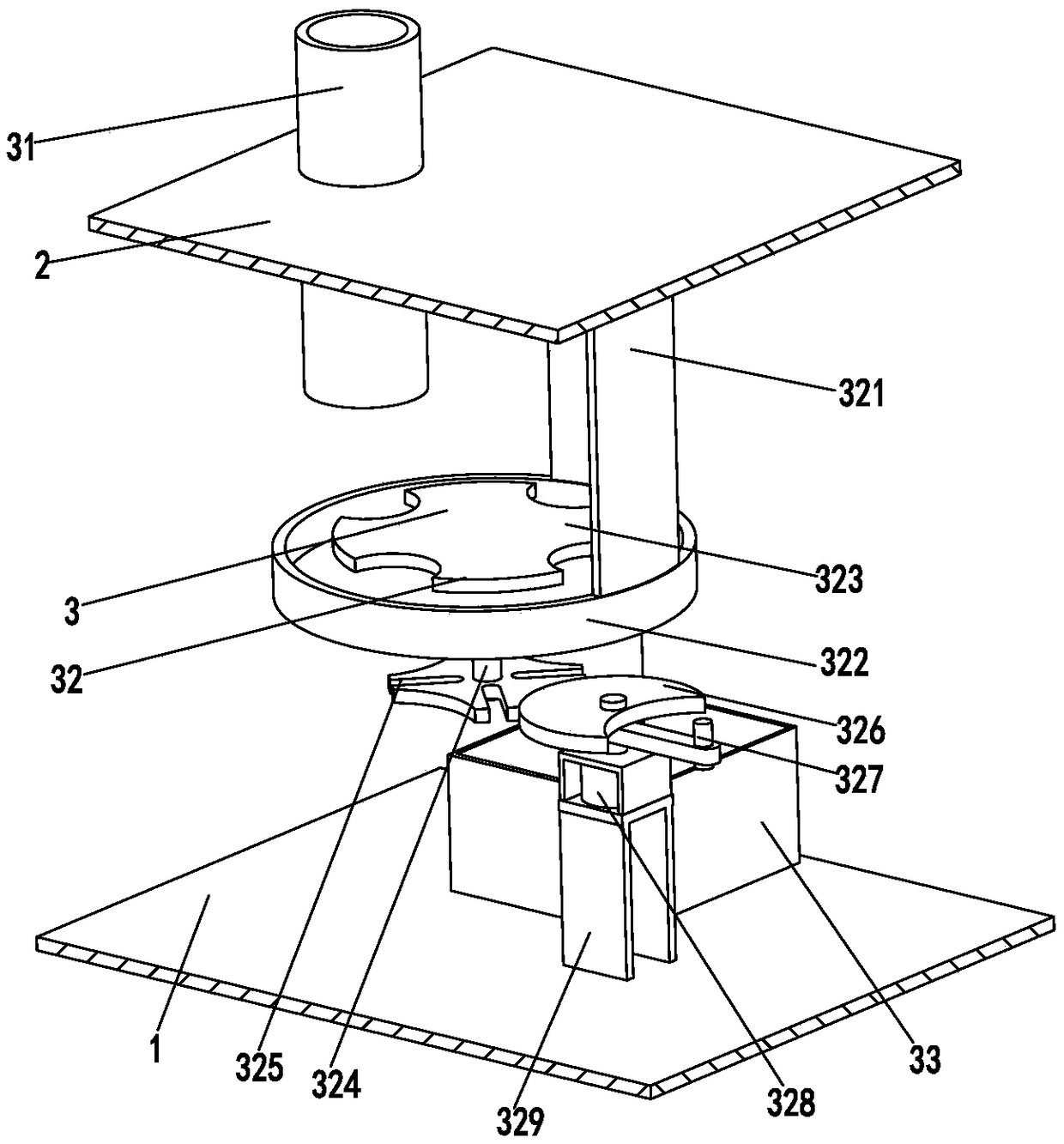

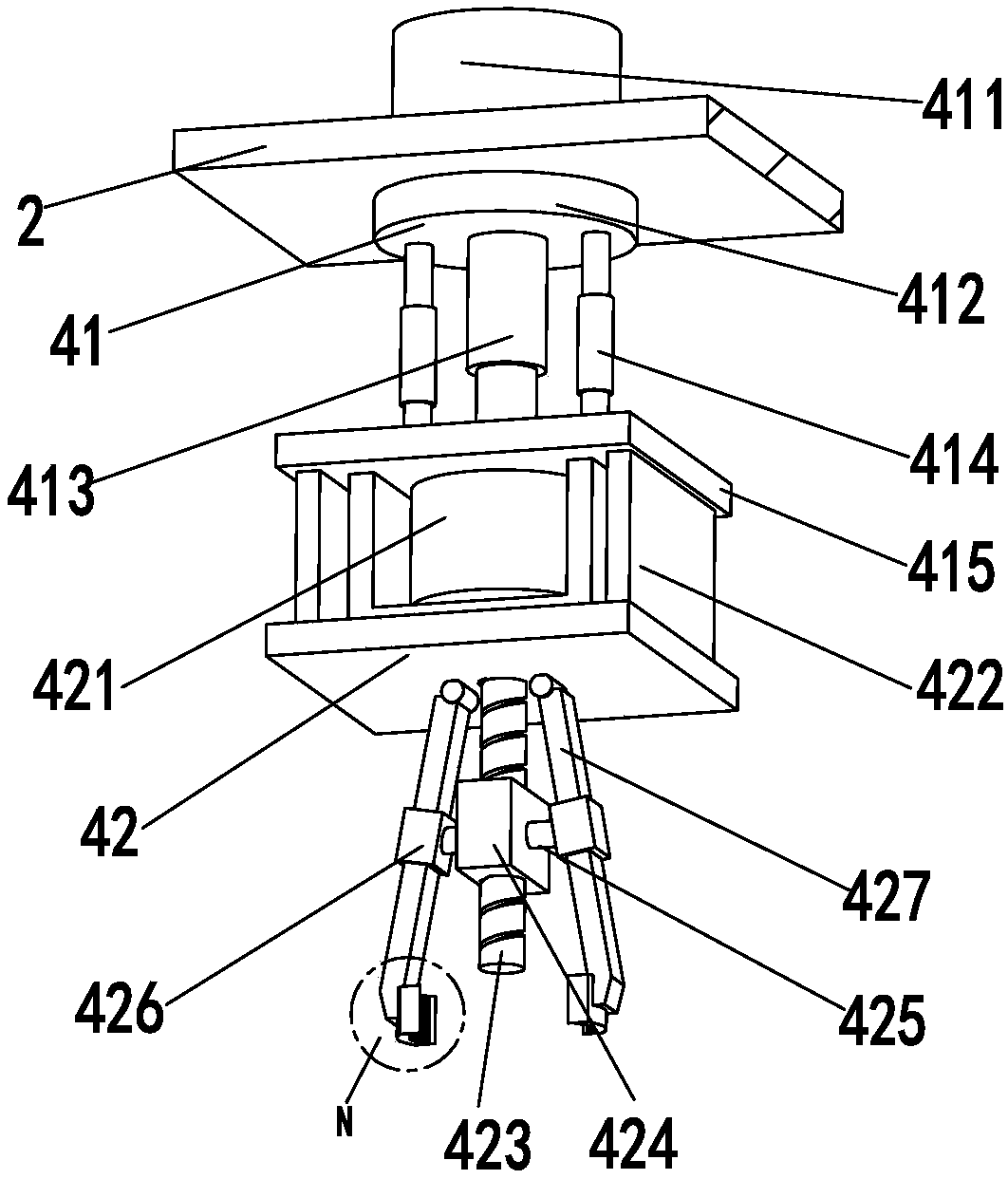

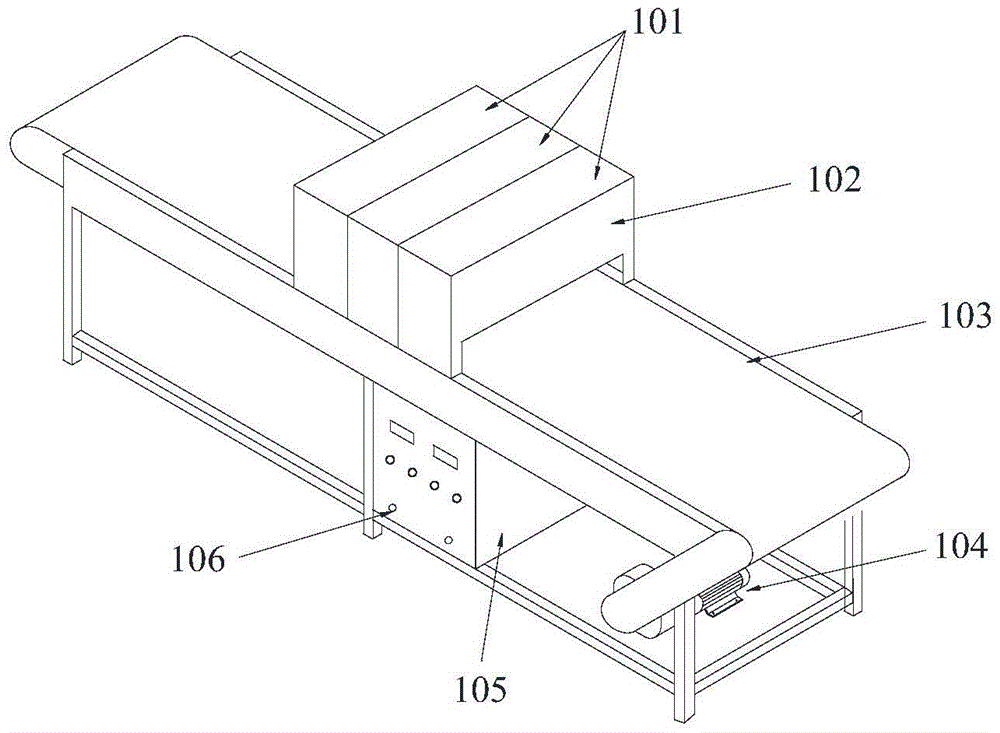

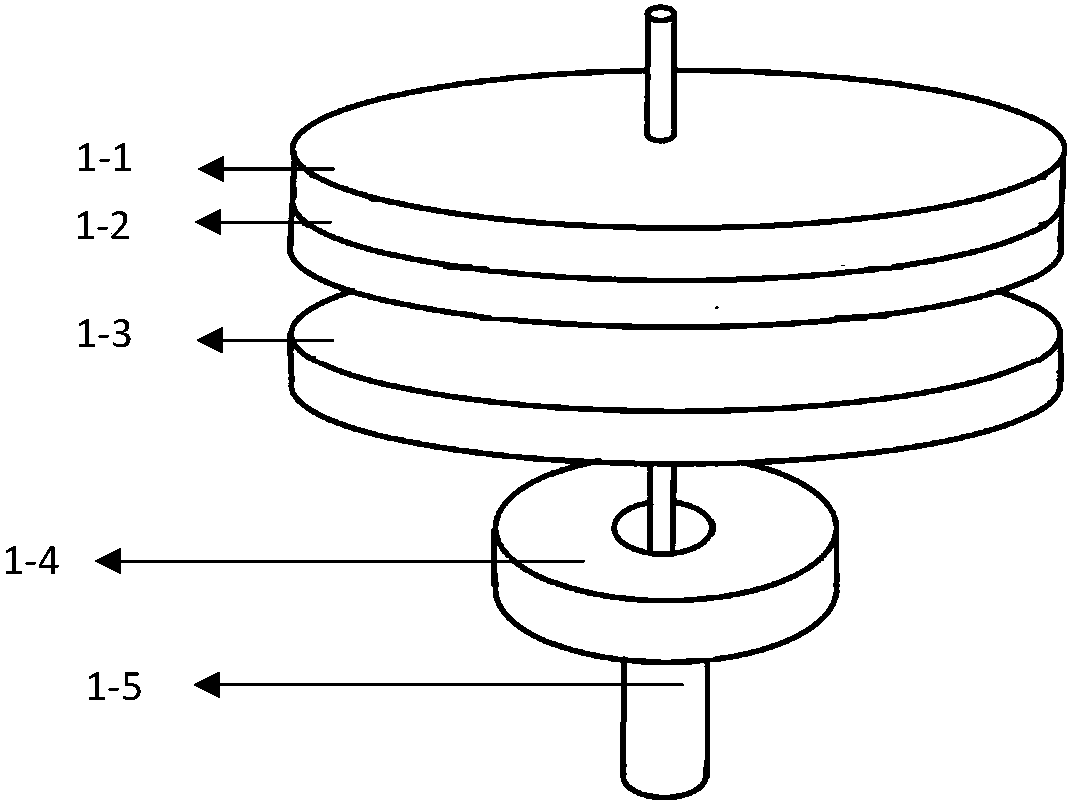

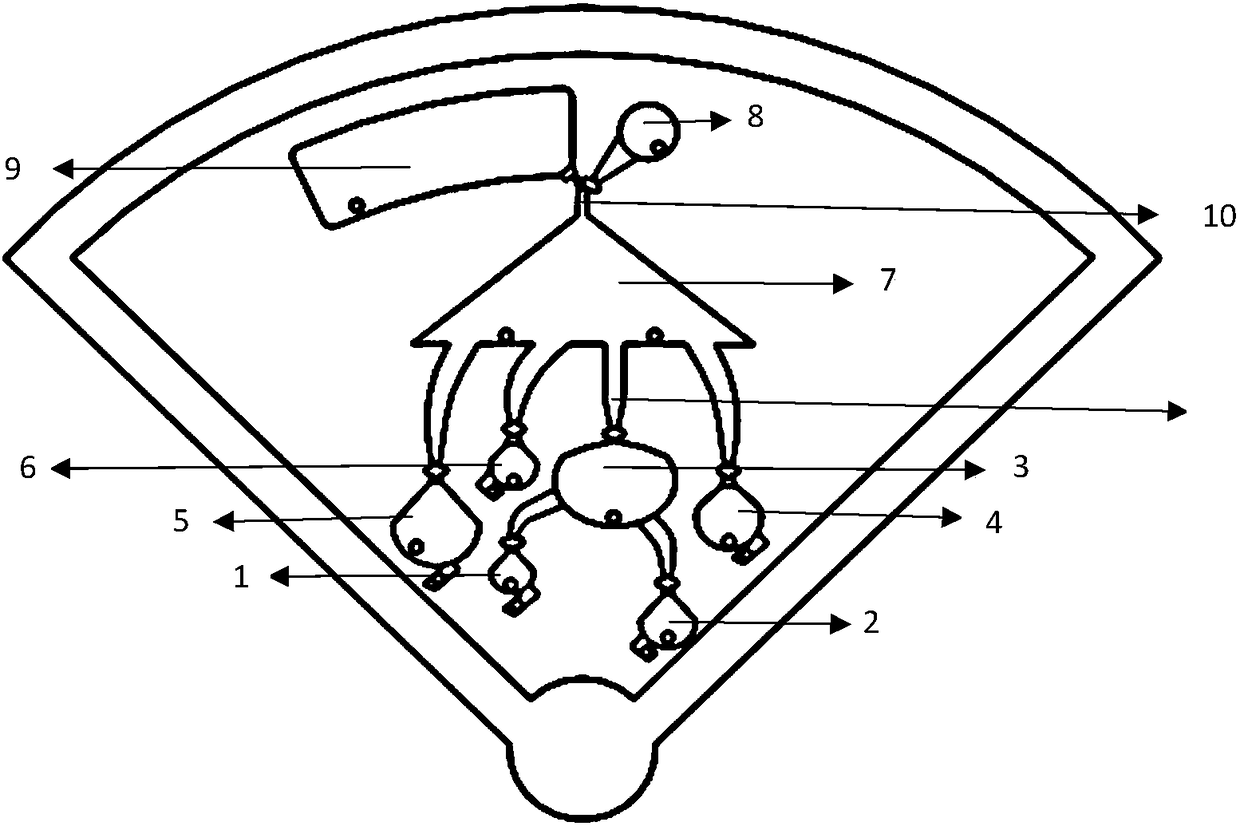

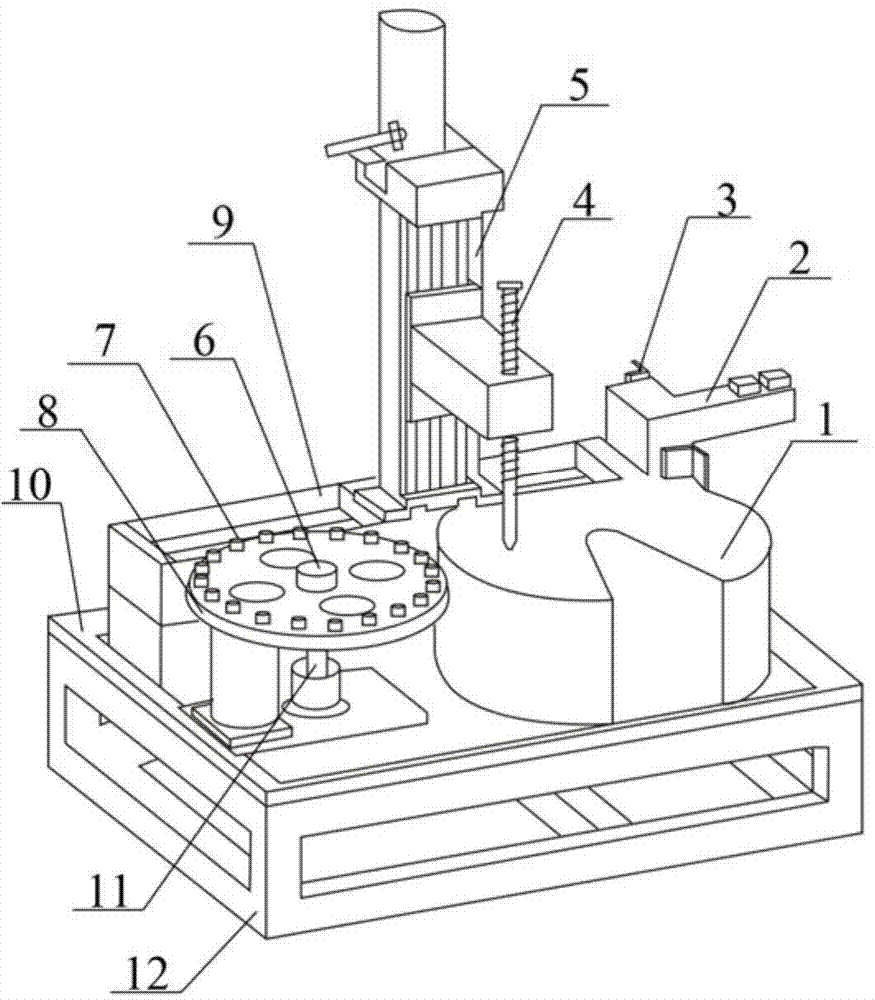

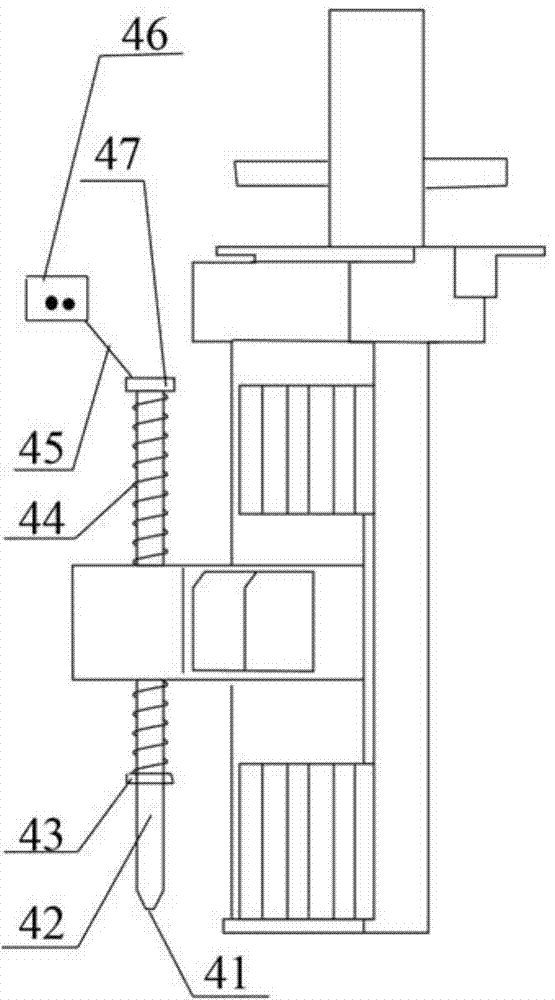

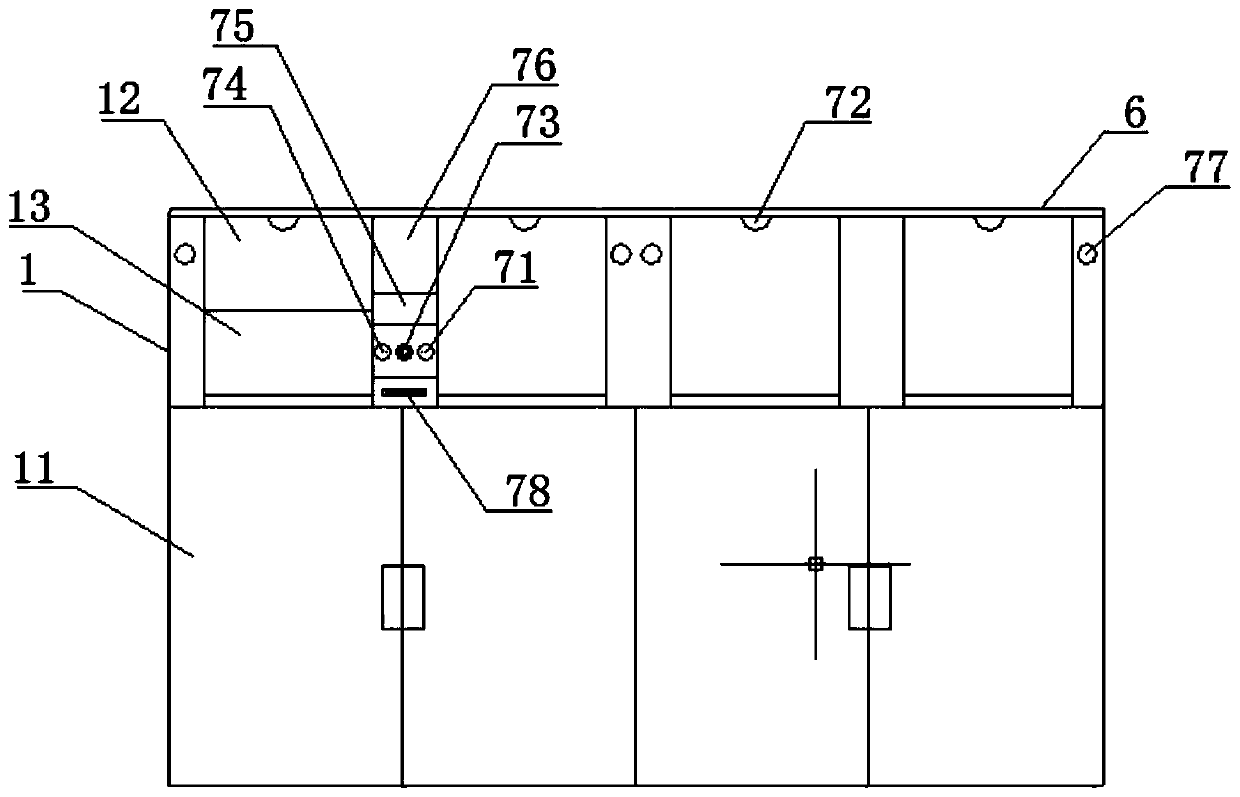

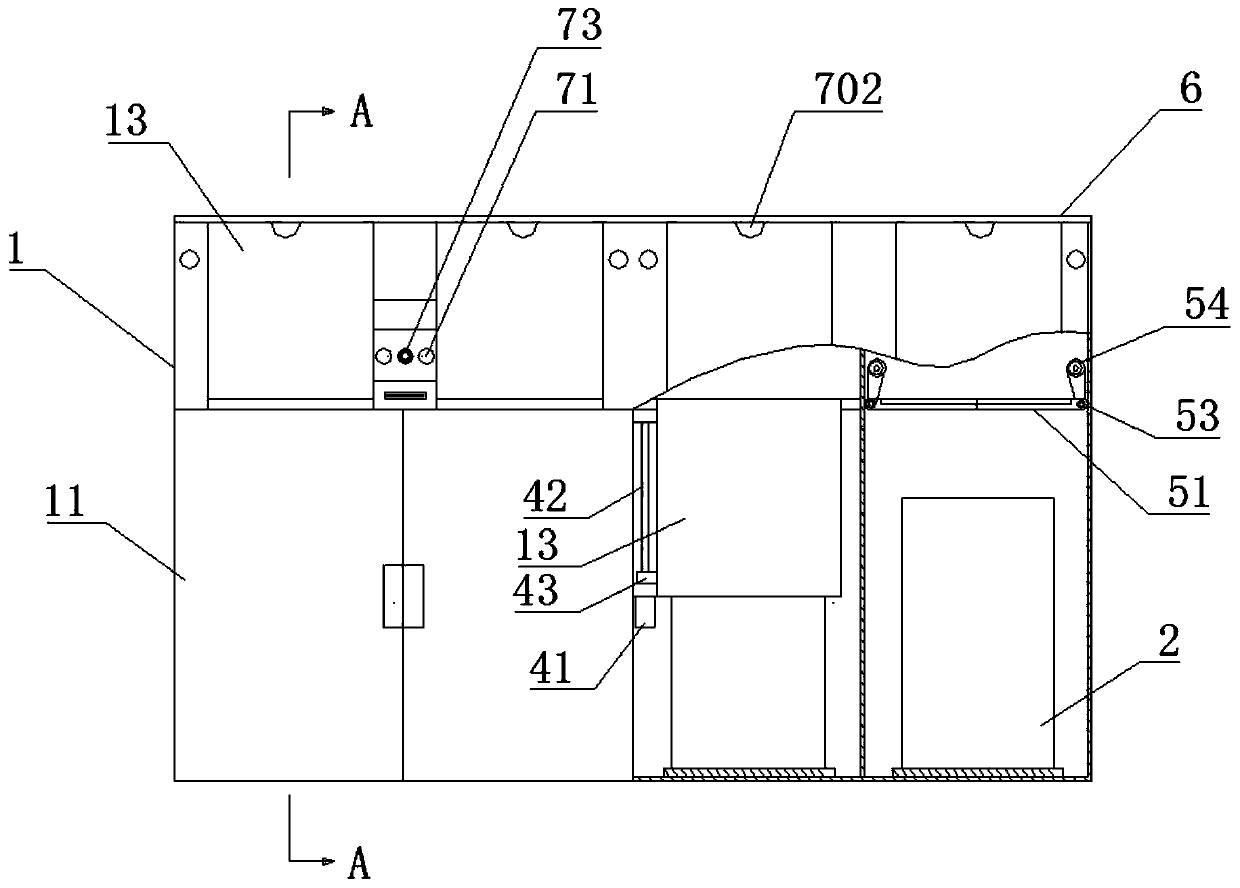

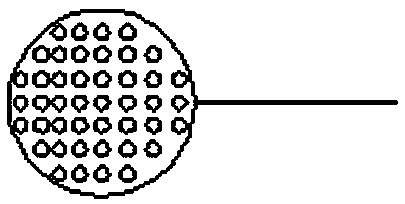

Automatic sorting device for irradiated particles

The invention relates to the nuclear technological field and particularly relates to an automatic sorting device for irradiated particles. The device comprises a base, a particle automatic picking unit, a particle collection unit and a particle measuring unit. The particle collection unit comprises a sample bottle and a lofting bottle which are arranged on the base. The measuring unit comprises a shielding cavity and a measuring instrument, and the measuring instrument is opposite to the shielding cavity. The particle picking unit comprises a vacuum suction pen and a vacuum pump. The vacuum suction pen is fixed on the base movably and is arranged vertically, and a suction opening of the vacuum suction pen is downward. The vacuum pump is connected with the suction opening through a pipe, the vacuum pump pumps air in the vacuum suction pen through the suction opening to control the suction opening to suck samples to be detected. A control unit is further arranged. By means of the device, automatic grabbing, detection, classification and putting of radiated coated fuel particles can be achieved, and the device is applicable to damage detection and analysis of high-radioactivity irradiated coated fuel particles.

Owner:TSINGHUA UNIV

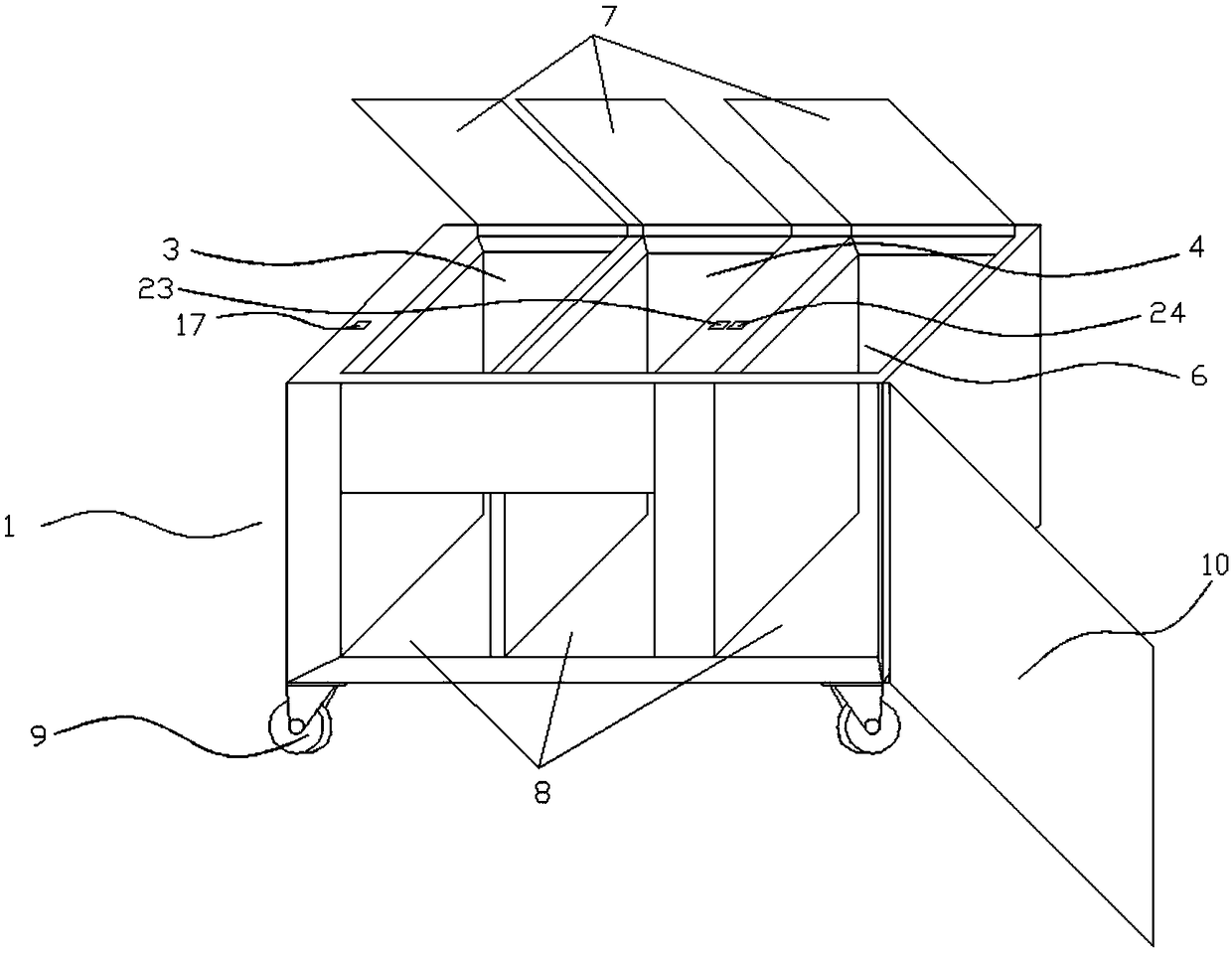

Intelligent garbage classification and collection box and control system thereof

PendingCN111332645AAvoid exposure or theftPromote waste separation and reduce waste productionWaste collection and transferRefuse receptaclesEmbedded systemAutomatic control

The invention relates to the technical field of garbage classification equipment, and discloses an intelligent garbage classification and collection box and a control system thereof. The intelligent garbage classification and collection box comprises a main box body of the collection box, wherein the interior of the main box body is partitioned into a plurality of classification box bodies throughpartitions, a collection bucket is arranged in each classification box body, a garbage pouring port is formed above each collection bucket, a pouring door is formed in front of each pouring port, andeach pouring door is driven through a push-pull motor to realize opening and closing for the corresponding pouring port; and an overturning plate is arranged between each pouring port and the corresponding collection bucket, a weighing sensor is installed on each overturning plate, and each overturning plate is