Organ-like forming device and working method thereof

A molding device and working method technology, applied in the field of biomedicine, can solve the problems of low cell concentration, high cell concentration, concentration difference, etc., and achieve the effects of high degree of automation, improved success rate, and shortened induction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

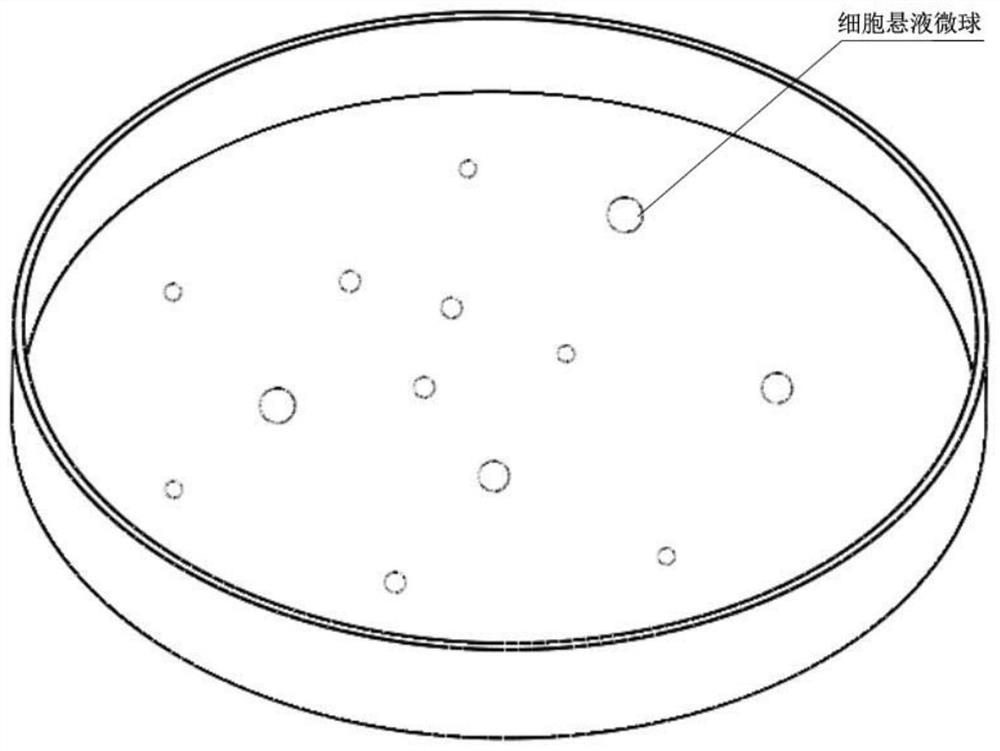

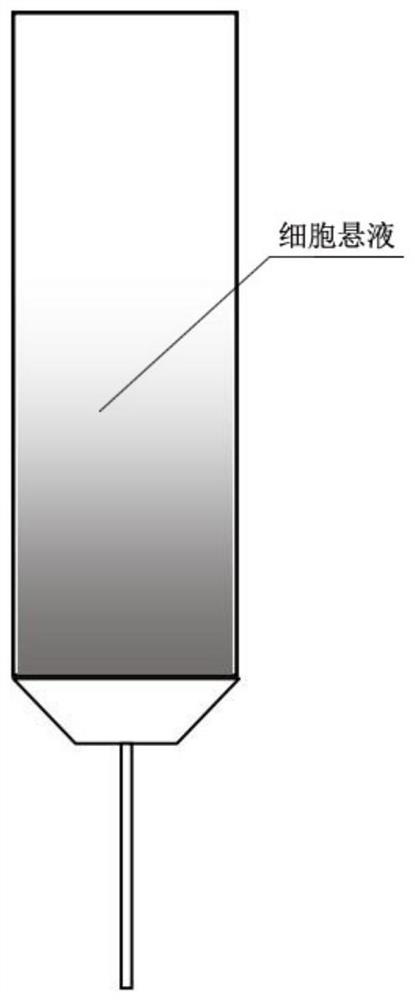

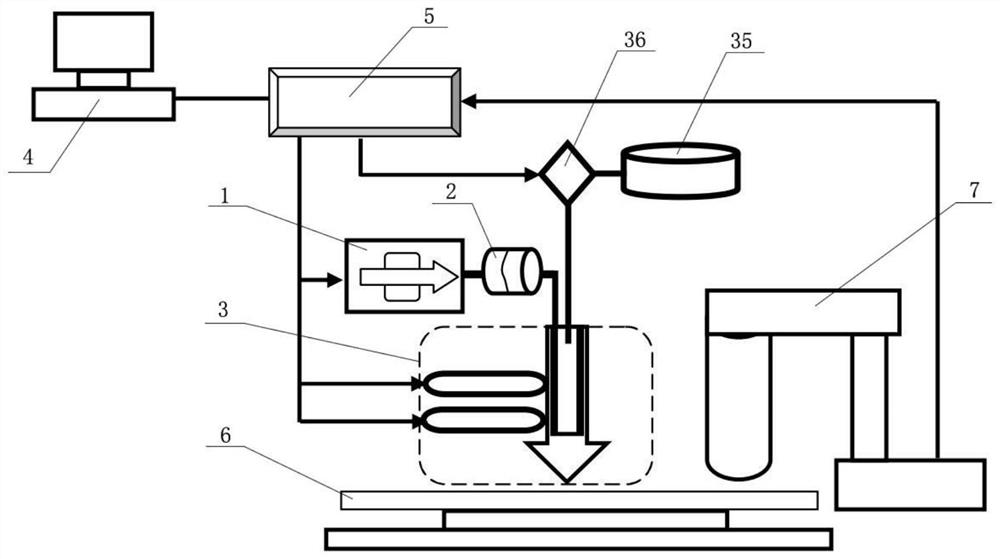

[0045] like image 3 and Figure 4 As shown, an organoid forming device includes a pump 1, a helical tube 2 connected to the pump 1 at one end and used for storing and transporting cell suspension, and connected to the other end of the helical tube 2 through air jet or high pressure. The electrostatic action extrudes the cell suspension transported by the spiral tube 2 to form the nozzle unit 3 of the cell suspension microspheres. In the present invention, the spiral tube 2 is a medical silicone rubber tube with an inner diameter of 0.7-3.6mm, and the liquid in it maintains a certain state of stability due to the adhesion with the tube wall and capillary adsorption, and does not It will flow spontaneously, so that the cell suspension can be stored stably in the spiral tube 2, so as to ensure the uniformity of the cell concentration during the formation of the cell suspension microspheres, and finally make the constructed organoids uniform in size, suitable for high-throughput...

Embodiment 2

