Patents

Literature

47results about How to "Achieve the purpose of flipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

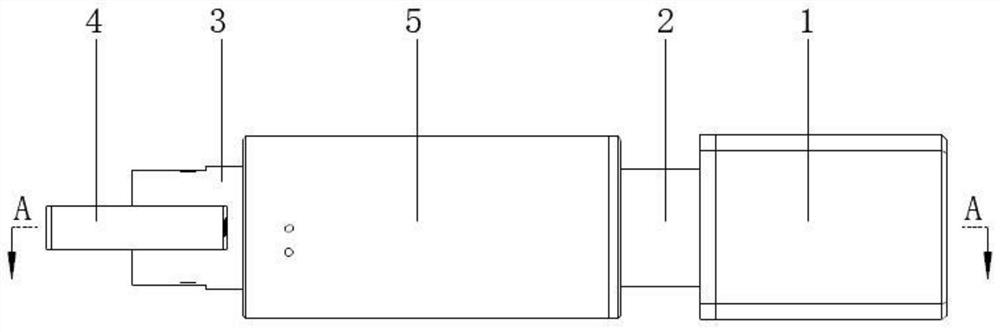

Fully-automatic magnetic ring chamfering-grinding equipment capable of carrying out dust removal on magnetic ring

ActiveCN109304650AAchieve finishingImprove consistencyEdge grinding machinesGrinding carriagesEngineeringFully automatic

