Approximate lattice oriented graphene preparation device and method

A technology for lattice orientation and preparation of devices, applied in the directions of graphene, nano-carbon, etc., can solve the problems of producing graphene, unable to apply graphene in a large area, unable to use vapor deposition method, etc., to avoid waste, maintain uniformity, Effect of Discharge Control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

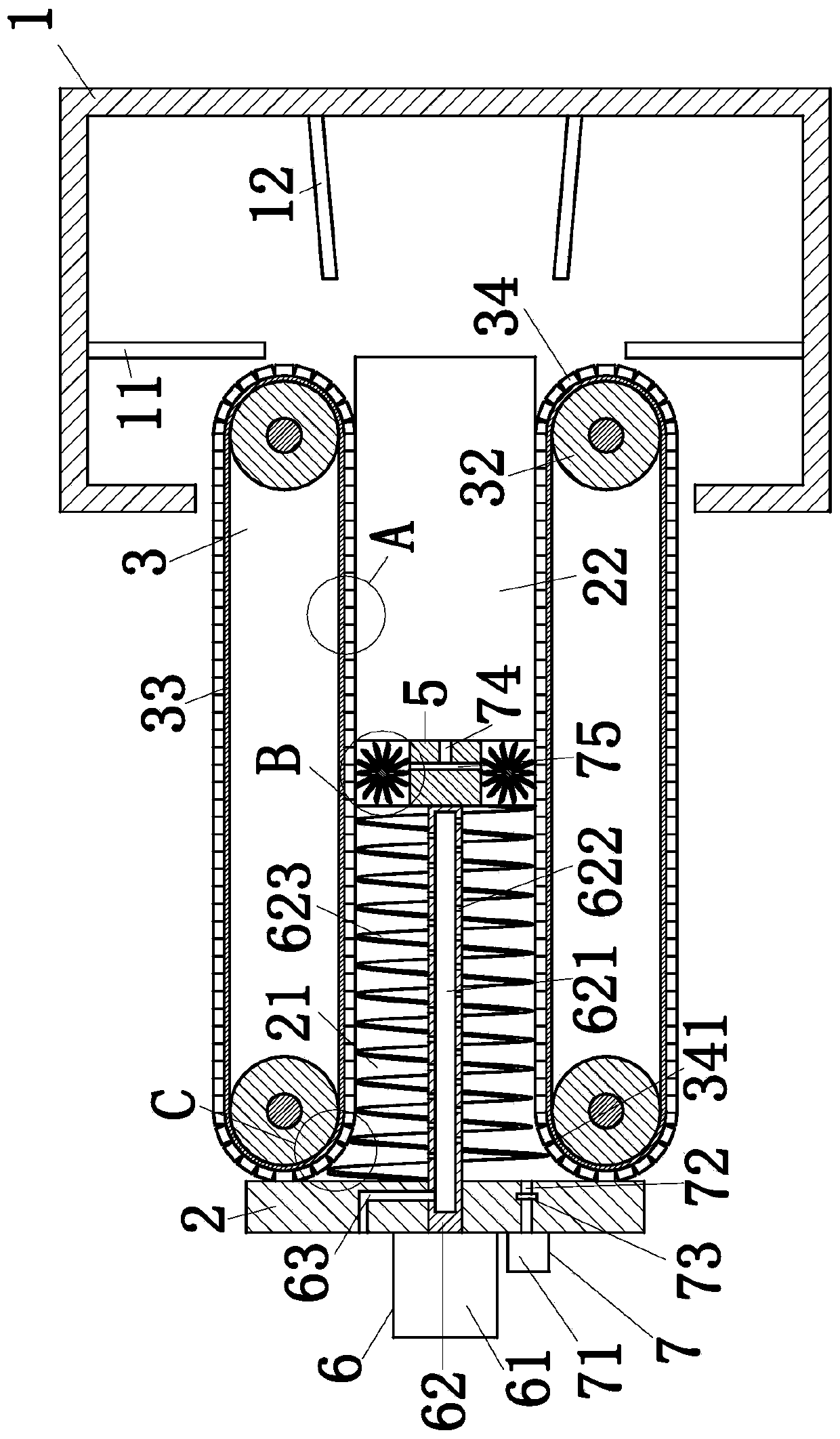

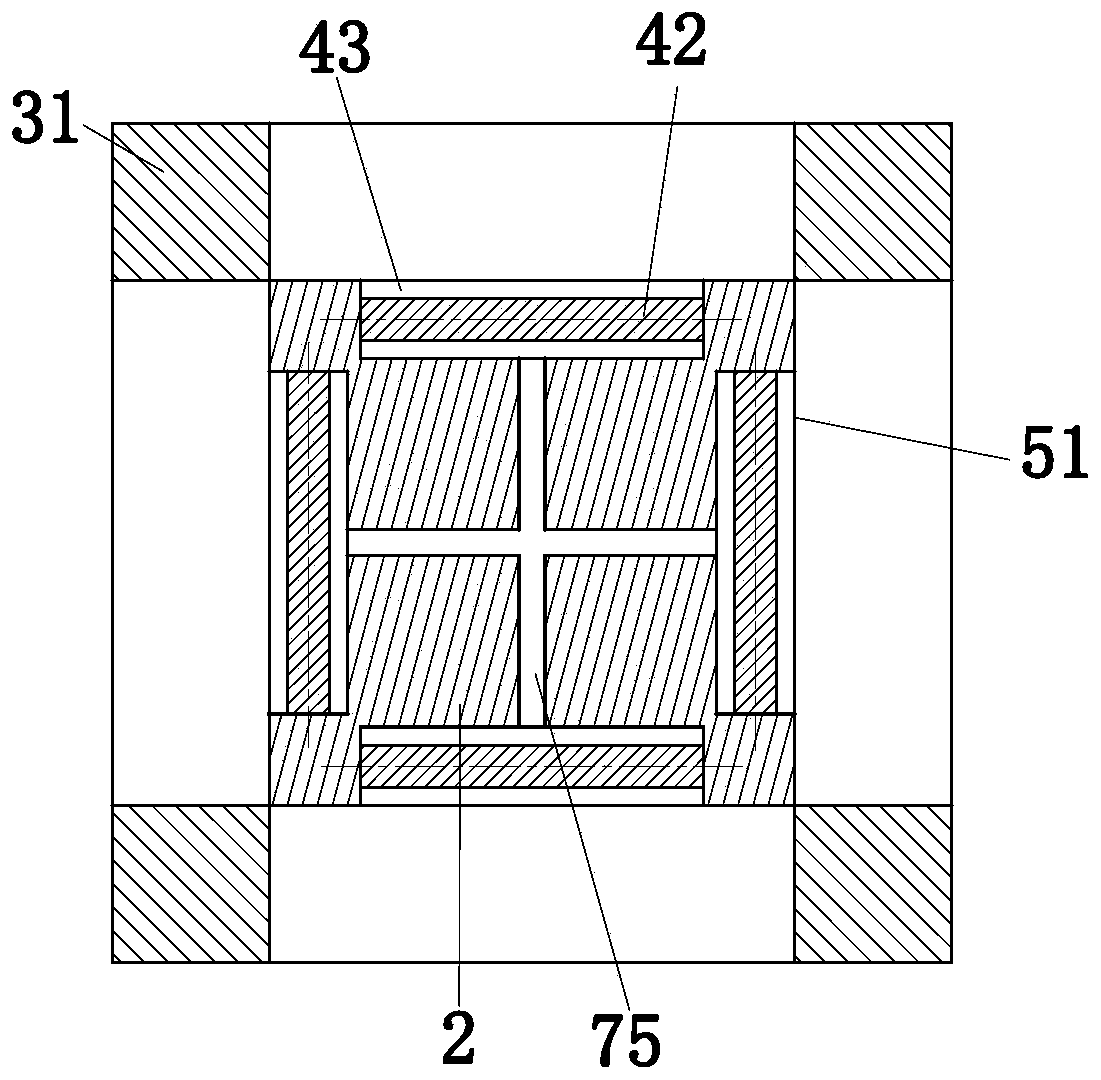

[0026] use Figure 1-Figure 5 A preparation device and method for graphene with approximate lattice orientation according to an embodiment of the present invention are described as follows.