[0051] This embodiment is similar to Embodiment 1, the difference is that, as Image 6 and Figure 7 As shown, the spray head unit 3 includes a spray head hose 31 arranged at the other end of the spiral tube 2, a needle 32 connected to the end of the spray head hose 31 away from the spiral tube 2, and set on the A third pinch valve 37 on the nozzle hose 31 close to the needle 32 is connected to a high-voltage direct current source 38 . The nozzle hose 31 is actually integrated with the spiral tube 2. It is also a medical silicone rubber tube. The needle 32 is a steel needle 32. The high-voltage DC source 38 can connect the needle 32 to a high-voltage DC of 1kv-15kv. A high voltage electrostatic field is formed below.

[0052] like Figure 7 As shown, the needle head 32 is provided with a wiring clamp 39, the high-voltage DC source 38 is connected to the wiring clamp 39 through wires, and the pump 1 is a constant-current pump 1 .

[0053] like Image 6 As shown, the presen...

Embodiment 3

[0055] A working method based on the organoid forming device described in embodiment 1, wherein, comprising the following steps:

[0056] S1. The controller 4 controls the first pinch valve 33 and the second pinch valve 34 to open, and the controller 4 controls the pump 1 to rotate in reverse to suck the cell suspension containing cells or microtissues into the spiral tube 2 through the nozzle hose 31 in use;

[0057] S2. The controller 4 controls the first pinch valve 33 to keep open, the second pinch valve 34 to close, and the pump 1 rotates forward for one beat to squeeze the cell suspension from the spiral tube 2 to fill the space of the nozzle hose 31;

[0058] S3. The controller 4 controls the first pinch valve 33 to close, the second pinch valve 34 to open, the controller 4 controls the solenoid valve 36 to open, and the air pump 35 releases the filtered high-pressure gas through the needle 32, so that the nozzle hose A certain volume of cell suspension in 31 is pushed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com