driven through an overturning motor to enable garbage to fall into the corresponding collection bucket. According to the intelligent garbage classification and collection box and the control system thereof, classification and collection for many types of the garbage can be realized, and control over classification, pouring and weighing for the garbage is realized through the control system; the garbage pouring data of users can be intelligently collected, opening for the pouring ports and overturning of the overturning plates can be automatically controlled, and a high automation degree is achieved; and realization for network operation and remote control is facilitated.

Owner:山东海纳环境工程有限公司

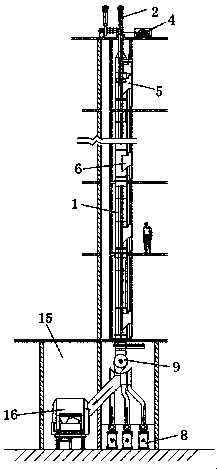

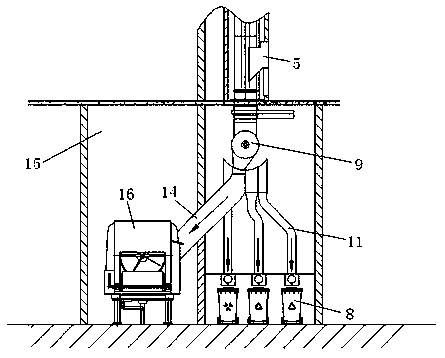

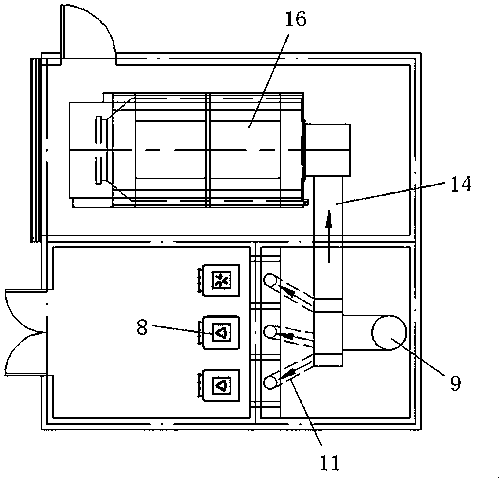

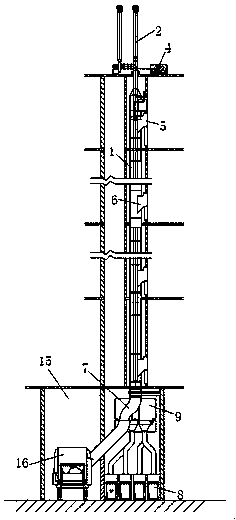

Hospital waste sorting collection system

PendingCN108442651AReduce the impactSolve processing problemsVertical ductsCollection systemHospital waste

The invention relates to the technical field of waste collection systems, and discloses a hospital waste sorting collection system. The hospital waste sorting collection system comprises waste collection passages arranged in each layer in a penetrating mode, and a plurality of waste disposal doors arranged on the waste collection passages, and output passages communicating with the waste collection passages are arranged on the lower portions of the waste collection passages. A control unit of the collection system comprises control panels arranged on the waste disposal doors, the collection unit comprises a plurality of sorting trash cans and rotating output heads, the sorting trash cans are arranged on the ground below the output passages, the rotating output heads are arranged above thesorting trash cans, and the output passages communicates with the rotating output heads. The rotating output heads can rotate around a rotating shaft, so that different rotating angles are formed by the rotating output heads and the vertical direction, a plurality of waste collection openings are arranged below the rotating output heads in an arc-distributed mode, and the waste collection openingscorresponds to the corresponding sorting trash cans. The hospital waste sorting collection system transports different types of waste to different types of trash cans and realizes waste sorting and collection.

Owner:WUXI HUANYU SHUANGHUI ENVIRONMENTAL PROTECTION EQUIP CO LTD

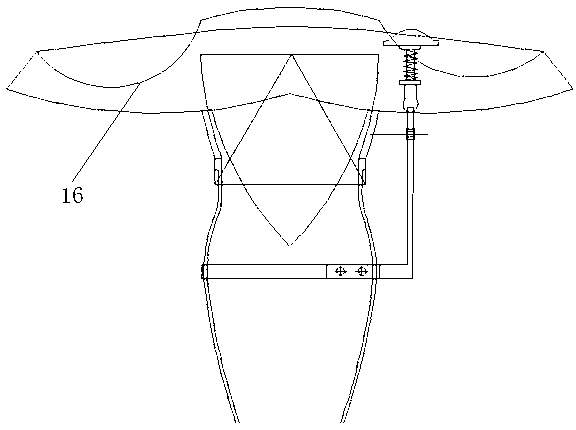

Leaf removing, skin cutting and stalk scraping type straw skin-stalk separation device and method

PendingCN111452162AAchieve peeling effectImprove mechanical propertiesOptical detectionCuttersEngineeringBiomass c

