Rapid demoulding device for cement block pouring

A demoulding device and cement block technology, applied in the direction of unloading device, manufacturing tools, etc., can solve the problems of low cement block yield, increase of workers, time-consuming and labor-intensive problems, and achieve the effect of improving efficiency, reducing time cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

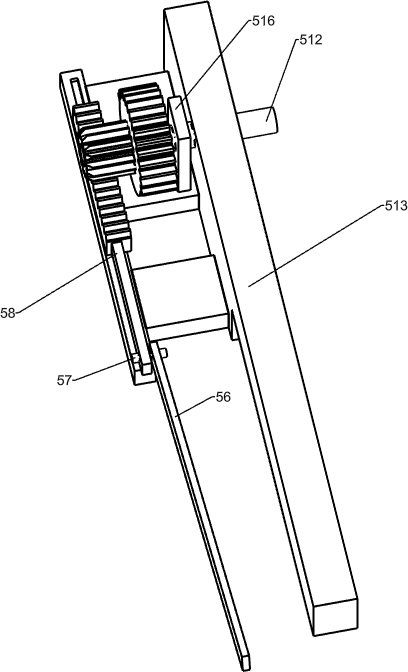

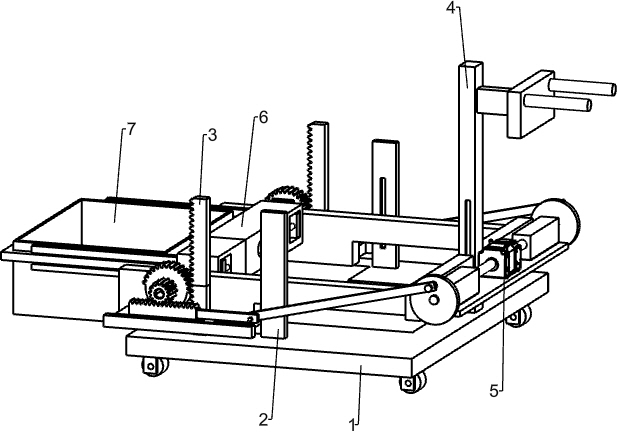

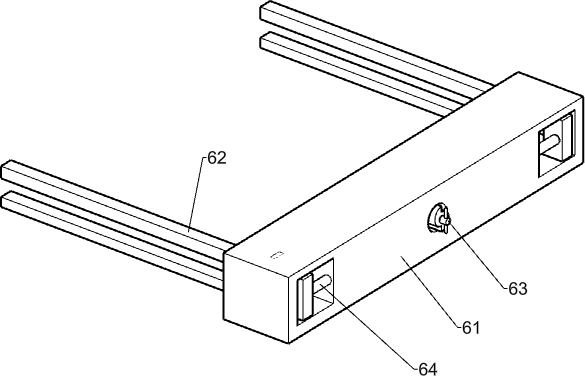

[0021] A quick release device for cement block pouring, such as figure 1 As shown, it includes a car board 1, a first slide rail 2, a first straight rack 3, a push block 4, a lifting mechanism 5, a clamping mechanism 6 and a cement frame 7, and the front and rear sides of the top of the car board 1 are connected with The first slide rail 2, the front and rear sides of the top of the vehicle board 1 are connected with the first straight rack 3, the first straight rack 3 is located on the left side of the first slide rail 2, and the right side of the top of the vehicle board 1 is connected with a push block 4 , when the worker needs to demould the cement block quickly, the worker can push the push block 4 to drive the vehicle plate 1 to the position of the cement block. Spur rack 3 is meshed, and clamping mechanism 6 is connected between the front and rear sides of lifting mechanism 5. Clamping mechanism 6 is clamped with cement frame 7. First, cement can be poured into cement f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com