Method for producing clean coke based on aluminum oxide transition state binder

A kind of technology of alumina and transition state, which is applied in coking oven, petroleum industry, solid fuel, etc., can solve the problem of high broken rate of coke, achieve the effect of wide source of raw materials, efficient utilization, and increase of utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

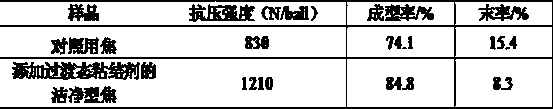

Embodiment 1

[0022] Implement the technical scheme of the method for producing clean coke based on the alumina transition state binder provided above by the present invention, the specific method is implemented as follows:

[0023] (1) Select the raw material composition and quality index of the alumina transition state binder as alumina Al 2 o 3 98.4wt%, metakaolin: active 1000mg lime / g, silica SiO 2 96wt%, pregelatinized starch: viscosity 1000mPa.s, limestone CaO56wt% and coal liquefaction residue: residual oil + asphaltene 80wt%;

[0024] ⑵Crush the silica, limestone and coal liquefaction residue, which are the raw materials of the alumina transition state binder, respectively to a particle size of ≤3mm; alumina, metakaolin and pregelatinized starch are used for later use;

[0025] (3) Weigh 20 kg of crushed silica, 20 kg of limestone and 50 kg of coal liquefaction residue in parts by weight, and weigh 20 kg of alumina, 10 kg of metakaolin and 10 kg of pregelatinized starch, mix them ...

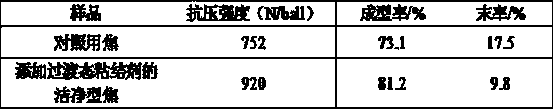

Embodiment 2

[0035] Implement the technical scheme of the method for producing clean coke based on the alumina transition state binder provided above by the present invention, the specific method is implemented as follows:

[0036] (1) Select the raw material composition and quality index of the alumina transition state binder as alumina Al 2 o 3 98.5wt%, metakaolin: activity 1100mg lime / g, silica SiO 2 96.6wt%, pregelatinized starch: viscosity 900mPa.s, limestone CaO54wt% and coal liquefaction residue: residual oil + asphaltene 75wt%;

[0037] ⑵Crush the silica, limestone and coal liquefaction residue, which are the raw materials of the alumina transition state binder, respectively to a particle size of ≤3mm; alumina, metakaolin and pregelatinized starch are used for later use;

[0038] (3) Weigh 16kg of crushed silica, 17.5kg of limestone and 52.5kg of coal liquefaction residue in parts by weight, and weigh 22.5kg of alumina, 9kg of metakaolin and 12.5kg of pregelatinized starch, mix the...

Embodiment 3

[0049] Implement the technical scheme of the method for producing clean coke based on the alumina transition state binder provided above by the present invention, the specific method is implemented as follows:

[0050] (1) Select the raw material composition and quality index of the alumina transition state binder as alumina Al 2 o 3 98.6wt%, metakaolin: active 1200mg lime / g, silica SiO 2 97.2wt%, pregelatinized starch: viscosity 800mPa.s, limestone CaO53wt% and coal liquefaction residue: residual oil + asphaltene 70wt%;

[0051] ⑵Crush the silica, limestone and coal liquefaction residue, which are the raw materials of the alumina transition state binder, respectively to a particle size of ≤3mm; alumina, metakaolin and pregelatinized starch are used for later use;

[0052] (3) Weigh 12 kg of crushed silica, 15 kg of limestone and 55 kg of coal liquefaction residue in parts by weight, and weigh 25 kg of alumina, 8 kg of metakaolin and 15 kg of pregelatinized starch, mix them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com