Autoclaved aerated concrete block partitioning and trimming device

A technology for concrete blocks and trimming devices, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as burrs, unsatisfactory trimming effects, uneven surface of blocks, etc., achieve good flatness, improve cutting and molding efficiency and Quality, the effect of ensuring the molding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

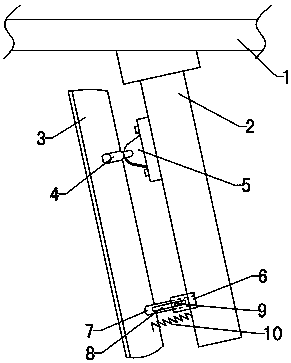

[0014] figure 1 It is the best embodiment of the present invention, below in conjunction with attached figure 1 The present invention will be further described.

[0015] Refer to attached figure 1 : An autoclaved aerated concrete block splitting and trimming device, comprising a scraper 3, a mounting bracket 2 and an angle adjustment mechanism, the scraper 3 is obliquely installed on the concrete block embryo body splitting frame 1 through the mounting bracket 2, the upper part of the scraper 3 The mounting bracket 2 is connected through a rotating mechanism, and the lower part is flexibly connected with the mounting bracket 2 through an angle adjustment mechanism.

[0016] The upper part of the mounting bracket 2 is fixedly connected to the frame 1, and is arranged obliquely, and the mounting bracket 2 is arranged in parallel with the scraper 3. The rotating mechanism includes a rotating shaft 4 and a bearing seat 5, one end of the rotating shaft 4 is fixedly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com