Patents

Literature

220results about How to "Good cooking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

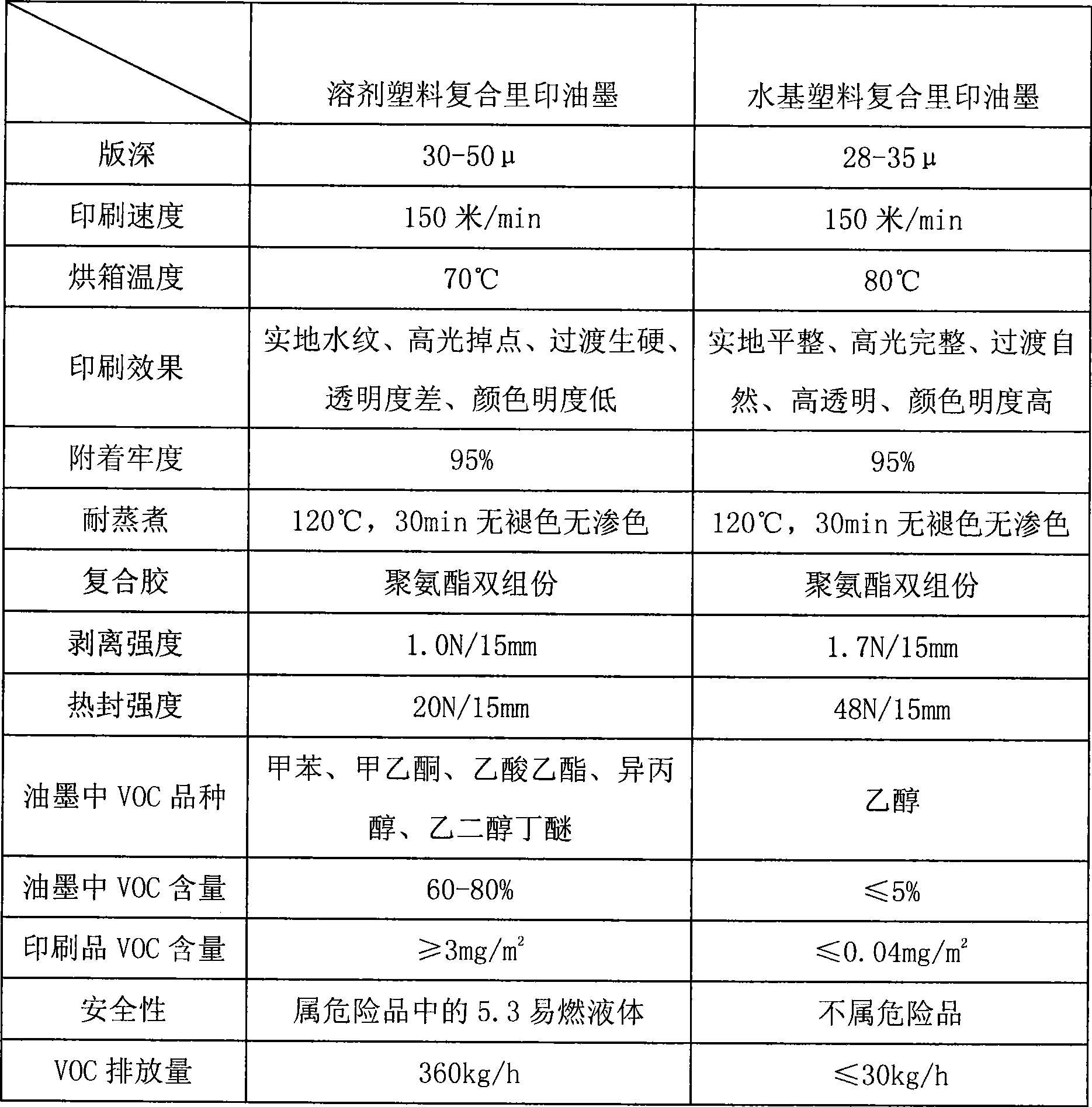

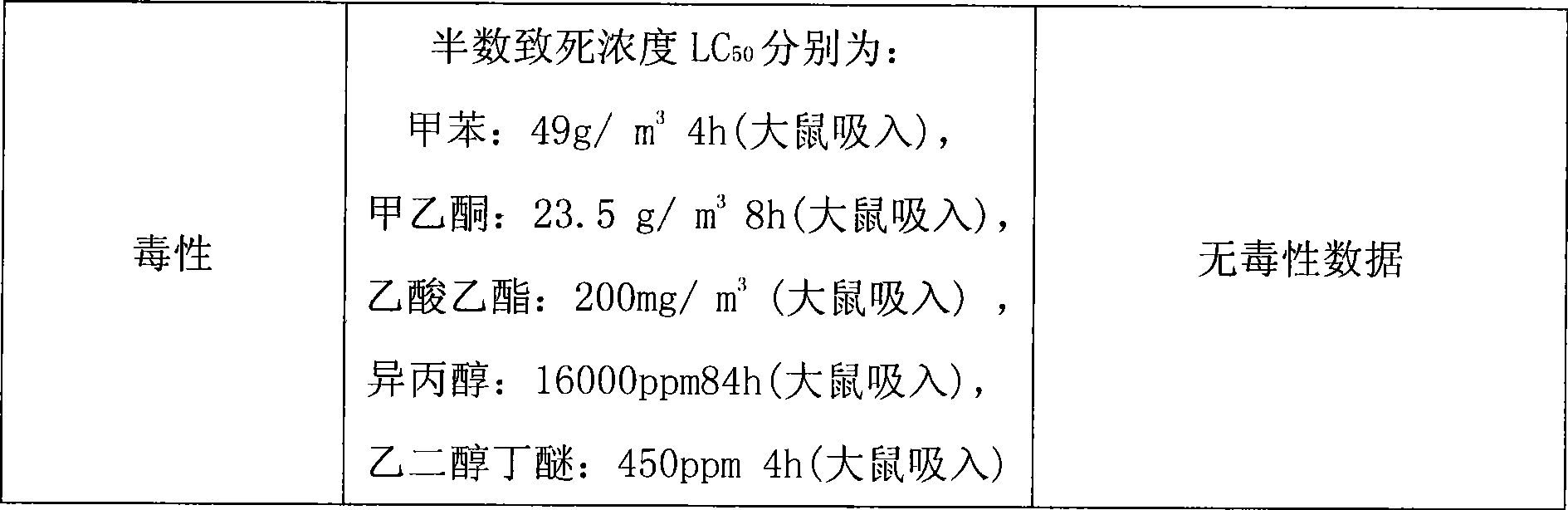

Water-based plastic composite inner-printing ink

The invention discloses a water-based plastic composite printing ink, in particular to a water-based ink needed in the plastic film intaglio printing composite process. To solve problems, the invention provides the water-based ink which remarkably improves composite strength, sealing strength and printing mass relative to the prior solvent ink on the premise of not reconstructing the prior printing equipment or adjusting the printing process; the water-based ink adopts the following technical proposal: the water-based plastic composite printing ink is prepared from the following raw materials in weight portion: 10 to 35 portions of aqueous polyurethane emulsion, 0 to 8 portions of aqueous acrylic resin, 0 to 7 portions of aqueous wetting dispersant, 0.2 to 2 portions of aqueous dampness levelling agent, 0.1 to 2 portions of aqueous defoaming agent, 0.1 to 5 portions of PH regulator, 6 to 30 portions of pigment, 0 to 5 portions of ethanol and 6 to 73.6 portions of water. The water-based ink can be widely applied in the field of ink manufacturing.