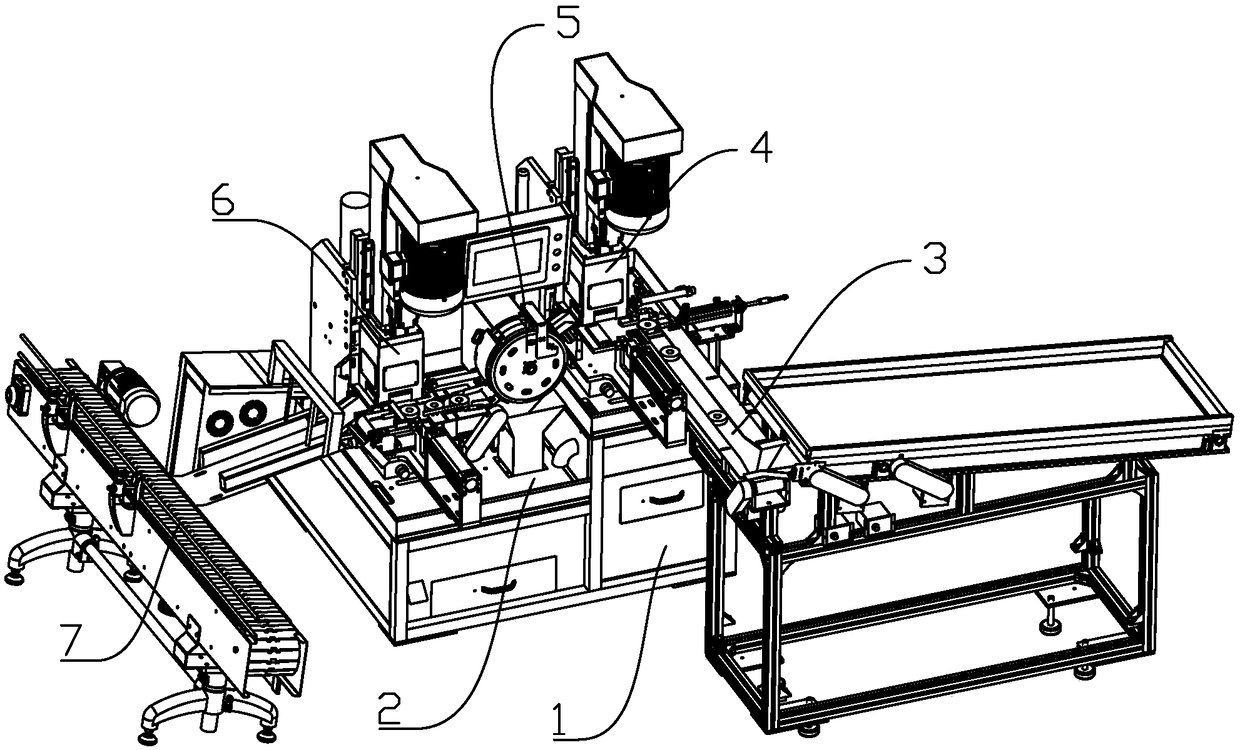

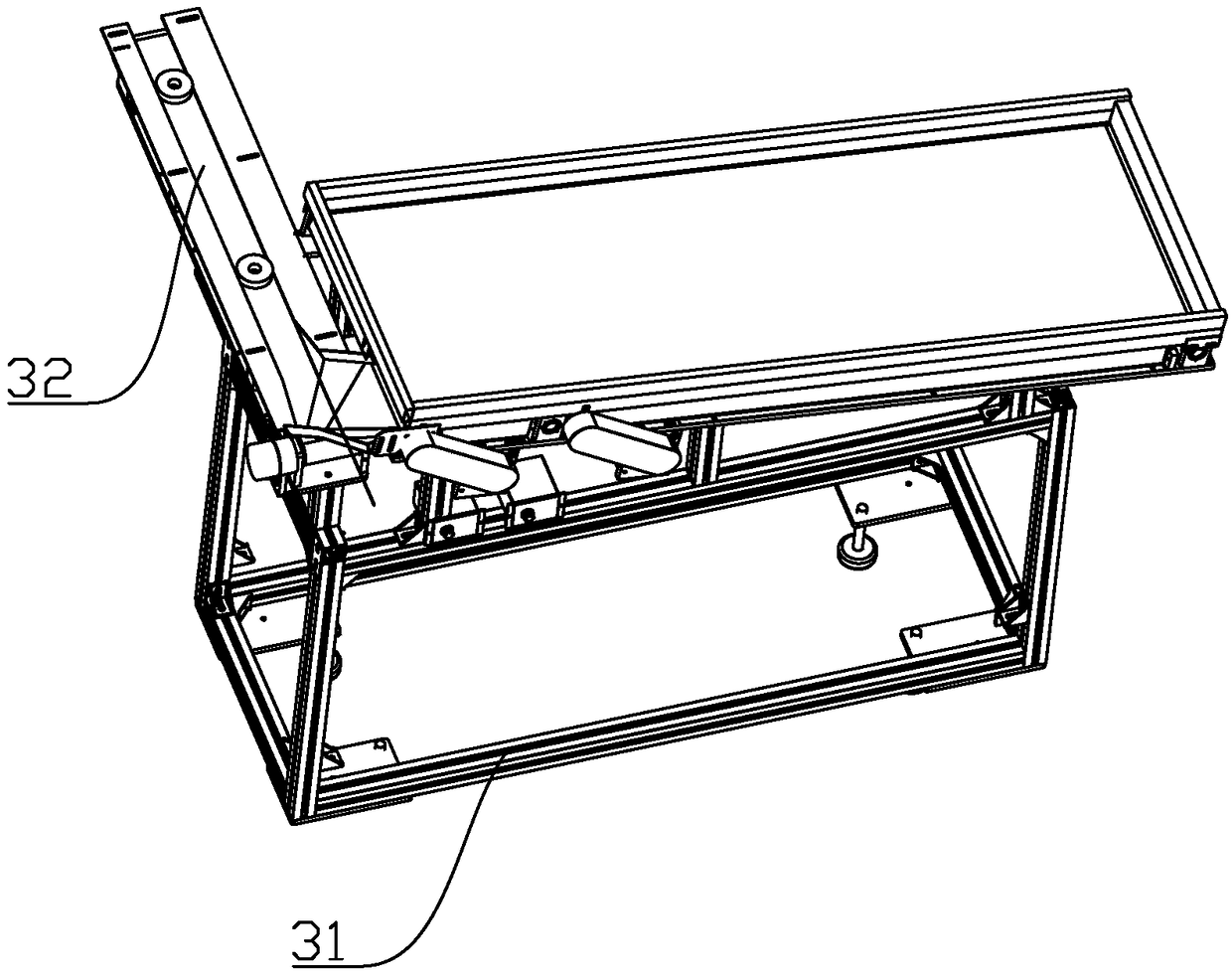

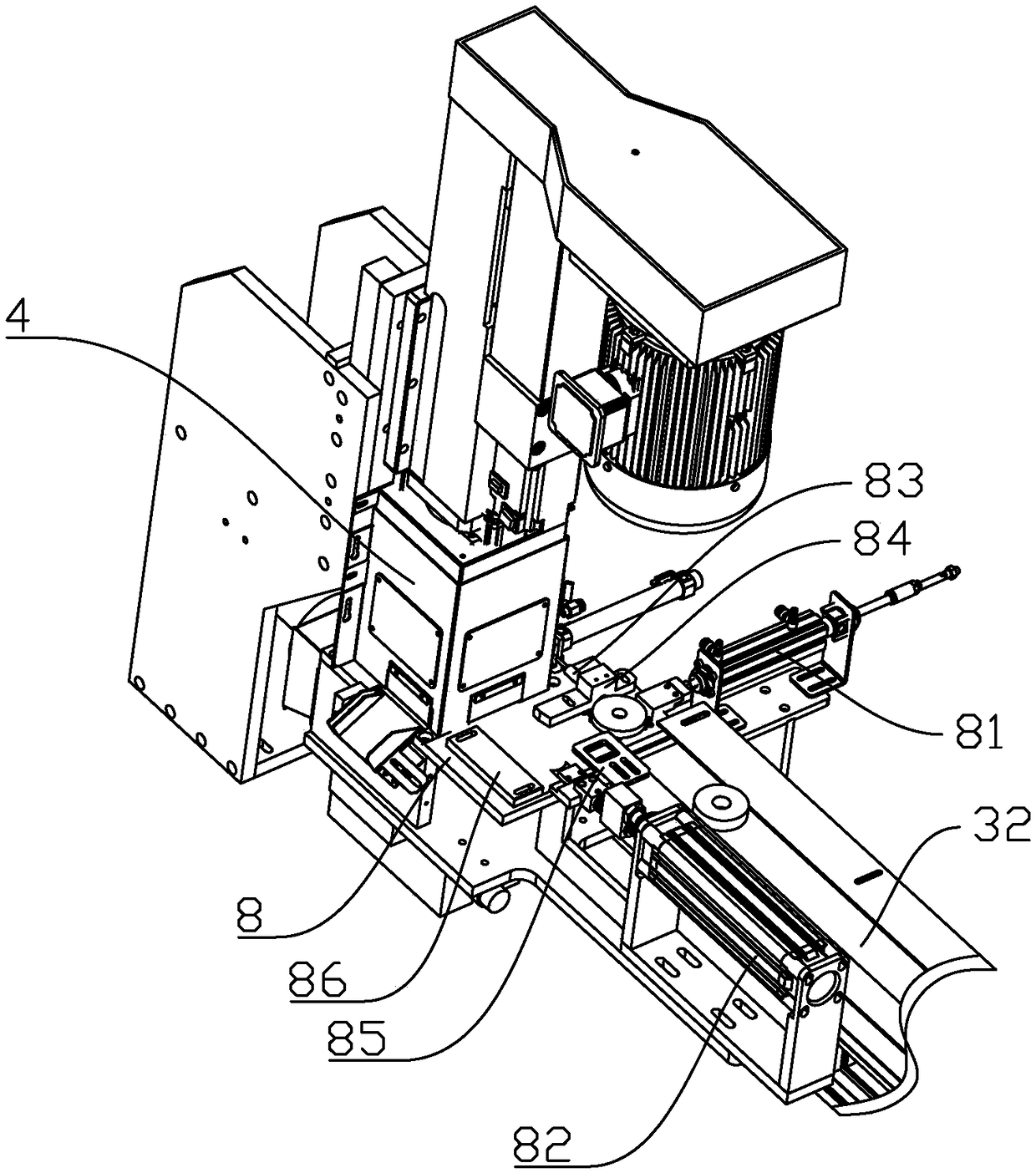

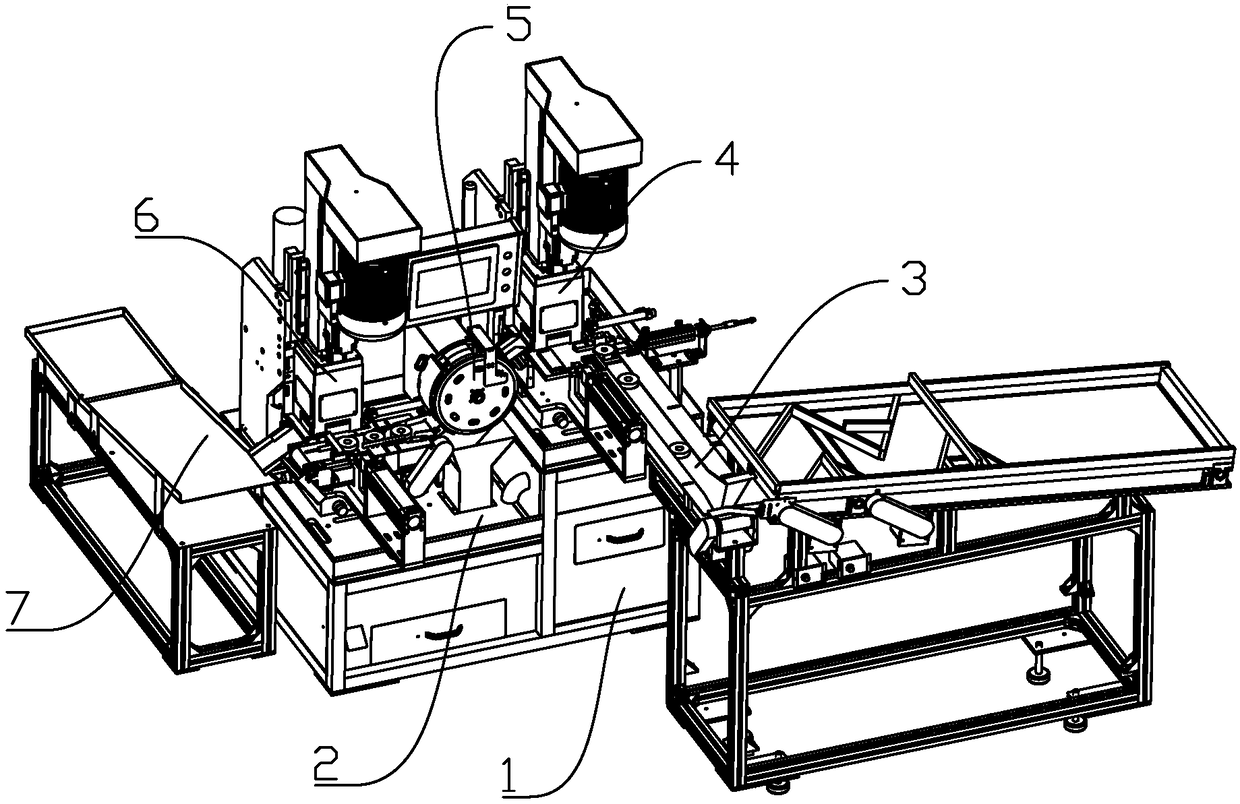

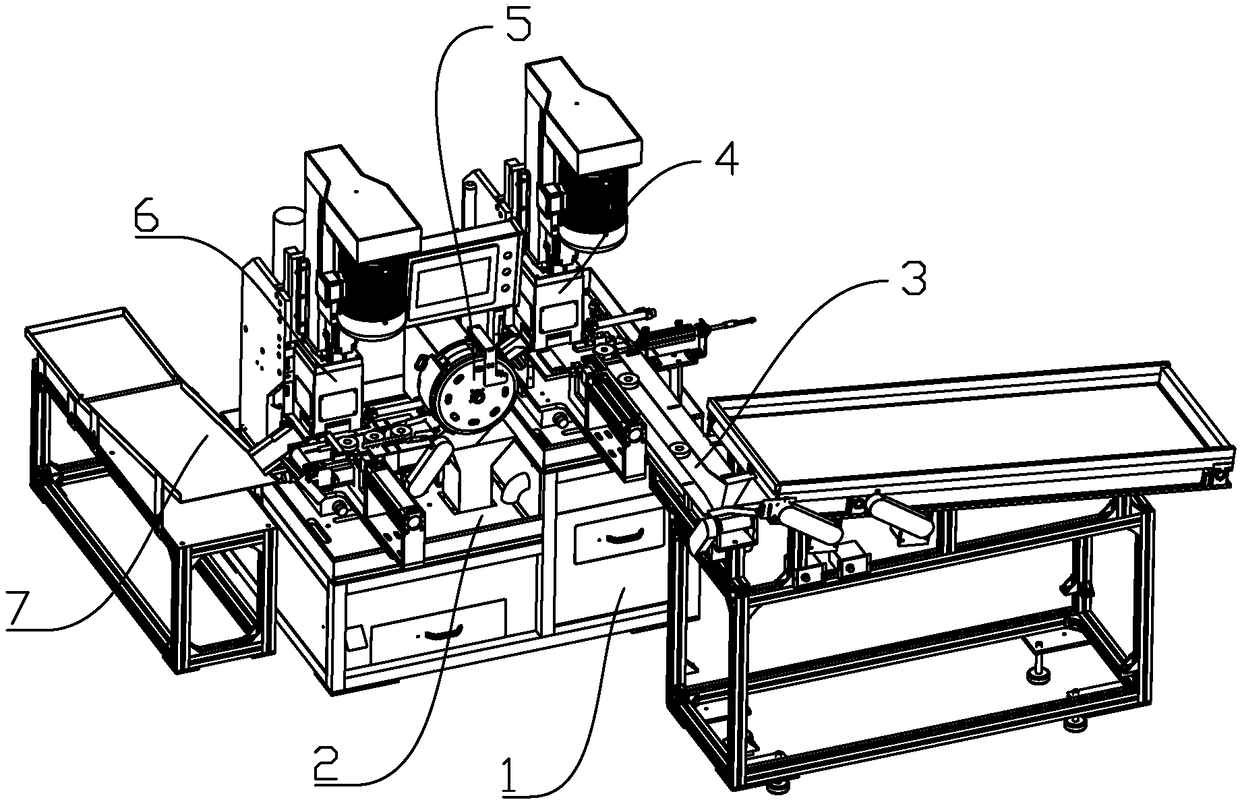

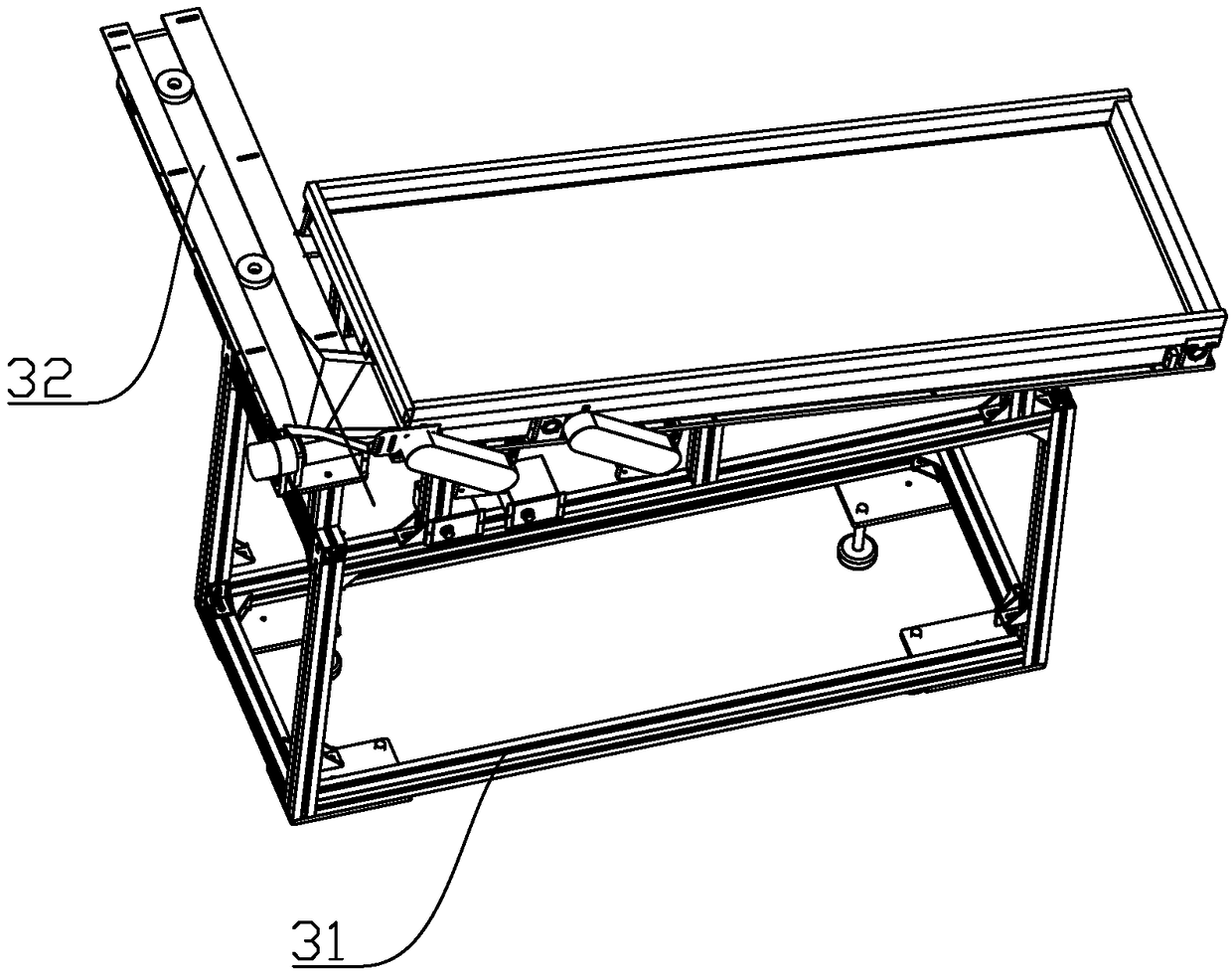

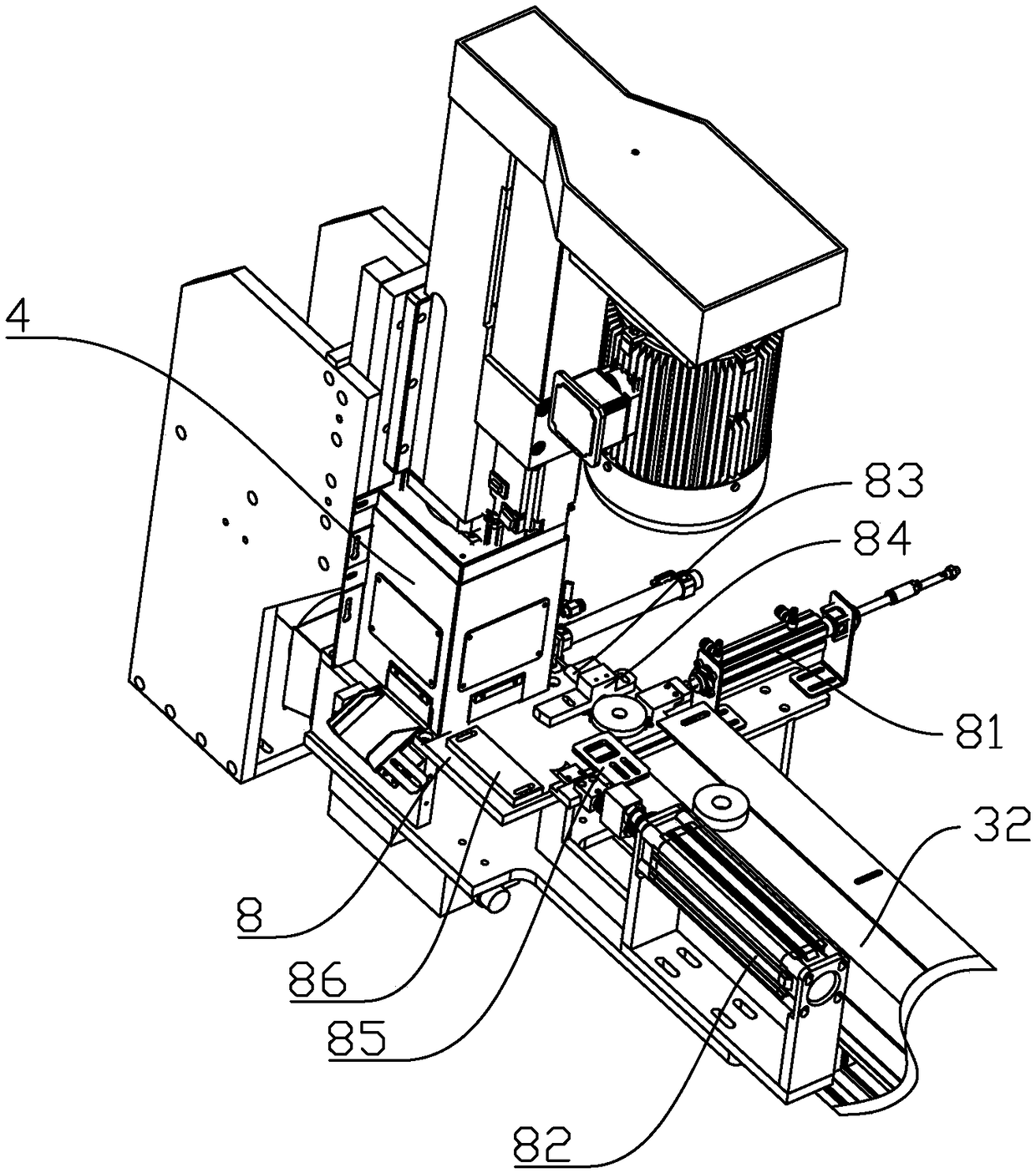

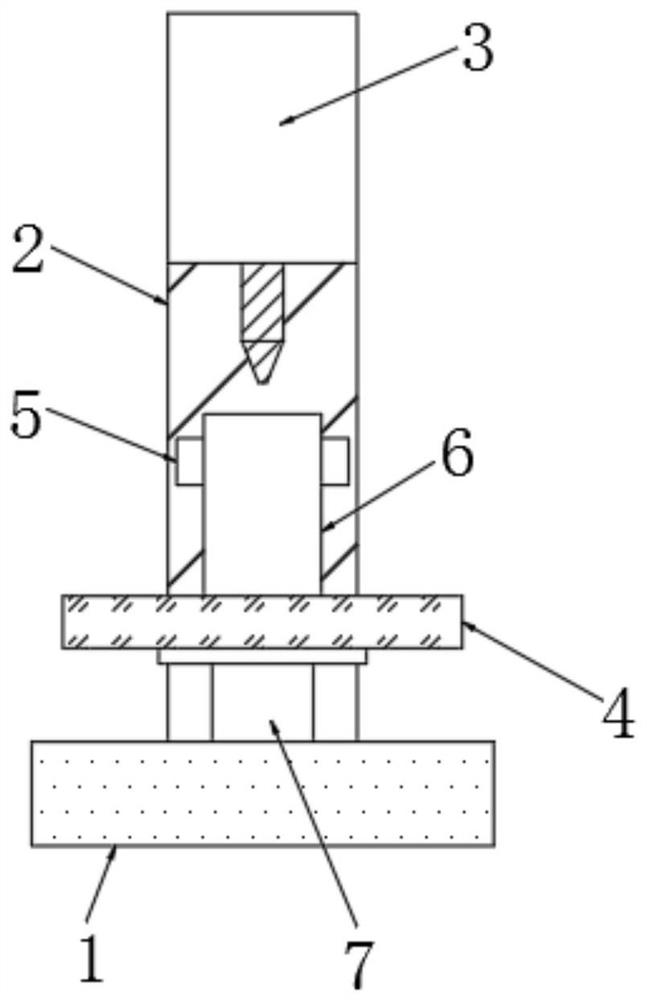

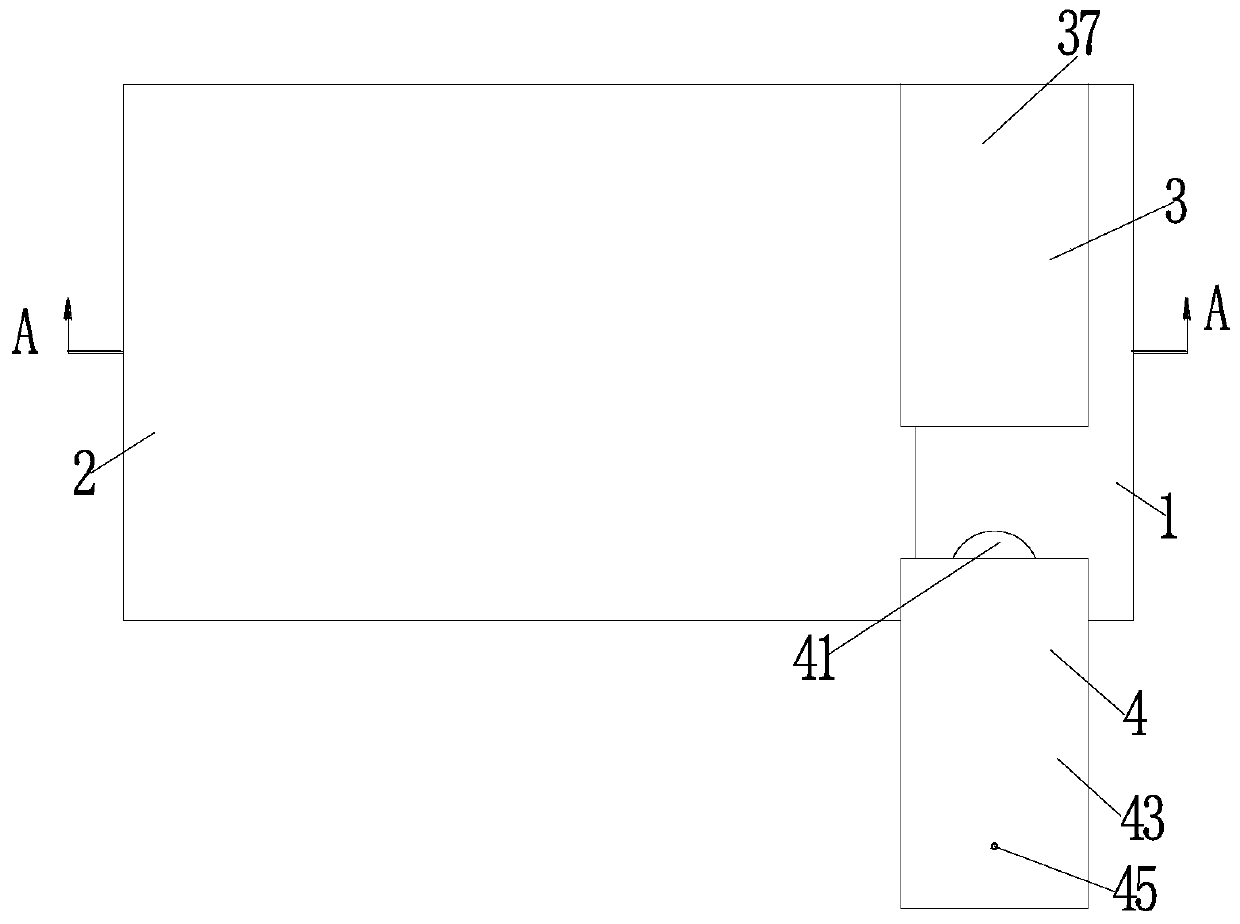

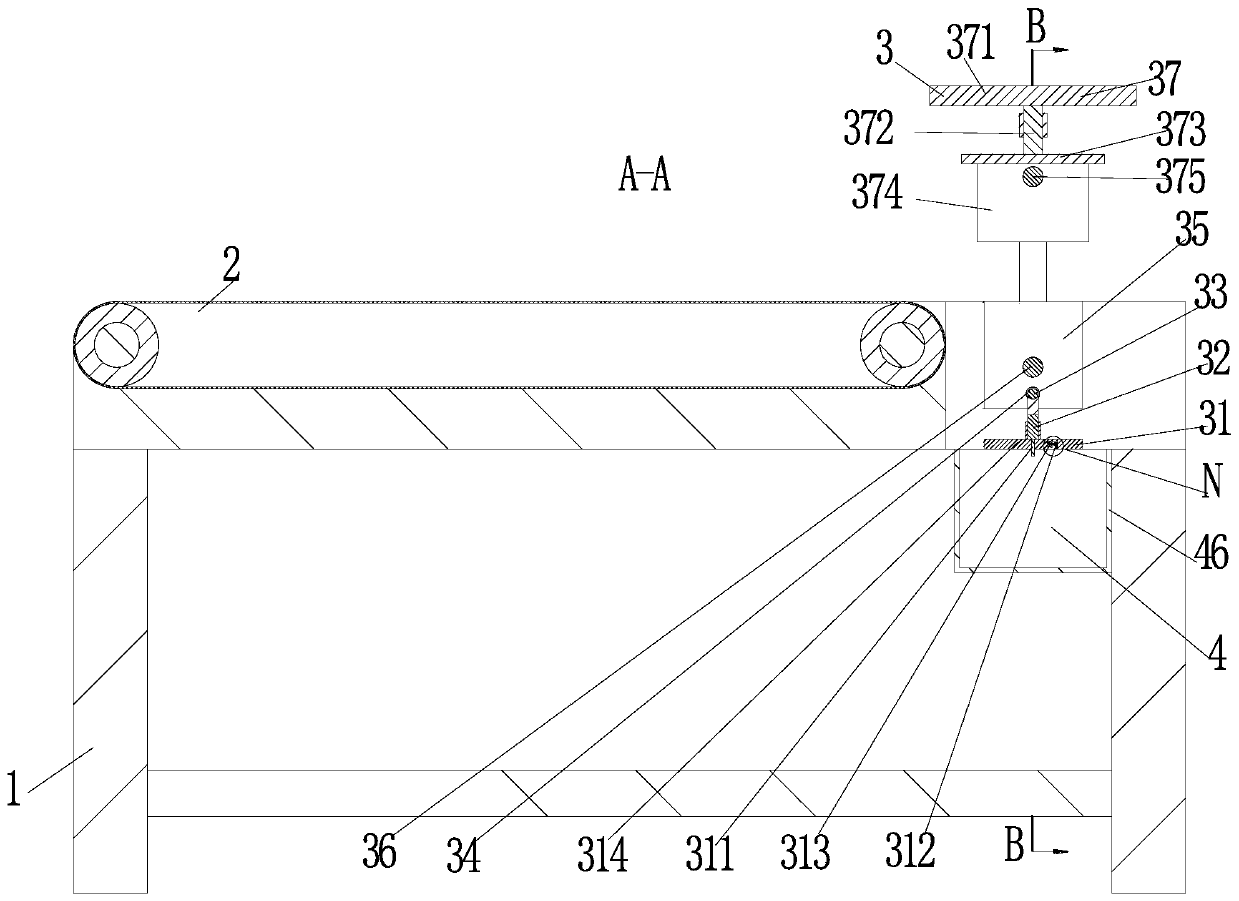

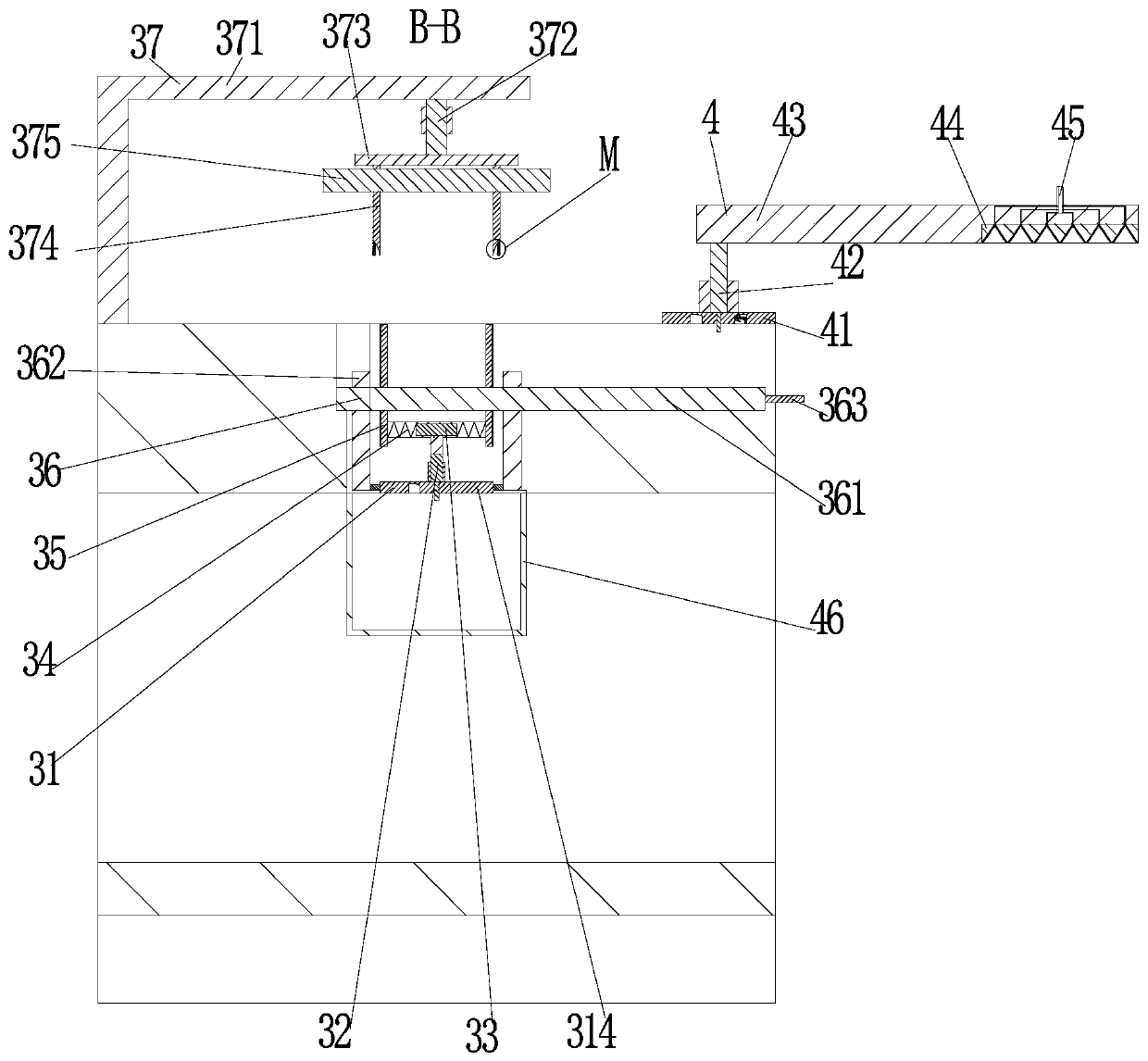

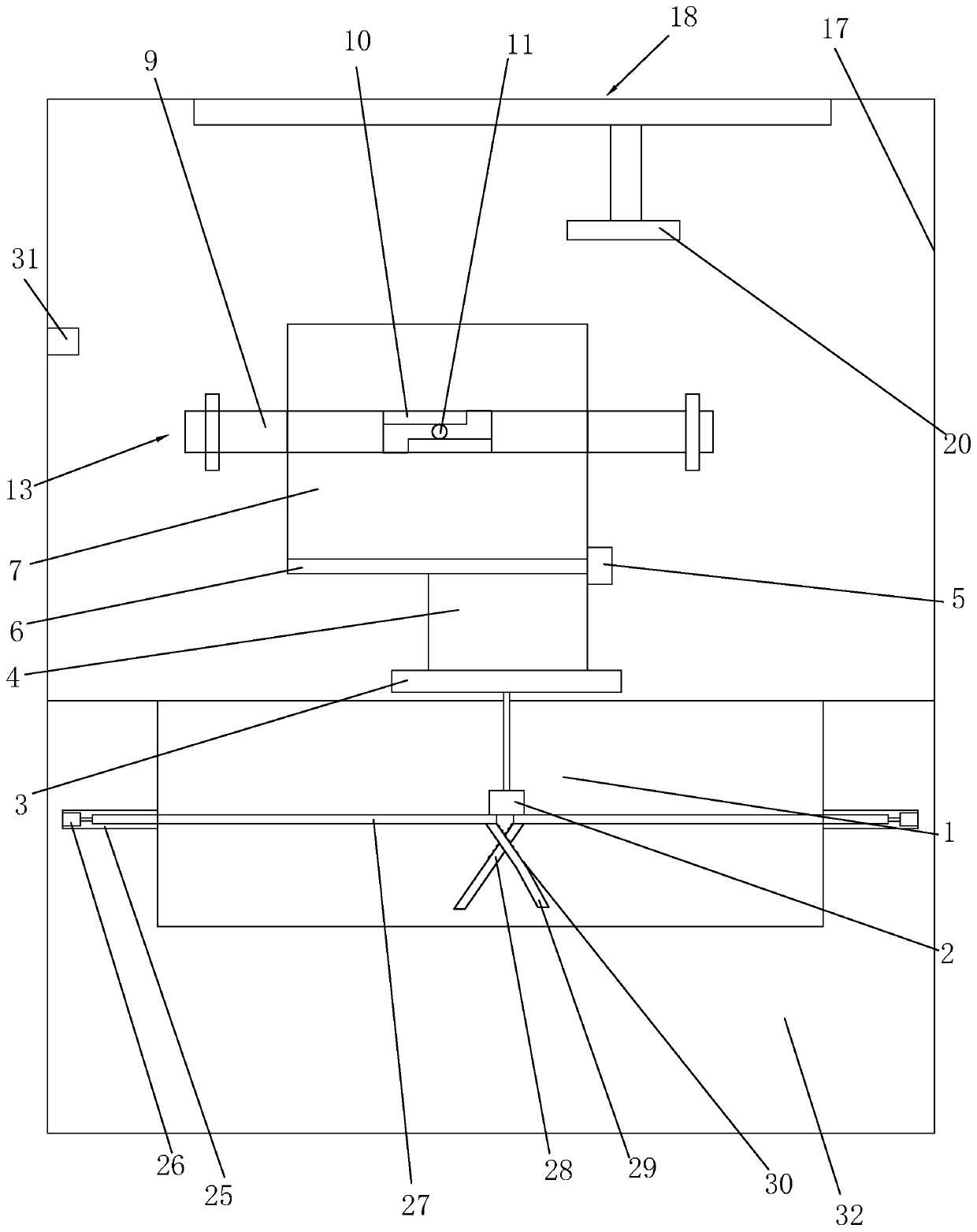

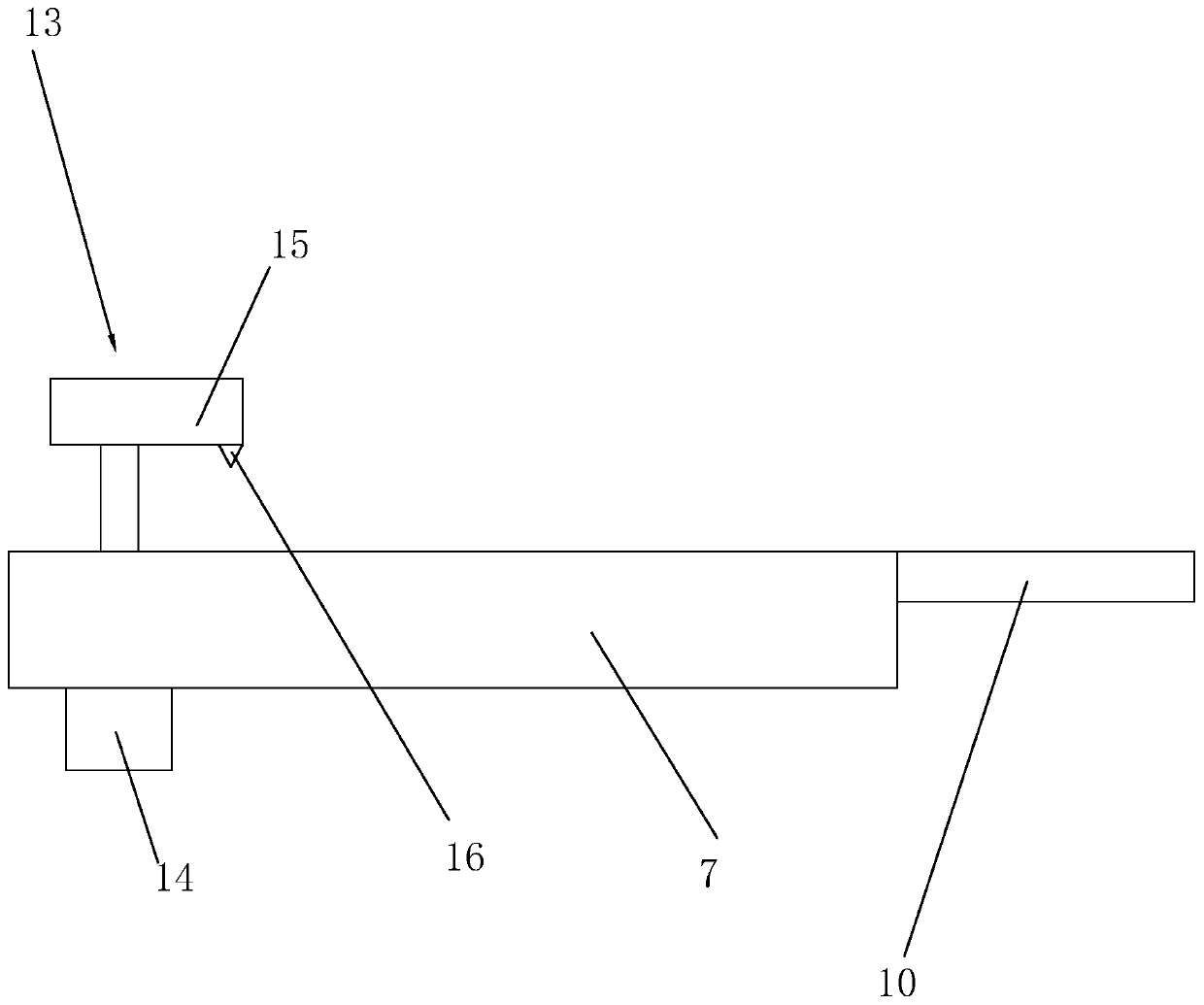

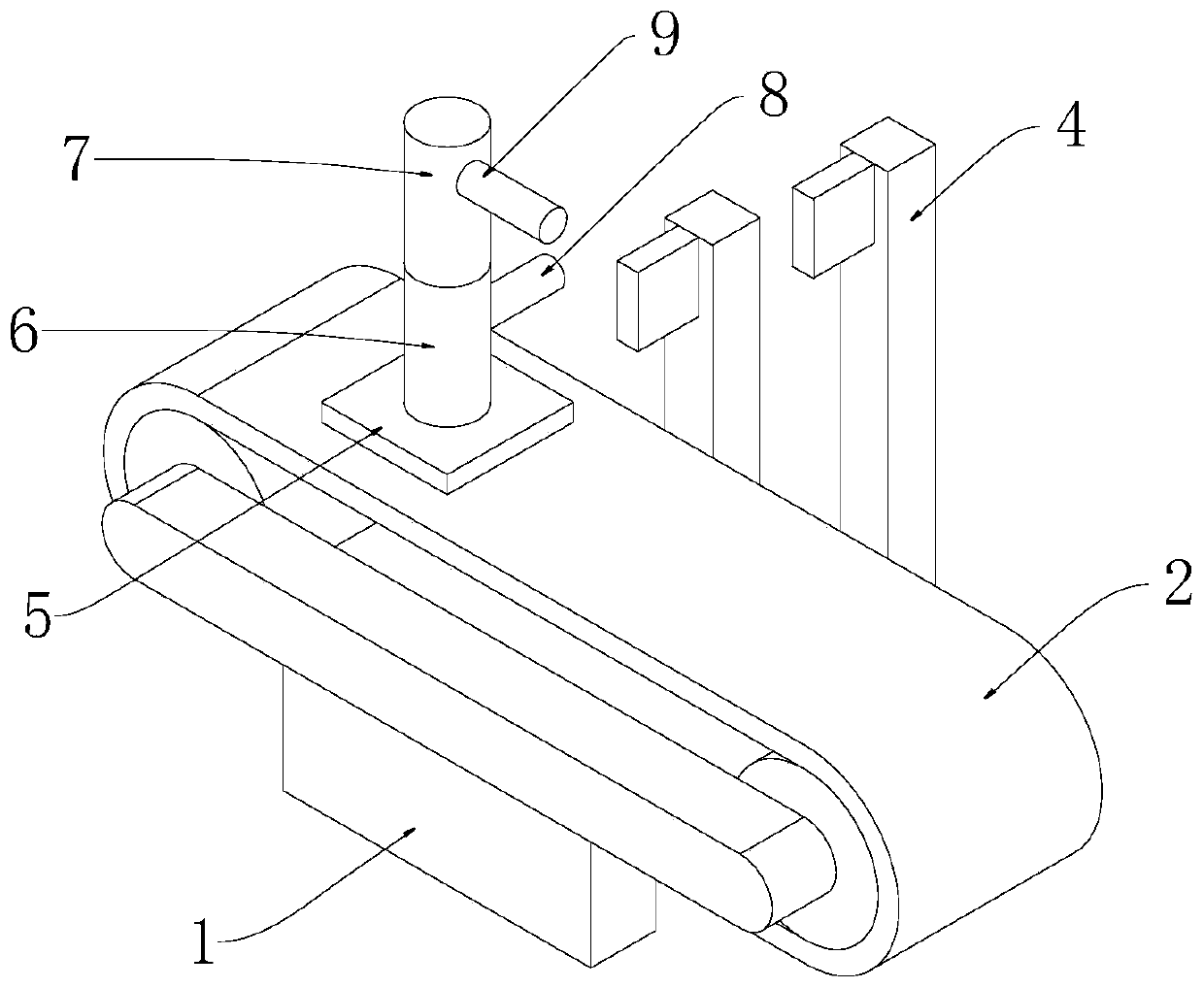

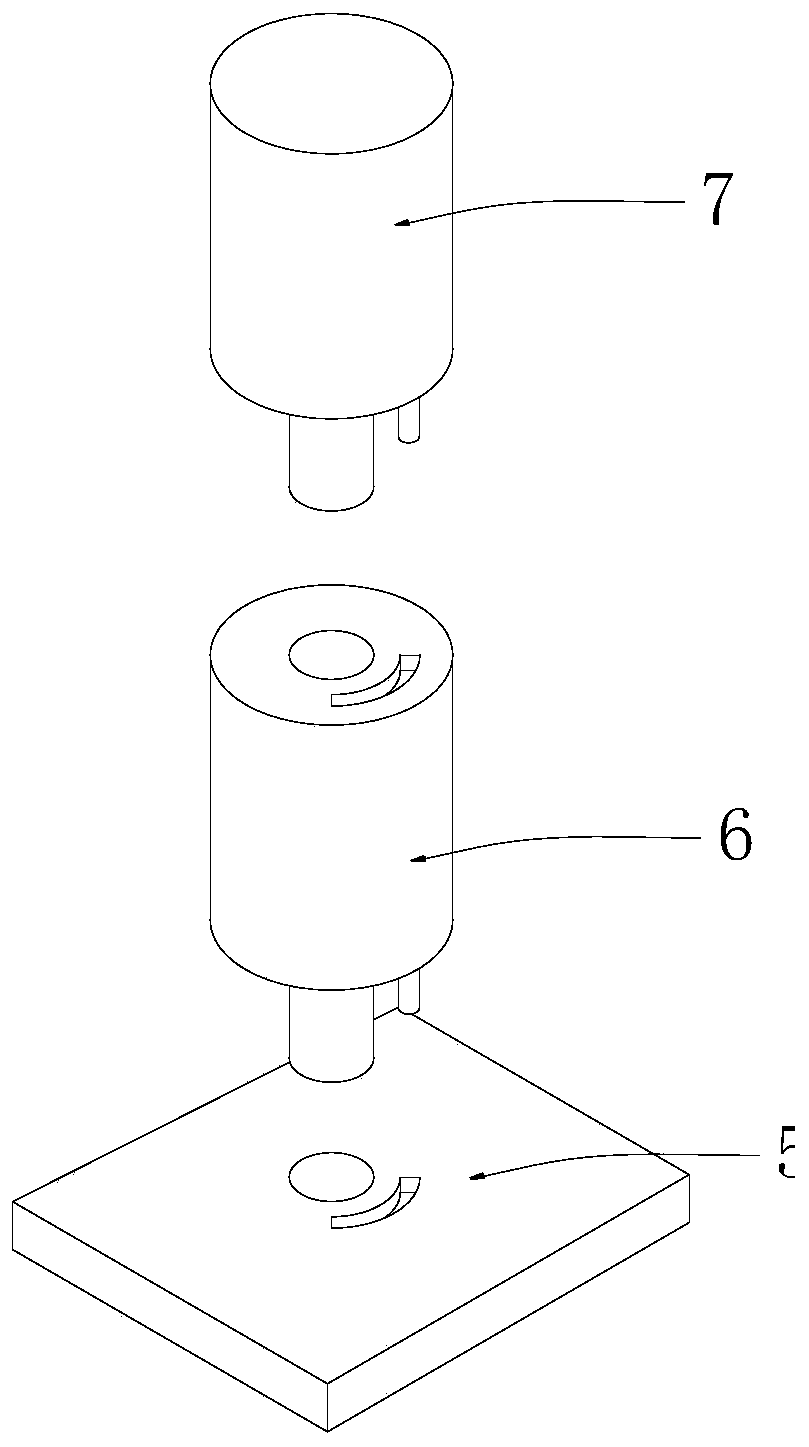

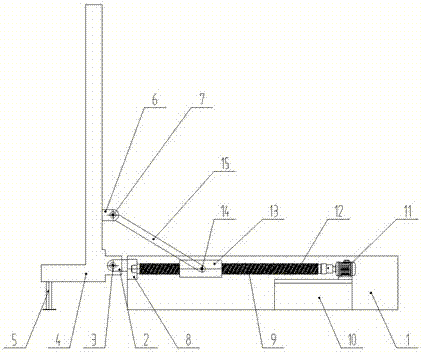

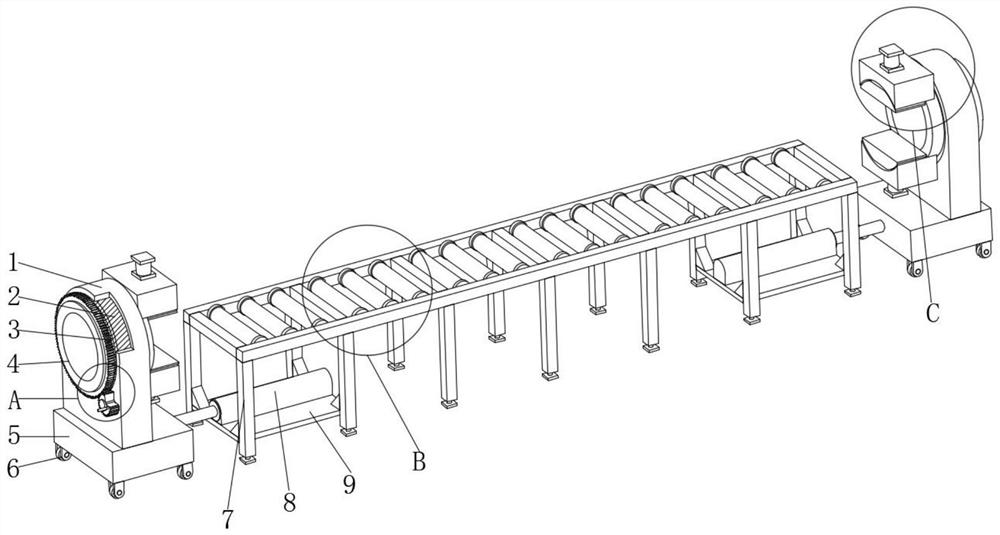

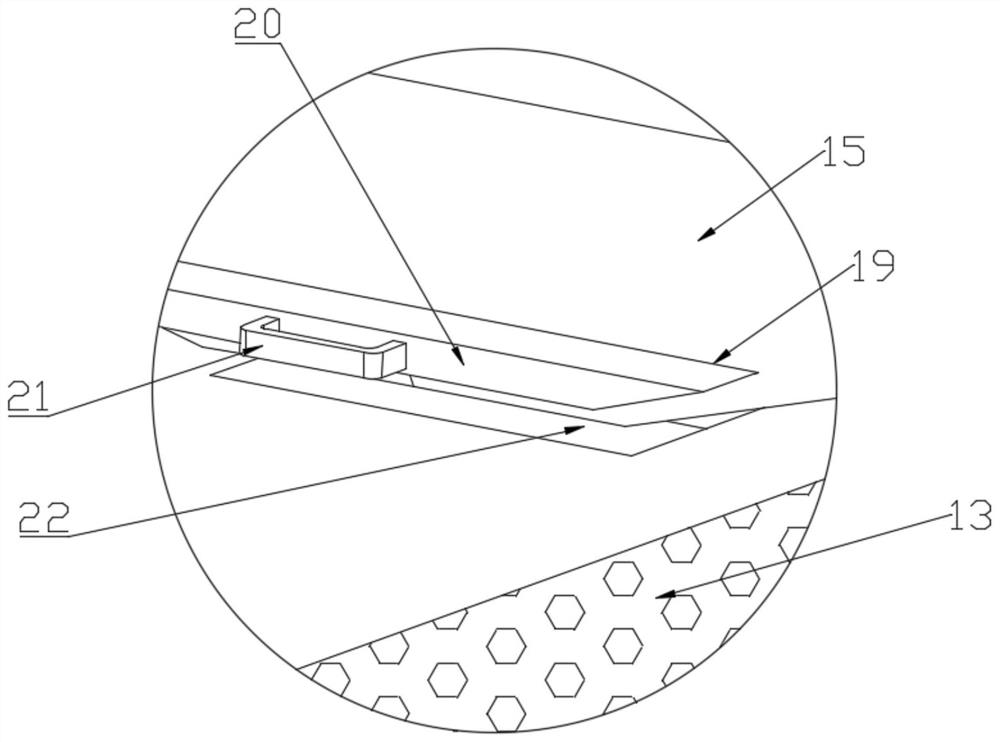

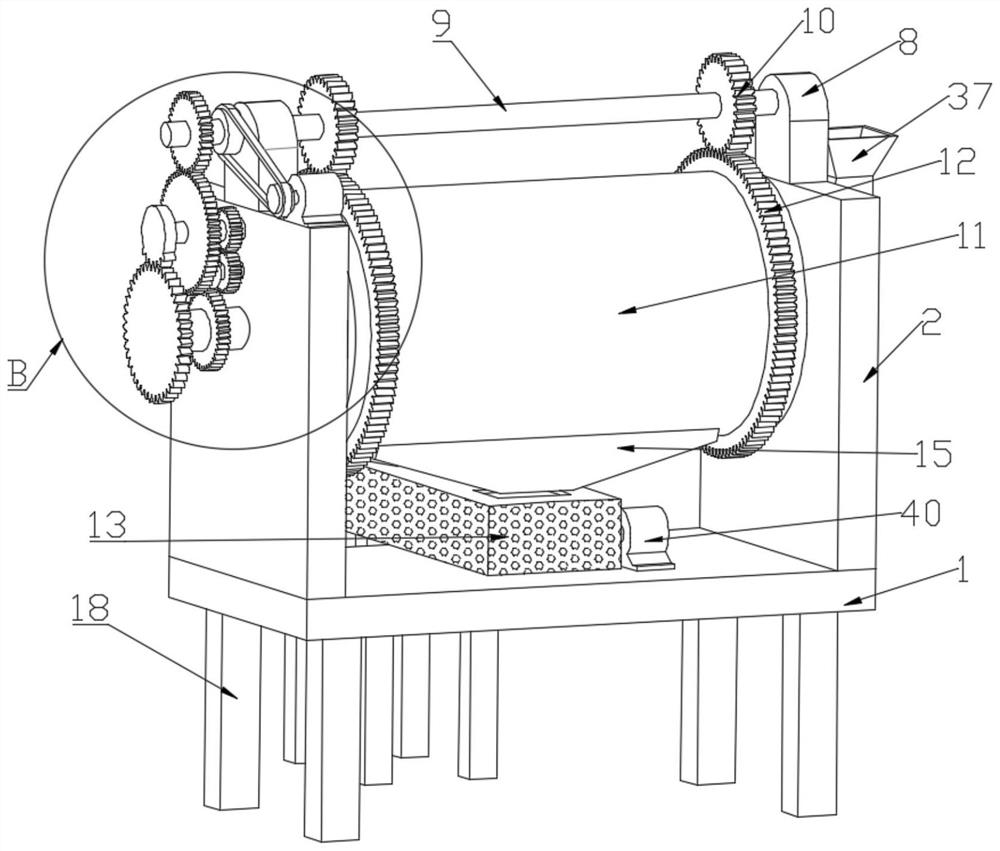

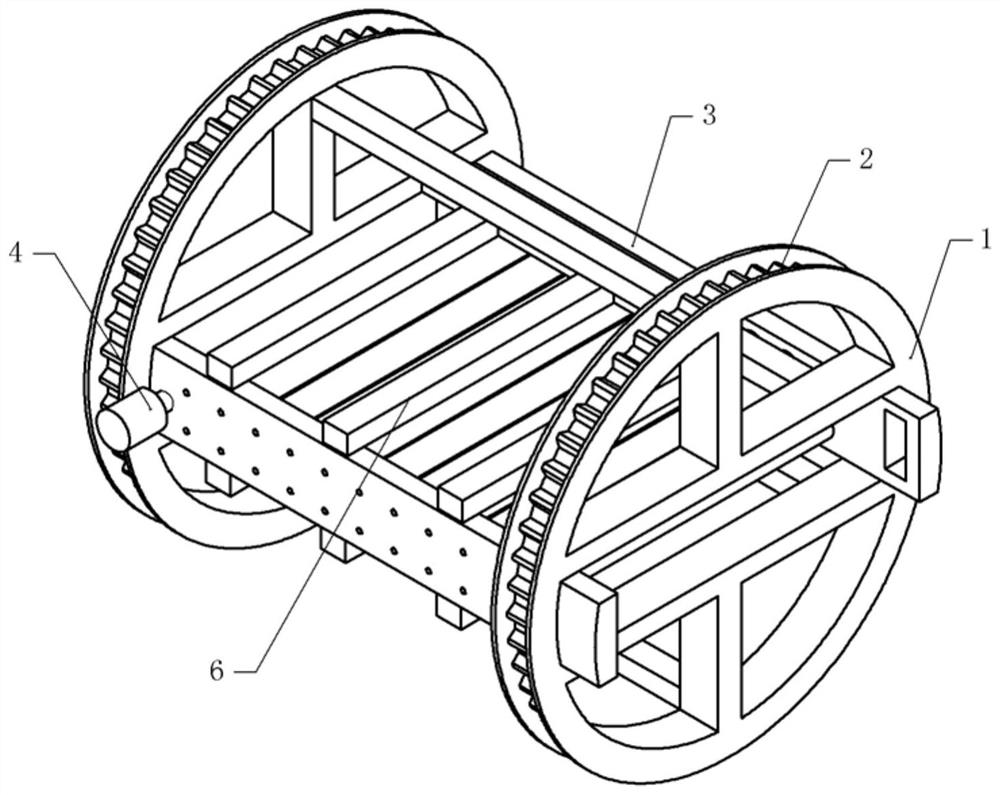

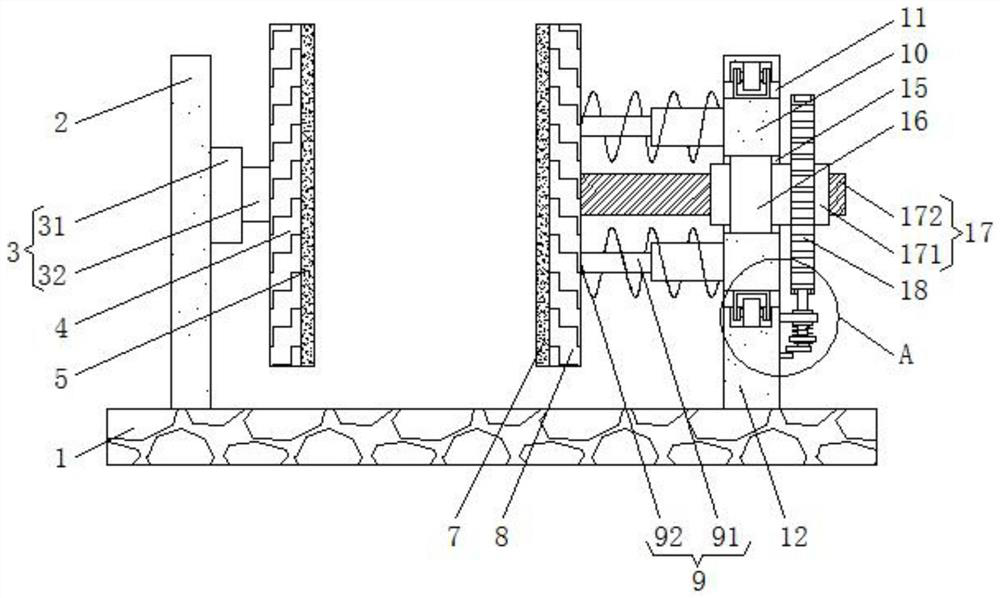

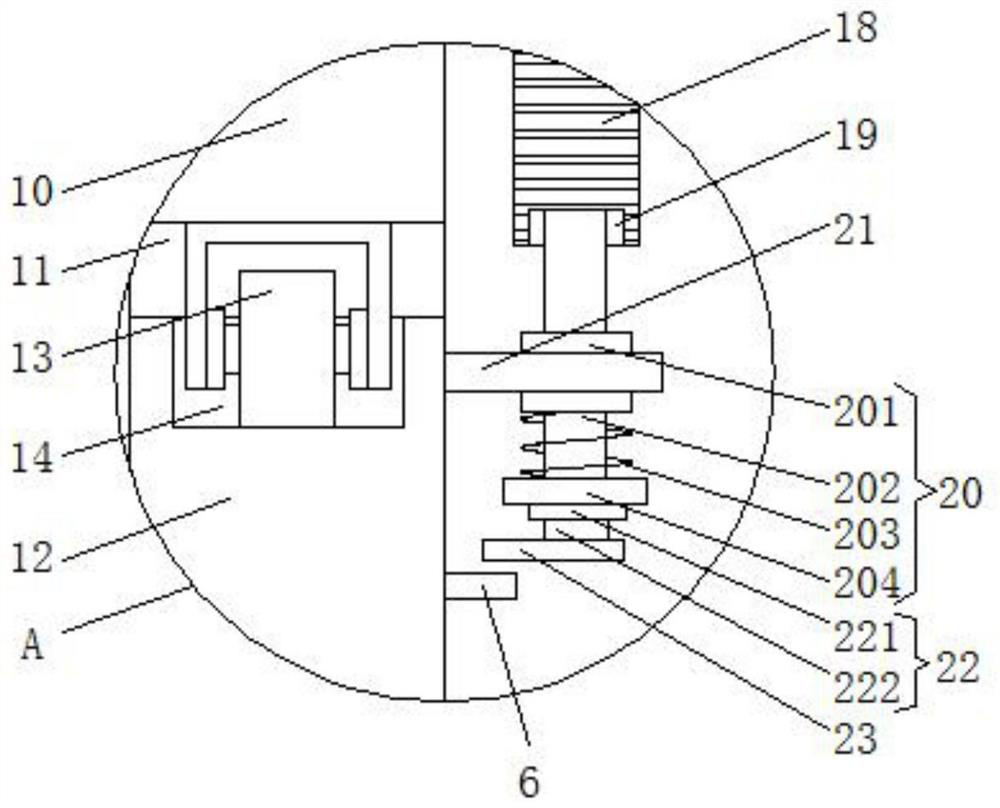

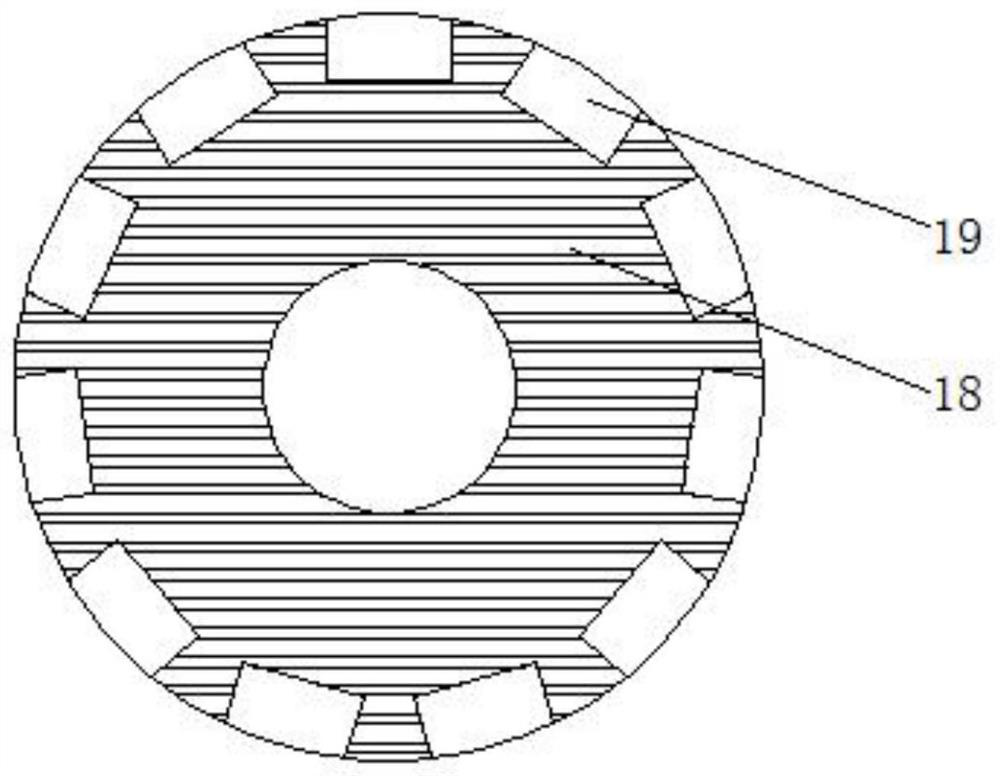

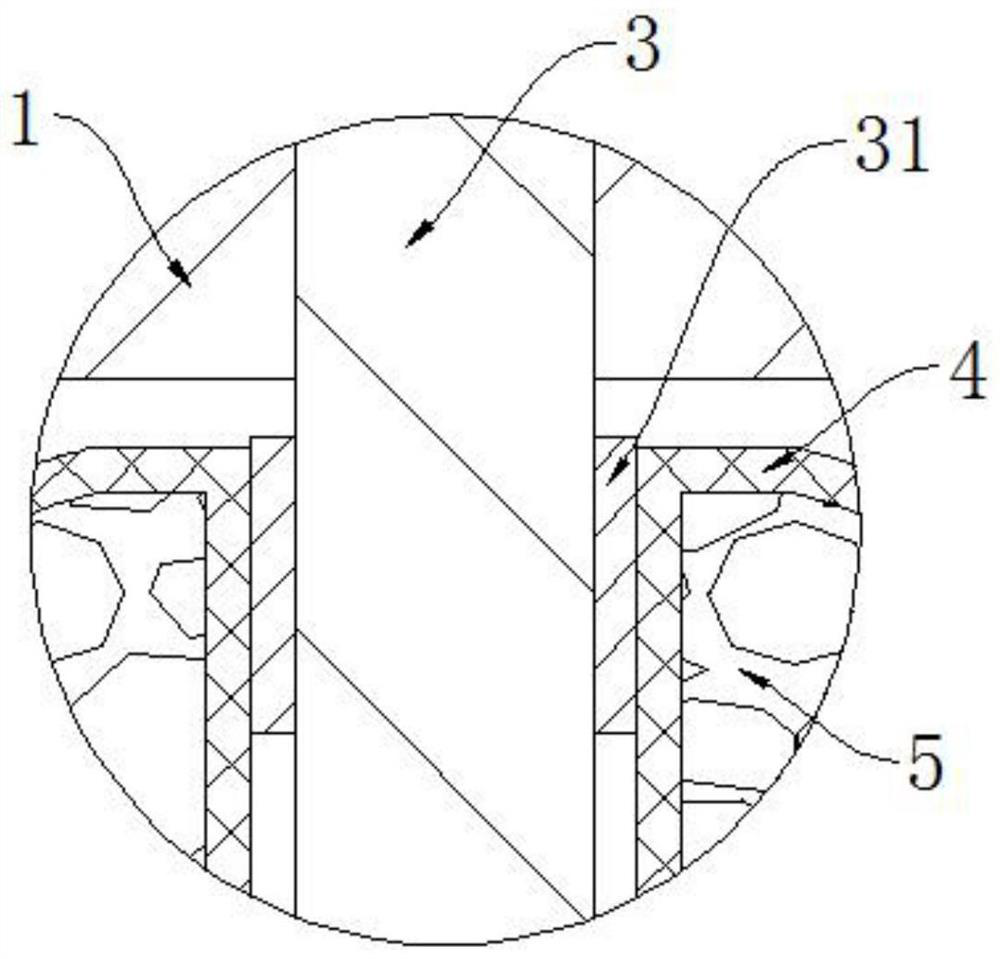

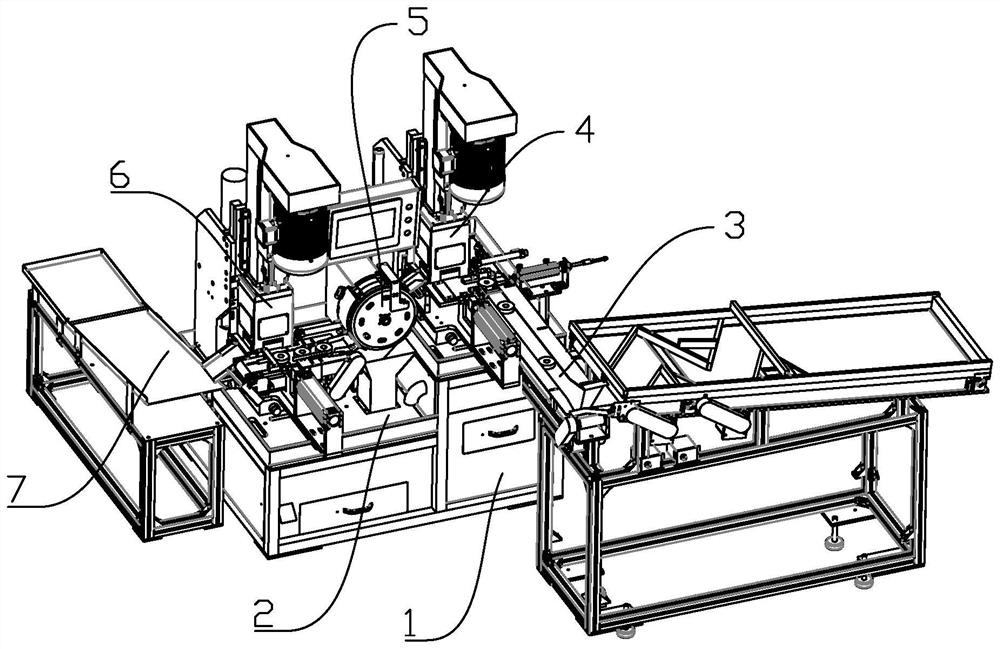

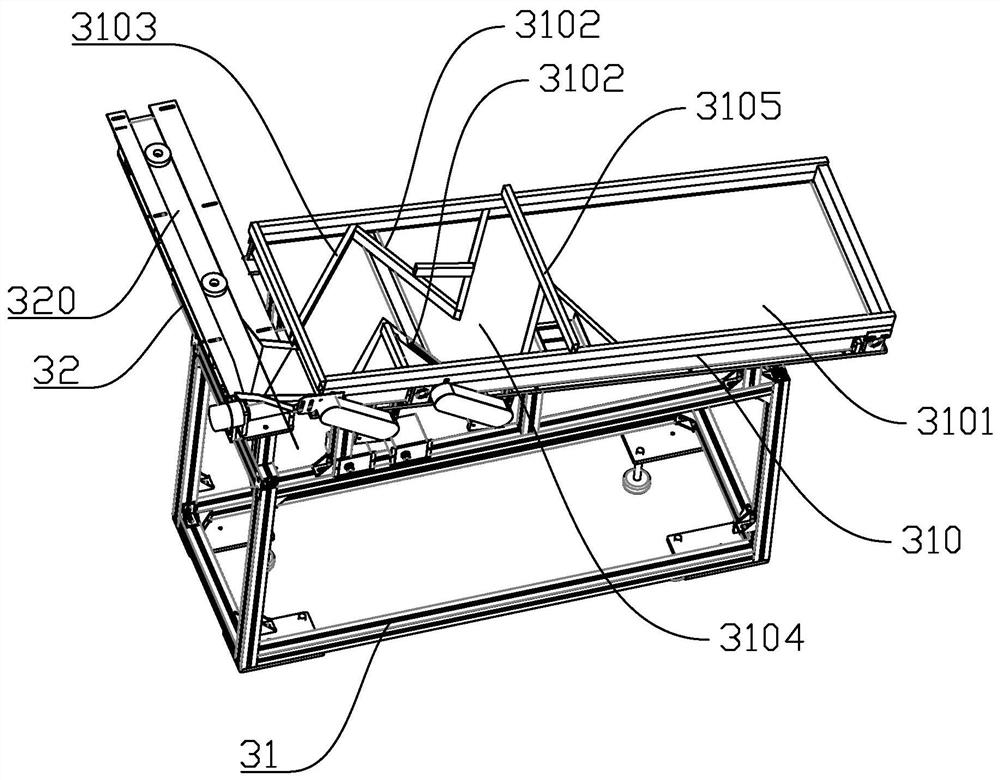

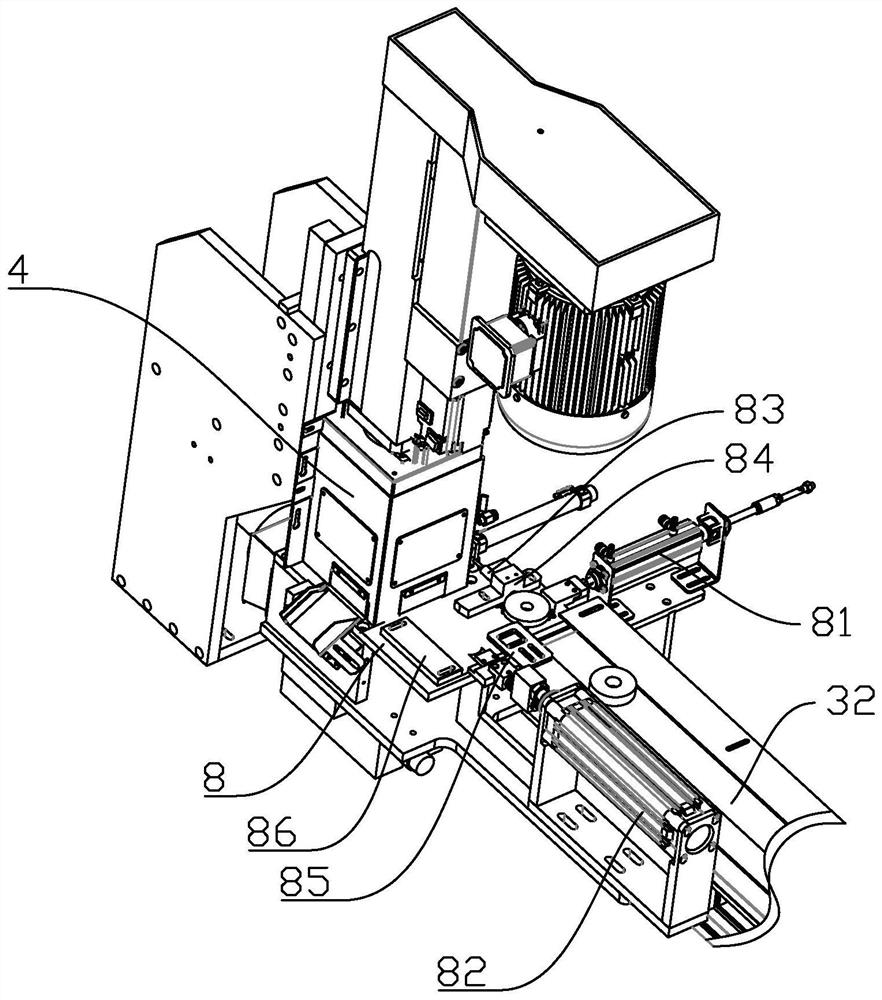

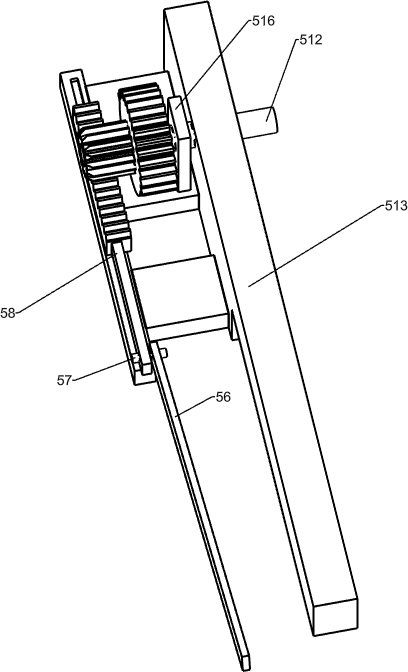

The invention discloses fully-automatic magnetic ring chamfering-grinding equipment capable of carrying out dust removal on a magnetic ring. The fully-automatic magnetic ring chamfering-grinding equipment comprises a seat, a loading mechanism, a first grinding mechanism, an overturning mechanism, a second grinding mechanism and an unloading mechanism, wherein each of the first grinding mechanism and the second grinding mechanism comprises a chamfering head assembly and a push-out assembly, each chamfering head assembly comprises a main shaft motor, a main shaft support, a power head and a chamfering disc, each main shaft motor is connected with the corresponding chamfering disc through the corresponding power head, each chamfering disc is provided with two chamfering tool installation blocks, through holes are formed in each two chamfering tool installation blocks, each chamfering disc is provided with a cross hole, and each two chamfering tool installation blocks correspond to the inner rings and the outer rings of the magnetic ring in position separately, and fixed by virtue of screws; a limit block is arranged below each chamfering head assembly, and the section of each limit block is lower than the magnetic ring; and each push-out assembly comprises a push-out cylinder and a push-out block. The fully-automatic magnetic ring chamfering-grinding equipment has the following advantages and effects: chamfering-grinding can be carried out on the inner rings and the outer rings of the two end surfaces of the magnetic ring separately, the labor is much saved, and the productionefficiency is increased.

