A composite bone grafting instrument

A technology of bone implants and instruments, applied in the direction of bone implants, etc., can solve the problems of uneven application range of implanted crushed bone, difficulty in grasping the speed of bone grafting, etc., and achieve the effect of wide application range and uniform crushed bone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

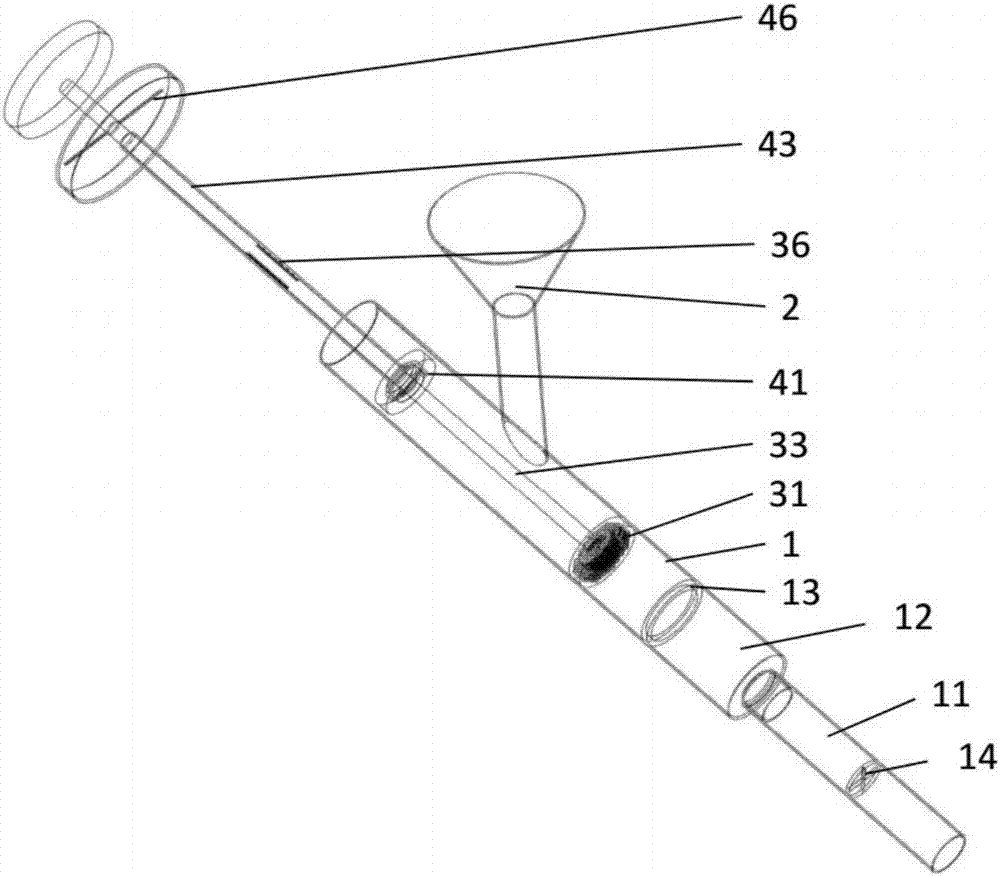

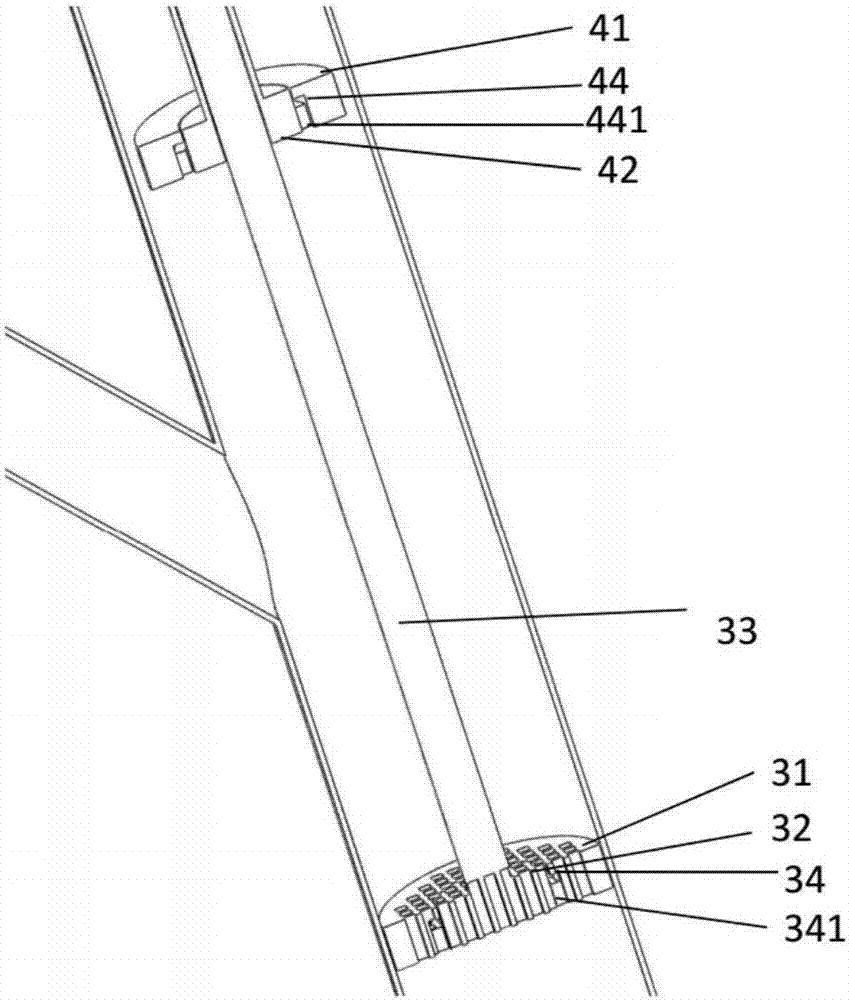

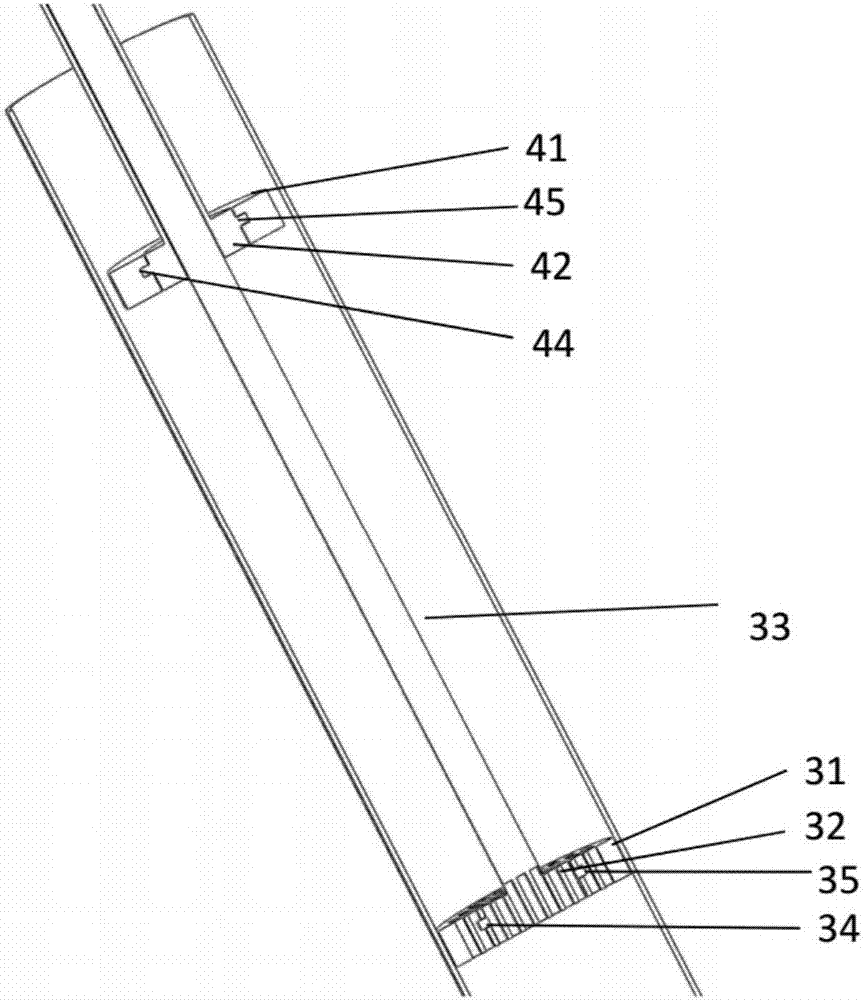

[0027] Example 1 A composite bone grafting instrument

[0028] A composite bone grafting instrument, comprising a bone grafting sleeve 1, a bone grafting funnel 2, a large push plate 31 with holes, a large push plate 41 without holes, a push plate push-pull rod 33 with holes, and a push plate push-pull rod 43 without holes; The bone grafting funnel 2 is set on the side of the bone grafting casing 1; before the bone grafting, the bone grafting funnel 2 is located between the push plate 31 with large holes and the push plate 41 without holes; the push plate with large holes and the push plate 41 without holes Set in the casing 1; the push-pull rod 33 of the push plate with holes is connected with the push plate 31 with large holes, and the push-pull rod 43 of the push plate without holes is connected with the push plate 41 without holes; Below the push plate 41, the push plate push-pull rod 33 with holes is sleeved on the outside of the push plate push-pull rod 43 without holes;...

Embodiment 2

[0031] Example 2 A composite bone grafting instrument

