Novel fast-molding injection molding die

An injection mold, fast technology, applied in the field of injection molding, can solve problems such as easy air bubbles, prolonging cooling time, product ejection marks, etc., to ensure product molding, reduce cooling time, and ensure molding rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

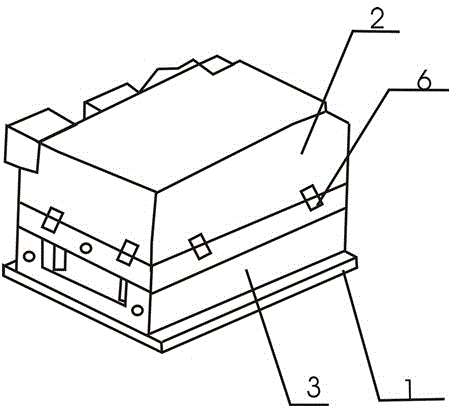

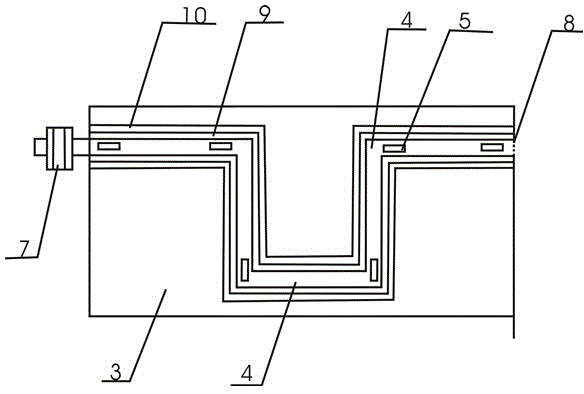

[0012] The invention is a new type of rapid prototyping injection mold, which includes a bottom plate 1, a movable mold 2, a fixed mold 3, a pouring system 4, and an ejection structure 5, and is characterized in that it also includes a fixed lock block 6, a filter 7, and an air vent. 8. Heating layer 9, cooling layer 10, the base plate 1 is fixed with a fixed mold 3, the fixed mold 3 is provided with a pouring system 4, the front side of the pouring system 4 is provided with a filter 7, and the rearmost side is provided with an exhaust hole 8 The ejection structure 5 is provided at the corresponding position of the fixed mold 3 and the pouring system 4, a heating layer 9 is provided outside the pouring system 4, a cooling layer 10 is installed outside the heating layer 9, and a movable mold 2 is installed on the upper side of the fixed mold 3, Corresponding fixed lock blocks 6 are installed on the movable mold 2 and the fixed mold 3, and the heating layer 9 and the cooling laye...

Embodiment 2

[0014] After the present invention is installed, the movable mold 2 and the fixed mold 3 are firmly fixed together by the fixed lock block 6. During use, the raw material first flows through the filter 7 and then enters the pouring system 4. The filter 7 can remove the Air filtration prevents air from entering the product. When the raw material flows into the gating system during injection molding, it will generate pressure on the internal air, and the air will be discharged from the vent hole 8, which also avoids the generation of air in the injection molded product to a certain extent. When the raw material is injected into the pouring system 4, the heating layer 9 starts to function, so as to prevent the raw material from being cooled for a long time after injection, and ensure the molding rate of the product. When the injection molding material is full of the mold, turn off the heating function of the heating layer 9 and turn on the cooling layer 10 to cool the product to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com