Owner:山西鹰鲲科技有限公司 +1

Full-quality vegetable nutritional fine dried noodles and preparation method thereof

InactiveCN104041748AUnique flavorGood cooking resistanceNatural extract food ingredientsFood ingredient functionsAdditive ingredientGrape seed

The invention discloses full-quality vegetable nutritional fine dried noodles and a preparation method of the full-quality vegetable nutritional fine dried noodles. The full-quality vegetable nutritional fine dried noodles are prepared from following raw materials in parts by weight: 90-100 parts of wheat flour, 10-13 parts of starch, 10-12 parts of spinaches, 5-8 parts of purple carrots, 5-8 parts of celeries, 5-8 parts of purple amaranthus mangostanus, 4-6 parts of yellow pumpkins, 2-4 parts of moutan barks, 1-3 parts of pseudo-ginsengs, 3-5 parts of dandelions, 2-4 parts of melon seeds, 3-4 parts of raspberries, 2-4 parts of millet, 1-3 parts of grape seeds, 2-3 parts of table salt and 0.1-0.3 part of soda. The fine dried noodles produced by the method provided by the invention have deep green natural color and luster, unique flavor, good boiling fastness and smooth mouth feel, and can improve the appetite and the eating interests of people. Furthermore, water is not additionally added; the water of vegetables is completely used for kneading dough; in dough kneading and pulping processes, low-temperature operation is adopted so as to ensure that nutritional ingredients are not changed and lost due to the reason that the temperature is too high; components including dietary fibers are also remained; original nutrition and flavor of the vegetables can be kept; the full-quality vegetable nutritional fine dried noodles have the effects of nutrition, health and intestinal tract improvement and are real natural, green and safe food.

Owner:傅筱萸 +1

Instant refreshing wet water vermicelli and processing method thereof

InactiveCN104222903ASolve the problem of single form typeOptimize rehydration conditionsFood ingredientsFood shapingPotato starchXanthan gum

The invention provides instant refreshing wet water vermicelli and a processing method thereof. The instant refreshing wet water vermicelli comprises the following components in parts by weight: 40-50 parts of sweet potato starch, 4-10 parts of pea starch, 0.3-1 part of edible salt, 0-0.5 part of konjac glucomannan, 0-0.5 part of xanthan gum, 0.03-0.1 part of sodium polyacrylate, 0.05-0.1 part of sodium dehydroacetate and 35-45 parts of water. The wet water vermicelli refers to potato type instant refreshing wet water vermicelli which is smooth in taste and rapid to eat and can be made into bean vermicelli or vermicelli. The making process is easy to realize, the requirements of customers for the taste of the bean vermicelli and eating convenience and rapidness can be met, and the forms, types and sales market of the instant bean vermicelli are expanded.

Owner:YUNLIAN GRAIN PURCHASE & SALE

Edible mushroom noodle and its preparation method

InactiveCN1593194AGood cooking resistanceGreat tasteFood preparationHorticultureBiotechnologyEdible mushroom

The edible mushroom noodle provided by the invention comprises edible mushroom fermentation liquor and flour by the weight ratio of 0.3-0.35:1, wherein the edible mushroom can be one or mixture of fragrant mushrooms, pleurotu ostreatus, golden mushrooms, white fungus, black fungus and glossy ganoderma.

Owner:安徽淮北天宏集团实业有限公司

Alum-free starch noodles and sheet jelly as well as a preparation method thereof

ActiveCN102669605ANo loss of edible performanceSafe edible performanceFood preparationHydrogenPhospholipid

The invention discloses alum-free starch noodles and sheet jelly as well as a preparation method thereof. The product is prepared from starch, modified phospholipid and certain ancillary materials, wherein the ancillary materials comprise propylene glycol alginate, sticky corn starch, hydrogen potassium sorbate, esterified modified starch, sodium glycerophosphate and octenyl succinic starch ester. Compared with the original starch noodles containing alum, the alum-free starch noodles have the benefits that the prepared product is free from alum and safer, and the edible performance does not decrease obviously.

Owner:HEILONGJIANG GANGJIN FOOD TECH DEV

A kind of buckwheat health-care noodles and preparation method thereof

ActiveCN102258170AReduce generationEnhance lipid-lowering blood sugarFood preparationPolygonum fagopyrumPearl barley

The invention discloses buckwheat health-care noodles and a preparation method thereof. The preparation method comprises the following steps of: mixing buckwheat powder, Indian buead powder, pearl barley powder, Chinese yam powder, white waterlily powder, kudzuvine root powder and lily powder to obtain mixed powder; adding water, wheat powder and salt into the mixed powder; and kneading dough, ageing, flaking, slitting, drying and cutting off to obtain the minor cereal health-card noodles. The product of the invention synthesizes flavor of wheat flour, buckwheat, medicinal and edible materials such as Indian buead, pearl barley, Chinese yam, white waterlily, kudzuvine root and lily, has strong flavor, white color and high boiling fastness, does not muddy soup and break, is difficult to age, is not provided with any food additive, is nutritional and safe, and has the effects of adjusting fat and reducing sugar, invigorating qi and strengthening spleen, tonifying kidney and securing essence, calming heart and tranquilizing mind, beautifying skin and keeping young and the like. The product accords with the development tendency of the modern food industry and has a good market prospect.

Owner:HUNAN LIUYANG RIVER ECOLOGICAL AGRI TECH DEV GROUP

Quick-frozen and fresh-keeping thousand-layer Tofu and preparation method thereof

The invention discloses quick-frozen and fresh-keeping thousand-layer Tofu and a preparation method of the quick-frozen and fresh-keeping thousand-layer Tofu. The quick-frozen and fresh-keeping thousand-layer Tofu comprises the following components in parts by weight: 13-15 parts of soy isolate protein, 0.1-0.25 part of glutamine transaminase, 2-3 parts of cassava acetate modified starch, 5-8 parts of soybean oil, 0.3-0.6 part of aginomoto, 0.3-0.6 part of white sugar, 0.4-0.7 part of complex adhesive, 2.5-3.5 parts of duck egg white and 68-75 parts by weight of water. The quick-frozen and fresh-keeping thousand-layer Tofu disclosed by adopting the preparation method is prepared from the raw materials of the soy isolate protein, the glutamine transaminase, the cassava acetate modified starch, the soybean oil, the aginomoto, the white sugar, the complex adhesive and the duck egg white, keeps the original tender and fresh taste of Tofu, has a special tender, crisp, tasty, delicious taste, and has better elasticity and toughness, and strong soup water absorbing capacity; and regardless of frying, stir-frying, oil-frying, stewing or blending other seasonings, the quick-frozen and fresh-keeping thousand-layer Tofu is special in flavor and delicious in taste when being eaten.