The invention discloses a leaf removing, skin cutting and stalk scraping type straw skin-stalk separation device and method, belongs to the technical field of biomass energy utilization, and solves the problems that an existing separation machine is incomplete in straw skin-stalk separation, poor in separation effect, low in production capacity and high in energy consumption. The device is characterized in that a feeding device, a leaf removing device, a positioning and cutting device, a clamping device and a stalk scraping device are arranged on a rack in sequence; the feeding device is usedfor feeding the straw into the leaf removing device; the leaf removing device is used for removing straw leaves, tearing off the straw leaves, tearing off the leaves, and feeding the straw into the positioning and cutting device; the positioning and cutting device is used for positioning and cutting the straw, longitudinally cutting the straw and feeding the straw into the clamping device; the clamping device is used for clamping the straw and driving the straw to move forwards to the stalk scraping device; and the stalk scraping device is used for separating the straw skin and stalk. The device and the method are used for straw skin-stalk separation treatment.

Owner:NORTHEAST FORESTRY UNIVERSITY

Dustbin with sorting, collecting and pre-disposal functions

InactiveCN108861236AReduce volumeWork lessWaste collection and transferRefuse receptaclesSteel platesFood waste

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

Environment detection sampling device

PendingCN111351682AImprove sampling efficiencyRealize accurate samplingWithdrawing sample devicesEdaphicDrive motor

The invention discloses an environment detection sampling device. The environment detection sampling device comprises a device body; and the device body comprises a soil sampling and collecting mechanism, the soil sampling and collecting mechanism comprises a drilling barrel, a spiral conveying roller is nested in the drilling barrel, a dispersing barrel penetrates through the upper part of the drilling barrel, the spiral conveying roller is connected with a driving motor through a shaft coupling, and the spiral conveying roller is in transmission connection with the drilling barrel through atransmission gear set. Through the arrangement of the drilling barrel with a discharging opening formed in the upper portion, an inner material stirring plate connected with the spiral material conveying roller, an outer scraping plate fixedly connected with the drilling barrel, the dispersing barrel, a discharging pipe and a collecting pipe, soil of different depths is lifted, soil of non-targetdepths is discharged, soil of target depths is collected, and accurate sampling of soil of the designated depth is achieved; and through the arrangement of a material guide pipe and a bearing seat which is linked with the drilling barrel and rotates, soil of different depths is collected and stored in a classified mode, classified collection of samples is achieved, and the overall efficiency of soil sampling is improved.