Owner:WENZHOU POLYTECHNIC

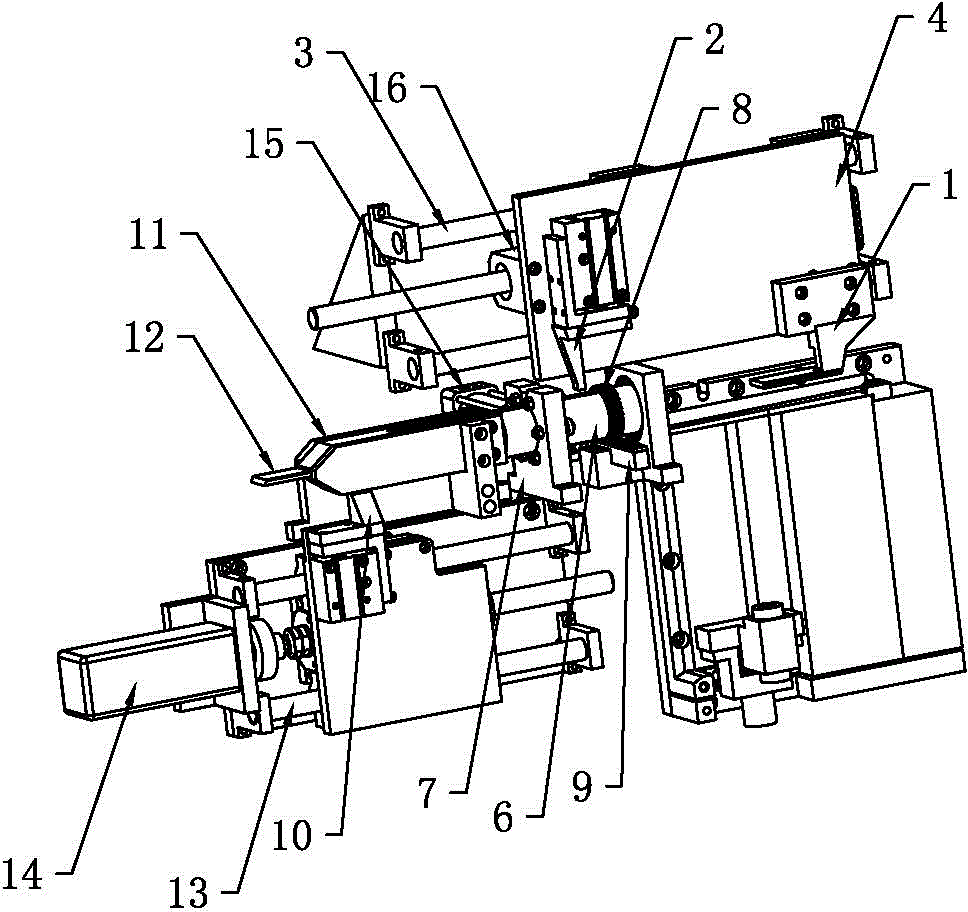

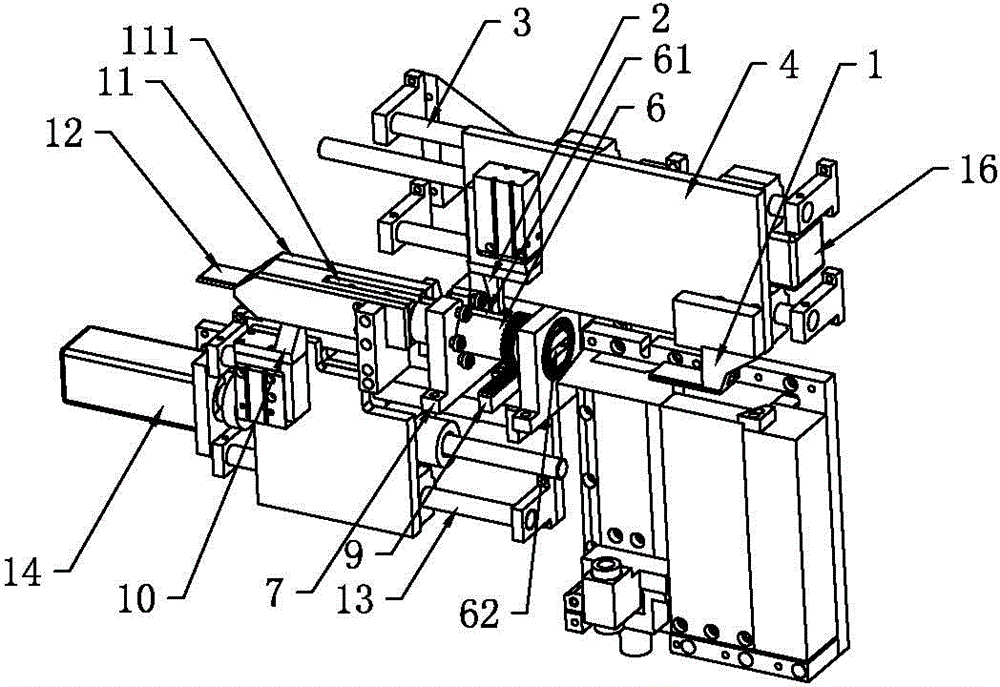

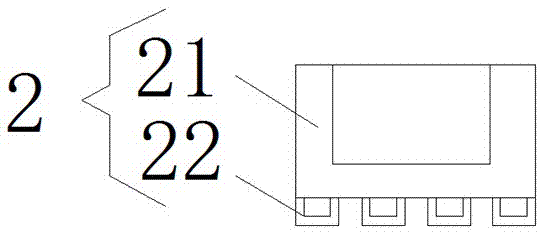

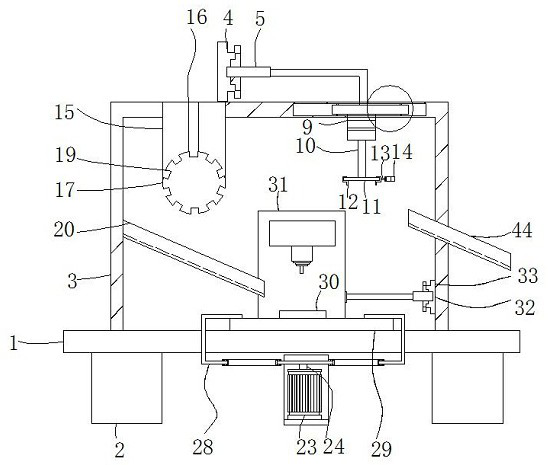

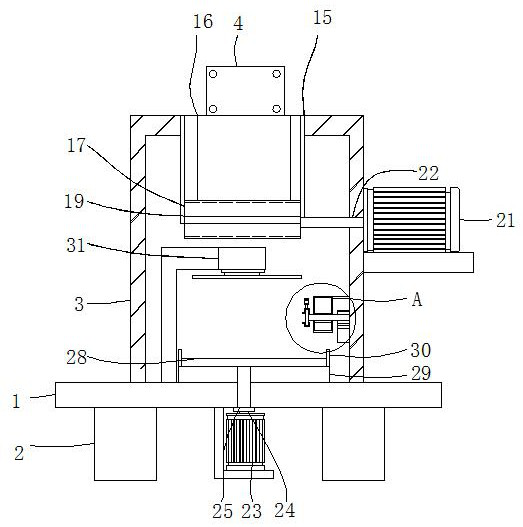

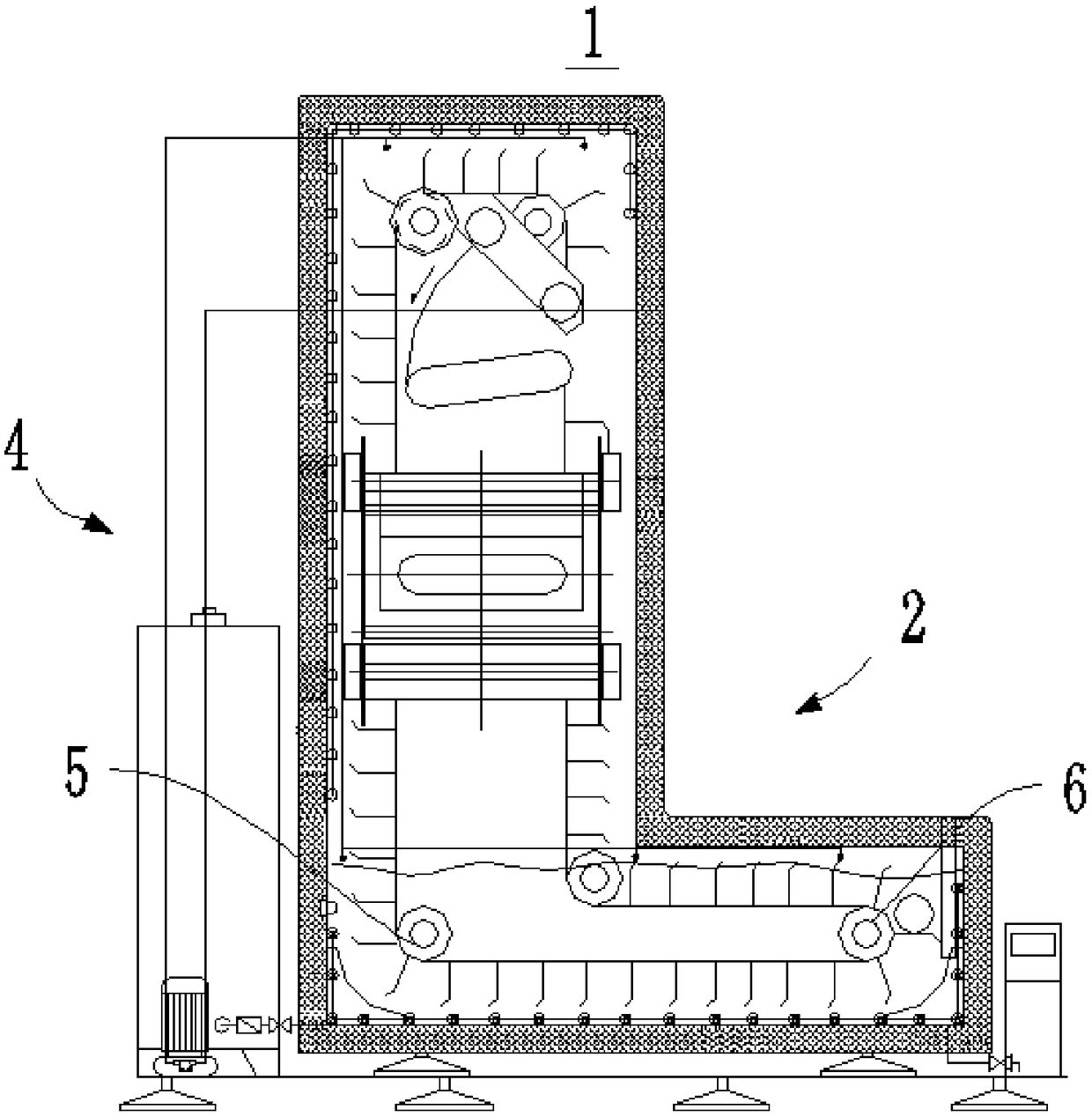

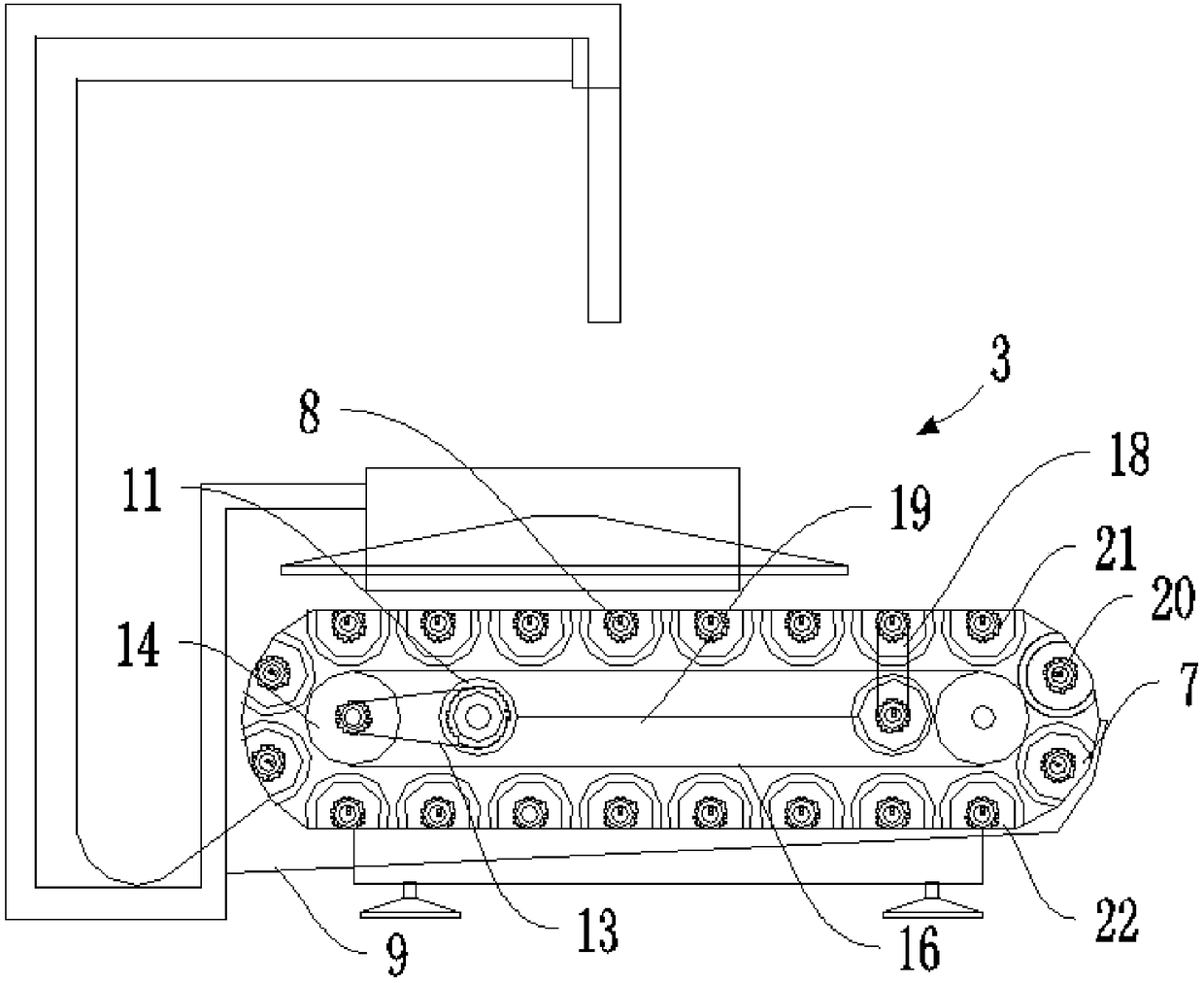

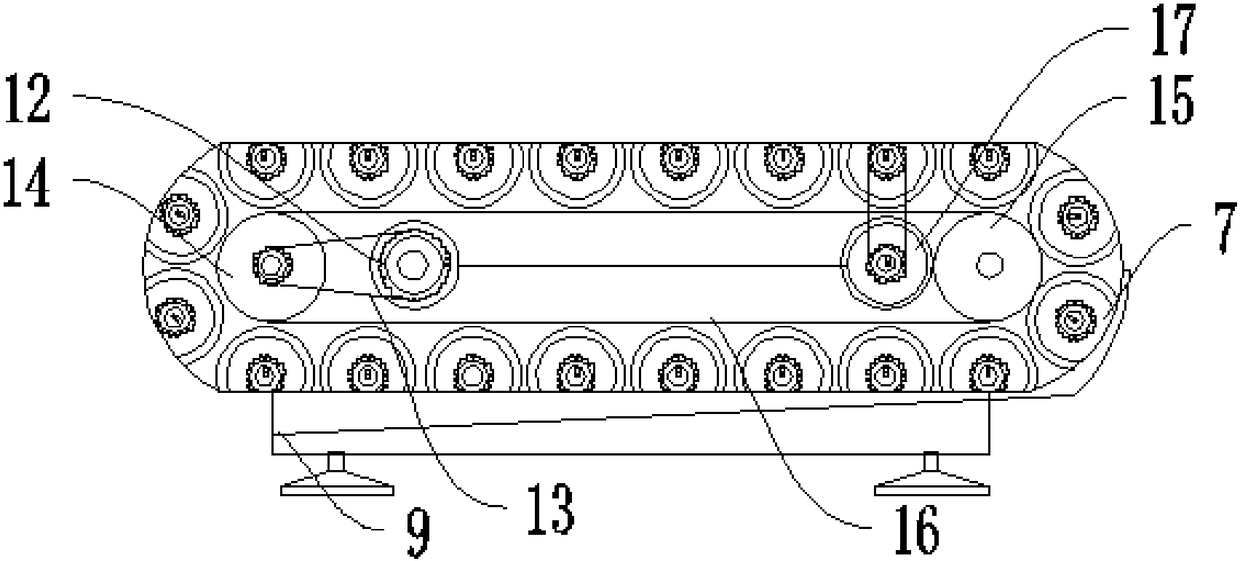

Full-automatic magnetic ring chamfering grinding equipment for continuously conveying magnetic rings

ActiveCN109396555AAchieve finishingImprove consistencyEngineeringElectrical and Electronics engineering

The invention discloses full-automatic magnetic ring chamfering grinding equipment for continuously conveying the magnetic rings. The full-automatic magnetic ring chamfering grinding equipment comprises a base, a feeding mechanism, a first grinding mechanism, an overturning mechanism, a second grinding mechanism and a discharging mechanism, wherein the first grinding mechanism and the second grinding mechanism both comprise a chamfering head assembly and a pushing-out assembly, the chamfering head assembly comprises a main shaft motor, a main shaft support, a power head and a chamfering disc,the main shaft motor is connected with the chamfering disc through the power head, the chamfering disc is provided with two chamfering tool mounting blocks, through holes are formed in the two chamfering tool mounting blocks, a transverse hole is formed in the chamfering disc, the two chamfering tool mounting blocks are connected the positions of the inner ring and the outer ring of the magnetic ring correspond to each other respectively and are fixed by screws; a limiting block is arranged below the chamfering head assembly, the height of the cross section of the limiting block is lower thanthat of the magnetic ring; and the pushing-out assembly comprises a pushing-out air cylinder and a pushing-out block. The full-automatic magnetic ring chamfering grinding equipment has the following advantages and effects that the inner ring and the outer ring of the two end surfaces of the magnetic ring can be subjected to chamfering and grinding, labor is saved, and production efficiency is improved.

Owner:WENZHOU POLYTECHNIC

Magnetic shoe feeding method

ActiveCN104787565AAchieve the purpose of flippingEasy to useConveyor partsStructural engineeringMechanical engineering

The invention discloses a magnetic shoe feeding method. A first pushing mechanism is used for pushing a single magnetic shoe in a stacked magnetic shoe pile to a turning mechanism. A Hall sensor senses the magnetoelectric effect caused by the single magnetic shoe, and signals are transmitted to a controller. The controller sends instructions to the turning mechanism according to the signals transmitted by the Hall sensor. The turning mechanism works according to the instructions, so that the purpose that magnetic shoes in different magnetic directions are turned is achieved. Then, a second pushing mechanism pushes the single magnetic shoe in the turning mechanism to a next process. The operation is carried out repeatedly and continuously. The single magnetic shoe in the magnetic shoe pile can be efficiently pushed, and magnetism turning adjusting direction is recognized automatically. Using of magnetic shoes with the same polarity in the next process is convenient.

Owner:GUANGZHOU FIRESTEP SELF CONTROL SPECIAL PURPOSE EQUIP +1

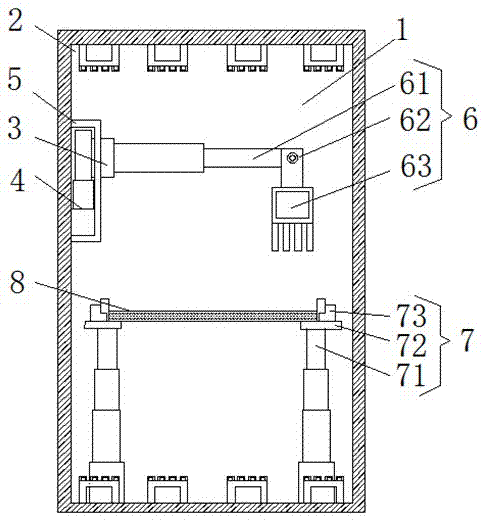

Disc turning-over device, and cleaning system and method

PendingCN109095137ASimple structureImprove turnover efficiencyConveyorsHollow article cleaningEngineeringMechanical engineering

The invention provides a disc turning-over device, and a cleaning system and method, and relates to the technical field of cleaning. The disc turning-over device comprises a disc turning-over slidinggroove. The disc turning-over sliding groove comprises a first inlet and a first outlet which communicate mutually, and the position of the first inlet is higher than that of the first outlet. The disc turning-over sliding groove comprises a first inclined section, the first inlet is formed in the high end of the first inclined section, and the width of the disc turning-over sliding groove is gradually decreased in the direction from the high end of the first inclined section to the low end of the first inclined section. The disc turning-over device is ingenious in structure, disc bodies can be turned over automatically after passing through the disc turning-over sliding groove, so that the disc bodies are output in the preset direction, the turning-over efficiency is high, and the turning-over effect is good; and according to the cleaning system and method, the forward and reverse disc bodies are forward placed firstly and then reversely placed to be conveyed into a cleaning tunnel, the cleaning efficiency is high, and the cleaning effect is good.

Owner:SHANDONG DINGTAISHENG FOOD IND EQUIP

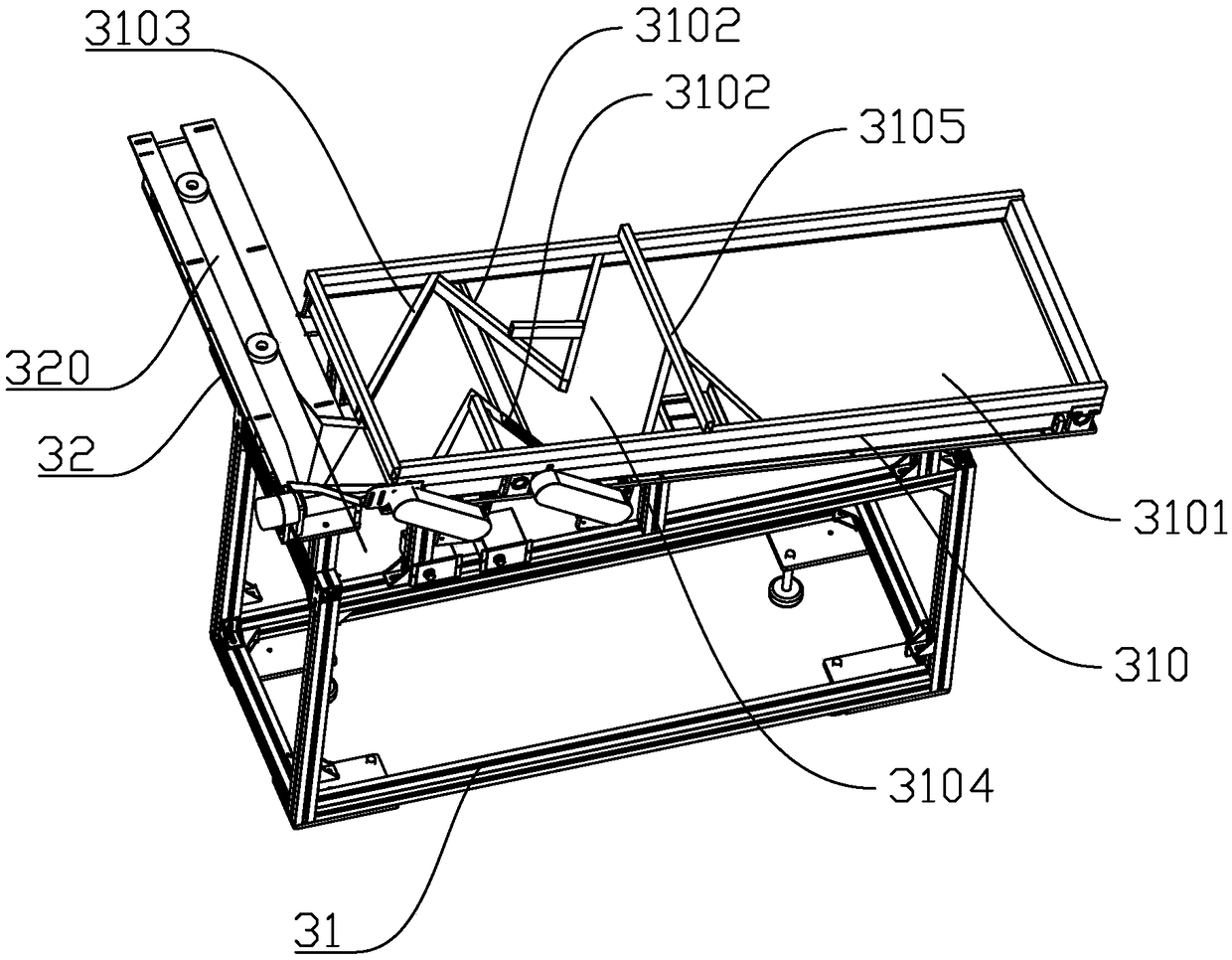

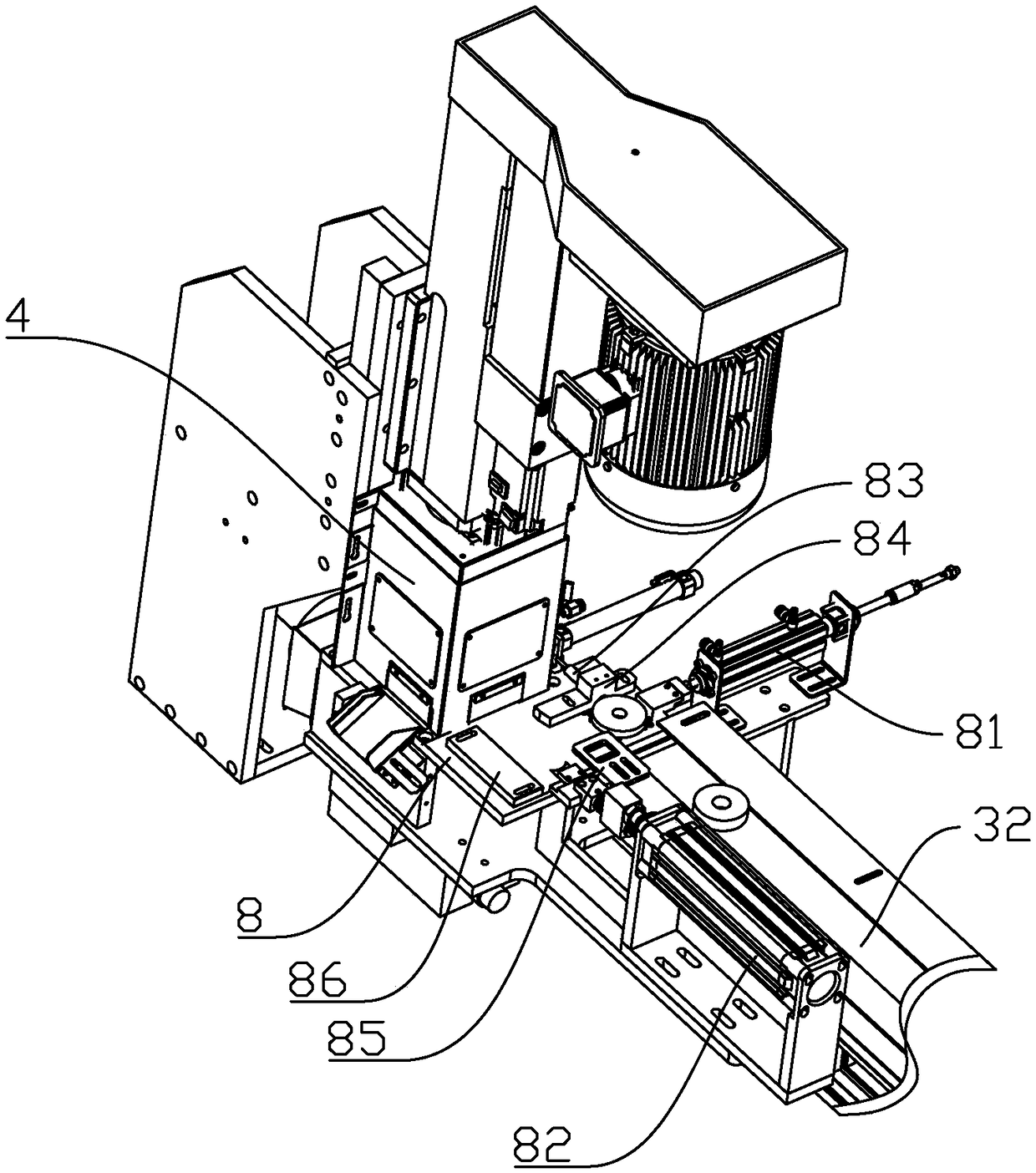

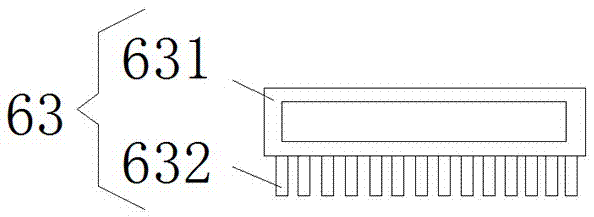

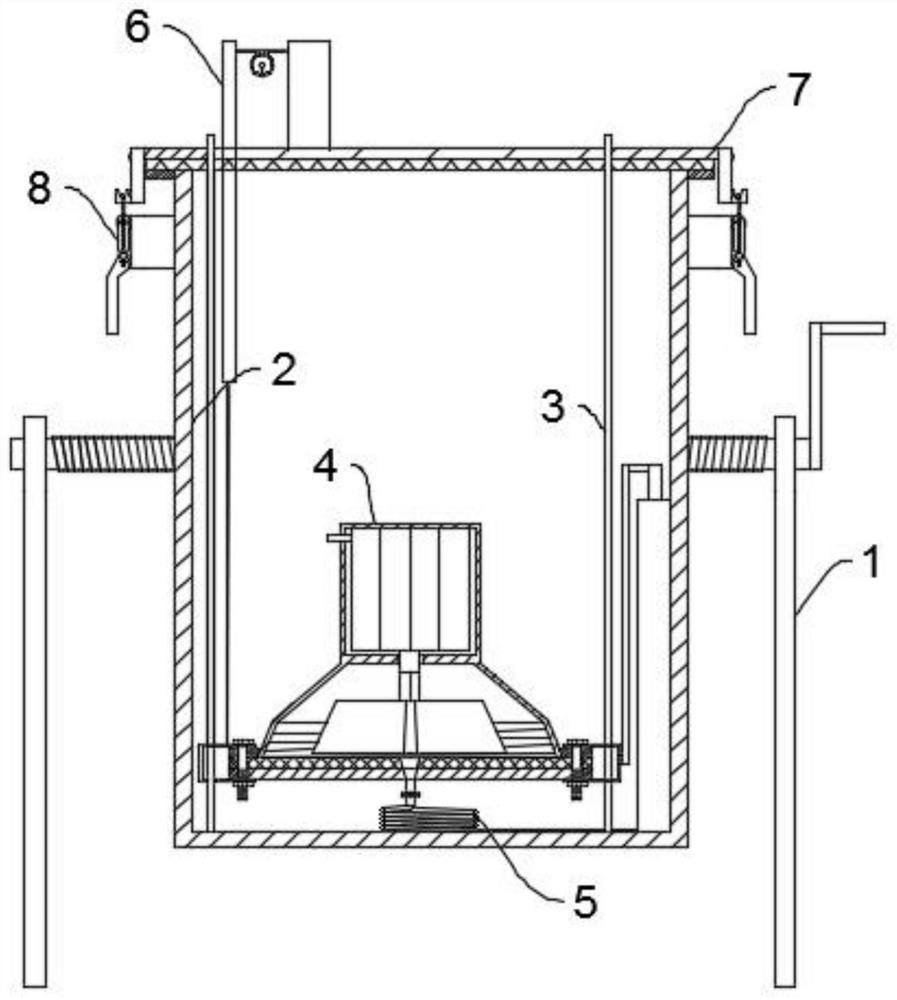

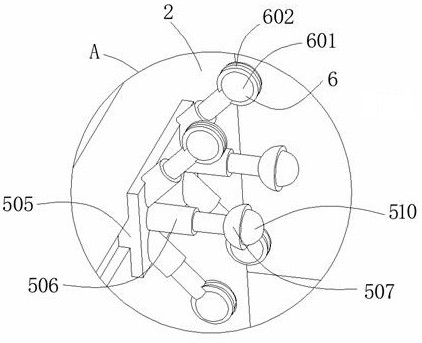

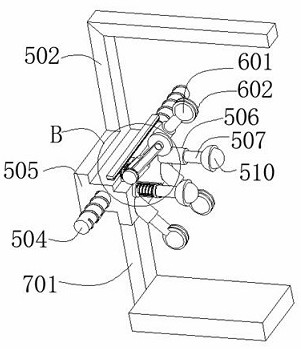

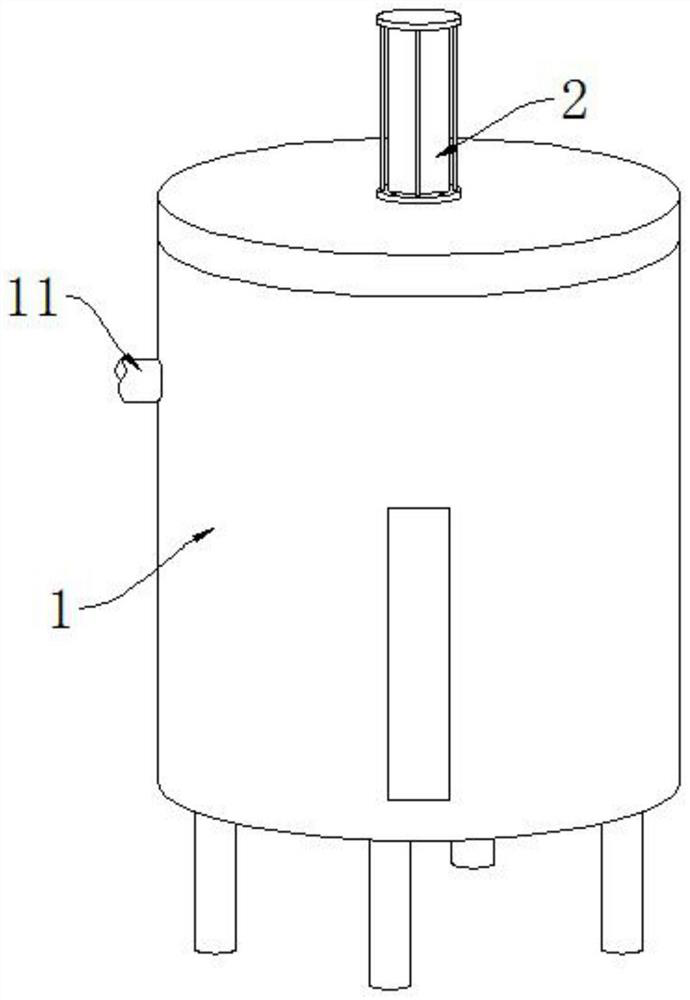

Full-automatic magnetic chamfering grinding device

ActiveCN109396556AAchieve finishingImprove consistencyElectrical and Electronics engineeringPush out