Owner:云鹤食品有限公司

Aluminium foil sealing film and preparation method thereof

ActiveCN102700819ADoes not affect ease of peelingImprove cooking temperatureSynthetic resin layered productsSealingPolymer sciencePolyethylene terephthalate glycol

The invention provides an aluminium foil sealing film and a preparation method thereof and belongs to the technical field of plastic packaging. The aluminium foil sealing film comprises a protective layer, a separation layer and a heat-seal layer, wherein the protective layer is a gloss oil layer or a PET (Polyethylene Terephthalate) film layer; the separation layer is an aluminium foil layer; and the heat-seal layer comprises the materials as follows: 15 to 25 wt% of polybutene, 25 to 35 wt% of ethylene-propylene copolymer and 40 to 60 wt% of HDPE (high-density polyethylene). As a sealing film for the bottle mouth of a polypropylene plastic bottle, the aluminium foil sealing film provided by the invention has the excellent properties of cooking resistance and easiness for uncovering, and when the cooking-resistant temperature is 121 DEG C, the sealing film is unchanged in color and is not stratified. The opening force is 5 to 25 N after the sealing film and the polypropylene bottle are heat-sealed at 200 DEG C, and the heat-seal strength of a heat-seal strip with the width of 15 mm is 5 to 25 N, which shows that the aluminium foil sealing film has the excellent properties of cooking resistance and easiness for uncovering at the same time.

Owner:ZHEJIANG GOLDSTONE PACKING

Method and device for producing fresh-keeping instant wet noodles

InactiveCN102069923AAvoid the dangerous situation of fried bagsOvercome secondary pollutionBagsPackage sterilisationMicrowave ovenBiochemical engineering

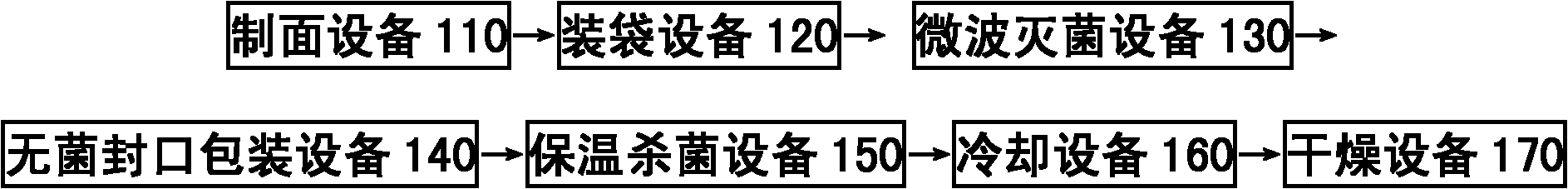

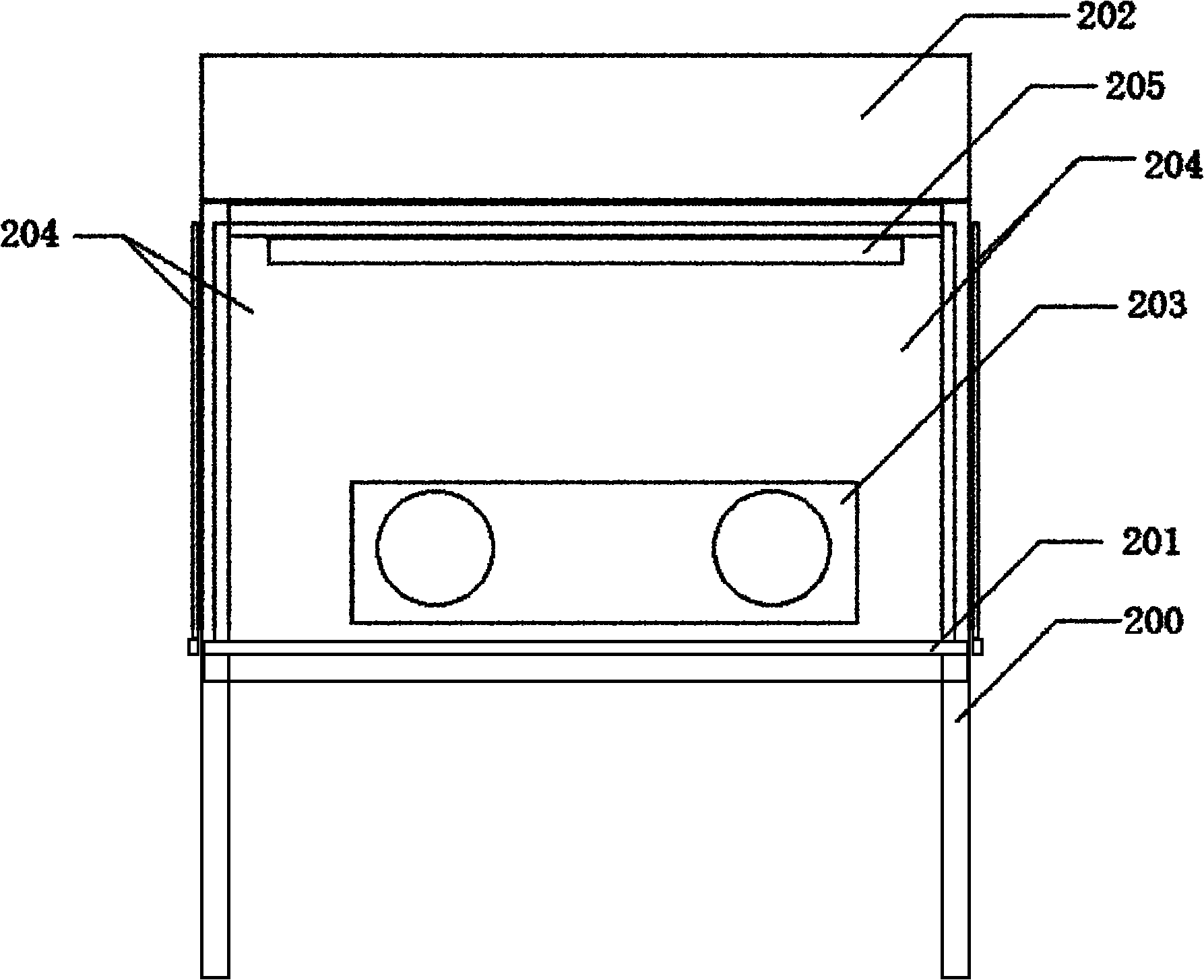

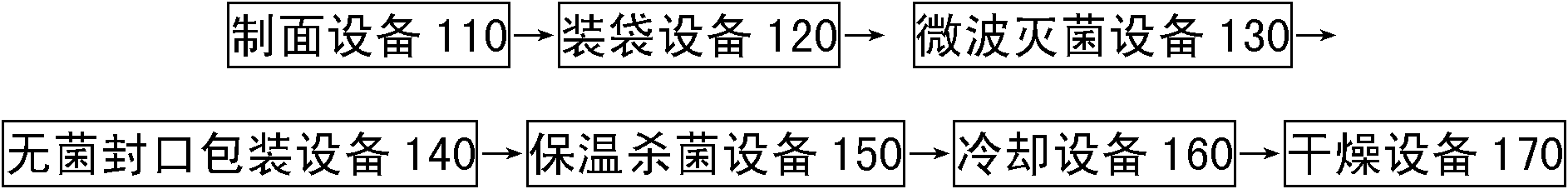

The invention discloses a method for producing fresh-keeping instant wet noodles, which comprises steps of noodle making, bagging, microwave sterilization, aseptic sealing packaging, heat preservation sterilization, cooling and drying. The method is characterized in that: the bagging comprises the following steps of: weighing the wet noodles, filling the wet noodles into packaging bags and pre-sealing the packaging bags in a way that openings of the packaging bags are incompletely sealed; and the aseptic packaging sealing comprises that: the wet noodles flow out of a delivery outlet of a microwave oven, enter aseptic sealing packaging equipment, and are completely sealed in an aseptic environment after reaching a section of channel for finishing the sealing. The production device comprises noodle making equipment, bagging equipment, microwave sterilization equipment, aseptic sealing packaging equipment, heat preservation sterilization equipment, cooling equipment and drying equipment. The method and the device ensure complete sterilization, short high-temperature sterilization time, production process completeness, high production controllability and stable quality, and the noodles have high elasticity, high gelatinization degree and long shelf life, and are difficult to break.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