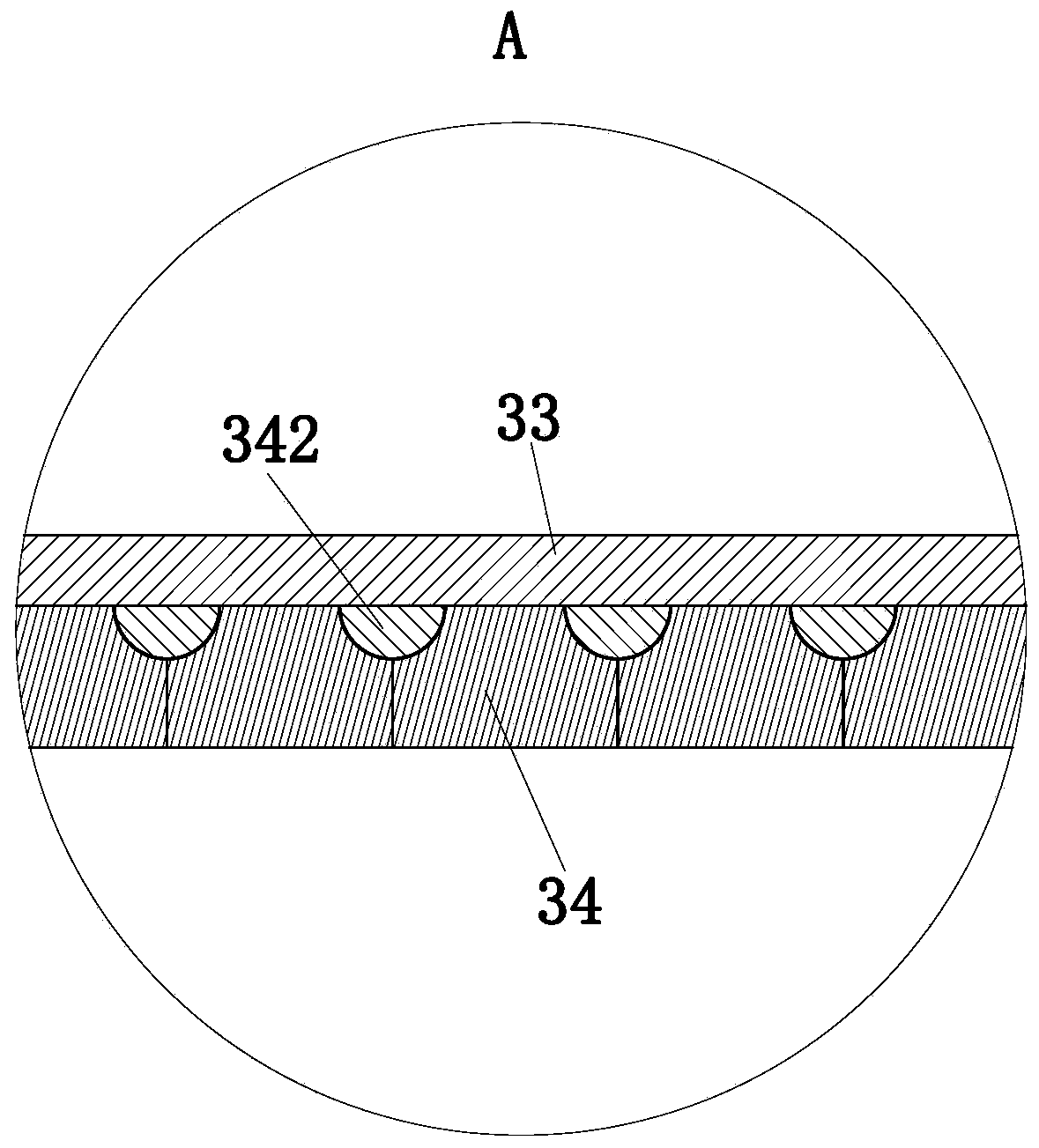

[0027] Such as Figure 1-Figure 5 As shown, a preparation device with approximate lattice orientation graphene described in the present invention includes a storage frame 1, a laminating plate 2, a transmission forming mechanism 3, a sealing mechanism 4, a baffle plate 5, a rotating ventilation mechanism 6, and a vacuum pumping mechanism. Mechanism 7; the transmission forming mechanism 3 is provided with four, the transmission forming mechanism 3 is symmetrically arranged up and down, left and right, and the two ends of the transmission forming mechanism 3 are provided with fillers 31, and the inner middle part of the transmission forming mechanism 3 is provided with a baffle plate 5, and the transmission forming mechanism The mechanism 3 includes a roller 32, a conveyor belt 33 and a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com