Owner:LULIANG UNIV

Pushing shunting mechanism of roxburgh rose sorting system

InactiveCN109592372ARealize classified collectionImprove sorting efficiencySortingConveyor partsAssembly lineEngineering

The invention discloses a pushing shunting mechanism of a roxburgh rose sorting system. The pushing shunting mechanism comprises a detection conveyor. A pushing shunting mechanism body is arranged onthe detection conveyor. The pushing shunting mechanism body comprises at least one pair of push rods and shunting passageways, wherein the push rods and the shunting passageways are arranged on the two sides of the detection conveyor. The push rods are suitable for pushing roxburgh rose into the assorted shunting passageways. The push rods and the shunting passageways are arranged on the two sidesof the detection conveyor, the roxburgh rose can be pushed into the different shunting passageways from the detection conveyor, and then the roxburgh rose is classified and collected; and compared with a traditional screening manner, the manner of an automatic assembly line is adopted, and the sorting efficiency of the roxburgh rose is greatly improved.

Owner:GUIZHOU UNIV

Oxidation separation, purification, regeneration and utilization method and device for fusion reactor hot room by means of cleaning waste gas

ActiveCN105654997ASolve processingSolve cleaningRadioactive decontaminationRadioactive gasRemote control

The invention relates to an oxidation separation, purification, regeneration and utilization method and device for a fusion reactor hot room by means of cleaning waste gas. The method includes the four process procedures of cleaning and decontamination, filtering and purification of solid and liquid impurities, oxidization separation and purification of gaseous radioactive impurities, preparation of low-temperature power gas, regeneration of volatile particles and long-distance pneumatic conveying of the volatile particles. The original cleaning waste gas is used, and the radioactive particles, residual radioactive gas and cleaning media can be collected in a classified mode and separated; the problem about minimization of radioactive waste in the hot room is solved. The radioactive particles and gaseous nuclear fuel can be effectively collected while it is guaranteed that the cleaning waste gas does not contaminate the environment as radioactive effluent. Besides, the original cleaning media can be recycled and reused so that a carbon dioxide dry ice blast cleaning scheme can become the preferred scheme for cleaning polluted radioactive surfaces in the hot room on the basis. The process scheme is simple in loop structure, easy to implement and suitable for the hot room environment of remote control operation.

Owner:UNIV OF SCI & TECH OF CHINA

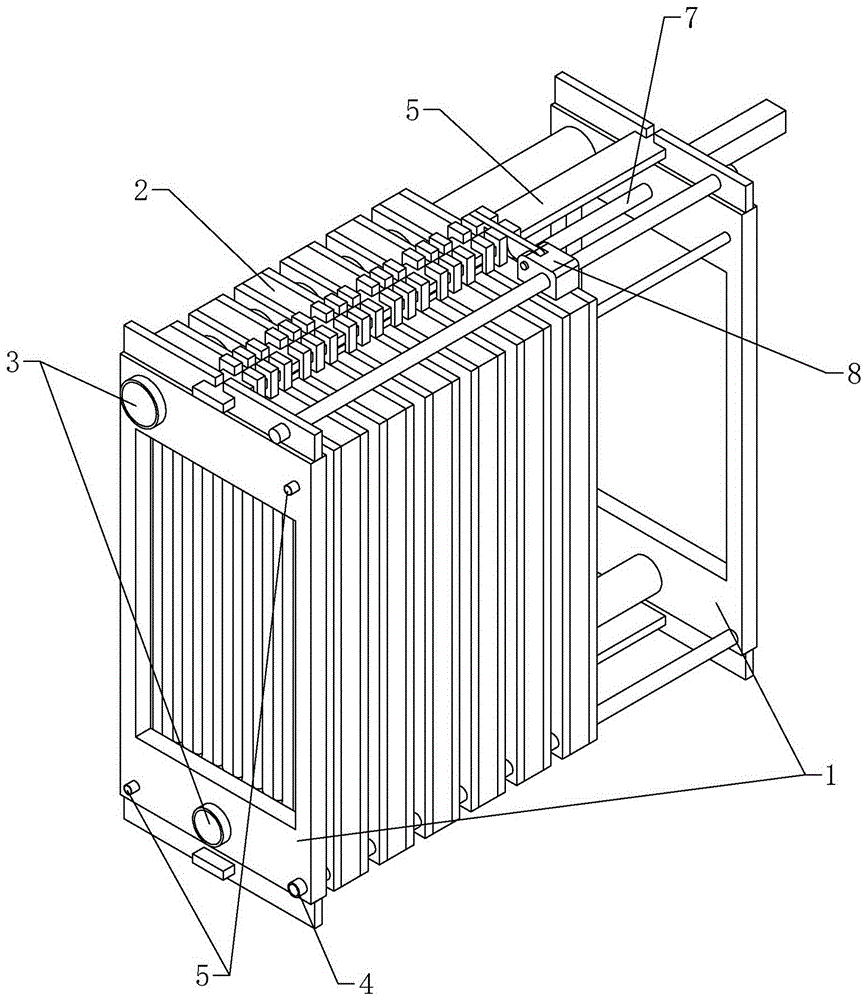

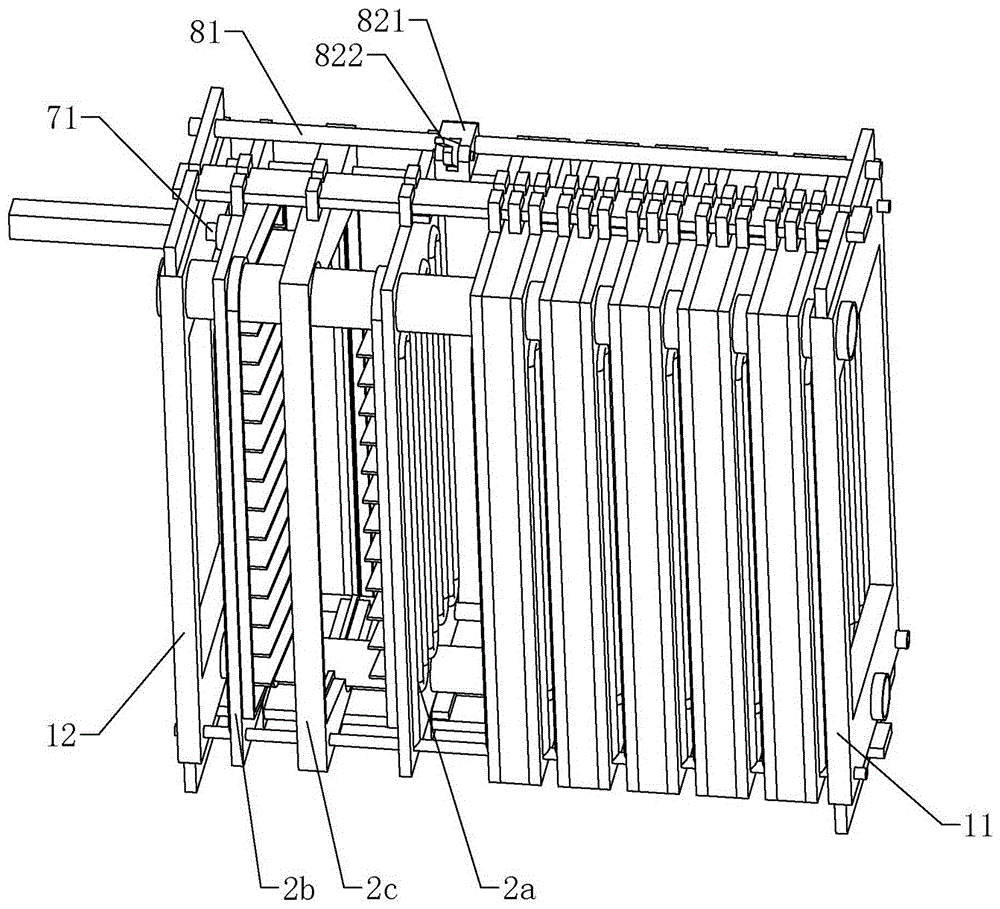

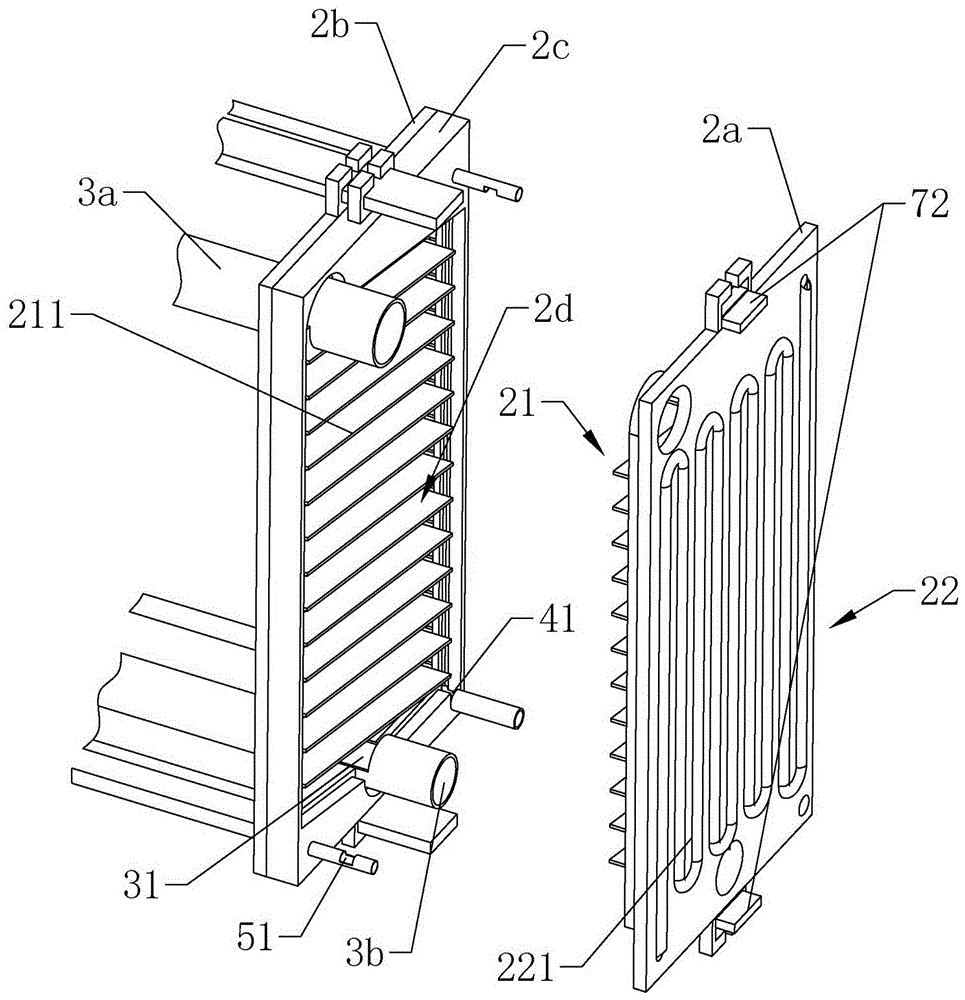

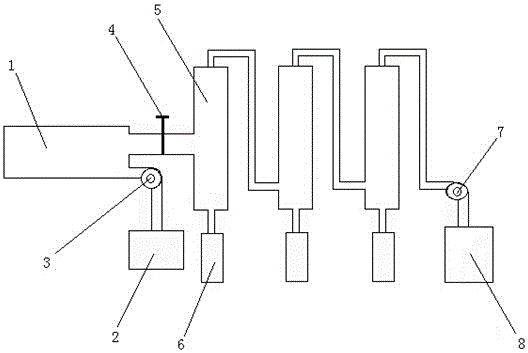

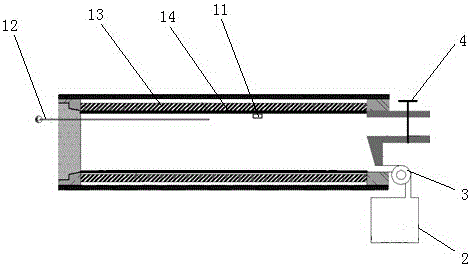

Oil gas recovery device

ActiveCN106064008AEasy to separateExtended service lifeGas treatmentDispersed particle filtrationMechanical engineeringEngineering

The invention relates to a recovery device and particularly relates to an oil gas recovery device which includes: a bracket board, a plurality of condensing filter units, a gas pipe, a recovery pipe, a condensing pipe, a slide rail, and a pressing mechanism. The bracket board includes a first bracket board and a second bracket board arranged on the two ends of the device respectively. Each condensing filter unit includes a first filter plate, a second filter plate, and a sealing pad plate, a filter chamber formed in the middles of the first filter plate and the second filter plate. Each of the first filter plate and the second filter plate includes a filtering surface and a condensing surface. A multilayer metal filtering plate and a collection channel for collecting condensed liquid are arranged on the filtering surface, wherein the collection channel is communicated with the recovery pipe. A gas pipe groove and a recovery pipe groove are disposed in zones, which are located in the filter chamber, relative to the gas pipe and the recovery pipe. A condensing pipe groove is disposed in a zone, which is located in the filtering surface, relative to the condensing pipe. The pressing mechanism includes a pressing rod arranged on the bracket board, and a pressing piece that is arranged on the first filter plate or the second filter plate.