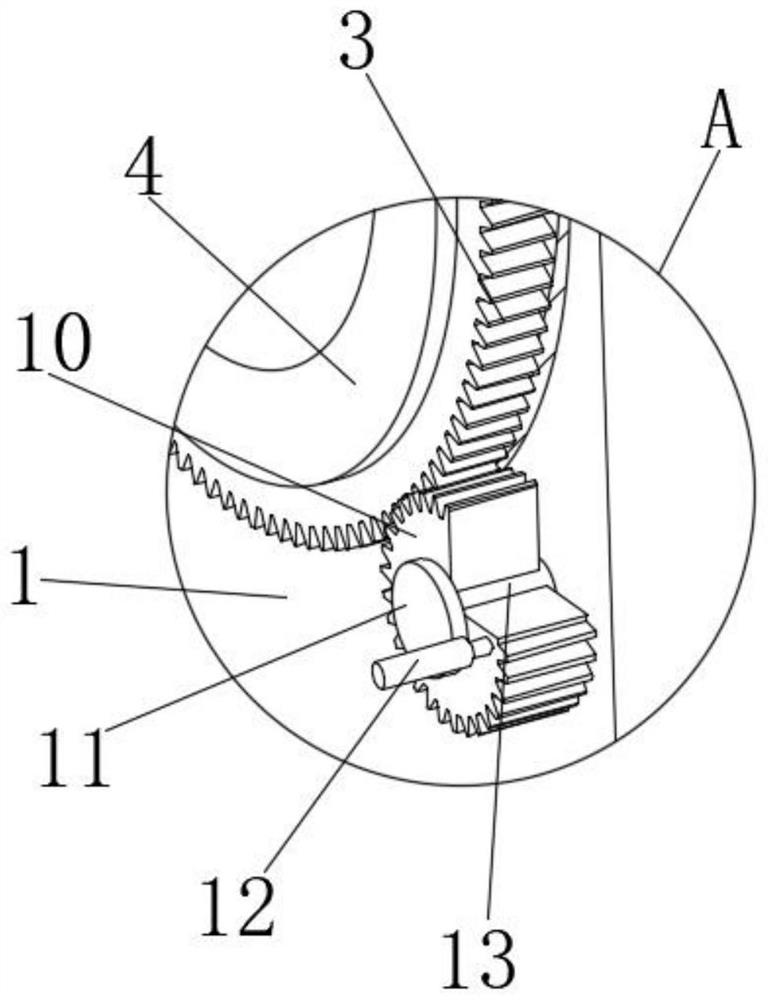

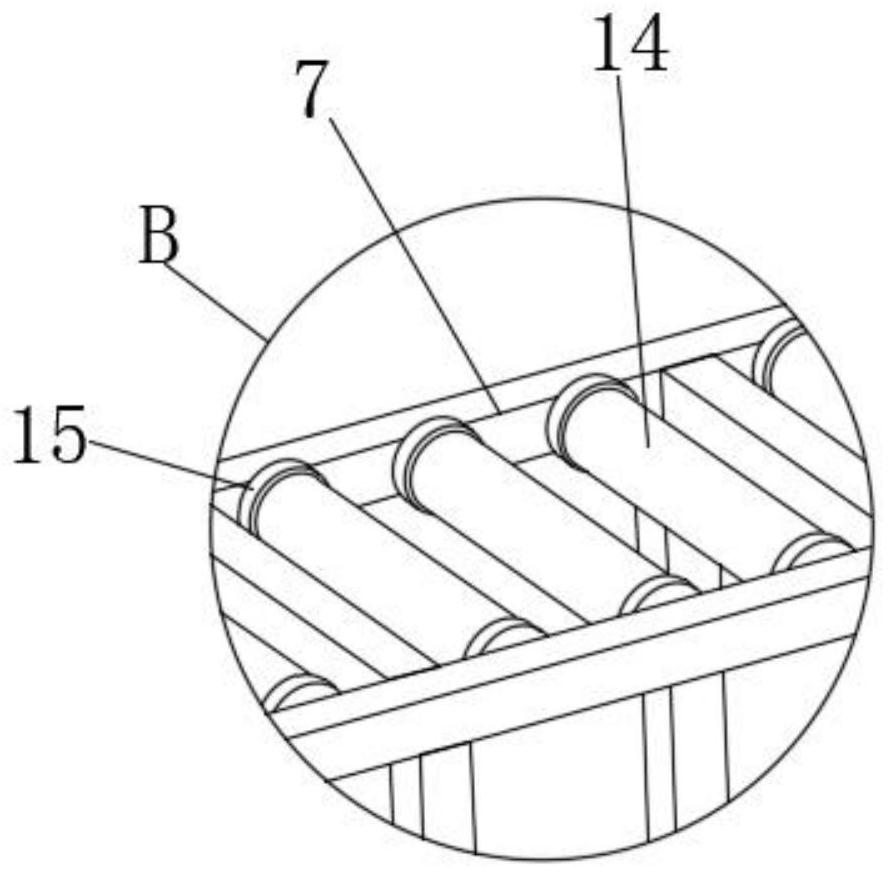

The invention discloses a full-automatic magnetic ring chamfering grinding device. The grinding device comprises a base, a feeding mechanism, a first grinding mechanism, a turnover mechanism, a secondgrinding mechanism and a discharging mechanism, wherein both the first grinding mechanism and the second grinding mechanism comprise chamfering head assemblies and pushing-out assemblies, each chamfering head assembly comprises a main shaft motor, a main shaft support, a power head and a chamfering disc, the main shaft motor is connected with the chamfering disc through the power head, the chamfering disc is provided with two chamfering tool mounting blocks, through holes are formed in the two chamfering tool mounting blocks, a transverse hole is formed in the chamfering disc, the two chamfering tool mounting blocks are matched with the positions of the inner ring and the outer ring of the magnetic ring respectively and are fixed by screws, a limiting block is arranged below the chamfering head assembly, and the cross section height of the limiting block is lower than the magnetic ring; the push-out assembly comprises a push-out air cylinder and a push-out block which are used to pushout the magnetic ring. The device has the advantages and effects that the inner rings and the outer rings of the two end surfaces of the magnetic ring can be chamfering ground, the labor is saved, and the production efficiency is improved.

Owner:WENZHOU POLYTECHNIC

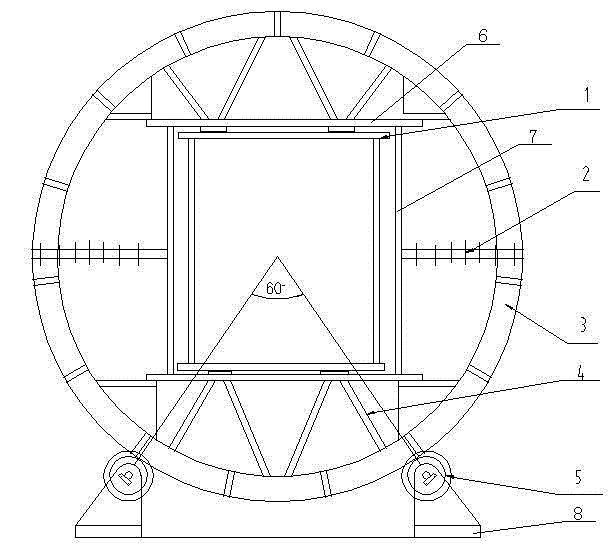

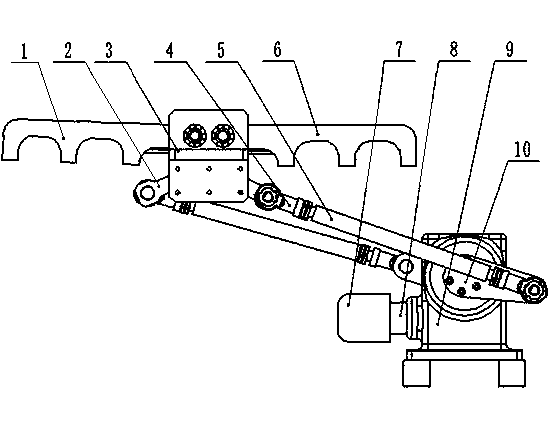

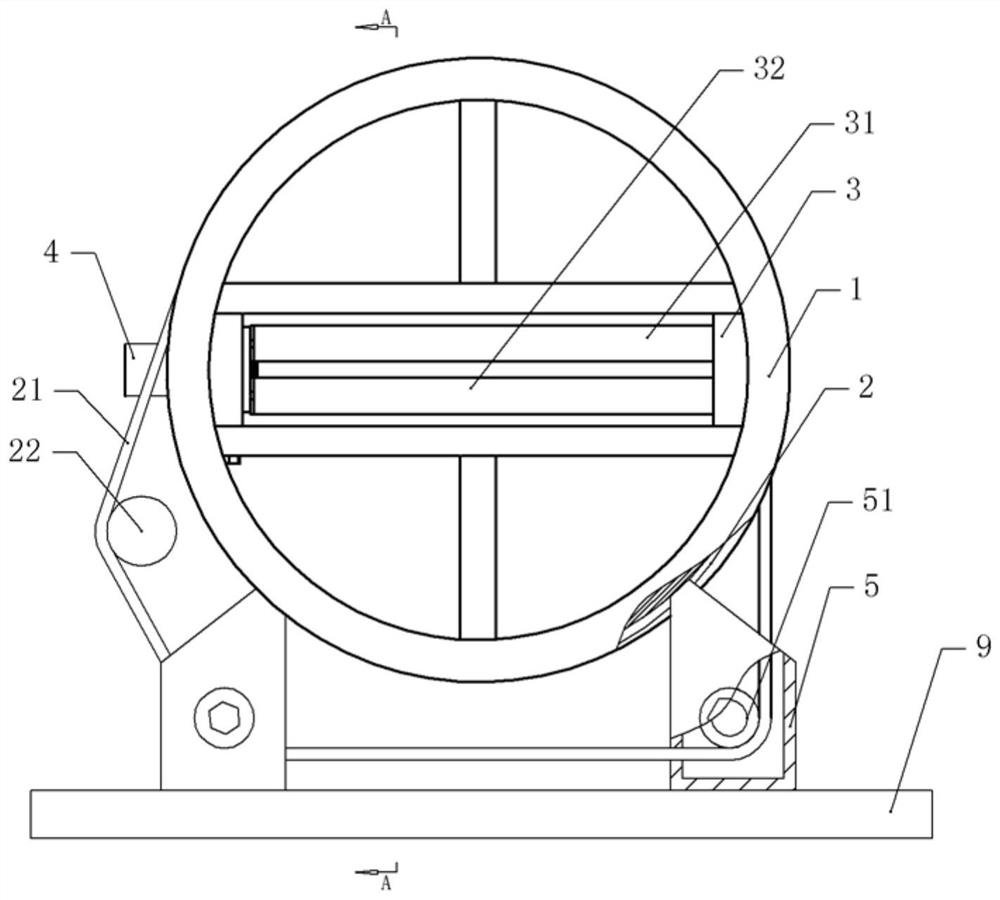

Roll-over stand for welding girder of crane

InactiveCN103331556AAchieve the purpose of flippingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a roll-over stand for welding a girder of a crane, which comprises a longitudinal supporting plate and a transverse supporting plate, wherein the longitudinal supporting plate is used for fixing the girder and is fixed on a roll-over ring through a V-shaped rib plate; the transverse supporting plate is fixed on the roll-over ring; two supporting wheels on two roll-over supports are matched in a rolling manner; the two supporting wheels are in rotational connection with the two roll-over supports respectively. According to the invention, as the girder is fixed in the roll-over ring in rolling connection with the supporting wheels on the two roll-over supports, and the roll-over ring rolls on the supporting wheels on the roll-over supports to realize the purpose that the girder overturns during welding, the welding efficiency and quality are greatly improved after the girder is overturned by the roll-over stand instead of a rope.

Owner:无锡国电华新起重运输设备有限公司

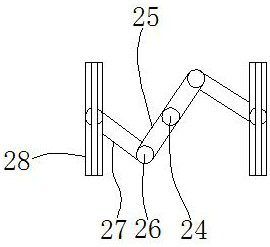

Split frame type electric cake overturning machine

The invention relates to a mechanism for overturning cake-shaped materials and provides a split frame type electric cake overturning machine. The split frame type electric cake overturning machine comprises a servo motor, a speed reducer, cranks, a connecting rod, a drive connecting rod and an overturning body, wherein the overturning body is of a split frame type structure and consists of two independent frame type turning plates. The turning plates are fixed on two side plate through rotary shafts, an input shaft of the speed reducer is connected with the servo motor through a coupler, and two-side output shafts of the speed reducer are respectively connected with two cranks. One end of the connecting rod is connected onto the cranks through a knuckle bearing, the other end of the connecting rod is connected onto the drive connecting rod through a knuckle bearing, and the drive connecting rod is connected with the turning plates of the overturning body. The split frame type electric cake overturning machine can achieve quick overturning and resetting of a spoke cake and can achieve cake transfer between two turning plates of the overturning body through closing-up and separation of the turning plates of the overturning body.

Owner:WUHAN FENJIN INTELLIGENT MACHINE CO LTD

Novel tea leaf drying machine

InactiveCN105444553AEvenly heatedAchieve the purpose of flippingPre-extraction tea treatmentDrying gas arrangementsAgricultural engineeringTea leaf

The invention discloses a novel tea leaf drying machine which comprises a machine body and a drying device. The drying device is arranged in the machine body. A groove is formed in one side of the inner wall of the machine body. A telescopic rod is fixedly arranged in the groove. A horizontal telescopic device is fixedly connected to the telescopic rod through a fixing block. Vertical telescopic devices are fixedly arranged at the bottom of the inner wall of the machine body. An object containing plate is arranged at the top of one vertical telescopic device and arranged below another vertical telescopic device. The surface of the object containing plate is provided with holes. According to the novel tea leaf drying machine, the two vertical telescopic devices and the horizontal telescopic device are arranged, the object containing plate is inclined through the different extension degrees of the two vertical telescopic rods, tea leaves move to the two edges and spread out through the horizontal telescopic device, and the turning purpose is achieved so that the tea leaves can be evenly heated.

Owner:无锡市茗雅东方茶艺科技有限公司

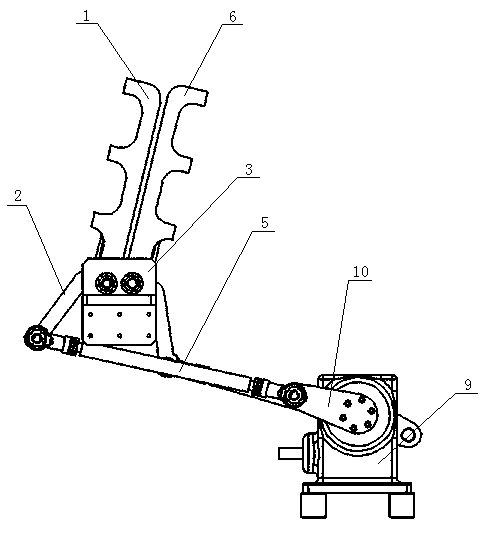

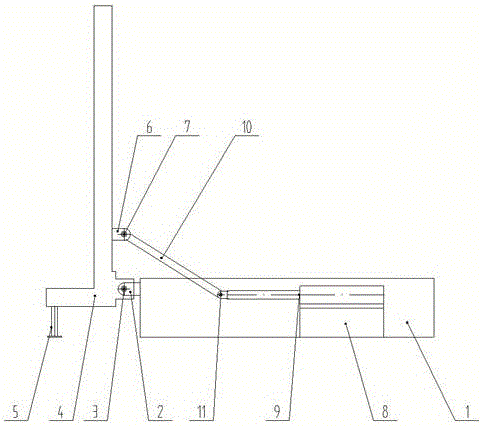

Oil cylinder connecting rod-driven overturning device

InactiveCN106241682ASimple structureEasy to useLifting devicesFluid-pressure actuatorsPetroleum engineering

The invention discloses an oil cylinder connecting rod-driven overturning device. The oil cylinder connecting rod-driven overturning device comprises a fixed bed body device, an overturning bed body device and an overturning device; a fixed bed body, a first connecting seat, a first rotating shaft and a supporting frame are arranged on the fixed bed body device; an overturning bed body, a supporting bolt, a second connecting seat and a second rotating shaft are arranged on the overturning bed body device; a connecting rod, a third rotating shaft and an oil cylinder are arranged on the overturning device. The oil cylinder connecting rod-driven overturning device is convenient to use; compared with the prior art, the connecting rod is driven to move through the hydraulic oil cylinder and the third rotating shaft, the overturning bed body rotates around the first rotating shaft under the actions of the connecting rod, the second rotating shaft and the second connecting seat, and the supporting bolt is in contact with the ground to achieve the purpose of overturning, so that the overturning bed body can be toppled by unloading the hydraulic oil cylinder; therefore, an expected purpose is achieved.

