Patents

Literature

103results about How to "Guaranteed to fall into" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

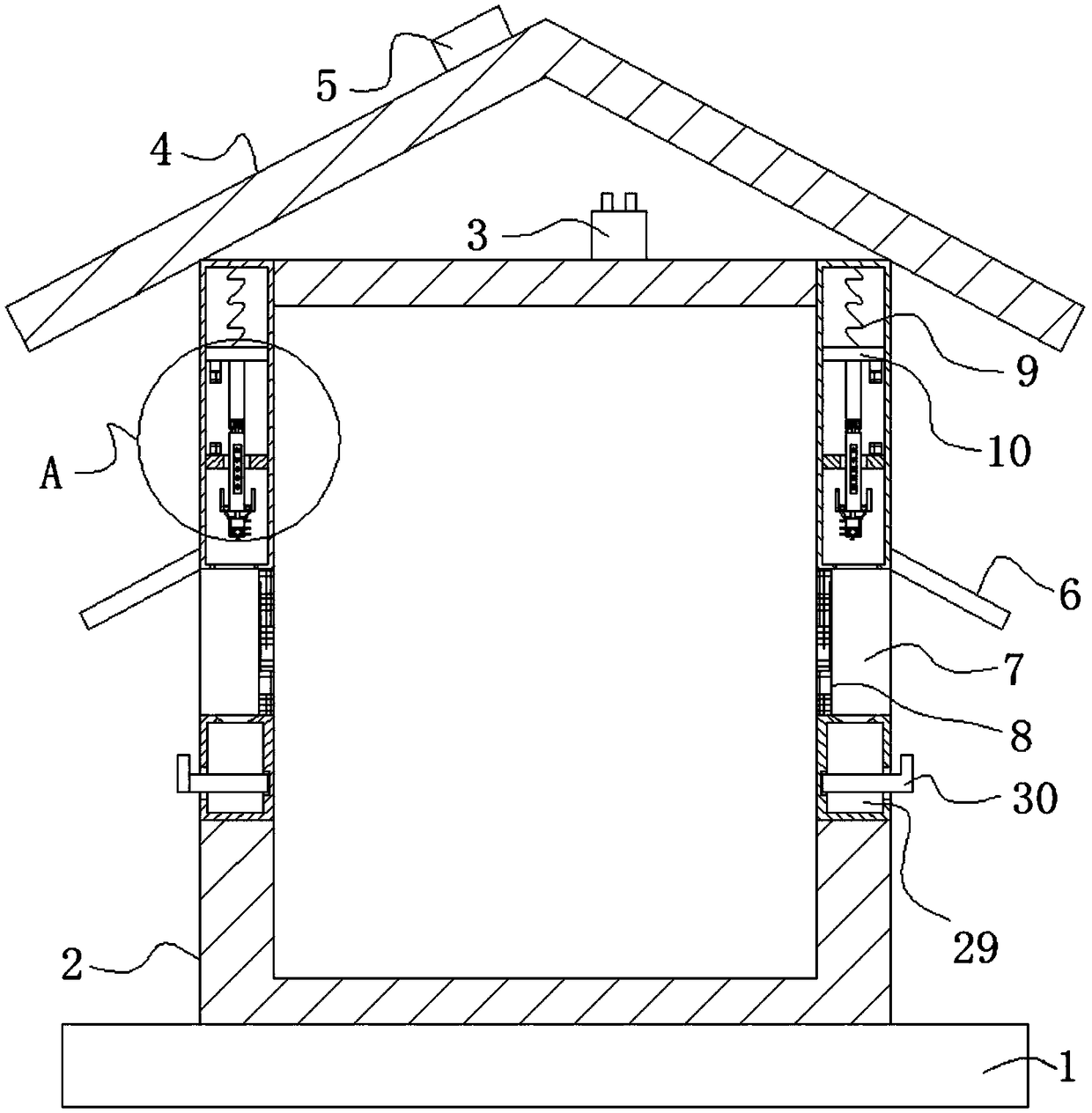

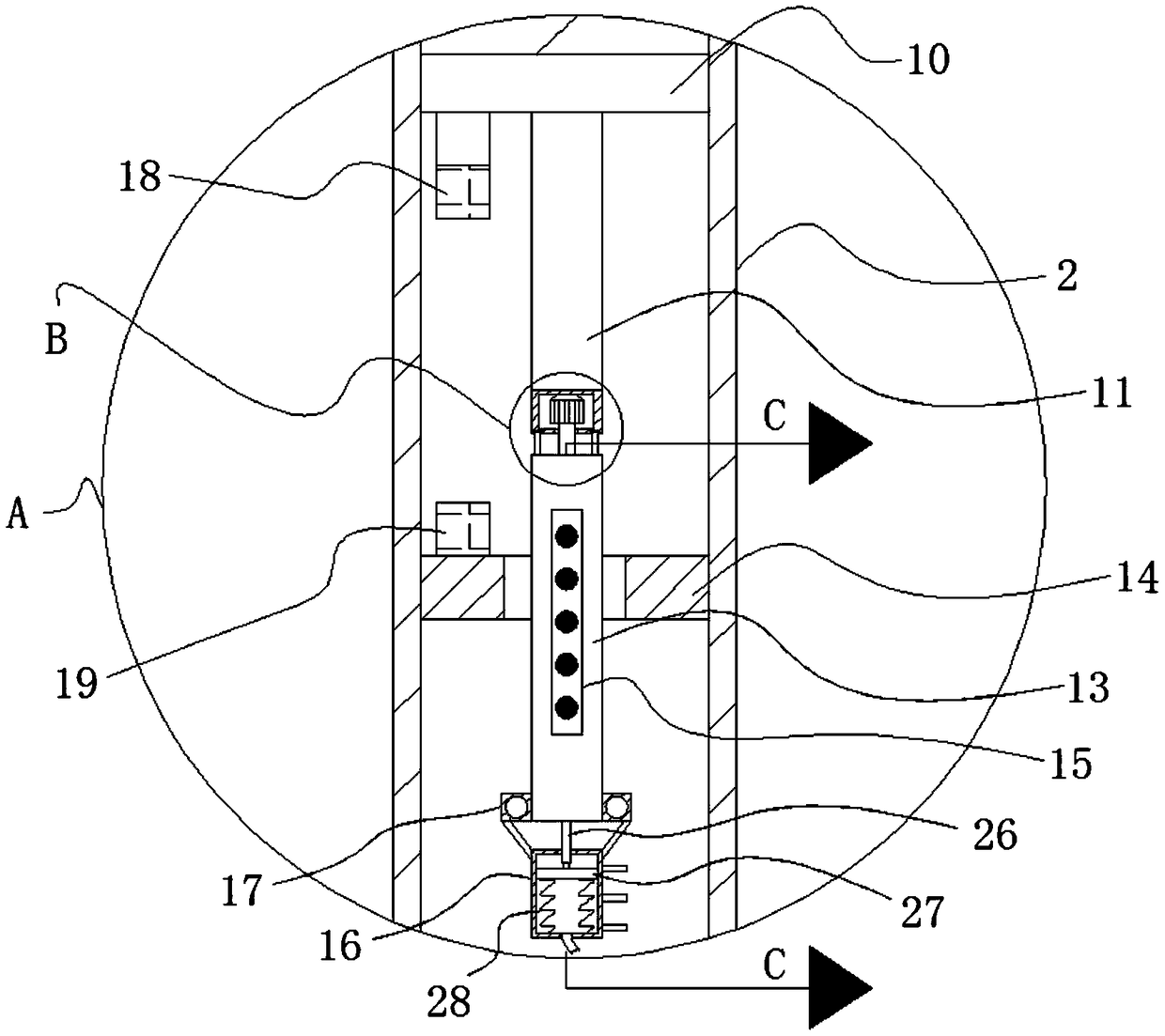

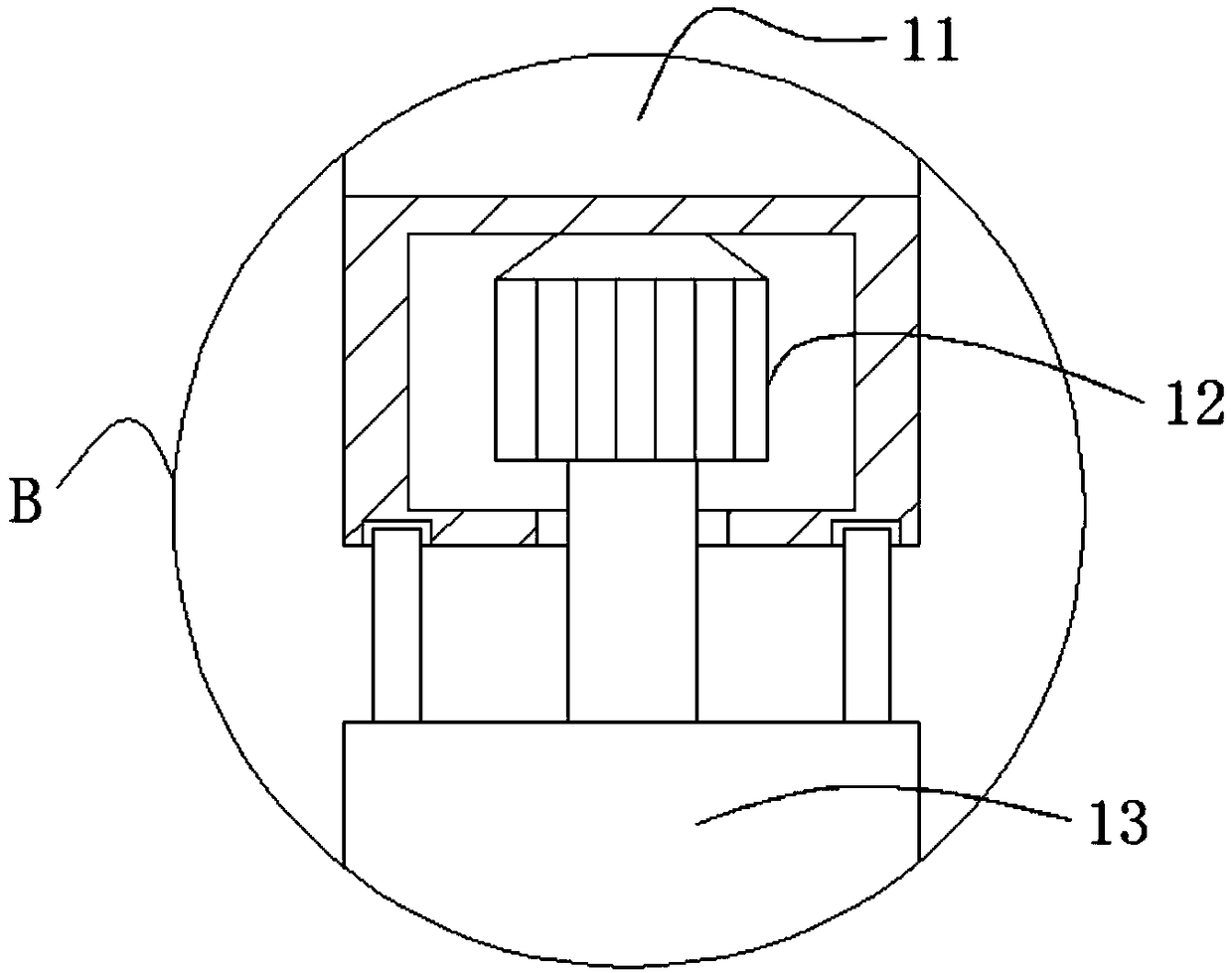

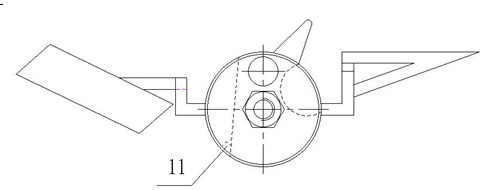

Clothing processing device

ActiveCN107794723AAvoid falling quicklySmooth continuous even closureOther washing machinesTextiles and paperStops deviceEngineering

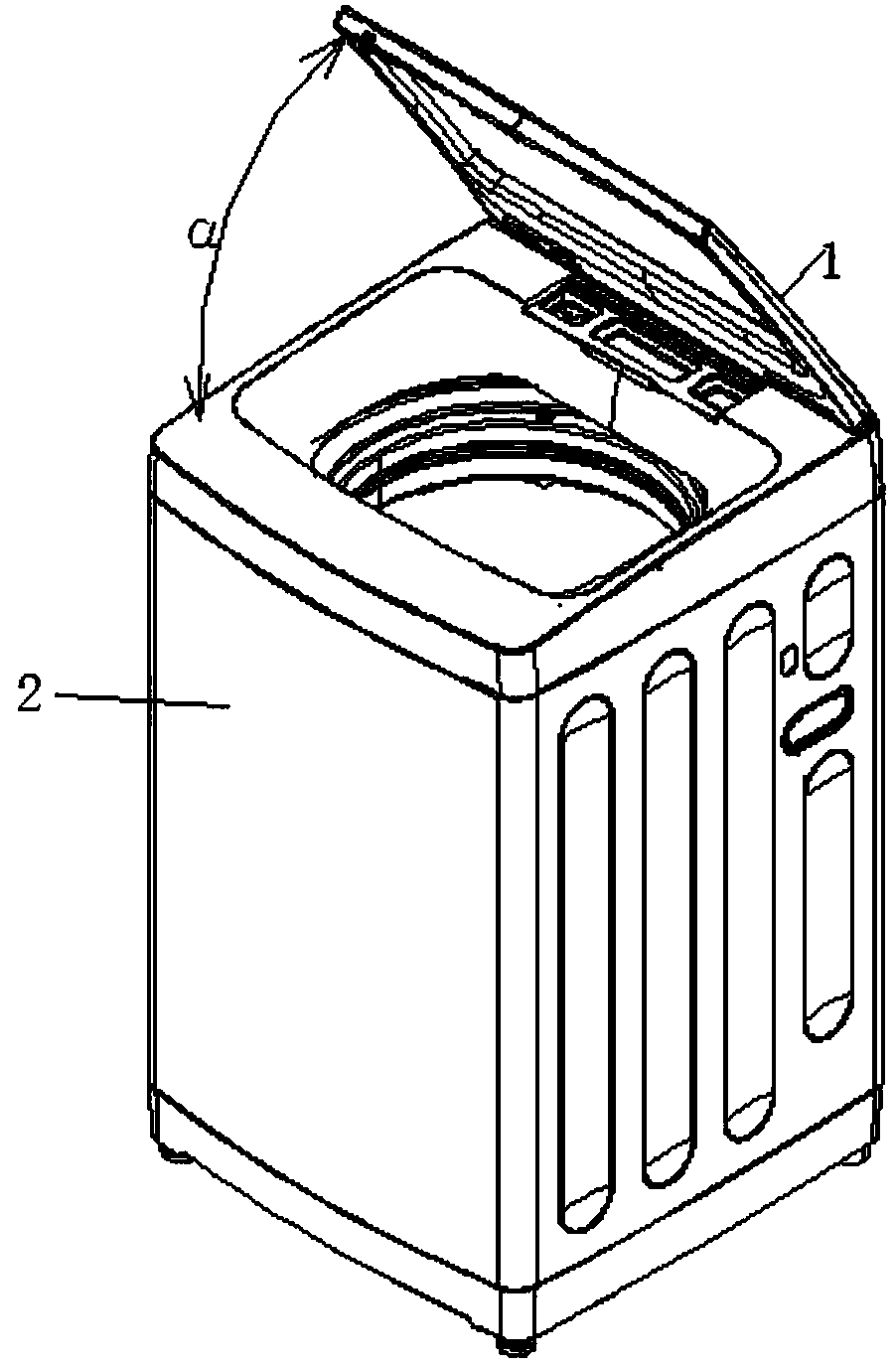

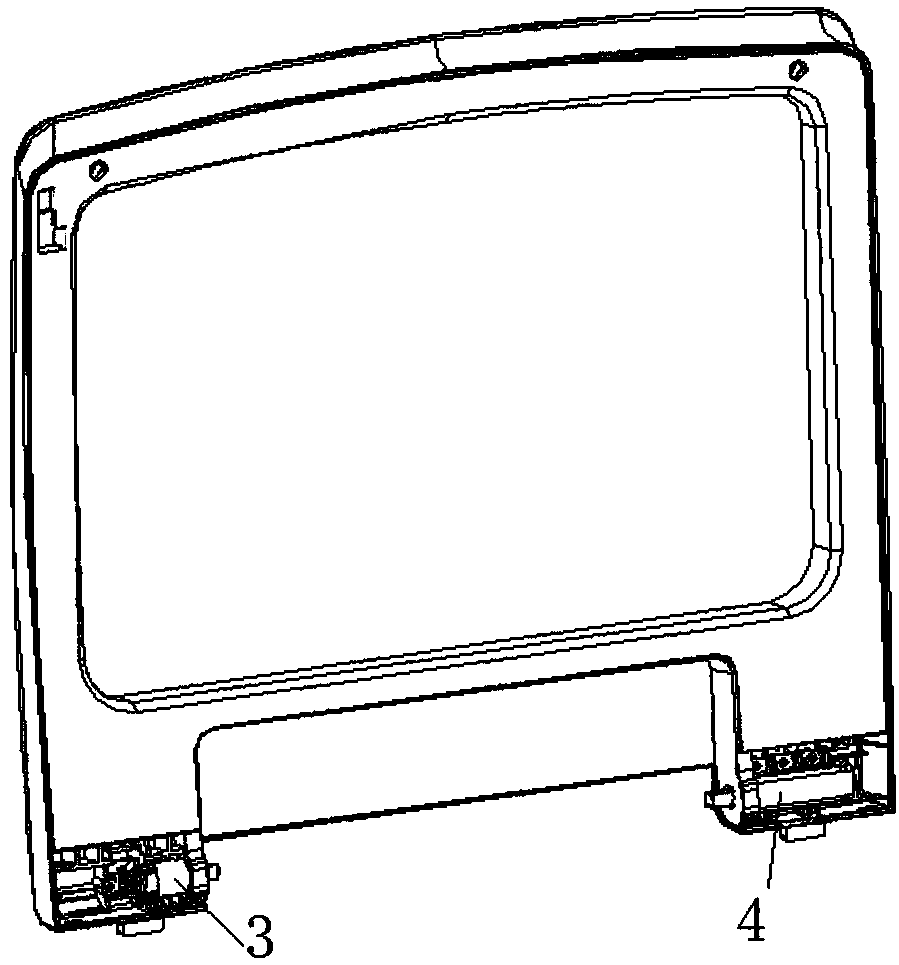

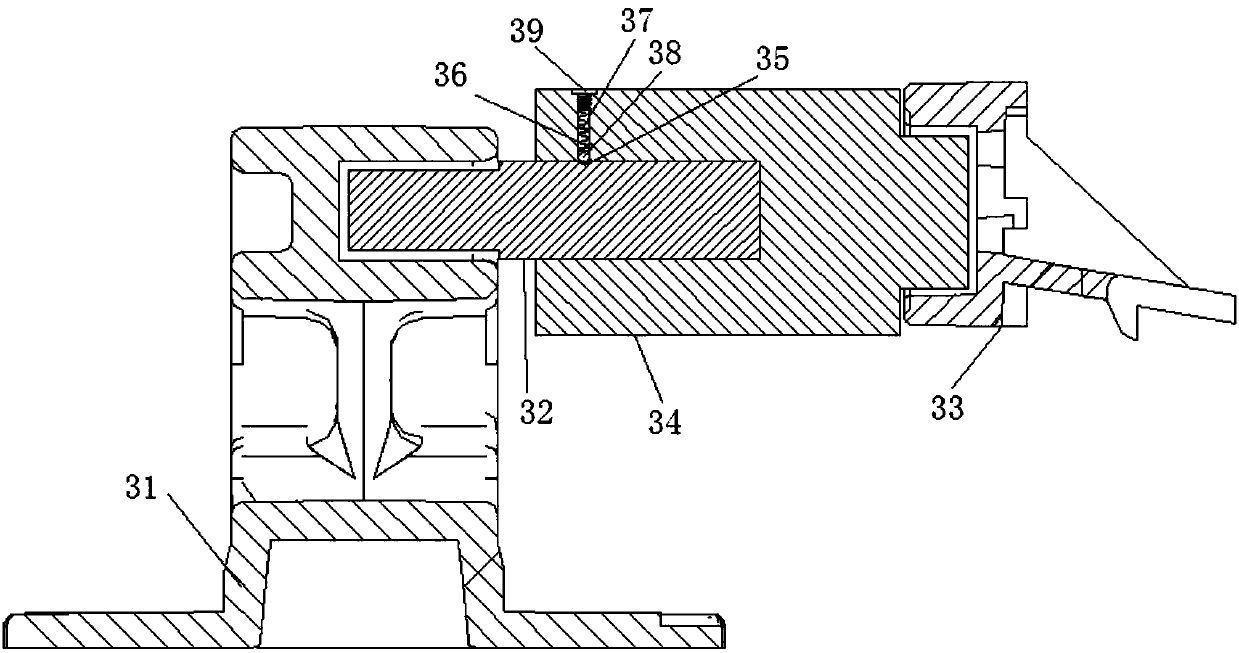

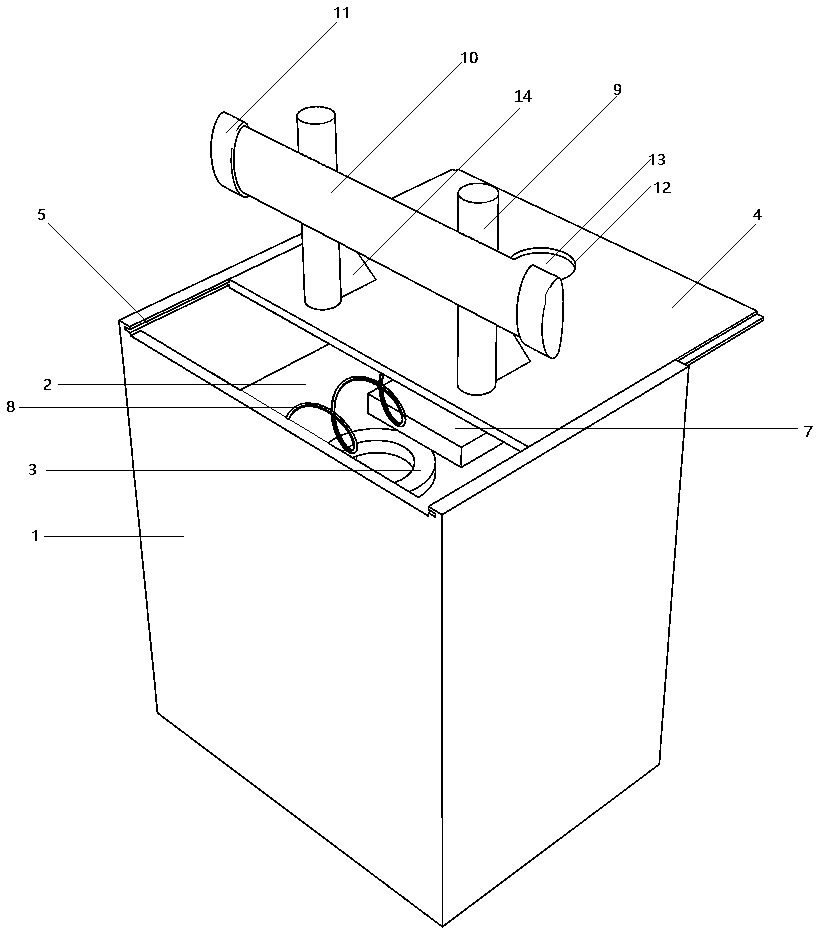

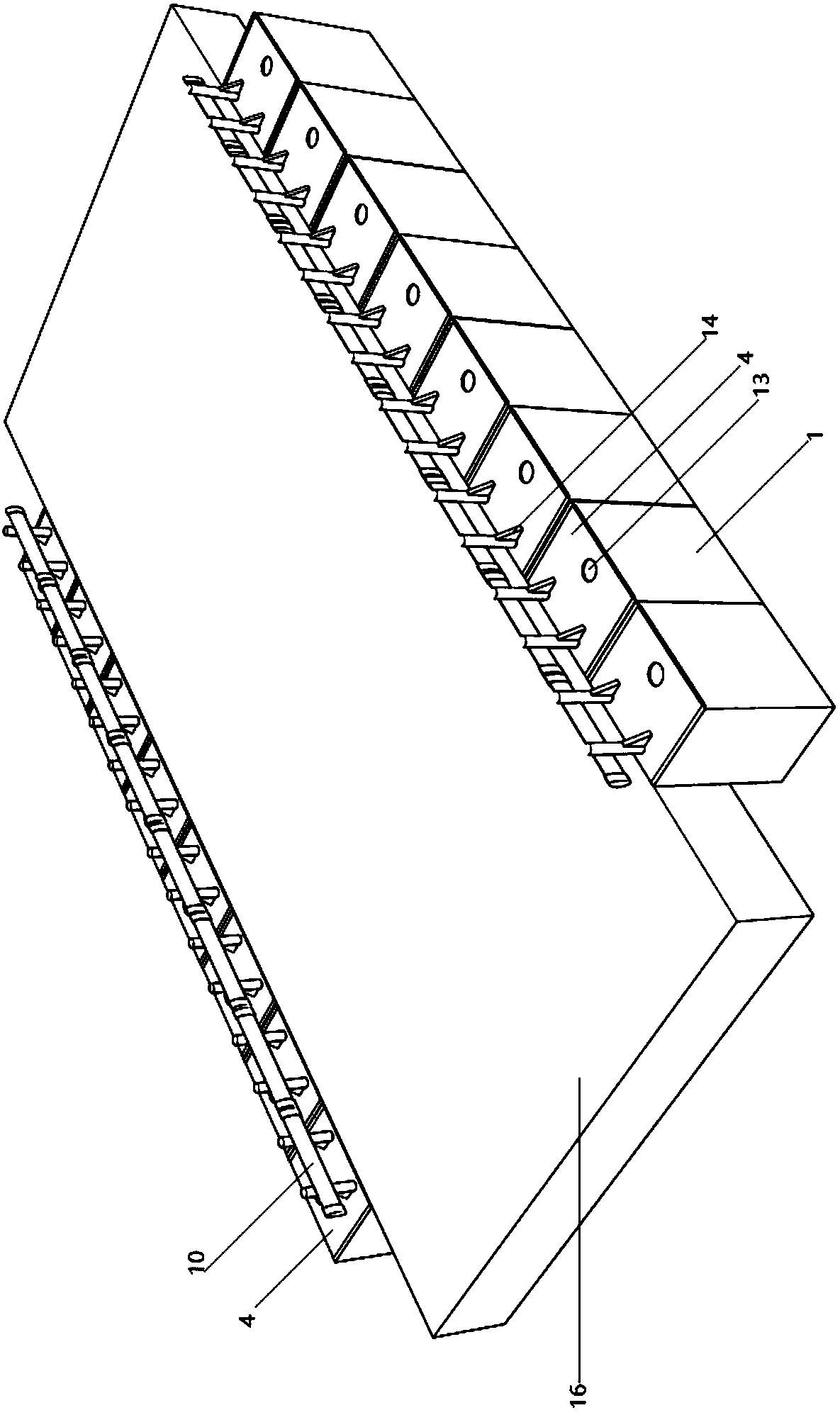

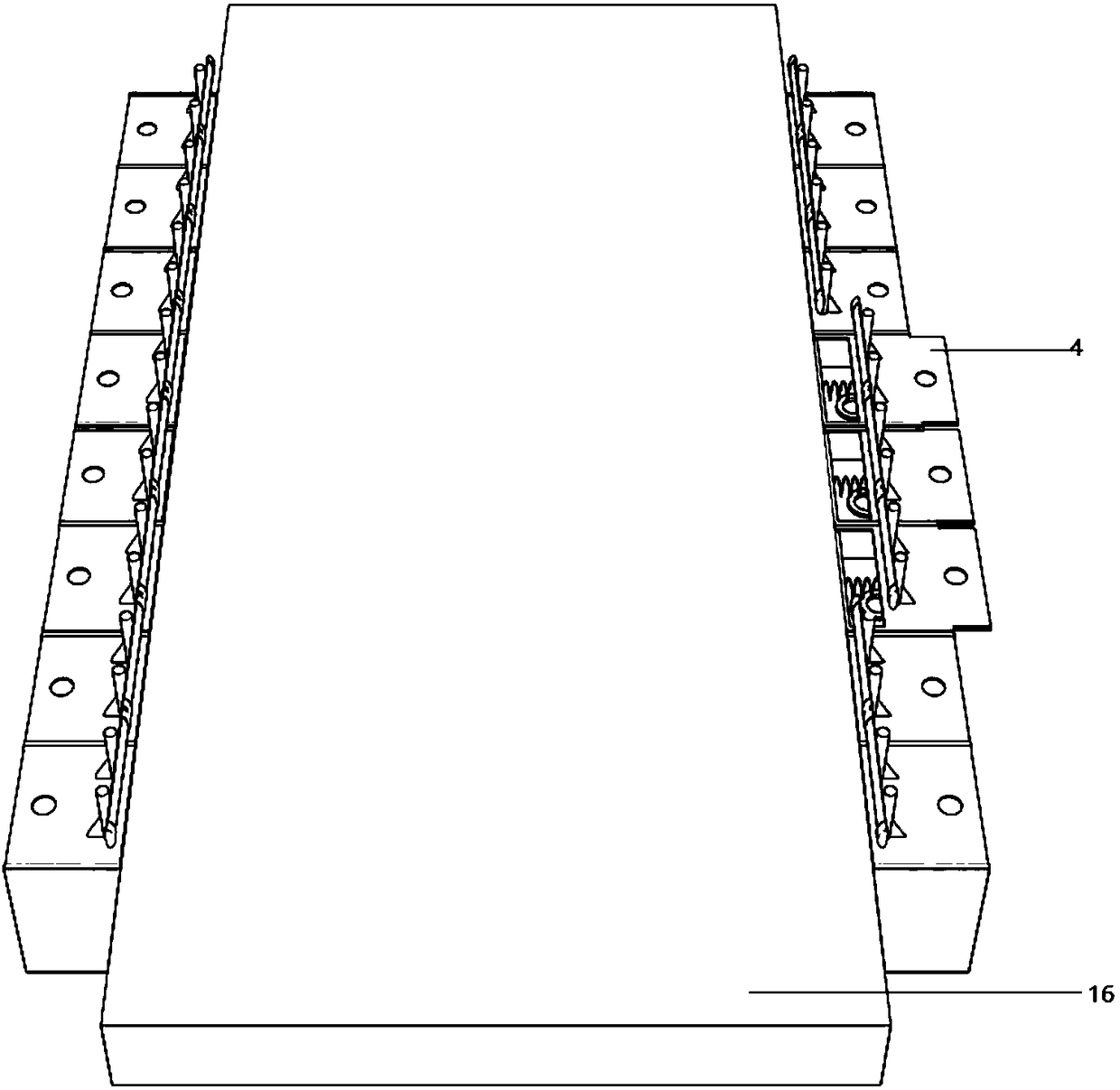

The invention discloses a clothing processing device. The device comprises a door cover and a device body, the door cover is connected with the device body through a hinge structure, and the hinge structure comprises a stopping damping hinge and an assistance damping hinge; the stopping damping hinge comprises a hinge base, a first shaft which is fixedly connected with the hinge base and a dampingdevice which is rotatably connected with the first shaft, and a stopping device which controls the door cover to be positioned at different angles is arranged on the contact portion between the firstshaft and the damping device; the assistance damping hinge comprises a mounting part which is fixed on the hinge base, a second shaft of which one end is fixed to the mounting part and a rotation part which can rotate around the second shaft and is fixedly connected with the door cover, a torsional spring sleeves the second shaft, one end of the torsional spring is connected with the end, away from the mounting part, of the second shaft, and the other end of the torsional spring is connected with the rotation part, so that the torsional spring generates application force. According to the clothing processing device, the door cover can be stopped at any angle, and the effects of free slowing-down in closing and assistance in cover opening can be achieved.