Owner:ZHEJIANG HUAQIANG ENVIRONMENTAL TECH

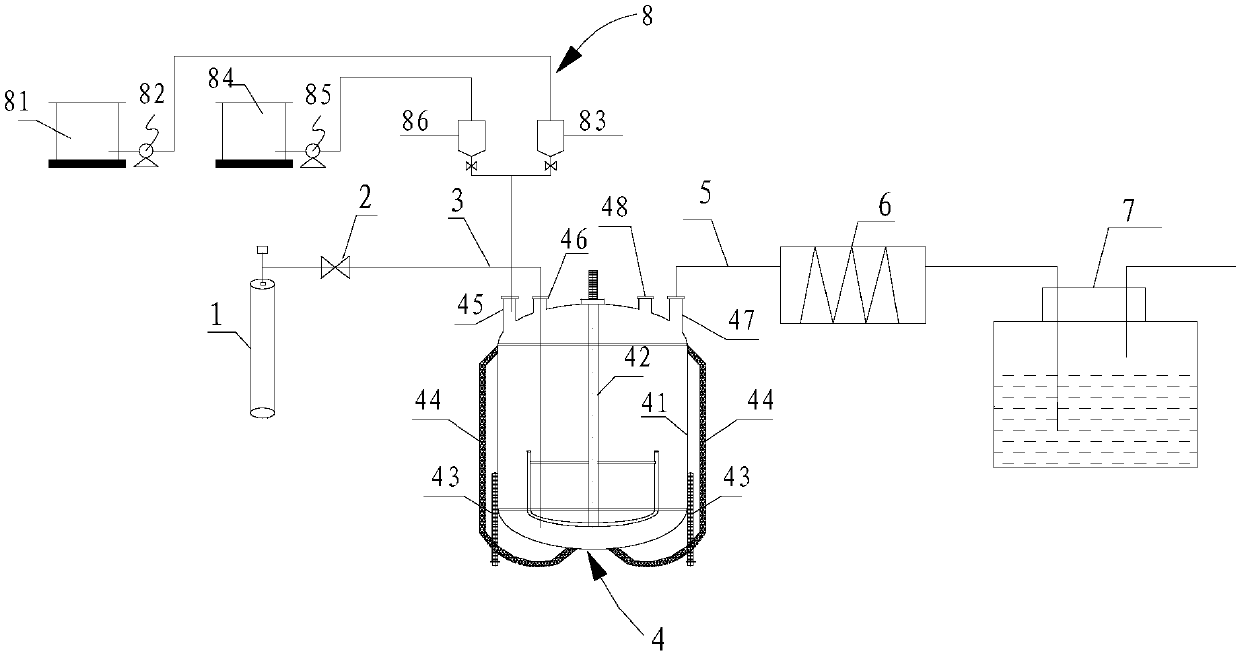

Device for producing fuel oil and gas by thermolysis of waste toner cartridge carbon powder

ActiveCN105802655APyrolysis reaction rate is fastImprove qualityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentFuel oilOil storage

The invention discloses a device for producing fuel oil and gas by pyrolysis of waste toner cartridge carbon powder. The device comprises a pyrolysis reactor 1, a solid residue storage tank 2, a powder pump 3, a valve 4, a condenser 5, an oil storage tank 6, a vacuum pump 7, and a non-condensable gas collecting bottle 8, wherein the storage tank 2 is connected with the lower part of an end part of the pyrolysis reactor 1, and the powder pump 3 is arranged on a pipeline between the storage tank 2 and the pyrolysis reactor 1; the upper part of the end part of the pyrolysis reactor 1 is connected with the condenser 5 by virtue of an oil-gas delivery pipe, and the valve 4 is arranged on the oil-gas delivery pipe between the pyrolysis reactor 1 and the condenser 5; and the oil storage tank 6 is connected to the bottom of the condenser 5, the gas collecting bottle 8 is connected with the condenser 5 by virtue of an oil-gas delivery pipe, and the vacuum pump 7 is arranged on the oil-gas delivery pipe between the gas collecting bottle 8 and the condenser 5. The processes of pyrolysis, condensation and collection of the device are performed synchronously to realize separate collection of pyrolysis oil, pyrolysis gas and solid residues, and the obtained fuel oil and gas are high in quality, so that the device has significant economic and environmental benefits.

Owner:SUN YAT SEN UNIV

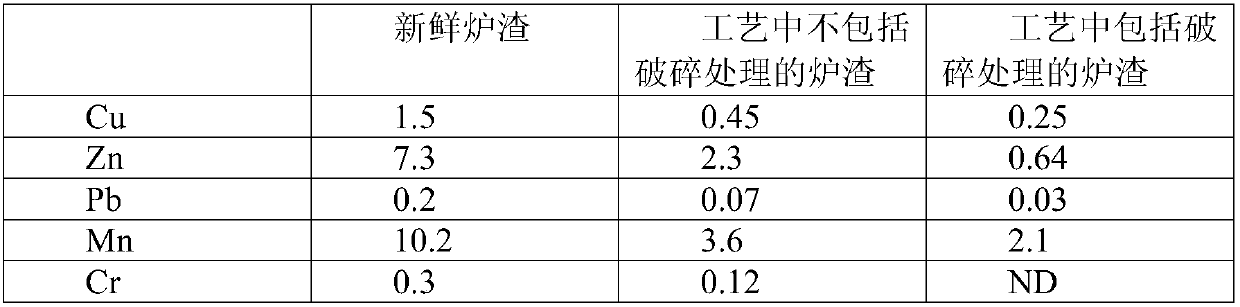

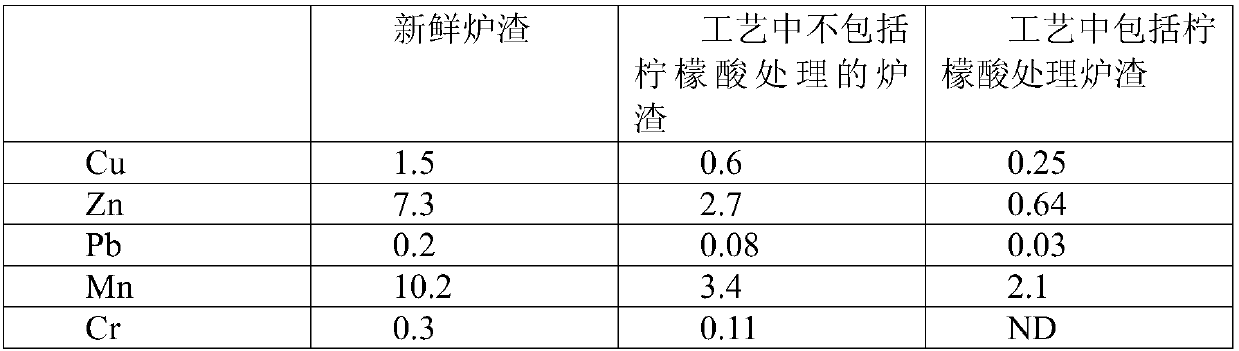

Method and device for reducing metal dissolution in domestic waste incinerator slag

The invention discloses a method for reducing metal dissolution in domestic waste incinerator slag. The method comprises the following steps that (1) domestic waste incinerator slag particles are crushed into particles with the particle size below 5 mm; (2) the crushed domestic waste incinerator slag is put into a reaction kettle, and citric acid solution is added until the crushed domestic wasteincinerator slag is just immersed for soaking; (3) MgCl2 is added into the reactor kettle, a reaction kettle heater is started to make the temperature in the reaction kettle reach 650-750 DEG C, meanwhile, carrier gas is stared, heat preservation is conducted for 1.5-2.5h, then the temperature is further raised to 900-950 DEG C, heat preservation is conducted for 1.5-2.5h, and gas in the reactionkettle is exhausted from an exhaust pipe, enters a condenser, and then enters a tail gas purifying device for being exhausted; and (4) the reaction kettle after the heat reaction is finished is cooledto the room temperature, the domestic waste incinerator slag is taken out, and condensation products at different heat preservation stages in the condenser serve as metal enriched products and are recycled in batched. The method for reducing metal dissolution in the domestic waste incinerator slag can reduce metal dissolution in the domestic waste incinerator slag, and meanwhile, metal in the domestic waste incinerator slag is recycled.

