Patents

Literature

48results about How to "Guaranteed molding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

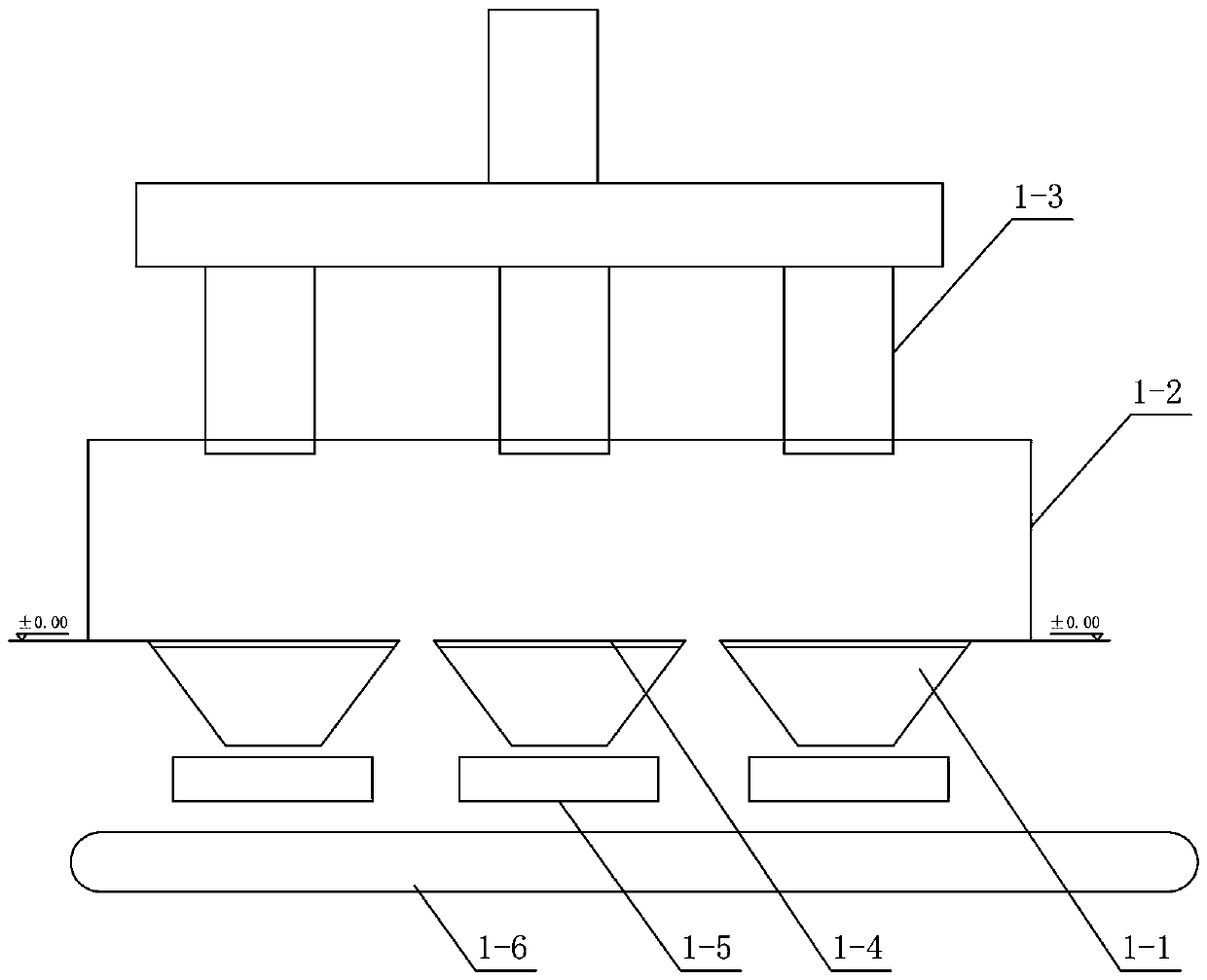

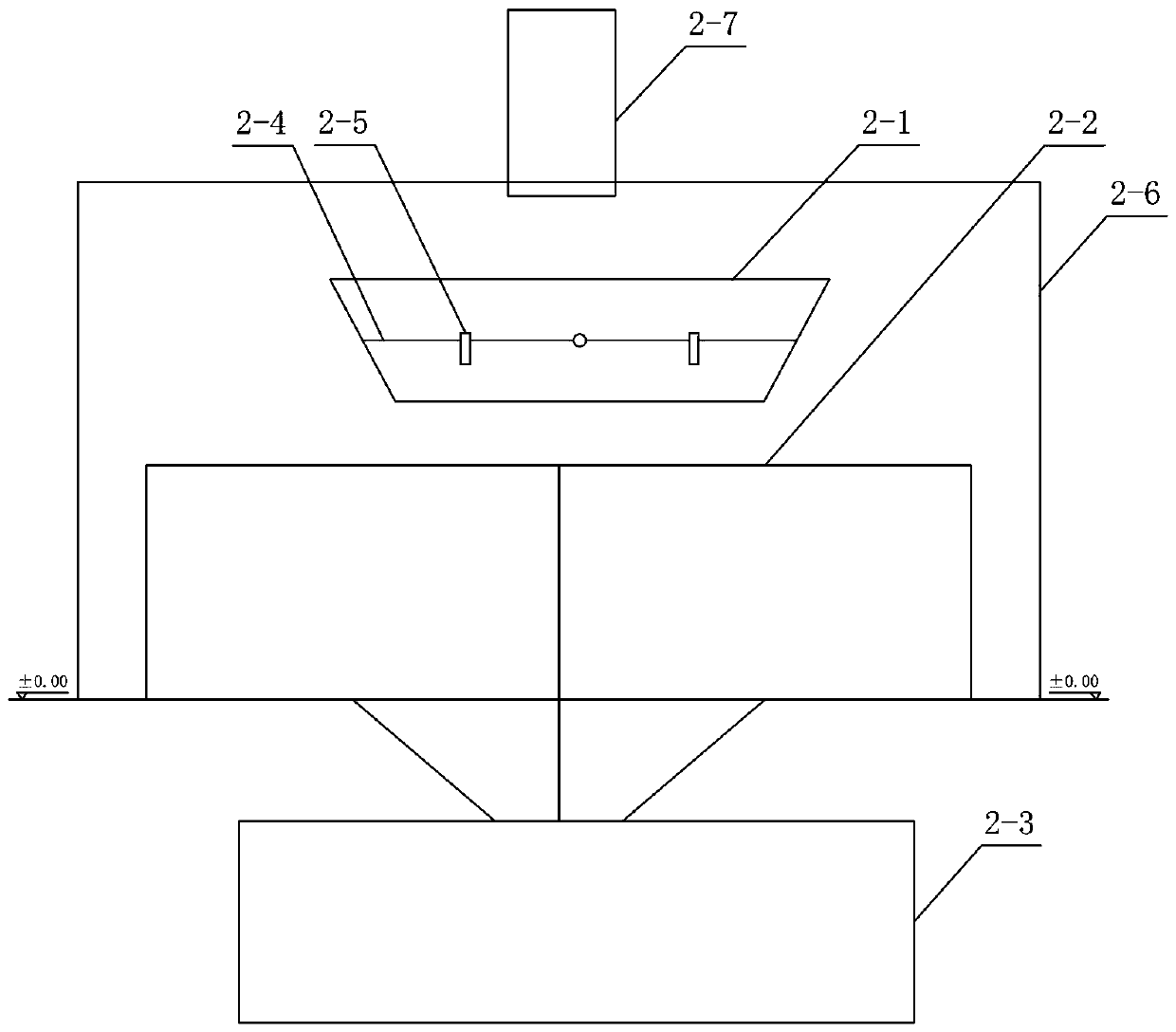

Method for processing pure sweet potato starch noodles

ActiveCN102524712AGuaranteed tasteGuaranteed cooking resistanceFood preparationPotato starchComposite material

The invention discloses a method for processing pure sweet potato starch noodles. The method comprises the following steps of: blending pulp, namely based on 50 kilograms of dry sweet potato starch, adding 30 to 35 kilograms of water and stirring; performing primary curing, namely adding the sweet potato starch subjected to pulp blending into a starch noodle machine, and extruding, curing and molding in a screw extrusion mode at the curing temperature of between 70 and 90DEG C and at the rotation speed of a motor of 600-900 rpm, so that starch sheets are cured by 60 to 70 percent; performing secondary curing, namely immediately putting the 60 to 70 percent cured starch sheets into water at the temperature of between 90 and 100DEG C, so that the starch sheets are completely cured; and spreading to air and age the cured starch sheets until the starch sheets are not sticky to hands, cutting the aged starch sheets, and airing or drying the cut starch noodles. According to the method, the molding rate of the starch noodles is high due to mechanical production, and the starch noodles are fine and smooth in mouthfeel, high in fastness to boiling, difficult to break; and the process is simple, the cost is low and the production efficiency is high.