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

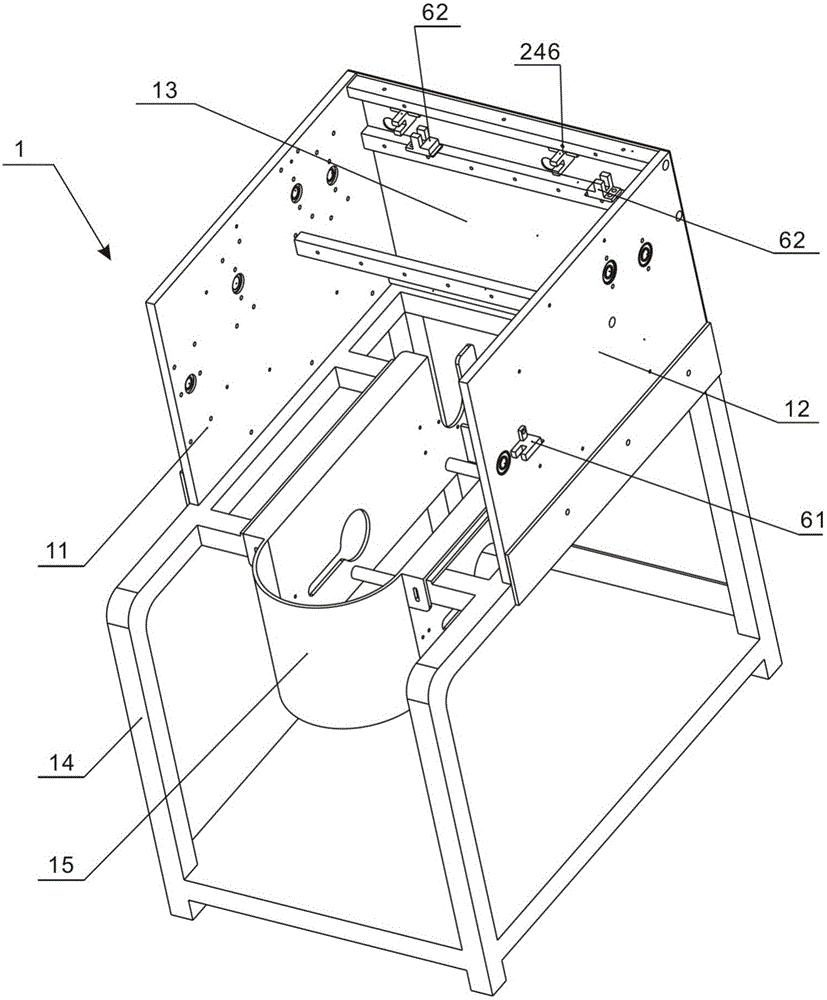

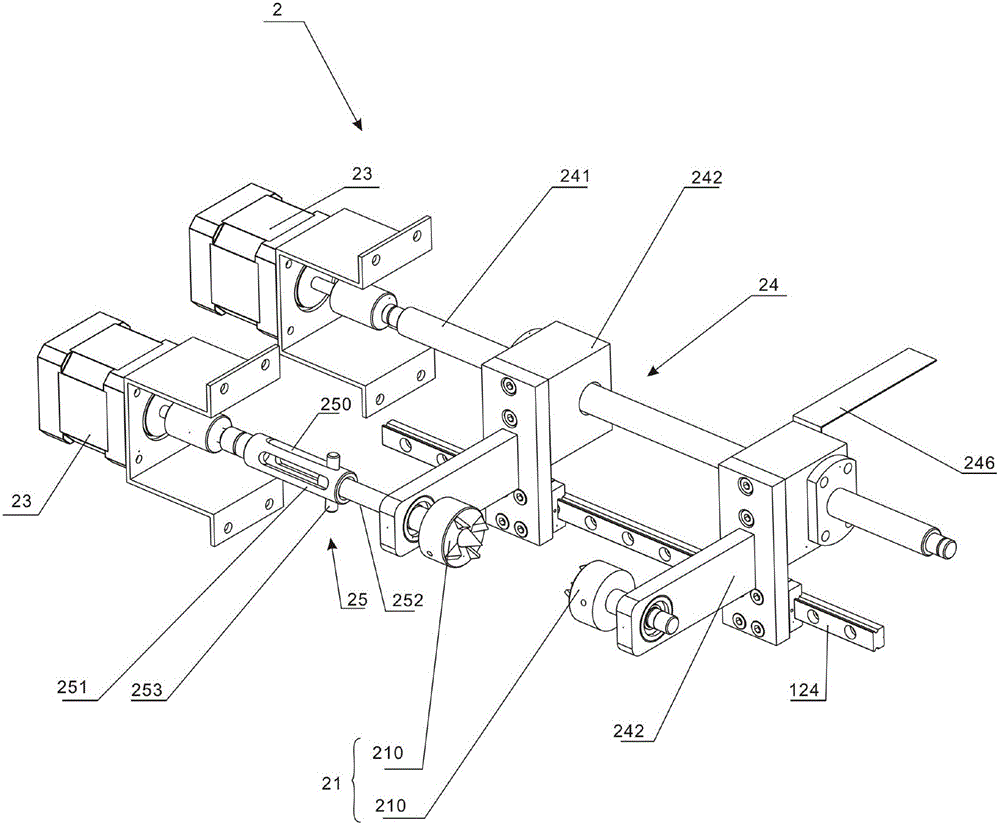

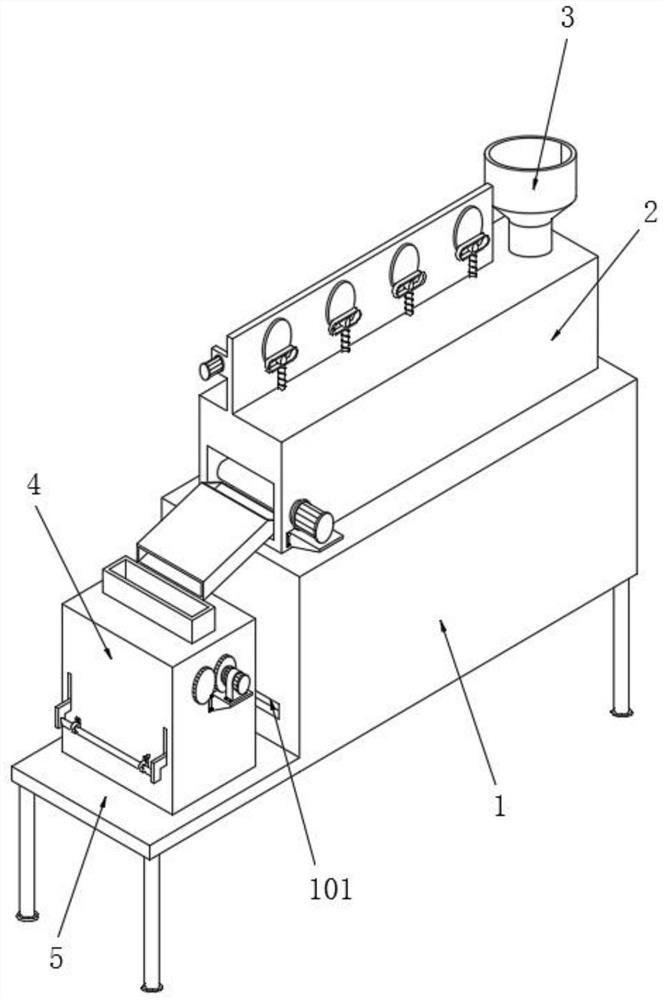

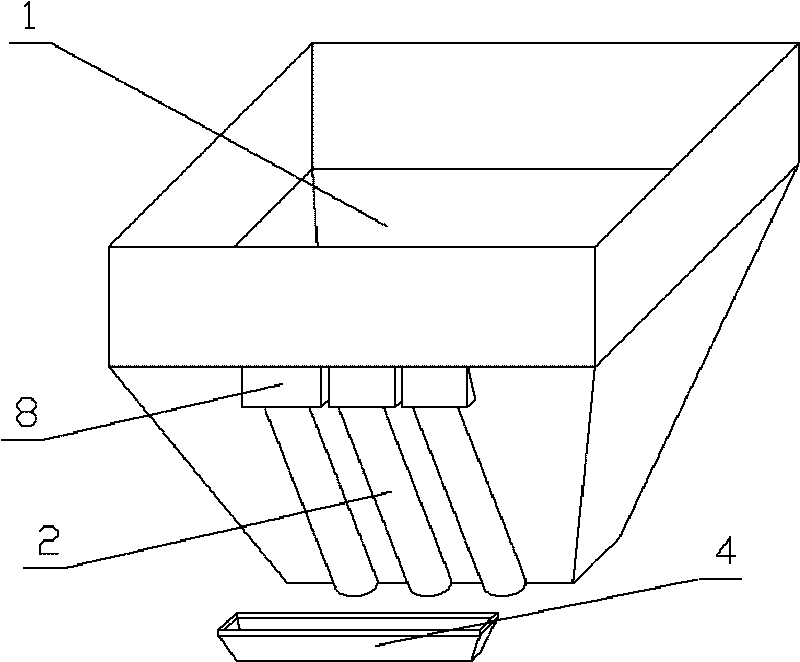

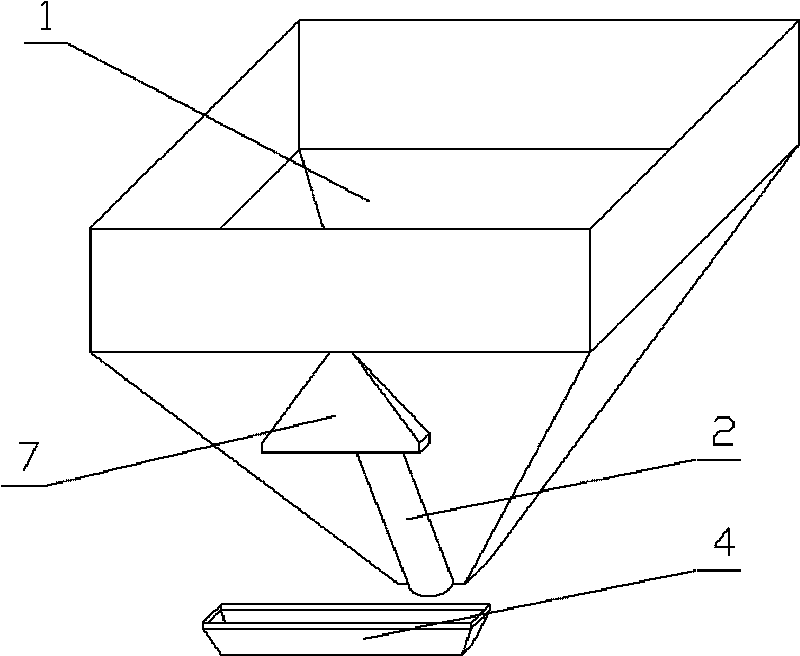

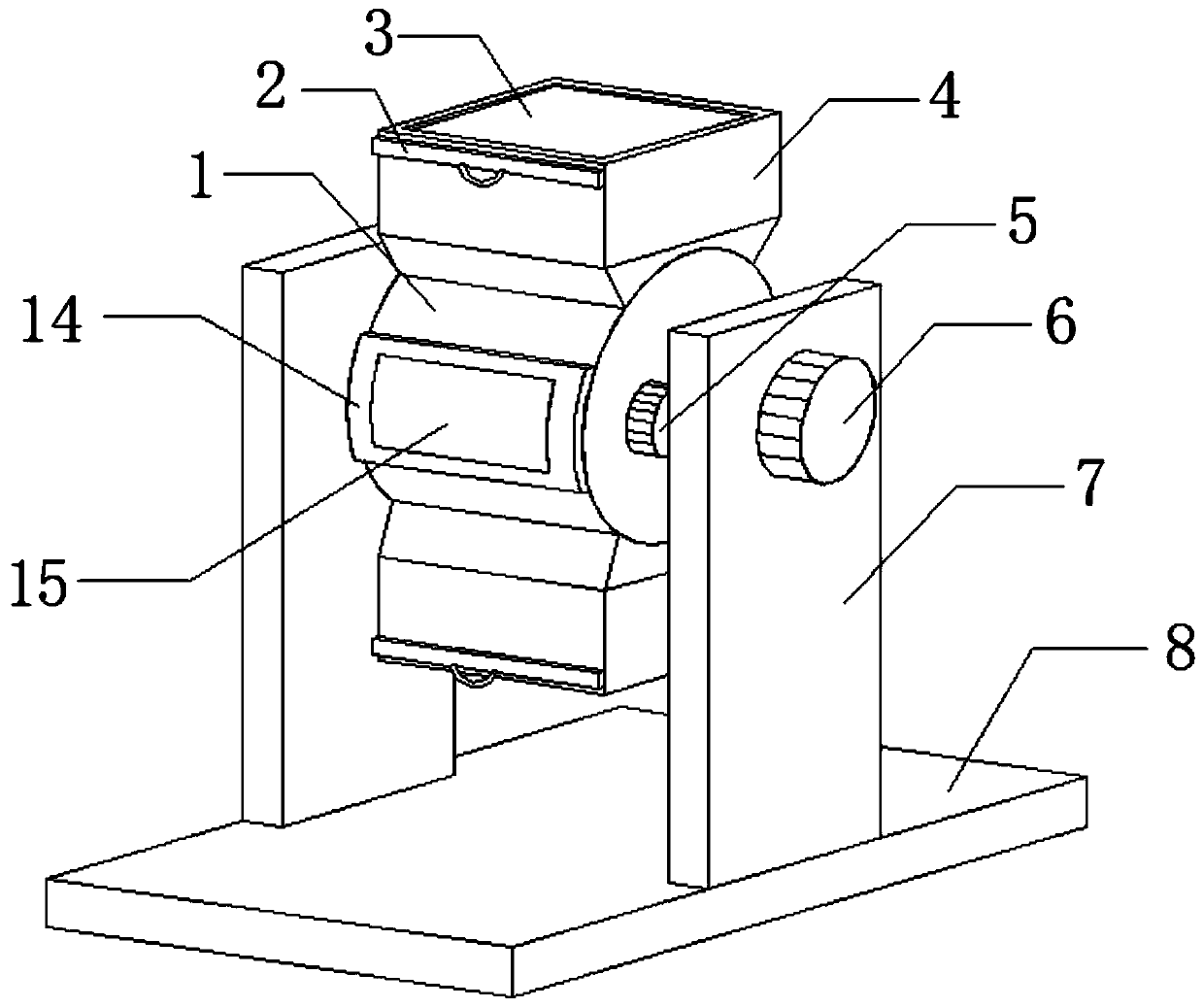

Automatic peeling machine

InactiveCN105768125AGuaranteed to fall intoRealize classified collectionVegetable peelingElectric machineryKnife blades

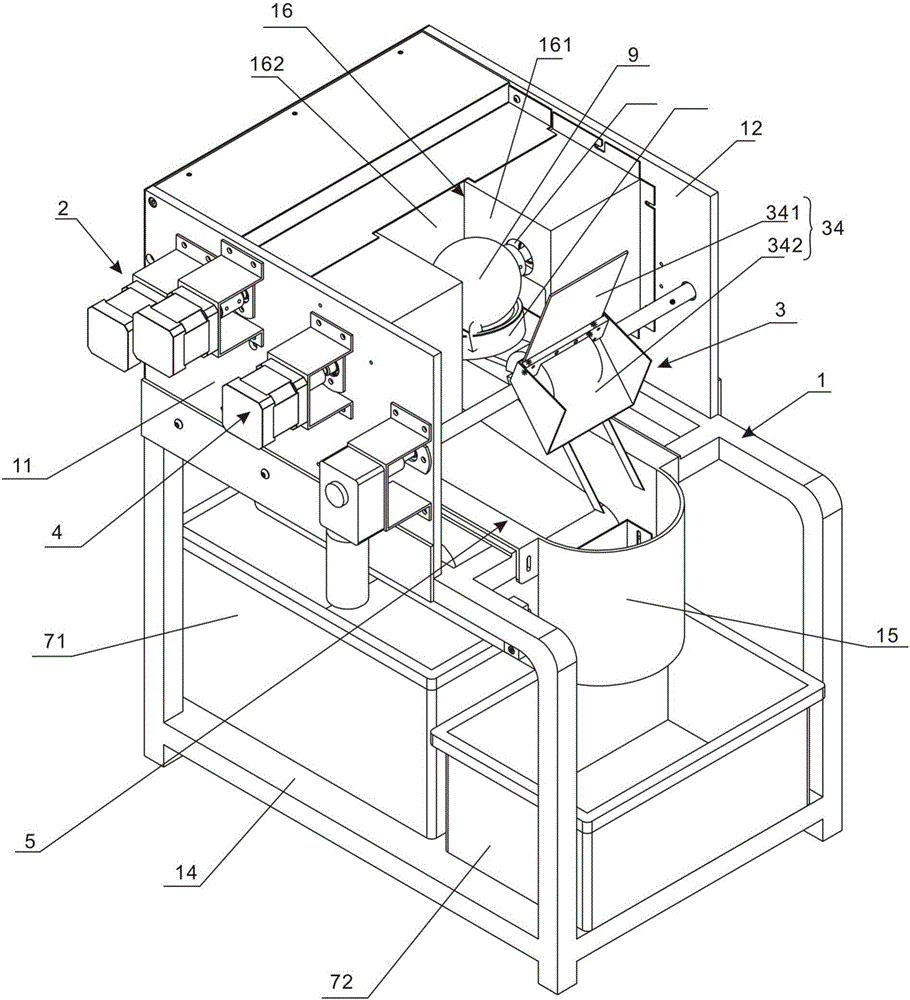

The invention discloses an automatic peeling machine. The automatic peeling machine consists of a body frame, a clamping and rotating unit, a positioning and end removing unit, a peeling unit and a separating and conveying unit; the positioning and end removing unit comprises an end removing motor, a rotating shaft, a positioning plate, a peel guiding assembly and an end cutting knife assembly; the end cutting knife assembly components include two end cutting blades; the positioning plate, peel guiding assembly and end cutting knife assembly rotate successively under the drive of the rotating shaft to the clamping and rotating unit. The separating and conveying unit comprises a conveying motor and a conveying belt, and the conveying belt is in a tilter arrangement. The positioning plate is used to place melons and fruits, the rotation of the rotating shaft can enable the peel guiding assembly to be cooperated with the melons and fruits to ensure fallings of fruit peels on the conveyor belt, and the end cutting knife assembly is used to cut the ends of the melons and fruits down to enable the fruit peels and the fruit flesh to be separated completely; the conveyor belt is in the tilter arrangement and can convey the fruit peels and ends to a fruit peel collection box, and the slope of the conveying belt is used to enable the fruit flesh to automatically slip into a fruit flesh collection box to effectively realize the classification and collection of the fruit flesh and the fruit peels and ends. The automatic peeling machine increases work efficiency.

