Chemical stirring and mixing system

A mixing and chemical technology, which is applied in the field of chemical mixing and mixing systems, can solve the problems of network structure blockage, reduce resource utilization, and affect the effect of filter press, so as to avoid hard stamping, increase resource utilization, and improve filter press effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

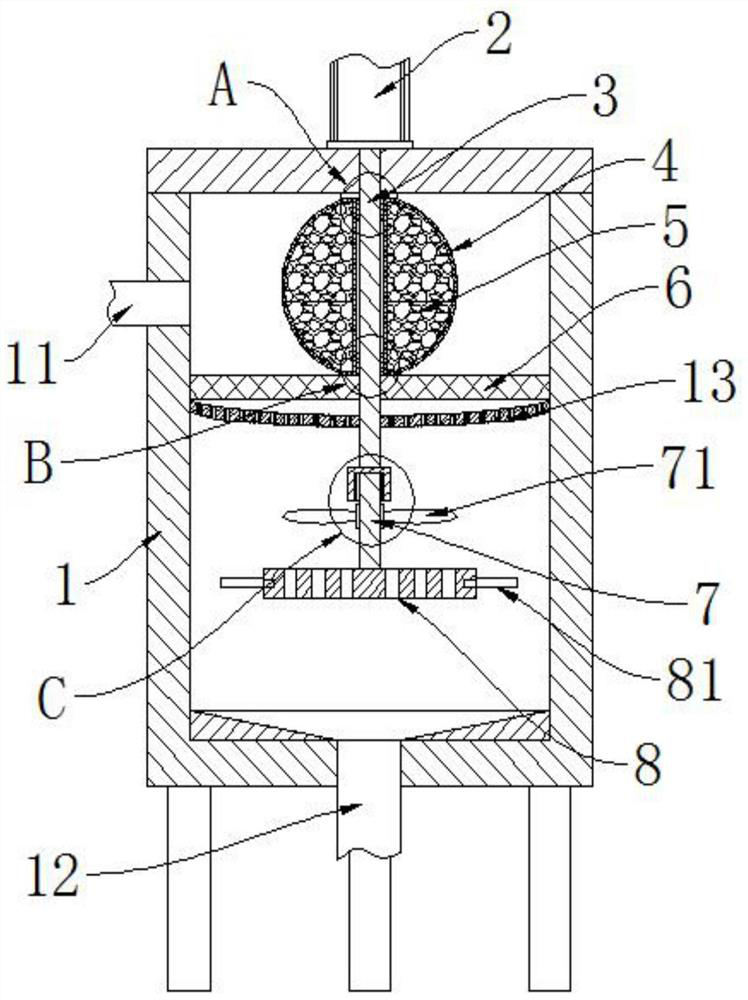

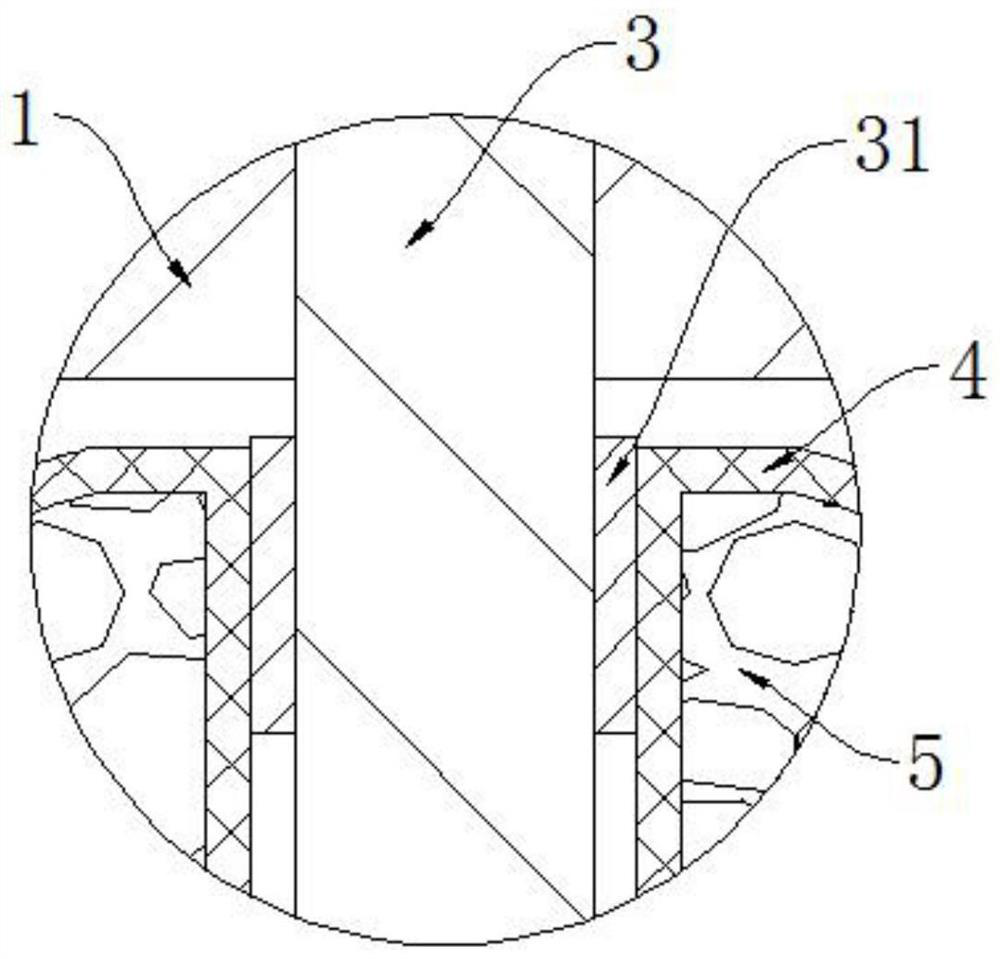

[0036] The specific implementation method is to use the feed pipe 11 to transport the stock solution into the tank body 1, and make the stock solution drop to the upper end of the filter screen 6. At this time, the filter screen 6 will filter the stock solution, and the mixed residue in the stock solution will be blocked on the filter screen. The upper end of the net 6, and make the surface of the raw liquid in the tank 1 under the arc-shaped honeycomb plate 13 and bury the fan blade 71, and then start the hydraulic cylinder 2, thereby driving the main shaft 3 to circulate up and down, and then make the fixed cylinder 31 circulate up and down move, thereby driving the upper part of the cloth bag 4 to move up and down. During the downward movement of the upper part of the cloth bag 4, the non-Newtonian fluid 5 will flow outward and impact the residue on the upper end of the filter screen 6, thereby realizing the filter press operation. During the up and down cycle movement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com