Owner:朱洪闯

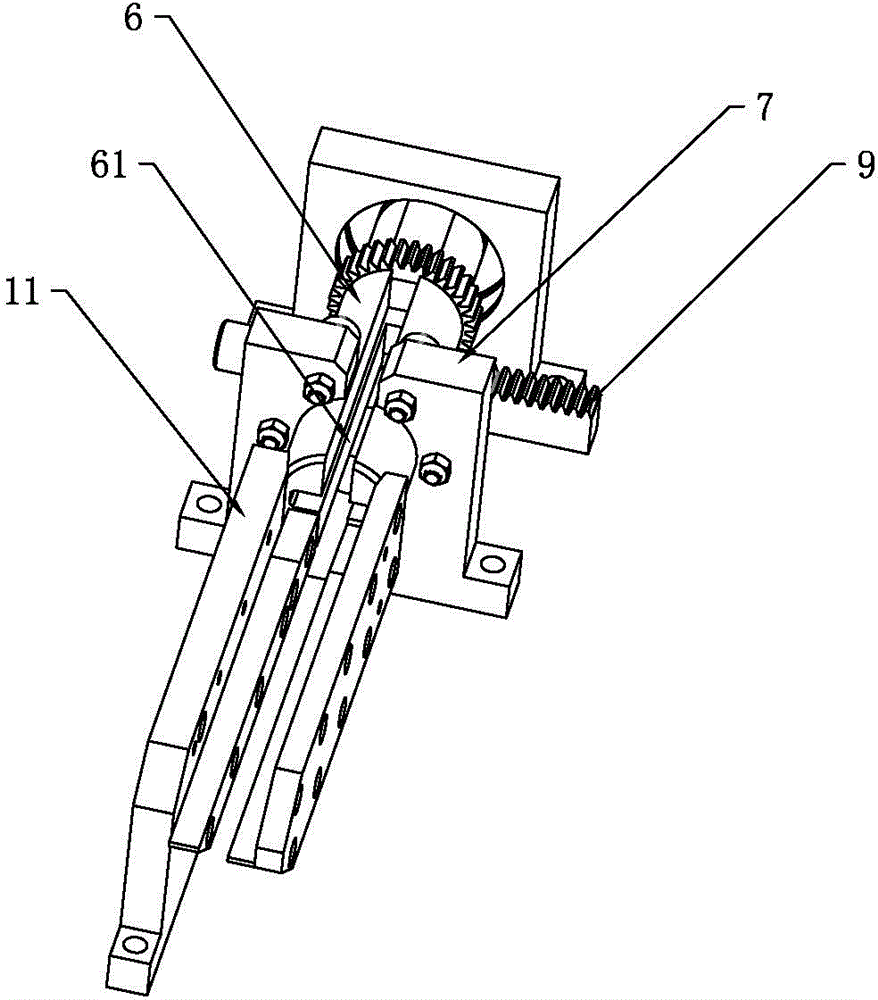

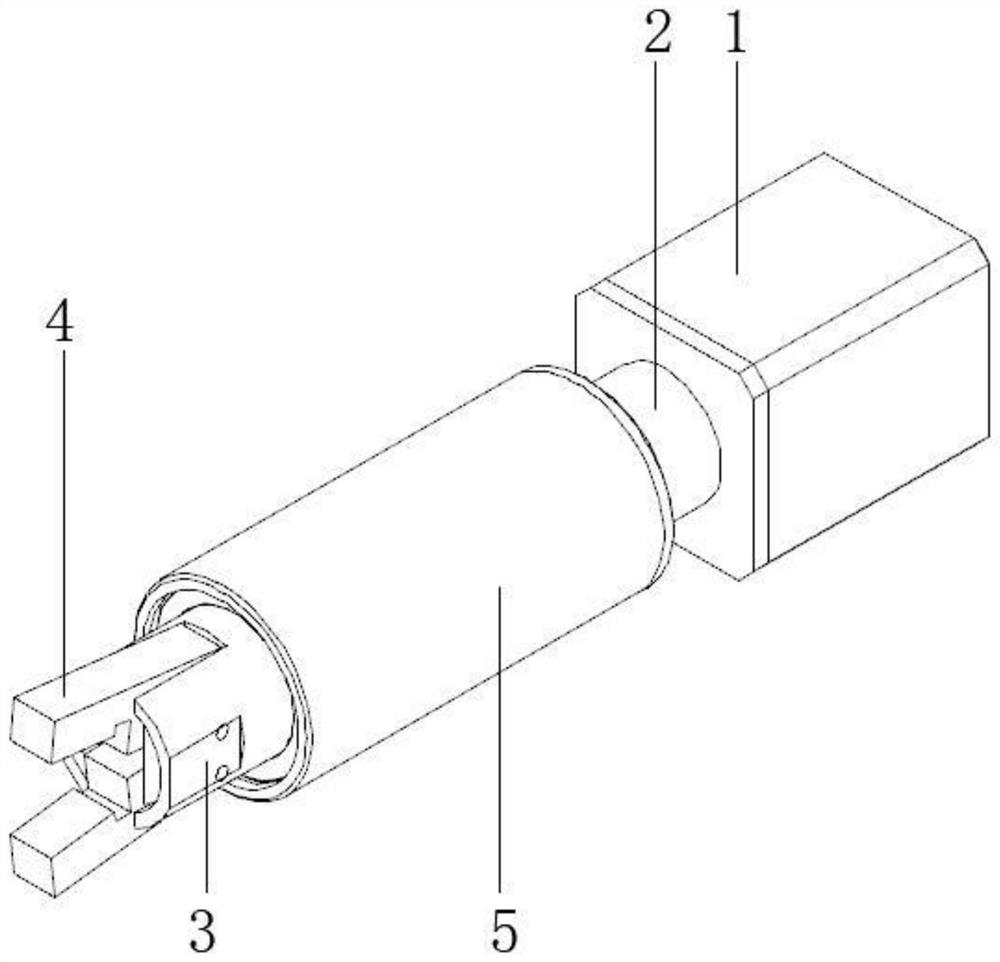

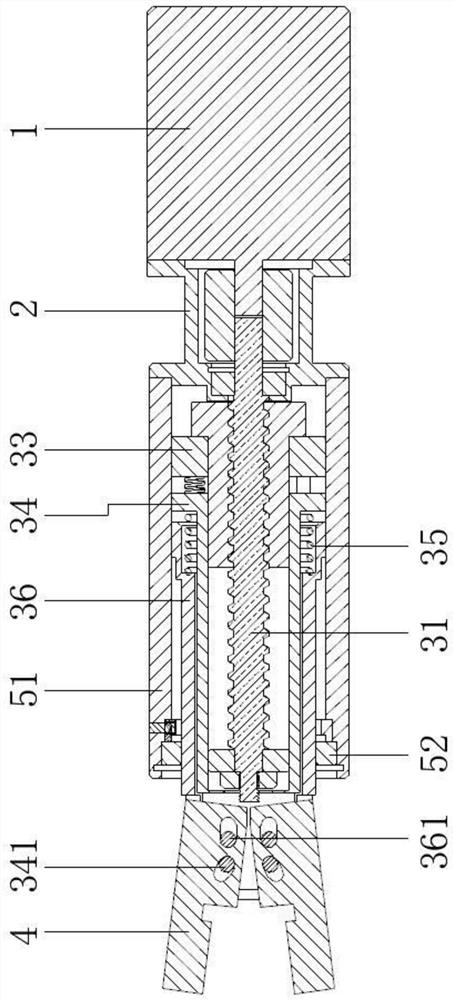

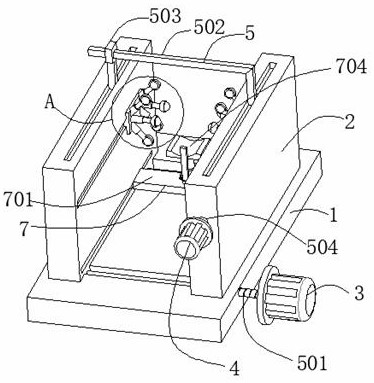

Clamp driven by motor

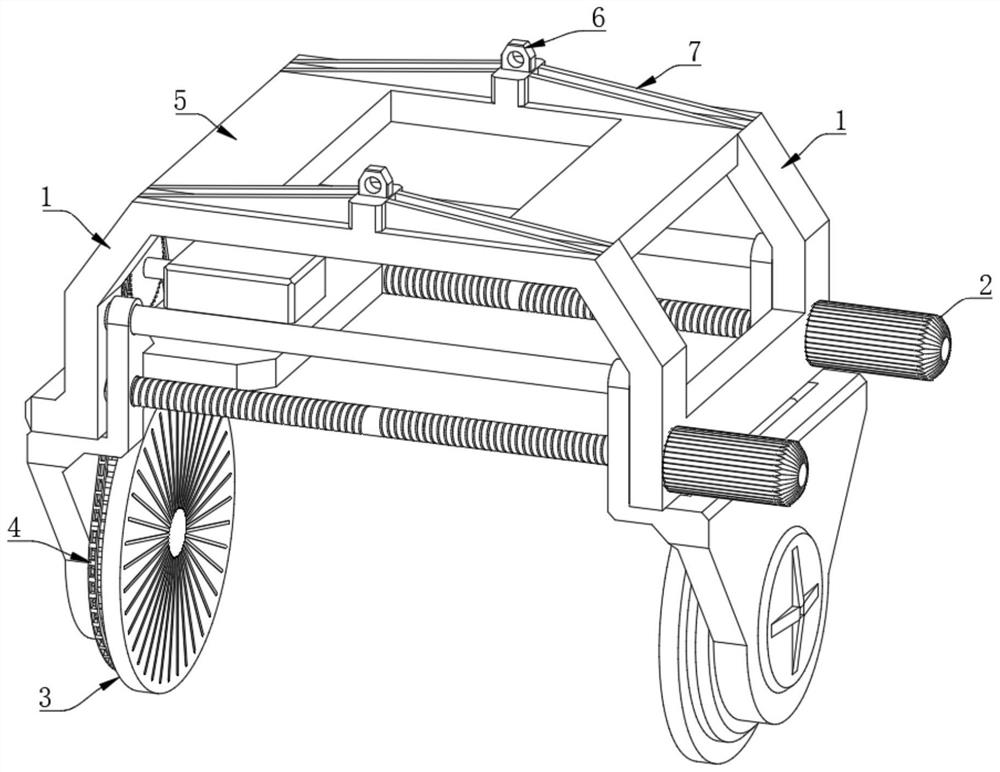

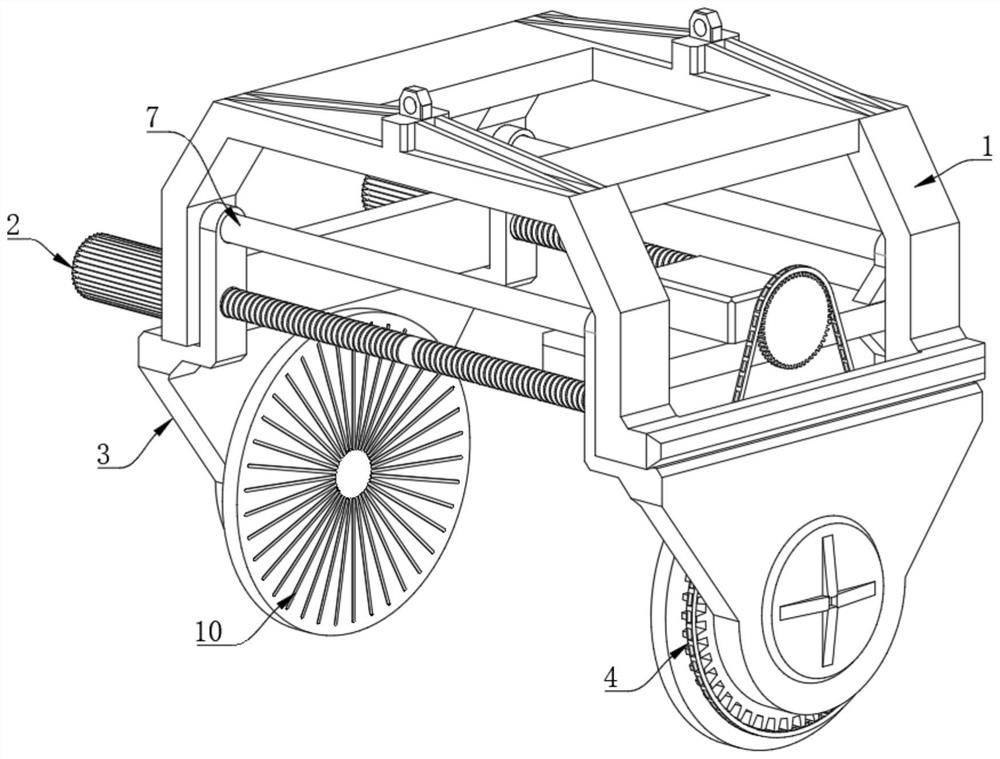

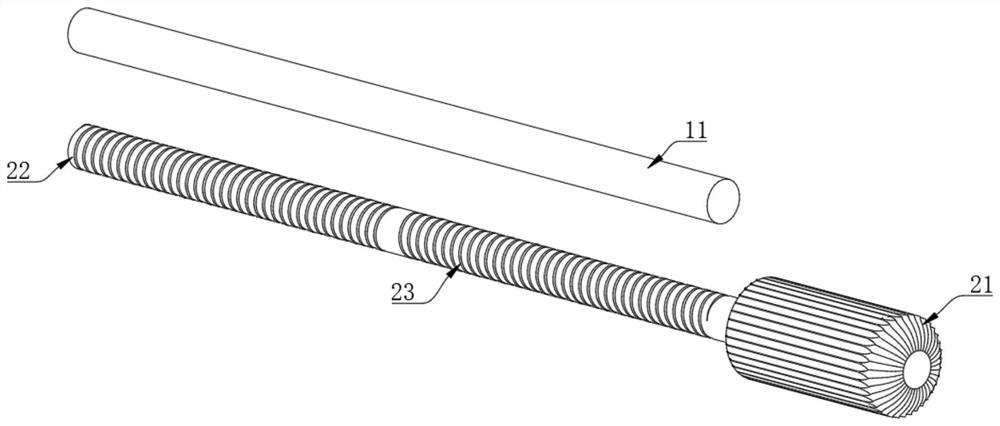

ActiveCN113021056AAchieve the purpose of flippingResolution timeFinal product manufactureMetal working apparatusLinear motionElectric machinery

The embodiment of the invention provides a clamp driven by a motor, and belongs to the technical field of clamping devices. The clamp driven by the motor comprises the motor; an action mechanism, wherein the action mechanism comprises a lead screw; a lead screw sleeve, wherein the lead screw sleeve is arranged on the lead screw in a threaded connection and sleeving manner; a pushing assembly, wherein the pushing assembly comprises a first moving part and a second moving part, wherein the second moving part is movably connected with the first moving part, and in addition, an elastic space is formed between the second moving part and the first moving part; and a clamping jaw, wherein the clamping jaw is respectively connected with the first moving part and the second moving part. The lead screw sleeve acts on the pushing assembly, the clamping jaw is in a clamping state through change of the relative position between the first moving part and the second moving part, advancing of the lead screw sleeve is limited through a lead screw bearing, linear motion of the lead screw sleeve is changed into turnover motion, and the lead screw sleeve can indirectly drive the clamping jaw to conduct turnover motion. The technical effect of executing the whole set of operation actions by using the single motor is achieved.

Owner:杨其建

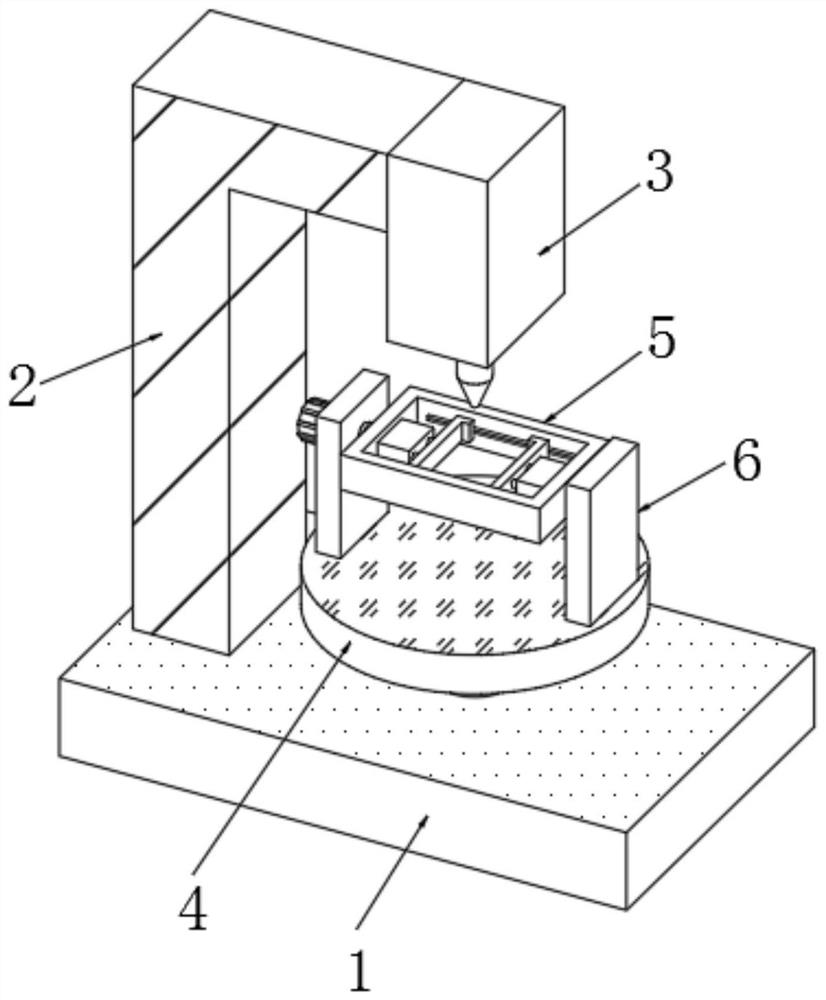

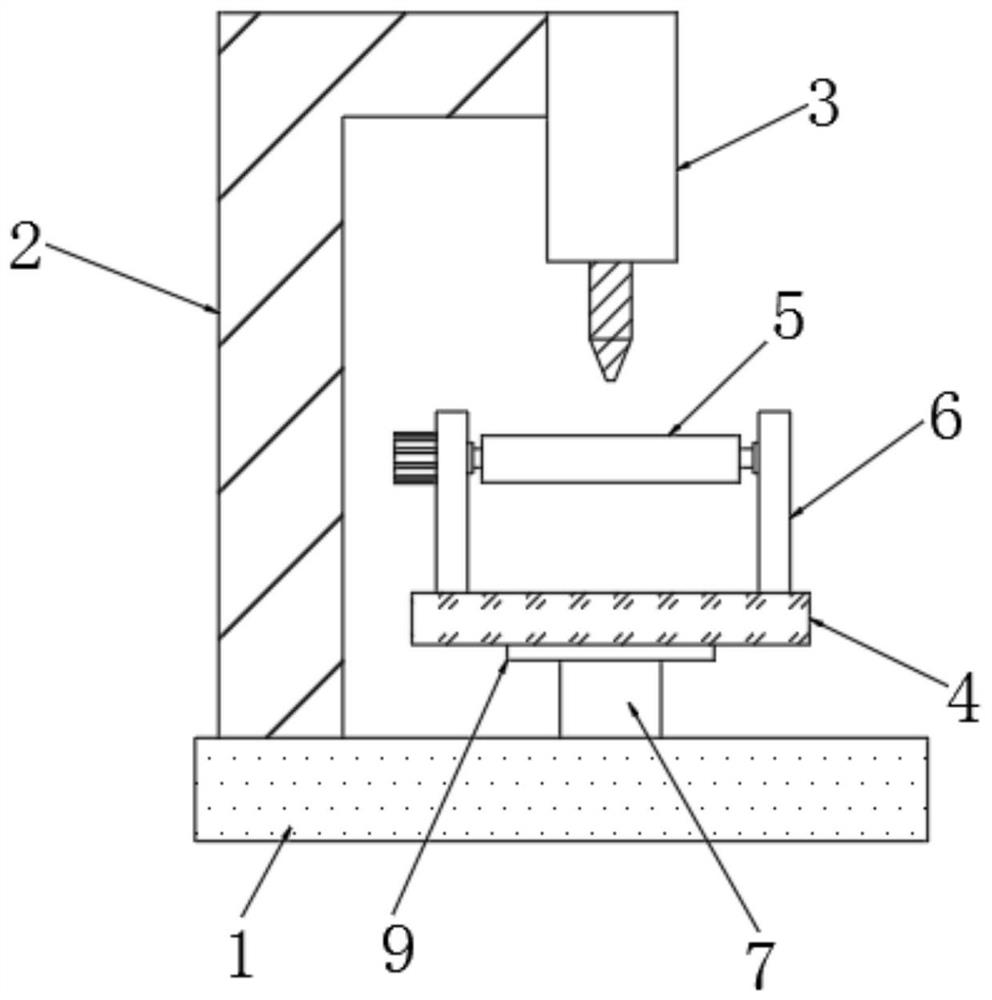

Drilling equipment for hydraulic valve part machining treatment

InactiveCN111872439APracticalImprove drilling accuracyWork clamping meansLarge fixed membersPhysicsDrill hole

The invention discloses drilling equipment for hydraulic valve part machining treatment, and relates to the technical field of hydraulic valve machining. The drilling equipment comprises a base, a rotary disc is arranged above the base, a fixing mechanism is arranged above the rotary disc, a turnover mechanism is arranged at the outer side of the fixing mechanism, and the turnover mechanism is used for driving the fixing mechanism to turn over. The drilling equipment for hydraulic valve part machining treatment is reasonable in structure and easy to operate, through the arranged fixing mechanism, fixing work of hydraulic valve parts can be directly achieved, convenience is provided for drilling work of the drilling equipment, the fixing mechanism can be suitable for fixing treatment of parts of different sizes, the practicability is high, and the drilling precision is effectively improved; and through the arrangement of the turnover mechanism, rotation of the fixing mechanism can be achieved, so that turnover of two to-be-machined parts is achieved, through an arranged rotating mechanism, rotation of the rotary disc can be achieved, rotation of the machined parts is achieved, the automation degree of the parts is improved, and the safety of the device in the using process is guaranteed.

Owner:常德华俊机械设备制造有限公司

Integral die cutting machine of plastic packing box

InactiveCN111452136AReduce volumeSmoothly fall intoMetal working apparatusStructural engineeringWaste material

The invention relates to an integral die cutting machine of a plastic packing box. The integral die cutting machine of the plastic packing box comprises a workbench, a belt conveyor, a die cutting device and a collection device. The belt conveyor is mounted at the upper end of the left side of the workbench, the die cutting device is mounted at the right end of the belt conveyor, and the collection device is mounted at the lower end of the die cutting device. In the integral die cutting machine, the die cutting device is used for cutting the packing box, and a first rotating frame is used forcontrolling the cutting position of the packing box so as to achieve the aim of completing cutting the packing box; through cooperation of a T-shaped column and a large spring, locating plates are located, and the distance between the locating plates is adjusted through a threaded frame; the packing box is cut through a cutting frame; the collection device is used for separating the packing box and the die cutting device; through a suction cup plate and an air inlet pipe, the packing box moves and is finally collected; and through a collection box, waste generated on the packing box after cutting is collected.

Owner:罗嘉宇

Go chess manual display device with turnover function and convenience in display operation

InactiveCN111067311AMeet actual needsAchieve the purpose of flippingShow cabinetsShow shelvesElectric machineDisplay device

The invention relates to a go chess manual display device with a turnover function and convenience in display operation. The device comprises a display table, a containing groove is formed in the display table, a rotating motor is arranged in an accommodating groove, the rotating motor is connected with a rotating disc, a base is arranged at the top of the rotating disc, one end of the base is fixedly connected with an overturning motor, the overturning motor is fixedly connected with a rotating shaft located above the base, the rotating shaft is fixedly connected with a fixing plate, the fixing plate is provided with a through groove penetrating through the fixing plate along the side face of the fixing plate, the fixing plate is provided with two symmetrically-arranged sliding plates located in the through groove, the sides, facing each other, of the sliding plates are integrally connected with racks, the two racks are meshed with a same gear, and the axis of the gear is fixedly connected with an adjusting motor. The display device has the advantage of having a turnover function so as to facilitate display.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH

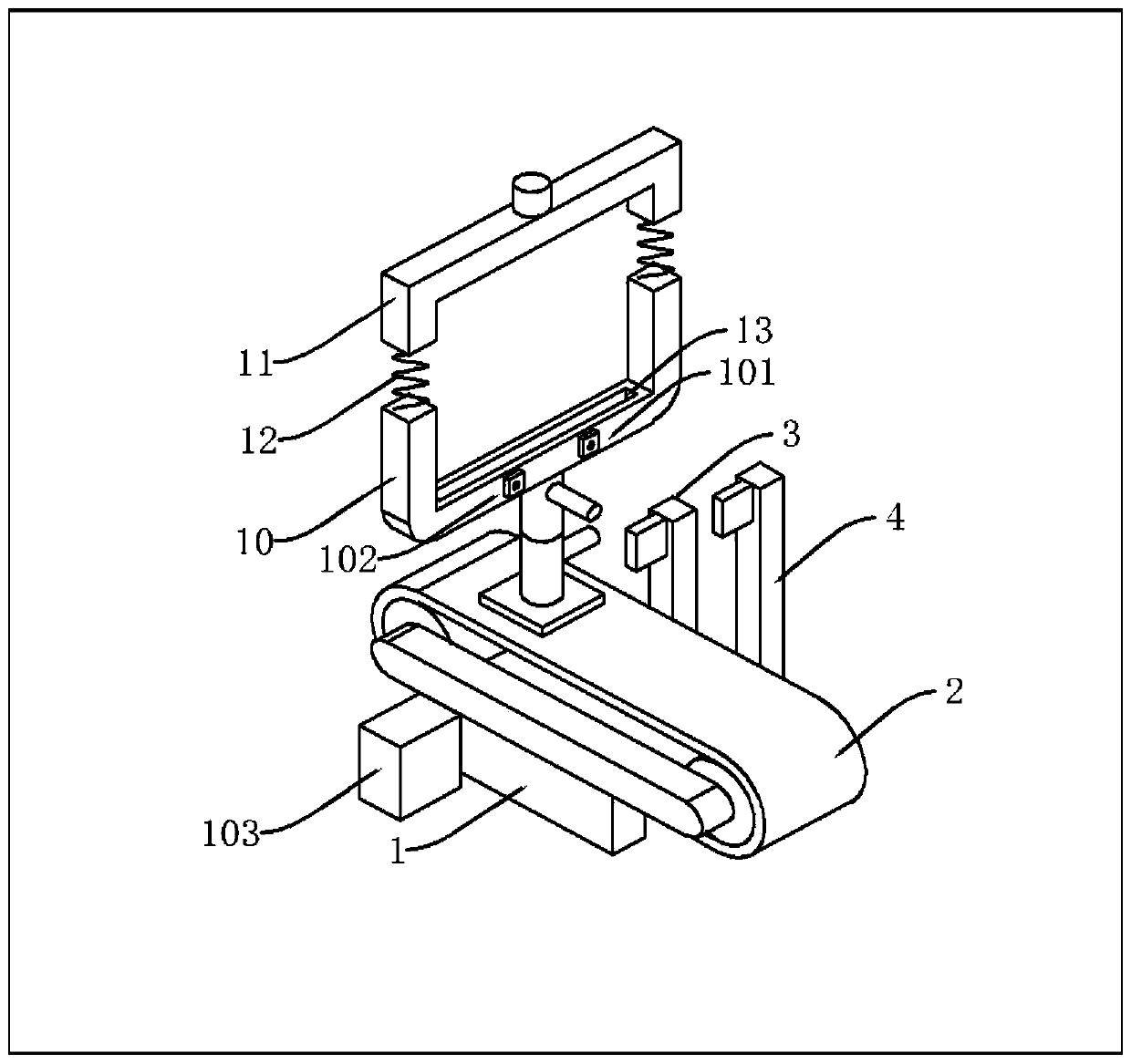

Efficient overturning chip detection and positioning device

InactiveCN111168599AAchieve the purpose of turningEasy to fixWork holdersStructural engineeringMechanical engineering

The invention discloses an efficient overturning chip detection and positioning device and belongs to the technical field of chips. The efficient overturning chip detection and positioning device comprises a support. A belt, a first baffle and a second baffle are arranged on the support. A connecting plate is arranged on the belt, and a first rotating pillar is arranged on the connecting plate. Asecond rotating pillar is arranged on the first rotating pillar. A first long rod and a second long rod are arranged on the first rotating pillar and the second rotating pillar correspondingly. A holding frame is arranged on the top of the second rotating pillar, and a clamping bar is arranged on the holding frame. By means of the efficient overturning chip detection and positioning device, the first rotating pillar can rotate to drive the second rotating pillar to rotate, the second rotating pillar can rotate further so as to drive the holding frame and the clamping bar to rotate, due to twotimes of rotation, the chips fixed to the holding frame and the clamping bar can be overturned, the overturning purpose is achieved, the work efficiency of personnel is improved, and the time cost isreduced.

Owner:佛山普瑞威尔科技有限公司

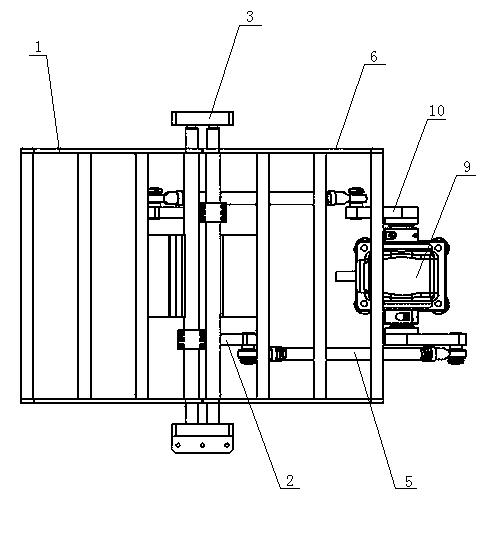

Turnover device driven by screw rod and nut

InactiveCN107539931ASimple structureEasy to useLifting devicesHoisting equipmentsEngineeringDrive motor

The invention discloses an overturning device driven by a lead screw nut, which comprises a fixed bed device, an overturned bed device and an overturning device. The fixed bed device is provided with a fixed bed, a first connecting seat, a first rotating shaft and a support frame; The turning bed device is provided with a turning bed, support bolts, a second connecting seat and a second rotating shaft; the turning device is provided with a fixed head, a lead screw, a motor, a nut, a third rotating shaft and a connecting rod. The structure of the present invention is simple and easy to use. Compared with the prior art, the motor drives the lead screw to rotate, and under the action of the lead screw nut pair and the connecting rod, the turning bed rotates around the first rotating shaft, and the support bolts contact the ground to achieve For the purpose of overturning, reversing the motor can make the overturning bed fall down, so that the expected purpose is achieved.

Owner:何婷

Multifunctional welding overturning device for trailer girder

InactiveCN112338431AEasy to weldAchieve the purpose of flippingWelding/cutting auxillary devicesAuxillary welding devicesGear wheelClassical mechanics

The invention relates to the technical field of overturning devices, in particular to a multifunctional welding overturning device for a trailer girder. The device comprises a supporting frame, wherein reciprocating components are installed at the two ends of the supporting frame, a supporting base is fixed to the upper portions of the reciprocating components, a bearing is fixedly installed in the upper end of the supporting base, and a cylinder is fixed into the bearing. One end of the cylinder extends out of the bearing to be provided with a rotating component, and the other end of the cylinder extends out of the bearing to be provided with a clamping component. A user operates a rocker to enable a gear to rotate, due to the fact that the gear is meshed with a gear ring, when the gear rotates, the gear ring is driven to rotate, then the cylinder is driven to rotate, the girder is driven to rotate through rotation of the cylinder, the overturning purpose is achieved, people can use the overturning device conveniently, and the overturning time is saved; and the working efficiency is improved, and workers can conduct welding more conveniently.

Owner:湖南宏弢科技有限公司

Double-concave special-shaped steel pipe machining equipment with automatic feeding function

InactiveCN112059039ATo achieve the purpose of timing and quantitative dischargeAutomatic Position CorrectionMetal-working feeding devicesPositioning devicesElectric machinerySlide plate

The invention discloses double-concave special-shaped steel pipe machining equipment with an automatic feeding function. The double-concave special-shaped steel pipe machining equipment comprises a base, wherein first supporting plates are installed at the two sides of the lower portion of the base, a first shell is installed at the upper portion of the base, a first hydraulic cylinder is installed at the upper portion of the first shell, and a first hydraulic rod is installed in the first hydraulic cylinder; and a first sliding plate is mounted at the top of the first hydraulic rod, and a rolling wheel is mounted on outer side of first sliding plate. According to the double-concave special-shaped steel pipe machining equipment with the automatic feeding function, by arranging a first motor, a first transmission shaft and a roller, a rotating mechanism is formed, the first motor is started to drive the first transmission shaft to rotate, the roller is driven to rotate, and parts clamped into the groove fall into the first sliding groove and slide to a second workbench along the first sliding groove, so that the purpose of timed and quantitative discharging is achieved.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

Recycling mechanism and deep-fried dough stick preparation machine

PendingCN108541727AAchieve the purpose of flippingRealize the recycling effectBaking ovenOil/fat bakingThermal insulationFixed frame

The invention provides a recycling mechanism and a deep-fried dough stick preparation machine, and belongs to the technical field of food preparing. The deep-fried dough stick preparation machine comprises a push supporting and fixing frame, a driving mechanism, a dough barrel, a thermal insulation box and a controller; the driving mechanism comprises a driver, a lifting push screw, a lifting pushdisk and a transmission rod; a connecting hole is formed in the supporting and fixing frame; the thermal insulation box is installed in the push supporting and fixing frame; the dough barrel is placed in the thermal insulation box; one end of the lifting push screw is connected with the driver; one end of the transmission rod is connected with one end, far away from the lifting push screw, of thedriver; the other end of the transmission rod penetrates through the connecting hole, and is connected with the lifting push disk; the lifting push disk is arranged in the thermal insulation box, andis located above the dough barrel; and the controller is in communication connection with the driving mechanism. The deep-fried dough stick preparation machine is simple in structure, as well as time-saving and labor-saving.