Frozen dumpling modifying agent, preparation method thereof and application

InactiveCN101744021AImprove dough sticking rollerImprove sticking phenomenonDough treatmentPre-baking dough treatmentFreeze thawingEnzyme

The invention belongs to the technical field of frozen dumpling processing by additives, in particular to a frozen dumpling modifying agent, a preparation method thereof and application. The frozen dumpling modifying agent is prepared from the following components in percentage by weight via mixing: 35 to 42 parts of active soybean meal, 25 to 38 parts of konjaku flour, 5 parts of complex enzyme, 8 to 12 parts of carrageenin and 10 to 20 parts of modified starch. The modifying agent can adapt to the process requirements of the mechanized production of the frozen dumplings, improve the quality of finished products of the frozen dumplings, effectively improve the mechanical stirring resistance degree of the flour dough of the frozen dumplings, reduce the roll adhesion phenomenon of cheeks during the mechanized production, can simultaneously improve the boil resistance performance, the smooth performance and the freeze-thaw stability of the frozen dumplings, and improve the external appearance and the mouth feeling of the frozen dumplings.

Owner:河南兴泰科技实业有限公司

Composite edible gelatin and the application thereof in the preparation of noodles

The invention discloses a compound food gum taking attainable glue main proportioning, and its application in noodle preparation. The comprised component and weight proportion are as follows: attainable glue 60-70%, konjaku flour 10-20%, guar gum 10-15%, and sodium carboxymethylcellulose 5-10%. The addition amount of said compound food gum is 0.2-1.0% of that of total weight of noodles. The invention is characterized by simplified process, reduced consumption, better taste; as for noodles prepared with compound food gum, it is characterized by increased boiling durability and strength, and low cost.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for producing five-cereal coarse cereal recombinant food

The invention discloses a method for producing a five-cereal coarse cereal recombinant food. The method comprises the following steps of: cleaning raw materials, drying, crushing and sieving with an 80-mesh sieve; and weighing the raw materials in a specific ratio, mixing uniformly, tempering, extruding by using a single-screw extrusion machine, cutting, and drying to obtain the five-cereal coarse cereal recombinant food. According to the method, five-cereal coarse cereals are developed deeply, so that sensory indexes of smells, colors, tastes and the like of products are similar to those of rice, so that the aims of 'refining of coarse grain' and 'the matching of staple grain and the coarse grain' are fulfilled, and the value of agricultural products of the five-cereal coarse cereals and the like is improved.

Owner:ANHUI YANZHIFANG FOOD

Method for processing pure sweet potato starch noodles

ActiveCN102524712AGuaranteed tasteGuaranteed cooking resistanceFood preparationPotato starchComposite material

The invention discloses a method for processing pure sweet potato starch noodles. The method comprises the following steps of: blending pulp, namely based on 50 kilograms of dry sweet potato starch, adding 30 to 35 kilograms of water and stirring; performing primary curing, namely adding the sweet potato starch subjected to pulp blending into a starch noodle machine, and extruding, curing and molding in a screw extrusion mode at the curing temperature of between 70 and 90DEG C and at the rotation speed of a motor of 600-900 rpm, so that starch sheets are cured by 60 to 70 percent; performing secondary curing, namely immediately putting the 60 to 70 percent cured starch sheets into water at the temperature of between 90 and 100DEG C, so that the starch sheets are completely cured; and spreading to air and age the cured starch sheets until the starch sheets are not sticky to hands, cutting the aged starch sheets, and airing or drying the cut starch noodles. According to the method, the molding rate of the starch noodles is high due to mechanical production, and the starch noodles are fine and smooth in mouthfeel, high in fastness to boiling, difficult to break; and the process is simple, the cost is low and the production efficiency is high.

Owner:贵州省印江县依仁食品有限公司

Flour improver for instant frozen dumplings, method for manufacturing flour improver and application thereof

InactiveCN104663763AGood lookingGreat tasteDough treatmentDough preparationBiotechnologySODIUM METAPHOSPHATE

The invention discloses a flour improver for instant frozen dumplings, a method for manufacturing the flour improver and application thereof. The flour improver for the instant frozen dumplings comprises, by weight, 2-5 parts of xanthan gum, 2-4 parts of guar gum, 2-4 parts of monostearin, 5-9 parts of stearic calcium and sodium lactate, 1-4 parts of composite phosphate, 1-3 parts of glutamine transaminase and 2-6 parts of sodium chloride. The composite phosphate comprises tetrasodium pyrophosphate, sodium tripolyphosphate and sodium hexametaphosphate. The method includes respectively sieving the xanthan gum, the guar gum, the monostearin, the stearic calcium and sodium lactate, the tetrasodium pyrophosphate, the sodium tripolyphosphate, the sodium hexametaphosphate, the glutamine transaminase and the sodium chloride by the aid of Number-CB36 sieves; mixing the xanthan gum, the guar gum, the monostearin, the stearic calcium and sodium lactate, the tetrasodium pyrophosphate, the sodium tripolyphosphate, the sodium hexametaphosphate, the glutamine transaminase and the sodium chloride with one another to obtain the improver for the instant frozen dumplings. The flour improver, the method and the application have the advantages that problems of frost cracking and the like of dumpling wrappers of existing instant frozen dumplings during instant freezing, mechanical packaging and low-temperature storing can be solved by the aid of the improver for the instant frozen dumplings, the smoothness, the boiling fastness and the freeze-thaw stability of the instant frozen dumplings can be enhanced, and the taste and the appearance of the instant frozen dumplings can be obviously improved.

Owner:SHANGHAI INST OF TECH

Stone-milled black soybean health-maintaining dried noodles

The invention discloses stone-milled black soybean health-maintaining dried noodles, which are prepared from the following raw materials in part by weight: 80 to 90 parts of stone-milled triticale flour, 10 to 15 parts of stone-milled black soybean flour, 5 to 10 parts of dark brown jam, 5 to 10 parts of grifola frondosa, 5 to 8 parts of coix seed powder, 4 to 6 parts of robiniae pollen, 5 to 8 parts of Chinese wolfberry powder, 5 to 8 parts of lily powder, 5 to 8 parts of cactus powder, 3 to 6 parts of wild persimmon powder, 3 to 6 parts of gordon euryale powder, 1 to 2 parts of refined salt, and 0.2 to 0.4 part of dietary alkali. The produced dried noodles are slightly ash black, have thick aroma of black soybean and unique flavor, are rich in proteins and other nutrition required by human beings, have the health-care effects of clearing free radicals, delaying senescence, improving nutritional anemia, enhancing immunity, calming, improving sleep and the like, and integrate nutrition and food therapy.

Owner:ANHUI DINGKANG FOOD

Boil-proof health-care konjak starch vermicelli

InactiveCN1341382AGood cooking resistanceUnique health functionFood preparationFood processingStarch

The present invention relates to a food processing method, in particular it relates to a boil-proof health-care konjak starch vermicelli. It is made up by adding konjack fine flour and other auxiliary material in the market starch with various types through the vermicelli production process. As compared with traditional high-quality starch vermicelli said invented product is smooth in surface, transparent and uniform in fineness, boil-proof and possesses a certain health-care function.

