Circulating crushing device for curing agent coating production

A technology of circulating crushing and curing agent, which is applied in the direction of grain processing, etc., can solve problems such as insufficient crushing, and achieve the effect of improving the effect, improving the sufficiency and smoothness, and improving the sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

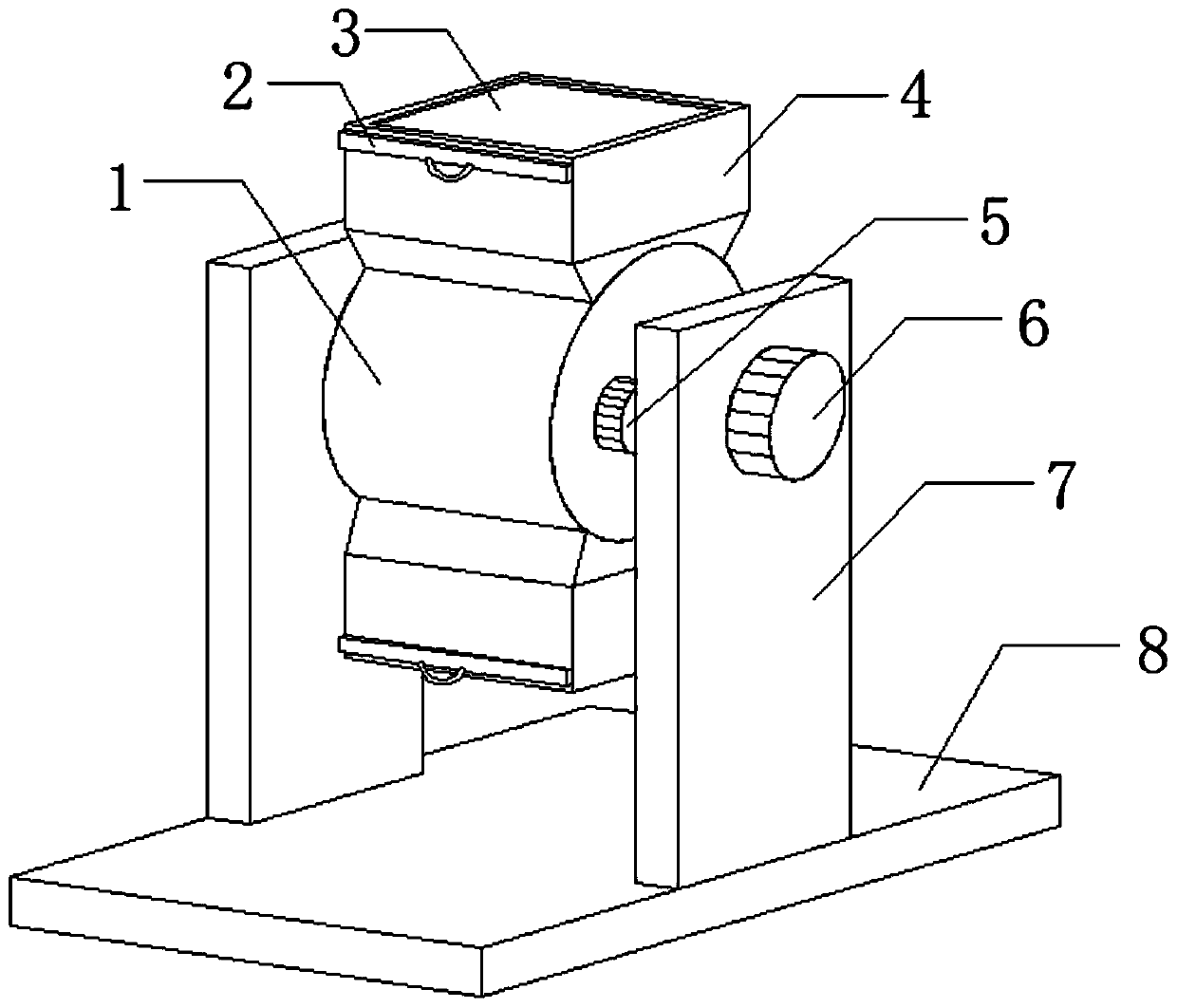

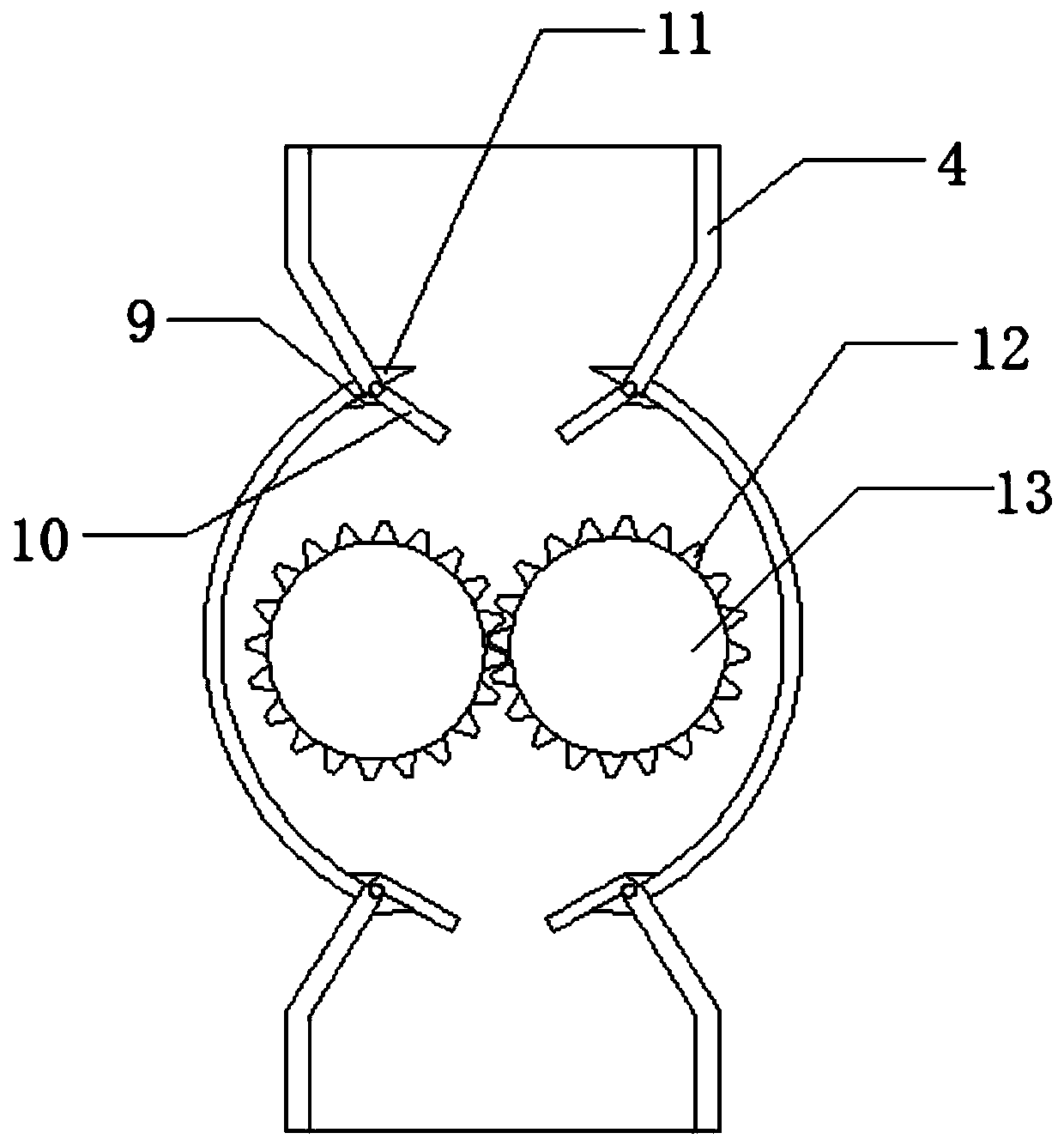

[0023] refer to Figure 1-2 , a kind of circulation crushing device for curing agent paint production, including a crushing box 1 and a support base 8, the outer walls at both ends of the top of the support base 8 are connected with a vertical support plate 7 by bolts, and the two support plates 7 are connected to each other The outer wall adjacent to one end is connected with the outer wall at two ends of the pulverizing box body 1 through a bearing respectively, and the top outer wall at one end of one of the supporting plates 7 is connected with a second stepper motor 6 by bolts, and the output shaft of the second stepper motor 6 is connected with the second stepper motor 6 by bolts. The middle outer wall of one end of the crushing box body 1 is connected, and the outer wall of one side of the crushing box body 1 is connected with a first stepping motor 5 by bolts, and the inner walls of both sides of one end of the crushing box body 1 are connected with rotating rollers 13 ...