Owner:姚俊 +1

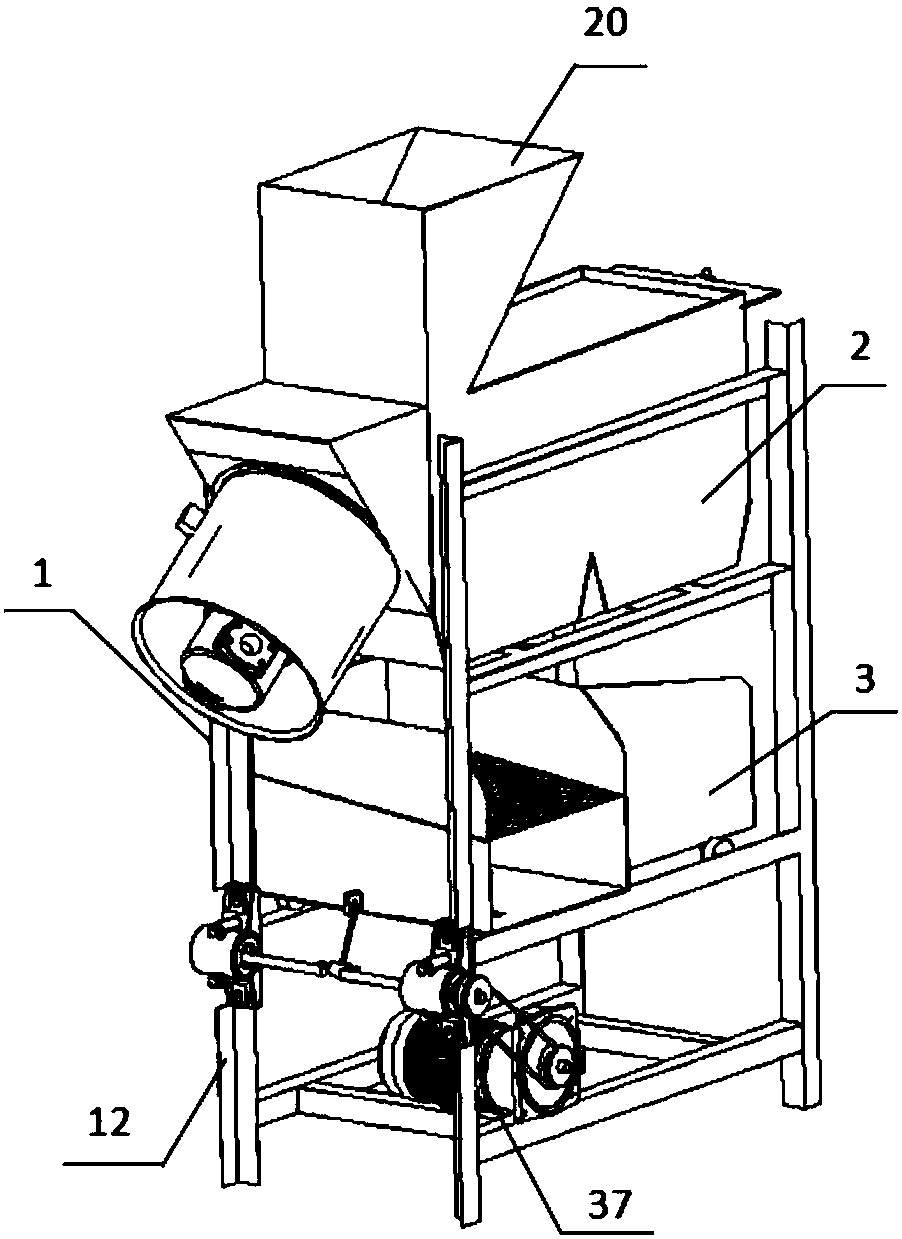

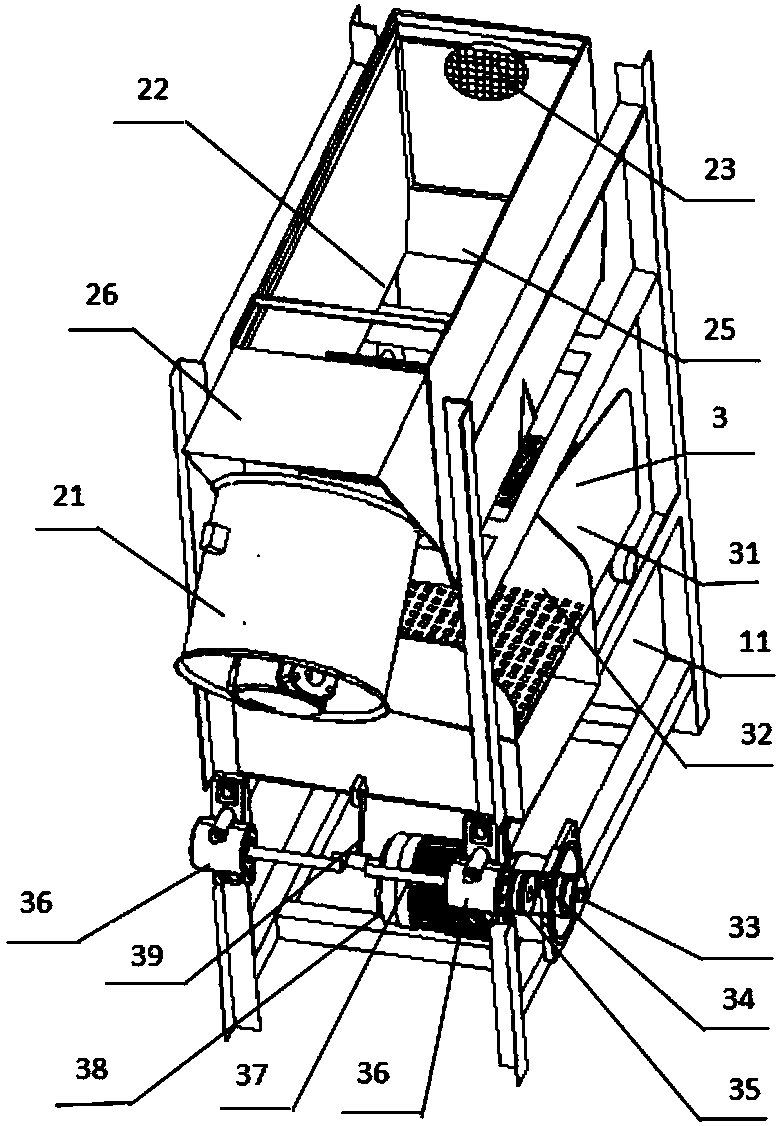

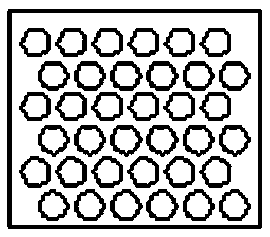

Winnowing screening device for waste power battery

ActiveCN108580292AReduce pollutionImprove separation rateSievingGas current separationPower batteryEngineering

The invention discloses a winnowing screening device for a waste power battery. The winnowing screening device comprises a machine frame, a winnowing device and a layered sieve; the layered sieve comprises a light material layering sieve, a heavy material layering sieve and a transmission device; the machine frame is of a frame structure welded by angle iron, and is divided into an upper layer, amiddle layer and a lower layer, the winnowing device is installed on the upper layer, and the layered sieve is installed in the middle layer; and the winnowing device comprises a feed hopper, an axialflow fan and a winnowing bin. According to the winnowing screening device, during operation, crushed waste power battery materials enter the hopper, wind power of the axial flow fan blows the waste power battery materials in an upwards inclined mode, and the waste power battery materials fall into the lower light material layering sieve and the heavy material layering sieve from the winnowing binin a parabolic shape, carbon powder in the waste power battery materials passes through meshes of the light material layering sieve and the heavy material layering sieve to fall into a discharging opening below, light-weight sheet aluminum foil is a sieve residue of the light material layering sieve, heavier flaky copper foil is a sieve residue of the heavy material layering sieve, so that classified collection of the waste power battery materials is realized.