Owner:天津市金利保健食品有限公司

Method for enzymatical producing corn vermicelli

The invention discloses a maize noodle production method in an enzyme method, and belongs to the food biotechnology processing field. The technical proposal comprises that maize starch is added into amylase buffer solution, and the amount of the amylase is 800 to 2000 units / g starch, the oscillation treatment is adopted, after the treatment, water is added to remove the residual enzyme activity, and the water is added until the moisture content is about 55 to 70 percent, and is then placed on a conveyor belt to form a slurry layer with the thickness about 1.5 to 2.5 mm, finally the fresh maize noodle product can be obtained cooling, cutting or silk extruding packaging the steamed pasty; if the dry product is required, the drying process of the noodle is connected. The invention adopts the biotechnology, the shaping is completed by heating with one step, the operation is simple, the production cost is low, the controlling is easy, and the equipment requirement is low. Chemical additive is not used in the product, thereby being more acceptable for consumers. The produced pasty has smooth taste, soft glutinousness and good flexibility, improved boiling fastness, as well as more transparent appearance.

Owner:CHINA AGRI UNIV

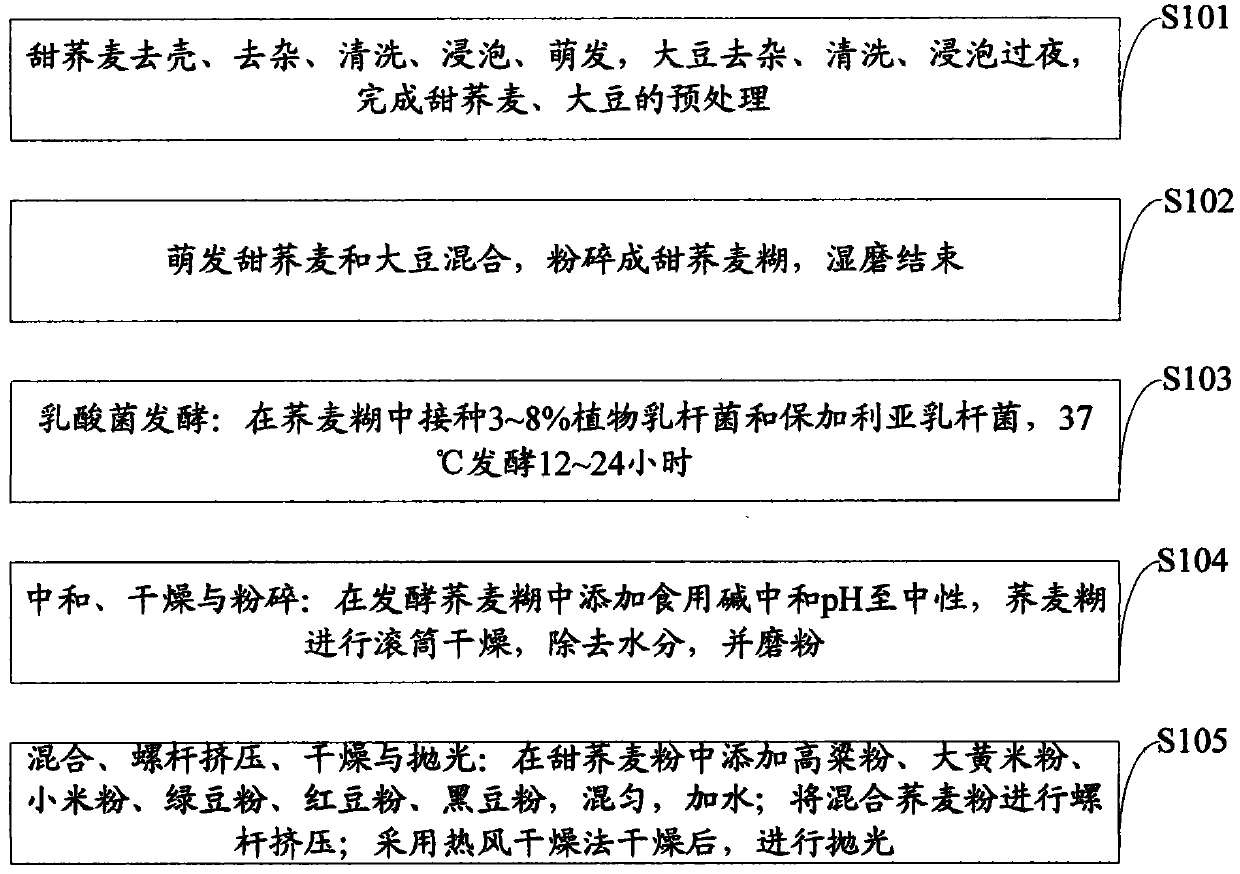

Formula and production method for sweet-buckwheat coarse-cereal mixed-bean recombinant rice

ActiveCN103621888AImprove processing qualityImprove nutritional qualityFood shapingFood ingredient functionsPolygonum fagopyrumGluten

The invention discloses a formula and a production method for sweet-buckwheat coarse-cereal mixed-bean recombinant rice. The formula comprises lactobacillus plantarum, Lactobacillus bulgaricus, soybean, sweet buckwheat, water, sorghum powder, large millet meal, millet meal, mung bean flour, red bean flour, black soya bean flour, vital gluten, egg white powder and dietary alkali. The production method comprises the following steps: pretreating sweet buckwheat and soybean; carrying out wet grinding and lactobacillus fementation; neutralizing a pH value; drying and crushing buckwheat paste; uniformly mixing sweet buckwheat flour with large millet meal, millet meal, mung bean flour, red bean flour, black soya bean flour and water; and subjecting buckwheat flour to screw extrusion, drying and polishing. The sweet-buckwheat coarse-cereal mixed-bean recombinant rice produced by using the production method tastes good, improves toughness and water retention performance of flour, has a regular shape, boiling resistance, good reconstitution properties and a high nutritional value; and the production method has the advantages of easiness, low cost and good development space.

Owner:广东澳思瑞雅健康美容生物科技有限公司

Health-care stone-milled triticale fine dried noodles

The invention discloses health-care stone-milled triticale fine dried noodles, comprising following materials in part by weight: 90-100 parts of stone-milled triticale flour, 30-40 parts of stone-milled buckwheat flour, 10-20 parts of black fungus powder, 10-15 parts of mulberry powder, 5-10 parts of black plum juice, 8-12 parts of raspberry juice, 5-10 parts of Hawk tea, 5-10 parts of the fruit of Chinese wolfberry, 5-10 parts of sweet potato stem, 5-8 parts of purslane, 5-8 parts of cushaw flower, 4-6 parts of polygonum multiflorum, 4-6 parts of sweet potato leaf, 2-5 parts of pseudo-ginseng, 2-5 parts of poria cocos, 1-2 parts of refined salt and 0.2-0.3 part of edible alkali. The fine dried noodles produced by the invention are lavender, have rich wheat fragrance, special taste and good cooking resistance, do not get burnt after being cooked, are non-stick and smooth, are rich in needed various trace elements and other nutrients, have health-care functions of nourishing yin, moisturizing lung, slowing down ageing, reinforcing qi, nourishing blood, increasing immunity, improving alimentary anemia, building brain and nurturing the soul, and are health-care noodles integrated with nutrition and dietary therapy.

