Environment detection sampling device

A sampling device and environmental detection technology, which is applied in the direction of sampling devices, can solve the problems of laborious sampling efficiency and low efficiency, and achieve the effect of improving the overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

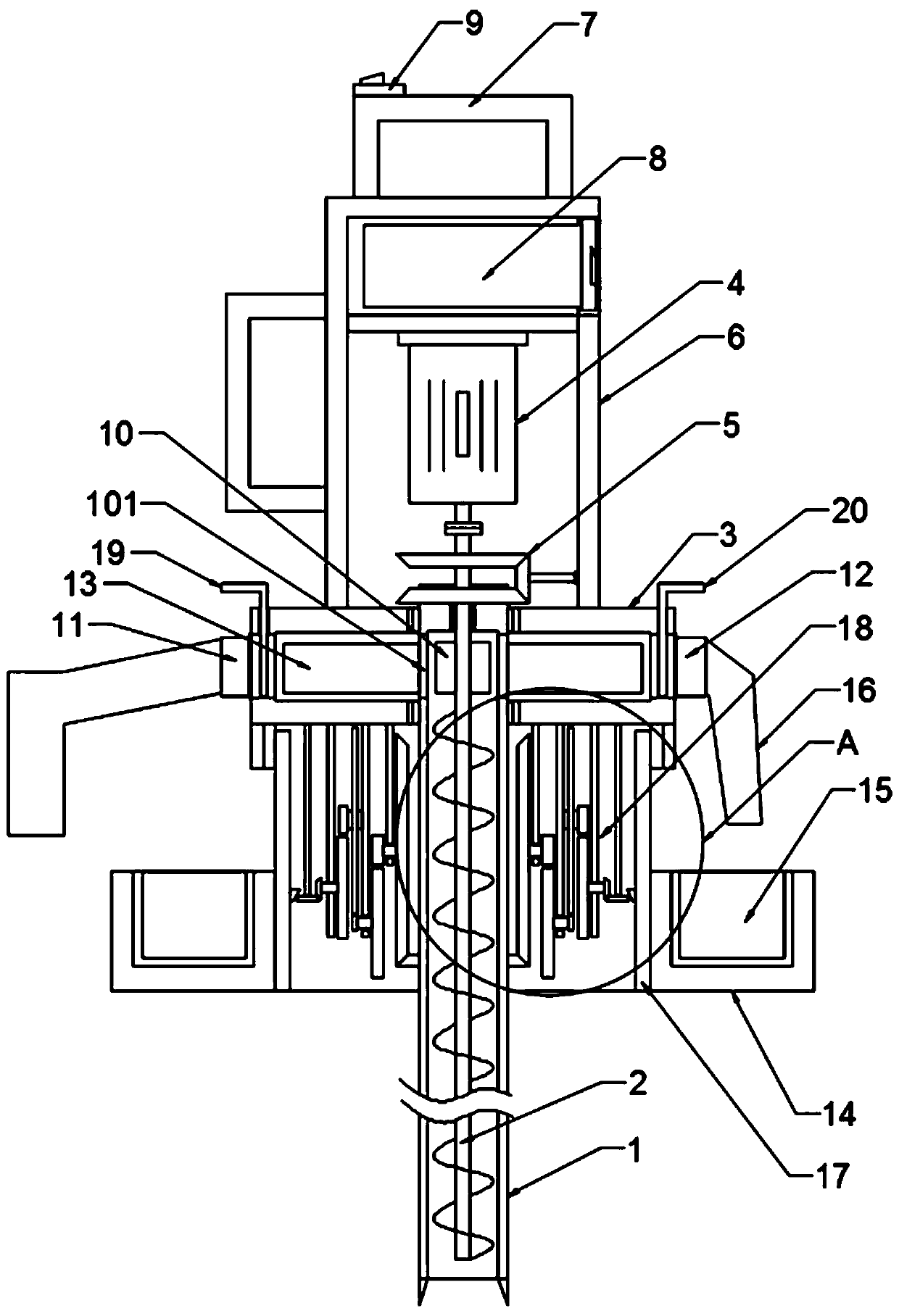

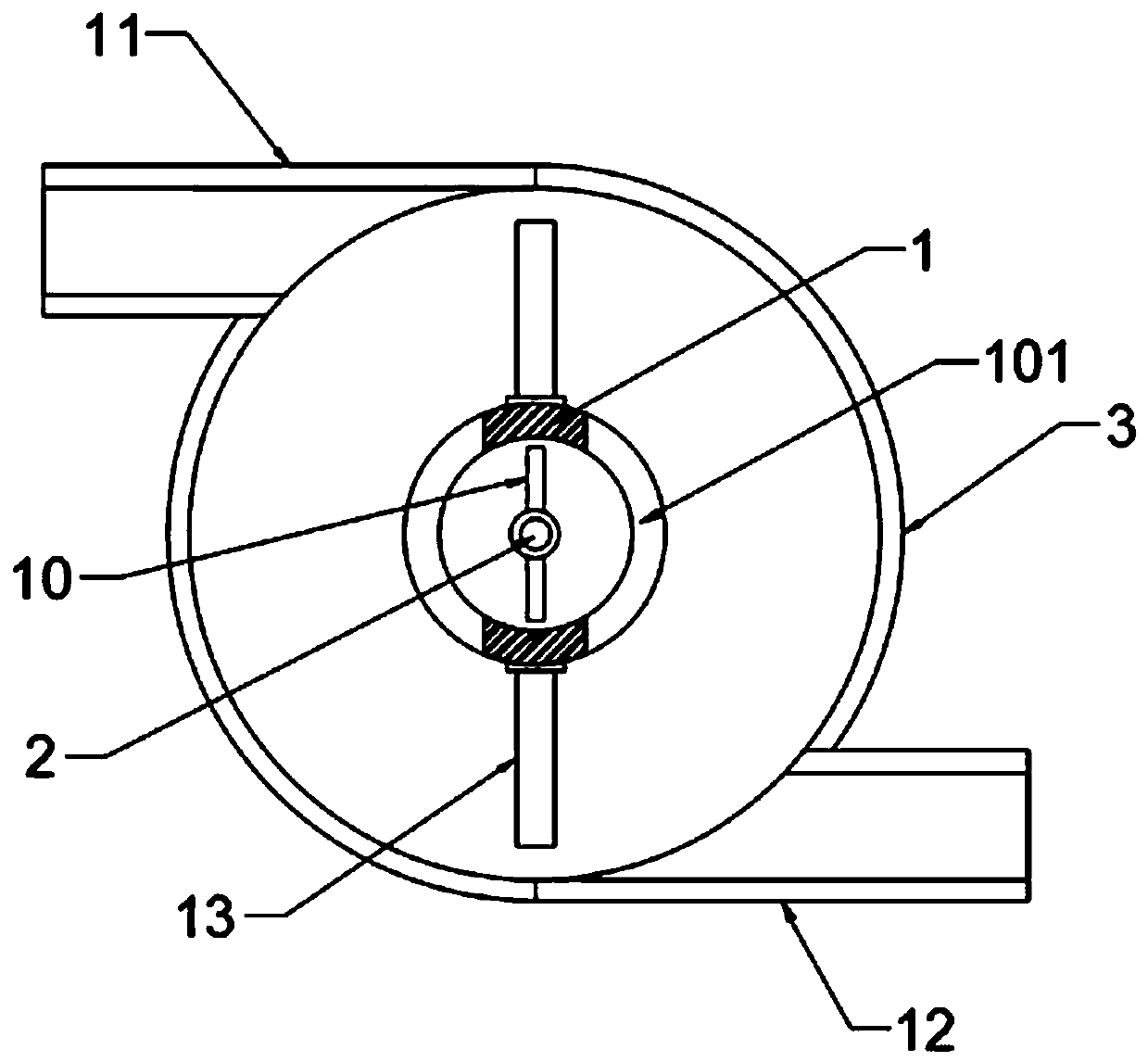

[0022] see Figure 1-5 , in an embodiment of the present invention, an environmental detection sampling device includes a device body; the device body includes a soil collection mechanism; the soil collection mechanism includes a drill barrel 1, and a screw conveyor roller is nested in the drill barrel 1 2. Dispersion cylinder 3 runs through the upper part of drill cylinder 1 and extends to the top of dispersion cylinder 3. Drill cylinder 1 is rotationally connected with dispersion cylinder 3 through a bearing sleeve, and the screw feed roller 2 extends to the top of drill cylinder 1; the screw feed roller 2. A drive motor 4 is connected through a coupling, and the screw feed roller 2 is connected to the drill barrel 1 for transmission through a transmission gear set 5; specifically, the drive motor 4 drives the screw feed roller 2 to rotate, and the screw feed roller 2 drives the drill barrel 1 Rotate, the rotation direction of the drill tube 1 is opposite to the rotation dir...

Embodiment 2

[0027] An environmental detection and sampling device, comprising a device body; the device body includes a soil collection mechanism; the soil collection mechanism includes a drill tube 1, a screw feed roller 2 is embedded in the drill tube 1, and the upper part of the drill tube 1 runs through the There is a dispersion cylinder 3 and extends to the top of the dispersion cylinder 3, the drill cylinder 1 is rotationally connected with the dispersion cylinder 3 through a bearing sleeve, and the screw feed roller 2 extends to the top of the drill cylinder 1; the screw feed roller 2 is connected with a The drive motor 4 and the screw feed roller 2 are connected and driven by the transmission gear set 5 with the drill barrel 1; specifically, the drive motor 4 drives the screw feed roller 2 to rotate, the screw feed roller 2 drives the drill barrel 1 to rotate, and the drill barrel 1 rotates in the direction Contrary to the rotation direction of the screw feed roller 2, when the dri...