Owner:贵州省印江县依仁食品有限公司

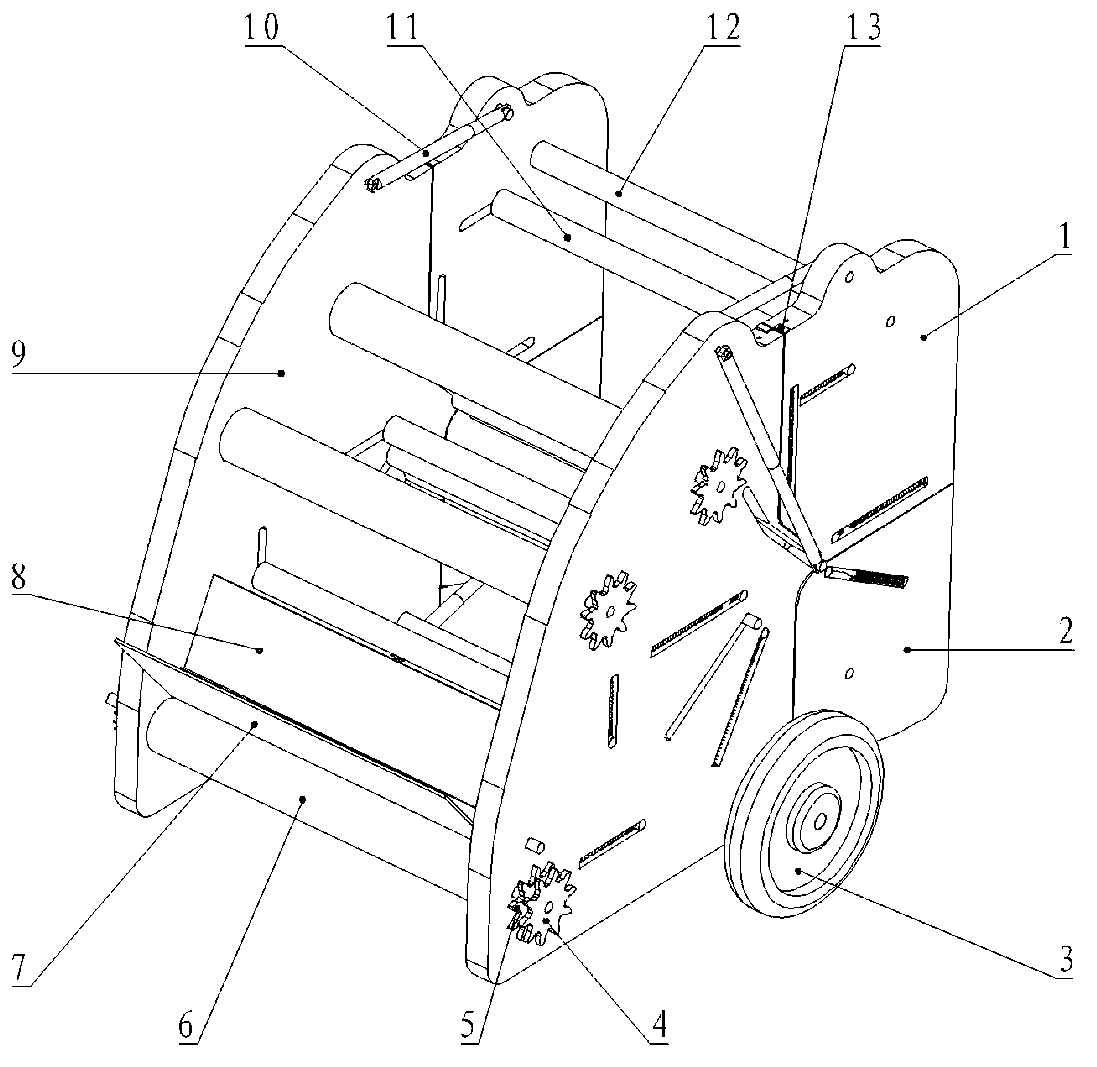

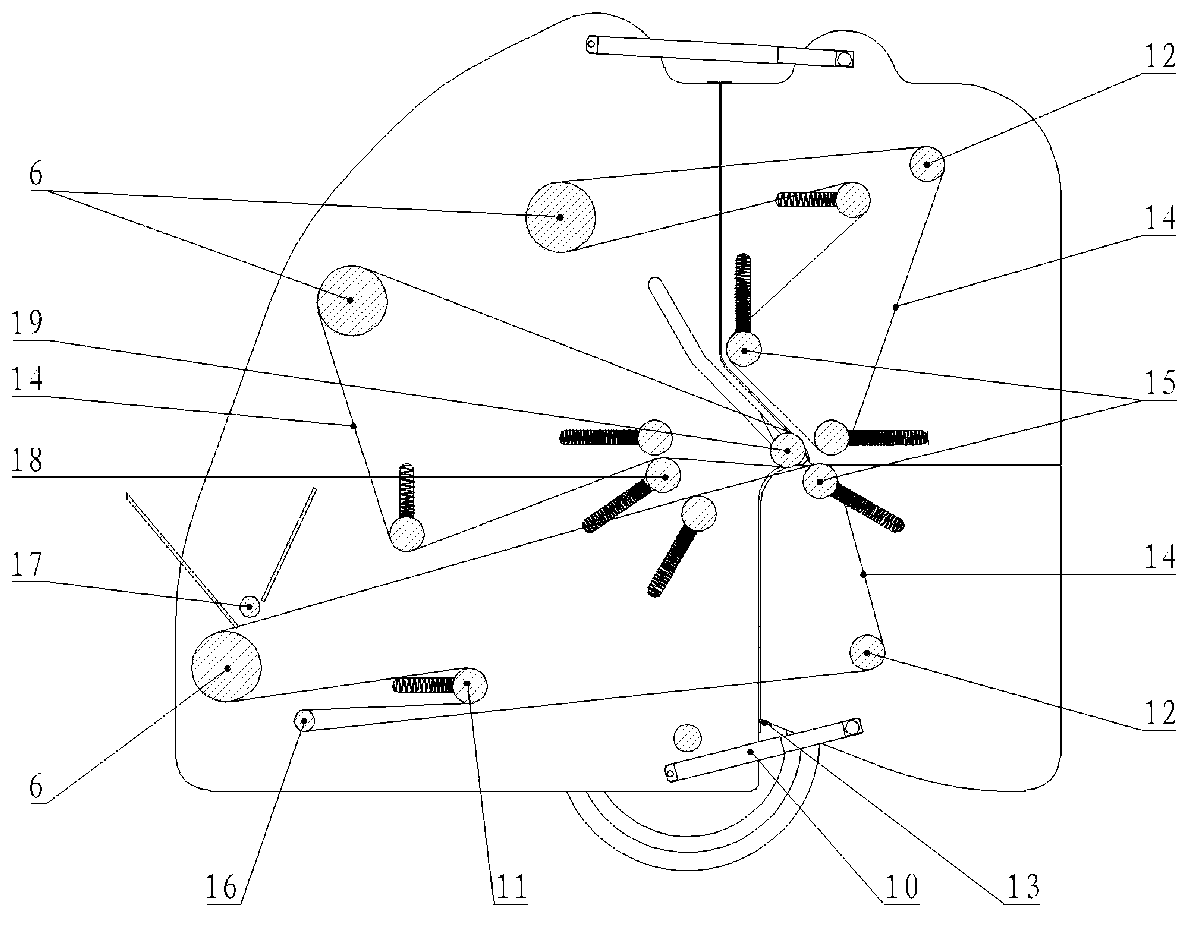

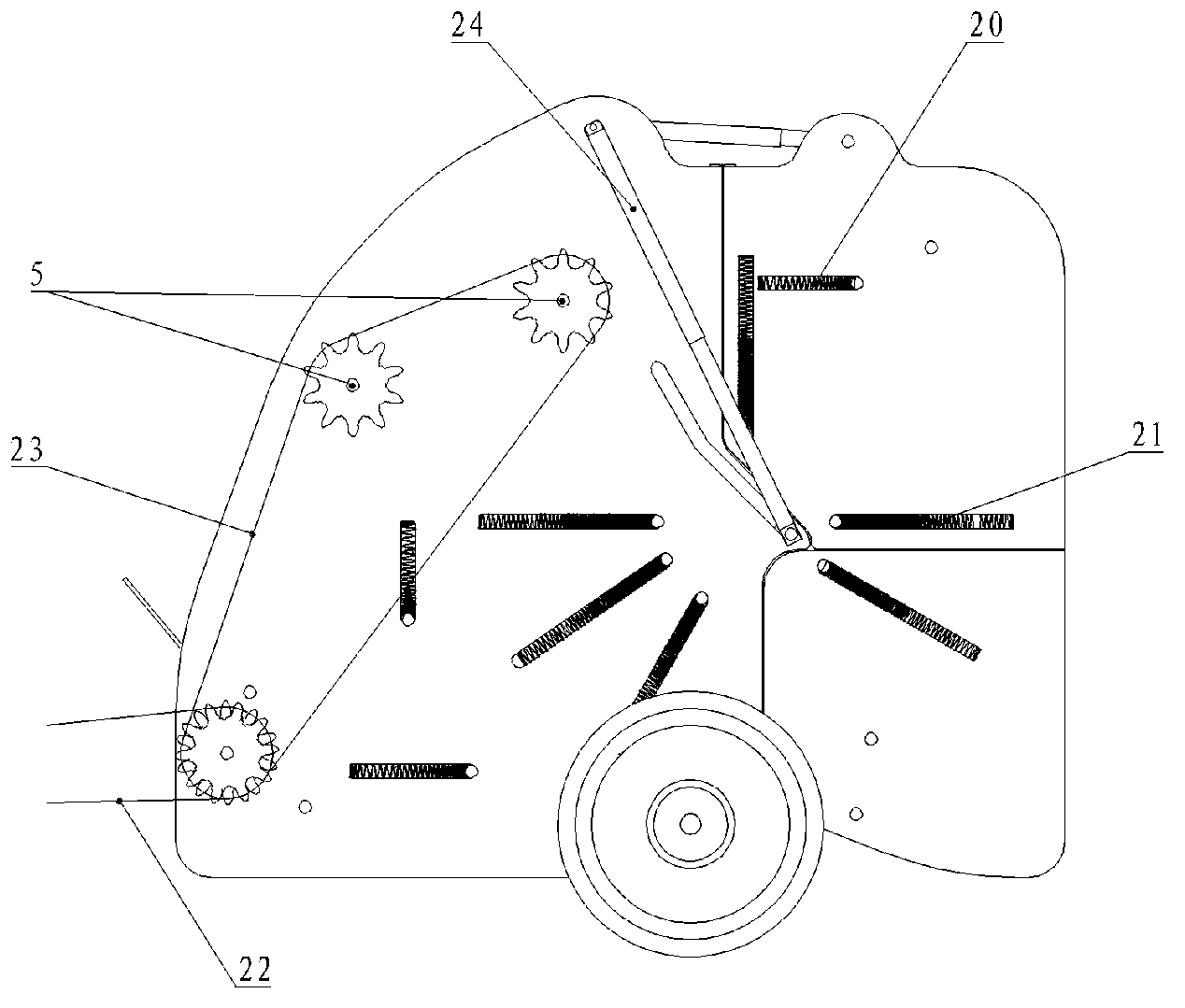

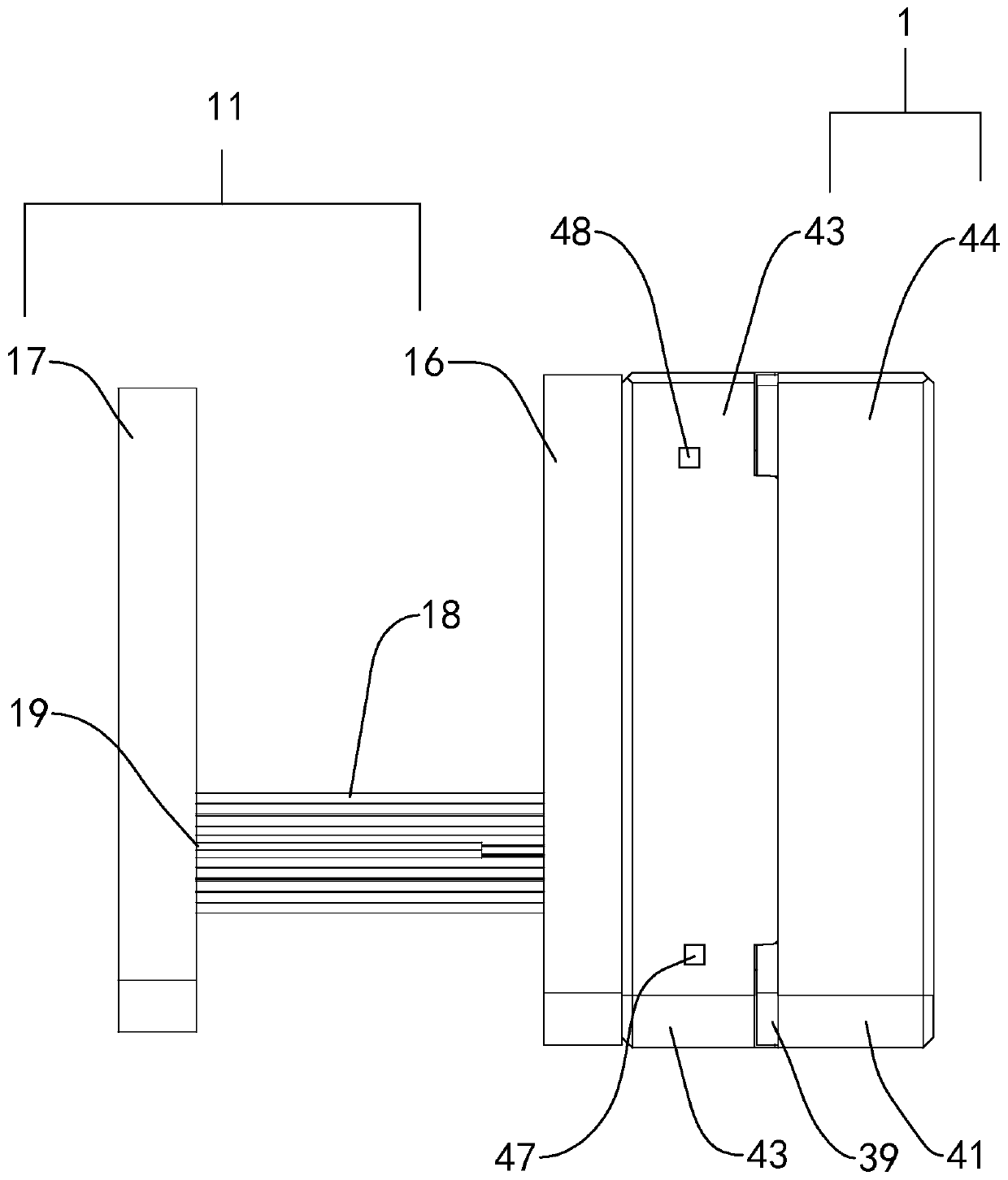

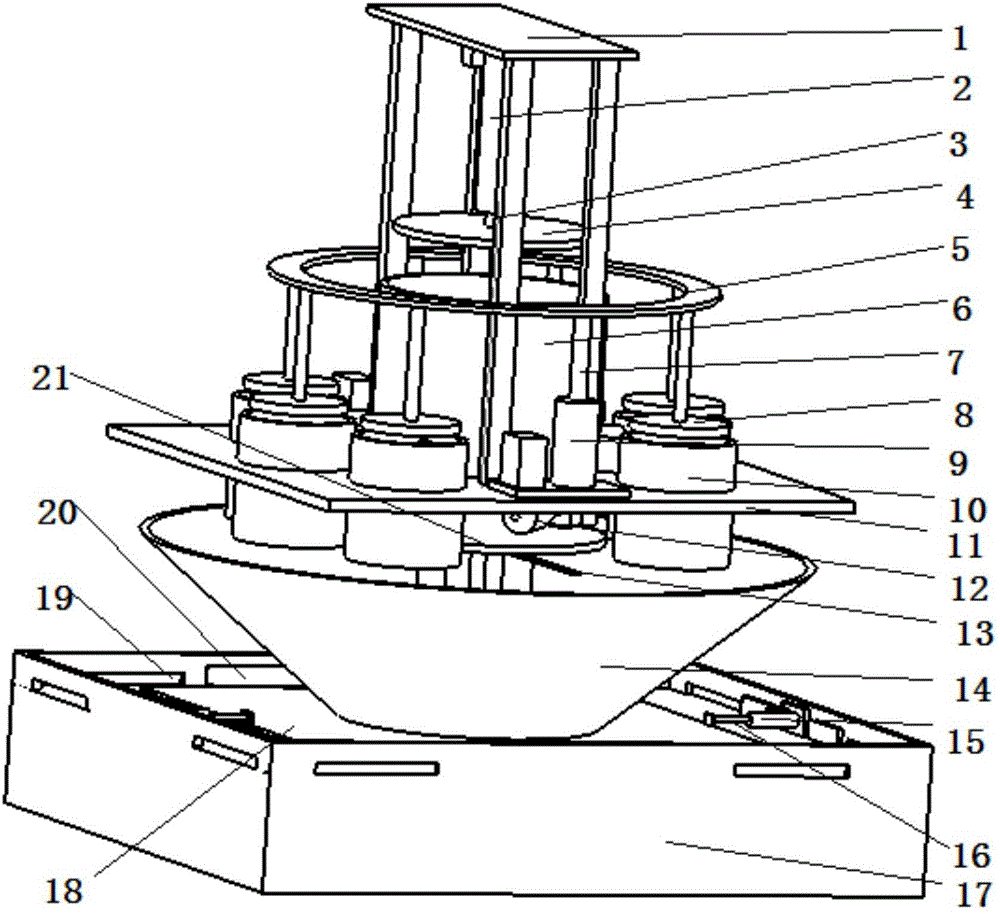

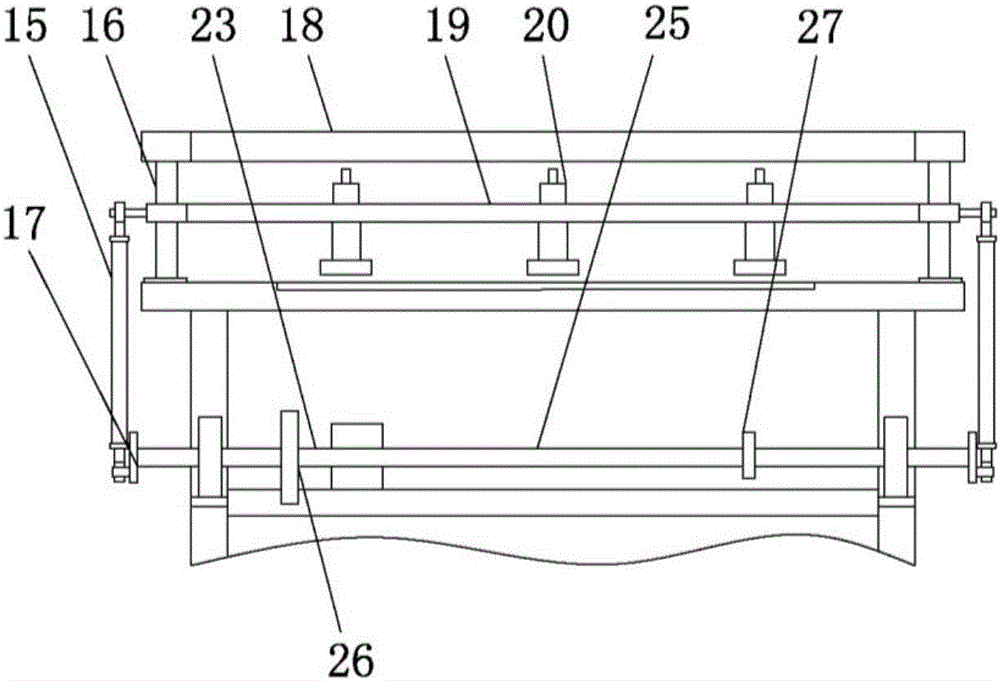

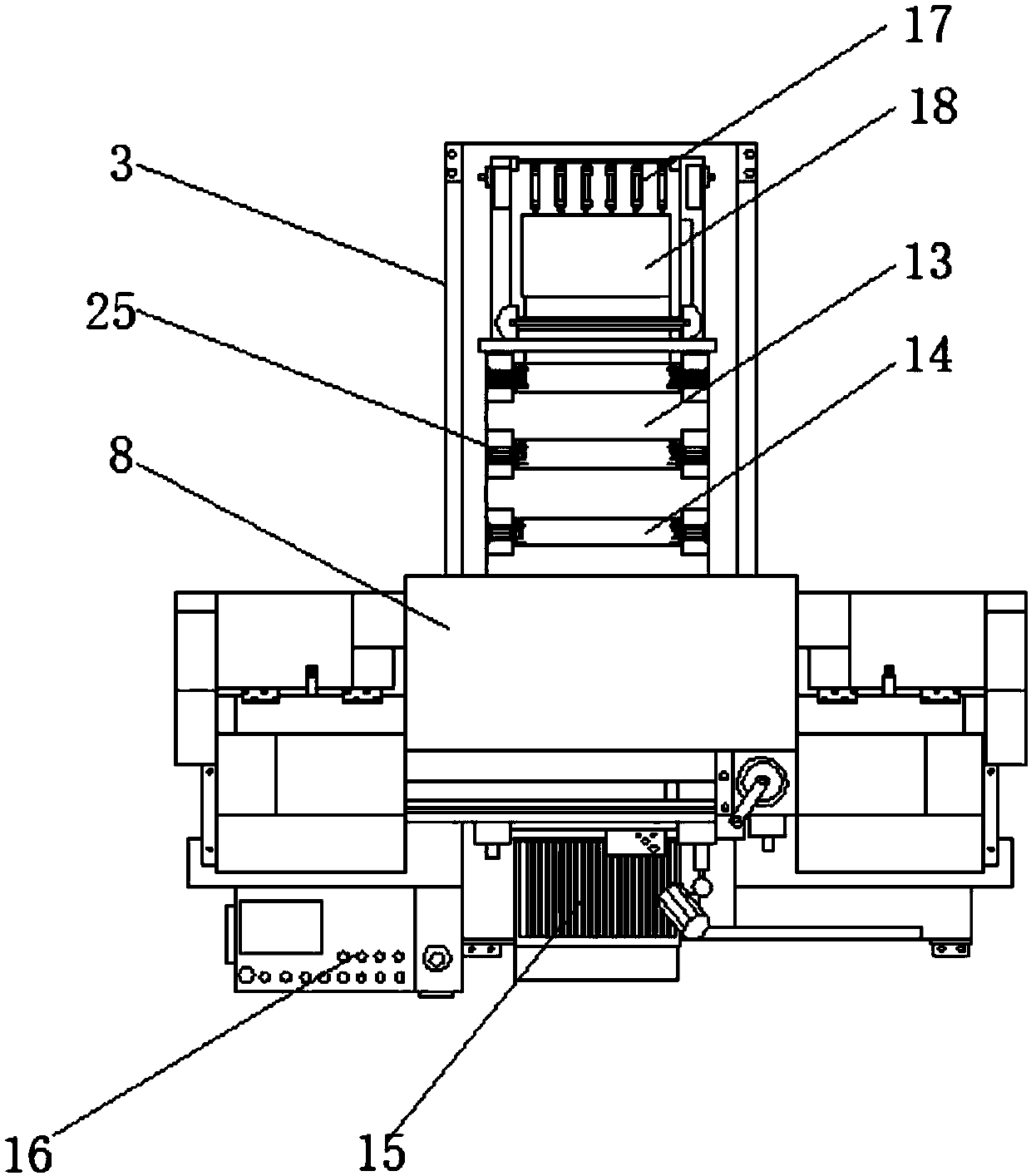

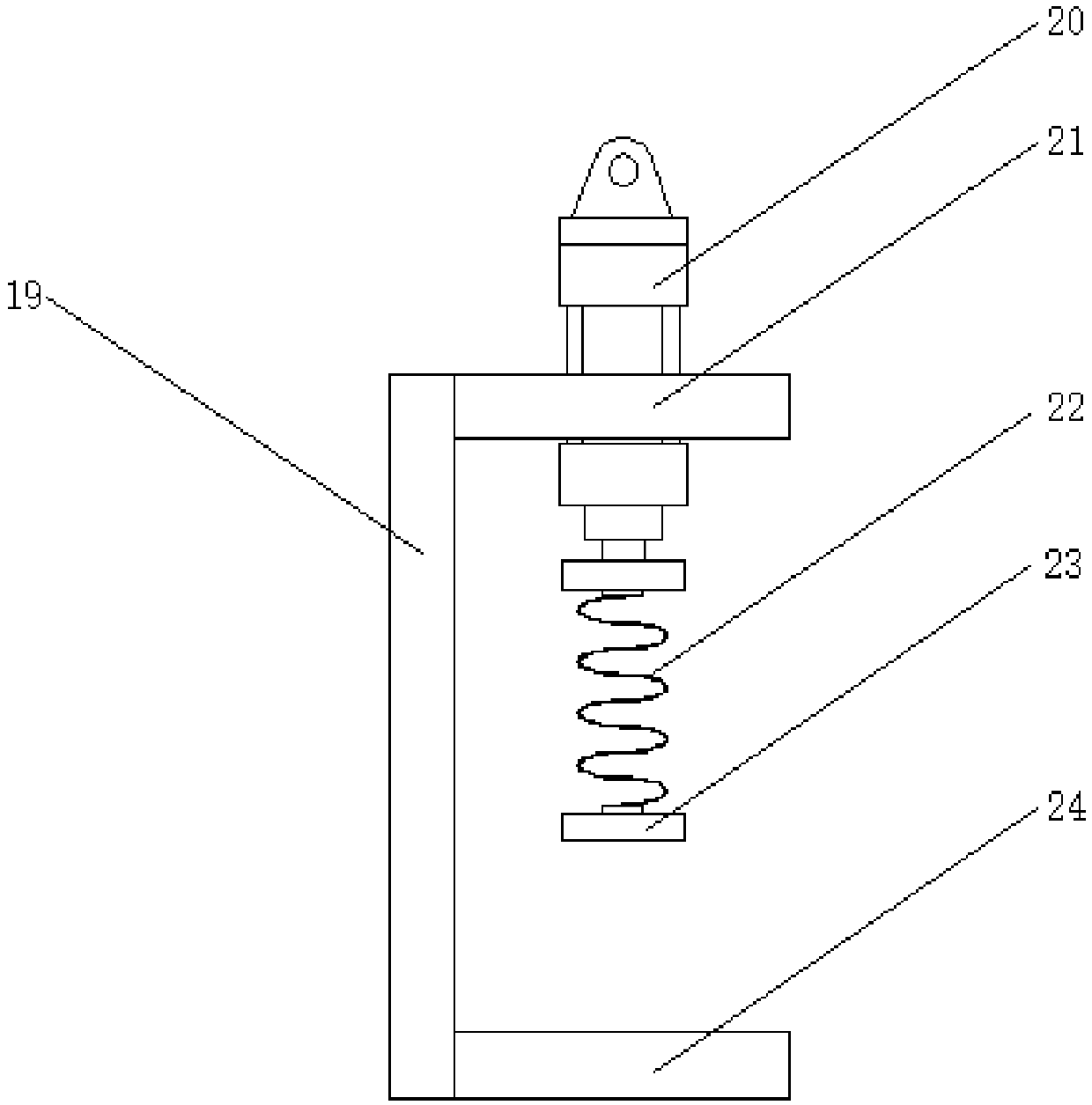

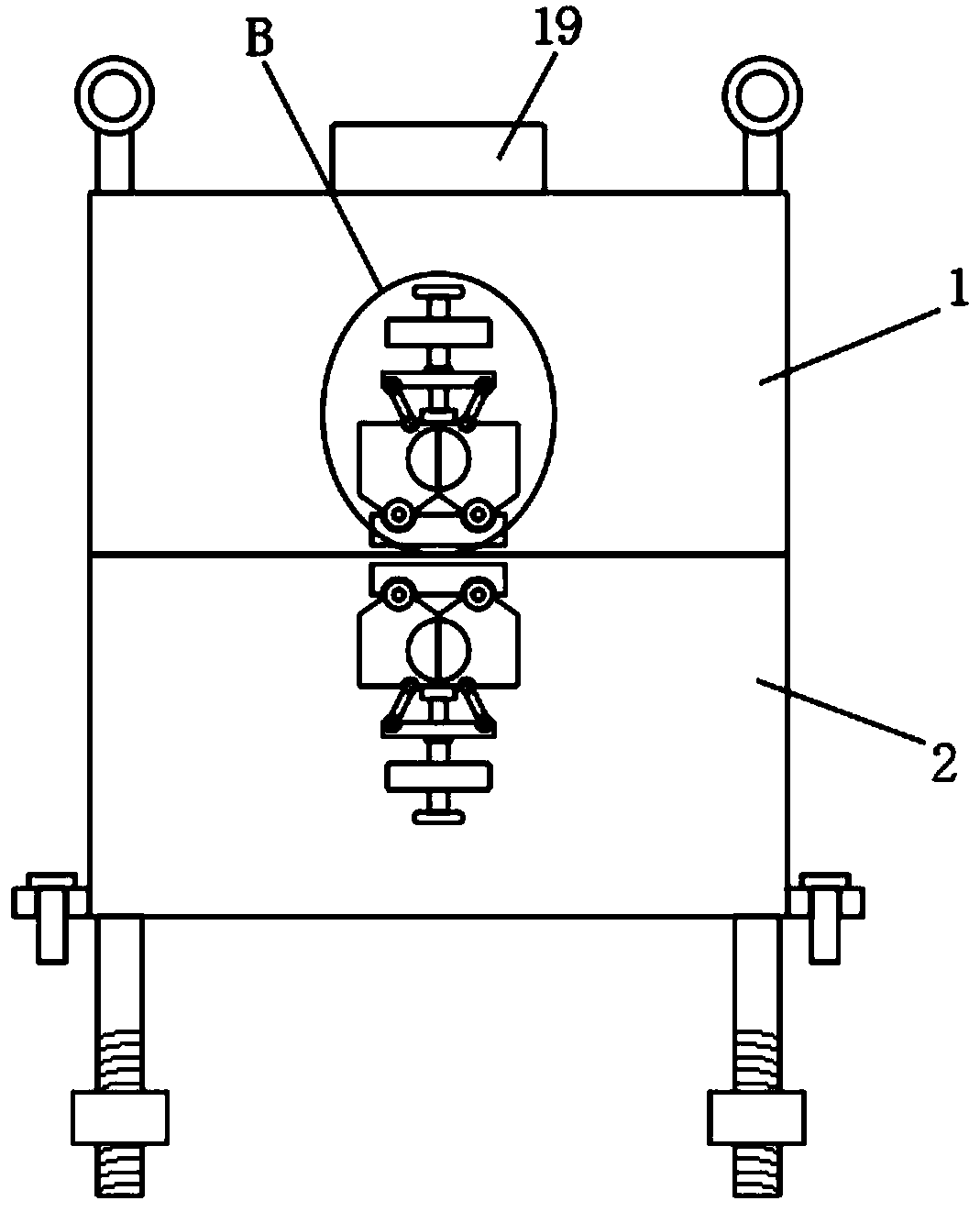

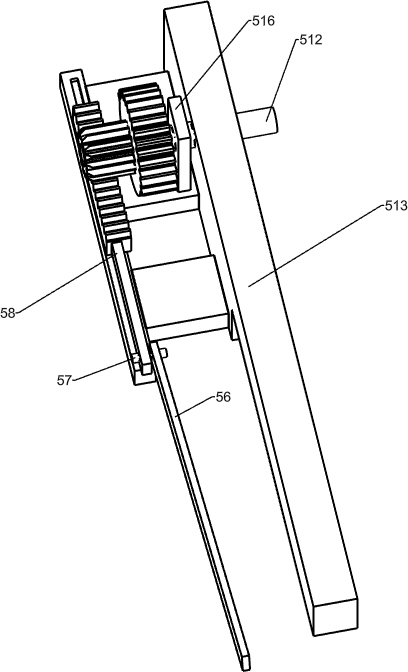

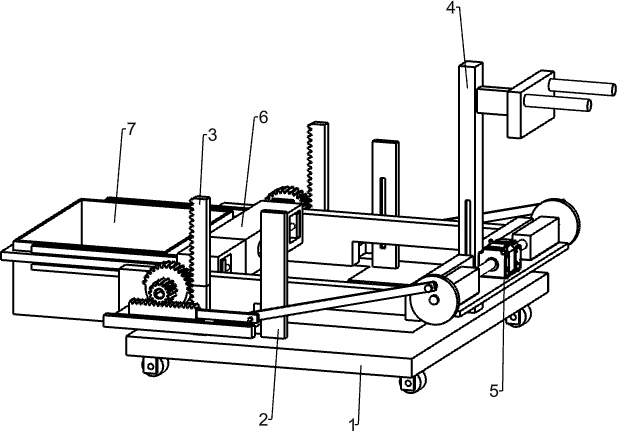

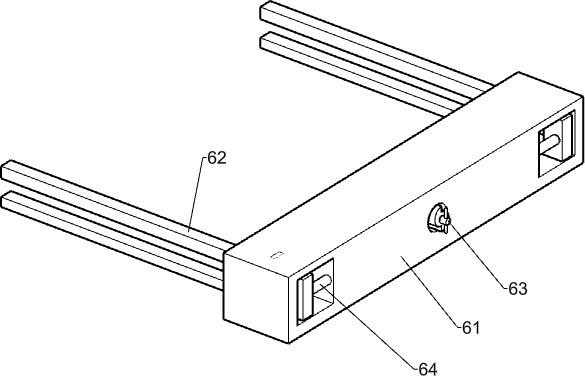

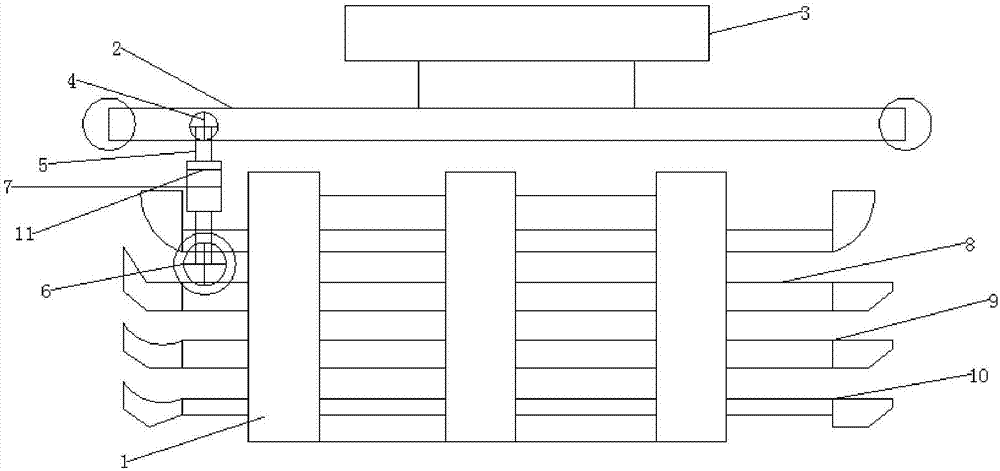

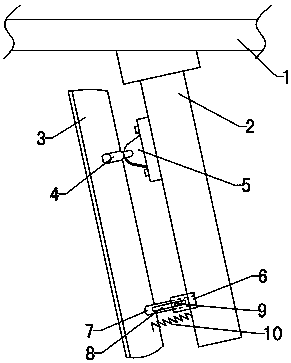

Room-changing belt-type binding machine

The invention discloses a room-changing belt-type binding machine. The binding machine consists of installation plates, a feed channel, a chain mechanism, a compressor and wheels, wherein the feed channel is arranged on the lower part in front of a space between the two installation plates and is connected with a discharge hole of a harvester; the compressor is arranged in middle of the space between the installation plates; and the chain mechanism is arranged on the front parts of the outer side surfaces of the installation plates. When the room-changing belt-type binding machine works, straws are primarily compressed, so that gaps among the stalks are fully reduced, part of gas is exhausted, the surfaces of fibers can be sufficiently contacted with one another, and the compression rate of the stalks can be improved since the fibers are staggered with one another in the compression process; and the stalks are secondarily compressed by a rubbing and pressing forming manner with a high core forming rate, thereby guaranteeing the forming rate of bales. When the compressor is used for forming roll cores, a hydraulic control mechanism implements force application in a rubbing and pressing process, so that compressing force is large, the bales are stressed uniformly in the compression process, and the shapes of hay cores and the formed bales are regular. The room-changing belt-type binding machine is simple in structure and low in cost, can achieve a high binding efficiency, and can be widely applied to agricultural production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