Owner:HEFEI UNIV OF TECH

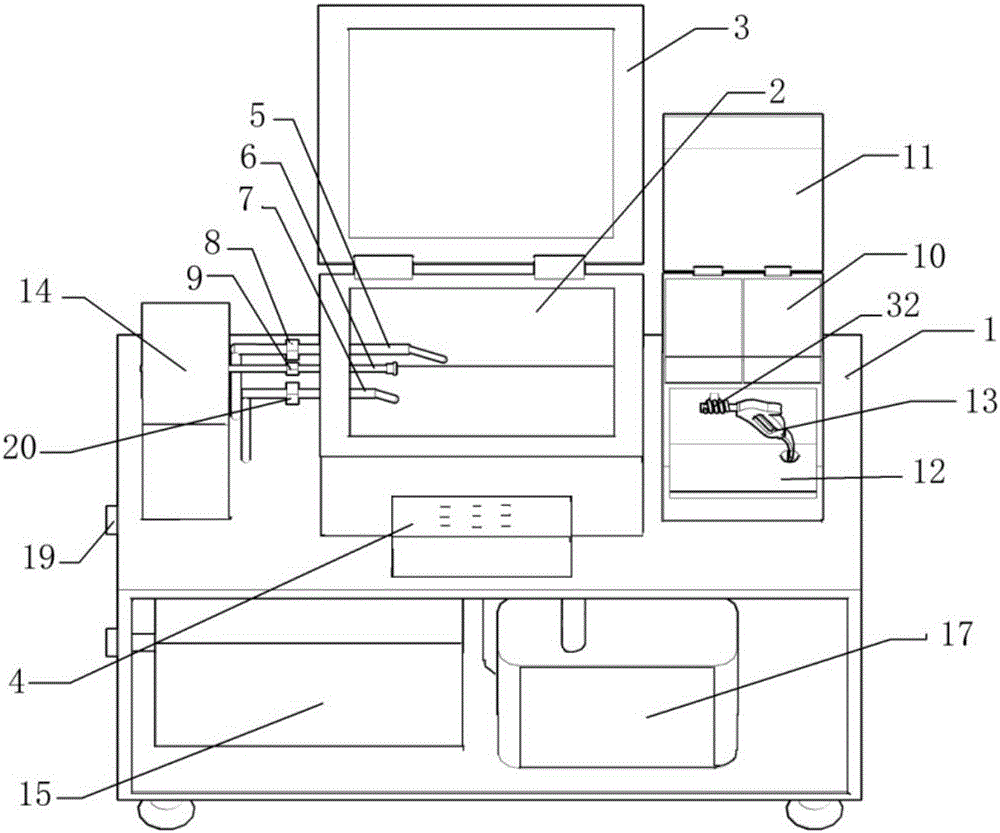

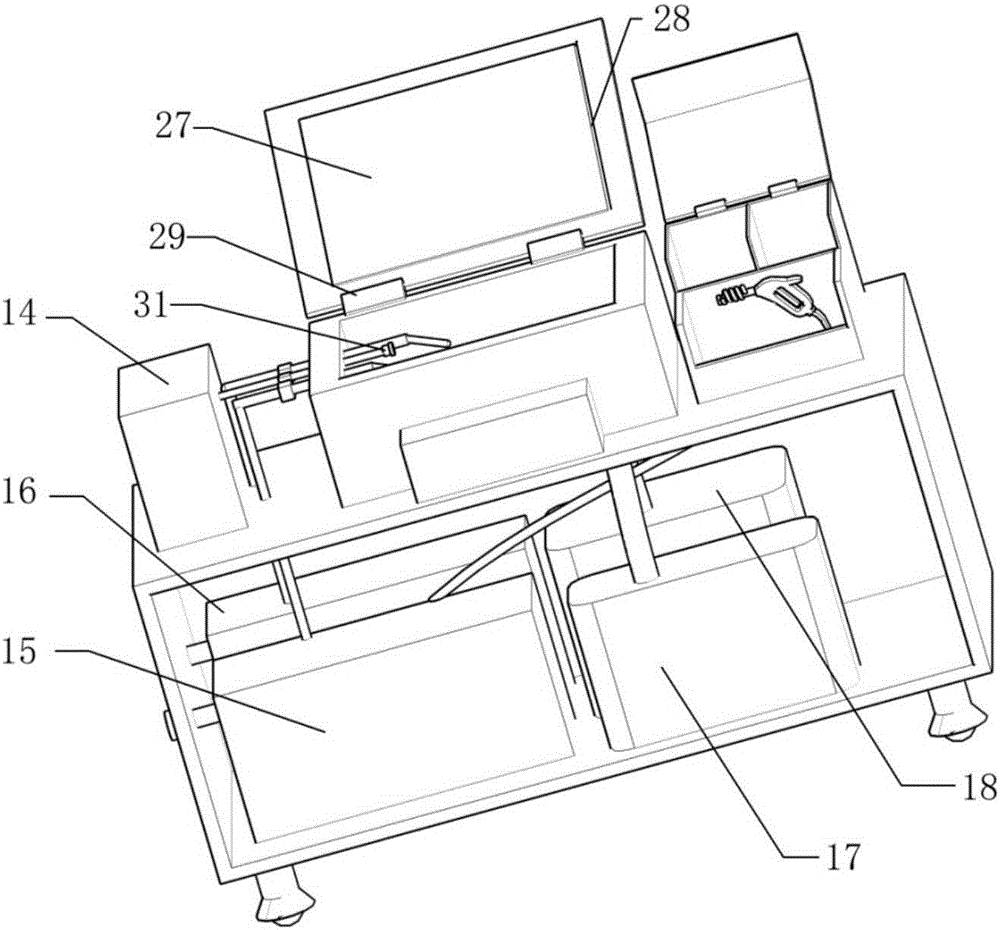

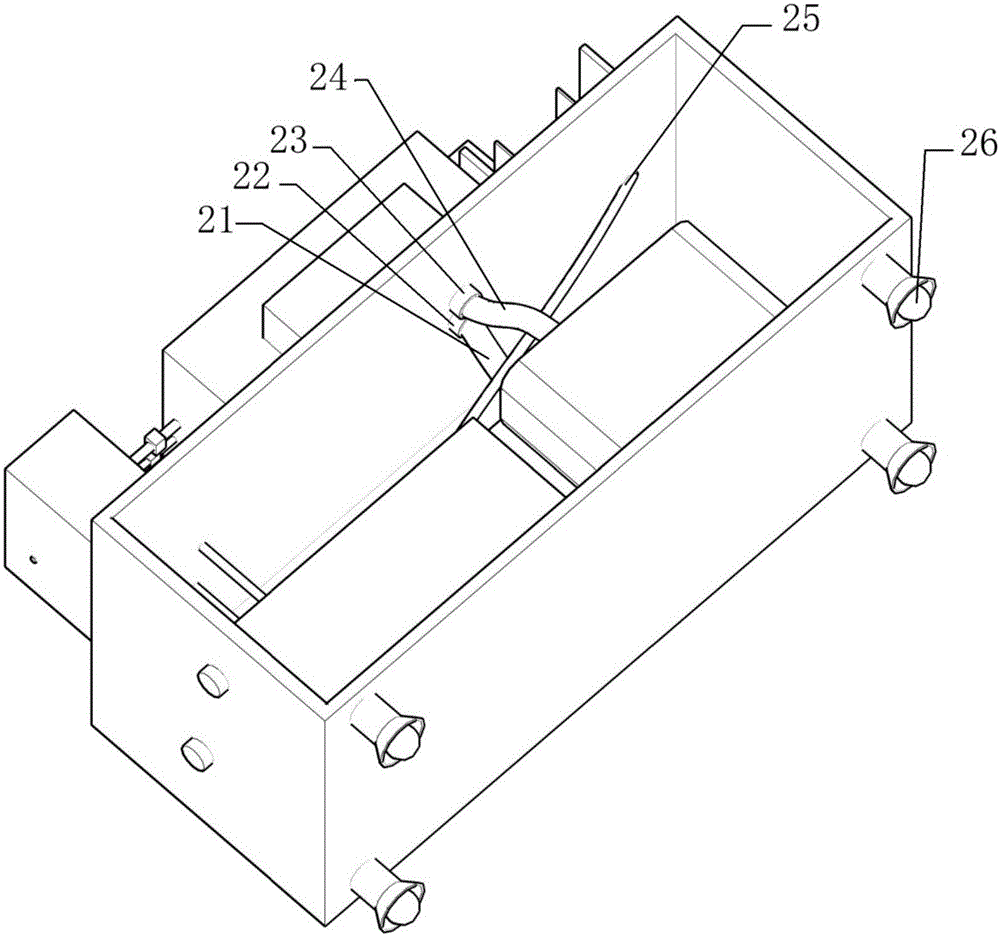

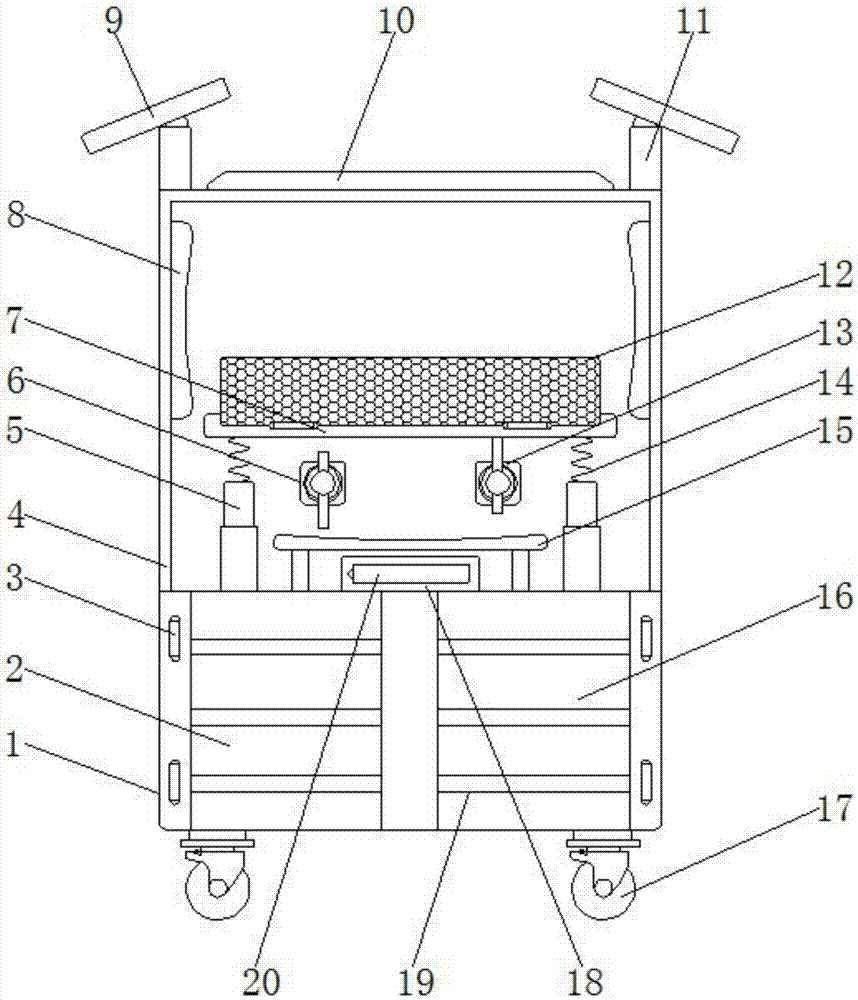

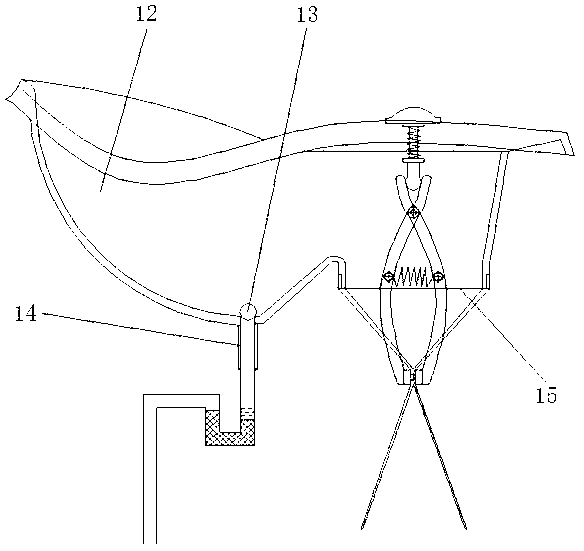

Multifunctional endoscope cleaning machine

InactiveCN106799382AReduce exposureShorten the timeHollow article cleaningCleaning using toolsEngineeringControl table

The invention belongs to the technical field of medical treatment, and discloses a multifunctional endoscope cleaning machine which comprises a body, a cleaning device, a drying device, a cleaning apparatus storage device, a cleaning liquid storage device and a control table. The cleaning device is arranged above the body, a heating unit of the drying device is arranged on the outer side of the cleaning device in a sandwiched manner, the cleaning apparatus storage device and the control table are further arranged on the outer side of the cleaning device, and the cleaning liquid storage device is arranged below the body. The cleaning machine is simple in structure and convenient to operate, cleaning and drying are integrated, the size of the cleaning machine is reduced, the cleaning machine can be moved to a needed place as the cleaning liquid storage device is arranged below the body, and operation of medical staff is coordinated.

Owner:CHENGDU KECHUANGGU TECH CO LTD

Air-curing device for pharmaceutical preparation technology of lung warming and phlegm reducing Chinese medicine lucid ganoderma

InactiveCN107328189AAchieve slight flippingRealize classified collectionBatteries circuit arrangementsElectric powerMedicinePharmaceutical technology

The invention relates to an air-curing device for a pharmaceutical preparation technology of lung warming and phlegm reducing Chinese medicine lucid ganoderma. The air-curing device comprises a lucid ganoderma storing shell, a storeroom to be sun-cured, a light condensation plate, springs and a storage battery. One side in the lucid ganoderma storing shell is provided with the storeroom to be sun-cured, an air-curing storeroom is arranged in the lucid ganoderma storing shell on one side of the storeroom to be sun-cured, the edge position of the top end of the lucid ganoderma storing shell is provided with a transparent protective cover, the bottom end in the transparent protective cover is movably provided with a reflective plate by an upright column, the bottom end of the transparent protective cover below the reflective plate is fixedly provided with an electric power shell, the storage battery is arranged in the electric power shell, the light condensation plate is fixed in the central position of the top end of the transparent protective cover, and angle adjusting rods symmetric about each other are mounted on the top end of the transparent protective cover on both sides of the light condensation plate. According to the invention, not only are the working efficiency during air-curing of the lucid ganoderma and the convenience when the air-curing device is used improved, but also the uniformity in the air-curing process is realized.

Owner:胡小爱

System for sorting and processing urine and shit

InactiveCN103222825ARealize classified collectionEasy to useBathroom accessoriesWater savingComputer science

The invention discloses a system for sorting and processing urine and shit. The system comprises a waterless urinal, a urine and shit separation water-saving closestool, a defecating pool and a urinating pool, wherein the defecating pool is arranged below the urine and shit separation water-saving closestool; the urine and shit separation water-saving closestool is connected with the urinating pool; and the waterless urinal is connected with the urinating pool. The system has a function of separating urine from shit; sorting and collection of shit and urine from a source are achieved; the urine and the shit are used as organic fertilizers; the system is light, comfortable, convenient to use, good in air isolation effect, energy-saving, environment-friendly and low in cost, and can be prevented from being stuck with urine or shit.

