Split type gas displacement type underground water sampler

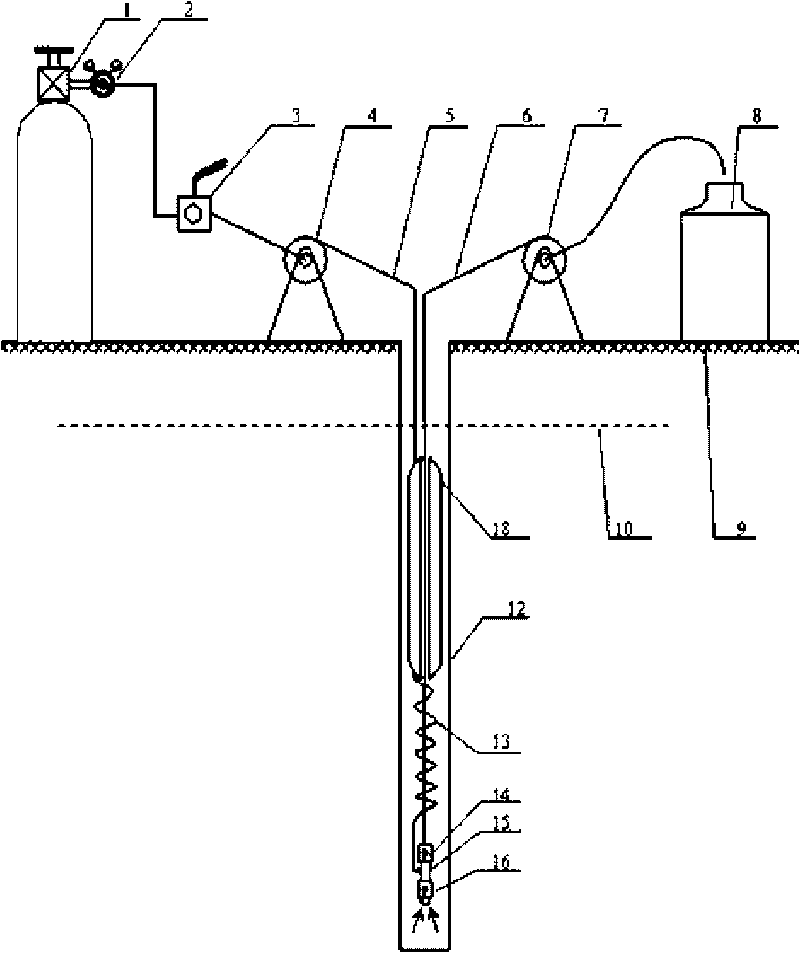

A gas replacement and groundwater technology, applied in the direction of sampling devices, etc., can solve problems such as overflow, gas, and large disturbance of groundwater, and achieve the effects of low gas pressure, high sampling efficiency, and small gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

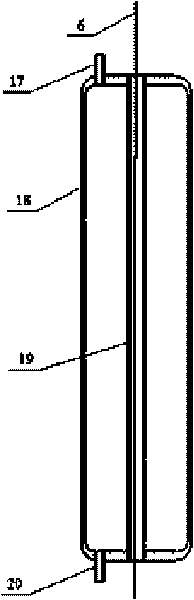

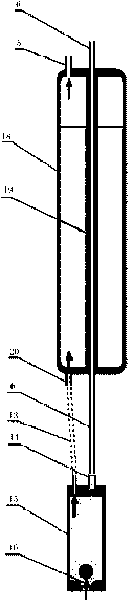

Method used

Image

Examples

Embodiment 1

[0033] Example 1: There is a monitoring well with a water level of 30 meters, and it is desired to obtain 200 liters of groundwater samples at a depth of 200 meters from the ground. Lower the sample holding tube and sampling unit into the monitoring well. The sample holding pipe 18 will be fixed at 10 meters below the water surface (that is, the depth of 40 meters from the ground), and the sampling unit will be lowered with the outlet pipe to drive the spiral plastic hose to a depth of 200 meters from the ground. To ensure that the sampling unit falls vertically in the well, tie a stainless steel or PVC weight to the bottom of the sampling unit. Groundwater sampling is realized by controlling the working gas pressure to 0.5Mpa. In this embodiment, the average sampling speed of the water sample is 2 L / min, and the sampling process of the water sample is completed after working for 100 minutes.

Embodiment 2

[0034] Embodiment 2: There is a monitoring well with a water level of 30 meters, and it is desired to obtain 50 liters of groundwater samples at a depth of 350 meters from the ground. During implementation, the sample holding tube and sampling unit are lowered into the monitoring well. The sample holding pipe will be fixed at 10 meters below the water surface (that is, at a depth of 40 meters from the ground), and the sampling unit will be lowered with the outlet pipe, driving the spiral plastic hose to a depth of 350 meters from the ground. Groundwater sampling is realized by controlling the working gas pressure to 0.5Mpa. In this embodiment, the average sampling speed of the water sample is 1 L / min, and the sampling process of the water sample is completed after working for 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com