Vertical type material-falling-preventing three-roll grinder and material grinding method

A three-roll mill, vertical technology, applied in grain processing, etc., can solve problems such as material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

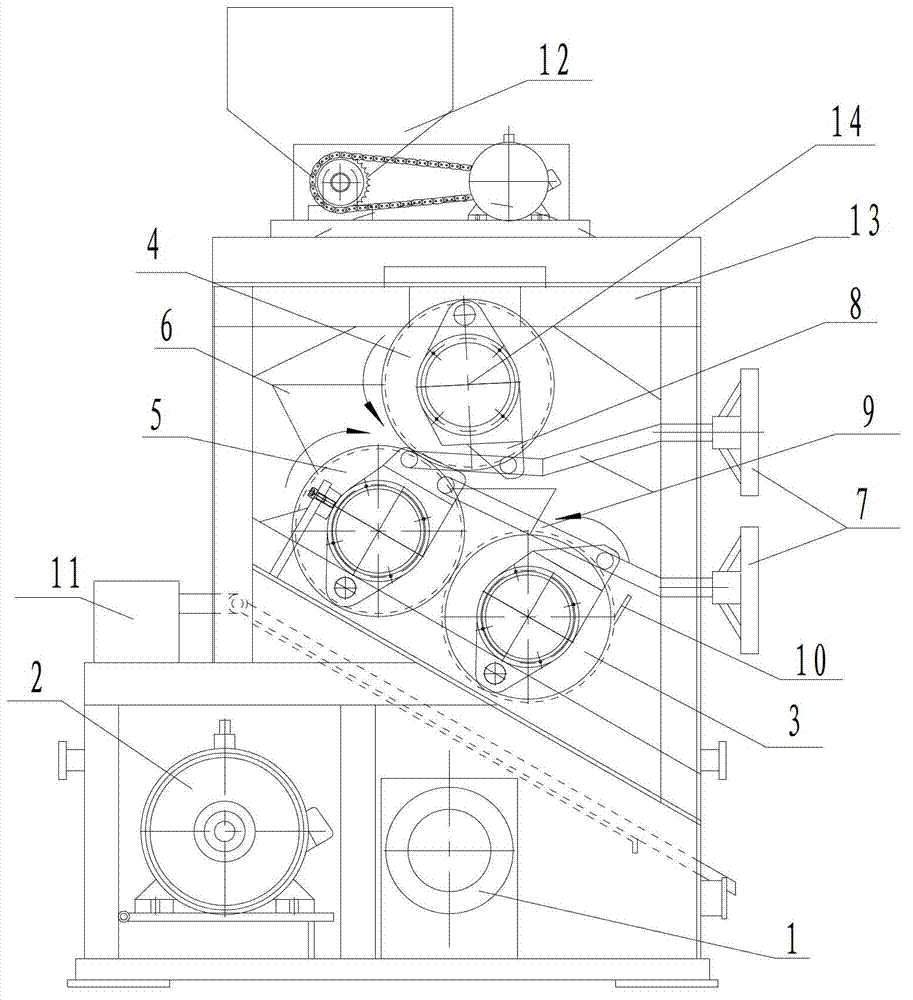

[0032] Embodiment 1, combining figure 1 , Figure 5 , Figure 6 , Figure 7 The manual type vertical three-roll mill will be described in detail.

[0033] The vertical anti-dropping three-roll grinding machine of the present invention comprises a frame 13, a feed port 12 arranged on the upper end of the frame 13, a bearing seat 8 pivotally arranged on the inner wall of the upper end of the frame 13, arranged on the upper end of the frame 13, and The bearing 14 in the bearing block 8 also includes the slow roller 4 sleeved in the bearing 14, the middle roller 5 that is arranged on the lower side of the slow roller 4 and is connected with the slow roller 4 with a gear, and is set On the other side below the slow roller 4 and the fast roller 3 connected with the middle roller 5 with gears, the cross-sectional circle of the slow roller 4 and the center line of the cross-sectional circle of the middle roller 5 are connected with the center line of the middle roller 5. The angle...