Owner:张永良

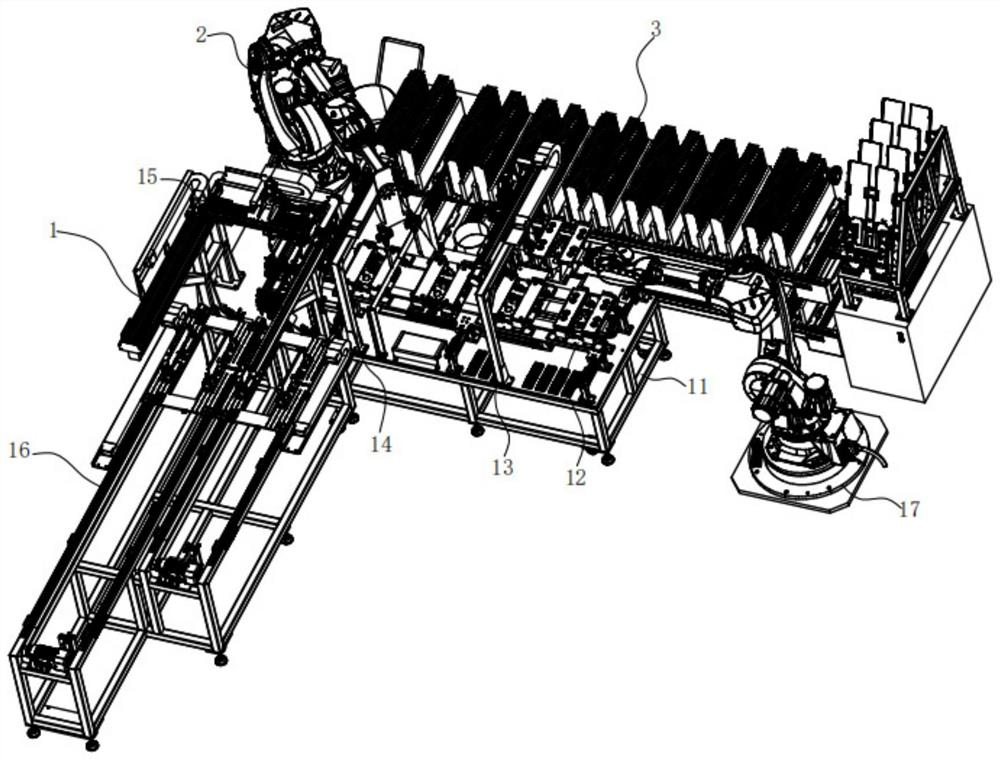

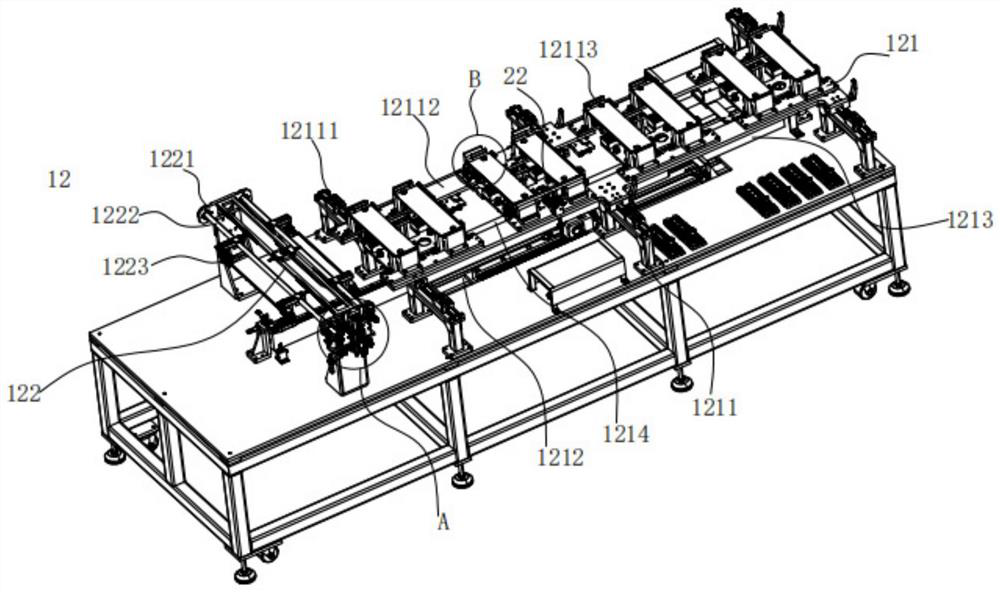

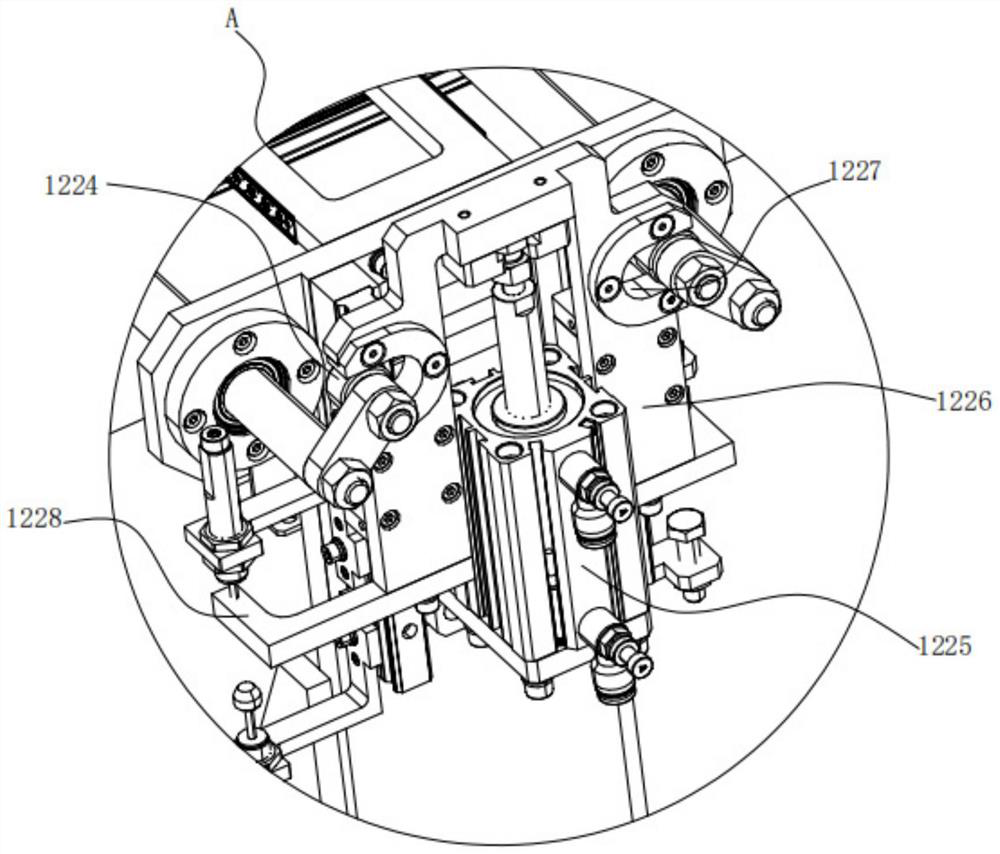

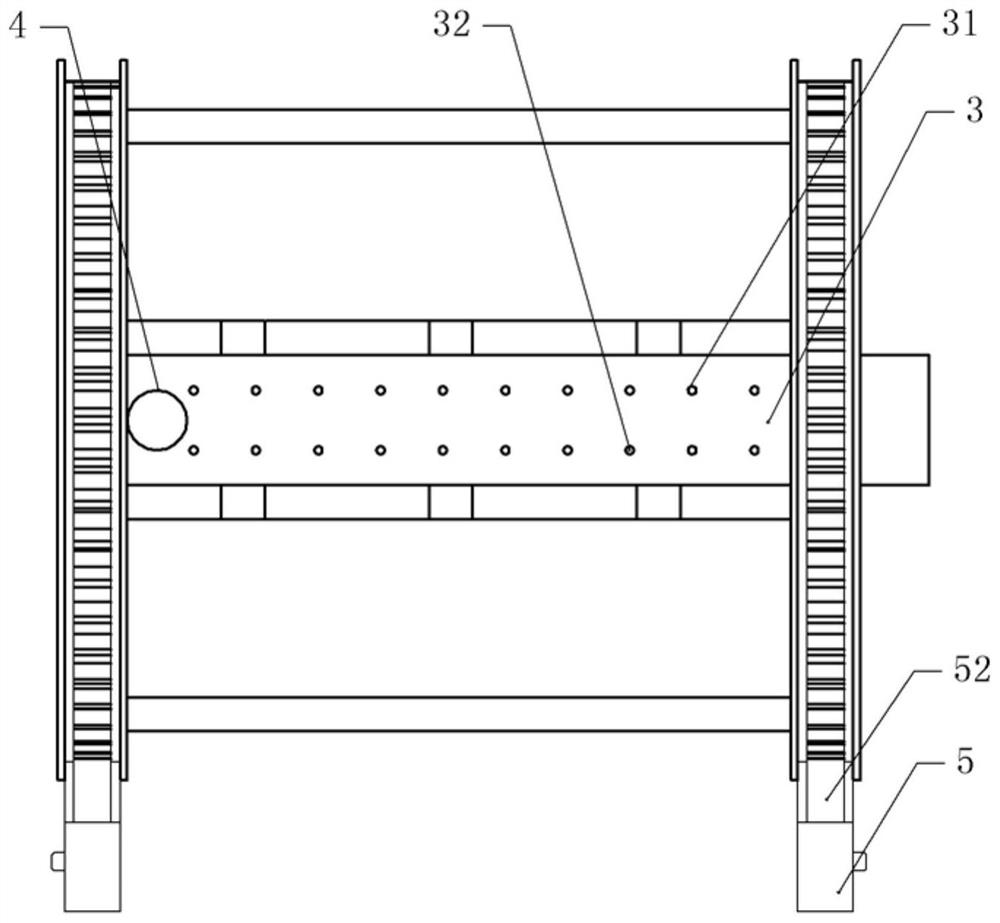

Side plate feeding equipment and gluing and power and free chain conveying equipment

PendingCN114873263AImprove feeding efficiencyImprove delivery efficiencyLiquid surface applicatorsConveyorsStructural engineeringMechanical engineering

The invention provides side plate feeding equipment and gluing and power and free chain conveying equipment. The side plate feeding equipment comprises a side plate conveying operation table; the side plate conveying mechanism comprises a side plate conveying mechanism and a side plate turnover mechanism, is mounted on the side plate conveying operation table and is used for conveying side plates; the side plate cleaning assembly is located above the side plate conveying mechanism and used for cleaning the side plates; through cooperation of the side plate conveying mechanism and the side plate overturning mechanism on the side plate conveying mechanism, conveying of side plates is achieved, the side plate cleaning assembly is arranged on the side plate conveying operation table, the side plates are cleaned in the side plate conveying process, the side plates are photographed through the photographing module, and the side plates are cleaned through the cleaning assembly. The cleaned and glued side plates are conveyed through the discharging gripper and conveyed to the next station through the side plate discharging sliding table, the complete process of cleaning, gluing and feeding of the side plates is achieved, and the feeding and conveying efficiency of the side plates is improved.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

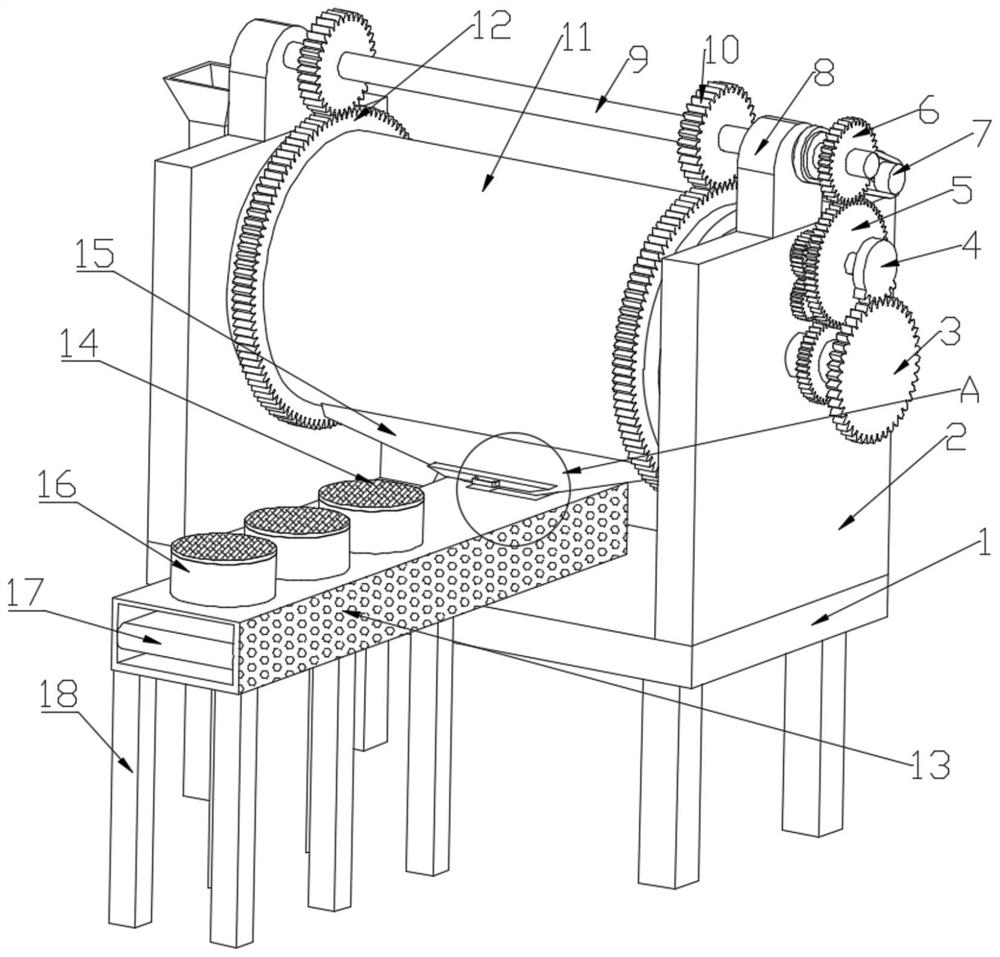

Drying equipment for biological food processing

PendingCN112595061AAchieve the purpose of stirringAchieve the purpose of flippingDrying chambers/containersDrying solid materialsDrive wheelDrive shaft

The invention discloses drying equipment for biological food processing in the field of food forming and drying. The drying equipment comprises a base, a supporting plate is fixedly connected to the upper end of the base, a bearing seat is fixedly connected to the upper end of the supporting plate, a first transmission shaft is rotatably connected into the bearing seat, and a fourth gear, a drivenwheel and a third gear are fixedly connected to the circumferential surface of the first transmission shaft; a first motor is fixedly connected to the upper end of the supporting plate, a driving wheel is fixedly connected to the output shaft end of the first motor, and the driving wheel is connected with the driven wheel through a belt; a first rotating shaft and a second rotating shaft are rotatably connected to the front end of the supporting plate, a fifth gear and a second gear are fixedly connected to the circumferential face of the first rotating shaft, and a first incomplete gear is fixedly connected to the front end of the first rotating shaft; and a sixth gear and a second incomplete gear are fixedly connected to the circumferential face of the second rotating shaft through shafts. According to the drying equipment for biological food processing, the used novel structure is simple in structure and low in manufacturing cost, and the to-be-dried food can be turned over only through simple operation.

Owner:胡松

Door flip device

ActiveCN110624780BReduce manual transportImprove transportation efficiencyLiquid surface applicatorsCoatingsDrive wheelElectric machinery

The invention relates to the technical field of door panel processing, and discloses a door panel turning device, which includes at least two runners, and two adjacent runners are respectively provided with connecting plates arranged in the axial direction of the runners; Between the connecting plates on the side, there are a number of pairs of roller groups uniformly distributed along the axial direction of the runner. For the sprocket, support seats are provided on both sides of the lower part of the runner, and a cavity with an upper opening is arranged in the support seat, the upper end of the support seat extends into the groove and the upper end of the support seat is slidingly connected with the side wall of the groove The cavity is provided with a tensioning wheel that is rotatably connected to the support seat, and one side of the running wheel is provided with a driving wheel, and the running wheel is provided with a chain set on the driving wheel, the tensioning wheel and the main sprocket, and the driving wheel Driven by drive motor. The invention has a simple structure, and the door panel is turned over to improve the working efficiency of turning over the door panel.

Owner:重庆市佳禾家具制造有限公司

Rear cover airtightness detection device for automobile electronic water pump production

InactiveCN112683460APoor air tightnessEasy to detectDetection of fluid at leakage pointEngine sealsStructural engineeringMechanical engineering

The invention discloses a rear cover airtightness detection device for automobile electronic water pump production, and belongs to the technical field of automobile electronic water pump rear cover airtightness detection. The rear cover airtightness detection device for automobile electronic water pump production comprises a rotating frame, a rectangular airtightness detection shell is fixed to the rotating frame, an automobile electronic water pump rear cover detection assembly is connected with a long rod in a sliding mode, an inflation mechanism is connected with the bottom end of the automobile electronic water pump rear cover detection assembly, the left end of the automobile electronic water pump rear cover detection assembly is connected with a pneumatic telescopic mechanism, the pneumatic telescopic mechanism is connected with a shell upper cover sealing structure, and pull ring pre-tightening mechanisms are arranged on the two sides of the shell upper cover sealing structure. According to the invention, the airtightness under each pressure effect can be conveniently detected, the detection effect is good, the function of adjusting parameters is realized, the airtightness or water tightness detection can be carried out on two surfaces of a test piece at the same time through positive and negative pressure testing, and the capability of exploring the hidden injury defect is strong.

Owner:严真诚

Turnover device for automobile part paint spraying

The invention discloses a turnover device for automobile part paint spraying, and relates to the technical field of automobile parts. The turnover device comprises a bottom plate, wherein a first baffle is fixedly connected to the upper surface of the bottom plate, a first rotating device is clamped on the right side face of the first baffle, the right end of the first rotating device is fixedly connected to the left side face of a first extrusion plate, the right side face of the first extrusion plate is fixedly connected to a first frosted plate, the first frosted plate is located on the left side of a second frosted plate, and the right side face of the second frosted plate is fixedly connected to the left side face of a second extrusion plate. According to the turnover device for automobile part paint spraying, through mutual cooperation of a threaded column, a threaded cap, a third bearing, a telescopic rod, a first spring, the first extrusion plate, the first frosted plate, the second extrusion plate and the second frosted plate, an automobile part is driven to rotate, and therefore a worker does not need to take down the automobile part to make a spraying surface smoother; and the work of the worker is facilitated.

Owner:诸暨市创新弹簧有限公司

Cylinder barrel machining center frame with accurate clamping and positioning functions

PendingCN113829261ATo achieve the purpose of clampingAchieve the purpose of flippingWork holdersGear wheelTransmission belt

The invention discloses a cylinder barrel machining center frame with an accurate clamping and positioning function. The cylinder barrel machining center frame comprises a base, a movable plate located at the top end of the base, a first motor arranged on one side of the base and a second motor arranged on one side of the movable plate. By arranging a turnover mechanism, the second motor is started, the second motor works to drive a second lead screw to rotate, the second lead screw rotates to drive a sliding block to move along the outer wall of the second lead screw, at the moment, a second gear located on the outer wall of the sliding block is pushed by a rack, and the second gear rotates; the second gear rotates to drive the first gear, the conveying belt, the rotating block and the rolling wheels to rotate, meanwhile, the other second gear connected with the second gear through a crawler belt also rotates to drive the other rolling wheel to rotate, at the moment, the two rolling wheels rotate to give thrust to materials, and under the action of the balls and the rolling wheels, the cylinder barrel rotates to drive the materials to rotate. The downward end of the cylinder barrel moves to the upper part, so that the purpose of overturning the cylinder barrel is achieved.

Owner:CHANGDE LIANJIA MACHINERY

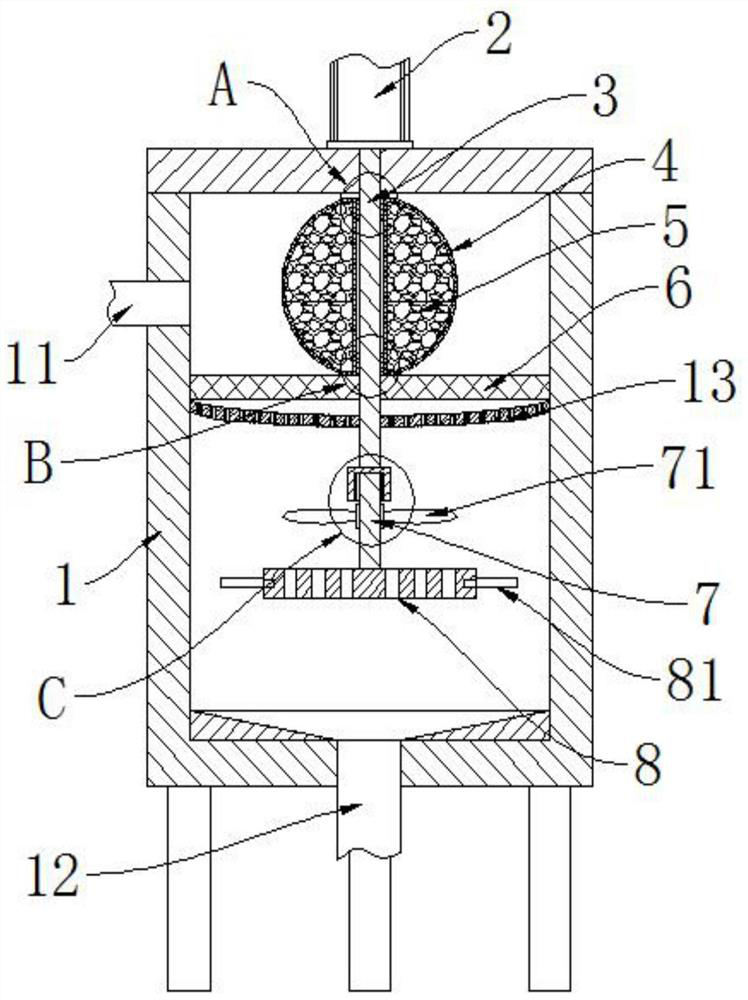

Chemical stirring and mixing system

InactiveCN114534543AAchieve the purpose of flippingEnable mixed jobsRotary stirring mixersTransportation and packagingCircular discEngineering

The invention relates to the technical field of chemical mixing, in particular to a chemical stirring and mixing system which comprises a tank body, the middle position of the upper end of the tank body is fixedly connected with a fixed part of lifting equipment, a movable part of the lifting equipment penetrates through the tank body and is connected with a vertically-arranged main shaft, and the main shaft is located in the tank body; a filter screen is fixedly connected to the upper side in the tank body and slidably connected to the outer end of a main shaft, the outer end of the main shaft is sleeved with a cloth bag, the cloth bag is filled with soft matter and arranged at the upper end of the filter screen, the lower end of the main shaft is rotationally connected with a vertically-arranged connecting shaft, and the lower end of the connecting shaft is fixedly connected with a disc. The lifting equipment is designed, and the main shaft, the connecting shaft and the disc are utilized, so that the stock solution in the tank body generates waves which are transmitted from the center to the outside, on one hand, mixing operation is realized, on the other hand, air can be blown to the filter screen, the purpose of turning over residues blocked at the upper end of the filter screen is achieved, the filter pressing effect is improved, and the resource utilization rate is increased.

Owner:王龙

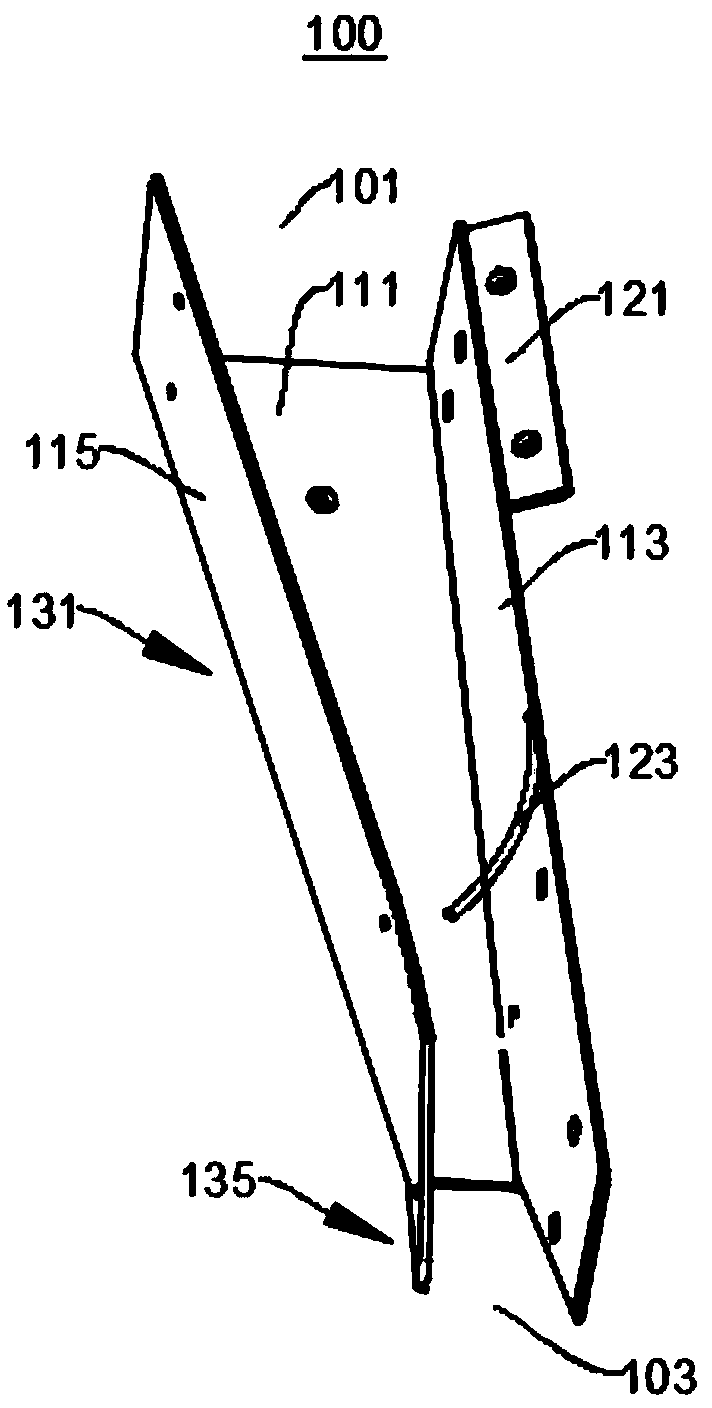

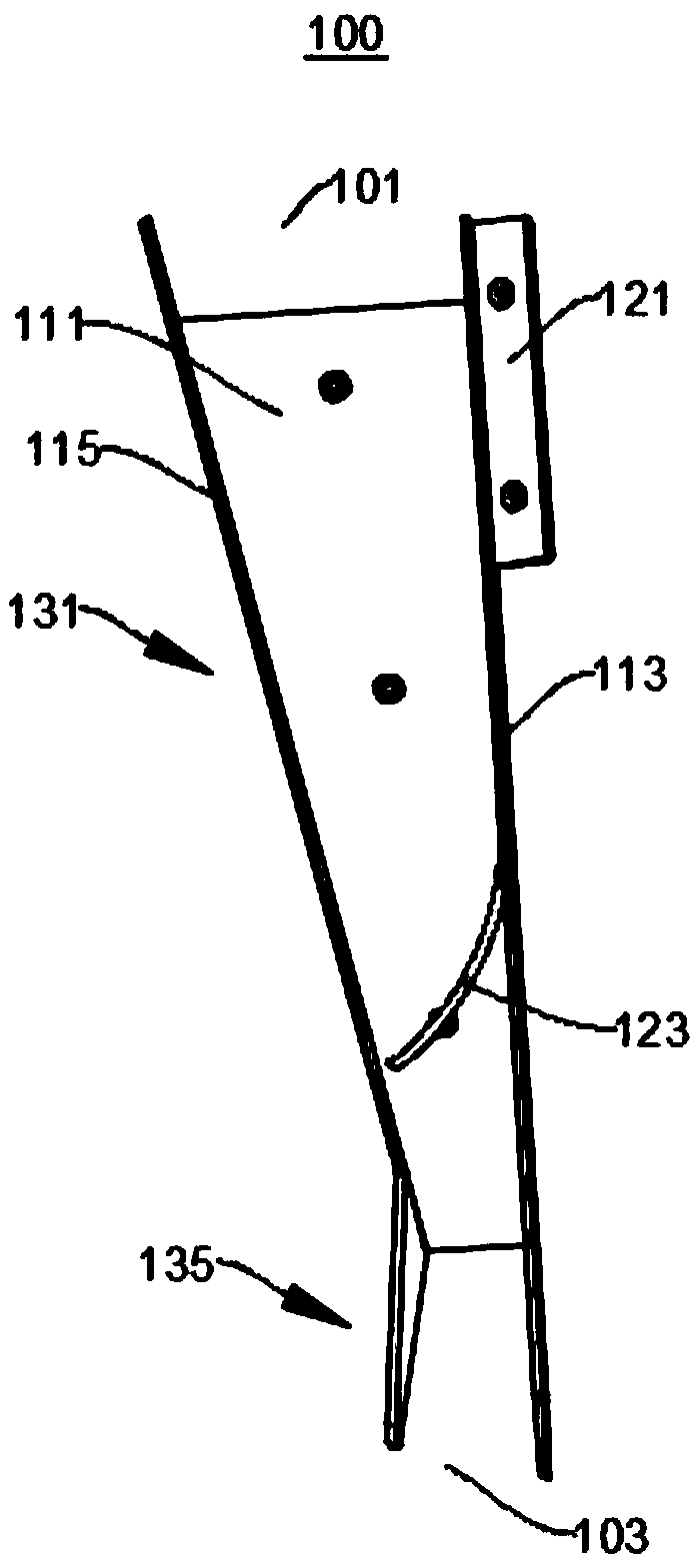

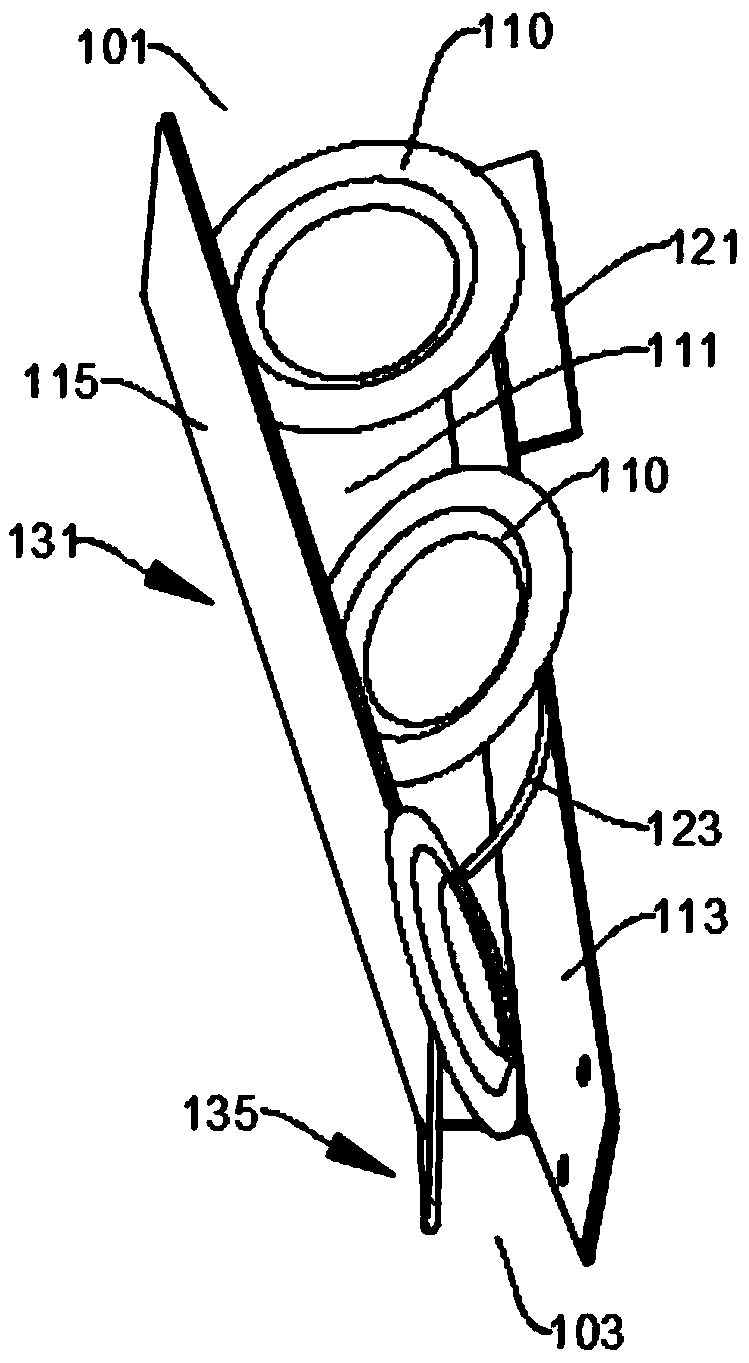

Overturning assembly for hoisted object and hoisting method thereof

PendingCN113979292AGood effectImprove efficiencyLoad-engaging elementsStructural engineeringMechanical engineering

The invention relates to the field of hoisting equipment, in particular to an overturning assembly for a hoisted object and a hoisting method thereof. According to the overturning assembly for the hoisted object and the hoisting method thereof, the overturning assembly comprises: a U-shaped connecting frame, wherein the opening of the U-shaped connecting frame faces downwards in the vertical direction; a clamping mechanism, wherein the clamping mechanism is located in the U-shaped connecting frame, and the clamping mechanism is used for clamping a heavy object; a driving mechanism, wherein the driving mechanism is installed on the armature frame, the driving mechanism is in transmission connection with the clamping mechanism, and the driving mechanism is used for driving the clamping mechanism to move; and an overturning mechanism, wherein the overturning mechanism is installed on the U-shaped connecting frame and the clamping mechanism, and the turnover mechanism is used for driving the clamping mechanism to rotate. According to the overturning assembly for the hoisted object and the hoisting method thereof, the overturning mechanism can drive the hoisted heavy object to rotate, so that the direct contact surface between the heavy object and the ground can be changed, and the situation that the heavy object collides with other objects when falling on the ground can be avoided.