[0032] A composite bone grafting instrument, comprising a bone grafting sleeve 1, a bone grafting funnel 2, a large push plate 31 with holes, a large push plate 41 without holes, a push plate push-pull rod 33 with holes, and a push plate push-pull rod 43 without holes; The bone grafting funnel 2 is set on the side of the bone grafting casing 1; before the bone grafting, the bone grafting funnel 2 is located between the push plate 31 with large holes and the push plate 41 without holes; the push plate with large holes and the push plate 41 without holes Set in the casing 1; the push-pull rod 33 of the push plate with holes is connected with the push plate 31 with large holes, and the push-pull rod 43 of the push plate without holes is connected with the push plate 41 without holes; Below the push plate 41, the push plate push-pull rod 33 with holes is sleeved on the outside of the push plate push-pull rod 43 without holes; ...

Embodiment 3

[0036] Example 3 A composite bone grafting instrument

[0037] A composite bone grafting instrument, comprising a bone grafting sleeve 1, a bone grafting funnel 2, a large push plate 31 with holes, a large push plate 41 without holes, a push plate push-pull rod 33 with holes, and a push plate push-pull rod 43 without holes; The bone grafting funnel 2 is set on the side of the bone grafting casing 1; before the bone grafting, the bone grafting funnel 2 is located between the push plate 31 with large holes and the push plate 41 without holes; the push plate with large holes and the push plate 41 without holes Set in the casing 1; the push-pull rod 33 of the push plate with holes is connected with the push plate 31 with large holes, and the push-pull rod 43 of the push plate without holes is connected with the push plate 41 without holes; Below the push plate 41, the push plate push-pull rod 33 with holes is sleeved on the outside of the push plate push-pull rod 43 without holes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com