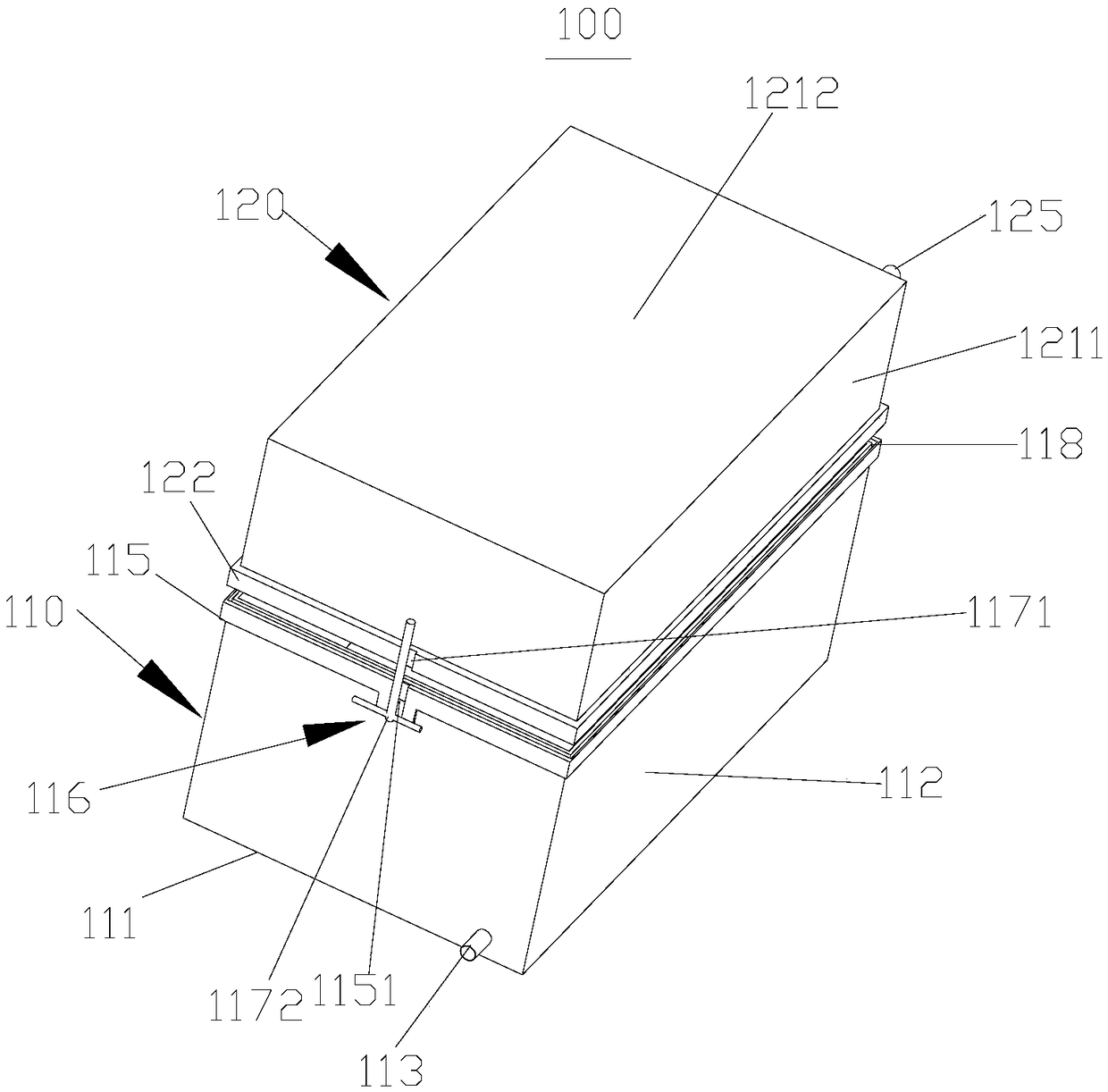

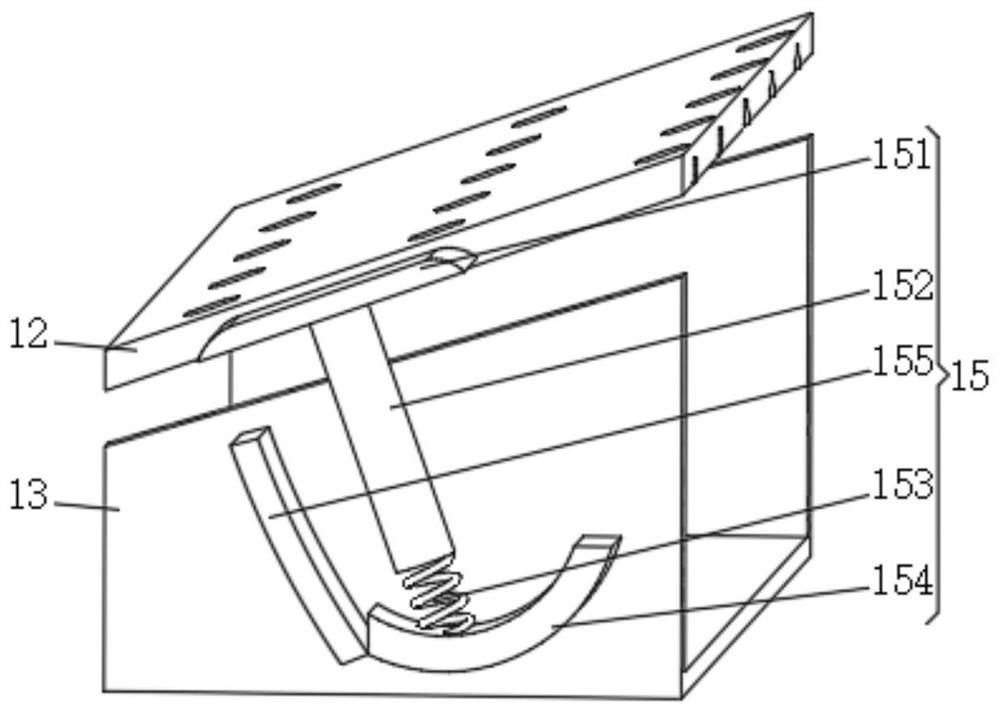

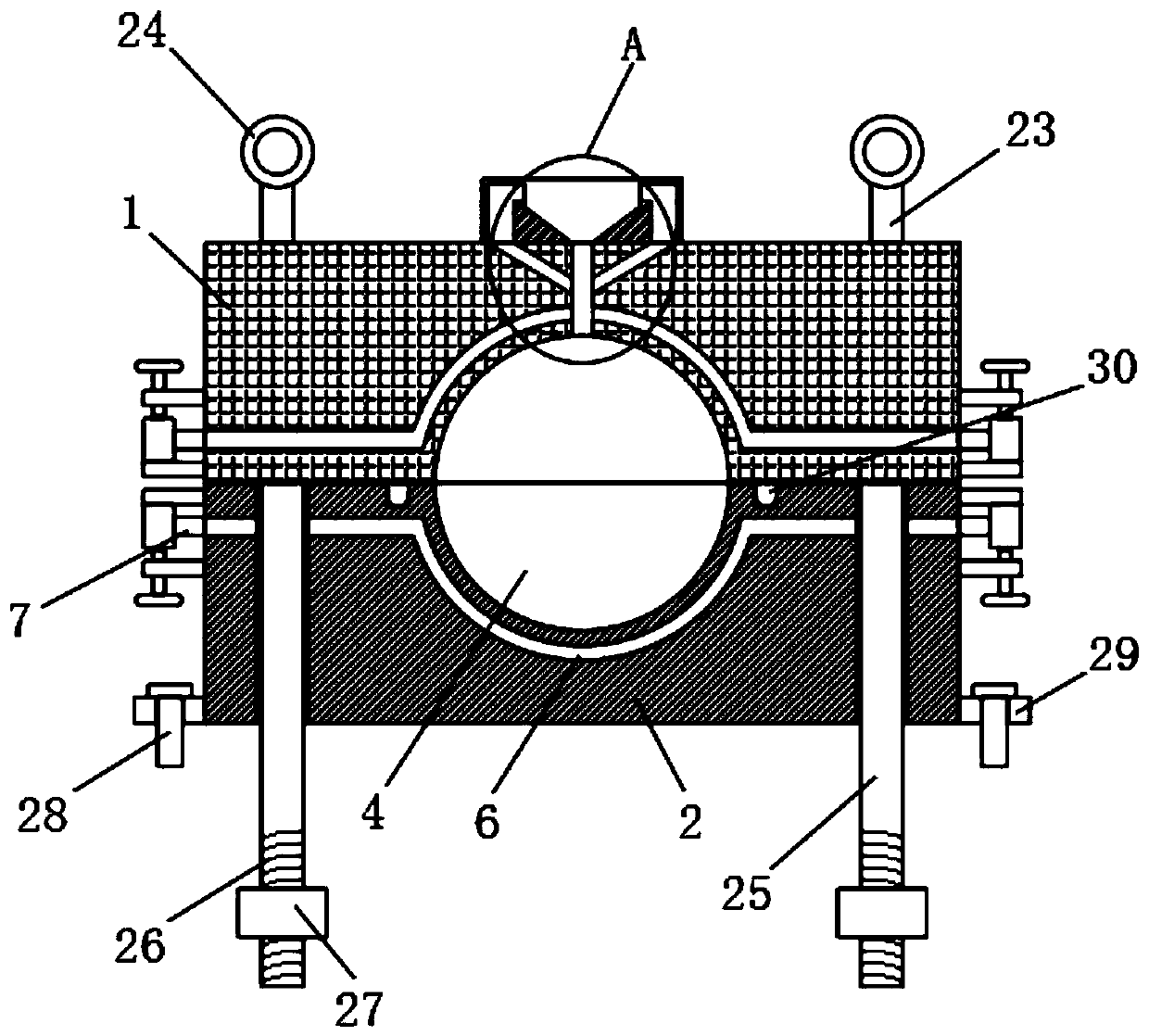

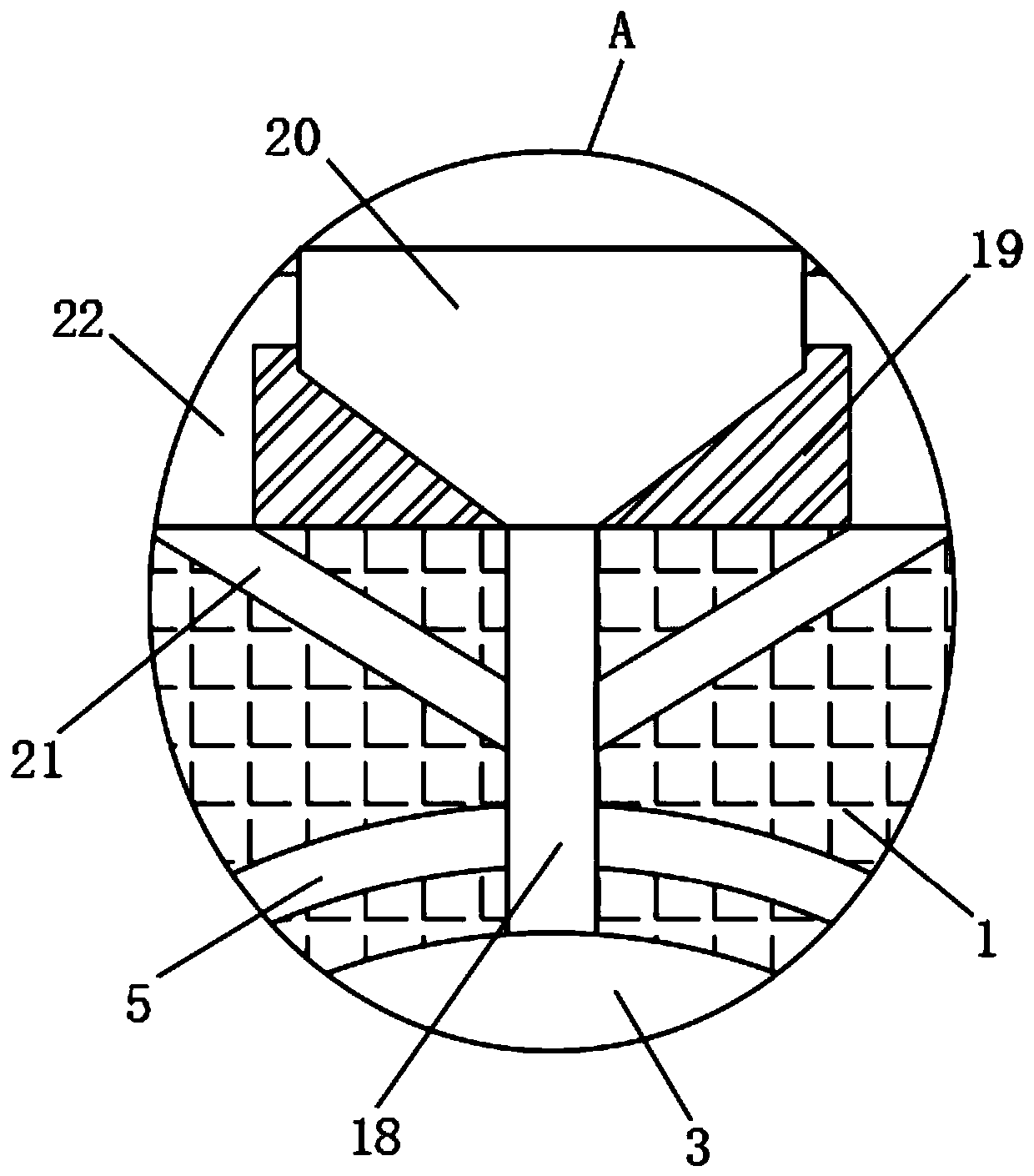

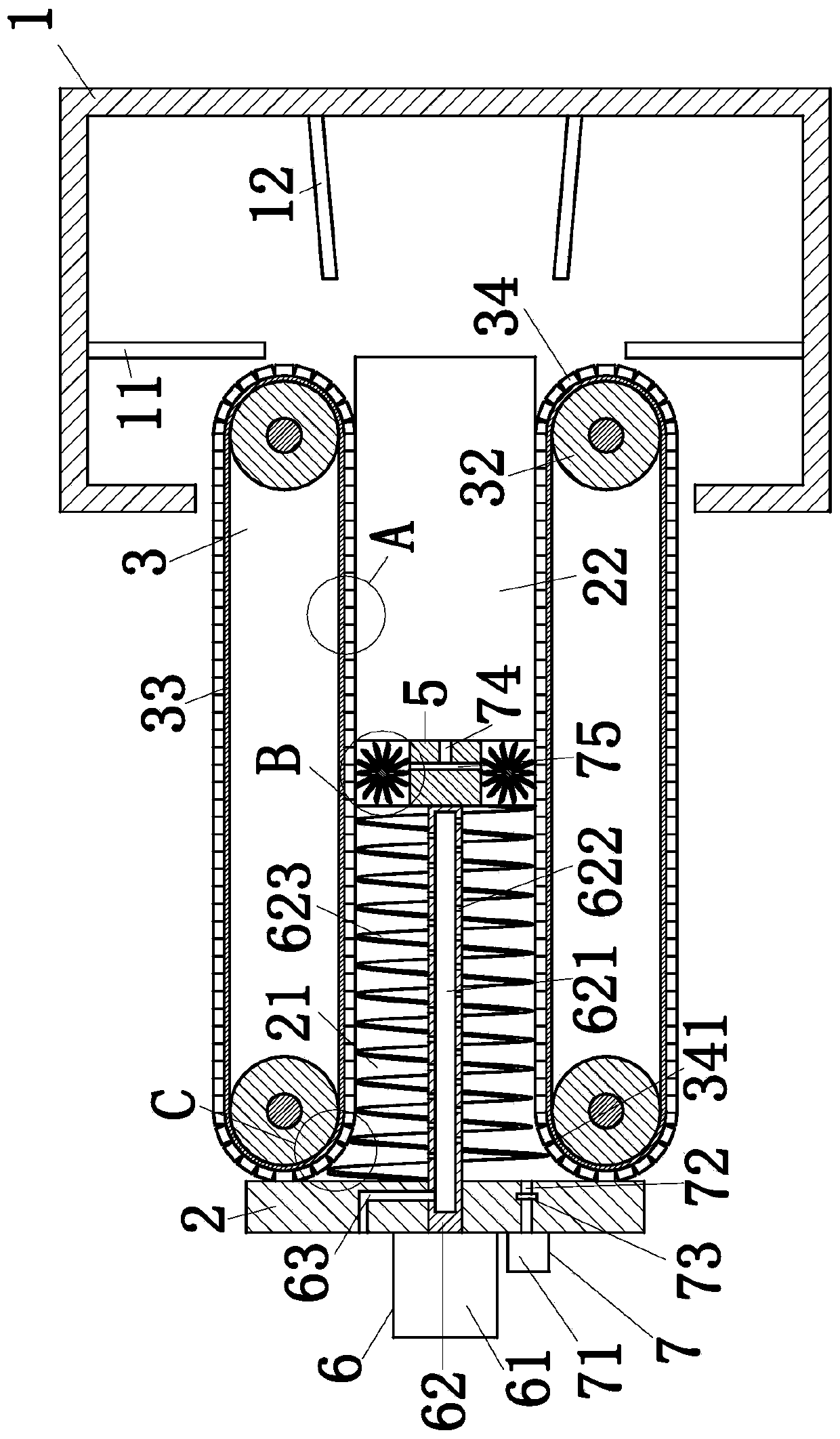

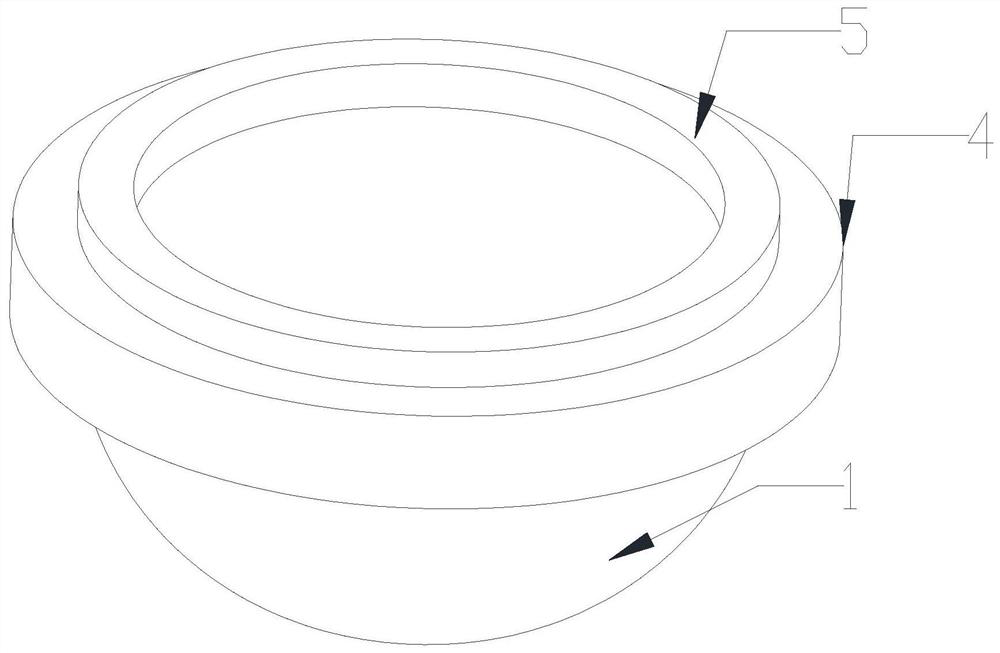

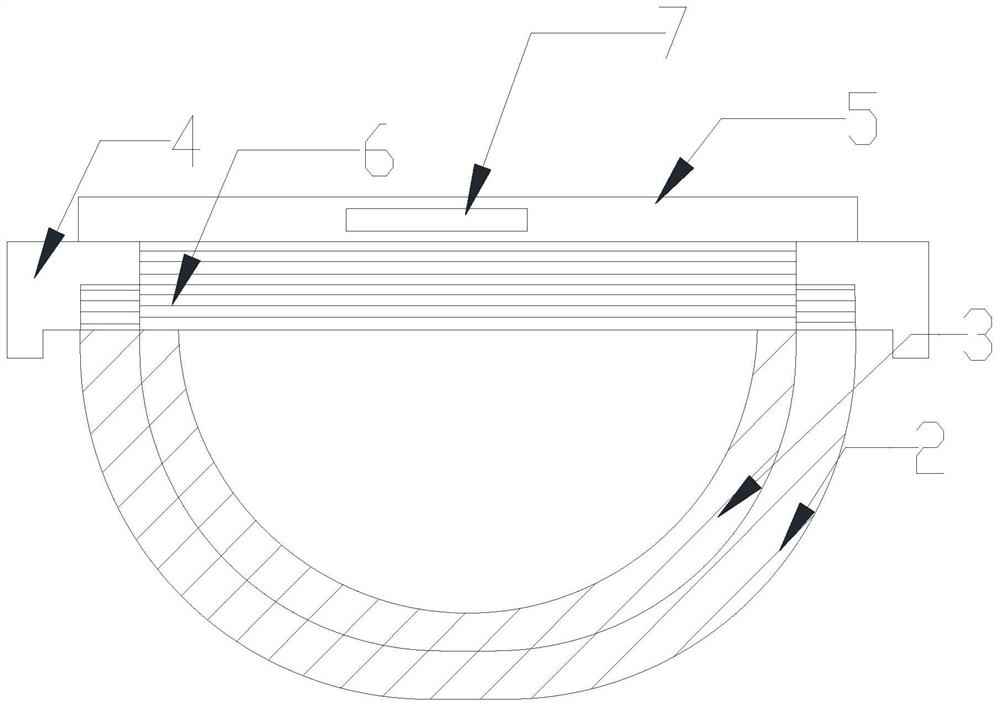

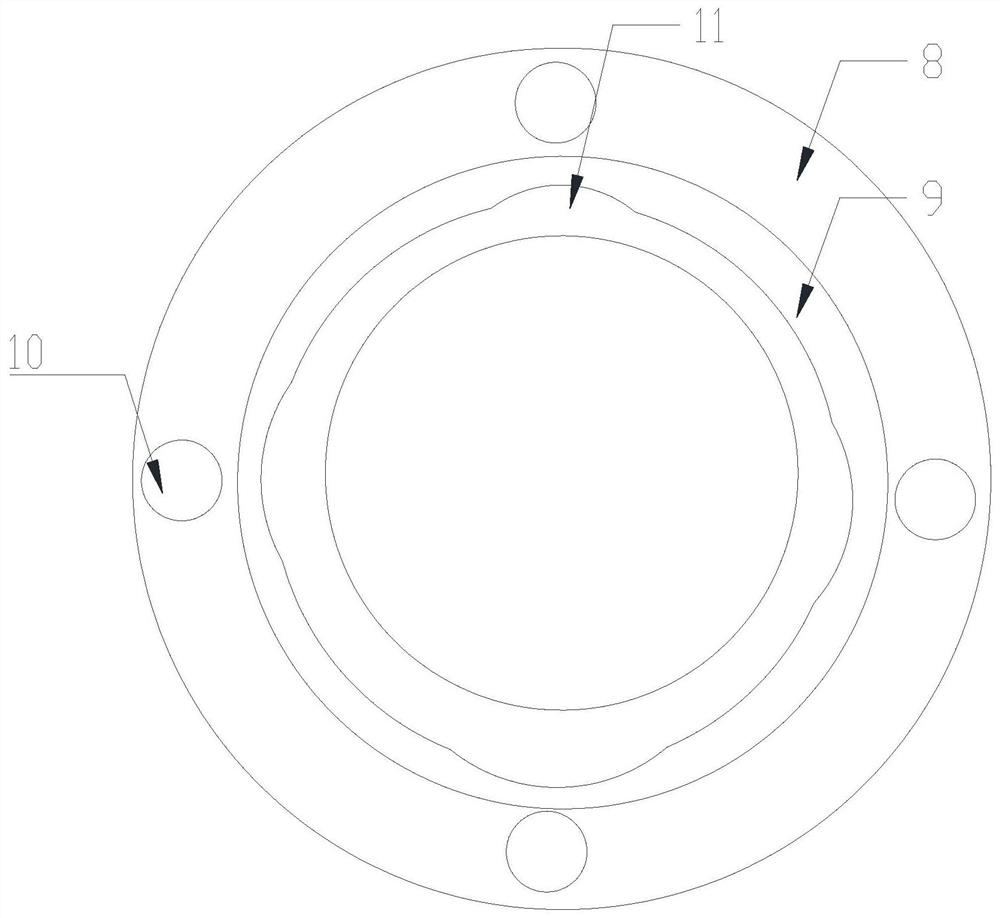

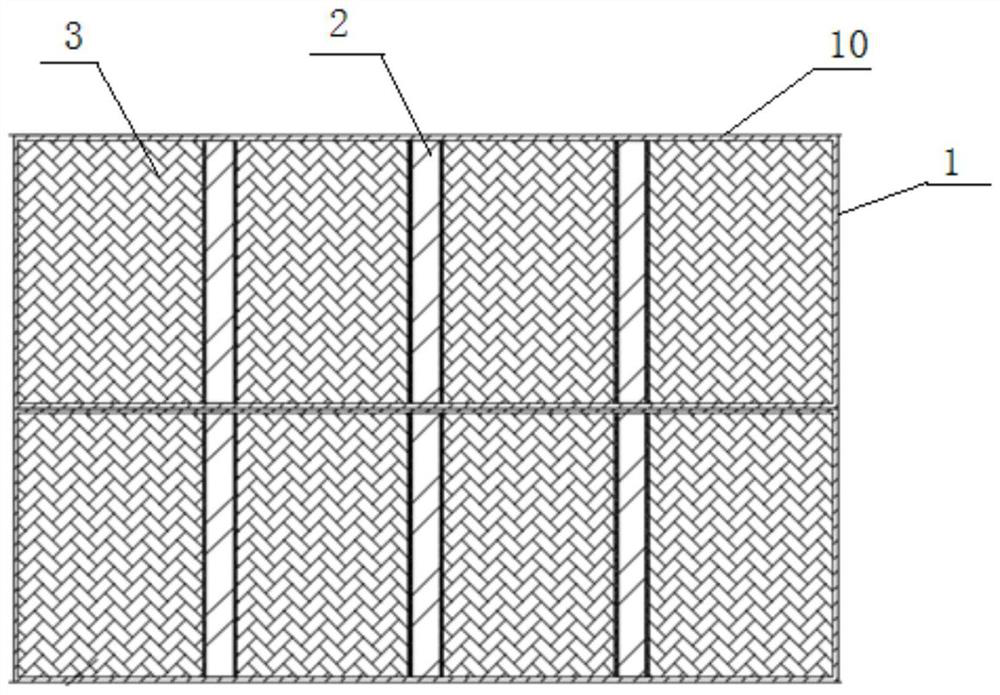

Cage for preparing rat model with hypoxic-ischemic encephalopathy and breeding device

PendingCN109463293AGuaranteed molding rateReduce mortalityAnimal housingBrain pathologiesHypoxic Ischemic Encephalopathy

The invention provides a cage for preparing a rat model with hypoxic-ischemic encephalopathy and a breeding device, and belongs to the field of auxiliary medical apparatuses. An air inlet pipe is arranged at the bottom of the side wall, and an exhaust device is arranged at the upper portion of a main cover body. After air is introduced, the air flows from bottom to top to form an air circulating passage. Due to the uniformity of the air in the cage, the rat model forming rate is ensured, and the rat death rate can be reduced; due to the high air uniformity, the rat model forming consistency can be ensured.