Owner:深圳市通达智能制造有限公司

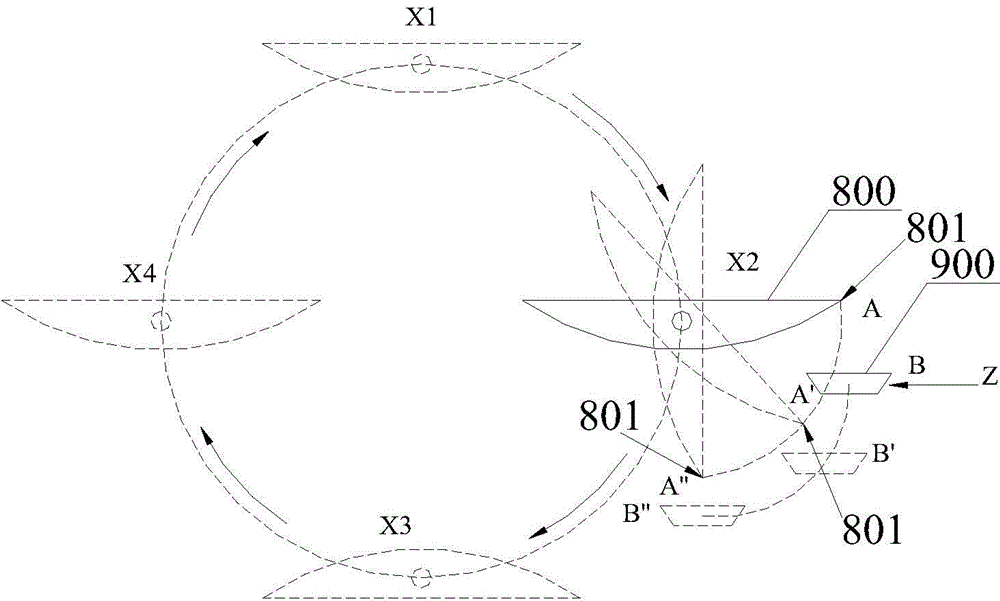

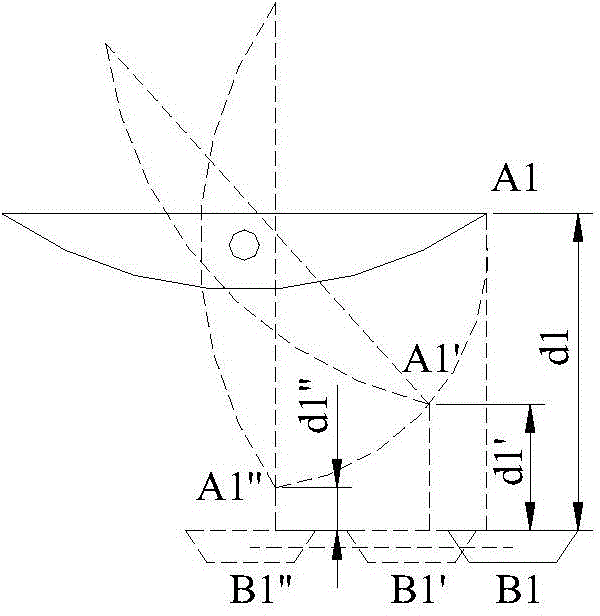

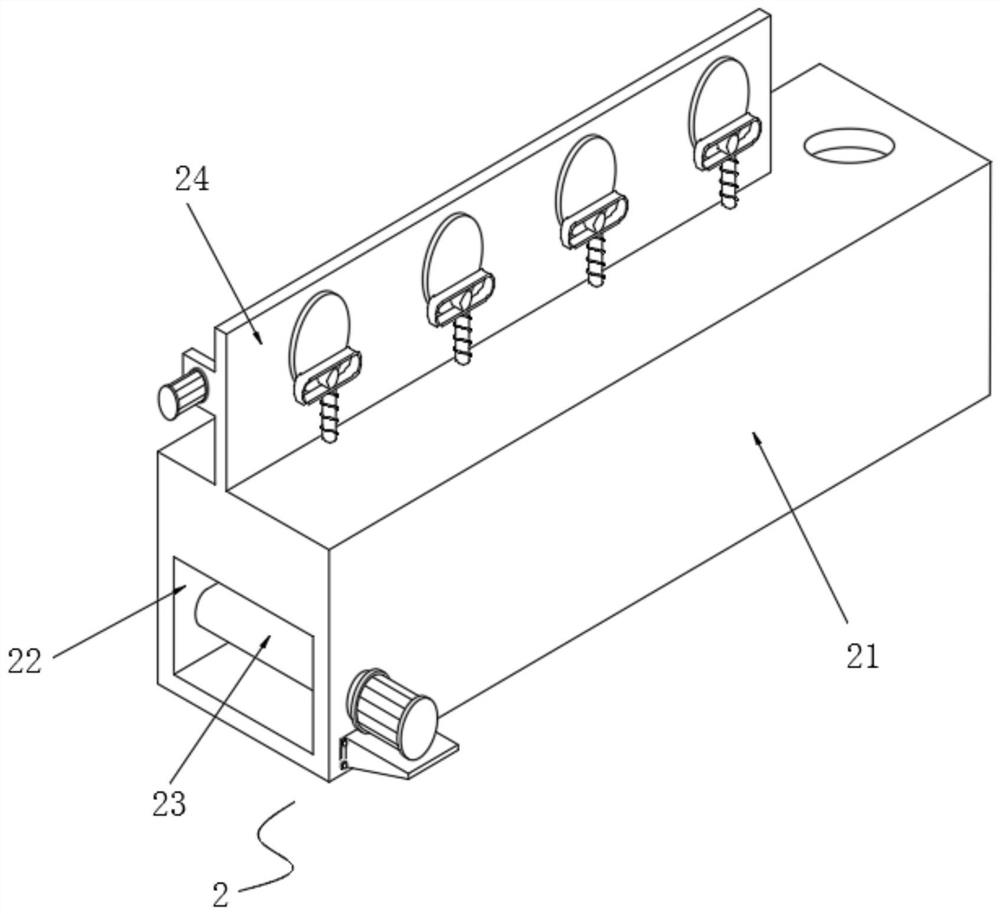

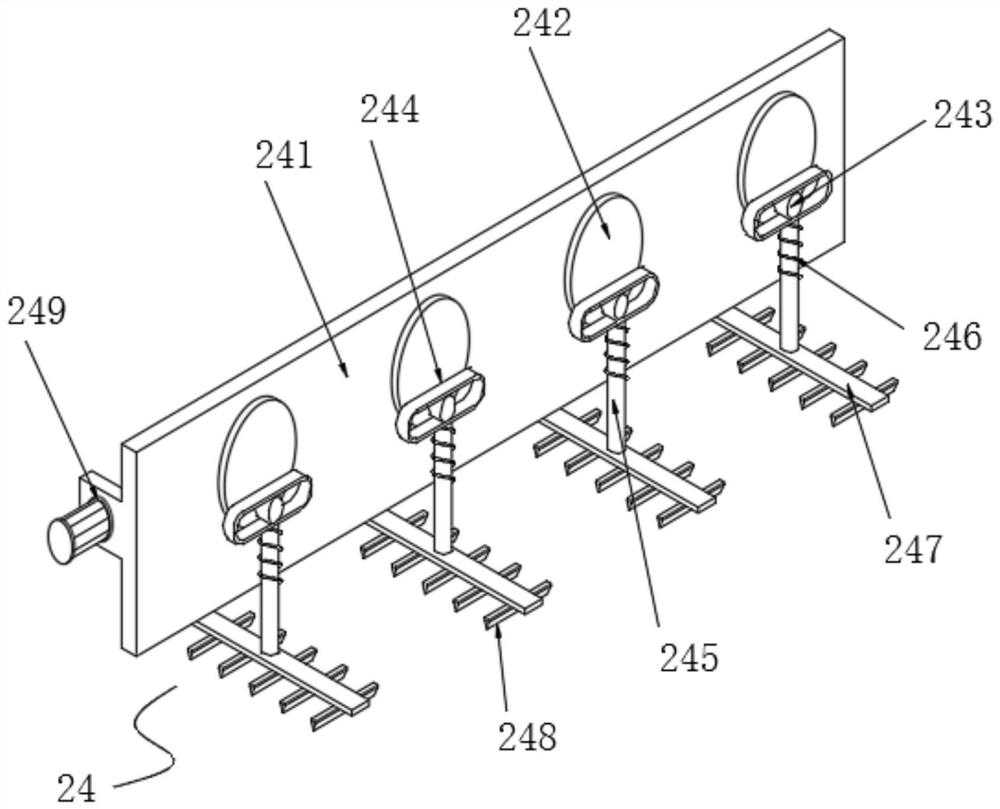

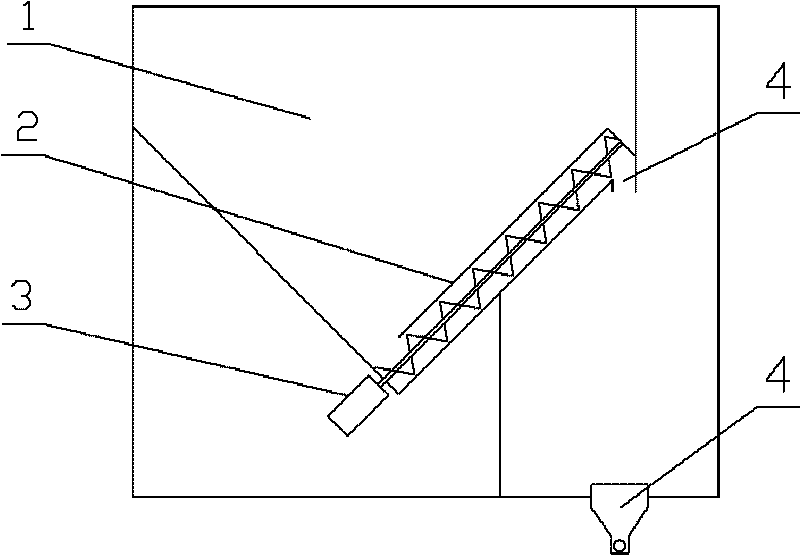

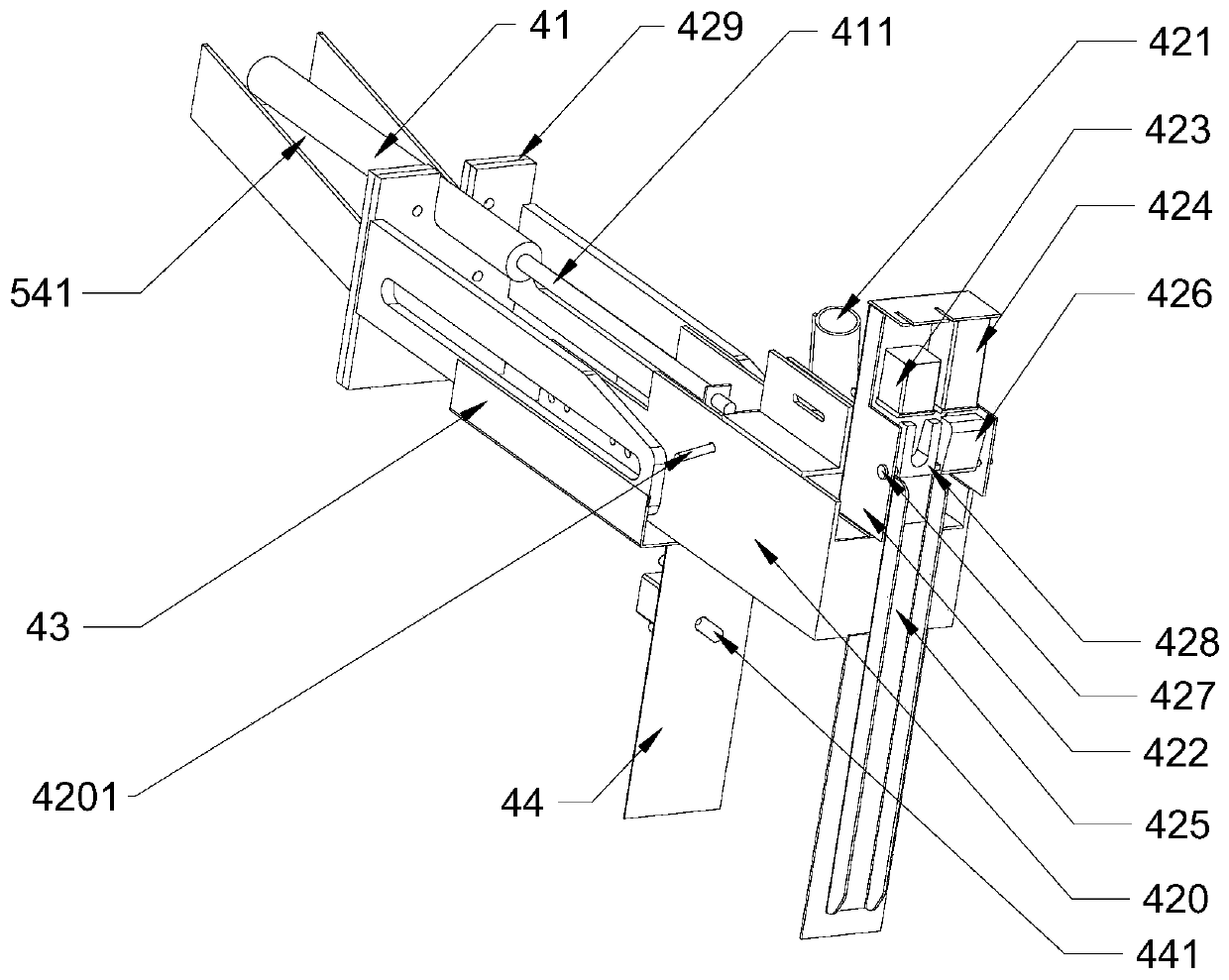

Automatic cooking equipment dish placing control method, assembly of same and follow-up discharging mechanism

ActiveCN105011734AGuaranteed to fall intoNo additional conversion steps requiredCooking vesselsConveyor partsWater resourcesFood material

The invention relates to the field of automatic cooking equipment, aims to solve a technical problem existing in the prior art and provides an automatic cooking equipment dish placing control method, assembly of the same and a follow-up discharging mechanism to directly transferring cooked dishes into containers from a pan, to shorten cooking procedure, to improve efficiency, and to reduce labor work and water resource and food material waste. A method that dishes are rotationally discharged while a pan body is manually rotated is changed and thought in an opposite way that with remaining of the rotating center of the pan body, the container is moved to follow up the movements of the discharging side edge of pan body, so dishes in the pan body can be ensured to fall into a container with small area; the container filled with the dishes can be directly put on the table; and conversion between containers can be avoided. Compared with the prior art, a procedure is reduced, so efficiency is improved and large labor work, water resource and raw material can be reduced.

Owner:李夏

Multifunctional electrical equipment box with ventilation and heat dissipation functions

ActiveCN108808523AIncrease resistanceReduce magnetismDispersed particle filtrationTransportation and packagingPower equipmentMagnet

The invention discloses a multifunctional electrical equipment box with ventilation and heat dissipation functions. The electrical equipment box comprises an electrical equipment box body, the multifunctional electrical equipment box with ventilation and heat dissipation functions is simple in structure, dust can be prevented from entering the electrical equipment box body by the aid of a filter net, dust is effectively prevented from entering the electrical equipment box body while the electrical equipment box body dissipates heat, a front shielding plate can prevent rainwater entering air holes, a first conductive piece and a second conductive piece are contacted, a motor drives a second connecting rod and a large brush plate to rotate, large soft bristles on the large brush plate are used for deeply treating dust on the filter net and enlarging the clearing area, when the second connecting rod rotates, a second permanent magnet attracts an iron block intermittently, a third connecting rod drives the large brush plate and a fourth connecting rod to move up and down under the action of a pull cord, a second spring and a third spring, so that the large soft bristles on the large brush plate rotationally move up and down for sweeping, and the sweeping efficiency is improved.

Owner:NANJING ADVANCED BIOLOGICAL MATERIALS & PROCESS EQUIP INST CO LTD

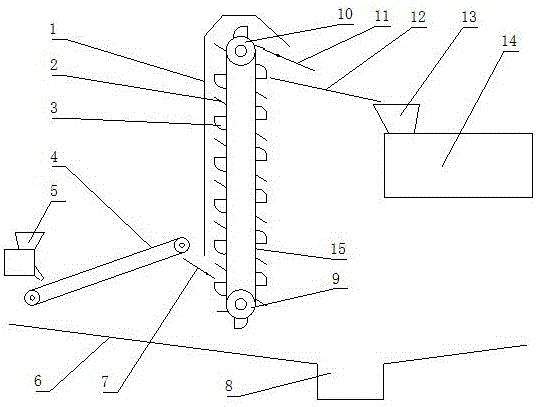

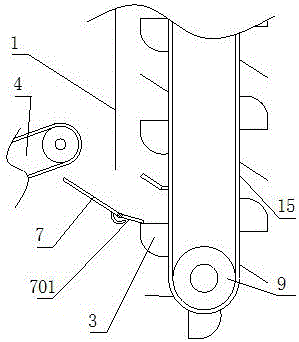

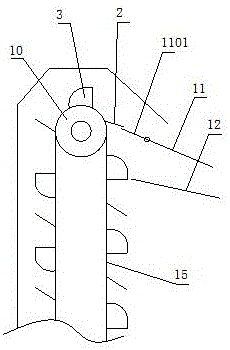

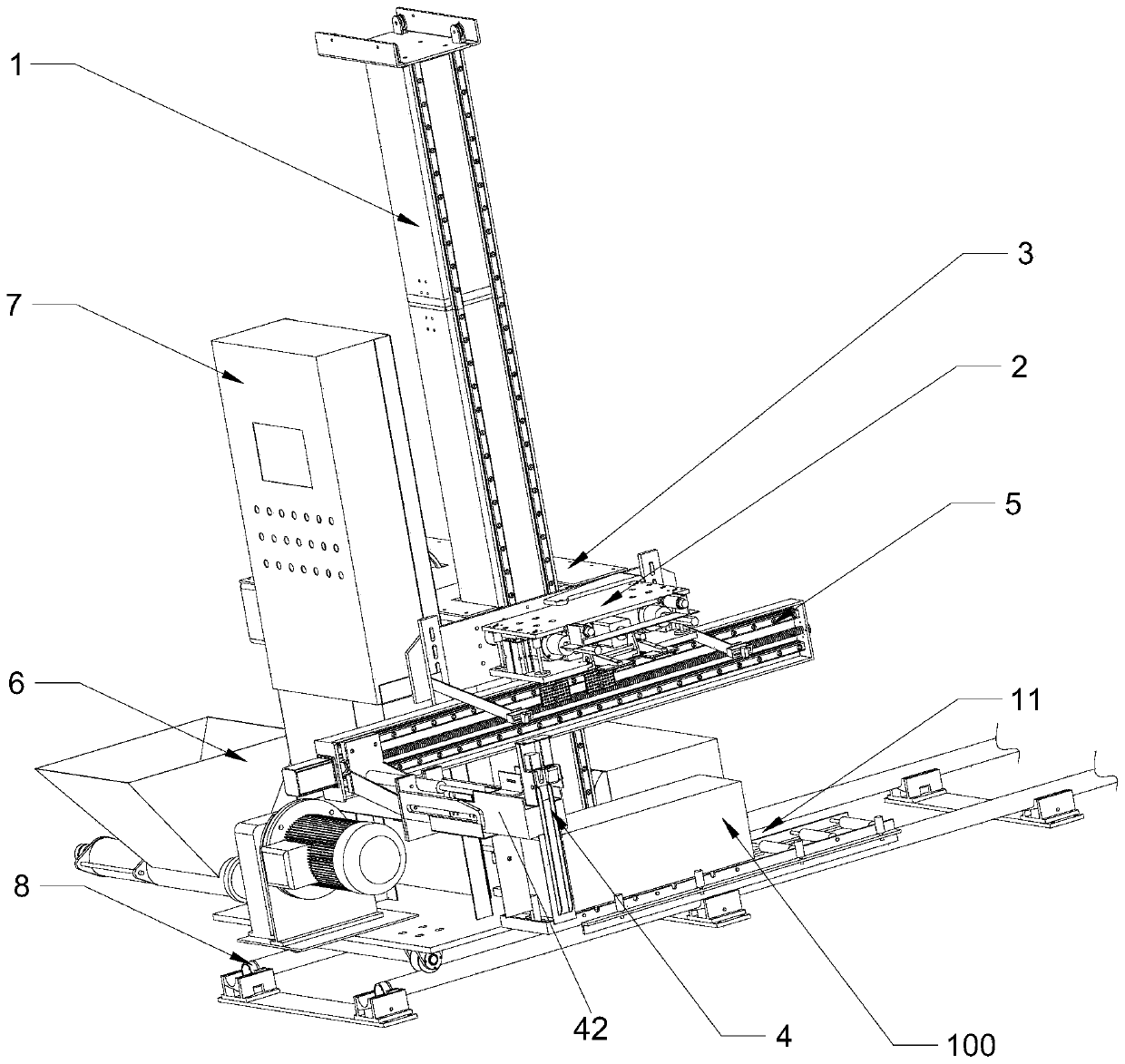

Broken glass feeding device

ActiveCN106494825AGuaranteed to fall intoBoost won't blockConveyorsConveyor partsEngineeringConveyor belt

The invention relates to a broken glass feeding device. A first guide plate is arranged between a breaking and feeding mechanism and a vertical lifting mechanism. A first movable plate located at the tail end of the first guide plate extends to the position above hoppers, and the effects that broken glass can drop into the corresponding hoppers and meanwhile the first movable plate cannot stop the hoppers and tilting plates from rising are guaranteed. A second guide plate is arranged between a discharging mechanism and the vertical lifting mechanism. A second movable plate located at the tail end of the second guide plate extends to the position below the tilting plates. When the hoppers get over the top end of a lifting conveyor belt, the broken glass can be discharged out of the hoppers to creep down onto the second movable plate and the second guide plate along the tilting plates, and meanwhile the second movable plate cannot stop the tilting plates and the hoppers from descending. Meanwhile, a second auxiliary guide plate is arranged below the second guide plate and used for receiving the broken glass falling off from the second guide plate and a small amount of broken glass falling off from the gaps between the tilting plates, and therefore the effect that the broken glass cannot be scattered is further ensured.

Owner:SHANDONG LEHE HOUSEWARES CO LTD

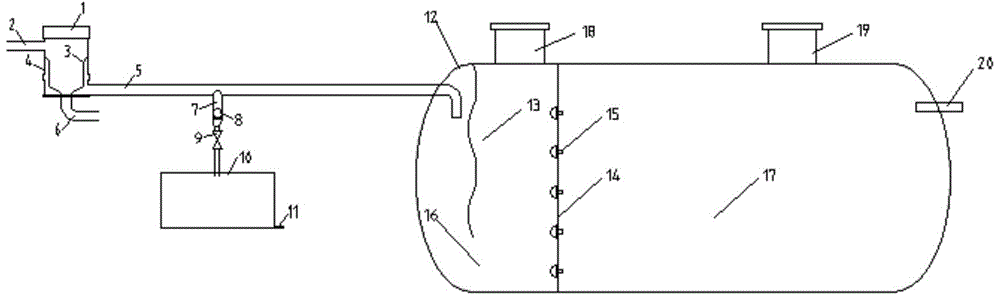

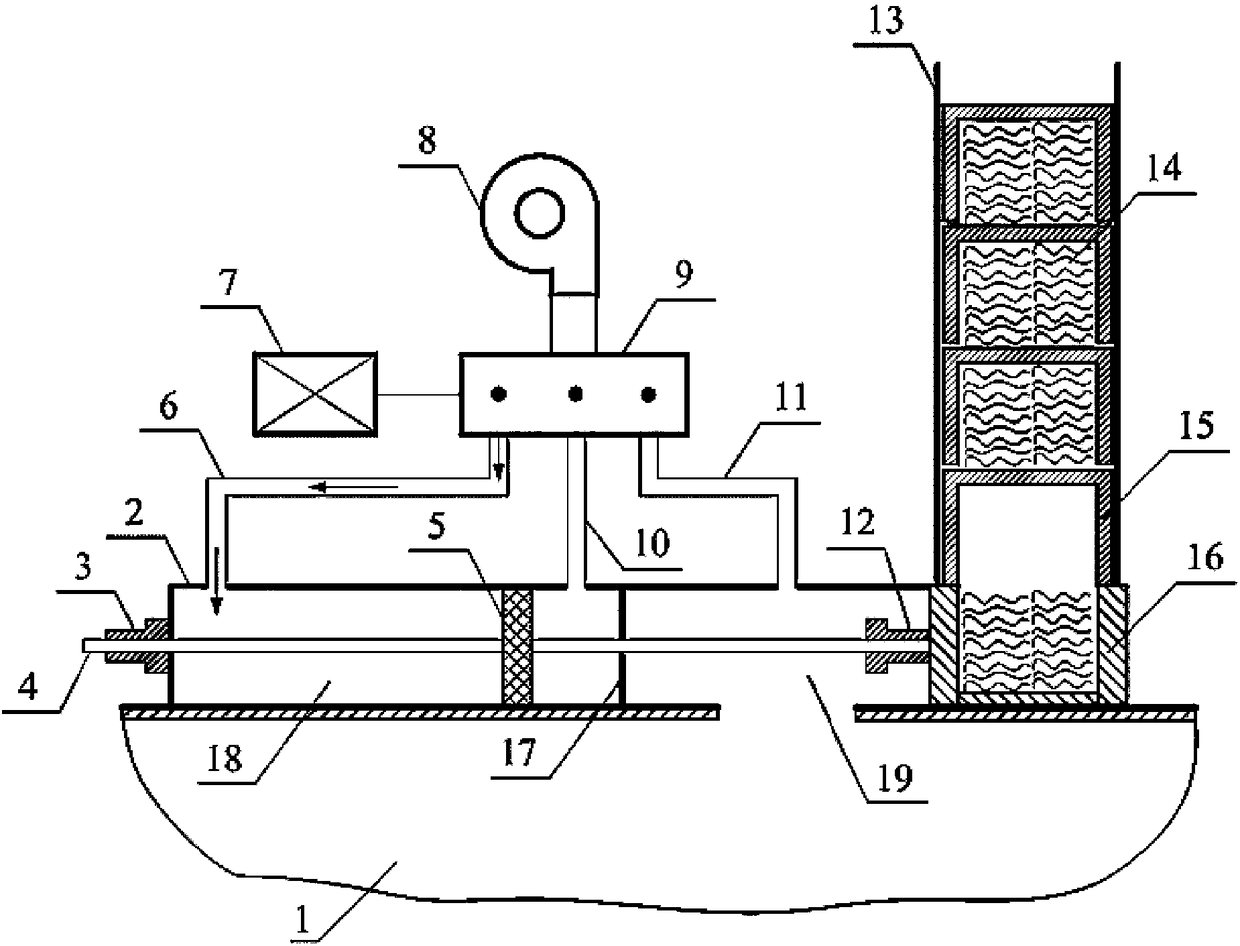

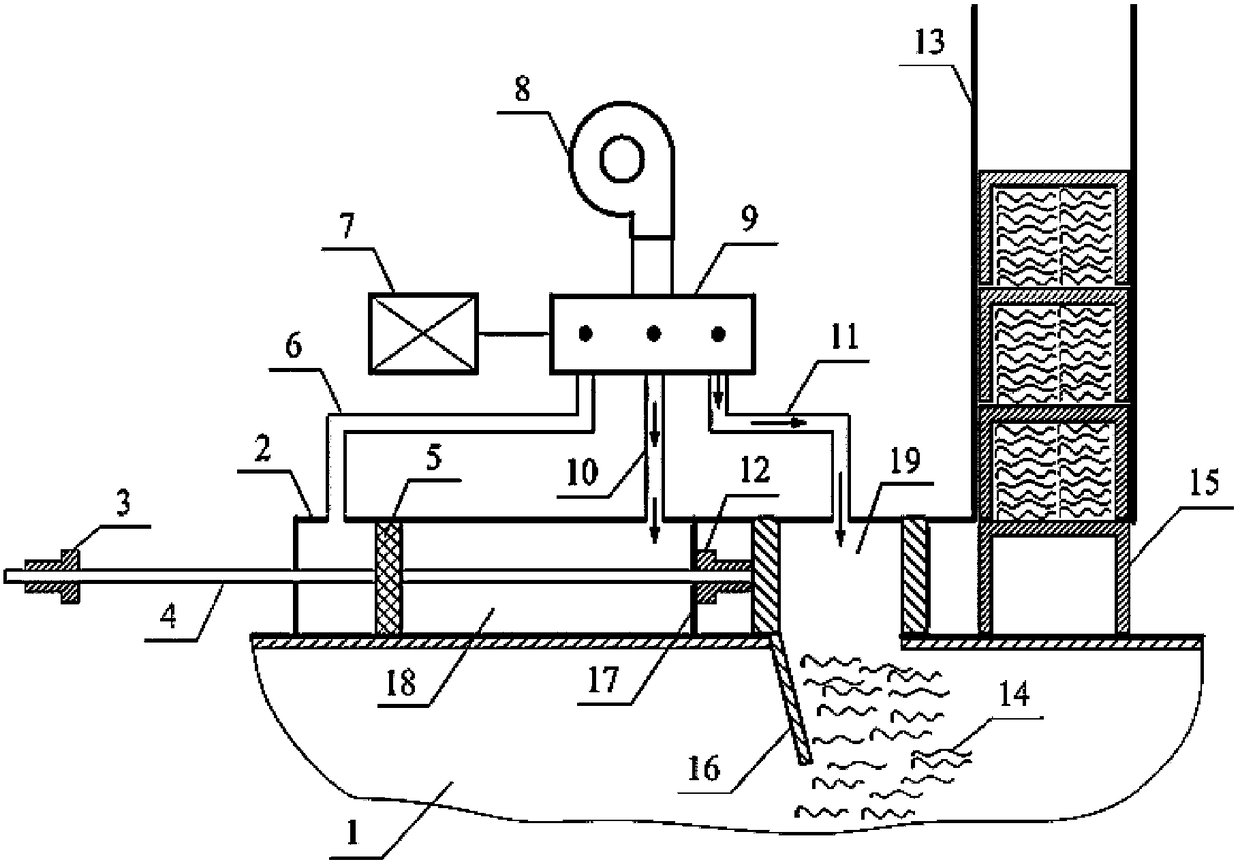

Power-free rainwater recycling system

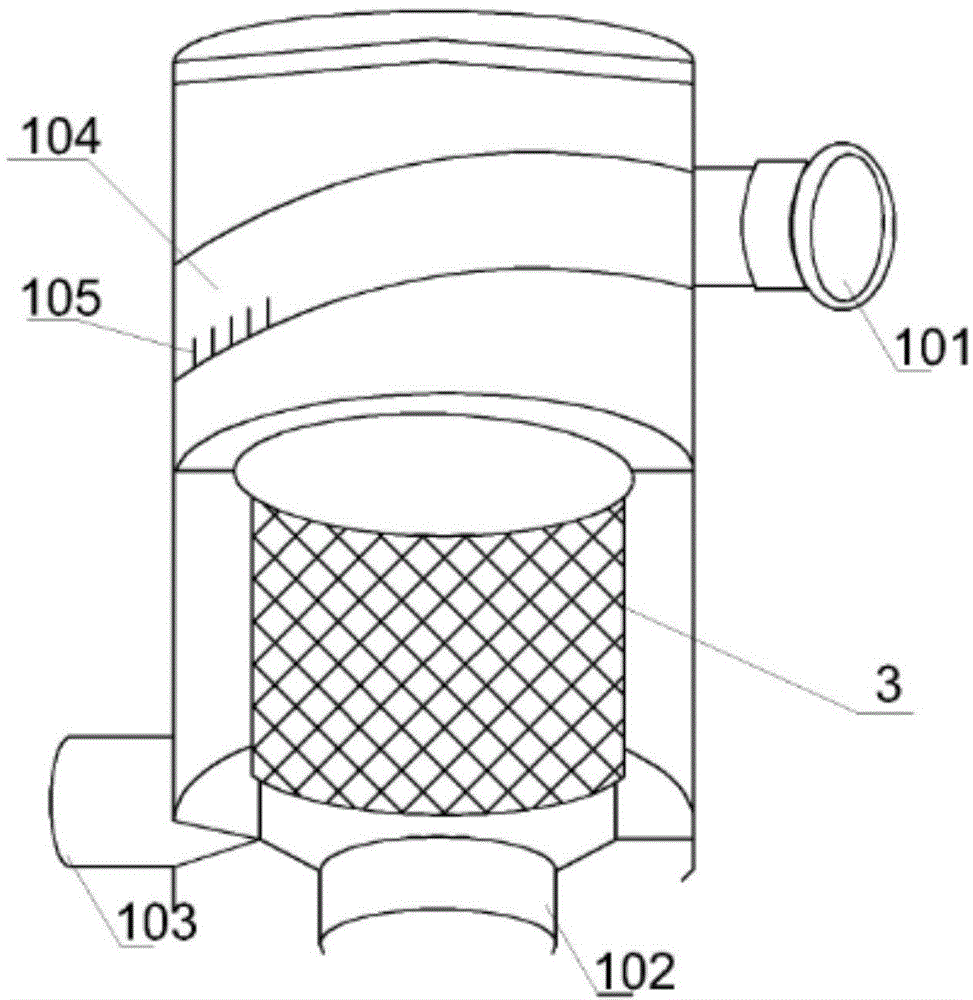

ActiveCN104674891AImprove cleanlinessSmooth internal spaceSewerage structuresGeneral water supply conservationGlass fiberRainwater harvesting

The invention discloses a power-free rainwater recycling system. The power-free rainwater recycling system comprises a waste flow water tank, wherein a centrifugal type rainwater separator is arranged at the upstream part of the waste flow water tank; one section of horizontal water inlet pipe is arranged in front of an inlet of the centrifugal type rainwater separator; a glass fiber reinforced plastic rainwater collection tank is arranged at the downstream part of the waste flow water tank. The process can be used for efficiently collecting rainwater; the power-free rainwater recycling system has a simple structure and is low in cost and easy to realize; the rainwater can be collected under the conditions of not using manpower and not consuming power; the special glass fiber reinforced plastic rainwater water collection tank is made of an environment-friendly material glass fiber reinforced plastic, and is industrially and wholly formed and produced in one step so that the power-free rainwater recycling system has good sealing performance and no leakage, and is acid-resisting and corrosion-resisting. An equipment overhauling opening is formed so that a worker can enter the inner part to overhaul and the construction is rapid; labor force and materials are saved; the treated rainwater can reach the standards and is recycled, and can be used as water for afforesting, vehicle washing, spraying, toilet flushing, landscapes and the like.