Embodiment 2

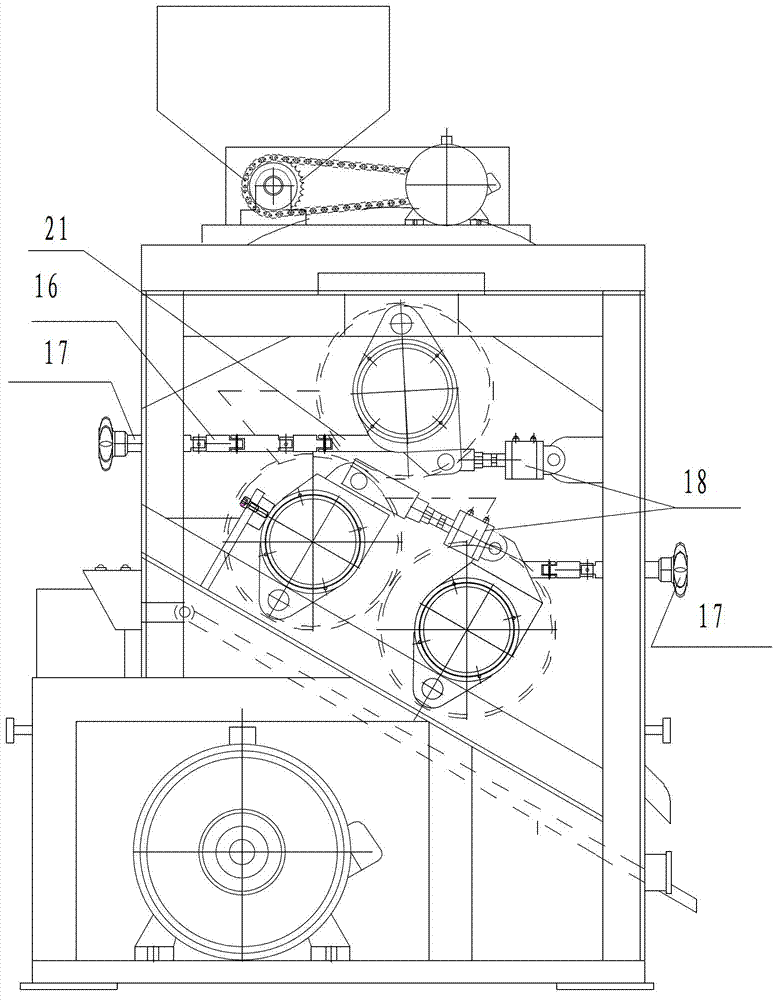

[0045] Example 2, combined with figure 2 , Figure 5 , Figure 6 , Figure 7 Describe in detail the mechanical fine-tuning button-controlled hydraulic vertical three-roll mill.

[0046] The vertical anti-dropping three-roll grinding machine of the present invention comprises a frame 13, a feed port 12 arranged on the upper end of the frame 13, a bearing seat 8 pivotally arranged on the inner wall of the upper end of the frame 13, arranged on the upper end of the frame 13, and The bearing 14 in the bearing block 8 also includes the slow roller 4 sleeved in the bearing 14, the middle roller 5 that is arranged on the lower side of the slow roller 4 and is connected with the slow roller 4 with a gear, and is set On the other side below the slow roller 4 and the fast roller 3 connected with the middle roller 5 with gears, the cross-sectional circle of the slow roller 4 and the center line of the cross-sectional circle of the middle roller 5 are connected with the center line of...

Embodiment 3

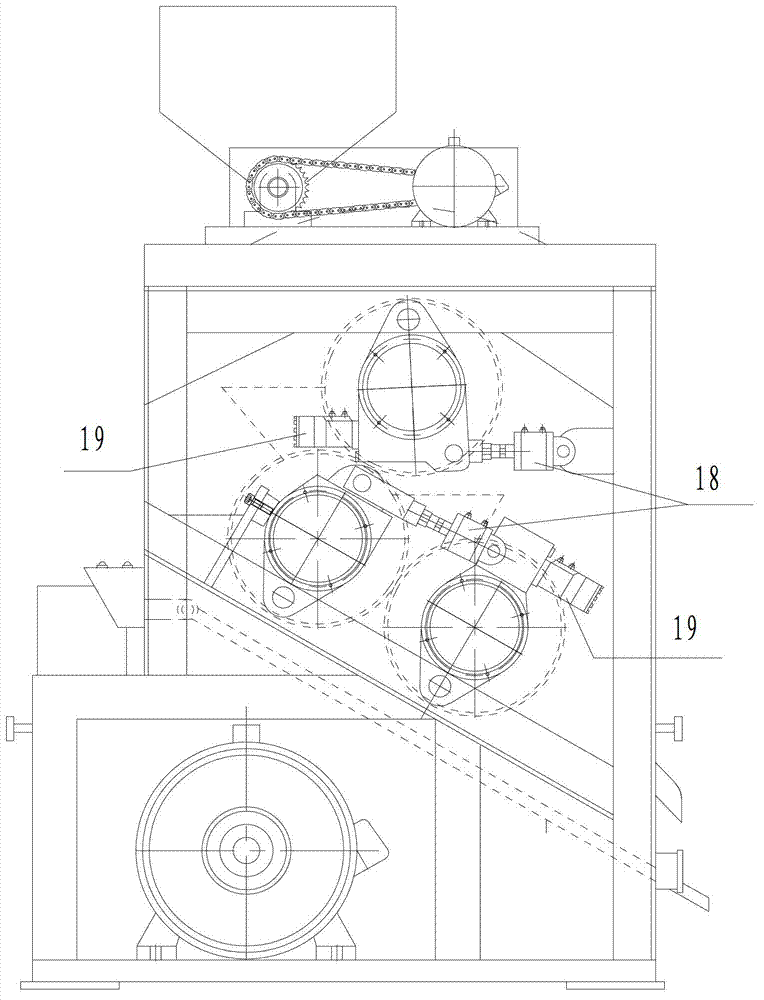

[0061] Example 3, combined with image 3 , Figure 5 , Figure 6 , Figure 7 The hydraulic motor fine-tuning button-controlled hydraulic vertical three-roll grinder is described in detail.

[0062] The vertical anti-dropping three-roll grinding machine of the present invention comprises a frame 13, a feed port 12 arranged on the upper end of the frame 13, a bearing seat 8 pivotally arranged on the inner wall of the upper end of the frame 13, arranged on the upper end of the frame 13, and The bearing 14 in the bearing block 8 also includes the slow roller 4 sleeved in the bearing 14, the middle roller 5 that is arranged on the lower side of the slow roller 4 and is connected with the slow roller 4 with a gear, and is set On the other side below the slow roller 4 and the fast roller 3 connected with the middle roller 5 with gears, the cross-sectional circle of the slow roller 4 and the center line of the cross-sectional circle of the middle roller 5 are connected with the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com