Owner:成都合拓创展生物科技有限公司

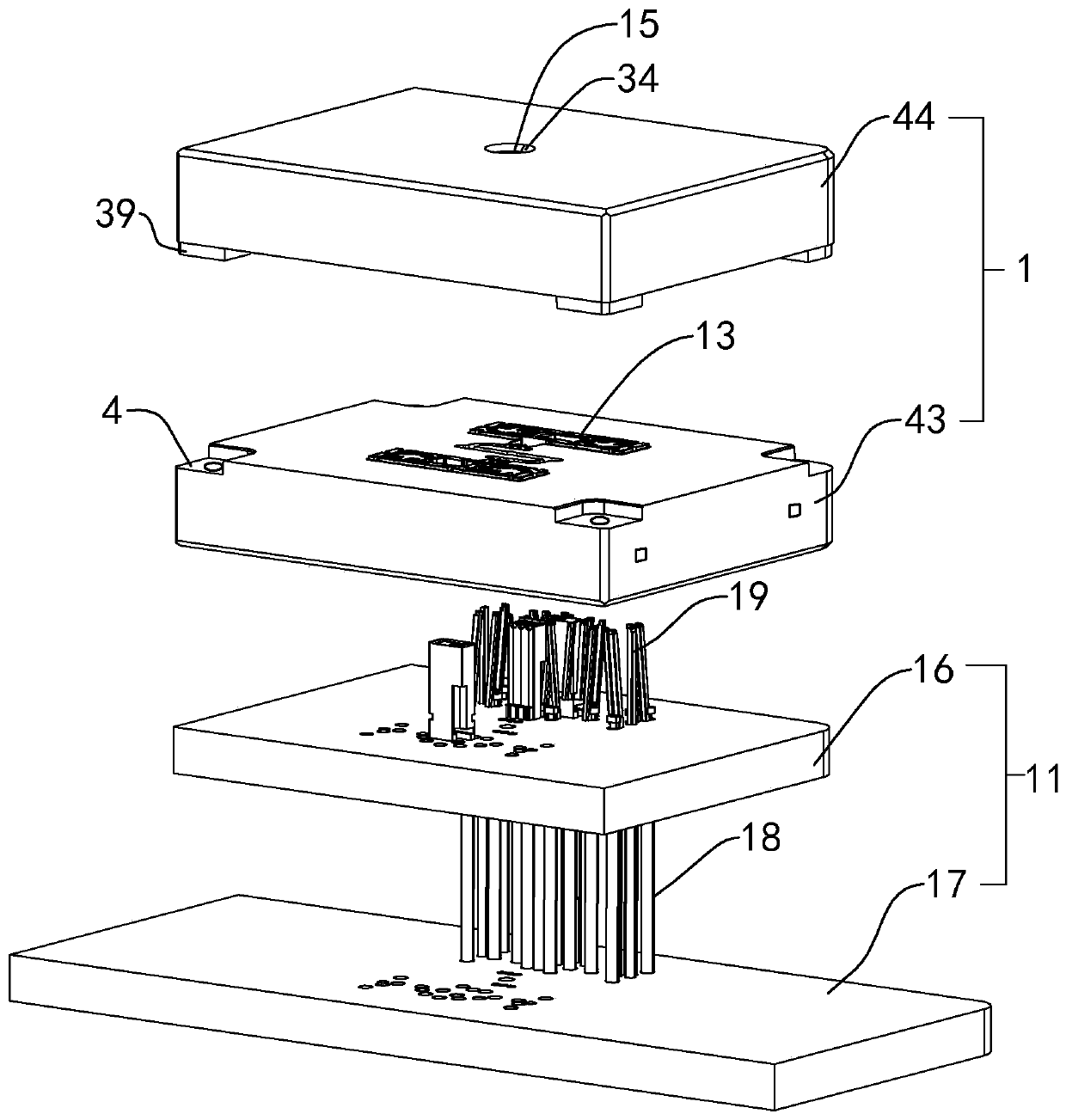

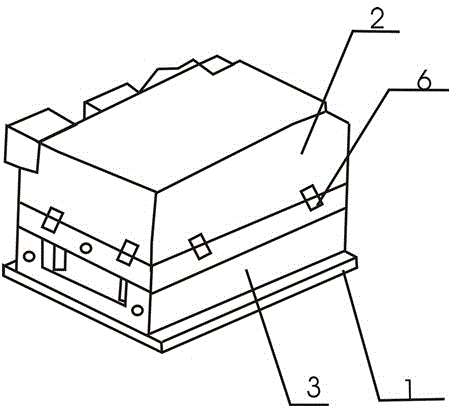

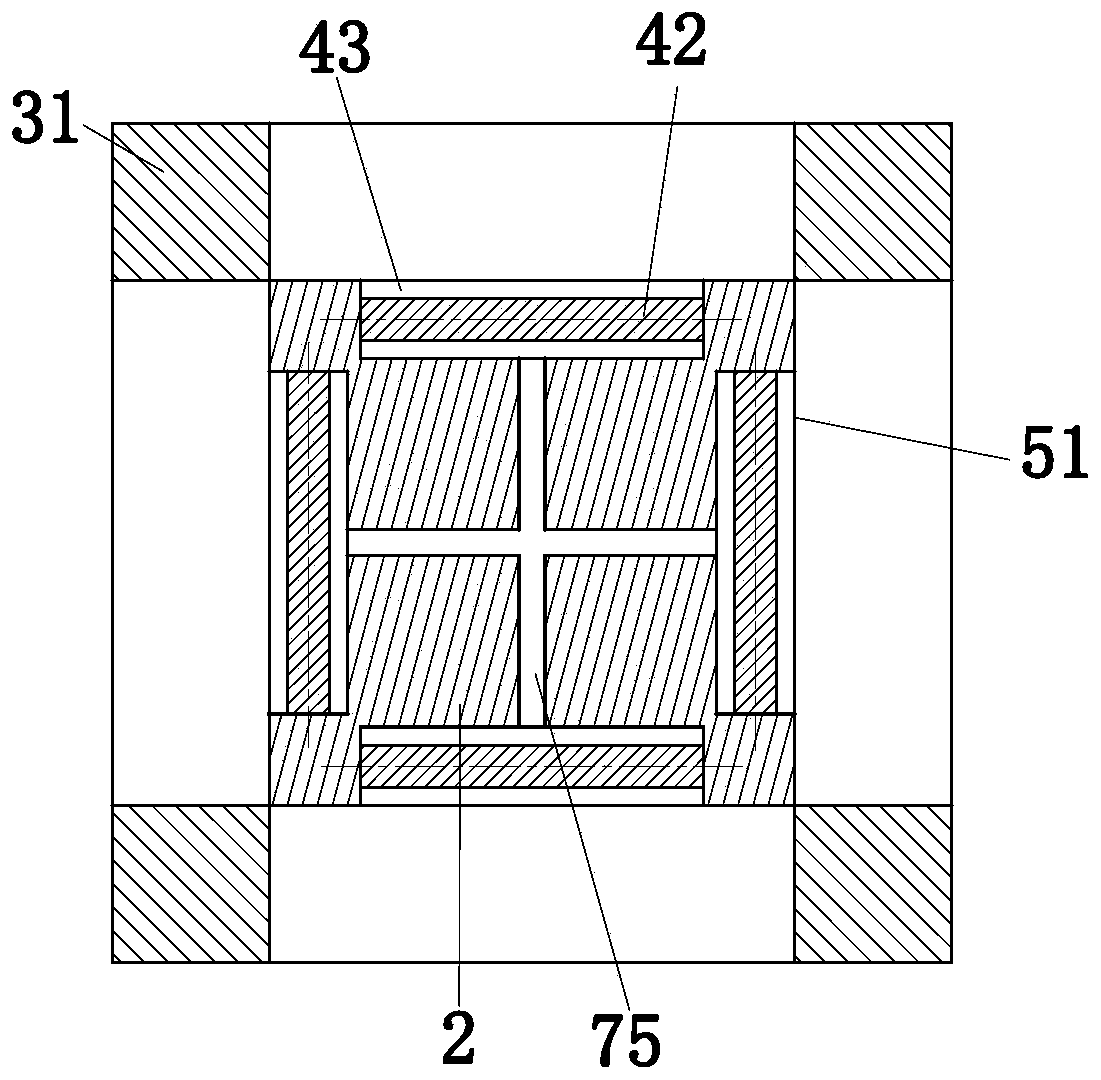

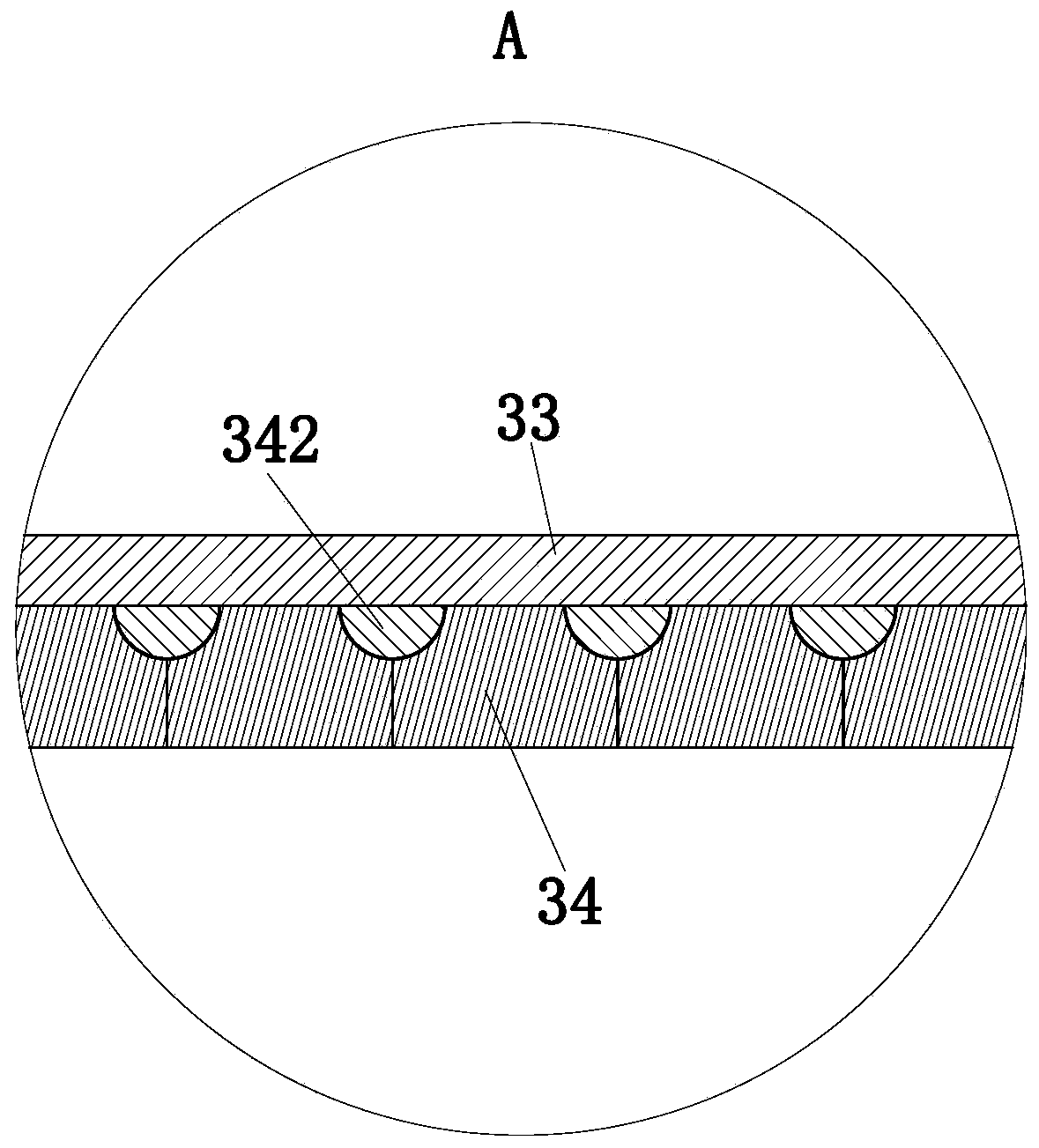

Mould capable of demoulding keycap through short oblique pins

The invention relates to a mould capable of demoulding a keycap through short oblique pins. The mould capable of demoulding the keycap through the short oblique pins comprises an injection molding assembly and an ejection assembly, wherein the injection molding assembly comprises a fixed die and a movable die; the butt-joint surfaces of the movable die and the fixed die form a keycap forming cavity; an injection molding inlet communicating with the keycap forming cavity is formed in the fixed die; the ejection assembly comprises a top plate and a bottom plate clinging to the movable die; multiple ejection rods and support rods fixed onto the bottom plate are arranged on the bottom plate; multiple fixed holes for the ejection rods and the support rods to penetrate through are formed in theejection rods; the short oblique pins clamped with the ejection rods are arranged on the ejection rods; grooves clamped with the ejection rods are arranged on the short oblique pins; semi-cylindricalclips clamped into back grooves are arranged on the ejection rods; cylindrical bulges are arranged on one sides, far away from the grooves, on the short oblique pins; and support holes for placing thesupport rods are further formed in the movable die. The mould capable of demoulding the keycap through the short oblique pins provided by the invention has the effects that through reducing the lengths of the short oblique pins on the ejection rods, the linearity when the short oblique pins are pushed by the bottom plate is increased, and the yield of the keycap is further ensured.

Owner:苏州亿源精密模具有限公司

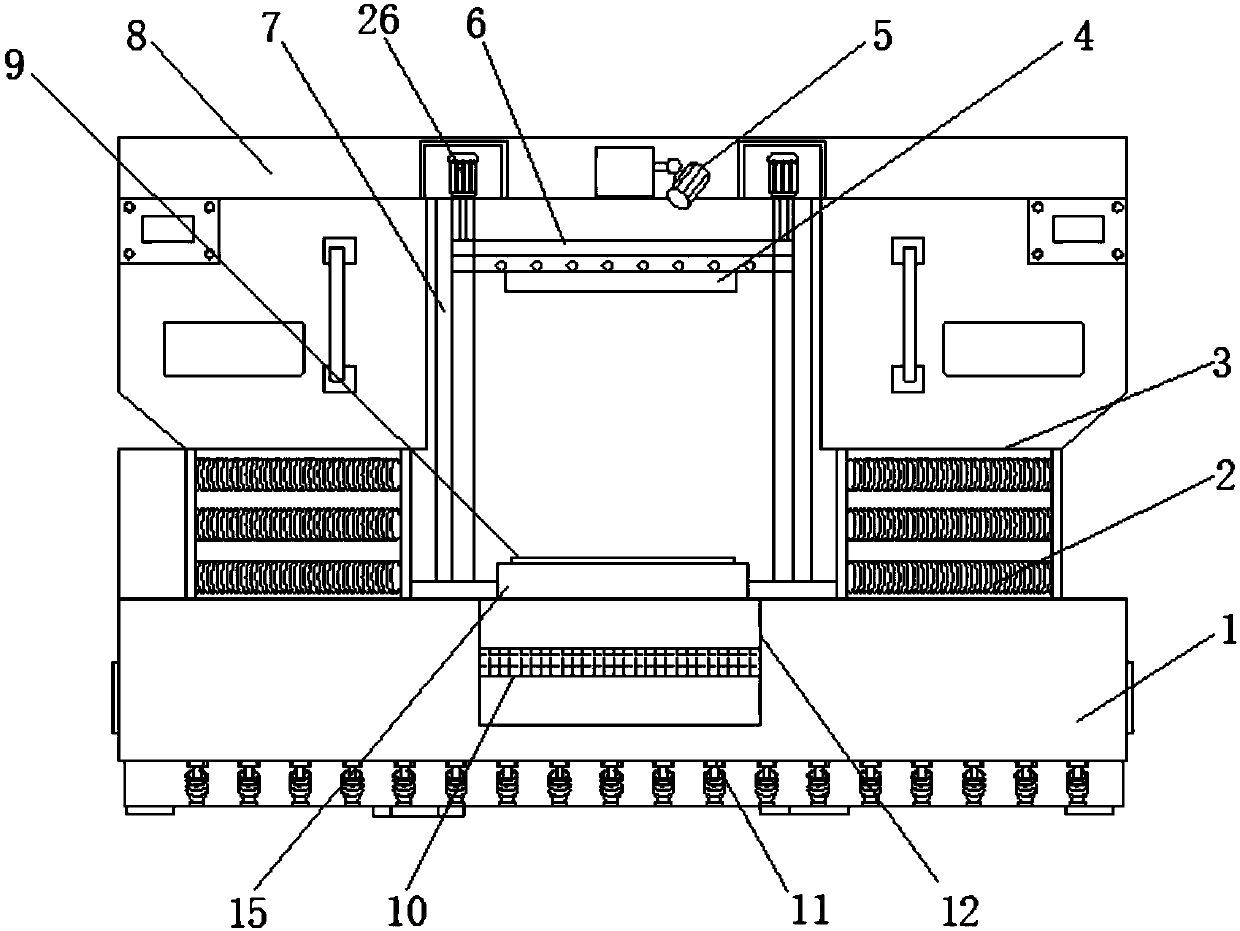

Particle-forming disk pelleting machine

InactiveCN106378059ANot easy to stickImprove molding rateDrying solid materials with heatGranulation by material expressionHydraulic cylinderInfrared lamp

The invention provides a particle-forming disk pelleting machine. The particle-forming disk pelleting machine comprises a base, a pelleting device and a spheroidizing device, wherein the pelleting device is rotationally connected with the base; the base is also provided with a high energy accumulation infrared lamp; the pelleting device comprises a main material pressing barrel and a side material pressing barrel; the main material pressing barrel and the side material pressing barrel are communicated through a pipeline; a main material pressing mechanism is arranged above the main material pressing barrel; a side material pressing disk is arranged above the side material pressing barrel; multiple small holes which are uniformly distributed are formed in the bottom part of the side material pressing barrel; a cutter is also arranged at the bottom part of a first support; the spheroidizing device comprises a spheroidizing plate and a material retaining plate; first hydraulic cylinders are arranged at two symmetric sides of the spheroidizing plate. According to the particle-forming disk pelleting machine provided by the invention, the granulation rate of a water quality improver is increased through a simple device, the processing cost is reduced, the processing efficiency is increased to the same degree, and the benefit is increased.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