Owner:广西威尔森环保科技开发有限公司

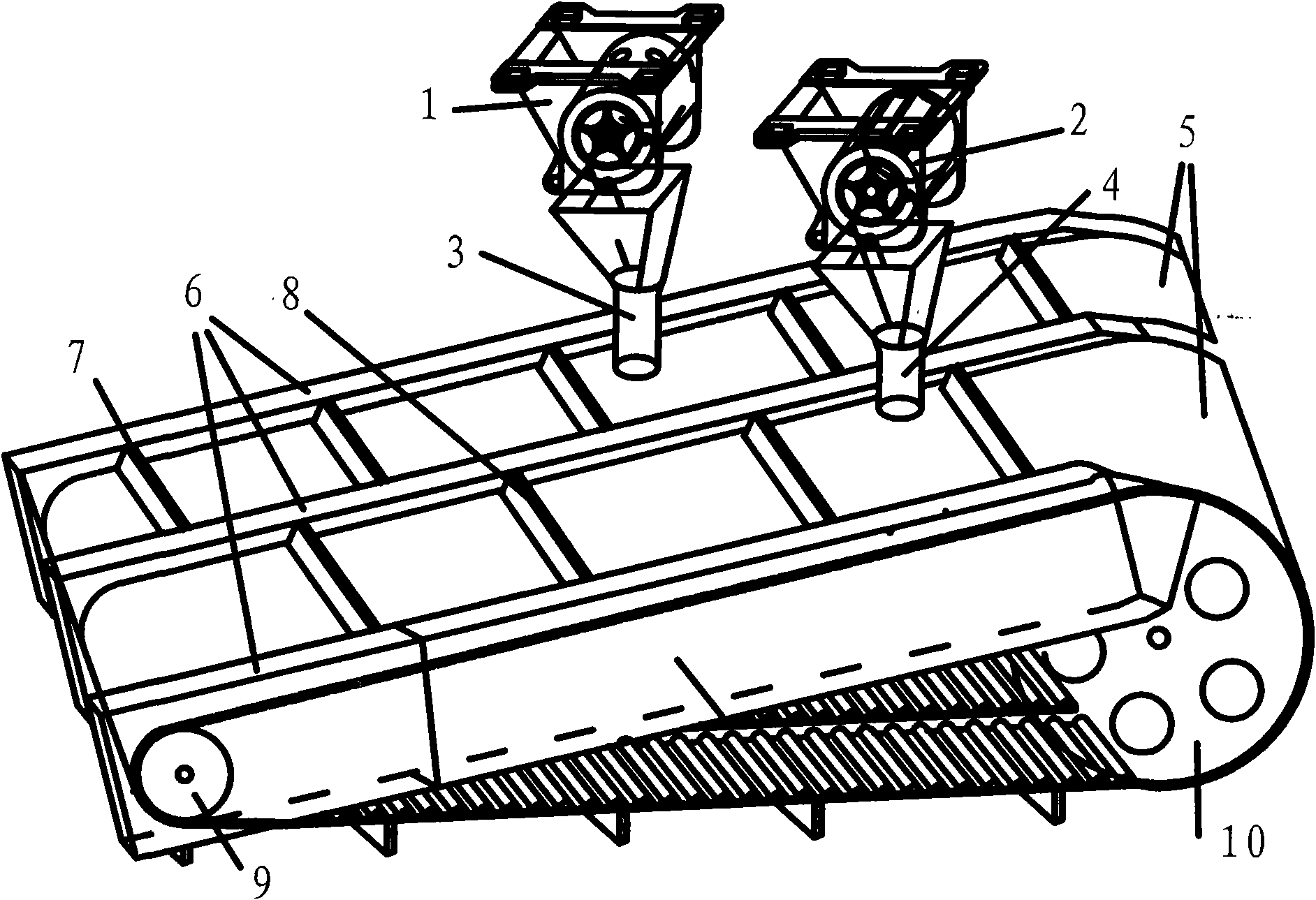

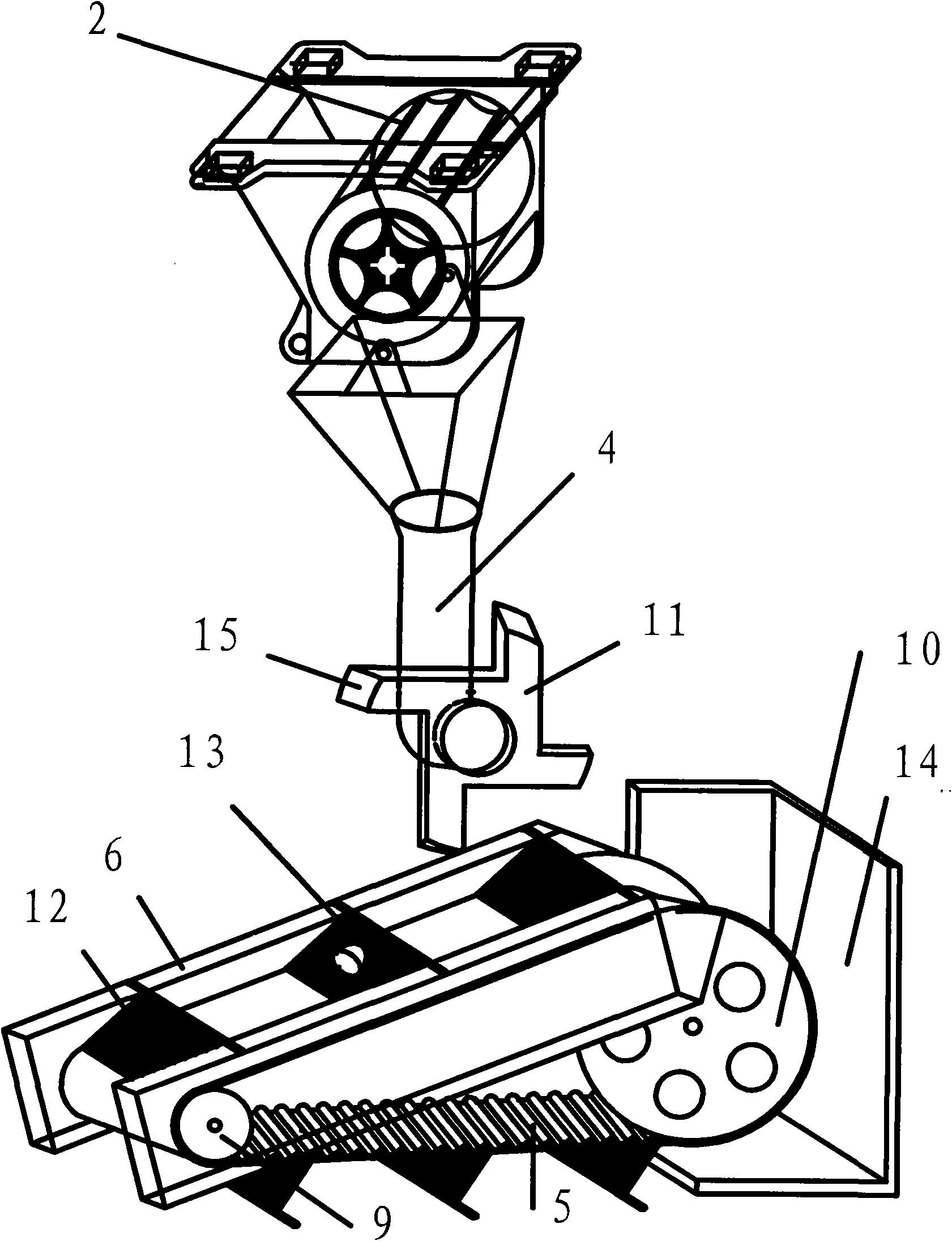

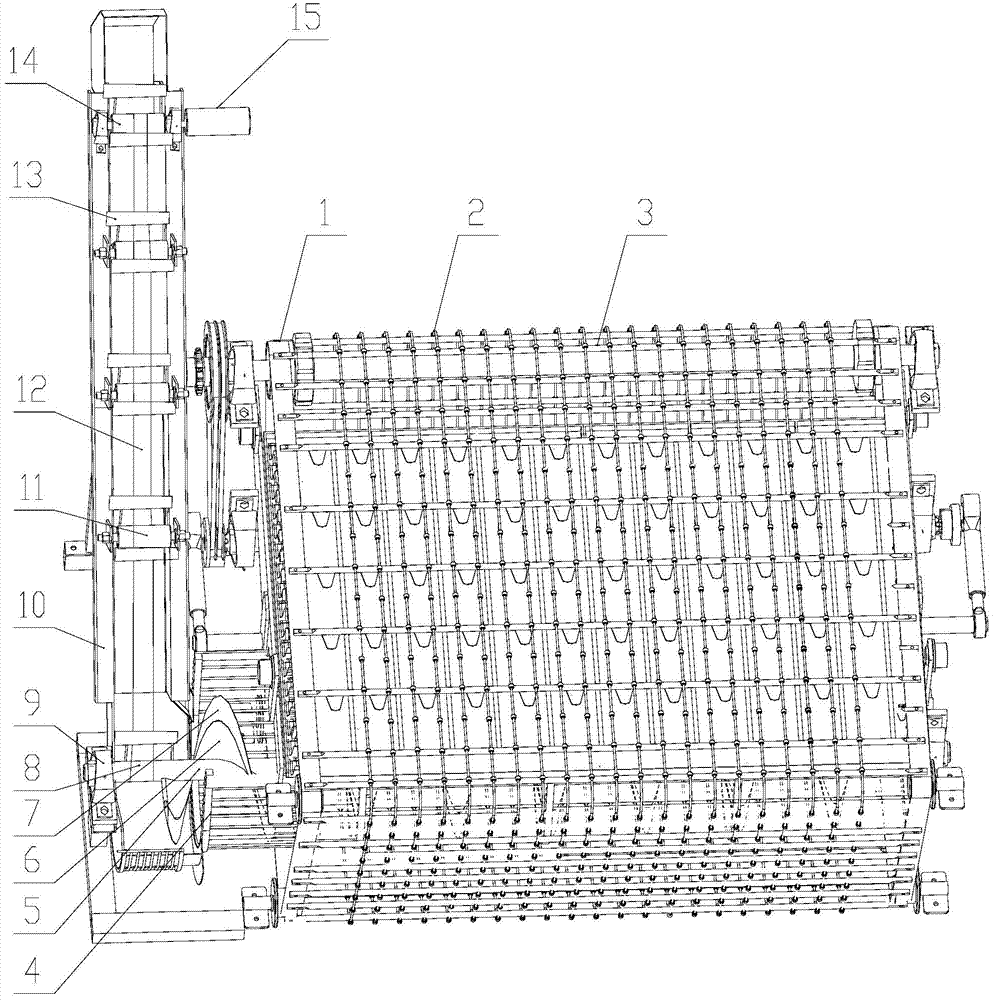

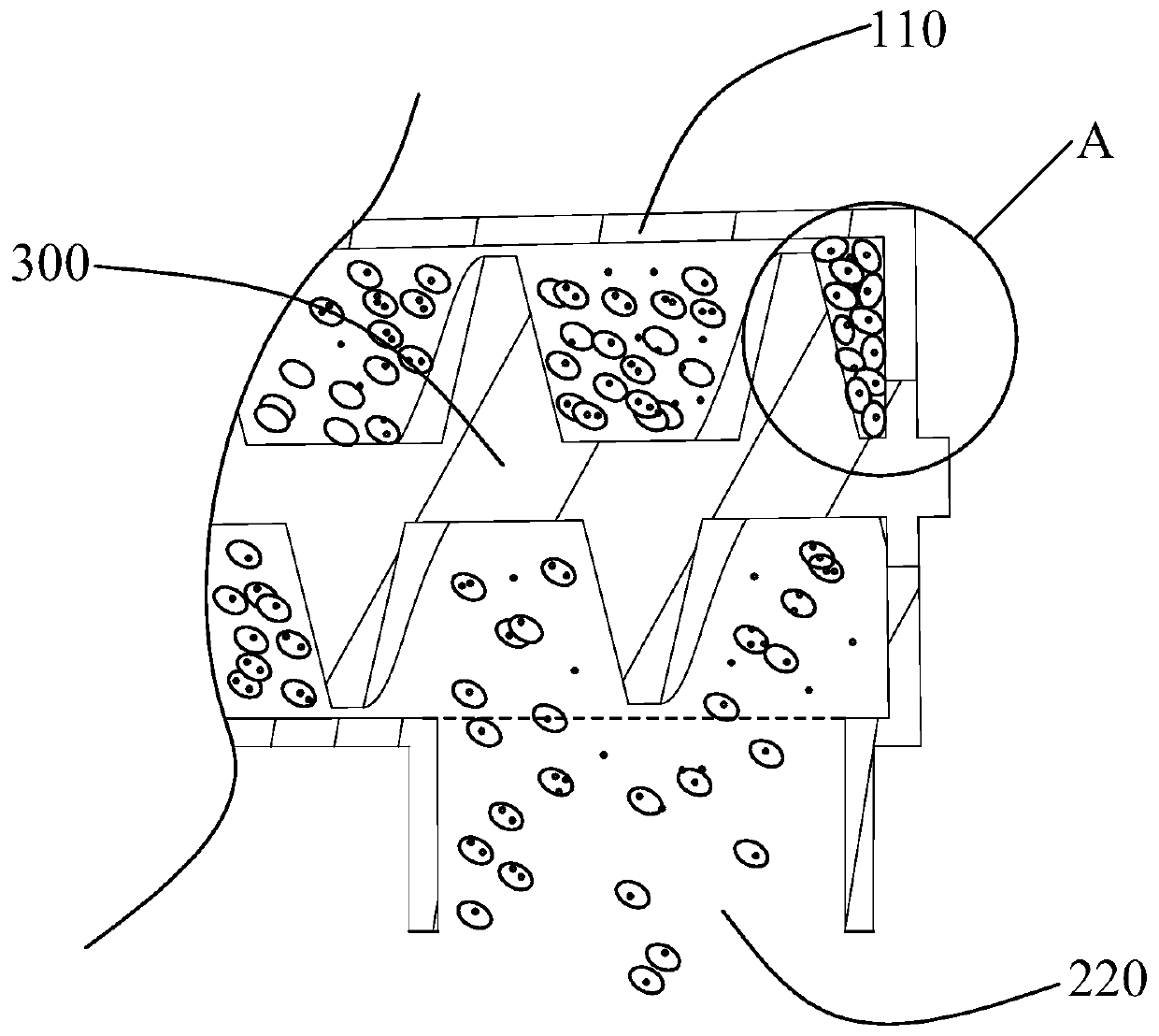

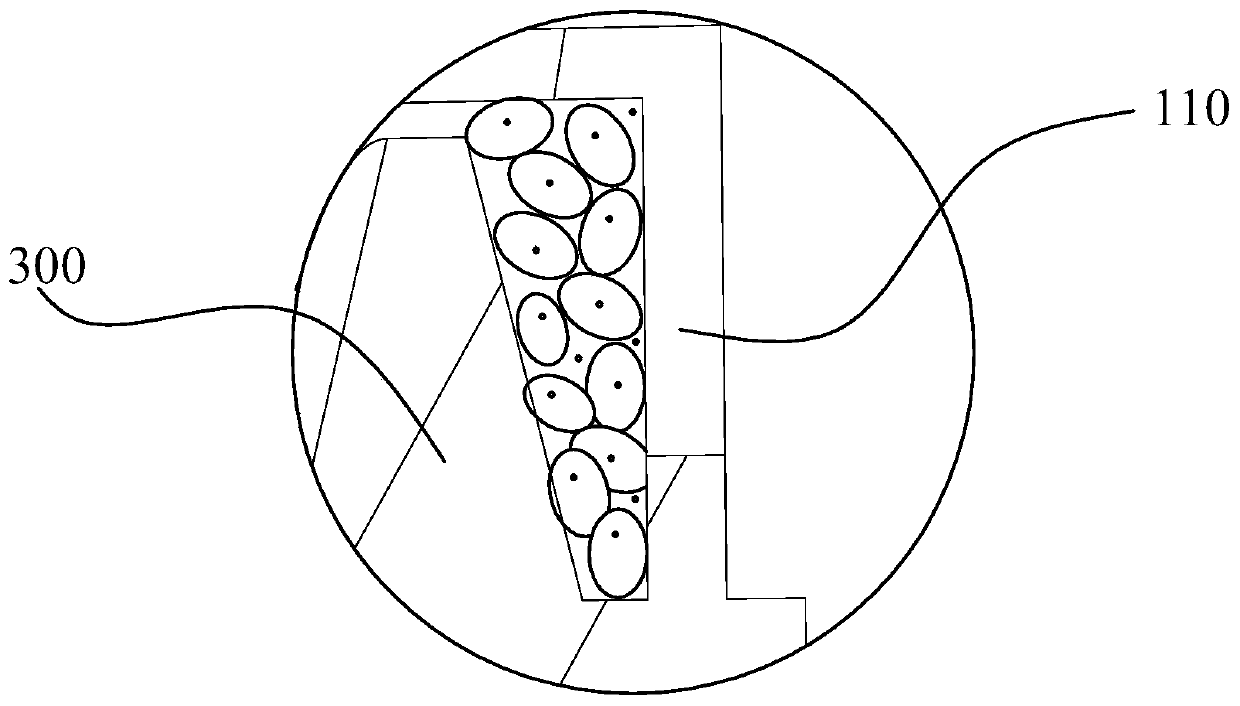

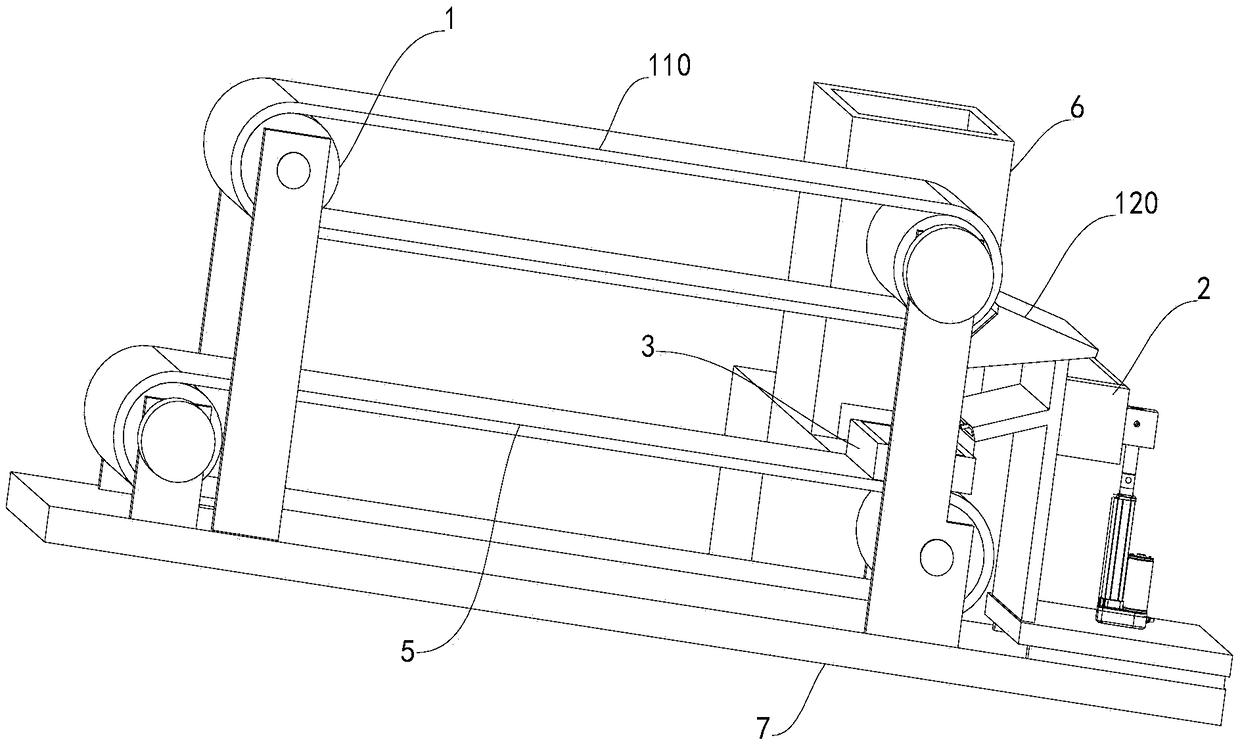

Seed metering and fertilizer feeding device of seeder

InactiveCN102246623AIncrease profitReduce flipFertiliser distributersAgriculture gas emission reductionGratingEngineering

The invention relates to a seed metering and fertilizer feeding device of a seeder. The seed metering and fertilizer feeding principles and structures are essentially the same, namely, the work stations are staggered at a mechanical angle. The device comprises a seed fetching device, a fertilizer fetching device, a feed pipe and a fertilizer pipe. The device is characterized in that the device also comprises a conveyor belt mechanism installed below the feed pipe and the fertilizer pipe; conveyor belts in the conveyor belt mechanism are oblique downwards; transverse small grating plates for separating the seeds or fertilizers are also installed on the surfaces of the belts along the forward directions; the distances between the small grating plates are longer than the dividing distance between the work station of the seed fetching device and the work station of the fertilizer fetching device; and enlargement of the seed charge distance is realized through synchronous operation. The device can improve the hill distance accuracy and the seed and fertilizer isolation, can increase the operation speed and is suitable for planting of such sparse tilling crops as maize, cotton and the like and planting of grains, beans or intercropping of two inter-row crops.

Owner:孙士杰

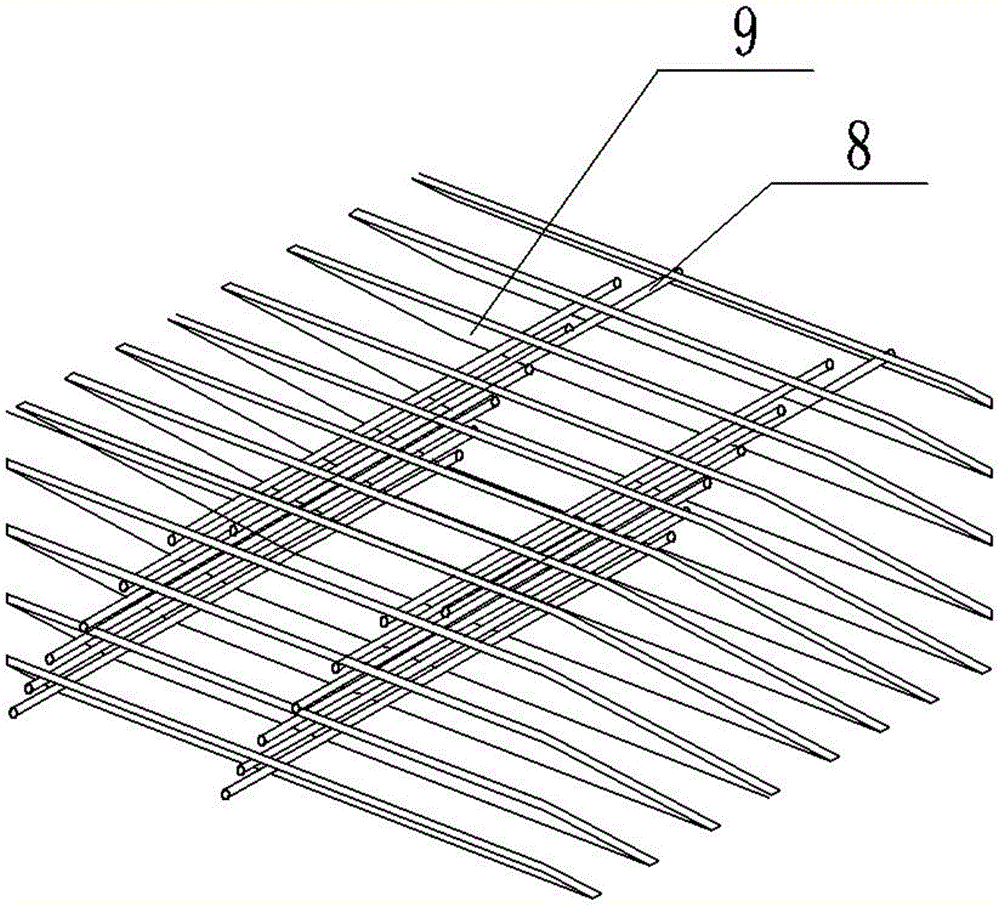

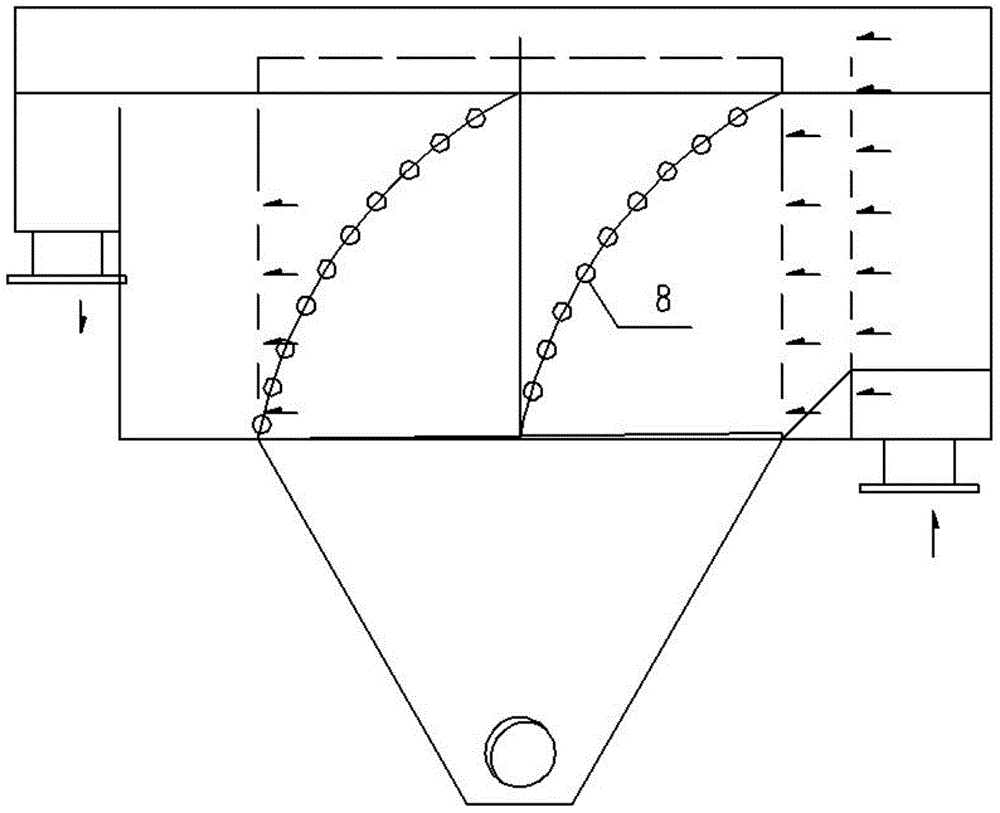

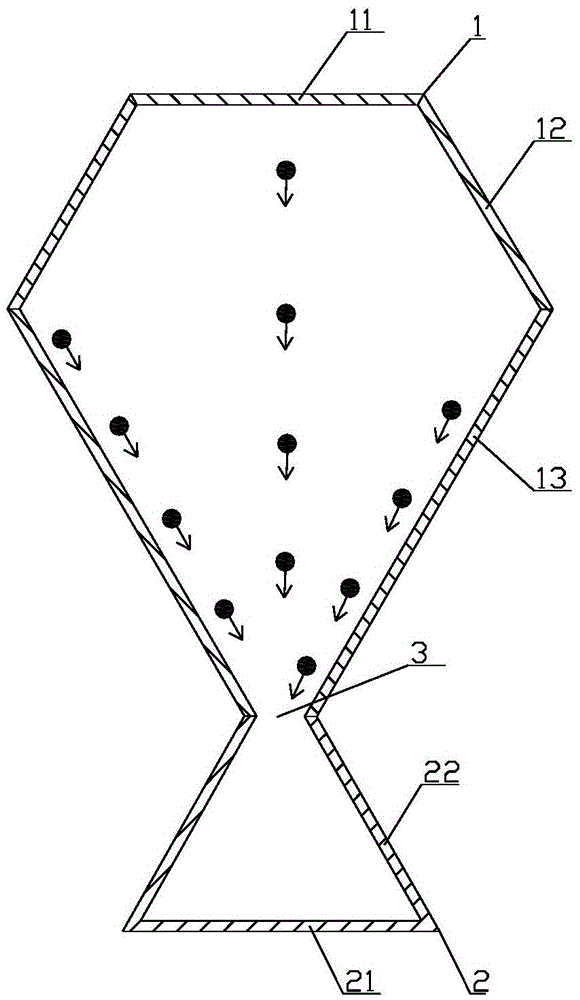

Efficient inclined plate oil removal and sand settlement apparatus

The invention discloses an efficient inclined plate oil removal and sand settlement apparatus. The apparatus includes a pool body and a sand hopper positioned below the pool body; the lower side surface of one end of the pool body is provided with a water inlet tube, and the lower side surface of the other end of the pool body is provided with a water outlet tube; the bottom of the sand hopper is provided with a sand outlet tube; a position close to the water inlet tube end in the pool body is provided with a water distribution weir, the water distribution weir comprises a body and through holes uniformly distributed on the body; a position close to the water outlet end in the pool body is provided with a water outlet weir; and a plurality of inclined plates formed through serial connection of vortex street columns distributed according to an Achimedean spiral are arranged between the water distribution weir and the water outlet weir, the length direction of the vortex street columns is vertical to the direction of flowing of water into the inclined plates from the water distribution weir, and the length direction o a gap formed by adjacent inclined plates parallels to the direction of flowing of water into the inclined plates from the water distribution weir. The apparatus has the advantages of fast and efficient sand-water separation, stripping of organic matter from the sand grains, gravity flow of an oil-containing supernatant through a water outlet device, and regular discharge of water and oil removed sand grains falling into the sand hopper.

Owner:天津同创环境科技有限公司

Crushing equipment for health care products and method

ActiveCN112827619AImprove the effectShorten the timeSievingScreeningMedicinal herbsStructural engineering

The invention discloses crushing equipment for health care products and a method. The crushing equipment comprises a first box body, a feeding mechanism is arranged on the upper surface of the first box body, a feeding opening communicating with the feeding mechanism is formed in the upper surface of the rear side of the feeding mechanism, and a supporting plate is arranged at the front side of the lower portion of the first box body; and a crushing and screening mechanism is arranged on the upper surface of the supporting plate. The invention relates to the technical field of health care product machining. According to the crushing equipment for the health care products and the method, a dicing assembly is arranged at the position, located at the front side of the feeding opening, of the upper surface of the feeding box, and before medicinal materials of the health care products are crushed and ground, under the work of the dicing assembly, a cutter on a limiting strip plate can continuously move up and down, so that the medicinal materials on a conveying belt can be cut. If some medicinal materials are too large in size, the cutter can cut the medicinal materials into small blocks, subsequent grinding and smashing work on the medicinal materials is facilitated, then the medicinal material smashing effect can be improved, and time is saved.