Owner:ANHUI DINGKANG FOOD

Longevity noodles containing selenium-rich triticale and preparation method thereof

InactiveCN104026471AAvoid destructionHigh glutenFood ingredient functionsFood preparationWater ChestnutsSe element

The invention discloses longevity noodels containing selenium-rich triticale. The longevity noodels are prepared from the following raw materials in parts by weight: 95-97 parts of stone-ground selenium-rich triticale powder, 2-3 parts of highland barley powder, 1-2 parts of poria cocos, 0.5-1 part of folium quercidentaatae, 1-2 parts of purslane, 1-2 parts of large-leaved chrysosplenium, 1-2 parts of bitter herbs, 1-2 parts of water chestnut stems, 3-5 parts of barleys, 1-2 parts of fermented bean curds, 3-5 parts of Chinese yam, 3-5 parts of konjaku flour, 0.4-0.6 part of blueberry juice, 1-2 parts of refined salt, and 0.2-0.3 part of edible soda. The fine dried noodles produced by the method disclosed by the invention present orchid, the fine dried noodles are rich in wheat flavor, unique in special flavor and good in boiling fastness; after the fine dried noodles are boiled, the fine dried noodles are not pasty, are not stuck to teeth, are not coarse and are soft and refreshing, and the mouth feel of the fine dried noodles is not sticky; the fine dried noodles are rich in various micro elements and other nutrition desired by humans, the fine dried noodles have the health-care efficacies of nourishing yin and moisturizing lung, delaying senescence, benefiting qi and nourishing blood, enhancing immunity, improving nutritional anemia, benefitting brain and nourishing nerves and the like, and the longevity fine dried noodles integrate nutrition and dietetic therapy.

Owner:ANHUI DINGKANG FOOD

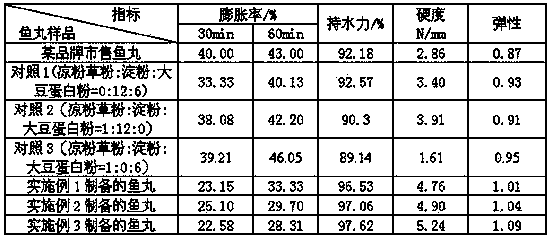

Method for improving gel strength and boiling fastness of minced fillet product

InactiveCN103960696AHigh gel strengthGood cooking resistanceFood preparationGel strengthBiotechnology

The invention belongs to the technical field of processing of aquatic products, and particularly relates to a method for improving the gel strength and boiling fastness of a minced fillet product. The method comprises the steps of semi-unfreezing of frozen minced fillets, blending, molding, heating and cooling. The method is characterized in that the blending step is divided into four stages, including empty blending, salt blending, seasoning blending and mixing blending, wherein in the seasoning blending stage, edible starch and condiments are added; in the mixing blending stage, bean jelly, grass meal and soybean protein powder are added. By adding the bean jelly, the grass meal, the soybean protein powder, the edible starch and the like into the minced fillets in proportion for promoting the formation of a gel network structure of the minced fillet product, the gel strength of the minced fillet product can be enhanced remarkably, the volume expansion of the minced fillet product in a boiling process is alleviated, and the water-holding capacity, hardness and elasticity of the minced fillet product are improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

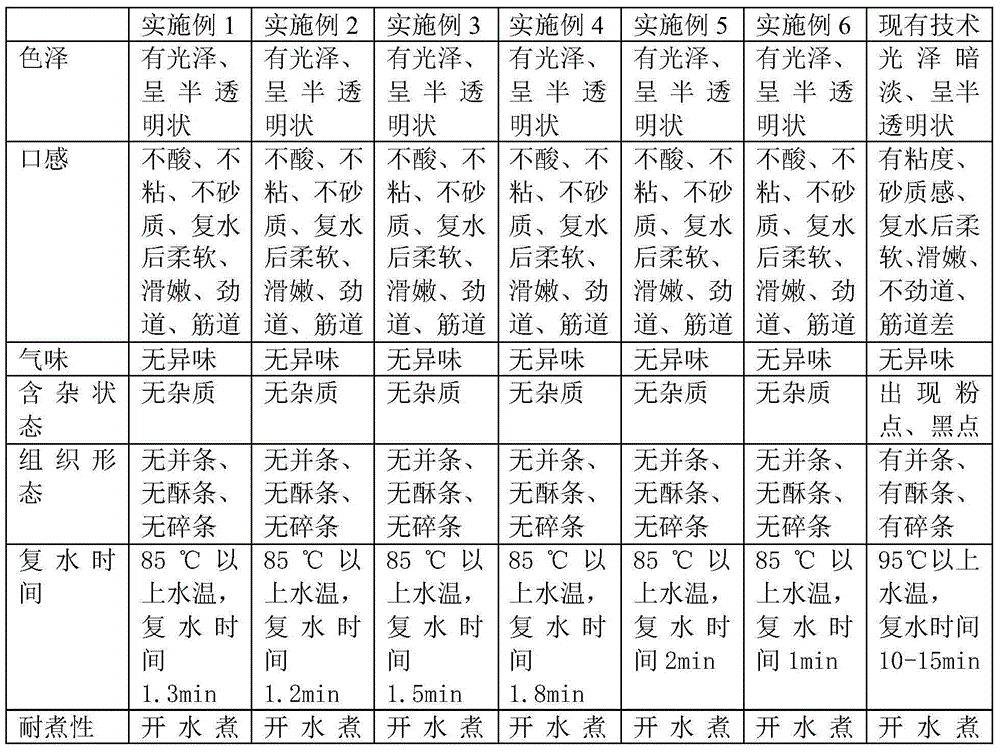

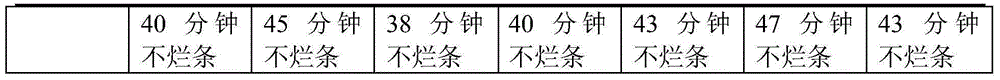

Manufacturing process of convenient vermicelli

InactiveCN105076946AExtended shelf lifeGood fresh-keeping effectFood preparationSlurryExpiration date

The invention provides a manufacturing process of convenient vermicelli and belongs to the technical field of vermicelli processing. The process includes the following operating steps of raw material preparation, thickening, pulp mixing and pulp preparing, coating, decoating, aging, slitting, bagging, vacuumizing, sterilization, and encasement and storage input. The finished convenient vermicelli is obtained. The pH value of pulp prepared in the pulp mixing and pulp preparing step is controlled to be 3.5-4.0 through acid, then coating and decoating operation is conducted, and then aging is conducted through a normal temperature aging process. In the pulp mixing process, the pulp is prepared into the acid pulp with the pH value of 3.5-4.0, the pulp is in an acid environment, the expiration date of the convenient vermicelli can be prolonged, and the shelf life of the convenient vermicelli is prolonged by 3-5 months. The prepared finished convenient vermicelli is good in freshness keeping effect, bright, quick in soaking rehydration, split but not mushy after 40 minutes, smooth and chewy in taste, good in boiling fastness and free of burnt soup.