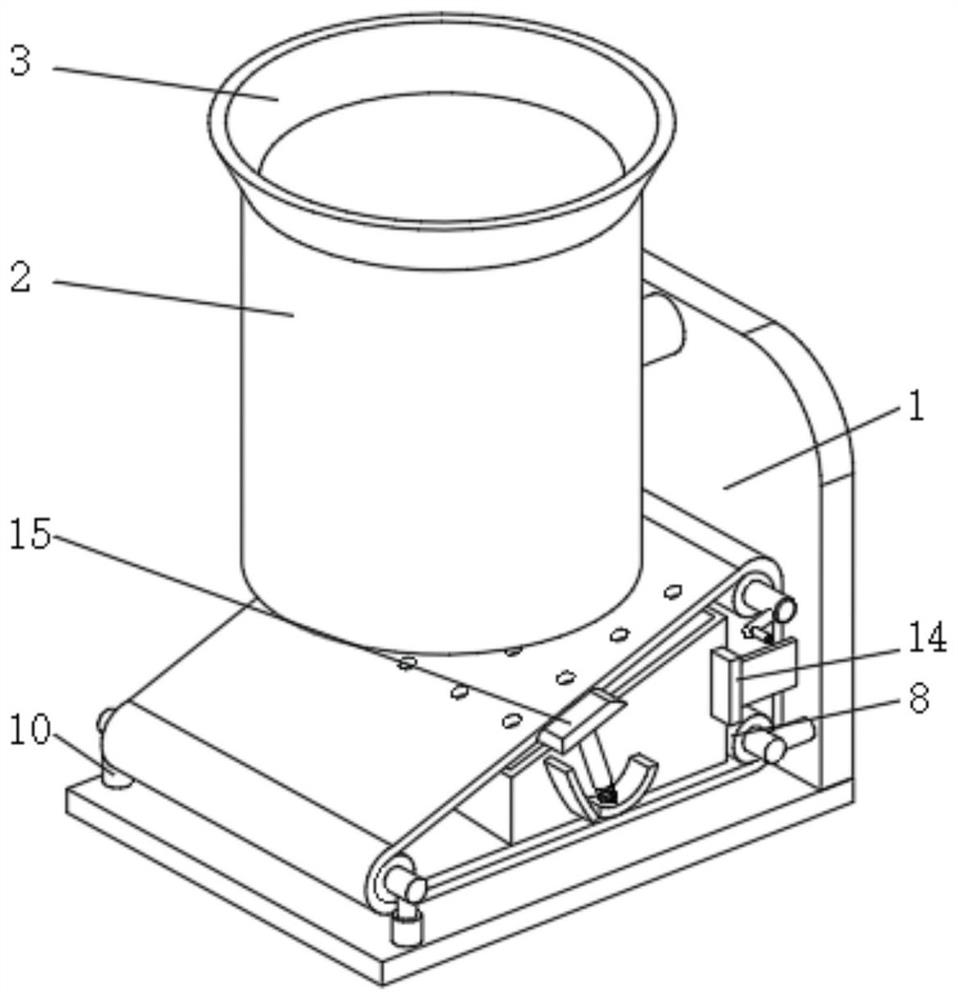

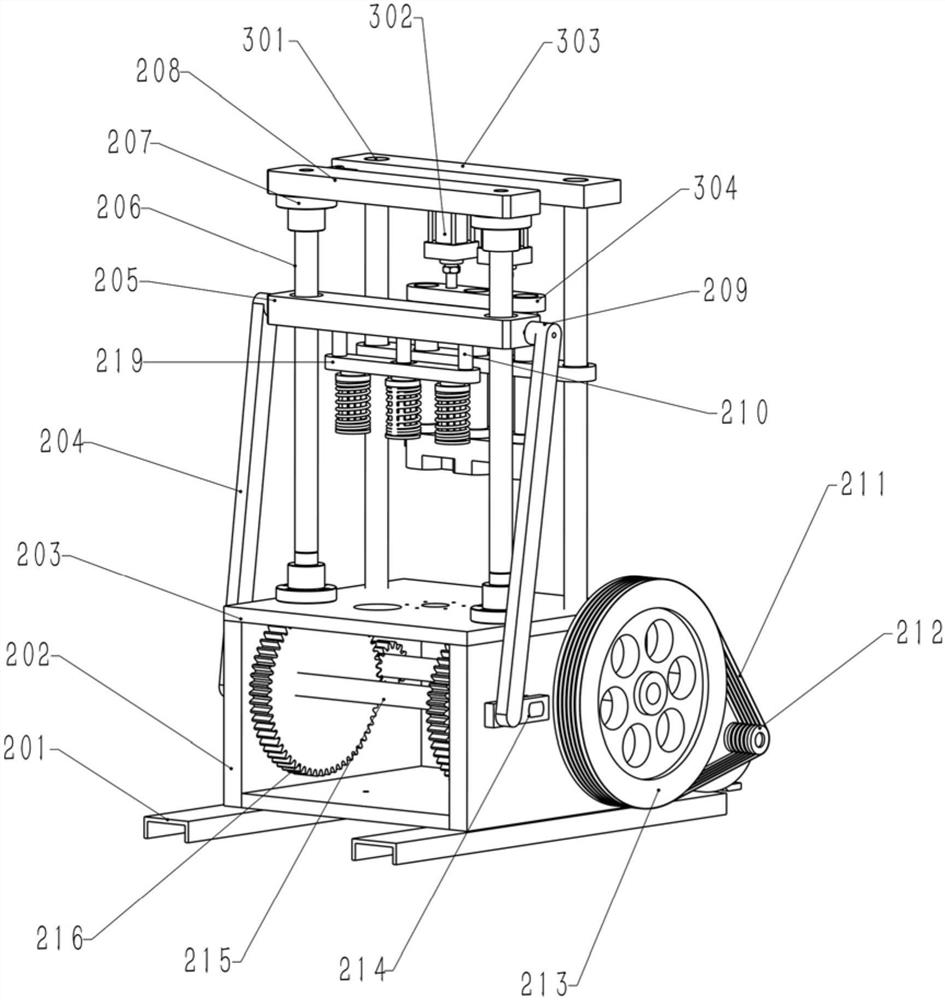

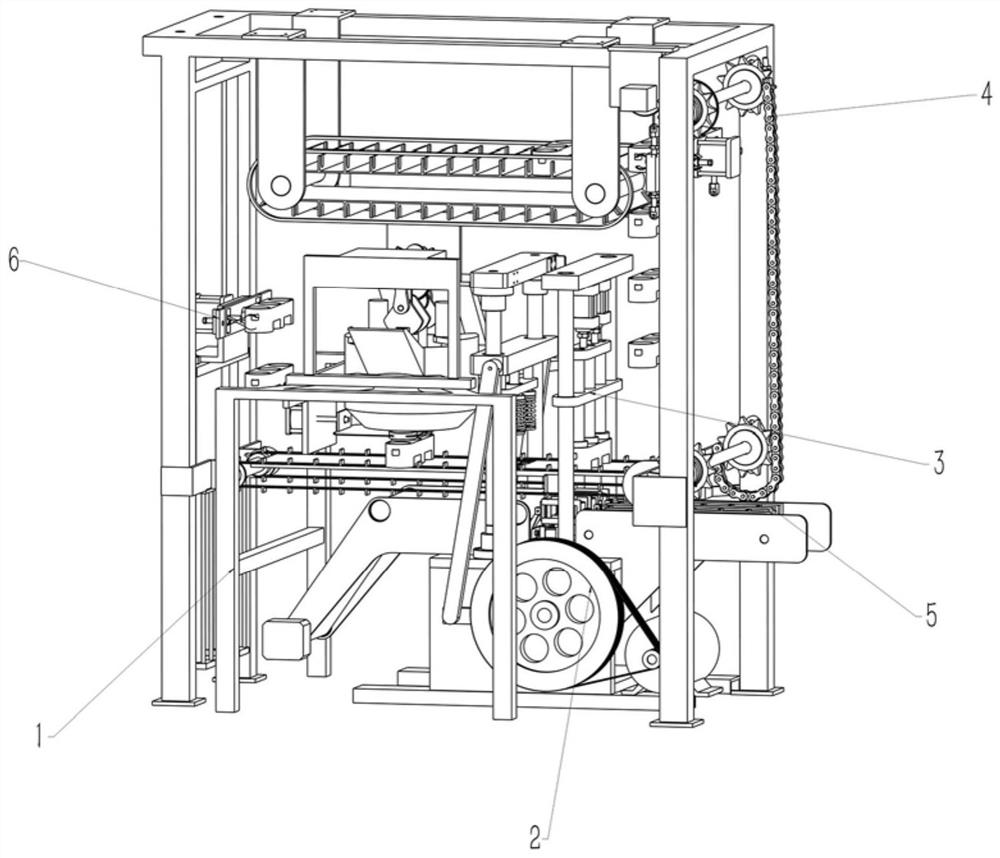

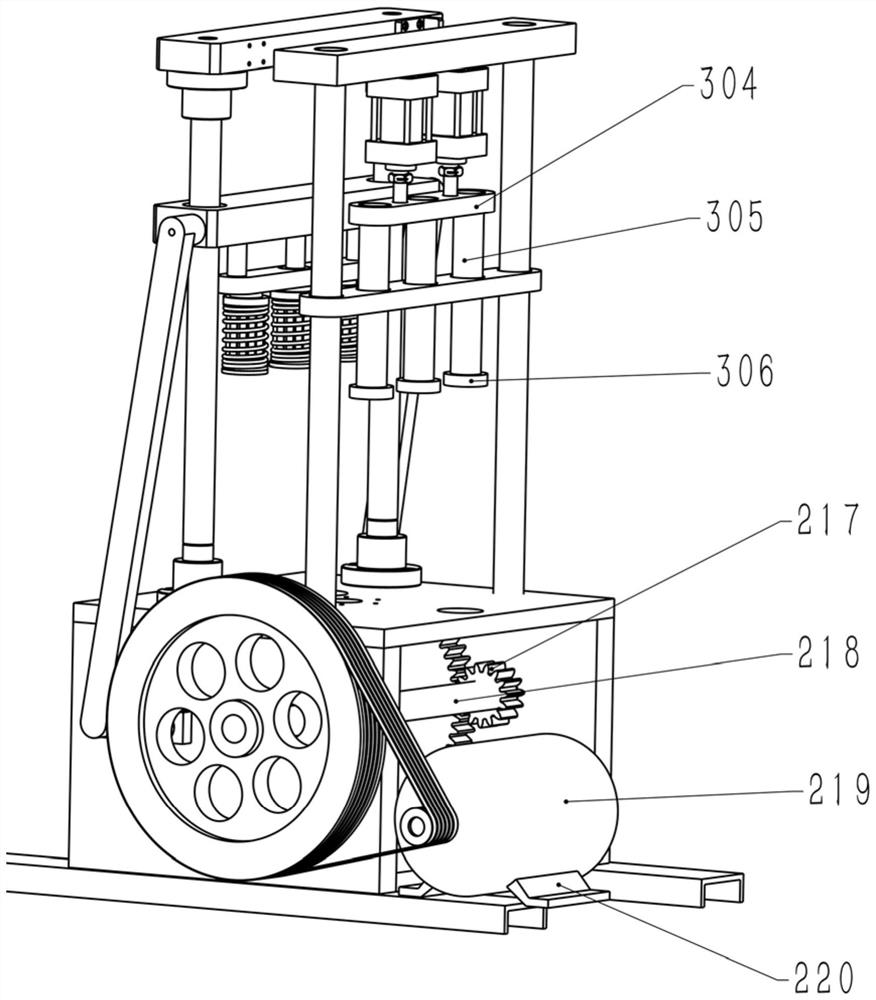

Mechanical cake pressing machine

InactiveCN105660760AGuaranteed molding rateImprove molding rateDough extruding machinesCircular discManufacturing technology

The invention belongs to the technical field of food machine manufacturing and relates to a mechanical cake pressing machine. The mechanical cake pressing machine comprises a support part, a conveying belt device, a dough pressing device, a cake pressing mechanism and a transmission device. A motor is arranged in the transmission device to respectively drive the conveying belt device and the cake pressing mechanism to work. A second eccentric disc and the length and wrapping structure of a second chain guarantees that a flywheel in a second drive device does not rotate when pressing blocks press down, and a conveying belt stops moving. The mechanical cake pressing machine is simple in structure, convenient to operate and capable of greatly increasing cake production efficiency and saving a large amount of manpower.

Owner:闫爱军

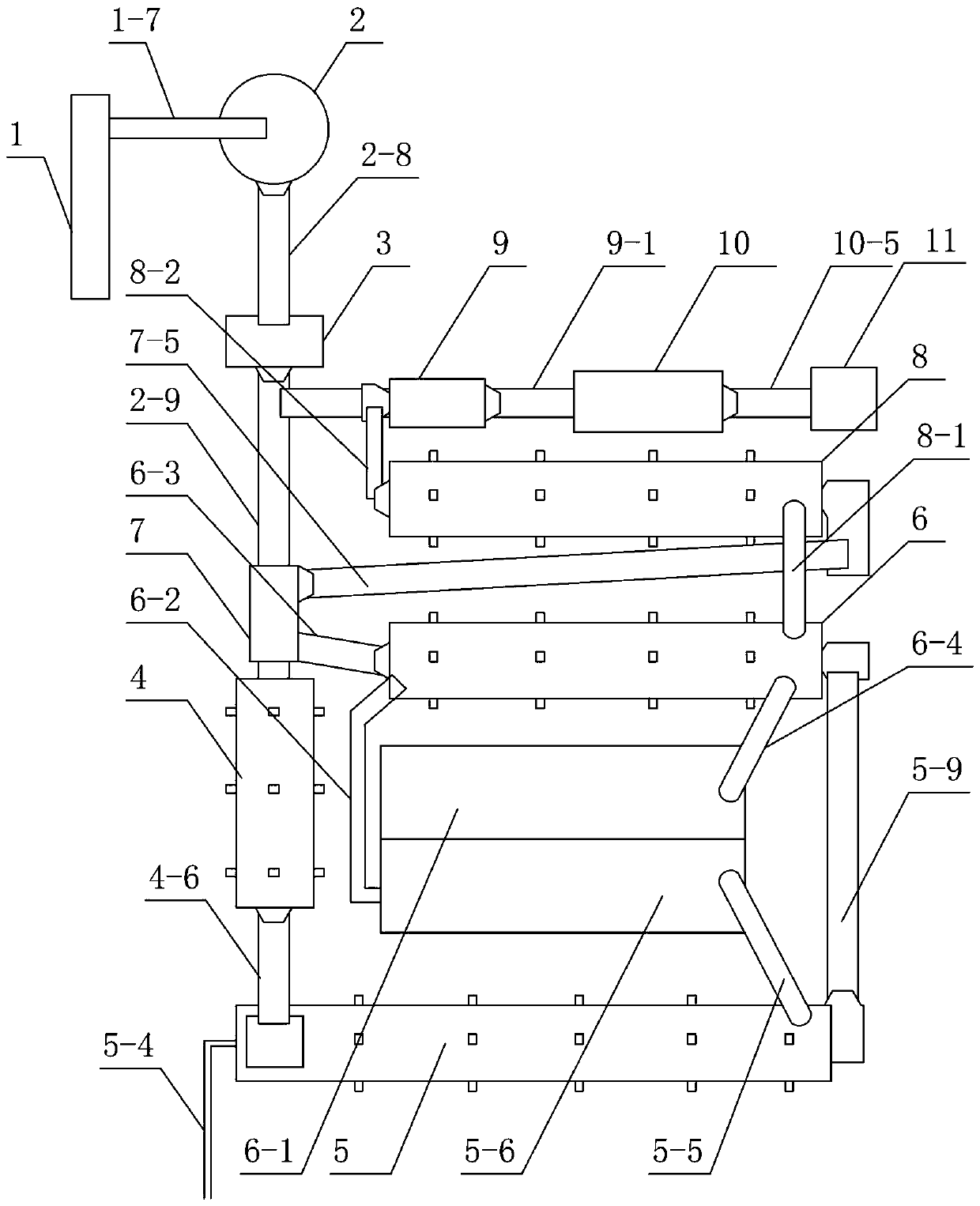

Fertilizer processing system

The invention discloses a fertilizer processing system. The system sequentially comprises a feeding device (1), a stirring device (2), a crushing device (3), a primary granulating device (4), a secondary granulating device (5), a primary cooling device (6), a primary screening device (7), a secondary cooling device (8), a secondary screening device (9), a coating device (10) and a weighing and bagging device (11), wherein the rear end of the secondary granulating device (5) is provided with an air outlet pipeline (5-5), and the other end of the first air outlet pipeline (5-5) is provided witha first gravity settling chamber (1). The technical purposes of high particle balling rate and few impurities are achieved through two times of granulation, two times of cooling and two times of screening, a dust removal procedure is arranged at the position of each device of the whole system, and particularly, the problem of dust raising in the fertilizer production process is solved in a targeted mode by adopting a multi-time gravity settling device at the station with the large dust amount.

Owner:安阳市宝康农资有限责任公司

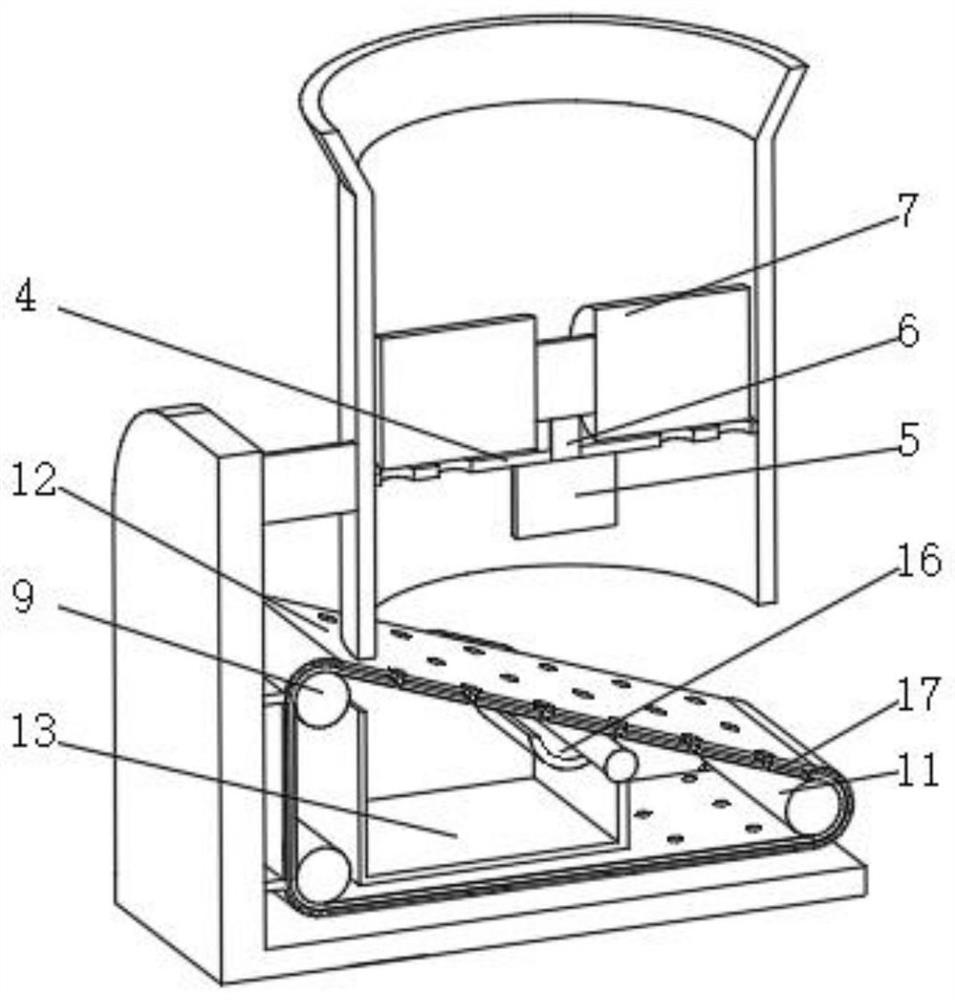

Biomass fuel processing and forming device

InactiveCN113663899ATo achieve the purpose of cleaningMake full use of structural featuresSievingScreeningElectric machineEngineering

The invention discloses a biomass fuel processing and forming device, and relates to the technical field of biomass energy. The biomass fuel processing and forming device comprises a base, one side of the base is fixedly connected with a forming cylinder through a fixing column, the top of the forming cylinder communicates with a feeding cylinder, the inner wall of the forming cylinder is fixedly connected with a fixing plate, forming holes are evenly formed in one side of the fixing plate, a driving motor is fixedly connected to the bottom of the fixing plate, an output shaft of the driving motor is rotationally connected with a rotating rod, one end of the rotating rod penetrates through the fixing plate and is fixedly connected with a pressing wheel, a first driven roller is rotationally connected to one side of the base through a rotating seat, and the side, close to the driven roller, of the base is rotationally connected with a driving roller through a rotating seat, and one side of the base is connected with a second driven roller through a hydraulic rod. According to the biomass fuel processing and forming device, the purpose of collecting formed and unformed straw particles in a classified mode is achieved, and the forming rate of finished products and the utilization rate of waste are guaranteed.

Owner:淮北特旭信息科技有限公司

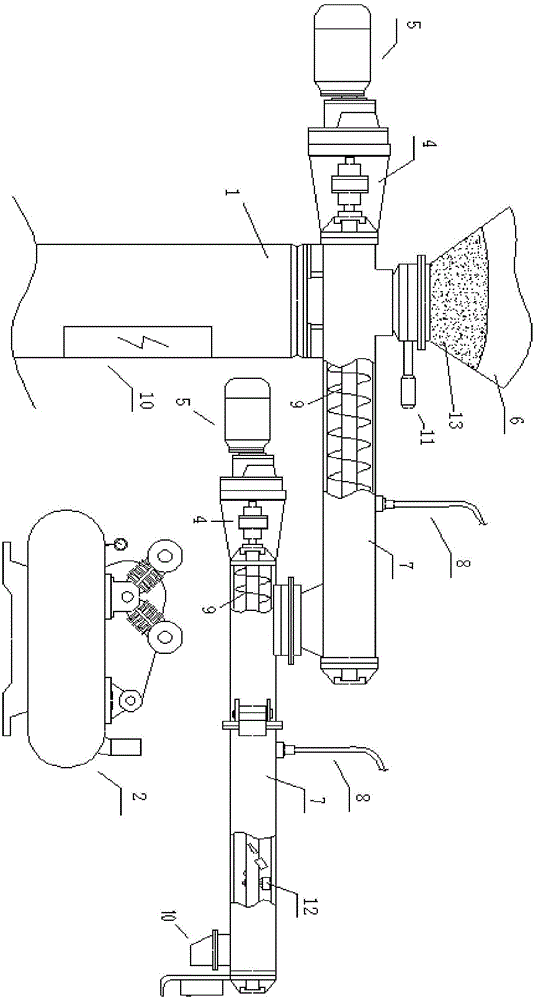

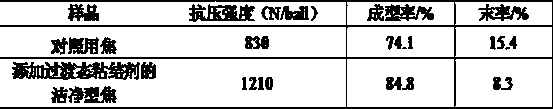

Intelligent tubular oppositely-opened type stirring machine

InactiveCN105688728AQuality assuranceGuaranteed molding rateTransportation and packagingMixer accessoriesCouplingSpiral blade

The invention discloses an intelligent tubular oppositely-opened type stirring machine which comprises a base, a multi-stage stirring pipe device and an air compressor.The multi-stage stirring pipe device is composed of a first-stage stirring pipe device body and a second-stage stirring pipe device body.The first-stage stirring pipe device body comprises a first-stage stirring pipe.The rear end of the first-stage stirring pipe is connected with a speed reduction electric motor through an elastic coupler.The first-stage stirring pipe is fixed to the base and communicated with a high-position bin.The second-stage stirring pipe device body comprises a second-stage stirring pipe.The second-stage stirring pipe is connected with the speed reduction electric motor through an elastic coupler.The discharge port of the first-stage stirring pipe is communicated with the feed port of the second-stage stirring pipe.Binder feeding systems are arranged on the first-stage stirring pipe and the second-stage stirring pipe respectively.Spiral blades are arranged in the first-stage stirring pipe and the second-stage stirring pipe respectively.A PLC electric appliance control cabinet is arranged on the base.The intelligent tubular oppositely-opened type stirring machine is reasonable in design and arrangement, the dry-to-wet ratio of clinker can be designed according to temperature differences of seasons and the humidity of air, and the amounts of dry materials, water and binder are arranged according to the proportion.

Owner:ANHUI CHENGUANG HIGH WEAR RESISTANCE TECH CO LTD

Continuous production processing system for clean coal

InactiveCN112026238AImprove molding rateStable Output ControlSolid fuelsShaping pressThermodynamicsProcess engineering

The invention relates to the technical field of efficient coal forming, in particular to a continuous production processing system for clean coal. Clean coal in a stock bin is rammed to different degrees through a ramming mechanism; a first inserting and pulling plate is matched with an extension inserting and pulling groove, so that it is guaranteed that after being tamped, the clean coal does not adhere into one piece; the redundant clean coal produced after tamping is conveyed out through a second rotating belt, so that it is ensured that the clean coal can be recycled again; then a formingassembly completes extrusion forming on the clean coal; the formed clean coal in a mold is separated through a mechanism of a demolding assembly; the formed clean coal is gradually conveyed out through a conveying assembly; a mold conveying assembly I can lift the mold upwards; when the mold is transported to the other end, the mold is downwards conveyed through the mold transmission assembly I;and the mold can be conveyed to the position below a charging barrel through a first rotating belt again, and thus cyclic machining is completed.