Owner:南京百纳福生物科技有限公司

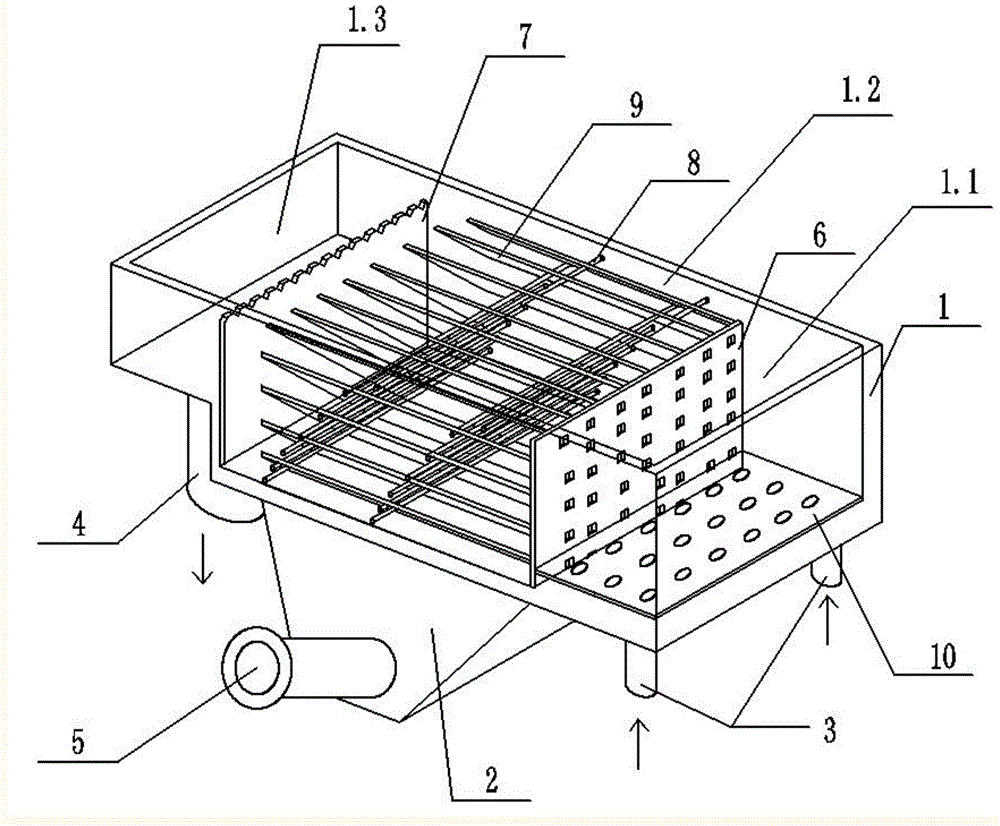

Testing fiber feeding device of heat exchanger

The invention provides a testing fiber feeding device of a heat exchanger. The testing fiber feeding device comprises an air cylinder with a rectangular cross section, a piston rod and a rectangular feeding box, wherein a partition plate is arranged in the air cylinder, a piston is arranged on the left side of the partition plate, the feeding box is arranged on the right side of the partition plate in a sliding mode, the right end face of the air cylinder is provided with an opening used for feeding the feeding box into and out of the air cylinder, the piston rod penetrates through the pistonand the partition plate in the length direction of the air cylinder, the right end of the piston rod is connected with the feeding box, and a feeding port is formed in the cylinder wall of the right side of the partition plate. According to the testing fiber feeding device, the uniform feeding of dust-accumulating indoor fibers is realized, the fiber-containing atmosphere environment with the stable and adjustable fiber concentration in a dust accumulation chamber is ensured, and an existing heat exchanger is accelerated to achieve the effect of dust accumulation after actually used for a plurality of years.

Owner:SHANGHAI JIAO TONG UNIV +1

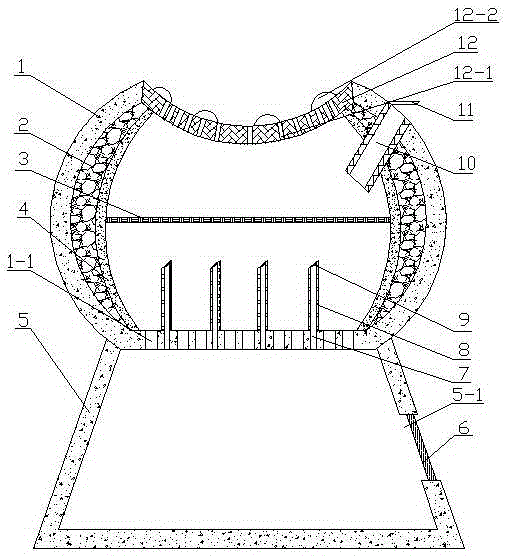

Closed fireplace with intake air distribution system

InactiveCN101701720AGuaranteed widthGuaranteed to fall intoDomestic stoves or rangesLighting and heating apparatusSocial benefitsCombustion chamber

The invention discloses a closed fireplace with an intake air distribution system, comprising a heath, a combustion conveyor and a hot air system. The heath is internally provided with a ventilation pipeline and a combustion chamber; the bottom of the combustion chamber is provided with a fireplace box in long groove structure; the length direction of the fireplace box is identical with the width direction of the fireplace; the bottom of the fireplace box is provided with a heating rod both sides of which are provided with air inlets; and the box wall of the fireplace box is provided with a plurality of secondary air inlets. The invention effectively solves the problems of fuel integration, low combustion efficiency and great environmental pollution existing in the traditional fireplace using wood grains as fuel, also solves the problems of flame integration, unobvious heat feeling and poor viewing effect existing in the traditional fireplace, has great fireplace flame width, strong heat feeling, good viewing effect, high heat efficiency, little environmental pollution and notable economic benefits and social benefits.

Owner:朱宏锋 +1

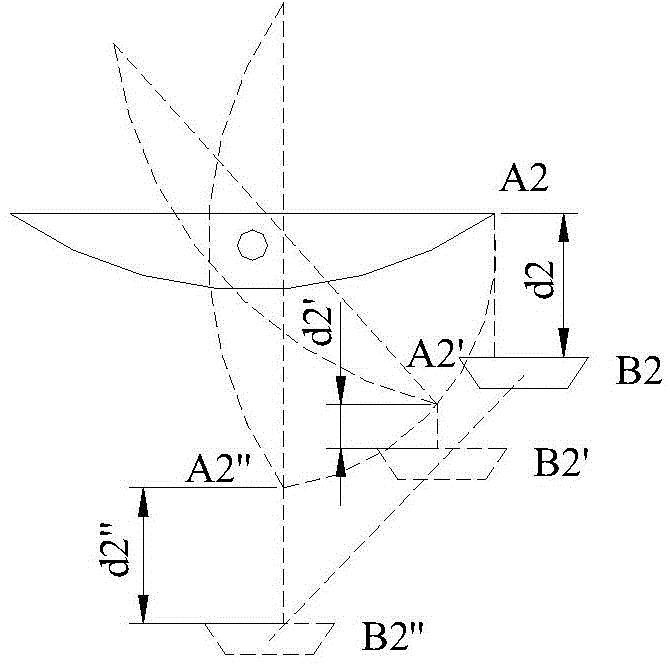

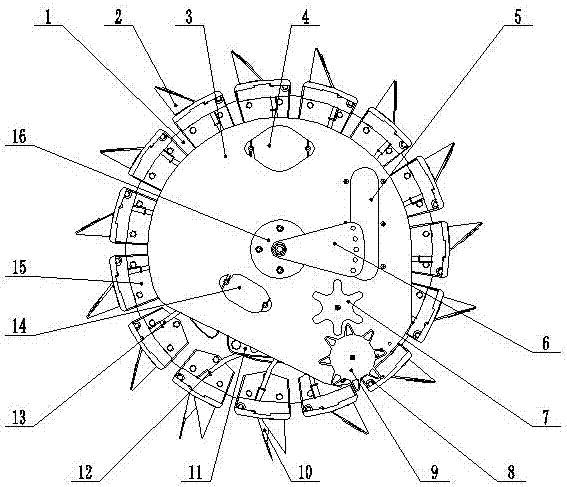

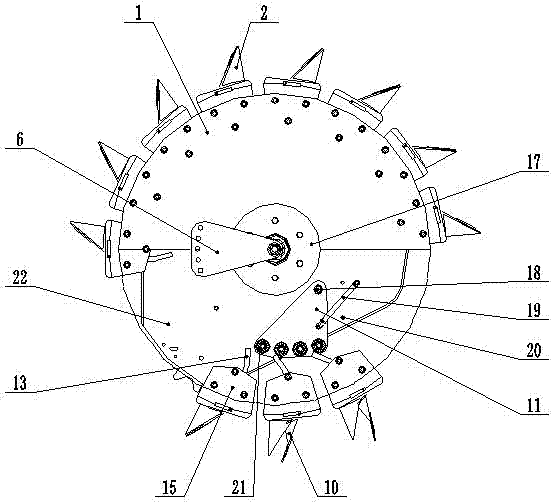

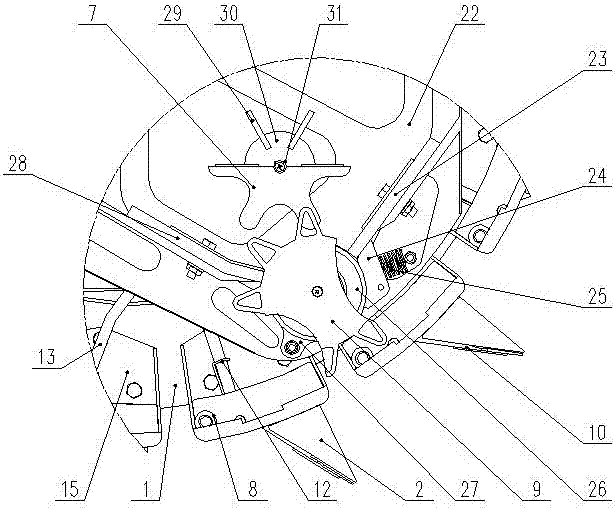

High-speed hilling disc

ActiveCN106941819AGuaranteed to fall intoReduce distanceDibble seedersSeed depositing seeder partsEngineeringAgitator

The invention provides a high-speed hilling disc. The high-speed hilling disc mainly comprises a movable disc, front and rear separator belts, a fixed disc group, a soil opener group, a seeding mechanism, a stirring wheel mechanism, a wobble-plate mechanism and the like, wherein the soil opener group is uniformly distributed on the circumference of the movable disc; the fixed disc group is connected with the movable disc through a flange; the stirring wheel mechanism and the seeding mechanism are arranged on the right lower part of the fixed disc group; the wobble-plate mechanism is arranged at the rear lower part of the fixed disc group; and the front and rear separator belts are arranged in the fixed disc group. According to the high-speed hilling disc, by means of the design of irregular shapes of fixed disc and fixed disc cover and cantilever assembly of the soil opener group, the linear speed of the soil opener group can be improved, the seed falling time can be reduced, and the sowing speed can be accelerated; the seeding mechanism ensures the sowing accuracy by means of the front and rear separator belts and a forced feed agitator, and seeding wheels and seeds are protected by the design of a floating protective plate; the stirring wheel mechanism ensures seeds to enter the seeding mechanism smoothly; and the wobble-plate mechanism continues the opening state of the soil opener group to ensure the sowing quality, and enables the hilling disc to rotate clockwise and counterclockwise without influencing the sowing quality, so that the operability is improved.

Owner:GANSU TAOHE TRACTOR MFG

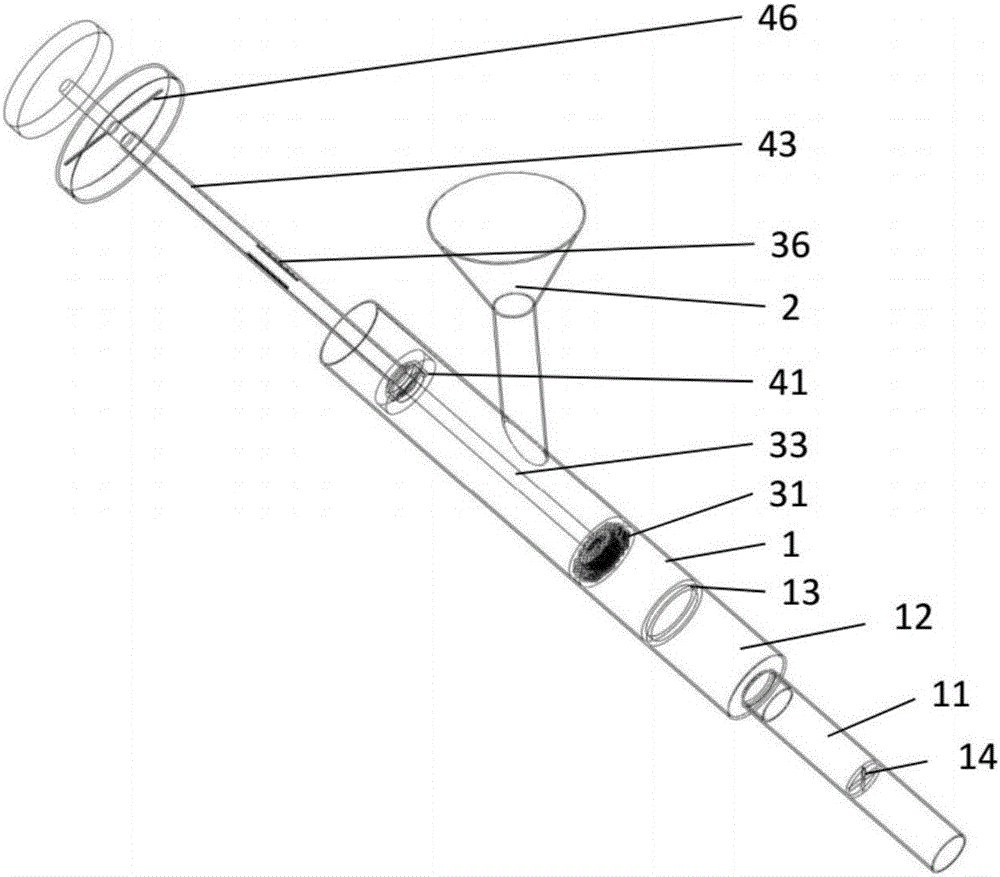

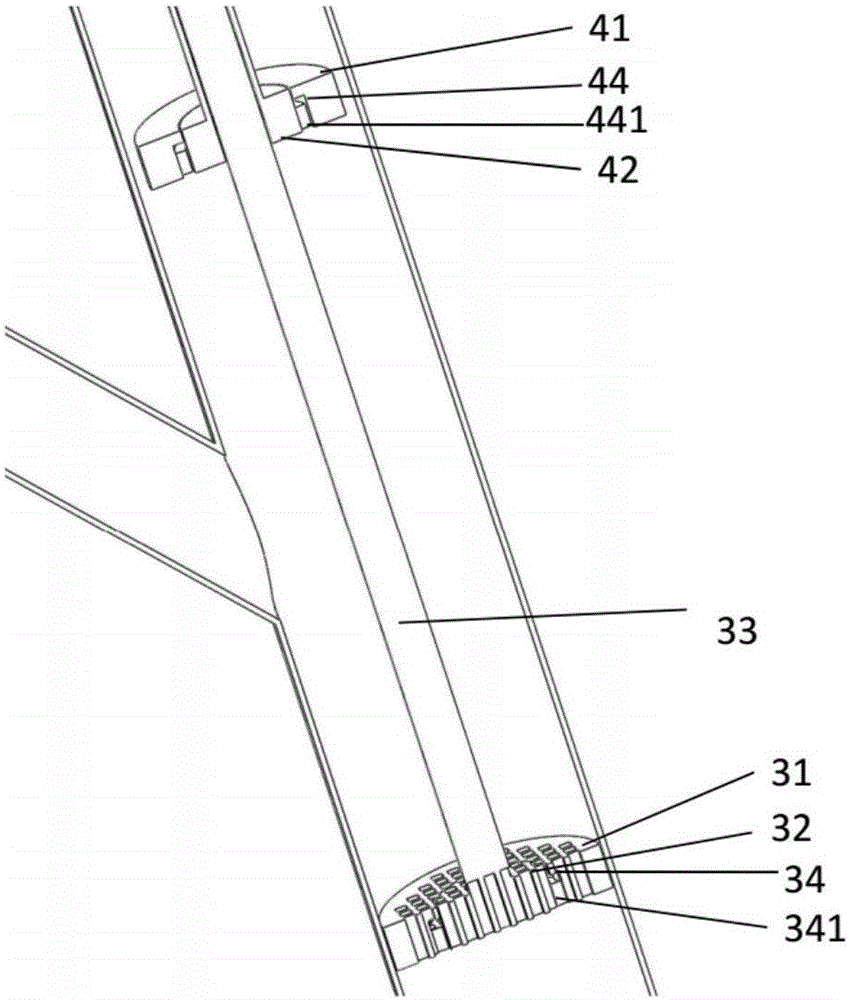

Composite bone grafting device

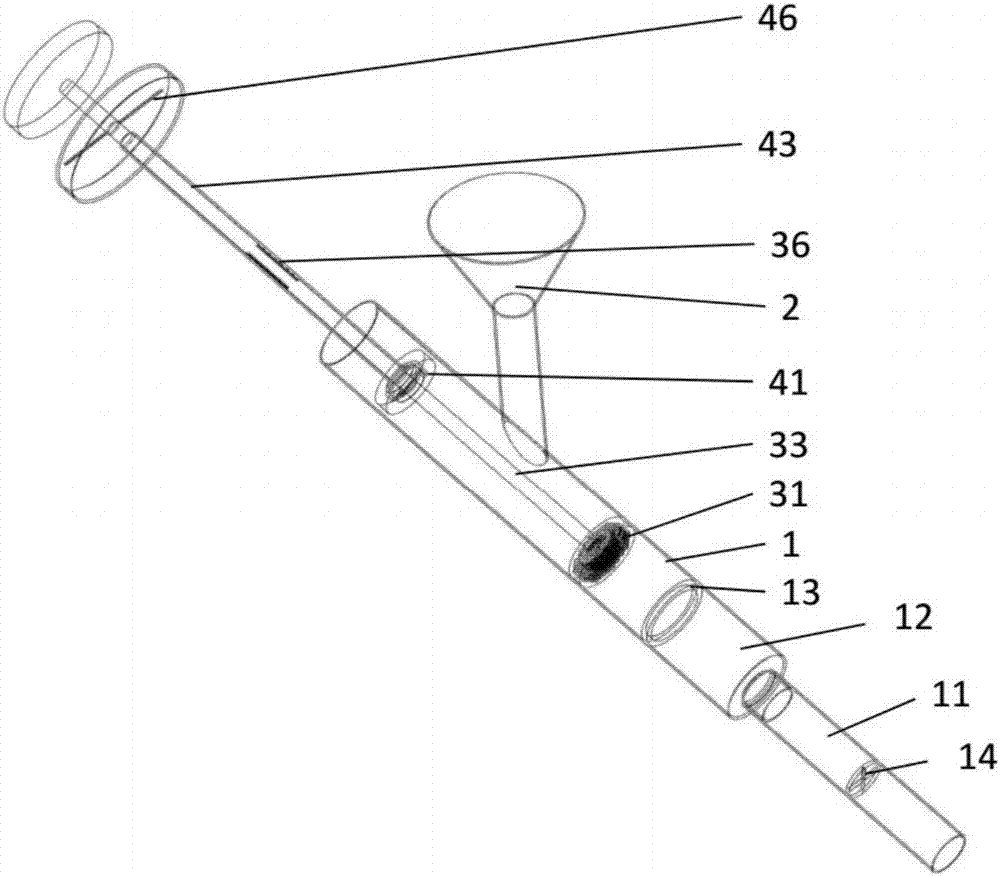

The invention discloses a composite bone grafting device which comprises a bone grafting sleeve, a bone grafting funnel, a large porous push plate, a large nonporous push plate, a porous push plate push-pull rod and a nonporous push plate push-pull rod. The composite bone grafting device is characterized in that the bone grafting funnel is arranged on the side surface of the bone grafting sleeve; the large porous push plate and the large nonporous push plate are arranged in the sleeve; the large porous push plate is arranged below the large nonporous push plate; the porous push plate push-pull rod sleeves the outer side of the nonporous push plate push-pull rod; a nonporous push plate and a small porous push plate can be separated out from the large nonporous push plate and the large porous push plate respectively; the porous push plate push-pull rod and the nonporous push plate push-pull rod are provided with corresponding connection structures; after the porous push plate contacts the nonporous push plate, the porous push plate push-pull rod is connected with the nonporous push plate push-pull rod. Screening is further carried out on a broken bone before bone grafting; the uniformity of the broken bone is ensured; compaction on the grafted bone can be ensured through the arranged separable small porous push plate and nonporous push plate; the success rate of the operation is ensured; the bone grafting time can be shortened.

