Long corridor floor support-free aluminum plastic formwork device

A technology for corridors and floor slabs, which is applied in the field of support-free aluminum-plastic mold devices for long corridor floors. The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

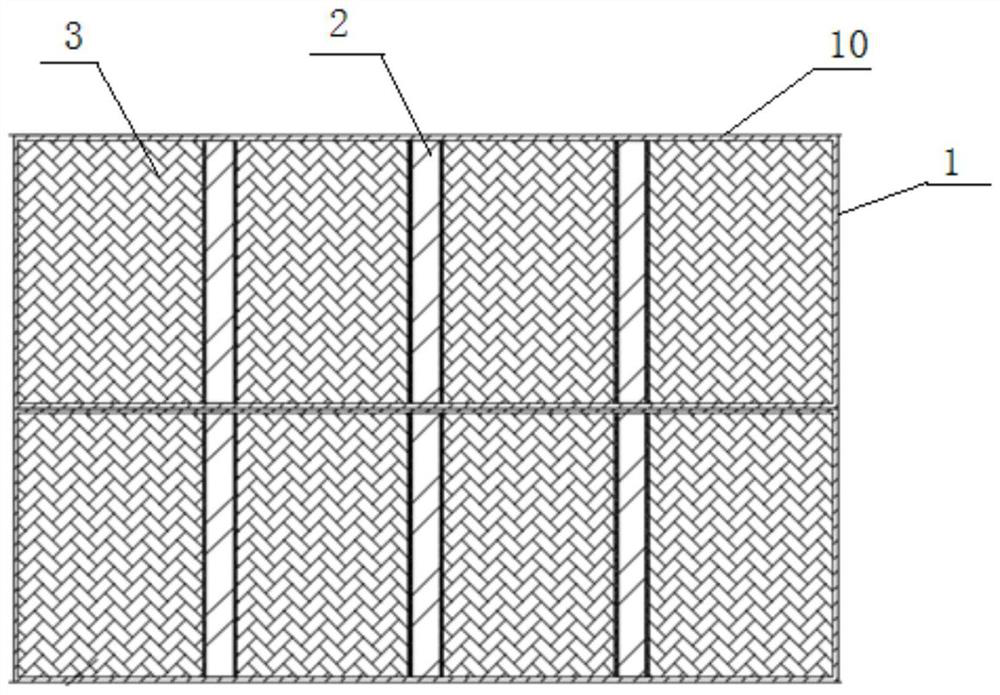

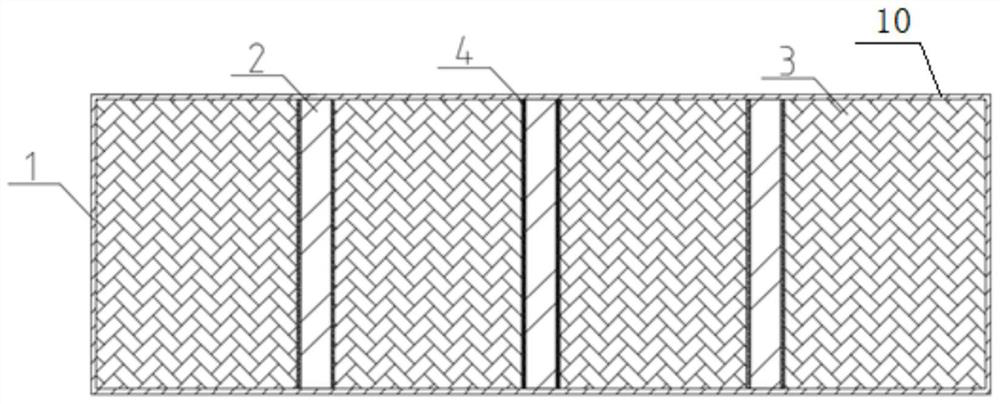

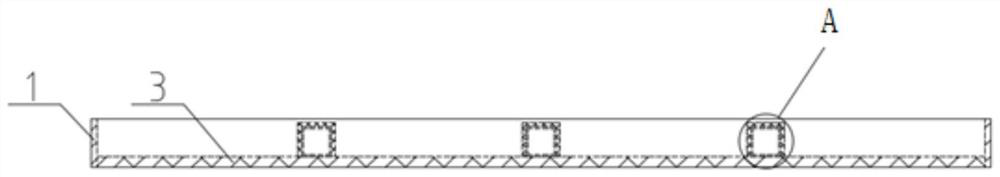

[0022] Such as Figure 1~3 A long corridor floor slab support-free aluminum-plastic molding device shown includes at least one formwork unit, each formwork unit includes two transverse side ribs 10, two longitudinal side ribs 1 and a bottom plate 3, two transverse side ribs 10 and Two longitudinal side ribs 1 are connected successively at intervals to form a square frame structure; one side of the frame structure is connected to the lower end of the beam formwork device 5, and the other side of the frame structure is connected to the wall The upper end of the column formwork device 7 is connected; the bottom plate 3 is fixed on the bottom of the frame structure, and the pouring cavity is formed between the upper surface of the bottom plate 3 and the inner wall of the frame structure; the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com