Owner:河北熙翔能源科技有限公司

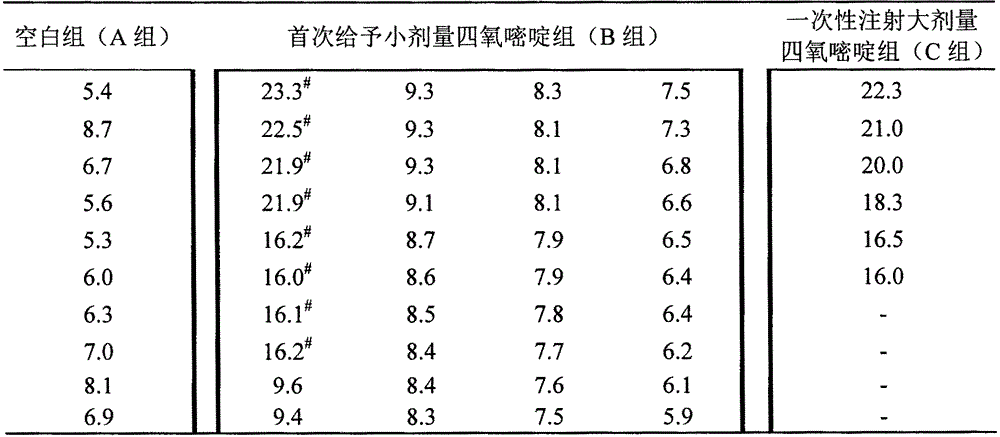

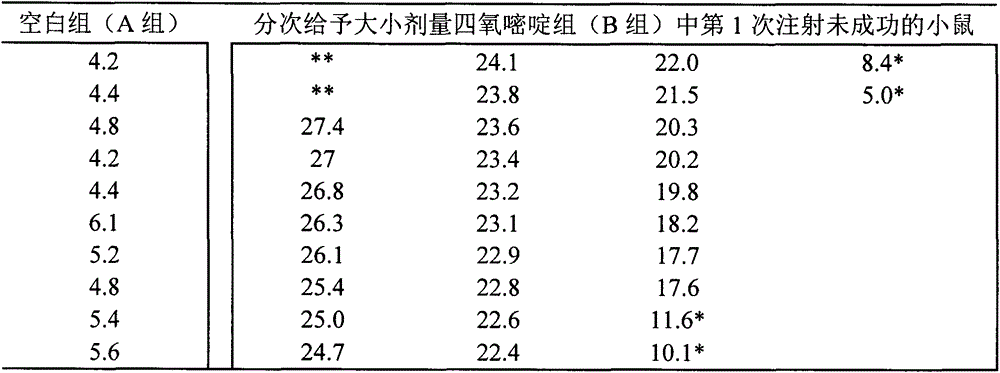

Method for quickly making models of diabetic mice

InactiveCN106377529AReduce deathReduce mortalityOrganic active ingredientsPharmaceutical delivery mechanismBlood glucose testing kitAnimals experiments

The invention discloses a method for quickly making models of diabetic mice. Male Kunming-strain mice are adopted, and are raised until body weights reach 30(+ / -)2g before an experiment, and then the experiment is carried out. The method comprises the following steps of enabling the mice to fast without depriving water for 18 hours, then directly injecting tetraoxypyrimidine from caudal veins with the dosages of 35mg per kilogram of the body weights, measuring blood sugar by using a blood sugar testing instrument on the sixth day after the injection, electing the mice succeeded in modeling, and continuously giving conventional raising to the mice; on the same day when the blood sugar is measured, continuously enabling the mice which are not modeled to fast without depriving the water until 24 hours, then injecting the tetraoxypyrimidine to the mice which are not modeled from the caudal veins with the dosages of 70mg per kilogram of the body weights once again, measuring the blood sugar by using the blood sugar testing instrument on the sixth day after the injection, and electing the mice succeeded in the modeling. The blood sugar values of the mice succeeded in the modeling are between 16.0mmol / L to 28.0mmol / L; the method for quickly making the models of the diabetic mice can be used for a relevant animal experiment in which the diabetic mouse is used as the model. The success rate of establishment of the model of the method reaches 85.00 percent; no death occurs; the modeling time is short; the experiment is simple and convenient, and is easy to operate.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

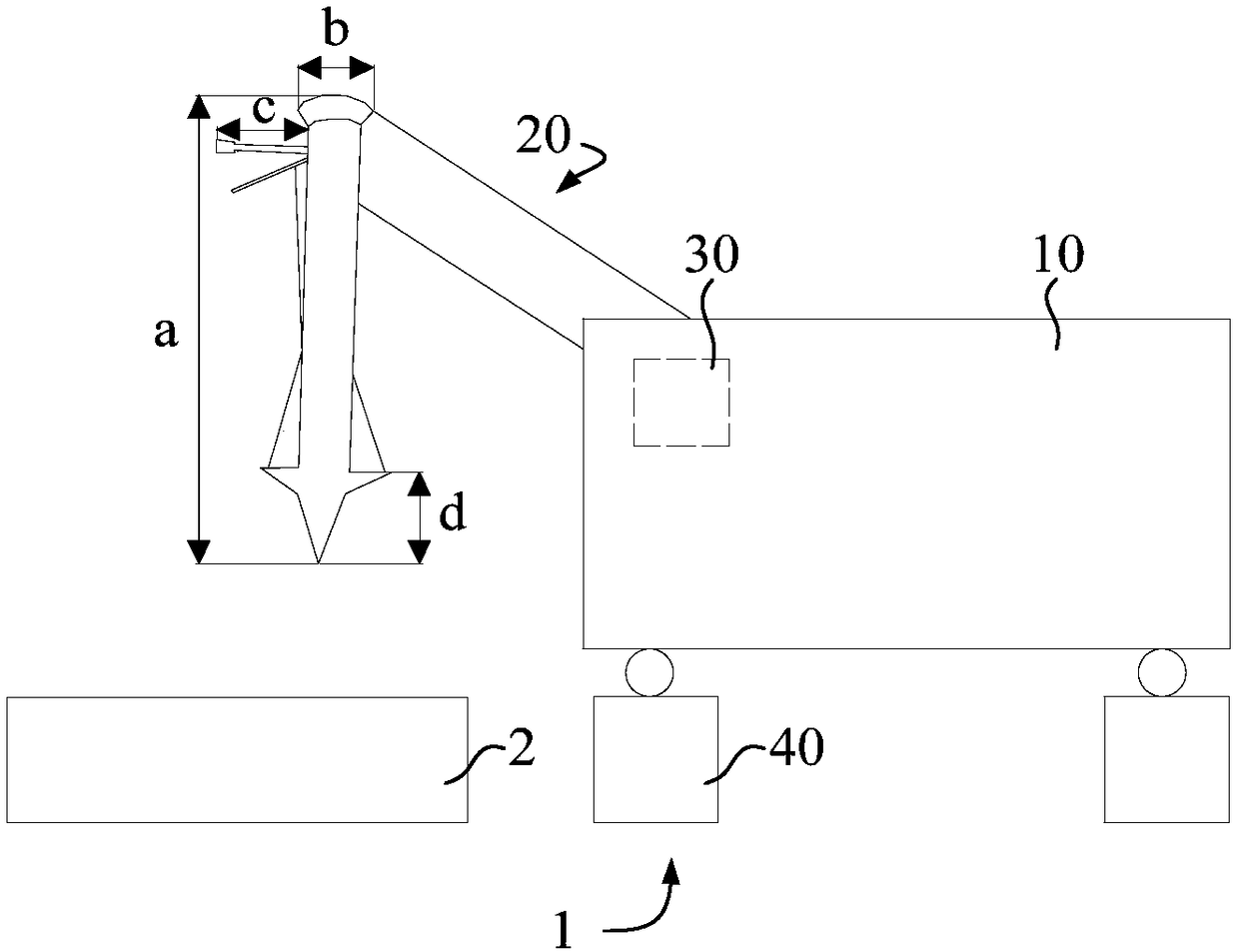

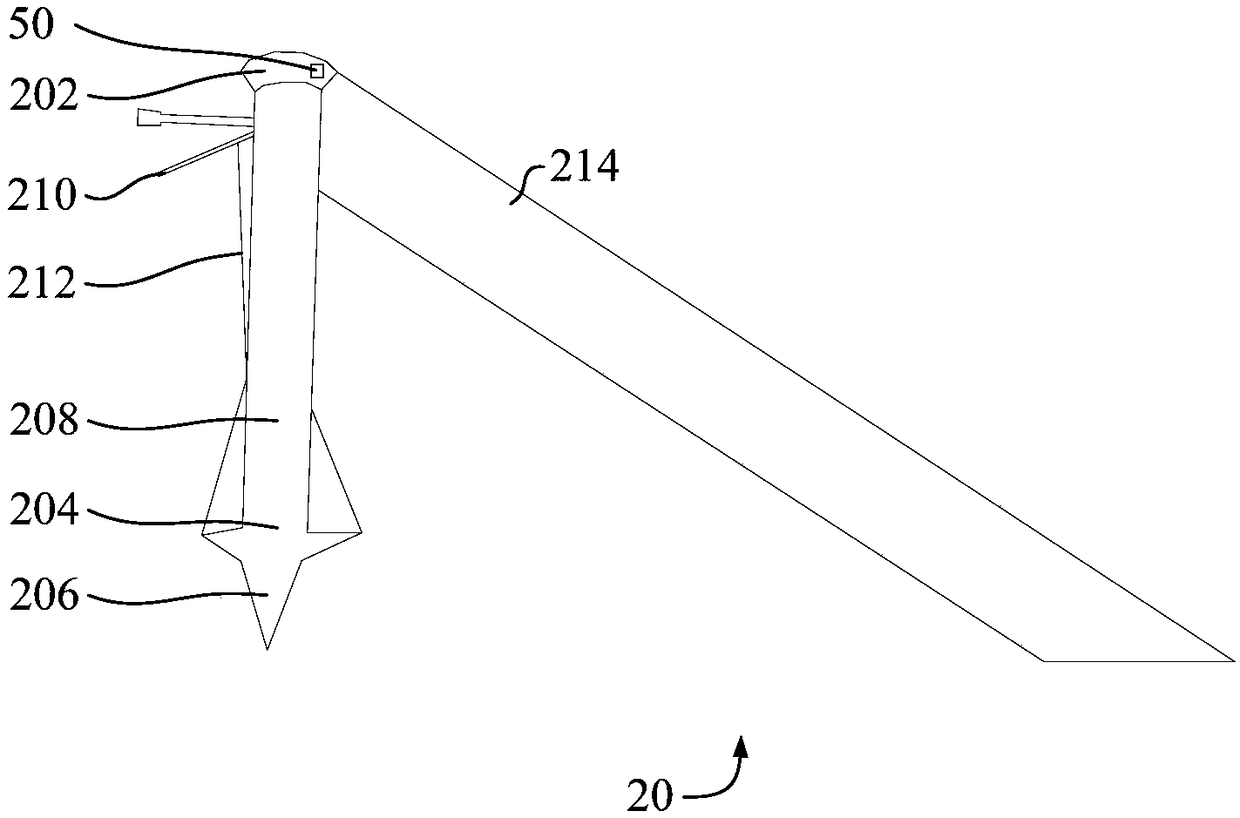

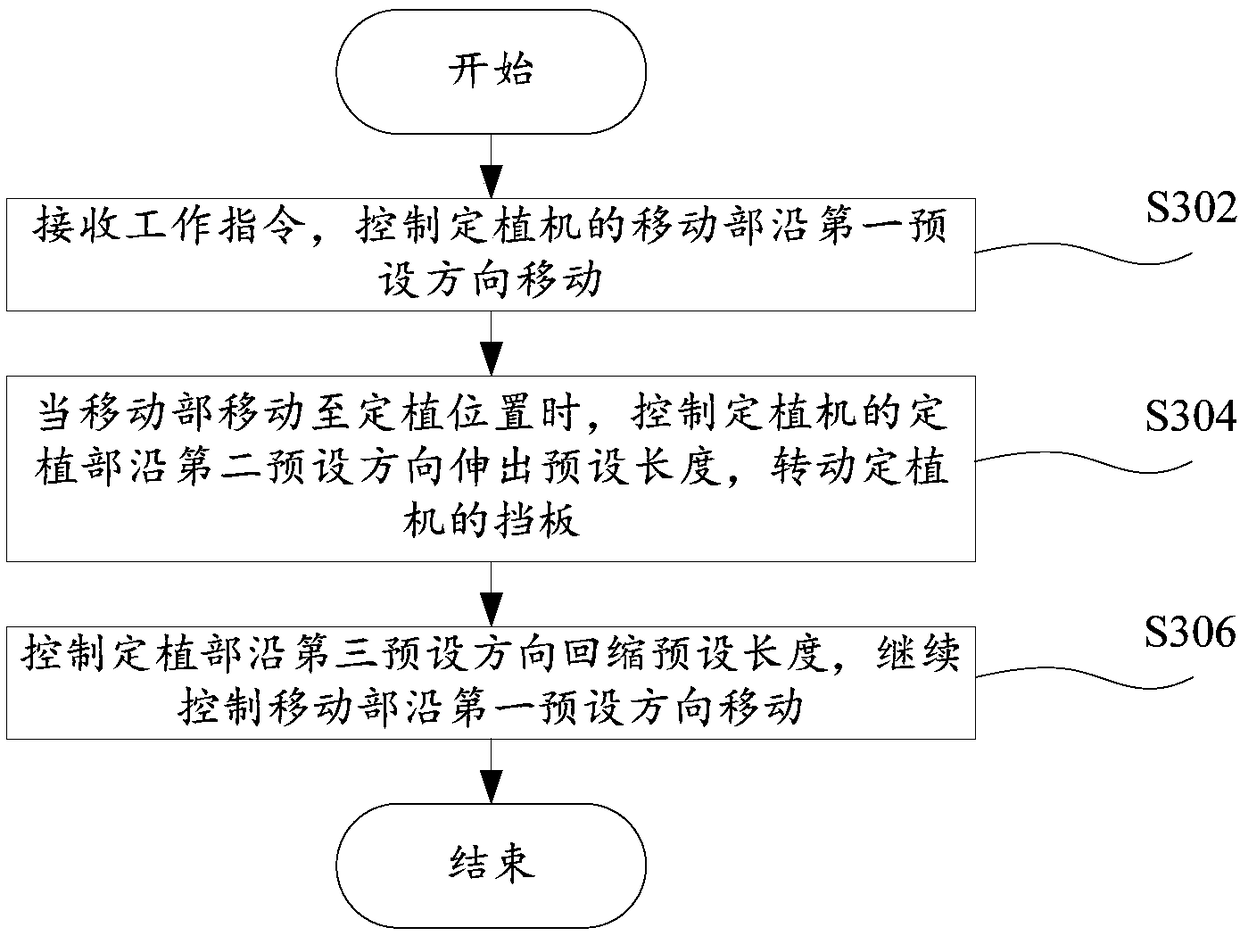

Field planting machine and control method thereof

PendingCN109463084AGuaranteed accuracyProblems affecting growthTransplantingProgramme control in sequence/logic controllersEngineeringX-machine

The invention provides a field planting machine, a control method of the field planting machine and a computer-readable storage medium. The field planting machine comprises a moving part, a field planting part and a driving part, wherein the field planting part is telescopically connected with the moving part; the field planting part is provided with an inlet, an outlet and a baffle; the inlet andthe outlet are communicated with each other; the baffle can cover the outlet; the driving part is respectively connected with the moving part and the field planting part; after a plant is put from the inlet, the driving part drives the moving part to move to a field planting position, and the field planting part is driven to extend to a seedling placement position, so that the field planting partis inserted into soil or a substrate so as to form a pit, and the driving part drives the baffle to rotate to open the outlet and drive the field planting part to retract. Therefore, the plant dropsinto the pit from the outlet. According to the reasonable arrangement of the structure of the field planting machine, automatic field planting is realized, convenience is brought to manual operations,time and labor can be saved, and the production cost is reduced.

Owner:SHENZHEN SPRINGWOODS HLDG CO LTD

Method and product for improving magnetic conductivity of iron-based magnetic powder core based on magnetic exchange length

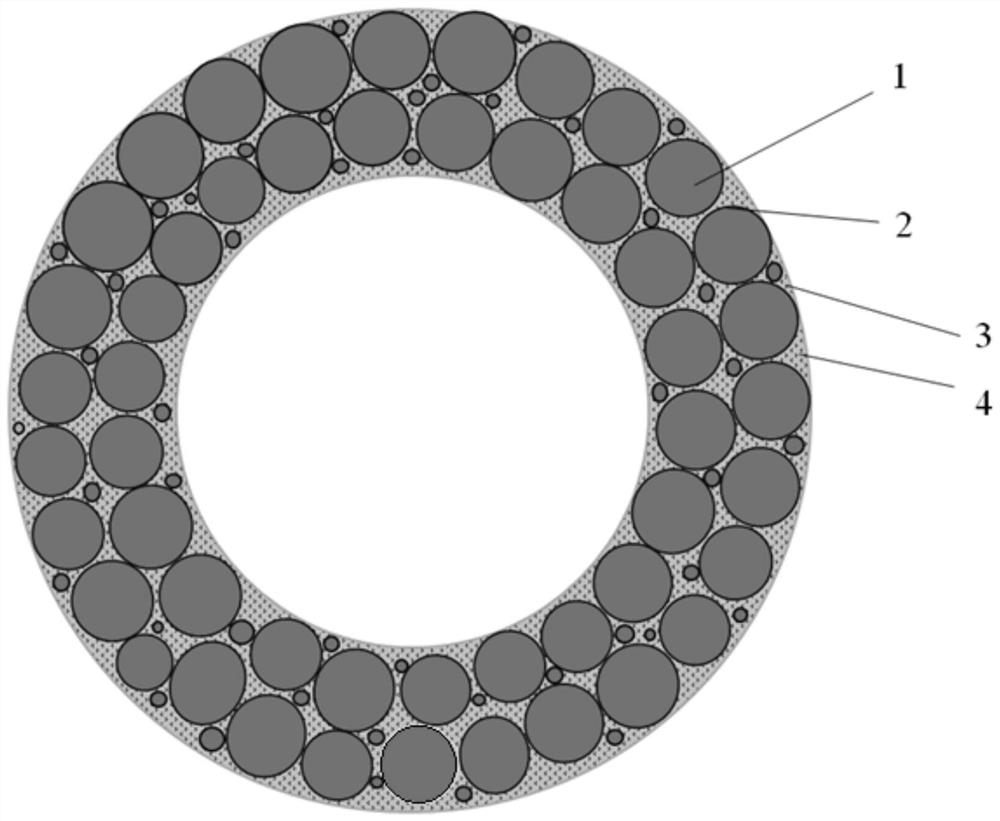

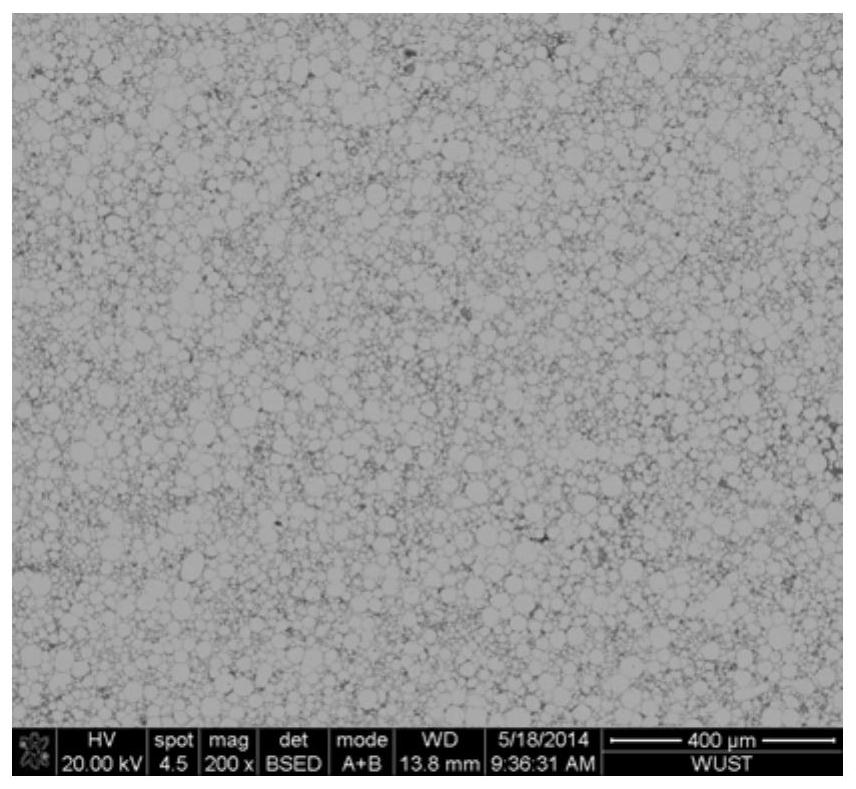

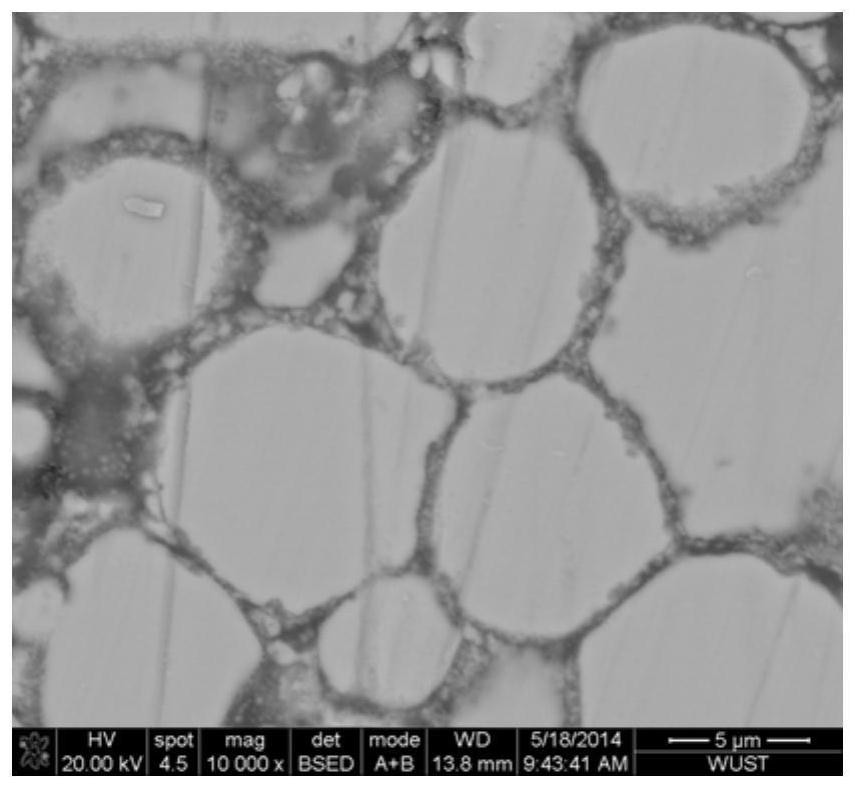

PendingCN113077953AImprove magnetic permeabilityIncrease contentInorganic material magnetismInductances/transformers/magnets manufacturePowder metallurgyMagnetic phase

The invention discloses a method and product for improving the magnetic conductivity of an iron-based magnetic powder core based on the magnetic exchange length, and belongs to the technical field of soft magnetic materials and powder metallurgy. The preparation method comprises the following steps: firstly, coating the surface of iron-based soft magnetic powder with a silicon dioxide insulating layer to obtain iron-based / silicon dioxide soft magnetic composite powder; then adding the nanoscale iron-based soft magnetic powder into the binder, uniformly mixing and ultrasonically dispersing to obtain the binder with uniformly dispersed nanoscale iron-based soft magnetic powder; and finally, uniformly mixing the iron-based / silicon dioxide soft magnetic composite powder, a binder with uniformly dispersed nano-scale iron-based soft magnetic powder and a release agent, performing compression molding, and performing heat treatment to obtain a product of which the distance between magnetic phases in the iron-based magnetic powder core is controlled within a magnetic exchange length (30-75nm), so that the magnetic induction intensity and the magnetic conductivity of the product are effectively improved. The method is simple in process, easy to operate, low in production cost and suitable for popularization and application.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

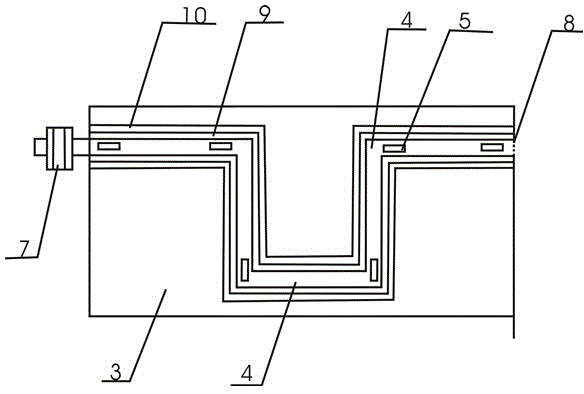

Novel fast-molding injection molding die

InactiveCN104908251AAvoid coolingAvoid affecting injection molding resultsBaseboardProcess engineering

The invention provides a novel fast-molding injection molding die. The novel fast-molding injection molding die comprises a baseboard, a movable die, a fixed die, a casting system and an ejection structure, and also comprises a fixed lock block, a filter, a gas discharge hole, a heating layer and a cooling layer, the baseboard is fixedly provided with the fixed die, the fixed die is provided with the casting system, the forefront side of the casting system is provided with the filter, the backmost side of the casting system is provided with the gas discharge hole, the heating layer is also arranged, a raw material injected to a complex injection molding die easily cools after a long time, and the heating layer avoids cooling of the injection molding raw material before injection molding when the raw material is injected, so the product molding yield is guaranteed. When the injection molding is completed, the heating layer is closed, and the cooling layer is started to cool a product and guarantee molding of the product, so the product can be ejected by the ejection structure.