Owner:启载生物科技成都有限公司

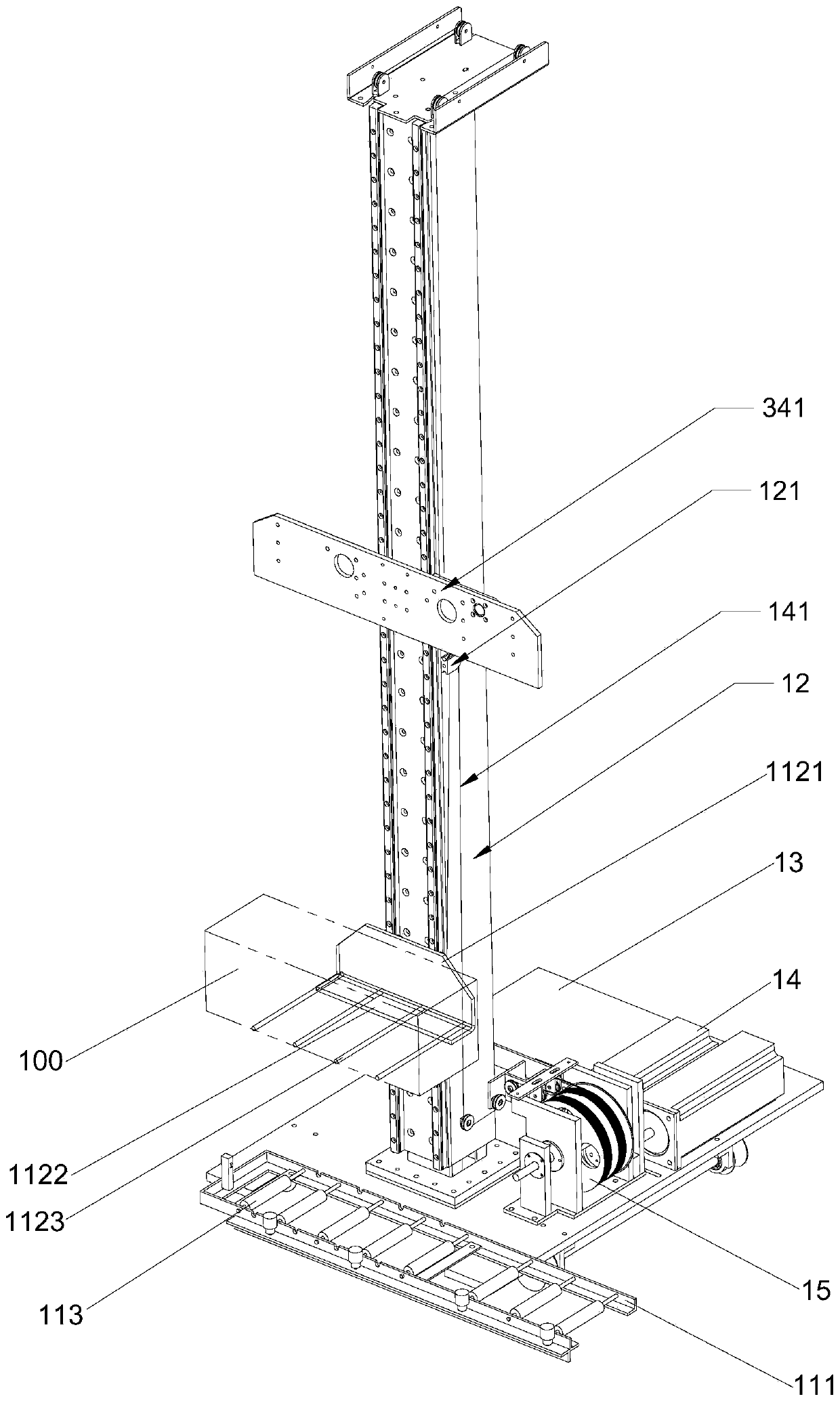

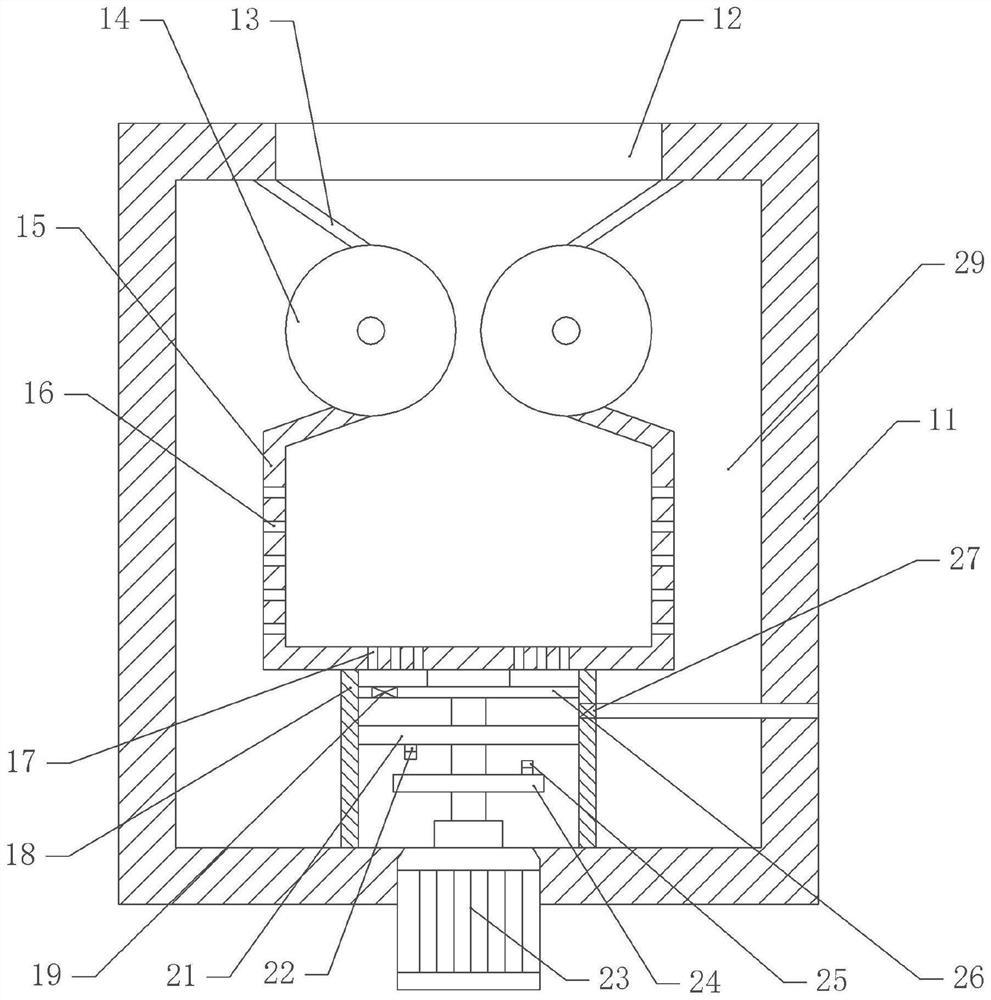

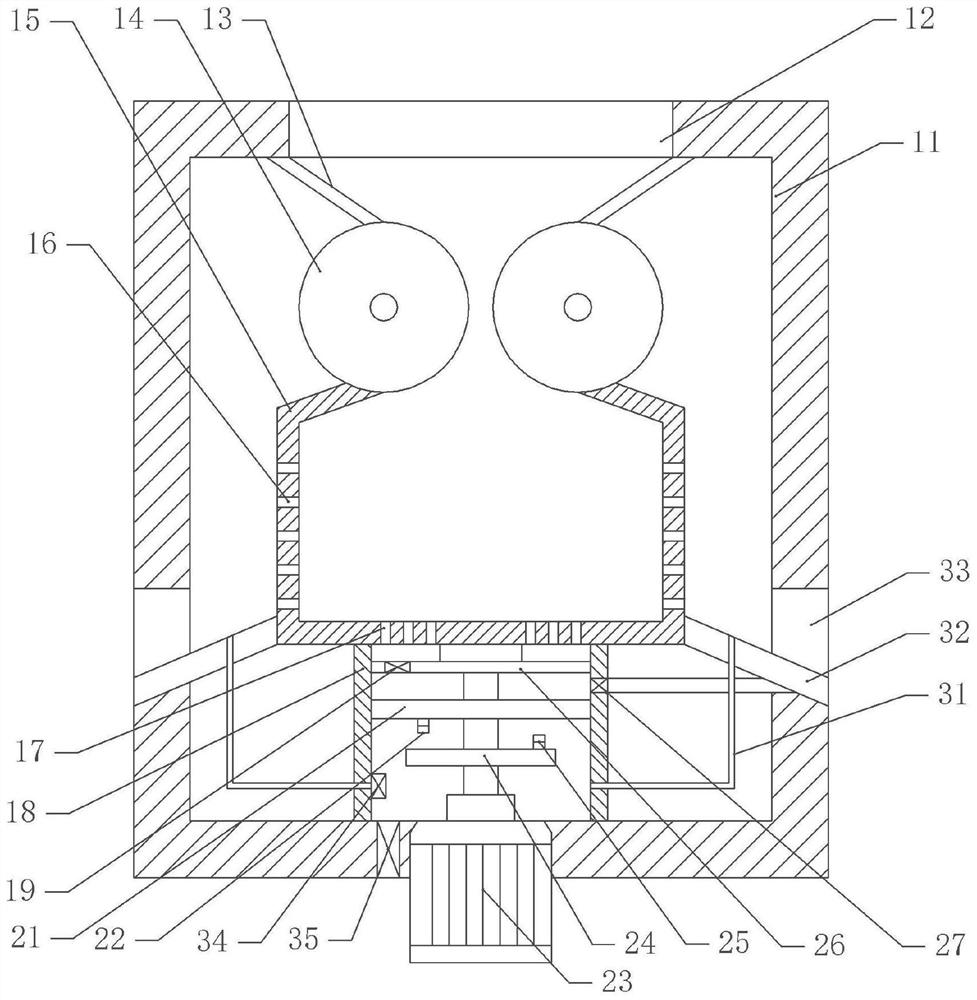

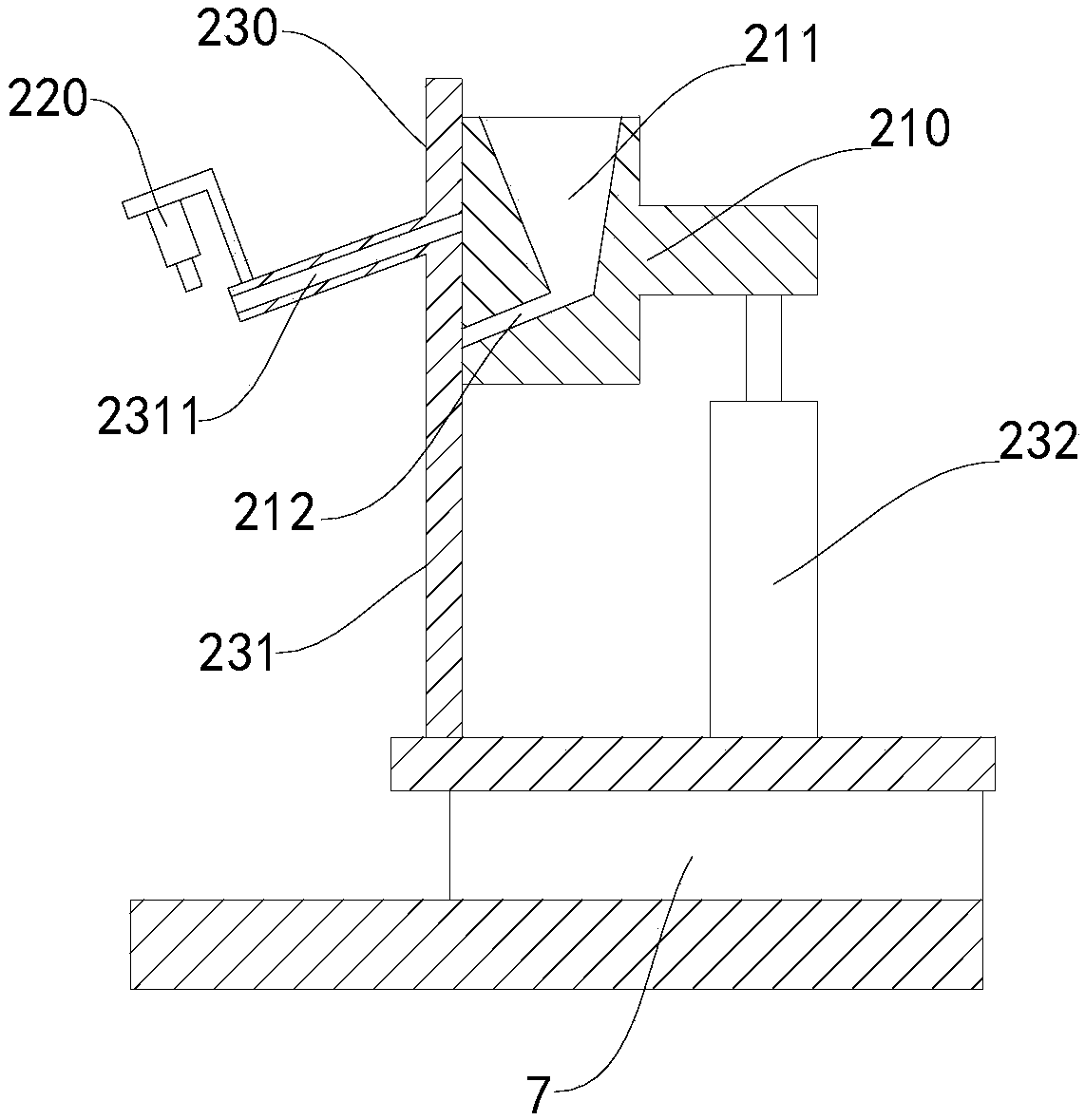

Intelligent coal sample quantitative weighing device and method

ActiveCN110231076APrecisely control the amount addedPrecise time controlFuel testingWeighing apparatus with automatic feed/dischargeControl systemEngineering

The invention discloses an intelligent coal sample quantitative weighing device and method. The device comprises a porcelain boat for placing a coal sample and a weighing module for weighing the coalsample in the porcelain boat. The weighing device is characterized by further comprising a lifting rotary mechanism for placing the porcelain boat on the weighing module or taking off the porcelain boat from the weighing module, and a vibration sampling mechanism for adding the coal sample in the porcelain boat by adopting a vibration way; the vibration sampling mechanism is located above the weighing module, the porcelain is placed on the weighing module along with the movement of the lifting rotary mechanism, and receives the coal sample falling from the vibration sampling mechanism due to vibration; the weighing module, the lifting rotary mechanism and the vibration sampling mechanism are cooperatively controlled by the control system in a unified way. The placing or taking-off of the porcelain boat on the weighing module is realized through the lifting rotary mechanism, the trace and step-by-step sample falling in the porcelain boat can be performed through the vibration sampling mechanism, thereby precisely controlling the adding quantity and adding time of the coal sample. the precise and reliable and full-automatic and intelligent quantitative weighing is realized, the quantitative weighing process is free from artificial participation, and the efficiency and the accuracy are higher.

Owner:HUNAN RAILWAY PROFESSIONAL TECH COLLEGE

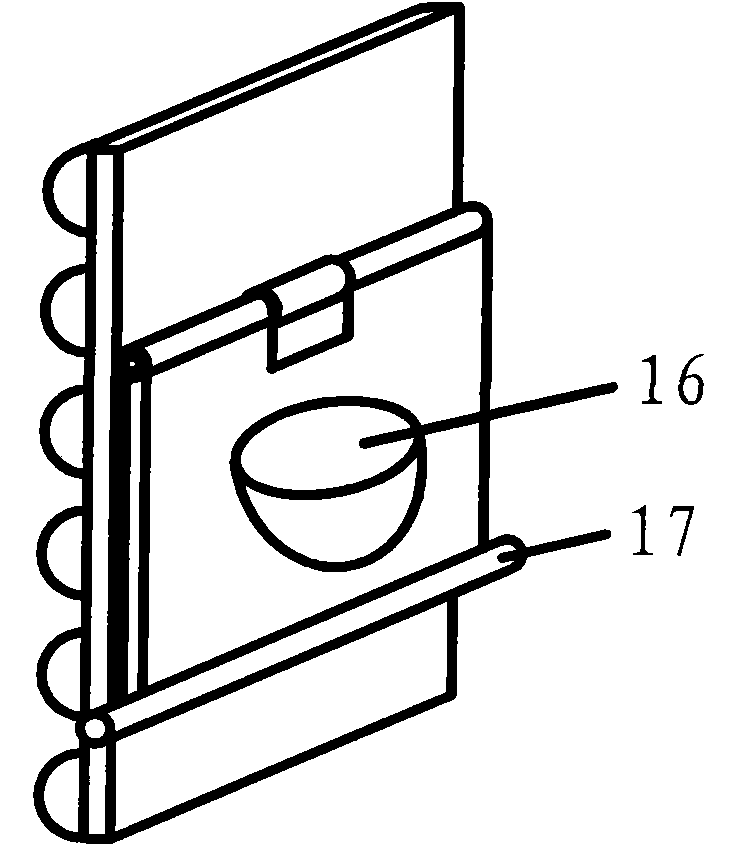

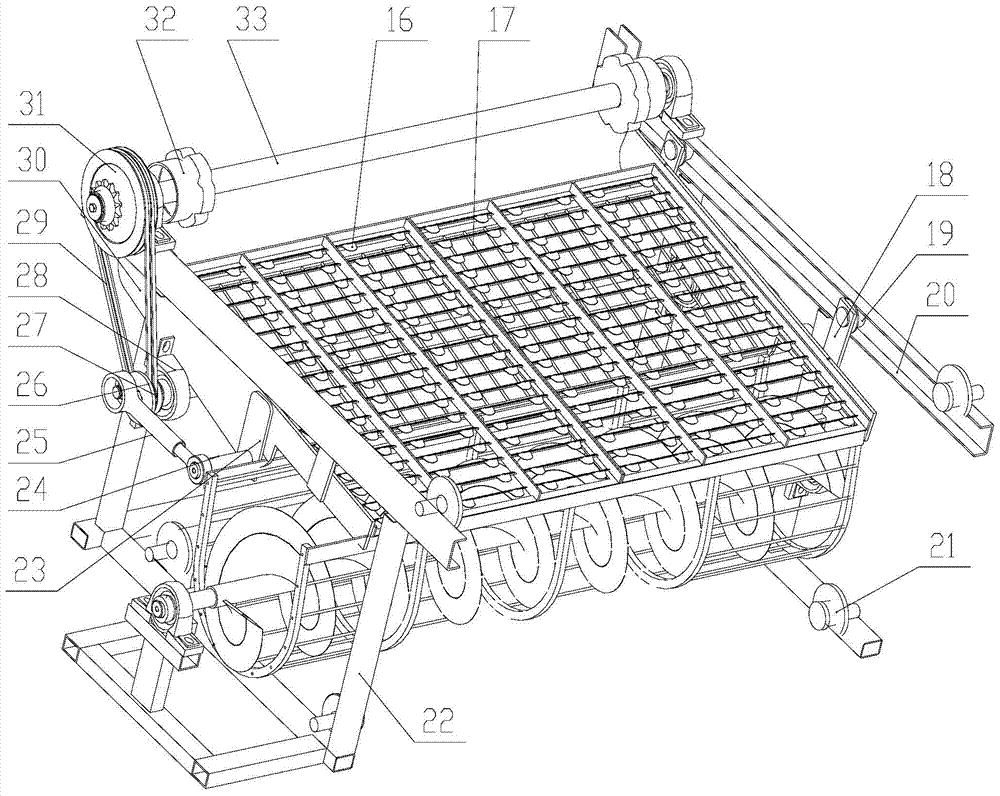

Secondary harvest device for peanut harvester

ActiveCN103609247AReduce the probability of missingIncrease productivityDigger harvestersEngineeringMechanical engineering

Owner:QINGDAO AGRI UNIV

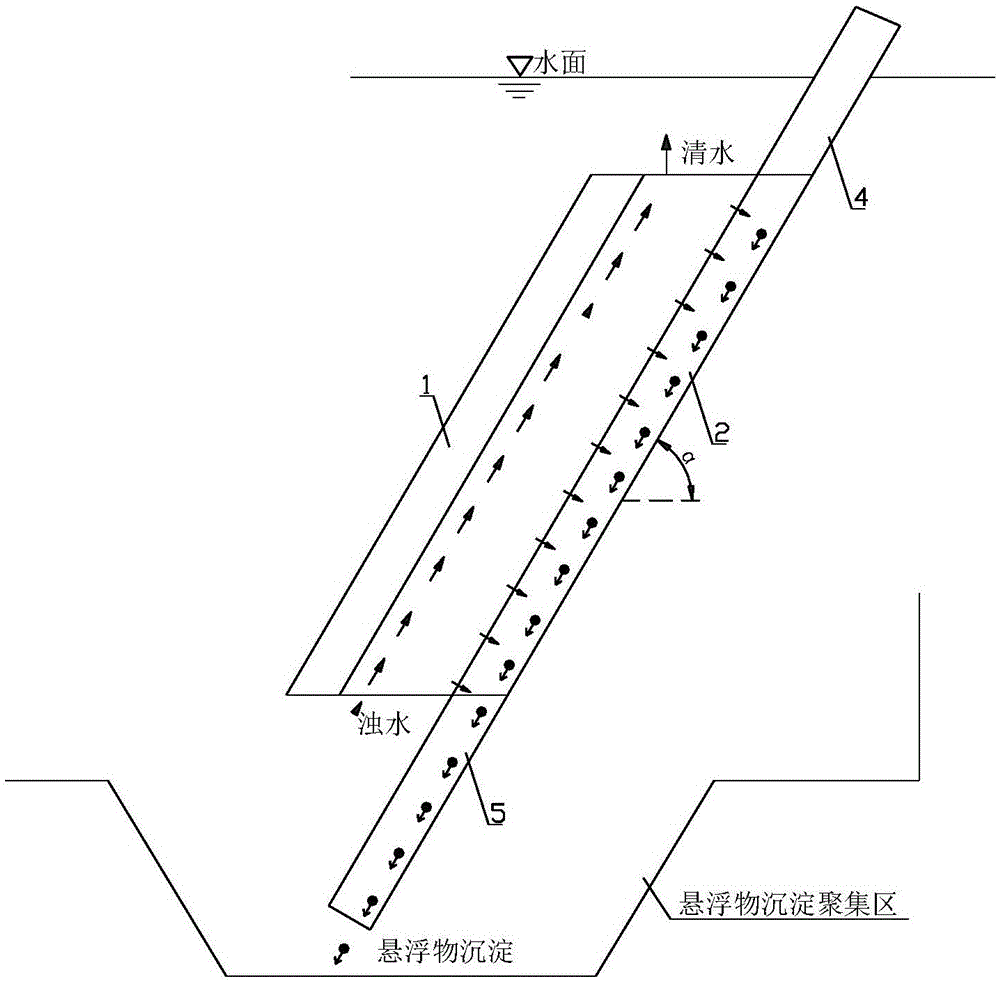

Continuous precipitation separation inclined tube

The invention discloses a continuous precipitation separation inclined tube. The continuous precipitation separation inclined tube comprises a precipitation tube and a mud sliding tube, wherein the mud sliding tube is parallelly and fixedly arranged under the precipitation tube side by side; an included angle between the precipitation tube and the horizontal plane is alpha; a mud sliding passage which is communicated with the precipitation tube and the mud sliding tube is arranged on the side wall, which is in fit with the mud sliding tube, of the precipitation tube; a cleaning tube and a mud discharging tube which are communicated with the mud sliding tube are respectively arranged at the top part and the bottom part of the mud sliding tube. The continuous precipitation separation inclined tube disclosed by the invention has the advantages that the structure is simple, the manufacturing is convenient, and the production cost is low; the mud sliding passage is used for separating the precipitation tube and the mud sliding tube, so that the influence of water flow on mud sliding can be reduced, separated flowing of water flow and precipitated / suspended matters is realized, and the precipitation effect is increased; since the cleaning tube is arranged at the top part of the mud sliding tube, on one hand, precipitated / suspended matters are enabled to be totally and downwards discharged through the mud discharging tube along the mud sliding tube, and on the other hand, water can be supplied to clean the mud sliding tube by utilizing a high-pressure water tube when the mud sliding tube is silted up; since the mud discharging tube is arranged at the bottom part of the mud sliding tube, discharged precipitated / suspended matters are enabled to fall into a suspended matter precipitation and accumulation area, and the precipitation efficiency is increased.

Owner:戴东宸

Sowing method of zostera marina seeds

InactiveCN103548443AGuaranteed survival rateWeight increaseSeed and root treatmentCultivating equipmentsObserved SurvivalZostera marina

The invention provides a sowing method of zostera marina seeds. The sowing method comprises the following steps: firstly, mixing the zostera marina seeds, stones and nitrogen fertilizers; then adhering the materials by glutinous rice flour; drying the mixture; and then sowing the mixture in a sea area. According to the method, the zostera marina seeds are placed in a slow-release system, so that certain weight is added to the zostera marina seeds which then can fall into a sowing area. In addition, components in the slow-release system can be provided for germination and growth of the zostera marina seeds, thus guaranteeing the survival rate of zostera marina.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

Mortar applying device and mortar applying method thereof

PendingCN109797975AGuaranteed to fall intoBuilding material handlingMechanical equipmentBiomedical engineering

The invention belongs to the technical field of mechanical equipment and discloses a mortar applying device. The mortar applying device comprises a mortar applying guide arm, a telescoping air cylinder and a mortar applying part and is characterized in that the mortar applying guide air is provided with a guide groove along the length direction, the telescoping air cylinder is arranged in the guide groove, the telescoping air cylinder rod of the telescoping air cylinder is connected with the mortar applying part, and a mortar outlet with openings in two ends is arranged in the mortar applyingpart in a penetrating manner. The mortar applying device can assist the mortar applying step during wall building.

