Method and product for improving magnetic conductivity of iron-based magnetic powder core based on magnetic exchange length

A magnetic powder core and magnetic exchange technology, which is applied in the fields of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc. Problems such as increased loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

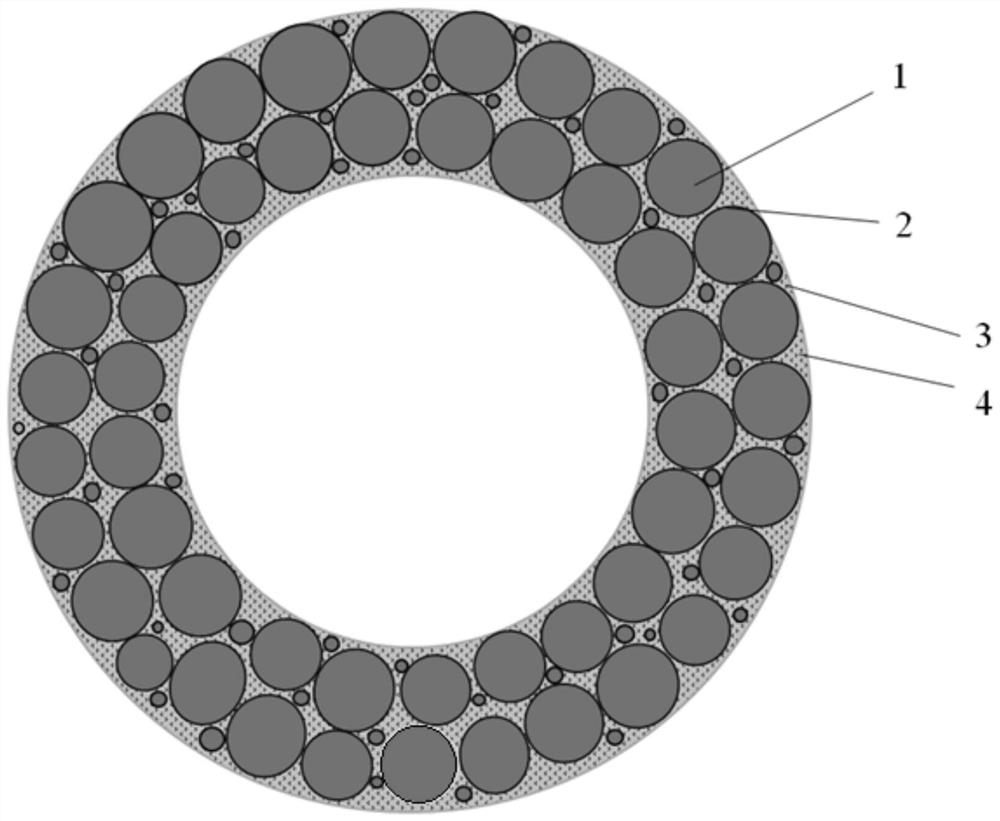

[0056] Such as figure 1 As shown, a kind of iron-based magnetic powder core product of the present embodiment, its preparation method comprises the steps:

[0057] (1) Inorganic coating: use the sol-gel method or fluidized vapor deposition method to coat the silicon dioxide insulating layer on the surface of the iron-silicon powder. The layer thickness is 30nm, and the iron-based / silicon dioxide soft magnetic composite powder is obtained.

[0058] (2) Binder configuration: Take an appropriate amount of nano-scale iron-silicon powder and add it to the silicone resin binder. After mixing evenly, perform ultrasonic dispersion. The time of ultrasonic dispersion is 30 minutes, and the frequency is 35kHz. It is 3nm, and the added mass of nano-scale iron-silicon powder and binder is determined according to the formula of the present invention. In this embodiment, the distance l between the nano-scale iron-silicon powders is set to 32, and finally a binder with evenly dispersed nano...

Embodiment 2

[0063] Such as figure 1 As shown, a kind of iron-based magnetic powder core product of the present embodiment, its preparation method comprises the steps:

[0064] (1) Inorganic coating: use the sol-gel method or fluidized vapor deposition method to coat the silicon dioxide insulating layer on the surface of the gas-atomized iron powder, wherein the particle size of the gas-atomized iron powder is controlled to be 30-150 μm, The thickness of the silicon dioxide insulating layer is 35nm, and the iron-based / silicon dioxide soft magnetic composite powder is obtained.

[0065] (2) Binder configuration: Take an appropriate amount of nano-scale aerosolized iron powder and add it to the silicone resin binder. The particle size is controlled to be 4nm, and the added mass of nano-scale gas atomized iron powder and binder is determined according to the formula of the present invention. In this embodiment, the distance l between the nanoscale gas-atomized iron powders is set to 30, and...

Embodiment 3

[0070] Such as figure 1 As shown, a kind of iron-based magnetic powder core product of the present embodiment, its preparation method comprises the steps:

[0071] (1) Inorganic coating: the silicon dioxide insulating layer is coated on the surface of sendust powder by sol-gel method or fluidized vapor deposition method, wherein the particle size of sendust powder is controlled to be 30-150 μm, and the silicon dioxide The thickness of the silicon insulating layer is 40nm, and the iron-based / silicon dioxide soft magnetic composite powder is obtained.

[0072] (2) Binder configuration: Take an appropriate amount of nano-scale sendust powder and add it to the epoxy resin binder, mix it evenly, and perform ultrasonic dispersion. The time of ultrasonic dispersion is 20min, and the frequency is 40kHz. The control is 1nm, and the added mass of nano-scale sendust powder and binder is determined according to the formula of the present invention. In this embodiment, the spacing l betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com