Owner:TIANJIN LIANJIE PLASTIC PROD

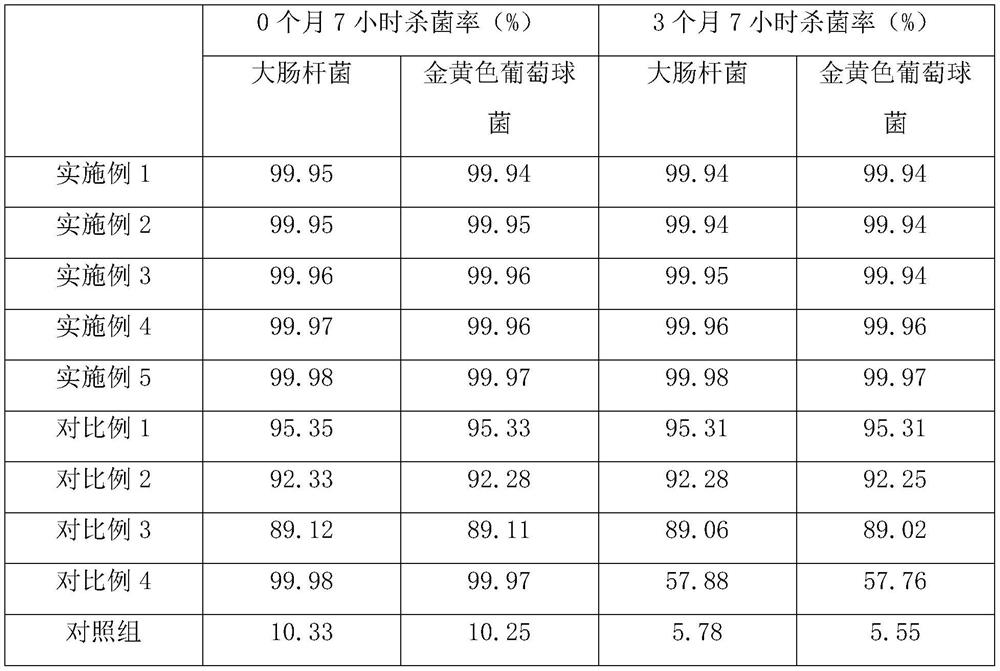

A kind of antibacterial toothbrush and manufacturing method thereof

ActiveCN108359236BExtend the life cycleWill not polluteDomestic articlesAntimicrobial actionPolymer science

Owner:杭州纳美智康科技有限公司

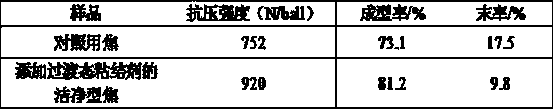

Method for producing clean formed coke based on lignin transition state binder

The invention relates to a method for producing clean formed coke based on a lignin transition state binder. The method comprises the following steps: selecting bauxite, silica and coal liquefaction residues, respectively crushing, adding lignin, slaked lime and pre-gelatinized starch, uniformly stirring and mixing, and carrying out dry grinding to obtain the lignin transition state binder; selecting blended coal, uniformly mixing the blended coal with the lignin transition state binder according to a ratio, carrying out cold press molding, carrying out dry distillation in a vertical dry distillation furnace, discharging the red hot furnace burden, and cooling to room temperature through a coke quenching process to obtain the clean formed coke. The raw materials are wide and rich in sourceand low in price, have the effects of a cold-hot state binder, and play a role in binding before the cold state binder fails and a hot state binder acts in the pyrolysis process so that the forming rate and the formed coke strength of the materials in the dry distillation furnace are guaranteed.

Owner:TAIYUAN UNIV OF TECH +1

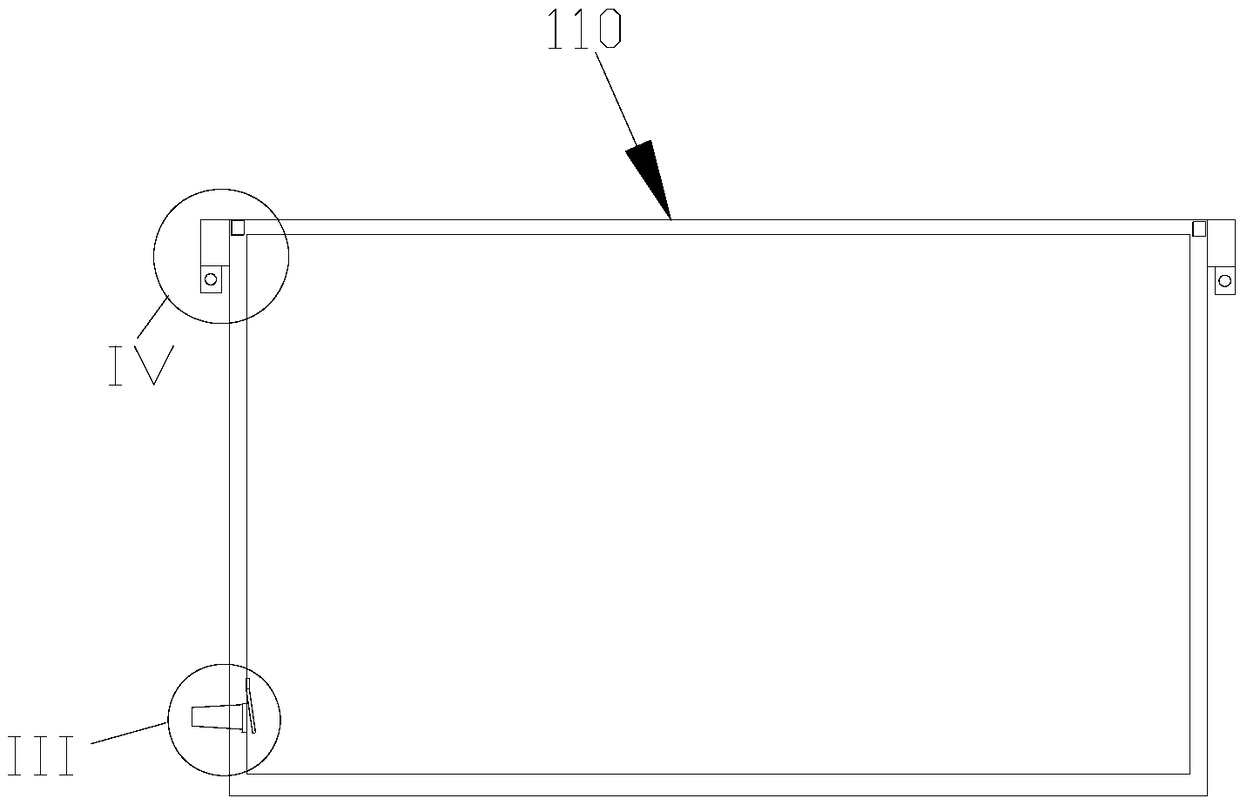

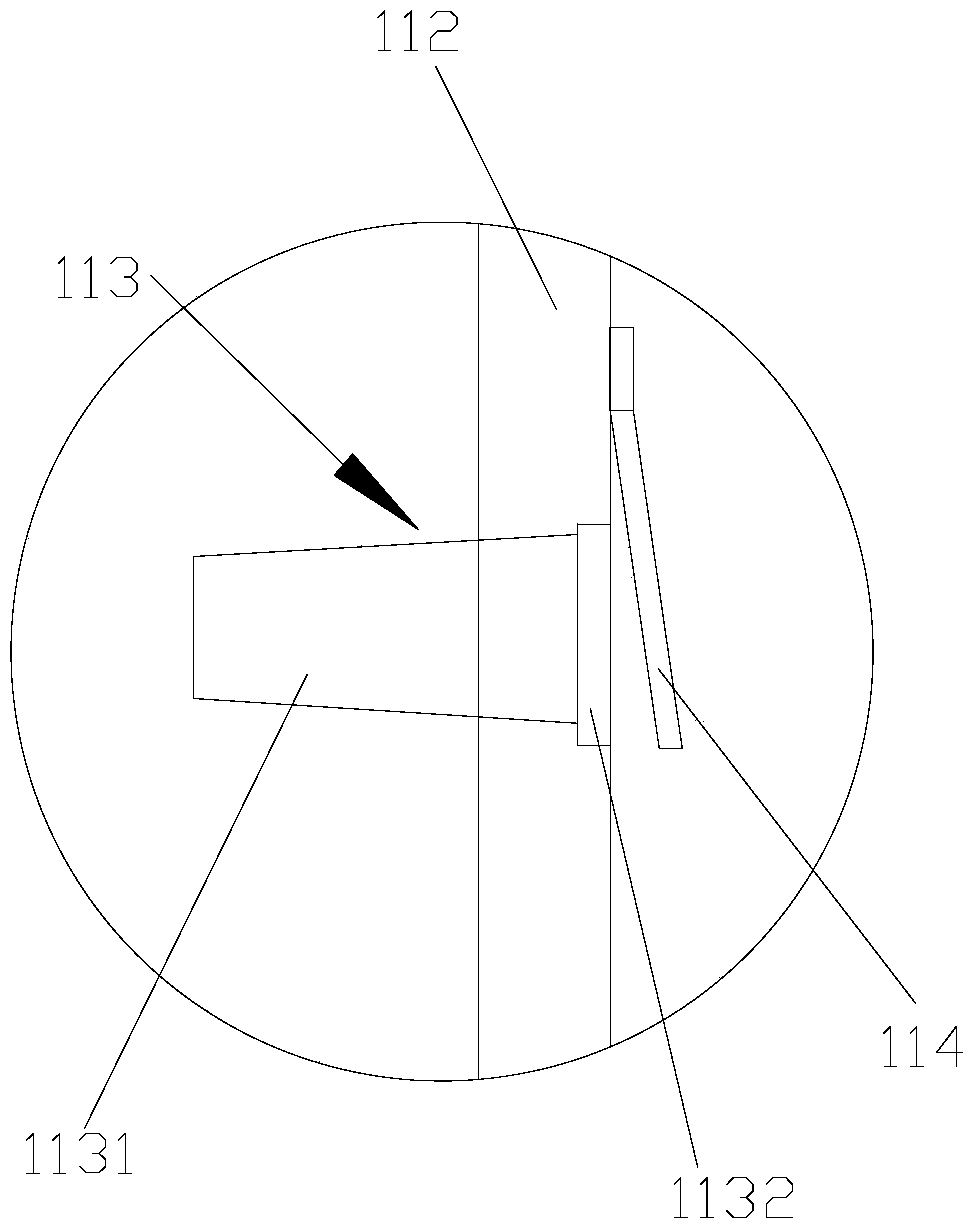

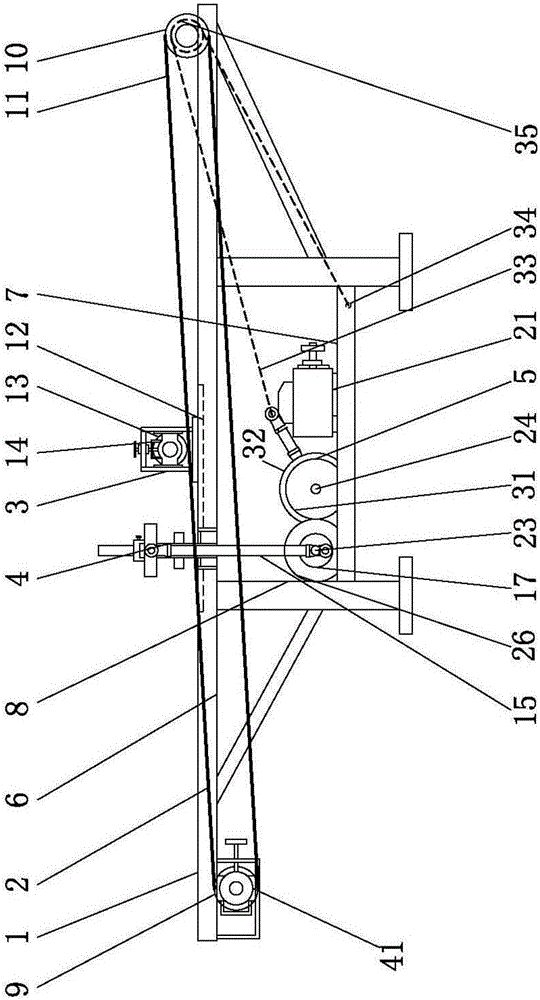

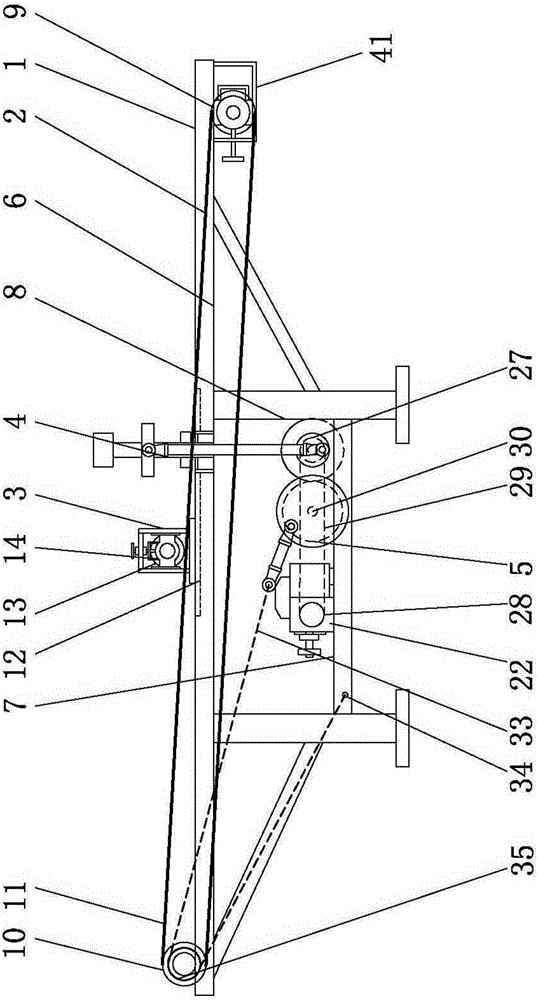

Automatic profile cutting equipment

InactiveCN108044186AGuaranteed molding rateEnsure safetyMetal sawing devicesMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses automatic profile cutting equipment. The automatic profile cutting equipment comprises a base, a stand column, a mounting plate, a workbench and a conveying belt. The conveyingbelt is evenly provided with profile placement positions. First telescopic motors are symmetrically mounted on the two sides of the profile placement positions. Fixing plates are mounted at the output ends of the first telescopic motors. Upper fixing bases are mounted on the sides, away from the upper portions of the output ends of the first telescopic motors, of the fixing plates. Second pneumatic cylinders are mounted in the middles of the upper fixing bases. Limiting springs are arranged at the output ends of the second pneumatic cylinders. Positioning plates are arranged at the bottoms ofthe limiting springs. Lower fixing bases are mounted on the sides, away from the lower portions of the output ends of the first telescopic motors, of the fixing plates. The automatic profile cuttingequipment is provided with the upper fixing bases, the lower fixing bases, the second pneumatic cylinders, the fixing plates, the limiting springs and positioning blocks which form a clamping mechanism jointly, profiles with different widths can be clamped, the clamping effect is better, and the shape rate of the machined profiles is ensured.

Owner:钟丽菊

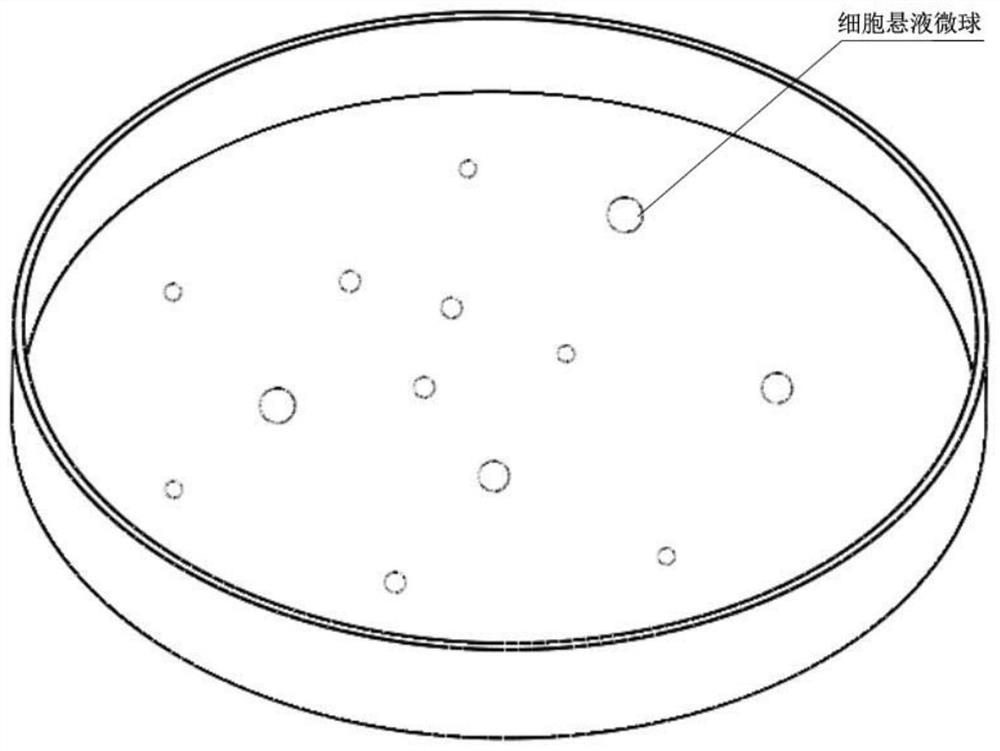

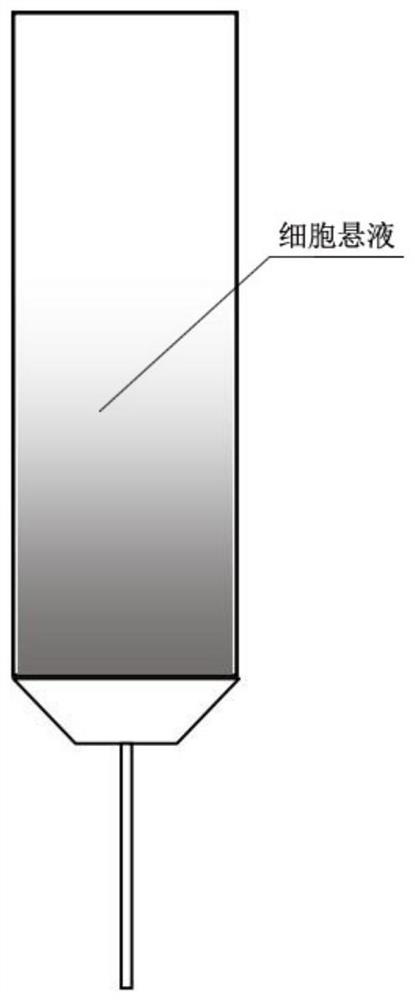

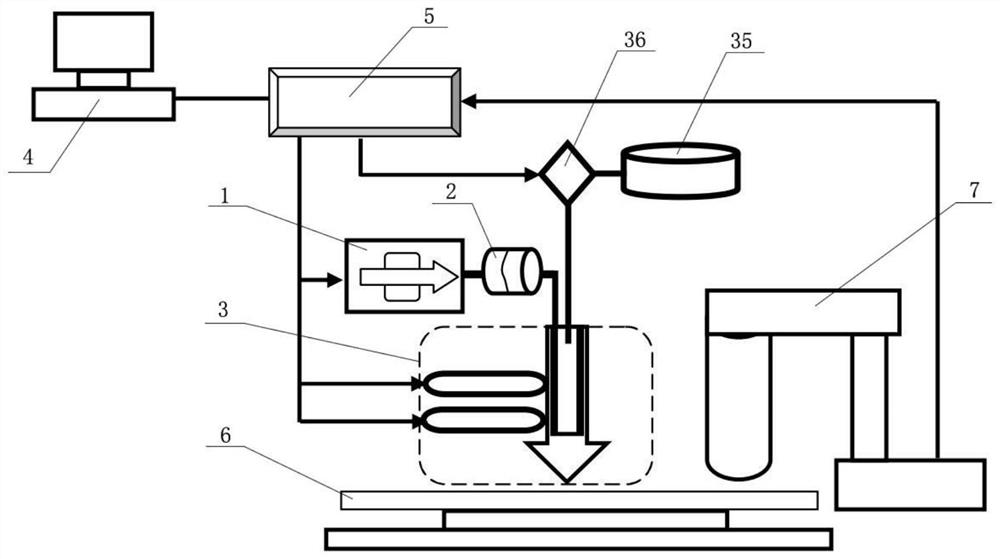

Organ-like forming device and working method thereof

PendingCN113293096AHigh degree of automationShorten induction timeBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryComposite material

The invention provides an organ-like forming device. The organ-like forming device comprises a pump, a spiral pipe and a spray head unit, one end of the spiral pipe is connected with the pump, the spiral pipe is used for storing and transporting cell suspension, and the spray head unit is connected to the other end of the spiral pipe and extrudes the cell suspension conveyed by the spiral pipe to form cell suspension microspheres through the airflow spraying effect or the high-voltage electrostatic effect. The invention further provides a working method of the organoid forming device. According to the method, the initial cell content of the obtained cell suspension sample liquid drops for organoid culture is uniform and consistent, so that the finally constructed organoid body is uniform in size.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Method for producing clean coke based on aluminum oxide transition state binder

The invention discloses a method for producing clean coke based on an aluminum oxide transition state binder. The method includes the steps: selecting and crushing silica, limestone and coal liquefaction residues, adding aluminum oxide, metakaolin and pregelatinized starch, uniformly stirring and mixing the materials and then performing dry grinding to obtain the aluminum oxide transition state binder; selecting blended coal, uniformly mixing the blended coal and the aluminum oxide transition state binder according to the proportion of the blended coal and the aluminum oxide transition state binder, performing cold pressing, performing dry distillation in a vertical dry distillation furnace, discharging red hot furnace charge and then cooling the red hot furnace charge to normal temperature by a coke quenching procedure to obtain the clean coke. Raw material sources are wide and rich, the cost is low, the clean coke has the functions of cold-hot state binders and functions in adhesionbefore the cold state binder loses efficacy and the hot state binder takes effect in the pyrolysis process, and the forming rate and the formed coke strength of the materials in the dry distillation furnace are ensured.

Owner:TAIYUAN UNIV OF TECH +1

Simple-to-assemble iron casting mould

ActiveCN110180992ASimple structureEasy to operateFoundry mouldsFoundry coresWater pipeMaterials science

The invention belongs to the field of moulds and particularly relates to a simple-to-assemble iron casting mould. On account of the problems that the existing water pipe is inconvenient to mount on water pipe joints and the discharging of air in machined grooves is un-thorough, the following technical scheme is provided. The iron casting mould comprises an upper mould and a lower mould, wherein anupper machined groove is formed in the lower end side wall of the upper mould, a lower machined groove matched with the upper machined groove is formed in the upper end side wall of the lower mould,an upper through hole matched with the upper machined groove is formed in the side wall of the upper mould, a lower through hole matched with the lower machined groove is formed in the side wall of the lower mould, and water pipe joints matched with the upper through hole and the lower through hole are separately formed in the two side walls of the upper mould and the lower mould. Two clamping blocks are driven to move towards each other or far away from each other through the cooperation of threaded rods, moving plates, swing rods and the like, and accordingly, the water pipe can be rapidly installed and disassembled, so that the cost is saved. Besides, by utilizing the structure including air holes, connecting grooves and the like, the air in the machined grooves is more thoroughly discharged, and the design is convenient and practical.