Embodiment 2

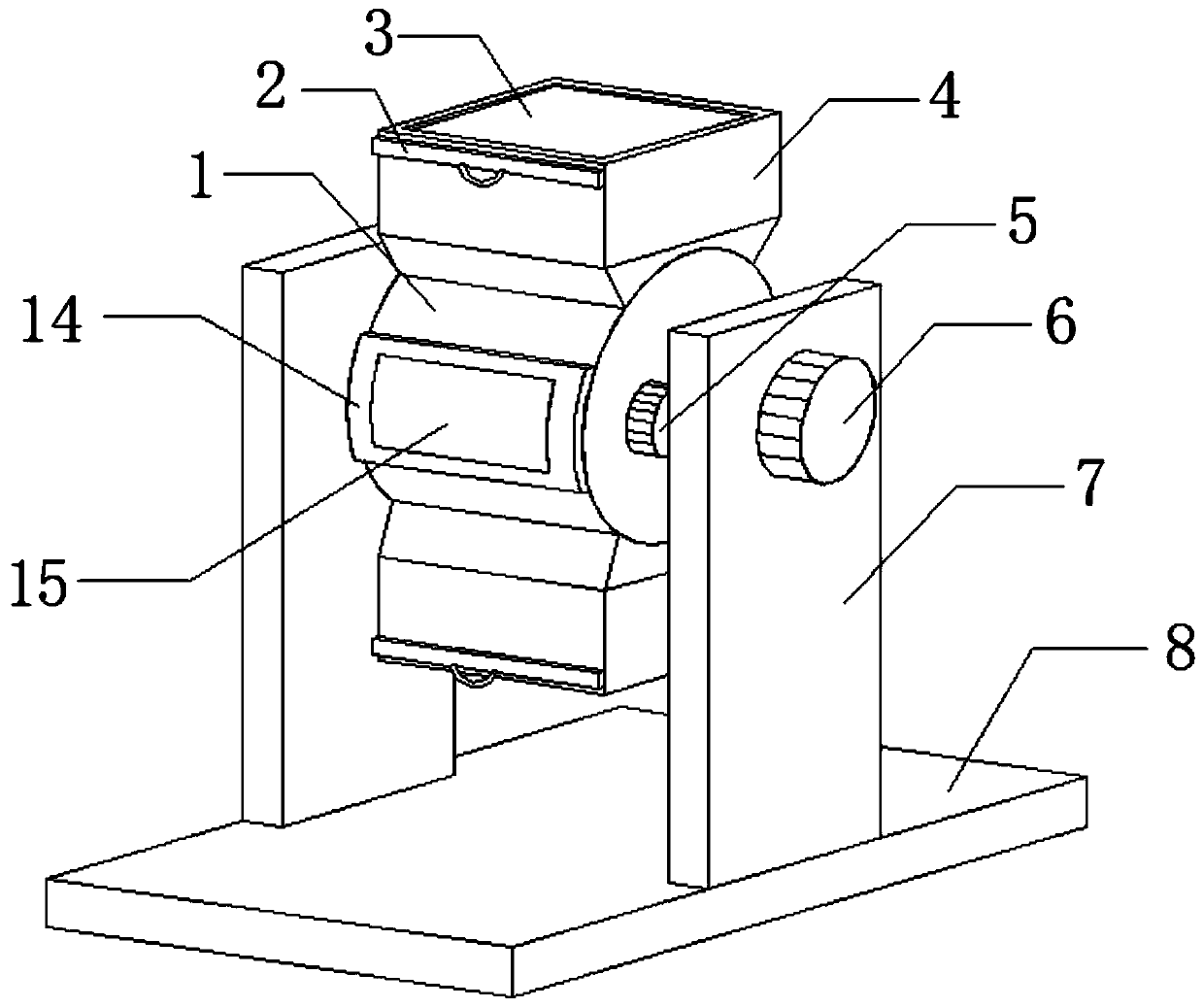

[0026] refer to Figure 2-3 , a kind of circulation pulverizing device for curing agent coating production, also includes the cleaning port that is opened on the outer wall of both sides of the crushing box body 1, and the bottom outer wall of the two cleaning ports is connected with a cleaning cover 14 through a hinge, and the cleaning cover 14 side The outer wall of the middle part is provided with a second opening, and the inner wall of the second opening is connected with a transparent observation window 15 by bolts. After the device is used, the user can clean and overhaul the inside of the device by opening the cleaning cover 14, which improves the efficiency of cleaning and overhauling the device. Convenience, at the same time, the transparent observation window 15 can conveniently observe whether the upper materials have all fallen into the lower material storage box 4, thereby ensuring the adequacy of crushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com