Centrifugal efficient wood chip granulator

A technology of granulator and sawdust, which is applied in the direction of presses, manufacturing tools, wood processing appliances, etc., can solve the problems that the compression chamber cannot dissipate heat in time, reduce the service life of the whole machine, and uneven feeding, so as to reduce equipment maintenance costs, The effect of prolonging the service life and ensuring the molding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

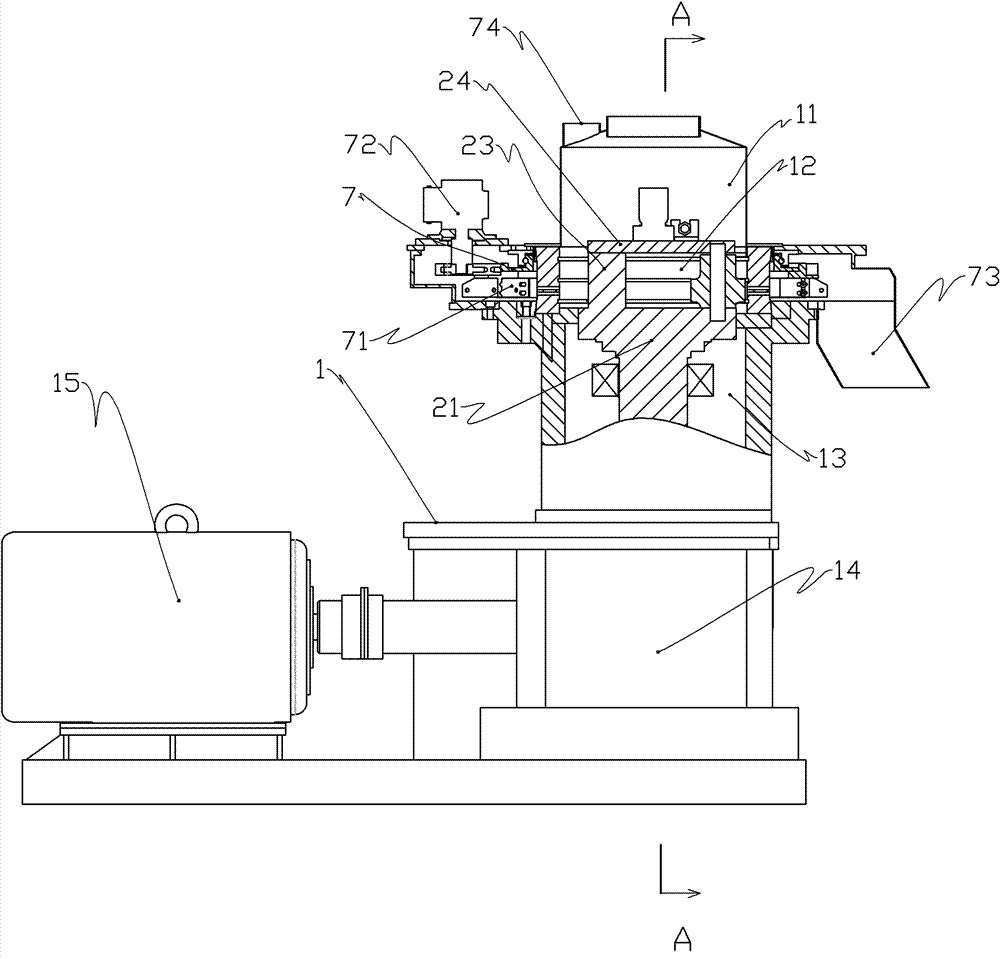

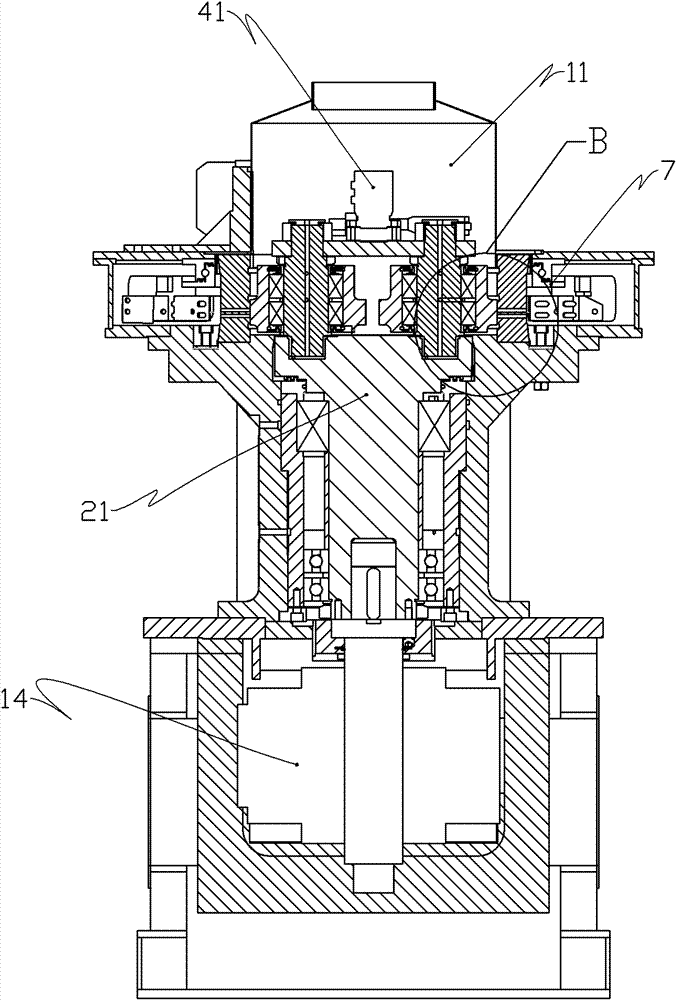

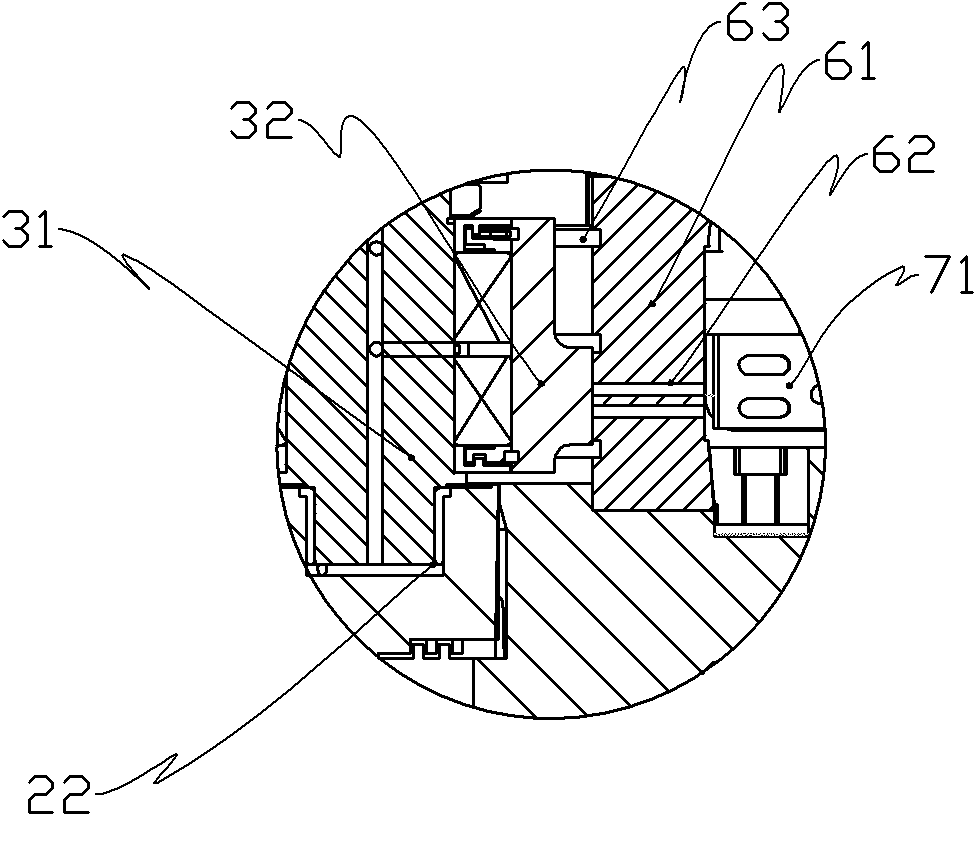

[0039] Such as Figure 1 ~ Figure 6 As shown, this kind of centrifugal sawdust pelletizer includes a cast-molded frame 1. The frame is divided into upper, middle and lower parts. The uppermost part is the silo 11 and the compression chamber 12, the middle part is the rotating spindle shaft chamber 13, and the lower part is Rotating main shaft power transmission mechanism. Install a reducer 14 in the lower part of the frame. The power input shaft of the reducer 14 is connected to the motor 15. The power output shaft and input shaft of the reducer used here are arranged at 90 degrees, and the power output shaft of the reducer 14 is connected to The rotating main shaft 21 is installed vertically on the frame 1. The rotating main shaft 21 is located above the reducer 14, and the journals at both ends of the rotating main shaft are equipped with bearings. The lubrication system is designed at the bearings, that is, the design is in the frame The first oil circuit for supplying oil ...

Embodiment 2

[0050] Such as Figure 7 , Figure 8 As shown, the difference from the first embodiment is that the pressure wheel adjustment mechanism is hydraulic automatic adjustment. The pressure wheel adjustment mechanism includes a drive shaft 81 mounted on the upper end of the rotating main shaft 21, and the upper end of the drive shaft 81 is fixedly mounted with a swing The rod 82, the swing rod 82 is driven by the first oil cylinder 83 installed on the support plate; a main gear 84 is fixedly installed on the drive shaft 81, and the main gear 84 respectively meshes with the slave gear 85 installed on the pressure roller shaft 31. The oil cylinder drives the main gear to achieve the purpose of adjusting the space positions of the three pressure wheels.

[0051] Teeth are provided on the outer side of the swing lever 82, and the swing lever can achieve a locking function under the control of the locking mechanism 86 to prevent the spatial position of the pressure wheel from changing during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com