Owner:广州云厦智能设备有限公司

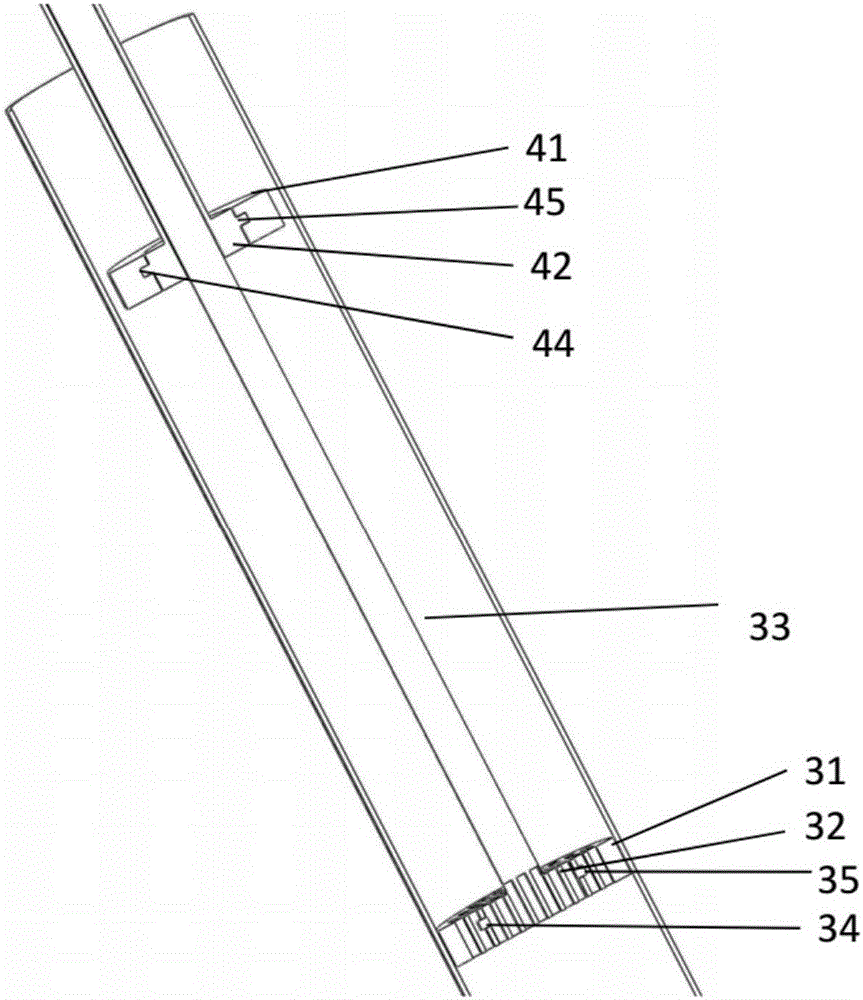

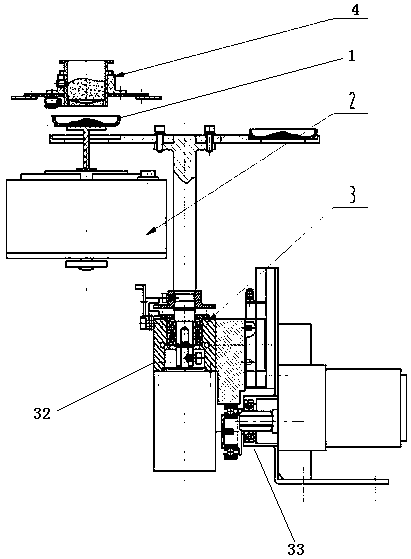

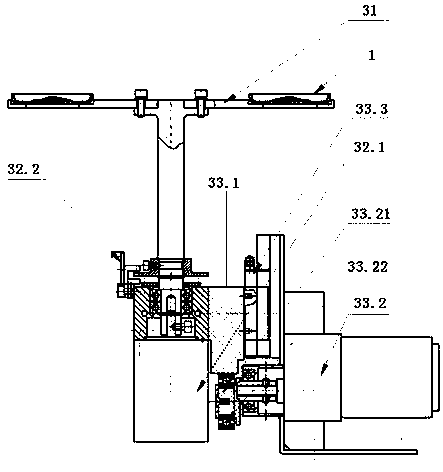

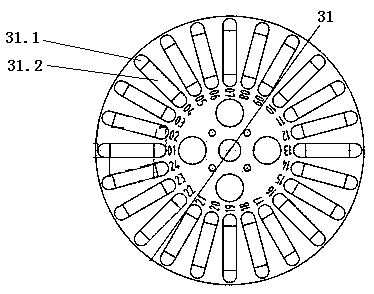

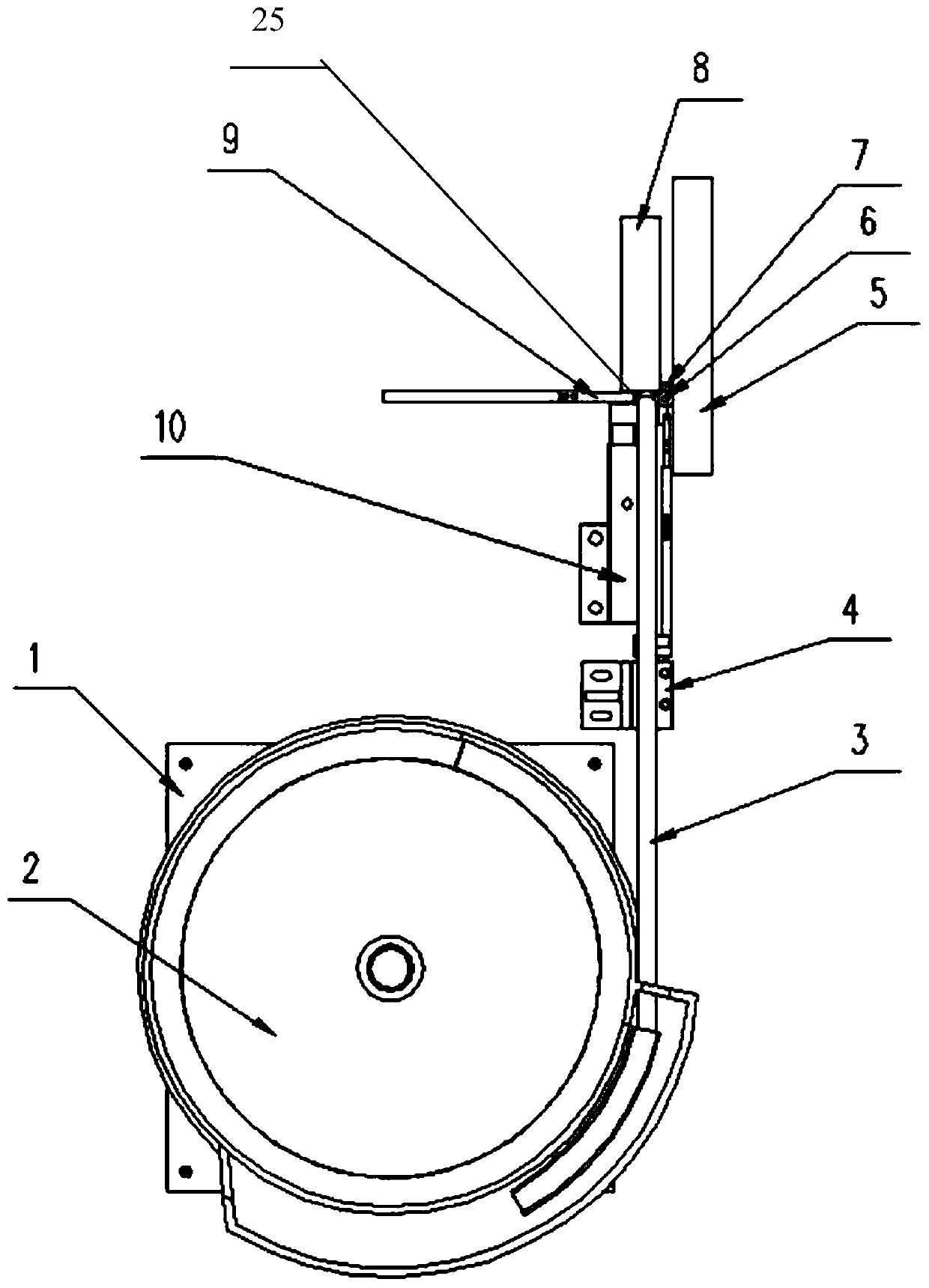

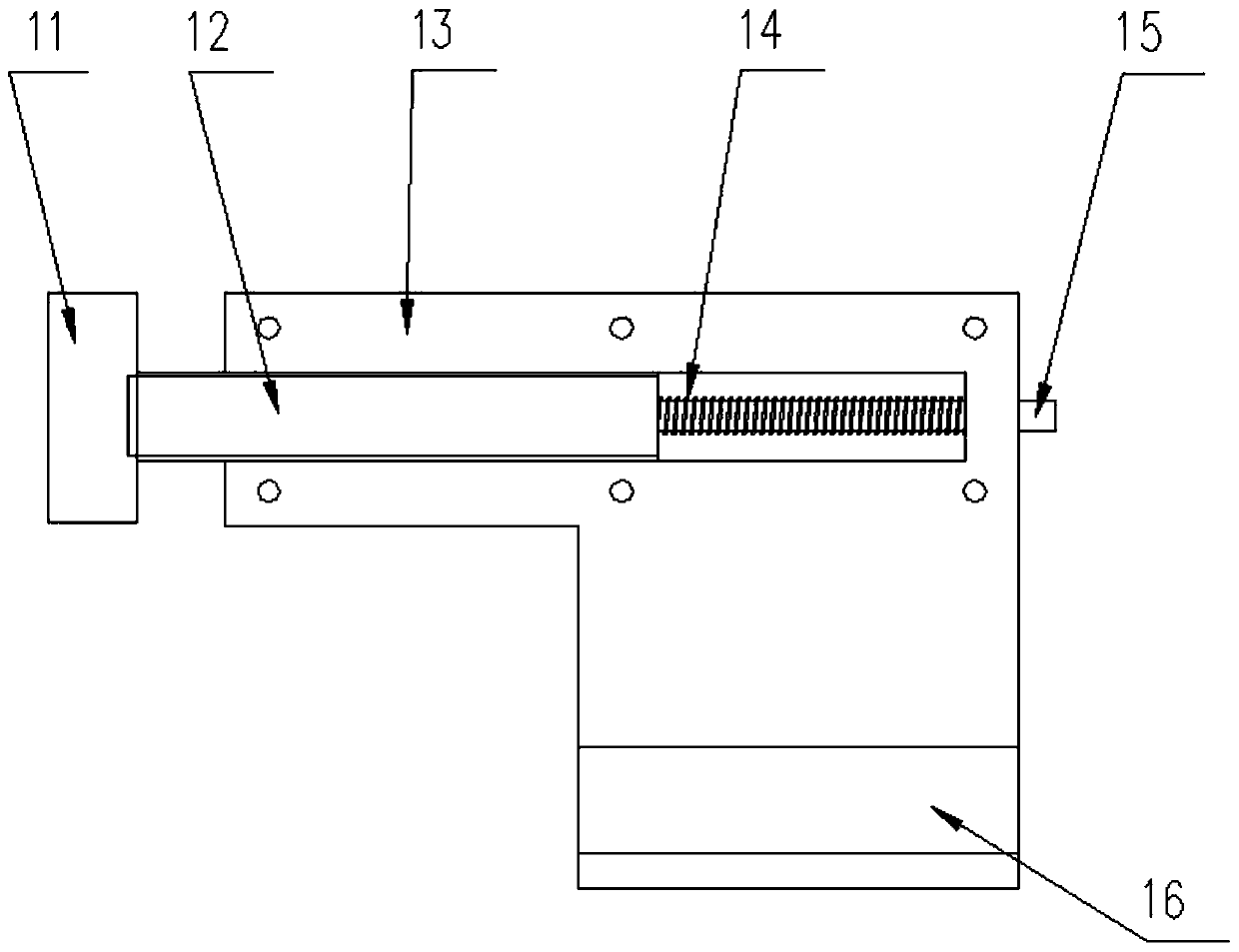

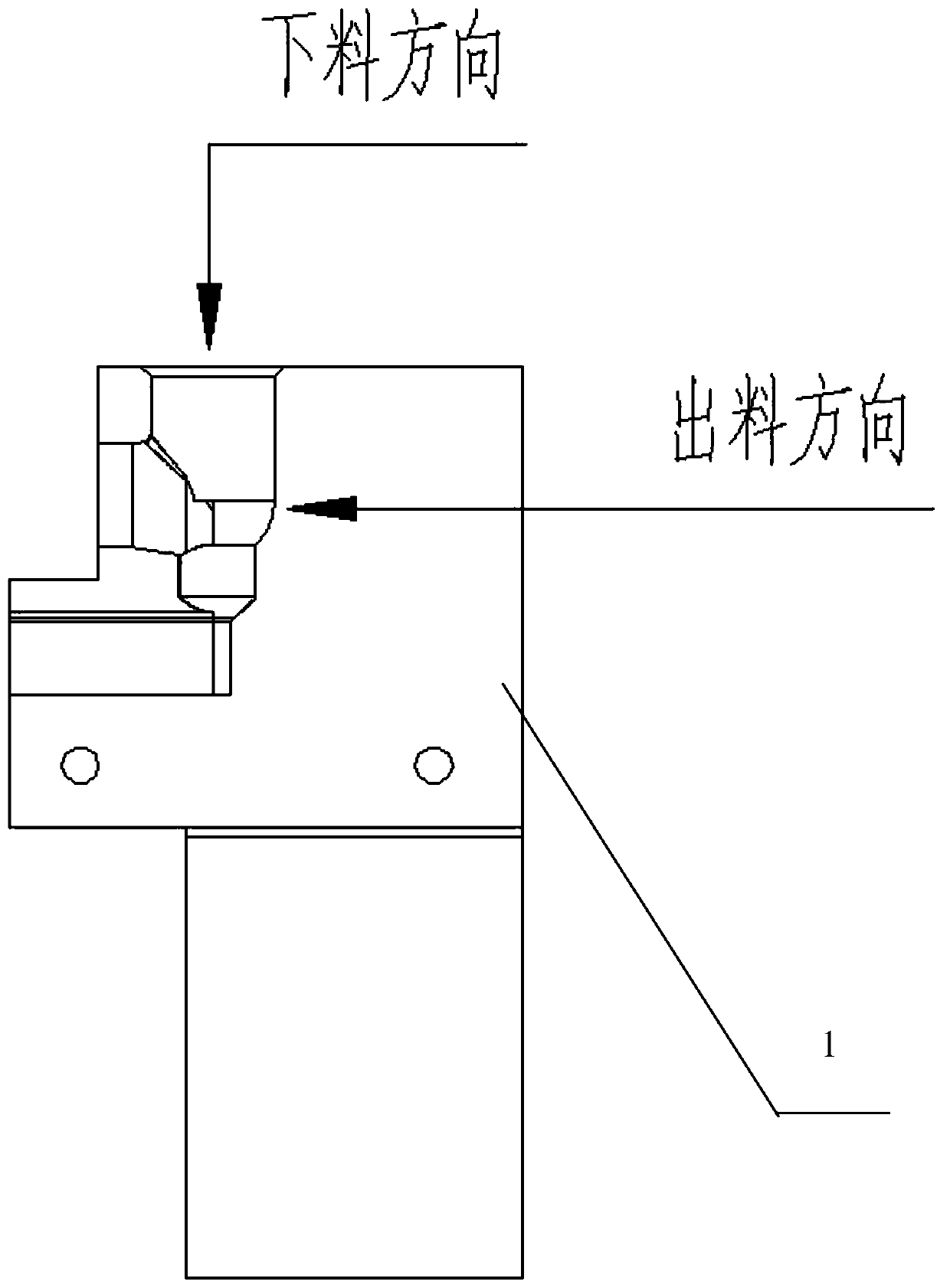

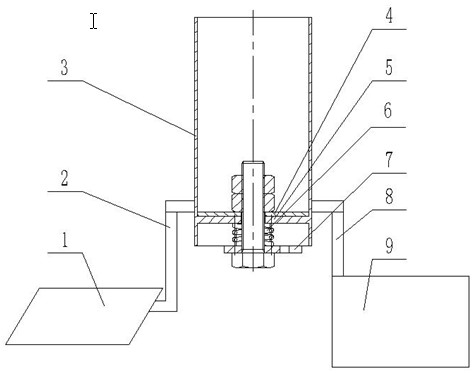

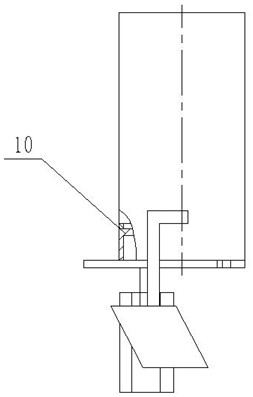

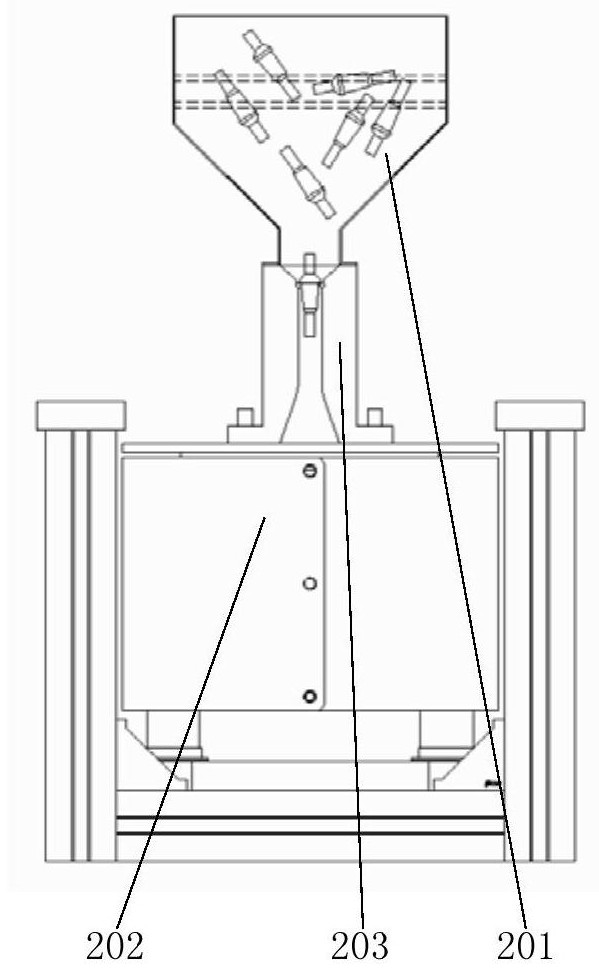

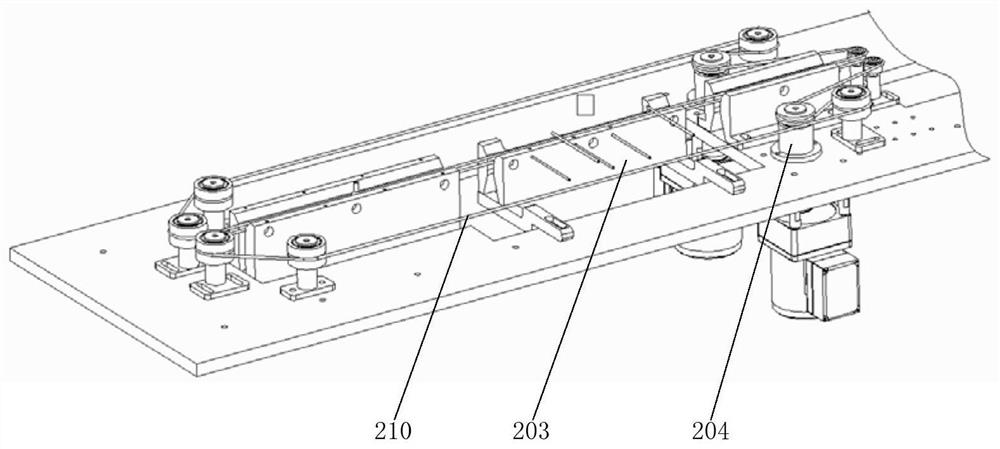

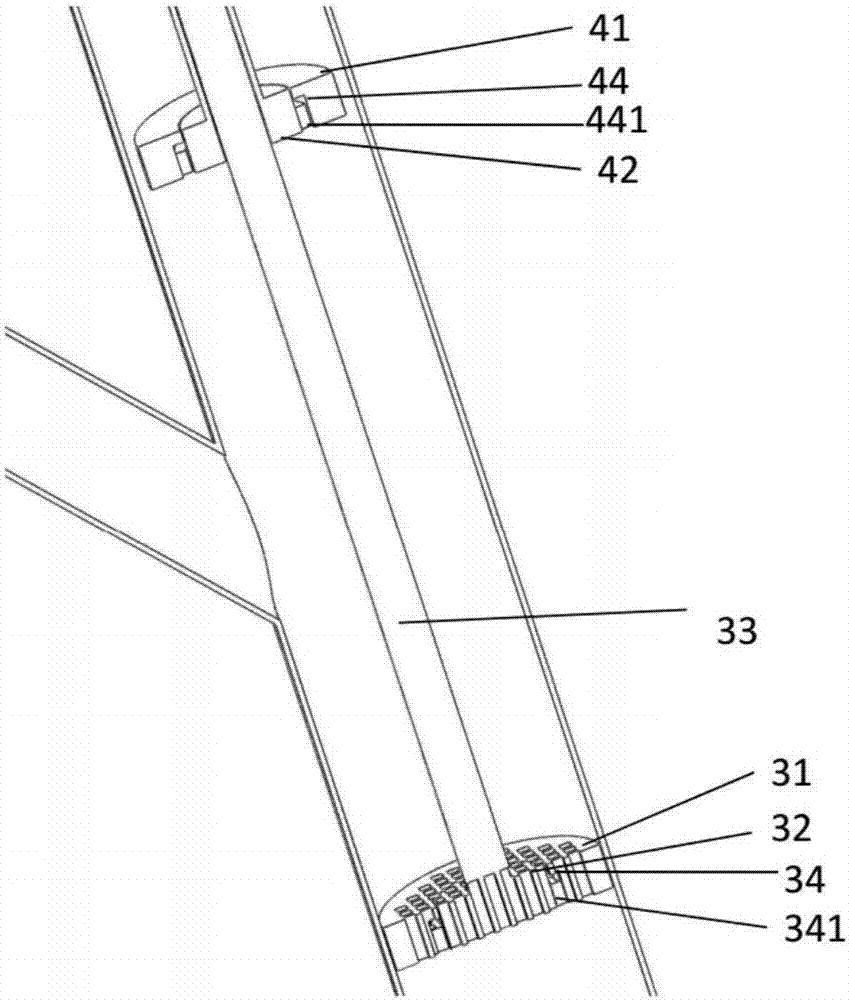

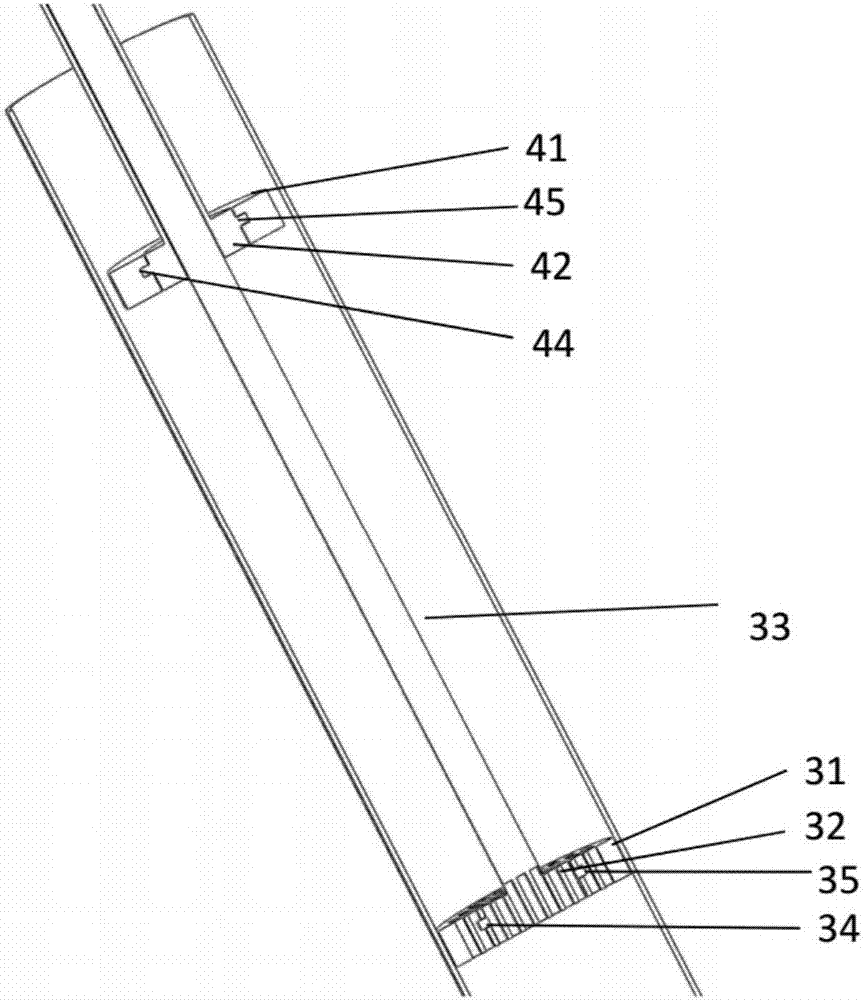

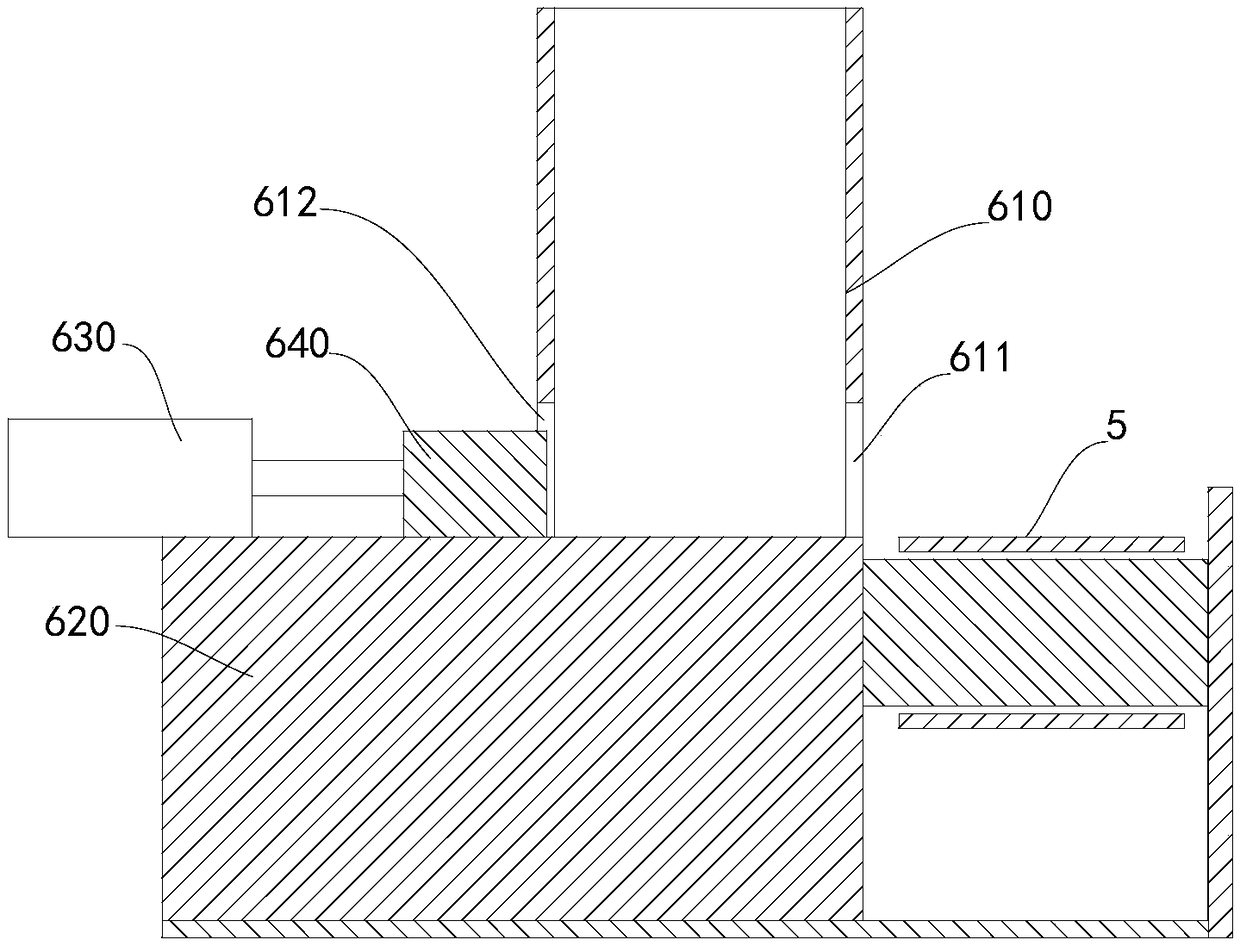

Automatic rubbing ball feeding device

ActiveCN111055186APrecise feeding positionGuaranteed to fall intoSpherical surface grinding machinesGrinding feedersMachine partsEngineering

The invention discloses an automatic rubbing ball feeding device. The automatic rubbing ball feeding device mainly comprises a vibrating disc frame body, a vibrating disc, a bent pipe, a pushing mechanism, a movable rubbing plate, to-be-machined parts of a spherical surface, a supporting plate, a fixed rubbing plate, a machine tool pushing plate and a clamping mechanism, wherein the vibrating discis arranged on the vibrating disc frame body, the discharging opening of the vibrating disc is connected with the bent pipe, the the to-be-machined parts of the spherical surface passe through the bent pipe, and the bottoms of the to-be-machined parts of the spherical surface are arranged in a support groove, namely, the bottom of the to-be-machined parts of the spherical surface are arranged onthe A position in the support groove. The device can achieve automatic feeding, the feeding position is accurate, and the device does not deviate in the feeding movement process. The to-be-machined parts of the spherical surface can be guaranteed to fall into the A position of the support groove, the to-be-machined parts of the spherical surface can be guaranteed to move to the joint of the feeding end of the support plate and the discharging end of the support groove, the position is accurate, and deviation and dumping cannot occur. When one end of a material ejecting rod and one end of an adjusting plate simultaneously push the upper parts and the lower parts of the to-be-machined parts of the spherical surface to move, the to-be-machined parts of the spherical surface can move stably inthe support plate without deviating and dumping.

Owner:DALIAN DEMAISHI PRECISION TECH CO LTD +1

Quantitative topdressing mechanism in corn intertillage period

InactiveCN113228905AAvoid breakingEasy to cause wastePlantingFertiliser distributersSoil scienceAgricultural engineering

The invention discloses a quantitative fertilization mechanism in a corn intertillage period, and aims to solve the problems that manual and mechanical topdressing operation in the intertillage period of corn planting is not easy to perform in a field, the working space is small, crops are easy to damage, fertilizer is wasted, the topdressing effect cannot be achieved and the like. The quantitative fertilization mechanism is characterized in that when the quantitative fertilization mechanism performs field operation, a furrow opener on the front side of the mechanism divides soil to two sides, and after quantitative topdressing operation is completed, a soil covering device on the rear side of a charging barrel covers the surface of the fertilizer with the soil, so that the fertilizer is in full contact with the soil, and the quantitative topdressing effect is achieved; the mechanism does not have working dead angles, so that fertilizer accumulation is avoided; no topdressing is omitted; the furrow opener, the charging barrel and the soil covering device work separately, so that the interference phenomenon does not exist; the arc-shaped design of a rotating plate ensures that the fertilizer in a fertilizer limiting sleeve completely falls into furrows; and bolts enable a fertilizer baffle and the rotating plate to coaxially move, so that the movement track of the fertilizer in the charging barrel is ensured, the smooth operation of quantitative topdressing is ensured, the manual topdressing cost can be reduced, and the topdressing effect in the corn intertillage period can be ensured.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

Hotpot stove

InactiveCN106765325AGuaranteed to fall intoWon't clogDomestic stoves or rangesLighting and heating apparatusEngineeringCombustion

A hotpot stove comprises an upper stove body and a lower stove body. The side wall of the upper stove body is of an arc structure. The upper stove body is internally provided with a hearth which is internally provided with a stove bridge. The lower stove body is of a halfpace structure with the hollow inside and is provided with a first opening. A stove door with adjustable opening degree is arranged at the first opening. The connecting position of the lower stove body and the upper stove body is provided with a plurality of stand columns and a plurality of ash outlets. The stand columns are internally provided with ventilation holes which penetrate through the bottom of the upper stove body. The upper surfaces of the stand columns are each of an oblique structure and are provided with filter nets. The side wall of the hearth is also of an arc structure. A cover plate is arranged above the hearth and provided with a plurality of fire outlets. The upper stove body is provided with an oblique feed pipe which communicates with the hearth. According to the hotpot stove, on the basis that a good hotpot taste is ensured, the combustion efficiency of charcoal can be improved, control over heating duration and degree is facilitated, and the hotpot stove is convenient to use and high in safety.