Owner:江苏大力神吊装设备有限公司

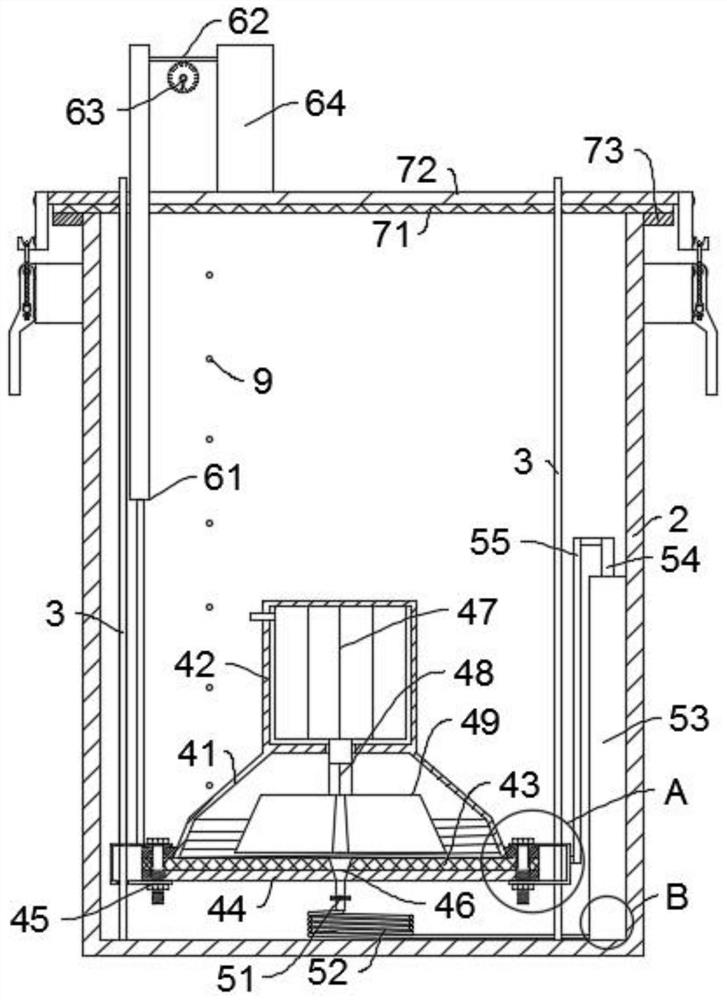

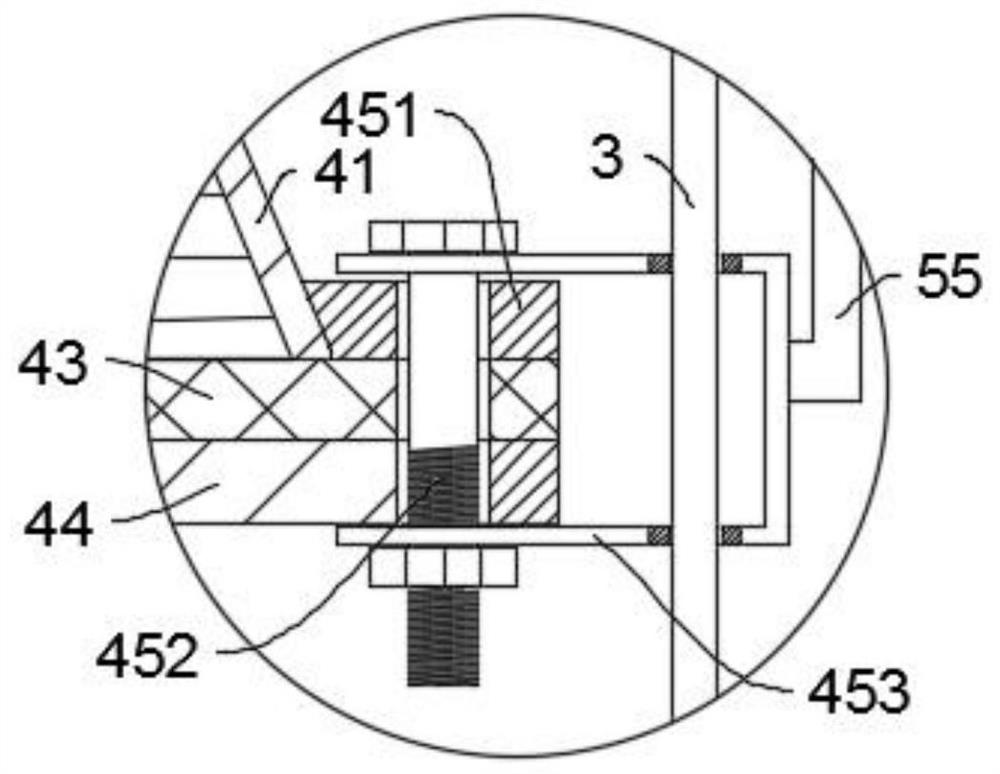

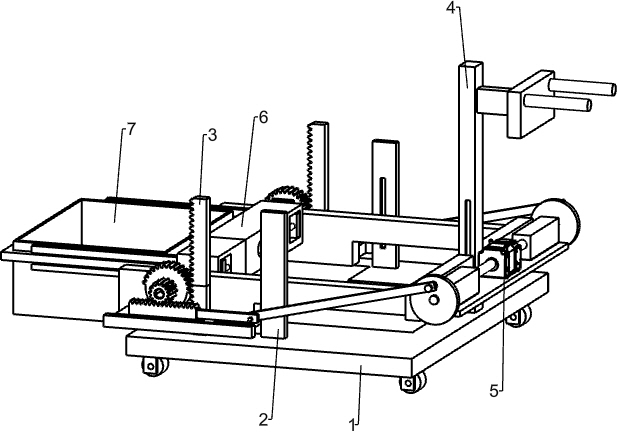

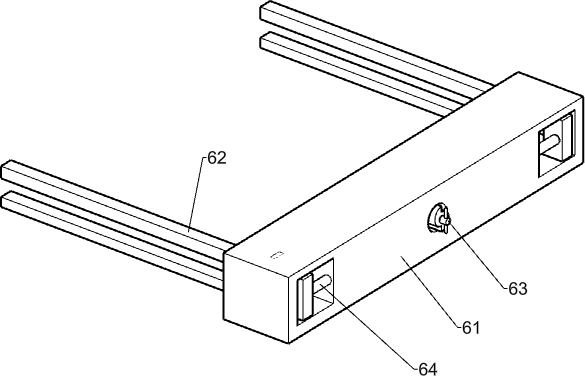

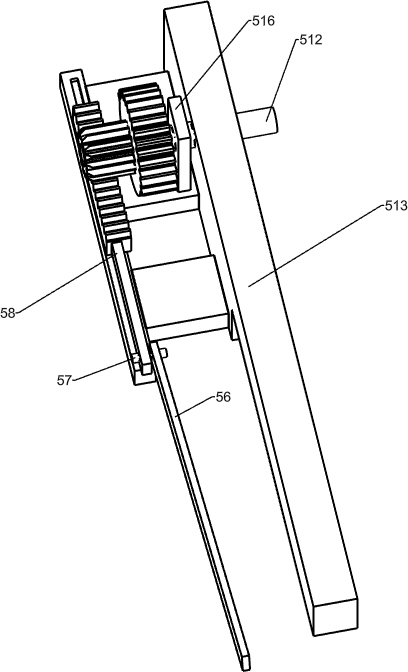

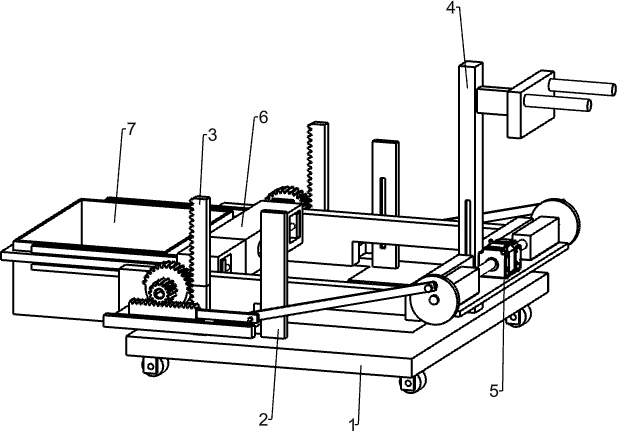

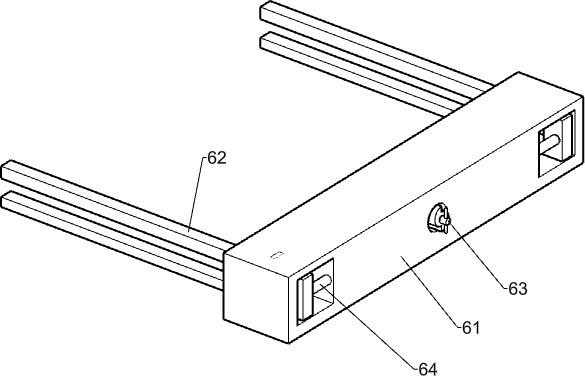

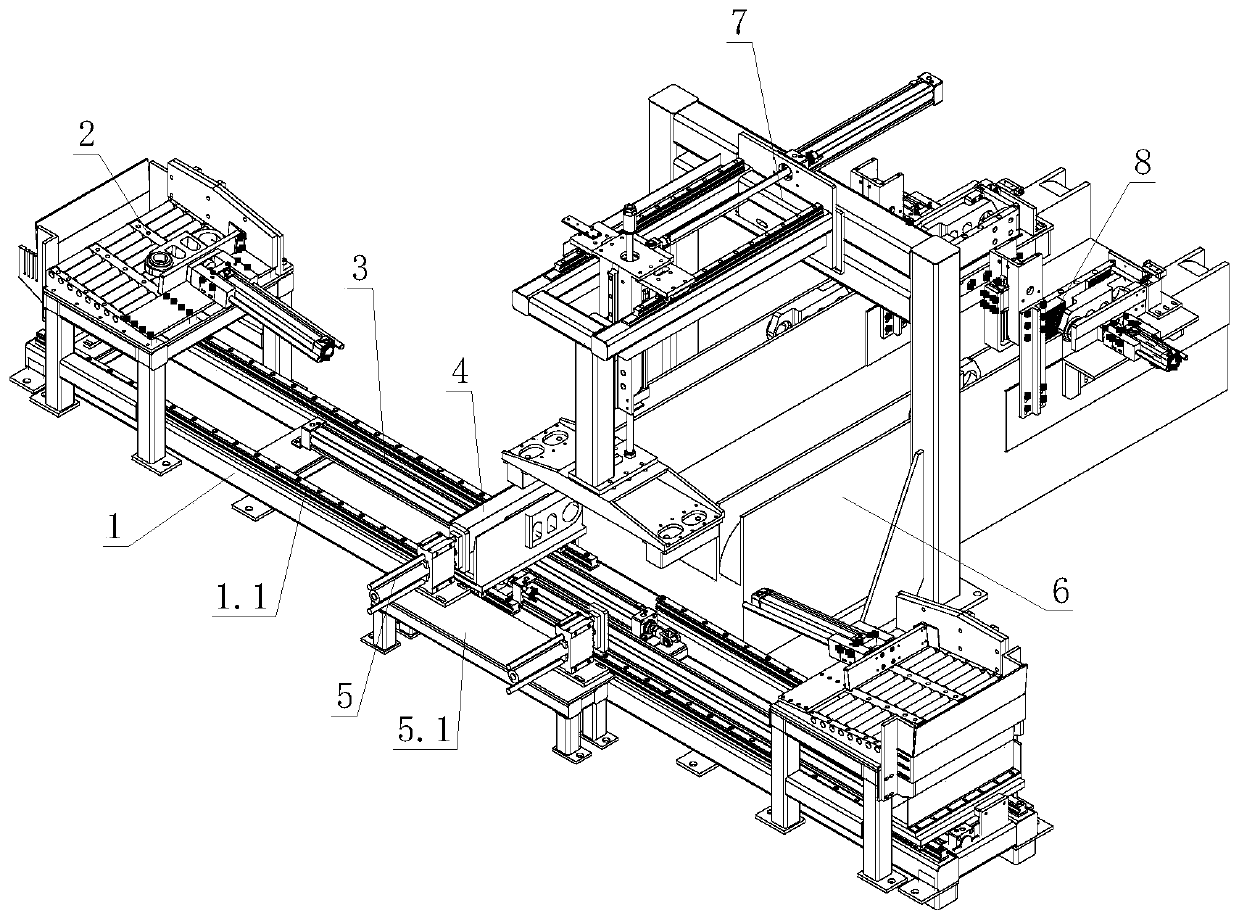

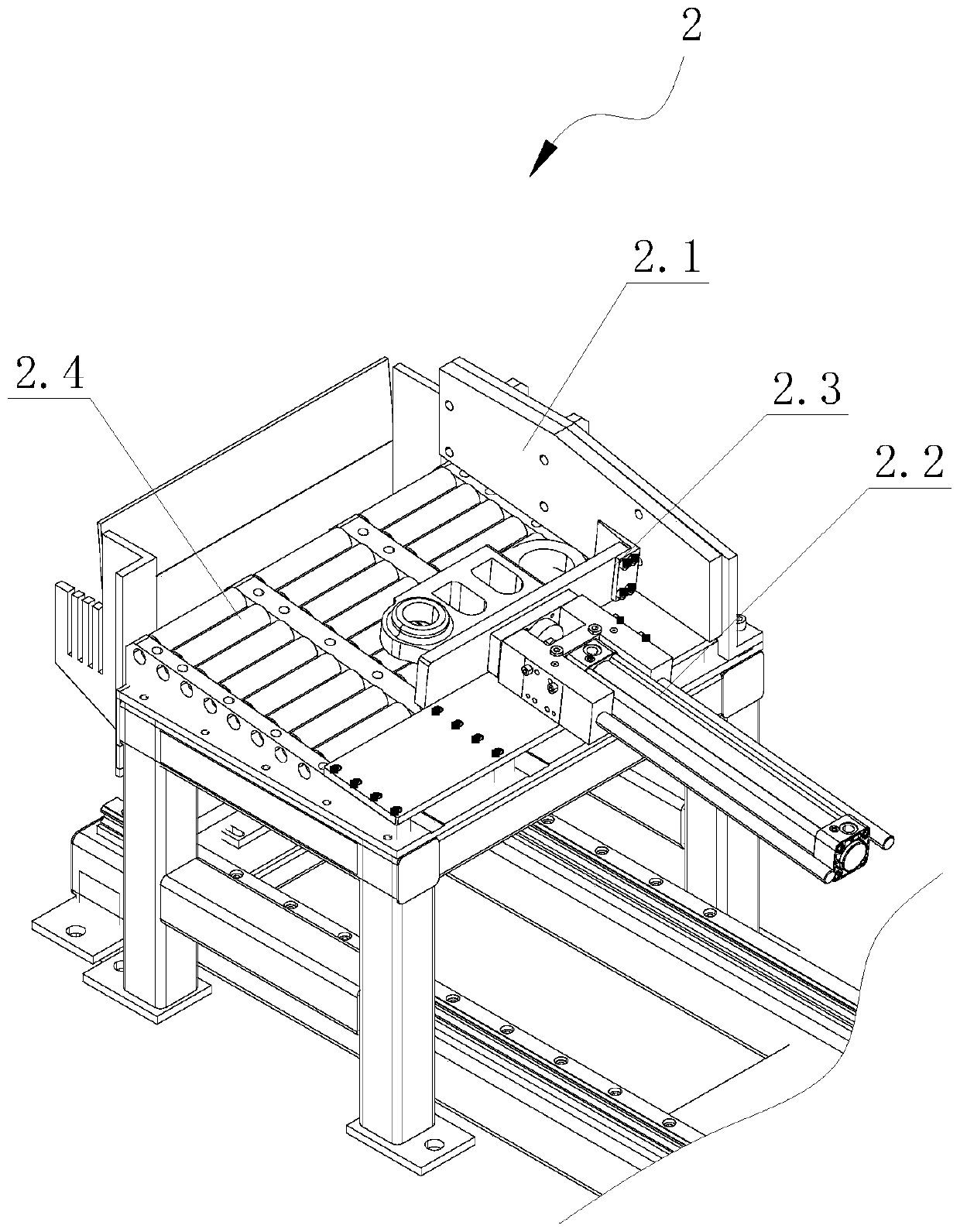

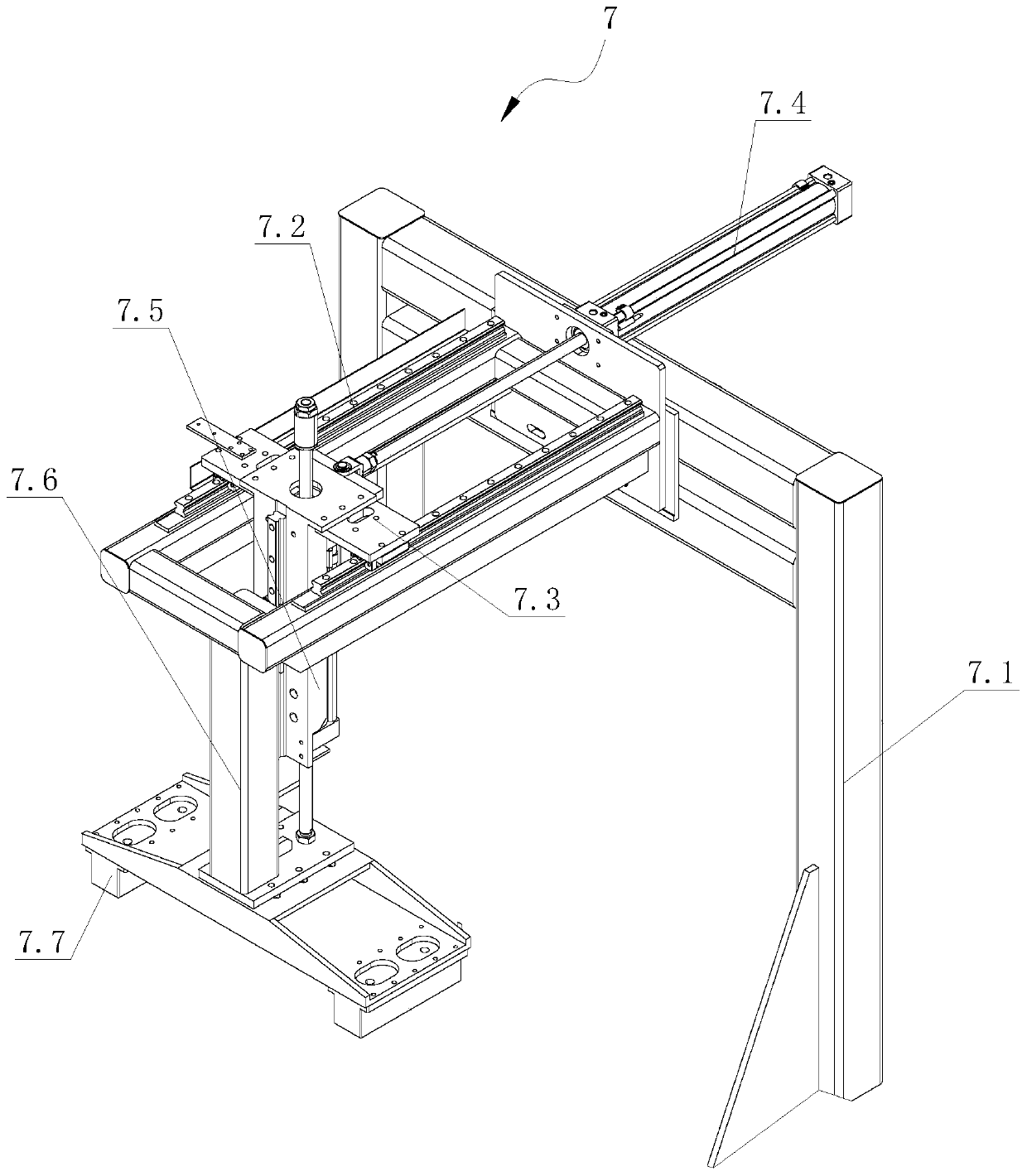

A fully automatic magnetic ring chamfering and grinding equipment that continuously conveys magnetic rings

The invention discloses full-automatic magnetic ring chamfering grinding equipment for continuously conveying the magnetic rings. The full-automatic magnetic ring chamfering grinding equipment comprises a base, a feeding mechanism, a first grinding mechanism, an overturning mechanism, a second grinding mechanism and a discharging mechanism, wherein the first grinding mechanism and the second grinding mechanism both comprise a chamfering head assembly and a pushing-out assembly, the chamfering head assembly comprises a main shaft motor, a main shaft support, a power head and a chamfering disc,the main shaft motor is connected with the chamfering disc through the power head, the chamfering disc is provided with two chamfering tool mounting blocks, through holes are formed in the two chamfering tool mounting blocks, a transverse hole is formed in the chamfering disc, the two chamfering tool mounting blocks are connected the positions of the inner ring and the outer ring of the magnetic ring correspond to each other respectively and are fixed by screws; a limiting block is arranged below the chamfering head assembly, the height of the cross section of the limiting block is lower thanthat of the magnetic ring; and the pushing-out assembly comprises a pushing-out air cylinder and a pushing-out block. The full-automatic magnetic ring chamfering grinding equipment has the following advantages and effects that the inner ring and the outer ring of the two end surfaces of the magnetic ring can be subjected to chamfering and grinding, labor is saved, and production efficiency is improved.

Owner:WENZHOU POLYTECHNIC

Rapid demoulding device for cement block pouring

ActiveCN111633802AImprove efficiencyReduce fatigueDischarging arrangementManufacturing engineeringSpur gear

The invention relates to a rapid demoulding device, and particularly relates to a rapid demoulding device for cement block pouring. The rapid demoulding device for cement block pouring is high in cement block yield and efficiency, the work fatigue of workers is reduced, and the forming rate of cement blocks is guaranteed. According to the technical scheme, the rapid demoulding device for cement block pouring comprises a vehicle plate, first sliding rails, first spur racks and the like, wherein the two sides of the top of the vehicle plate are connected with the first sliding rails; the two sides, connected with the first sliding rails, of the top of the vehicle plate are connected with the first spur racks; and the side, away from the first sliding rails, of the top of the vehicle plate isconnected with a hand push block. Through cooperation of the first spur racks, second spur racks, spur gears and other components, the components on the device move upwards to the proper position, the cement blocks can be conveniently overturned, part of the components on the device are overturned, the aim of overturning the cement blocks is achieved, efficiency is improved, and the work fatigueof workers is reduced.

Owner:梁小芳

A quick demoulding device for cement block pouring

The invention relates to a quick demoulding device, in particular to a quick demoulding device for cement block pouring. The purpose of the present invention is to provide a cement block with high yield and high efficiency, which can reduce the fatigue of workers and ensure the molding rate of the cement block. The quick release device for cement block casting. The technical solution is: a quick demoulding device for cement block pouring, including a car plate, a first slide rail, a first straight rack, etc.; both sides of the top of the car plate are connected with the first slide rails, and the top of the car plate is connected with a Both sides of the first slide rail are connected with a first spur rack, and the side of the top of the vehicle plate away from the first slide rail is connected with a push block. Through the cooperation of the first spur rack, the second spur rack, and the spur gear, the parts on the device move upward to a suitable position, which facilitates the turning of the cement block, and makes some parts of the device turn over to achieve the cement block The purpose of flipping is to improve efficiency and reduce worker fatigue.

Owner:梁小芳

Double-line conveying turnover machine

PendingCN111153168AImprove delivery efficiencySmall footprintConveyor partsMechanical conveyorsTruckProcess engineering

The invention relates to the technical field of double-line conveying turnover equipment and provides a double-line conveying turnover machine. The double-line conveying turnover machine comprises a base, feeding devices and two parallel truck-chain conveying lines. The feeding devices are located at the two ends of the base. The truck-chain conveying lines abut against the abutting base. Each feeding device comprises a feed rack, a first cylinder is connected to the sidewall of the feed rack, the output end of the first cylinder is connected with a conveying plate, and the feed rack is provided with material discharge holes. The double-line conveying turnover machine overcomes the defects in the prior art and is reasonable in design and compact in structure. The problems that an existingchain and rail link conveying device is low in conveying efficiency, and a turnover device is complex and not facilitates subsequent clamping are solved. Through the simple structure combination, thedouble-line conveying turnover machine adopts double-line conveying, improves the conveying efficiency, and meanwhile, reduces occupied space through combination of multiple conveying modes. Moreover,the turnover machine is simple, practical and convenient to implement, also has the locating function, facilitates subsequent clamping and has high practicality.

Owner:无锡市盛宝嘉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com