Owner:河北中祥农业发展有限公司

Stone-milled black corn health-maintaining dried noodles

The invention discloses stone-milled black corn health-maintaining dried noodles, which are prepared from the following raw materials in part by weight: 70 to 80 parts of stone-milled triticale flour, 20 to 30 parts of stone-milled black corn flour, 10 to 15 parts of black soybean powder, 10 to 15 parts of black jujube powder, 8 to 12 parts of spirulina powder, 5 to 10 parts of walnut kernel powder, 5 to 8 parts of balsam pear powder, 5 to 8 parts of kudzuvine root powder, 5 to 10 parts of fermented buckwheat powder, 4 to 6 parts of pine pollen, 4 to 6 parts of camellia pollen, 1 to 2 parts of refined salt, and 0.1 to 0.3 part of dietary alkali. The produced dried noodles are slightly ash black, have thick corn aroma, unique flavor and high boiling fastness, are not changed into paste after being cooked, do not stick teeth, are non-sticky in mouthfeel, non-coarse, soft, smooth, delicious and rich in proteins and other nutrition required by human beings, have the health-care effects of nourishing yin, moisturizing lung, delaying senescence, reinforcing qi, nourishing blood, enhancing immunity, keeping brain health, maintaining mental tranquility and the like, and integrate nutrition and food therapy.

Owner:ANHUI DINGKANG FOOD

Preparation method for compound chicken powder rich in flavor amino acid with high ratio and small molecular weight

The invention provides a preparation method for compound chicken powder rich in flavor amino acid with high ratio and small molecular weight and belongs to the technical field of food resource development and processing. According to the preparation method, the compound chicken powder is produced according to the following sequence: carrying out acid hydrolysis on soybean protein isolate; carrying out microwave vacuum freeze-drying to prepare plant protein hydrolysate; blending with pure chicken powder, a compound flavor agent, spices and the like; adding an embedding agent; and carrying out superfine grinding, microwave sterilization, and sealing and packaging to obtain a final product. According to the preparation method, microwave vacuum freeze-drying, superfine grinding and microwave sterilization technologies are adopted in a preparation process so that flavor substances in a compound chicken powder product keep the salty and fresh flavor and the flavescent color and luster to the greatest degree; meanwhile, micro-molecule flavor amino acid added in compound chicken powder and an embedding technology can be used for significantly improving the tolerance to heat, acid and alkali of a product. The compound chicken powder is scientific in formula, abundant in nutrition, and proper in umami. The preparation method is reasonable in procedures, simple to operate, short in production period and suitable for industrial production.

Owner:JIANGNAN UNIV +1

Preparation method of slow release type high-calcium milky chicken powder for hot pot

ActiveCN104026537AIncrease cooking resistanceLong-lasting aromaFood preparationCalcium EDTABatch production

The invention relates to a preparation method of slow release type high-calcium milky chicken powder for a hot pot, belonging to the technical field of seasoning processing. The preparation method comprises the following steps: mixing commercially available chicken powder (namely Jiahao Zhanwang low-salt chicken powder) of Guangdong Jiahao Foodstuff Co., Ltd. with yeast extracts, dissolving the mixture into sodium alginate to form mixed liquid, dropwise adding the mixed liquid into a calcium lactate solution to generate glue beads, taking out the glue beads, adding the glue beads into a chitosan solution, and carrying out film laminating and ageing so as to obtain slow release type high-calcium chicken powder microspheres for the hot pot; mixing the chicken powder microspheres with chicken powder turbid liquid, so as to prepare the milky chicken powder. The preparation method has the beneficial effects that the duration time of the fragrance can be prolonged due to the excellent slow release performance of the microspheres, the whole process is suitable for industrial batch production, the guarantee period of the product is long, and the sales scope of the product is beneficially extended.

Owner:GUANGDONG JIAHAO FOOD +1

Method for preparing golden mushroom nutritional noodles

InactiveCN102342432AUniform moistureAvoid excessive water absorptionDough treatmentFood preparationFerrous GluconateLYSINE HYDROCHLORIDE

The invention provides a method for preparing golden mushroom nutritional noodles. The method comprises the following steps of: putting common flour and water into a dough kneader, after kneading the dough for 5-10 minutes, adding golden mushroom powder, whole-egg powder, cabbage powder, corn starch, ferrous gluconate, calcium gluconate and L-lysine hydrochloride to the dough kneader, continuing kneading the dough for 5-20 minutes, then putting the dough into a ripening machine to be ripened for 5-20 minutes, and then carrying out calendering, strip cutting, drying and cutting-off processes in sequence to obtain the golden mushroom nutritional noodles. The invention has the following advantages: the preparation process is simple; the quality of a finished product is high; the shelf life is long; the noodles prepared by the method have balanced nutrition and fragrant and sweet taste; the taste of the noodles is easy to like by the children; and the noodles are especially suitable for serving as the complementary food of vegetables eaten by the children.

Owner:宜垦(天津)农业制品有限公司

High-fiber additive-free pure-corn noodle and environment-friendly production method thereof

ActiveCN103549282AImprove sensory qualityImprove bindingMulti-step food processesFood ingredient functionsFiberExtensibility

The invention relates to high-fiber additive-free pure-corn noodle and an environment-friendly production method thereof, belonging to a food processing technology. The preparation method of the high-fiber additive-pure pure-corn noodle comprises the steps of after impurities are removed through screening ripen corn kernels, melting and expanding through high-pressure steam, crushing, improving textures, carrying out fine-crushing, blending, forming and the like to produce the high-fiber additive-free pure-corn noodle. The high-fiber additive-free pure-corn noodle produced by adopting the invention has the advantages of being good in binding force, proper in extensibility and flexibility, good in boiling fastness, and pure in corn flavor, improving the digestibility of the corn foods, and developing the main food function and the nutrition health care function of the corn. The production method is mild in conditions in a production process, does not adopt any chemical and biological synthesis technologies, is free of pollution, waste residue, waste steam and harmful substances, and realizes the environment-friendly production; no non-corn grain raw materials and products are added, thus the pure flavor of the corn is ensured; no gluten fortifier, thickening colloid, enzyme preparation or preservative is added, no chemical reagents are used, thus the eating safety is ensured.

Owner:吉林省正源食品有限责任公司

Rice noodle

The invention discloses a rice noodle. The rice noodle is prepared from the following raw materials in parts by weight: 500 parts of rice, 3-3.5 parts of lotus root starch, 2-2.5 parts of honey, and 75-100 parts of water. The rice noodle is produced by virtue of the following steps: taking the raw materials in parts by weight, washing the rice, soaking for 30 minutes and then draining; grinding the rice, adding the water, the lotus root starch and the honey, stirring evenly, and then forming the noodles in a rice noodle machine. The rice noodles have the characteristics of good tenacity, difficulty in breakage, easiness in separation, cooking resistance, good taste and high nutritive value.

Owner:修文县佳家乐米粉加工厂

Instant corn noodle

InactiveCN104824556ADelicate tasteTaste effectFood freezingMulti-step food processesPowder mixtureCold store

The invention discloses an instant corn noodle. The instant corn noodle is prepared from corn keratin endosperm powder and corn farinaceous endosperm powder, and is prepared through the following steps: uniformly mixing the corn keratin endosperm powder with the corn farinaceous endosperm powder according to a ratio of 1:1, adding salt accounting for 0.6% of the weight of the above obtained powder mixture and normal temperature drinking water accounting for 30-35% of the weight of the powder mixture, fully stirring to obtain a wet powder mixture, putting the wet powder mixture in a spiral puffing machine, carrying out puffing extrusion to form cooked noodles, sending the cooked noodles to a regulating chamber, regulating, packaging the regulated noodles by a food stage plastic bag, rapidly sending the bag to a quick freeze chamber, quickly freezing, and moving to a cold store for storage in order to obtain the finished instant corn noodle. The instant corn noodle can be directly eaten after direct boiling without immersion, and has the advantages of good boiling fastness, no soup turbidity after long time boiling, good elasticity, no fracture, smoothness in mouth, and fine mouthfeel.