Owner:桃江县扬洋机电科技有限公司

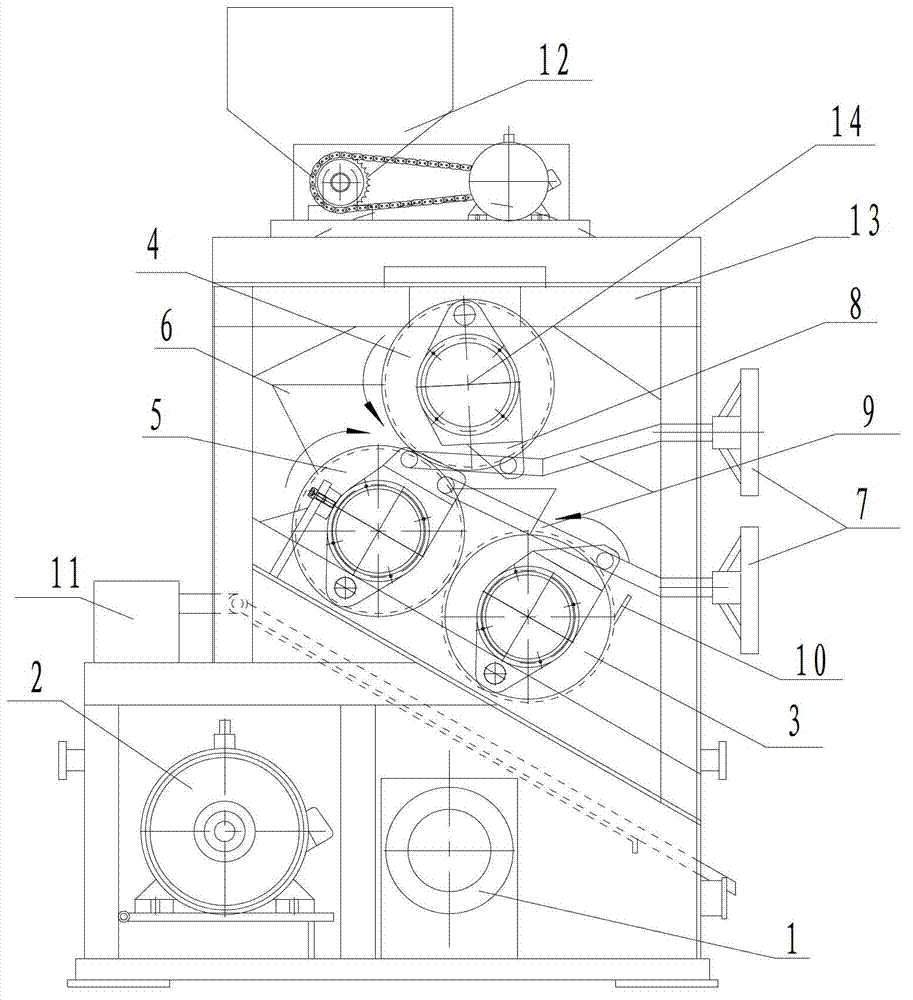

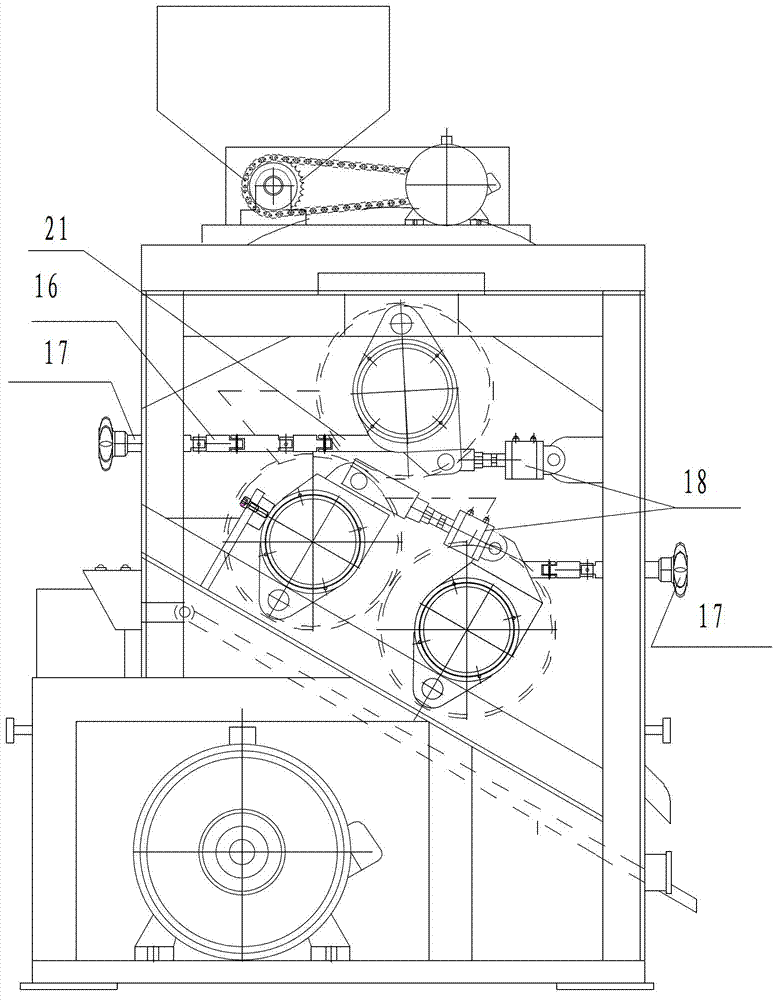

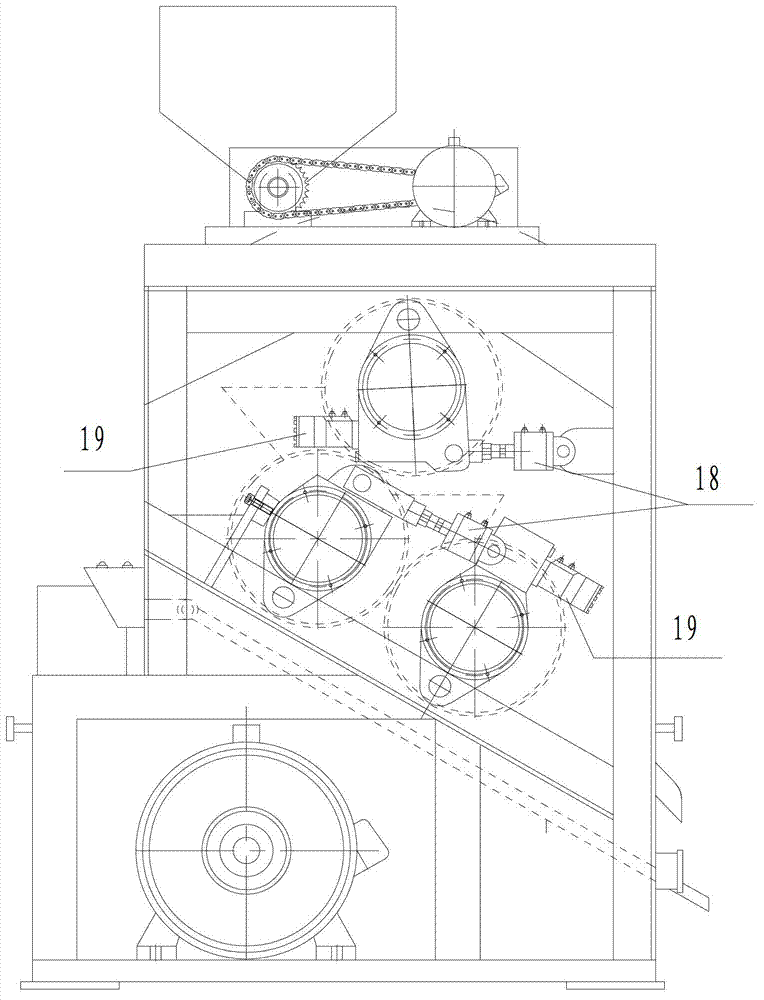

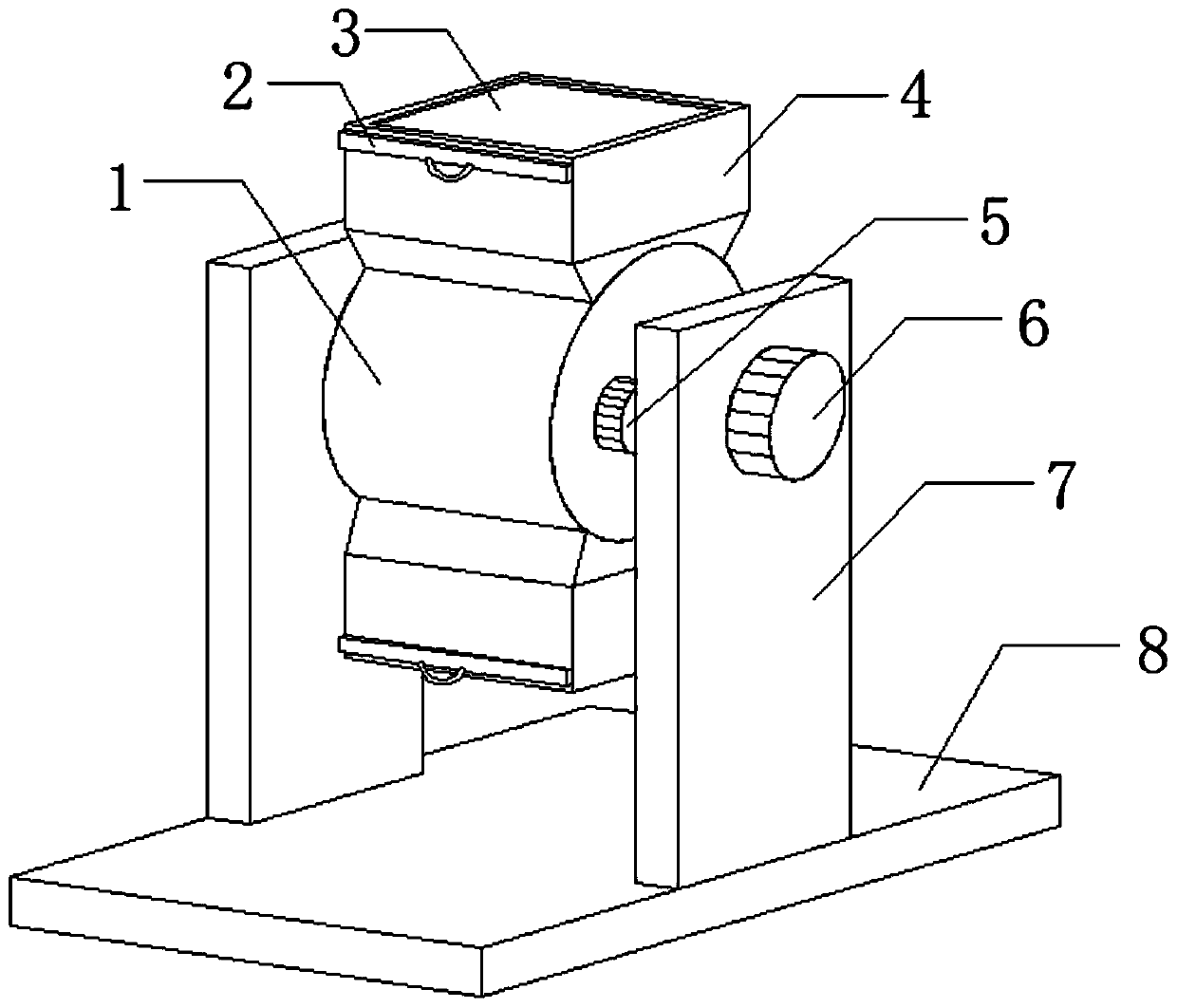

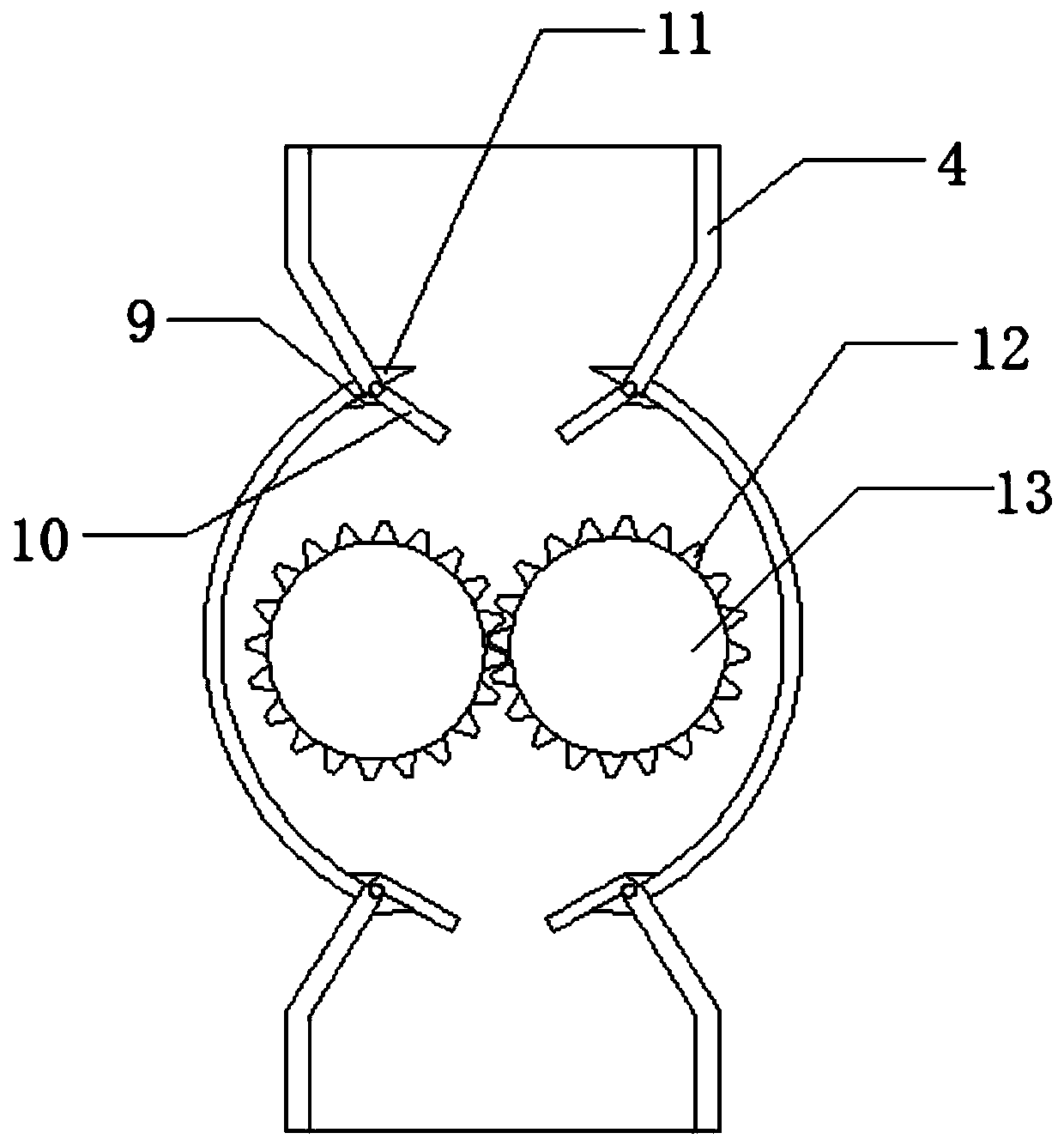

Vertical type material-falling-preventing three-roll grinder and material grinding method

The invention relates to the technical field of material grinding, and particularly relates to a vertical type material-falling-preventing three-roll grinder and a material grinding method. The vertical type material-falling-preventing three-roll grinder comprises a feeding port formed in the upper end of a rack, a bearing base pivoted on the inner wall of the upper end of the rack, a bearing arranged in the bearing base, a slow roll sleeved in the bearing, a middle roll arranged on one side below the slow roll, a rapid roll arranged on the other side below the slow roll as well as baffles which are used for preventing material leakage and are arranged on end surfaces of the middle roll and the rapid roll, wherein the three rolls of a common three-roll grinder are orderly arranged in the same plane, and materials can leak from the space between the slow roll and the middle roll and can not reach the rapid roll. The vertical type material-falling-preventing three-roll grinder and the material grinding method provided by the invention have the advantages that the three rolls are arranged in a three-dimensional manner and are not arranged in the same plane, and the baffles are additionally arranged, so that the materials can drop into a blanking device after being fully ground without causing processing leakage.

Owner:CHANGZHOU ZILI CHEM MACHINERY

Rice huller

ActiveCN114308191AAchieve the purpose of separationSeparation reachedSievingGrain huskingAgricultural engineeringMechanical engineering

The invention belongs to the technical field of rice processing equipment, and provides a rice huller which comprises a machine body with an opening in the upper portion and a plurality of driving parts arranged on the machine body, rubber rollers located below the opening are coaxially fixed to output shafts of the driving parts, and a gap is reserved between every two adjacent rubber rollers; a separation barrel located below the gap is arranged in the machine body, the upper portion of the separation barrel abuts against the rubber roller, a plurality of first separation holes are formed in the side wall of the separation barrel, a power piece is fixed to the machine body, and an output shaft of the power piece is fixedly connected with the separation barrel; a supporting cylinder located outside the power part is arranged on the lower portion of the separation cylinder and is in running fit with the separation cylinder, and a plurality of second separation holes communicating with the supporting cylinder are formed in the bottom of the separation cylinder. The rice processing device is simple in structure, rice is processed and produced, rice hulls in the rice processing process are removed, and the rice processing efficiency is improved.

Owner:重庆灏真现代农业有限公司

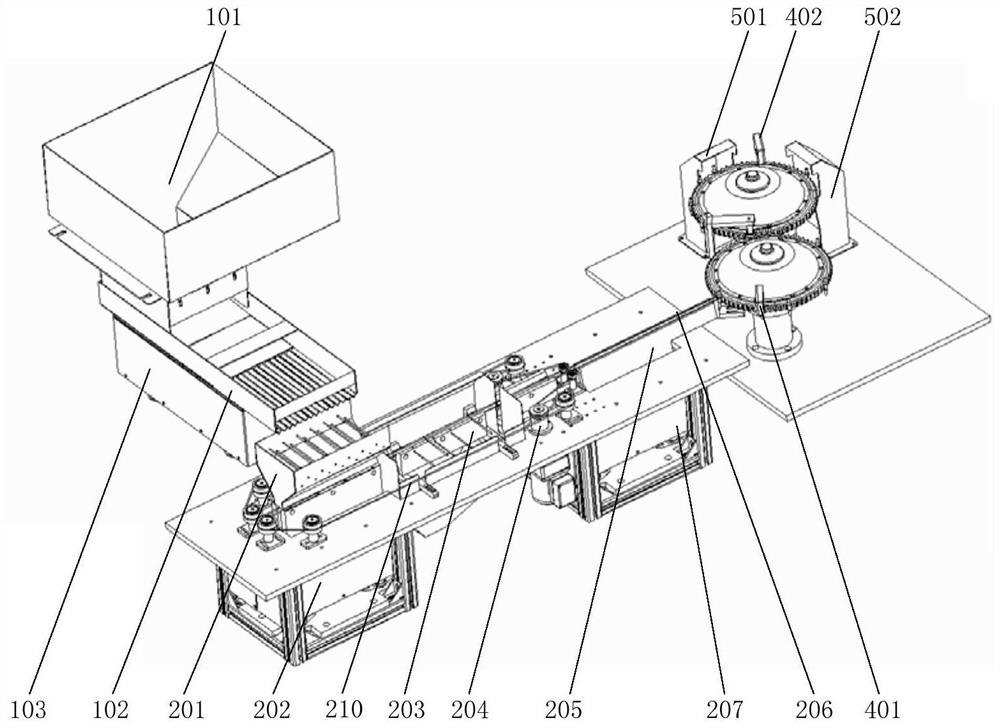

Full-automatic injection tube detection machine

PendingCN112198163AImprove detection accuracyThe detection process is fastOptically investigating flaws/contaminationImaging processingMachine vision

The invention provides a full-automatic injection tube detection machine. The full-automatic injection tube detection machine comprises a feeding device, a conveying device, an air suction turntable device, a detection device and a sorting device; the feeding device comprises a main material box and a feeding linear vibrator; the conveying device comprises a screening box, a screening linear vibrator, a guide rail, a circular belt and a transmission wheel set; the air suction turntable device comprises a first vacuum conveying module and a second vacuum conveying module; the circular belt is connected with the first vacuum conveying module, and the first vacuum conveying module is connected with the second vacuum conveying module; the detection device comprises a video detection module which is arranged at the edges of the first vacuum conveying module and the second vacuum conveying module; and the sorting device comprises a waste collecting module and a finished product collecting module. According to the full-automatic injection tube detection machine, the machine vision detection principle and the high-speed image processing technology are adopted, full-automatic and non-blindarea detection is conducted on an injection tube, and waste products are automatically removed; and the detection machine has the advantages of high detection speed and high detection precision.

Owner:无锡传奇科技有限公司

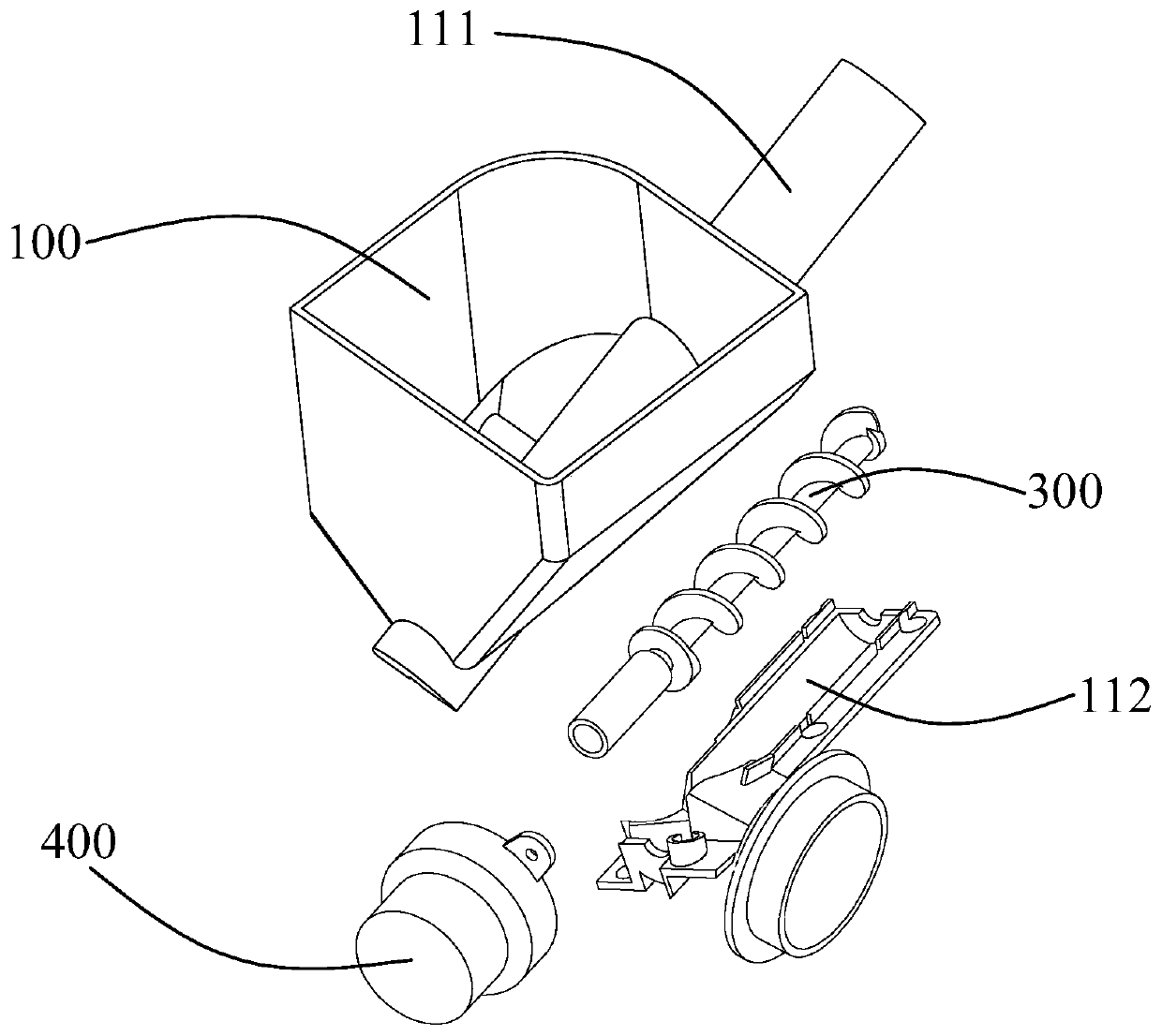

Conveying-reliable cooking utensil

The invention relates to a conveying-reliable cooking utensil. The cooking utensil comprises a stock bin, a conveying cavity and a screw provided with a conveying spiral, wherein the screw is arrangedin the conveying cavity, the stock bin is provided with a feeding port which communicates with the conveying cavity, a discharging port is arranged at the end, away from the feeding port, of the conveying cavity, and the volume, at the discharging port end, of a material channel between the screw and the conveying cavity is greater than the volume, at the feeding port end, of the material channel. By the adoption of the technical scheme, when a material passes through the discharging port end, the material gets rid of the material channel of the screw as fast as possible under the action of self-gravity and is discharged out of the conveying cavity through the discharging port, the situation that the material is carried in by the conveying spiral, continues to be conveyed and gets stuck at the tail end of the conveying screw is prevented, the phenomenon that dust particles adhere to the surface of the material again can be effectively reduced, a "pre-cleaning" effect is achieved, andconvenience is brought to the subsequent material cleaning and treatment process.

Owner:HONGYANG HOME APPLIANCES

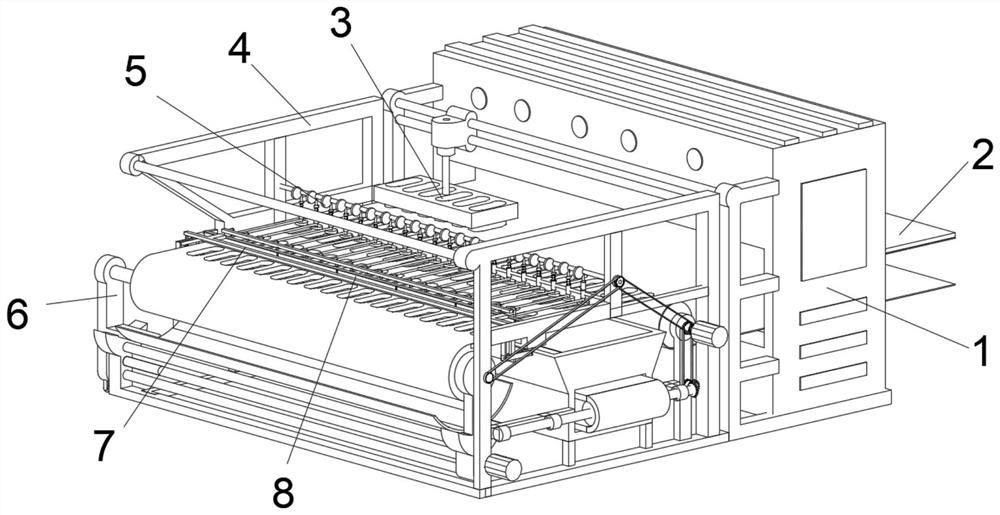

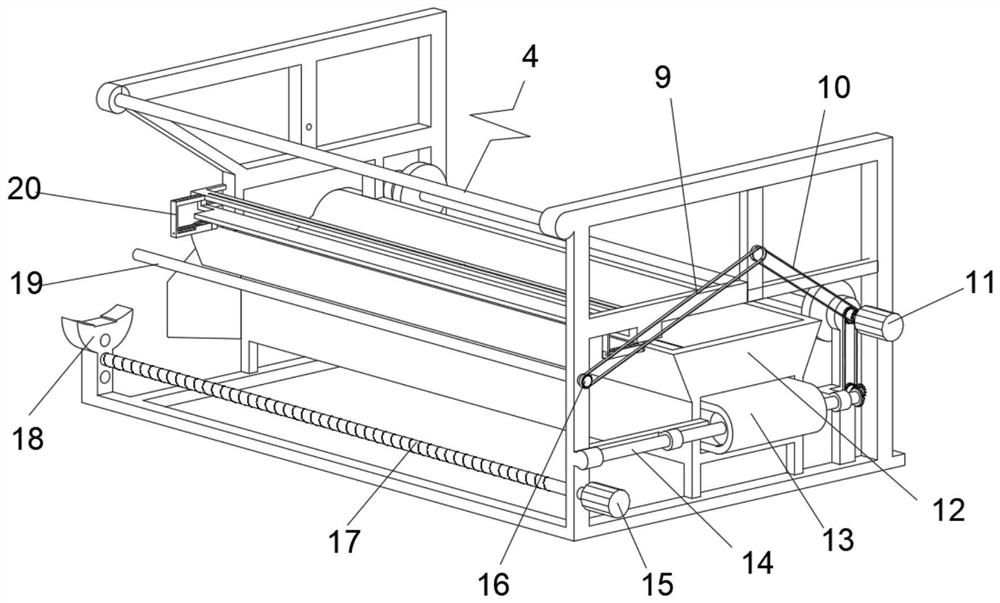

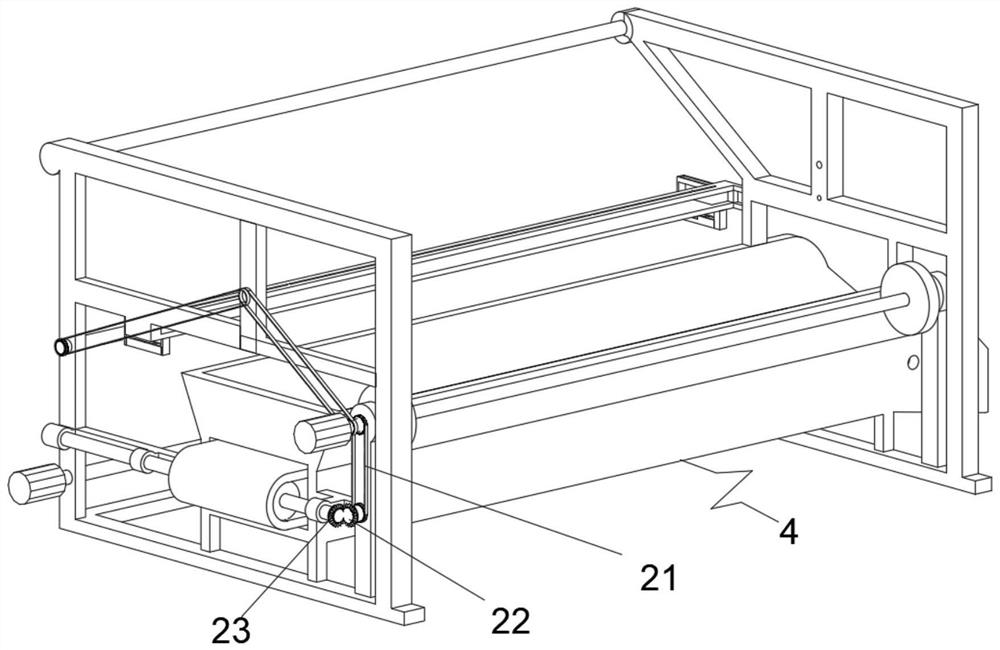

Automatic discharging and excess material winding synchronous device for insole production

ActiveCN113562509AEasy to cutRealize automatic cuttingPile receiversArticle deliveryKnife bladesIndustrial engineering

The invention discloses an automatic discharging and excess material winding synchronous device for insole production. The device comprises insole processing equipment, an insole raw material, an insole cutter, a limiting support frame, a trigger device, an excess material guide frame, an inserting frame and a cutting blade, one end surface of the limiting support frame is fixedly connected to the center of the side surface of the insole processing equipment, the insole raw material is slidably inserted into the center of the side face of the insole processing equipment, the insole cutter is slidably installed on the edge of the upper part of the side face of the insole processing equipment, the trigger device is slidably installed in the center of the interior of the limiting support frame, the inserting frame is slidably installed in the limiting support frame and located on the edge of one side of the trigger device, and the cutting blade is slidably mounted in the limiting support frame and located between the triggering device and the inserting frame. According to the device, through automatic discharging of insoles, the working efficiency of discharging of the insoles can be improved, meanwhile, excess materials can be automatically cut and wound, and the excess materials are prevented from being accumulated on the ground.

Owner:湖南健泰鞋业制造有限公司

Road and bridge anti-collision protection device

ActiveCN108517809ALimit the space to move forward and backwardPlay a protective effectBridge structural detailsRoadway safety arrangementsProtection mechanismEngineering

The invention discloses a road and bridge anti-collision protection device, and relates to the technical field of road and bridge protection. The road and bridge anti-collision protection device comprises protection mechanisms evenly arranged on the left side and the right side of a road. The protection mechanism on the right side comprises an installation box fixedly connected with one lateral side of the road. A negative pressure box is fixedly installed at the inner bottom of the installation box. A communication pipe is arranged at the upper end of the negative pressure box. A supporting plate is slidingly connected with the upper end of the installation box. A supporting column is fixedly connected with the middle of the lower end of the supporting plate. A sealing plate is fixedly connected with the lower end of the supporting column and in horizontal sliding seal fit with the upper end face of the communication pipe. A pressing spring is fixedly installed at the upper portion ofthe left side wall in the installation box. The right end of the pressing spring is fixedly connected with the side face of the supporting column. The right end of a protection transverse plate is fixedly connected with the middle of the side face of the supporting column. The road and bridge anti-collision protection device has the advantages that a vehicle is prevented from continuously movingand random colliding when tires are indented and suspended, the vehicle is prevented from turning through the pressure intensity difference between the upper side and the lower side of the opened negative pressure box, and a protection effect is achieved.

Owner:明光市德辉木业有限公司

A composite bone grafting instrument

The invention discloses a composite bone grafting device which comprises a bone grafting sleeve, a bone grafting funnel, a large porous push plate, a large nonporous push plate, a porous push plate push-pull rod and a nonporous push plate push-pull rod. The composite bone grafting device is characterized in that the bone grafting funnel is arranged on the side surface of the bone grafting sleeve; the large porous push plate and the large nonporous push plate are arranged in the sleeve; the large porous push plate is arranged below the large nonporous push plate; the porous push plate push-pull rod sleeves the outer side of the nonporous push plate push-pull rod; a nonporous push plate and a small porous push plate can be separated out from the large nonporous push plate and the large porous push plate respectively; the porous push plate push-pull rod and the nonporous push plate push-pull rod are provided with corresponding connection structures; after the porous push plate contacts the nonporous push plate, the porous push plate push-pull rod is connected with the nonporous push plate push-pull rod. Screening is further carried out on a broken bone before bone grafting; the uniformity of the broken bone is ensured; compaction on the grafted bone can be ensured through the arranged separable small porous push plate and nonporous push plate; the success rate of the operation is ensured; the bone grafting time can be shortened.

Owner:启载生物科技成都有限公司

Circulating crushing device for curing agent coating production

The invention discloses a circulating crushing device for curing agent coating production. The circulating crushing device comprises a crushing box body and a supporting base. The outer walls of the two ends of the top of the supporting base are fixedly provided with supporting plates which are vertically arranged. The outer walls of the adjacent ends of the two supporting plates are connected with the outer walls of the two ends of the crushing box body through bearings. The outer wall of the top of one end of one supporting plate is fixedly provided with a second stepping motor. According tothe circulating crushing device for curing agent coating production, through the arrangement of a baffle, a first limiting block and a second limiting block, the first limiting block and the second limiting block can effectively ensure that the baffle rotates within the range that the included angle between the baffle and the horizontal plane is from -30 degrees to 30 degrees. The baffle above the device can effectively ensure that materials fall from the position between two rotating rollers, and the crushing sufficiency is improved. The baffle below the device can effectively ensure that the materials fall into a material storage box below, and the sufficiency and smoothness of material guiding is improved.

Owner:湖北汉耐尔新材料科技有限公司

Candle subpackaging mechanism for box-packed birthday cake

InactiveCN109204971APrevent fallingCandle arrangement is simplePackaging automatic controlCandleEngineering

The invention concerns a candle subpackaging mechanism for box-packed birthday cake. The candle subpackaging mechanism for box-packed birthday cake comprises a candle subpackaging mechanism and a controller. The candle subpackaging mechanism comprises a candle subpackaging machine, a counting sensor and a shielding assembly. A candle storing cavity is arranged on the candle subpackaging machine. Acandle outlet is obliquely arranged at the candle subpackaging machine. The entrance of the candle outlet communicates with the candle storing cavity. The counting sensor is used for counting the number of the candles flowing from the exit of the candle outlet. The candle outlet is opened and closed through the shielding assembly. The counting sensor and the shielding assembly are respectively inelectric connection with the controller. The invention has the advantages that the box distributing process can be evenly achieved by machines, the problems that the work efficiency is low and the labour intensity is great during manual operation, and the large-scale and automatic production are not good for being realized are solved.

Owner:WUHAN BAIQI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com