Owner:DALIAN NATIONALITIES UNIVERSITY

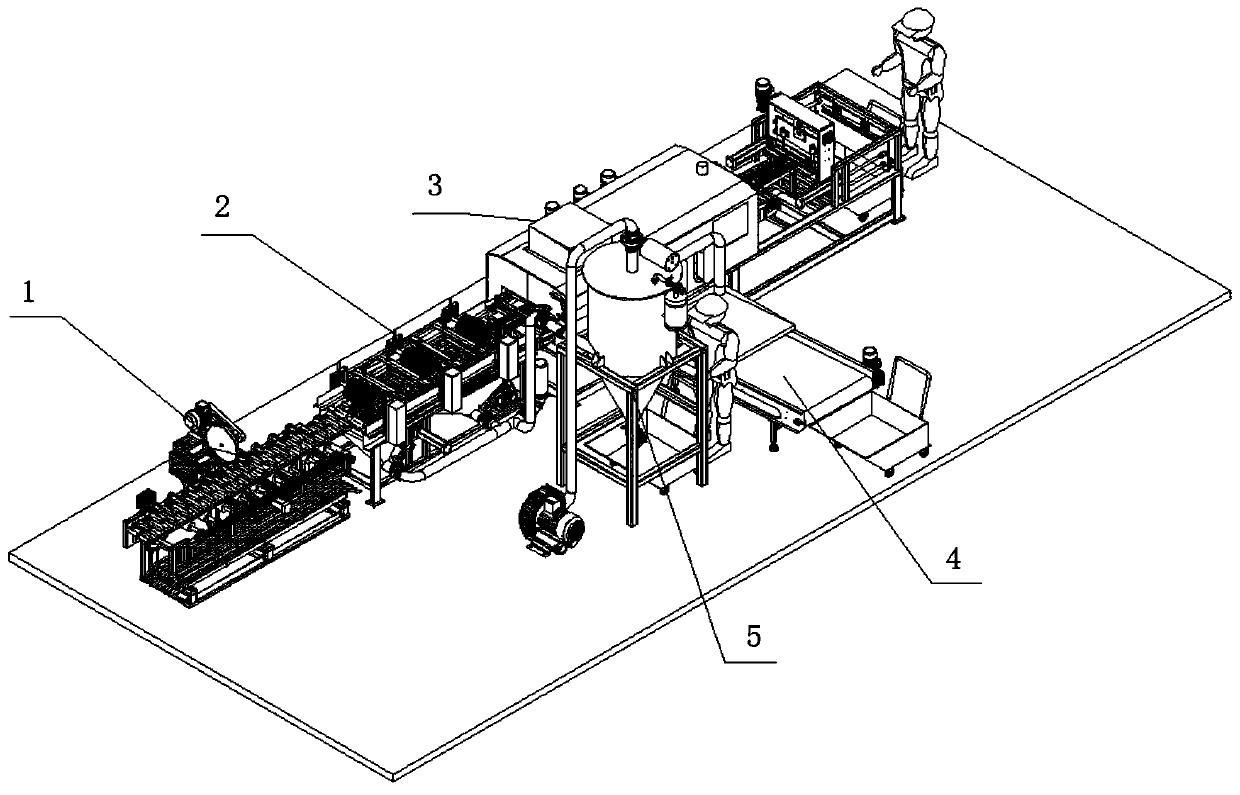

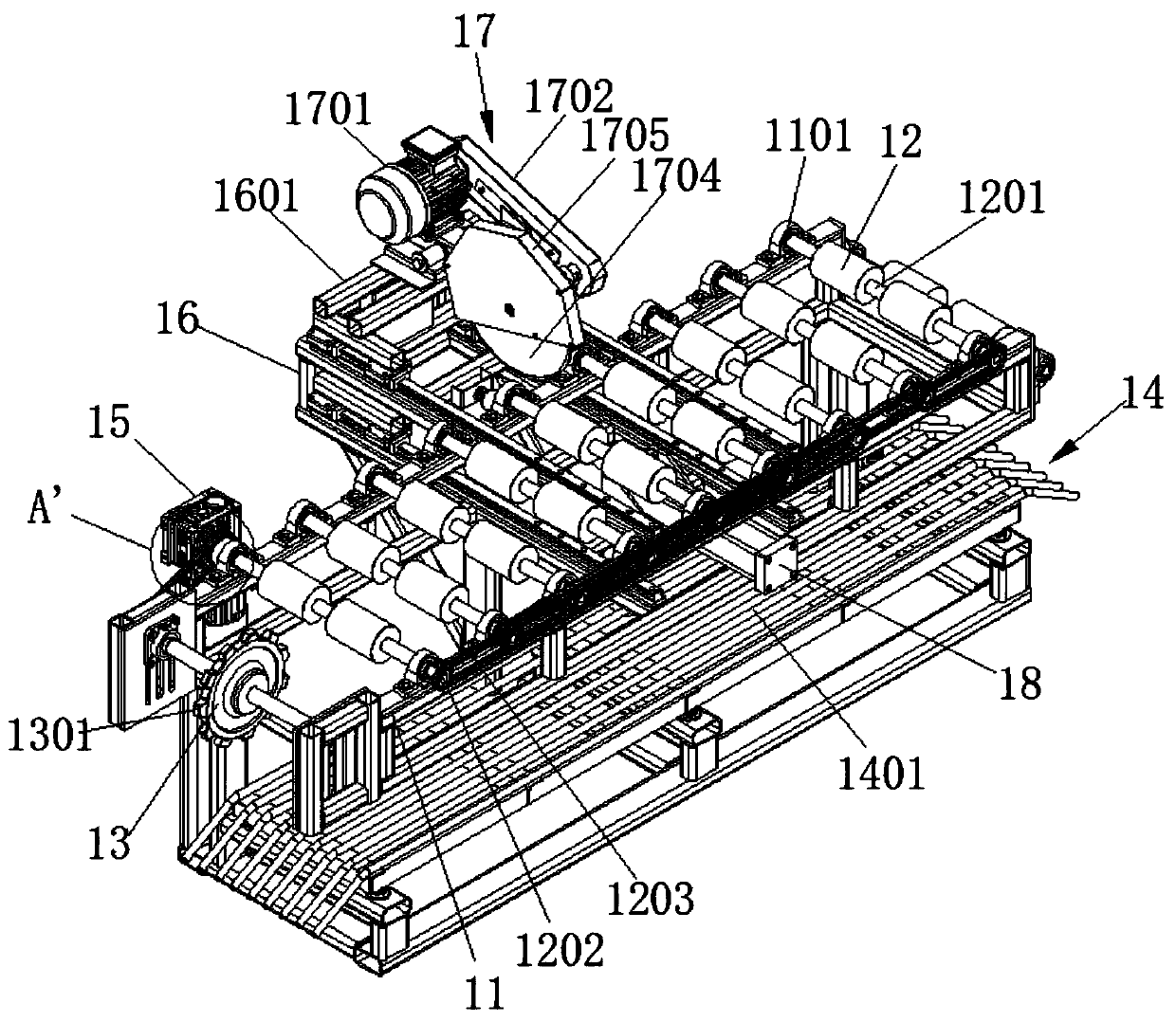

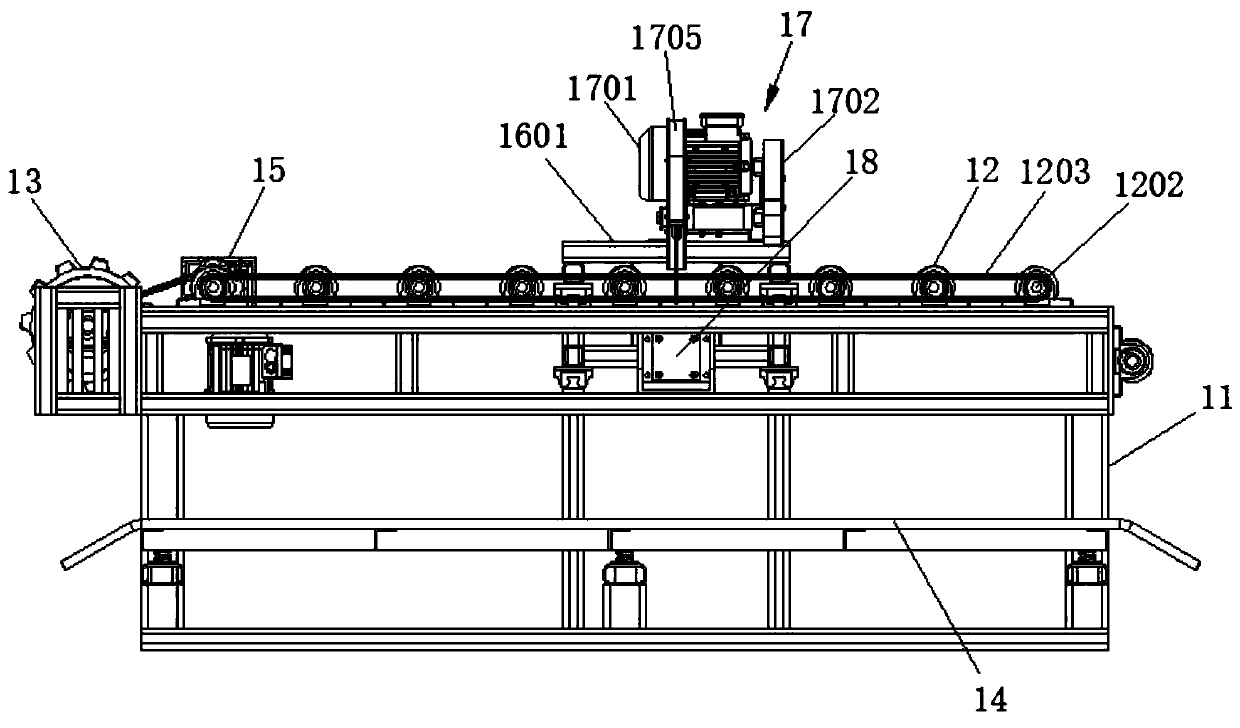

Waste rubber crawler belt material recycling production line

PendingCN110435048AImprove cutting recovery efficiencyNo displacementPlastic recyclingMetal working apparatusProduction lineSurface layer

The invention discloses a waste rubber crawler belt material recycling production line. The waste rubber crawler belt material recycling production line comprises a segmenting and cutting-off tool, asurface rough cutting tool, a surface treatment and separation device, a reclaimed material conveying structure and a vacuum recycling device; the segmenting and cutting-off tool is used for segmenting and cutting off a crawler belt; the surface rough cutting tool is used for carrying out rough cutting treatment on cut-off long-strip-shaped crawler belt surface rubber; the surface treatment and separation device is used for carrying out cutting treatment, embedded part separation, steel wire separation and steel wire shearing short and recycling on the roughly cut crawler belt remaining surface layer rubber; the reclaimed material conveying structure is used for conveying the cut surface rubber and an embedded part; and the vacuum recycling device is used for carrying out vacuum collectionand recycling on rubber particles left by the rough cutting treatment. According to the waste rubber crawler belt material recycling production line, residual rubber scraping, embedded part separation and steel wire shearing short and collection of the waste rubber crawler belt can be realized, the functions of the equipment are various, the classification and collection of all components in thewaste rubber crawler belt are effectively realized, the working synergy of all the mechanisms in the equipment is high, and the working efficiency is high.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

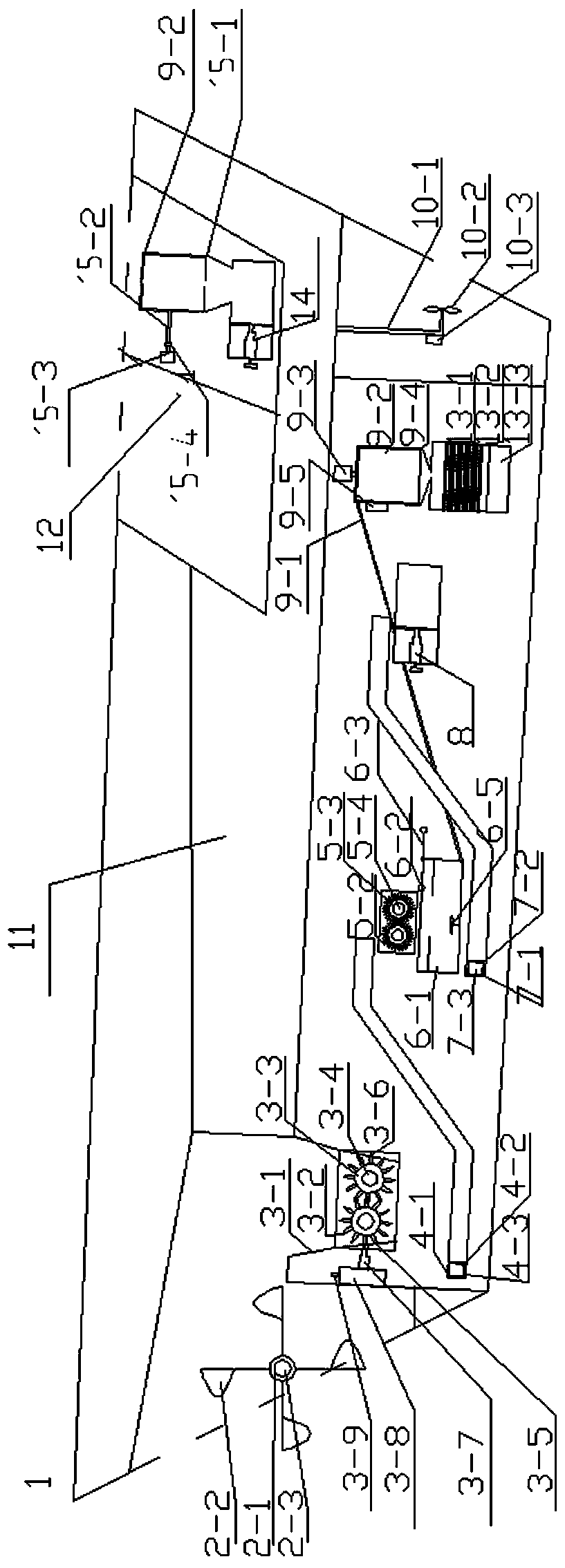

Integrated machine for collecting and processing plastic and paper garbage in rivers and lakes

ActiveCN109267551ASolve collection difficultiesRealize classified collectionWater cleaningWaterborne vesselsFiberRefuse collection

The invention relates to the field of garbage treatment equipment, in particular to an integrated machine for collecting and processing plastic and paper garbage in rivers and lakes, and solves the problem of salvage treatment of floating garbage in water bodies. The structure comprises a ship body, a trapping net A, a crusher, a transmission belt A, a pulverizer, a cleaning machine, a transmission belt B, a packaging machine A, a centrifugal machine, a spiral propeller, an electric control system and an operator moving area, wherein the trapping net A is positioned at the center of the frontend of the ship body, the spiral propeller is positioned at the central part of the tail part of the ship body, the crusher is arranged at the rear side of the trapping net A, the front end of the transmission belt A is positioned at the lower side of the crusher, the pulverizer is arranged below the rear end of the transmission belt A, the cleaning machine is arranged below the pulverizer, the front end of the transmission belt B is positioned below the cleaning machine, the lower side of the rear end of the transmission belt B is provided with the packaging machine A, the cleaning machine isconnected with the centrifugal machine through a pipeline, and a carbon fiber sewage treatment all-in-one machine is arranged under the centrifugal machine. And the purpose of classifying and collecting and processing the plastic and paper garbage in rivers and lakes is achieved.

Owner:TAIYUAN UNIV OF TECH

Hospital waste sorting collection system

PendingCN108442652AReduce the impactSolve processing problemsVertical ductsCollection systemHospital waste

The invention relates to the technical field of waste collection systems, and discloses a hospital waste sorting collection system. The hospital waste sorting collection system comprises waste collection passages arranged in each layer in a penetrating mode, and a plurality of waste disposal doors arranged on the waste collection passages, and output passages communicating with the waste collection passages are arranged on the lower portions of the waste collection passages. A control unit of the collection system comprises control panels arranged on the waste disposal doors, the collection unit comprises a plurality of sorting trash cans and rotating rotary tables, the sorting trash cans are arranged on the ground below the output passages, the rotating rotary tables are arranged above the sorting trash cans, waste outlets are formed in the rotating rotary tables, the waste outlets are connected with the output passages, a plurality of waste collection openings are formed below the rotating rotary tables, and the waste collection openings corresponds to the corresponding sorting trash cans. The hospital waste sorting collection system transports different types of waste to different types of trash cans and realizes waste sorting and collection.

Owner:WUXI HUANYU SHUANGHUI ENVIRONMENTAL PROTECTION EQUIP CO LTD +1

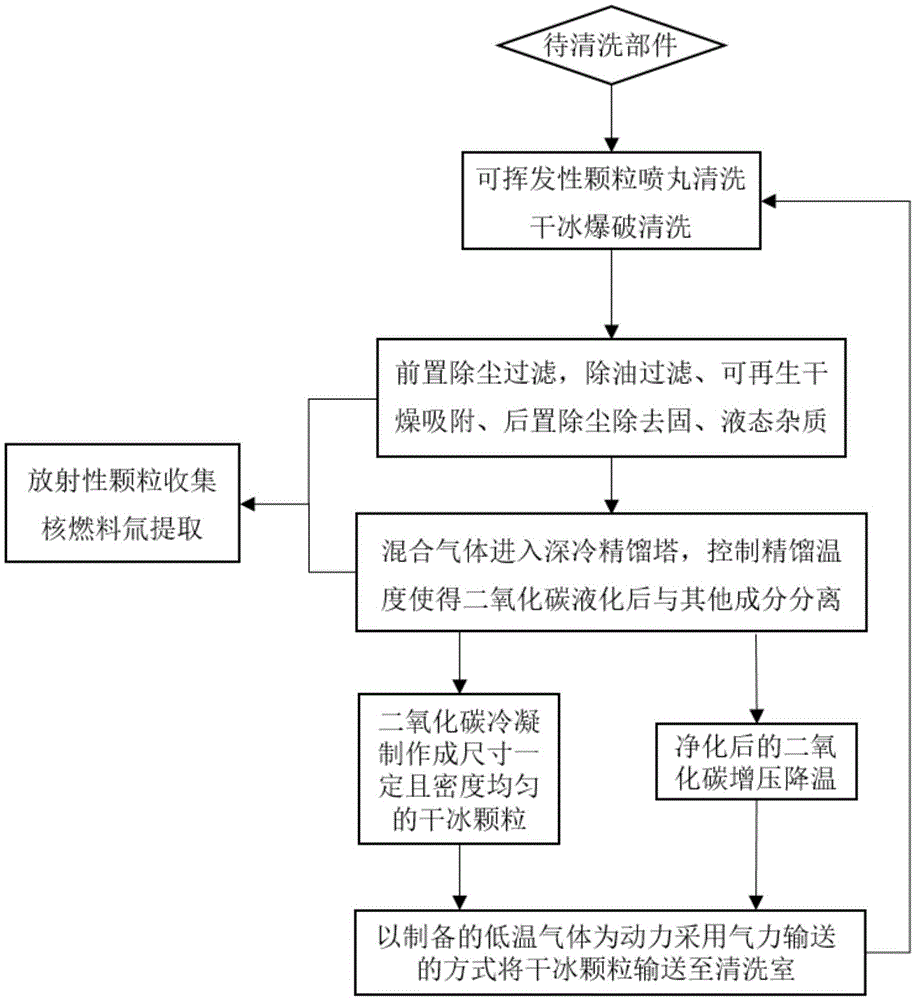

Method and device for purifying and recycling cleaning waste gas of hot cell of fusion reactor by cryogenic rectification

ActiveCN105632574ASolve processingSolve cleaningRadioactive decontaminationRadioactive gasSeparation technology

The invention relates to a method and a device for purifying and recycling cleaning waste gas of a hot cell of a fusion reactor by cryogenic rectification. The method comprises six technological processes including a decontaminating cleaning technology, a filtration and purification technology of solid and liquid-state impurities, a carbon dioxide cryogenic rectification separation technology, a low-temperature power gas preparation technology, a volatile granule regeneration technology and a long-distance pneumatic transmission technology. Radioactive particles and residual radioactive gases are collected in a sorting way together with or separated from a cleaning medium by utilizing the original cleaning waste gas. The effect that radioactive wastes in the hot cell are minimized can be realized. The radioactive particles and gaseous nuclear fuel are effectively collected while the cleaning waste gas is enabled not to pollute the environment as radioactive effluent, and an originally used cleaning medium is enabled to be recycled; on the basis, a carbon dioxide dry ice blasting cleaning scheme becomes a first selected option for cleaning a polluted radioactive surface in the hot cell; furthermore, the process scheme is simple in loop structure and easy to implement, thus being suitable for the remote control operation hot cell environment.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com