Owner:辽宁曙光食品有限公司

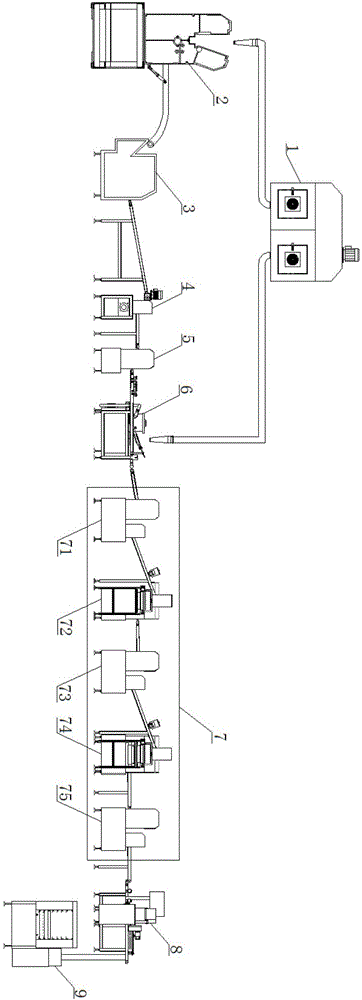

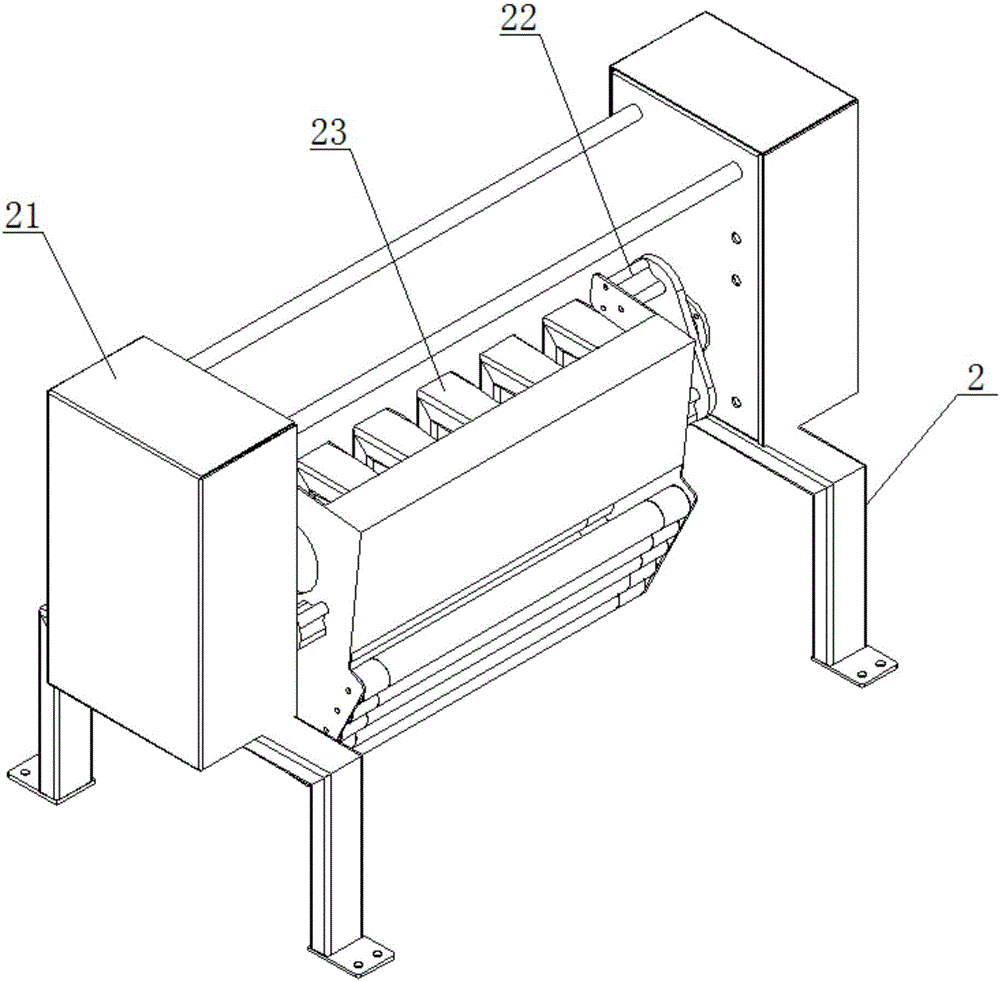

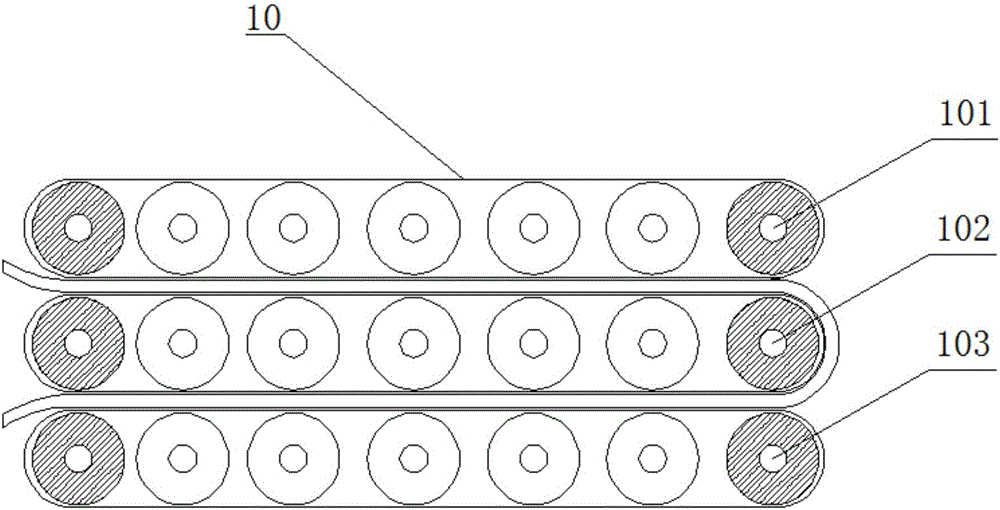

Fresh noodle processing technology and fresh noodle automated production device

InactiveCN106561758AIncrease toughness and cooking resistanceTaste chewyDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusChemistryForming processes

The invention discloses a fresh noodle processing technology and a fresh noodle automated production device. The fresh noodle processing technology comprises the steps of preparing flour mixing water, mixing flour, crushing, tabletting, folding and rolling flour into dough, folding, rolling, cutting and forming, packaging, preserving, and the like. According to the fresh noodle processing technology and the fresh noodle automated production device of the invention, dough is preliminarily processed through a flour mixer, a dough crusher, a compound tablet press and a folding processing device to make the raw material stirred evenly, preliminary rolling and folding are carried out, and then, rolling and folding are carried out repeatedly through folding and rolling devices. Thus, the toughness of noodles is increased in the noodle shaping process, and the same chewiness as handmade noodles is achieved. Moreover, the production device is fully automated, so that the work efficiency and the yield of noodles are improved greatly. There is no manual operation in the intermediate processing link, and thus, the noodles made are cleaner.

Owner:安徽新创智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com