Embodiment 3

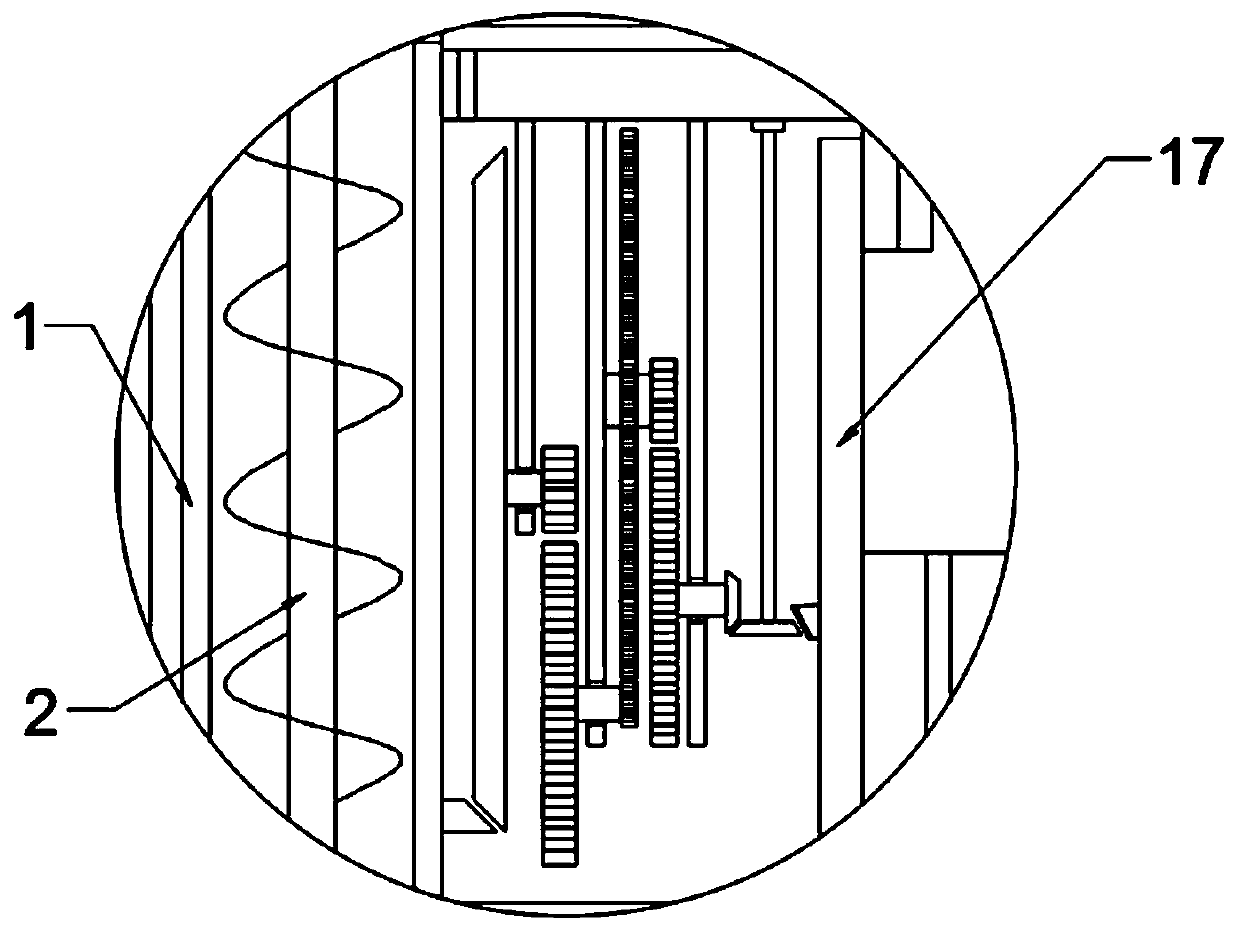

[0033] The difference between this embodiment and Embodiment 2 is that in order to realize the automatic sorting and loading of samples, the inner side of the drum 17 is connected to the drill tube 1 through a reduction gear set 18 for transmission, and the reduction gear set 18 transmits the power of the drill tube 1 to the rotary drum 1. Drum 17, rotating drum 17 drives the annular seat 14 to rotate slowly; specifically, the reduction gear set 18 includes multiple sets of small gears, large gears, and bevel gear rings, which are common transmission gear sets, and will not be described in detail in this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com