Owner:徐州万佳机电设备制造有限公司

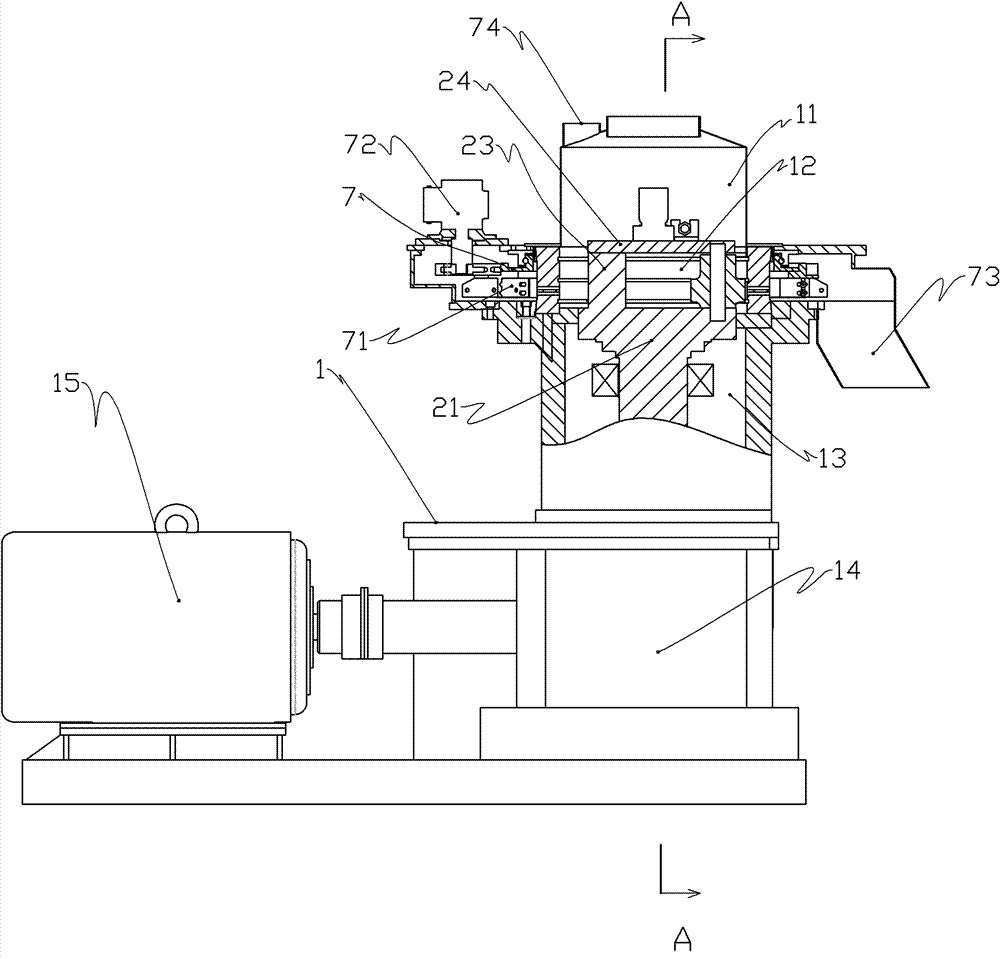

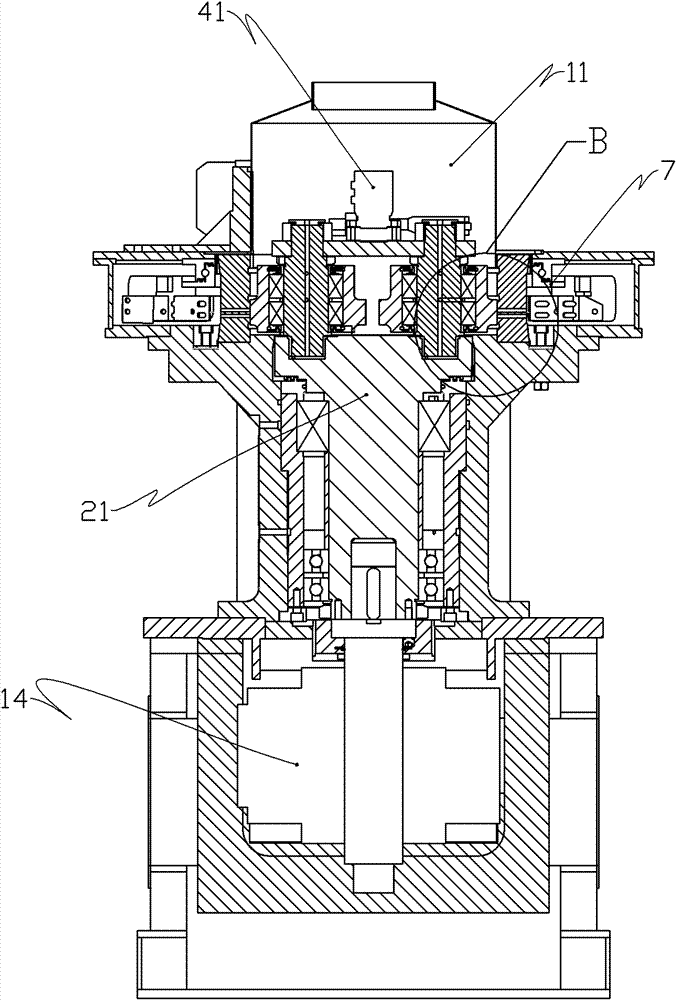

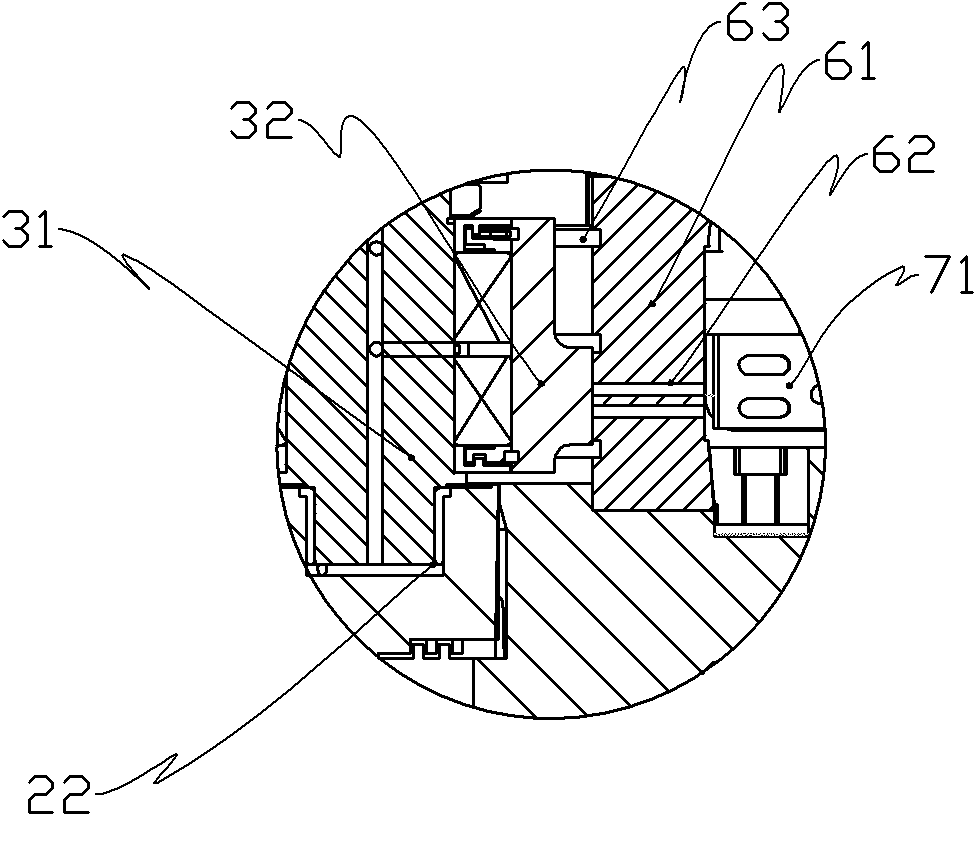

Centrifugal efficient wood chip granulator

ActiveCN102092070BReduce energy consumptionNo accumulationWood working apparatusGranulation by material expressionEngineeringMechanical engineering

The invention provides a centrifugal wood chip granulator which is granule manufacture equipment. The granulator comprises a frame, a die which is statically fixed on the frame, a rotating main shaft connected with a power mechanism and a pinch roller assembly arranged on the rotating main shaft, wherein a pinch roller adjusting device on the pinch roller assembly can ensure that the pinch roller and the inner surface of the die are constantly inscribed. Wood chips and other materials are fed from the upper end of the granulator, thus a static granulating mode of the die is created, and the materials in a compression cavity are ensured to be in a compressed and centrifuged state, so the granulation effect is good; axes of the die and rotating main shaft are superposed and in a vertical state, the die has a unique design, and the treatment efficiency and the treatment effect are improved.

Owner:山东宇龙机械有限公司

A quick demoulding device for cement block pouring

The invention relates to a quick demoulding device, in particular to a quick demoulding device for cement block pouring. The purpose of the present invention is to provide a cement block with high yield and high efficiency, which can reduce the fatigue of workers and ensure the molding rate of the cement block. The quick release device for cement block casting. The technical solution is: a quick demoulding device for cement block pouring, including a car plate, a first slide rail, a first straight rack, etc.; both sides of the top of the car plate are connected with the first slide rails, and the top of the car plate is connected with a Both sides of the first slide rail are connected with a first spur rack, and the side of the top of the vehicle plate away from the first slide rail is connected with a push block. Through the cooperation of the first spur rack, the second spur rack, and the spur gear, the parts on the device move upward to a suitable position, which facilitates the turning of the cement block, and makes some parts of the device turn over to achieve the cement block The purpose of flipping is to improve efficiency and reduce worker fatigue.

Owner:梁小芳

Approximate lattice oriented graphene preparation device and method

The invention belongs to the technical field of graphene preparation and particularly relates to an approximate lattice oriented graphene preparation device and method. The device comprises a collection frame, a fitting plate, four transmission forming mechanisms, a seal mechanism, a retaining plate, a rotary ventilation mechanism and a vacuumizing mechanism. The transmission forming mechanisms are in symmetrical arrangement vertically and bilaterally, two ends of each transmission forming mechanism are provided with filler parts, partition plates are arranged in inner middles of the transmission forming mechanisms, and each transmission forming mechanism comprises rollers, a conveying belt and silicon plates. The filler parts are used for enabling an airtight state of a cavity formed in the corresponding transmission forming mechanism. Each transmission forming mechanism is internally partitioned into two cavities by the corresponding partition plate, wherein the cavity on the left side of the partition plate is a heating cavity while the cavity on the right side of the partition plate is a cooling cavity. The conveying belts are in transmission connection with the outer surfacesof the rollers, and the silicon plates are uniformly and densely connected to the outer surfaces of the conveying belts. The approximate lattice oriented graphene preparation device and the method aremainly used for solving the problem of failure in large-area application of graphene due to failure in adoption of a vapor deposition method for graphene production in the prior art.

Owner:王青

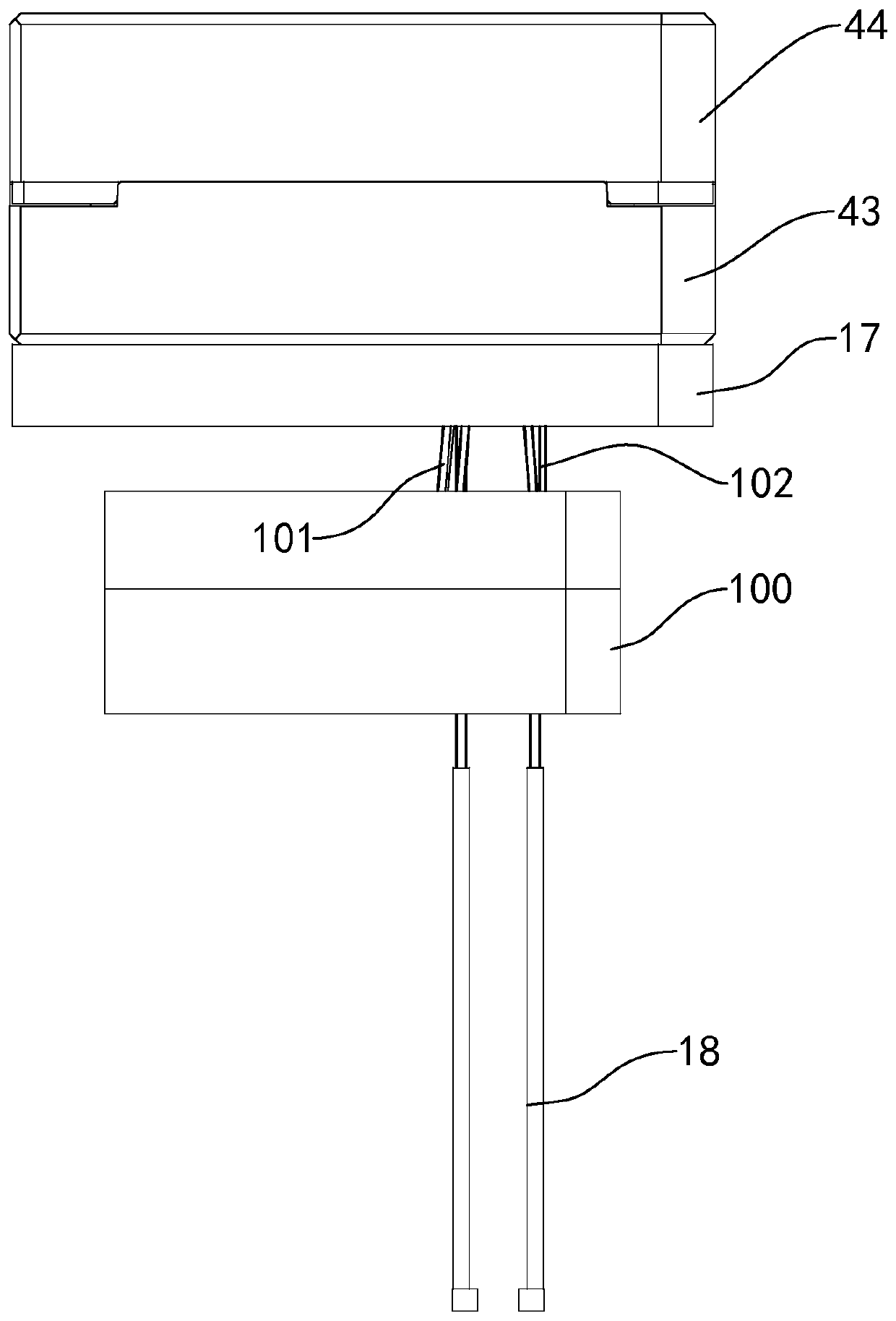

Temperature-controlled roller regulating device

InactiveCN107089033AGuaranteed molding rateAdjustable widthBag making operationsPaper-makingTemperature control

Owner:SUZHOU TIANJIA NEW MATERIAL TECH CO LTD

Method for processing pure sweet potato starch noodles

ActiveCN102524712BGuaranteed tasteGuaranteed cooking resistanceFood preparationPotato starchComposite material

The invention discloses a method for processing pure sweet potato starch noodles. The method comprises the following steps of: blending pulp, namely based on 50 kilograms of dry sweet potato starch, adding 30 to 35 kilograms of water and stirring; performing primary curing, namely adding the sweet potato starch subjected to pulp blending into a starch noodle machine, and extruding, curing and molding in a screw extrusion mode at the curing temperature of between 70 and 90DEG C and at the rotation speed of a motor of 600-900 rpm, so that starch sheets are cured by 60 to 70 percent; performing secondary curing, namely immediately putting the 60 to 70 percent cured starch sheets into water at the temperature of between 90 and 100DEG C, so that the starch sheets are completely cured; and spreading to air and age the cured starch sheets until the starch sheets are not sticky to hands, cutting the aged starch sheets, and airing or drying the cut starch noodles. According to the method, the molding rate of the starch noodles is high due to mechanical production, and the starch noodles are fine and smooth in mouthfeel, high in fastness to boiling, difficult to break; and the process is simple, the cost is low and the production efficiency is high.

Owner:贵州省印江县依仁食品有限公司

Autoclaved aerated concrete block partitioning and trimming device

InactiveCN110653929AImprove efficiencyQuality improvementCeramic shaping apparatusStructural engineeringMechanical engineering

The invention discloses an autoclaved aerated concrete block partitioning and trimming device, and belongs to the technical field of concrete block partitioning. The autoclaved aerated concrete blockpartitioning and trimming device is characterized by comprising a scraper (3), a mounting support (2) and an angle adjusting mechanism, wherein the scraper (3) is aslant mounted on a concrete block blank partitioning rack (1) though the mounting support (2), the upper portion of the scraper (3) is connected with the mounting support (2) through a rotary mechanism, and the lower portion of the scraper (3) is movably connected with the mounting support (2) through the angle adjusting mechanism. According to the autoclaved aerated concrete block partitioning and trimming device, the slant scraperis arranged behind a block cutting steel wire, and preferentially, aslant arranged, besides, one end of the scraper is rotatably mounted, the other end of the scraper is movably mounted, the end which is movably mounted can drive the end which is rotatably mounted to freely adjust the slant angle of the scraper, thus it is guaranteed that after being cut, blocks with different quality levels canall reach high flatness after being trimmed by the scraper, the cutting molding efficiency and quality on the blocks are improved, and the molding rate of the blocks is guaranteed.

Owner:山东铭城环保新材料科技有限公司

Method for producing clean coke based on alumina transition state binder

A method for producing clean coke based on an alumina transition state binder, the method is to select silica, limestone and coal liquefaction residue, crush them separately, then add alumina, metakaolin and pregelatinized starch, and mix them evenly through stirring , and then through dry grinding to obtain the alumina transition state binder; select the blended coal, and mix uniformly according to the ratio of the blended coal and the alumina transition state binder, cold press molding, dry distillation in a vertical carbonization furnace, and then After the red-hot charge is released from the furnace, it is cooled to normal temperature through the coke quenching process, and the clean coke is produced; the raw material source of the present invention is wide and abundant, and the price is low. The cold-state binder fails, and the hot-state binder plays a bonding role before it acts, which ensures the molding rate and coke strength of the material in the retort furnace.

Owner:TAIYUAN UNIV OF TECH +1

Flame cut lampshade and forming process thereof

The invention relates to the technical field of lampshades, in particular to a flame cut lampshade and a forming process thereof. The flame cut lampshade comprises a body and a base, the body comprises an outer lampshade body and an inner lampshade body, a cavity is formed in the inner lampshade body, and the outer lampshade body is located at the outer side of the inner lampshade body. When the flame cut lampshade and the forming process thereof are used, the outer lampshade body is is installed outside the inner lampshade body through connection of threaded grooves in the inner side of a first connector and connecting threads on the surface of a second connector, the inner lampshade body is made of tempered glass, when the lampshade is broken, the inner lampshade body and the outer lampshade body prevent glass from splashing to cause injuries, and safety is improved. By means of the flame cut lampshade and the forming process thereof, the process steps are simple and comprise material preheating treatment, mold preheating, material picking-out, injection molding, annealing, drilling, burr pressing treatment, cooling and demolding treatment, the working procedures are simplified, the actual production cost is low, meanwhile, the accuracy, integrity and molding rate of products are guaranteed, and good economic benefits and environmental benefits are generated.

Owner:江门市亮晶实业有限公司

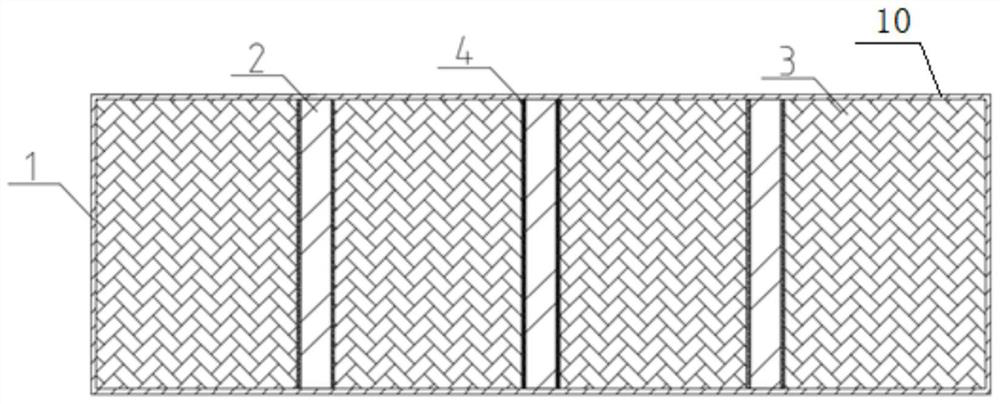

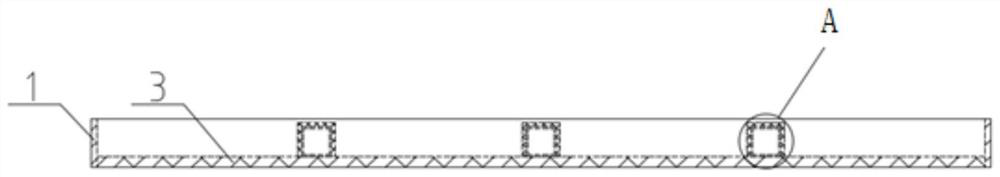

Long corridor floor support-free aluminum plastic formwork device

PendingCN113982252AFast assemblyLight weightForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabPlastic materials

The invention discloses a long corridor floor support-free aluminum plastic formwork device which comprises at least oneformwork unit, each formwork unit comprises two transverse side ribs, two longitudinal side ribs and a bottom plate, and the two transverse side ribs and the two longitudinal side ribs are sequentially connected at intervals to form a square frame structure in an enclosing mode; a longitudinal edge rib on one side of the frame structure is connected with the lower end of a beam formwork device, and a longitudinal edge rib on the other side of the frame structure is connected with the upper end of a wall column formwork device; the bottom plate is fixed to the bottom of the frame structure, and a pouring cavity is formed between the upper surface of the bottom plate and the inner wall of the frame structure; the transverse side ribs and the longitudinal side ribs are respectively made of aluminum profiles; and the bottom plate is made of a plastic material. The formwork device has the beneficial effects that the formwork units are of frame structures made of aluminum profiles, the bottom plates are made of plastic materials, the dead weight of the formwork device is greatly reduced, a vertical supporting vertical rod does not need to be adopted, the formwork device is suitable for a structural system with the large length-width ratio, the structure is simple, and the construction efficiency is greatly improved.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Method for producing clean coke based on water glass transition state binder

A method for producing clean coke based on a water glass transition state binder, the method is to select kaolin, silica, limestone and coal liquefaction residue, break them separately, then add water glass powder and pregelatinized starch, and mix evenly through stirring , and then through dry grinding to obtain the alumina transition state binder; select the blended coal, and mix the blended coal and the water glass transition state binder in proportion, cold press molding, dry distillation at high temperature, and then reduce to At room temperature, clean coke can be obtained; the source of raw materials in the invention is wide and abundant, and the price is low. It acts as a bond before it acts, ensuring the molding rate and coke strength of the material in the retort furnace.

Owner:太原科瑞康洁净能源有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com