Formula and production method for sweet-buckwheat coarse-cereal mixed-bean recombinant rice

A production method and technology of sweet buckwheat, applied in the field of sweet buckwheat miscellaneous grains, miscellaneous beans and recombined rice, can solve the problems of low flavonoid content and poor taste of sweet buckwheat rice, achieve high nutritional value, good taste, improve processing quality and nutritional quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

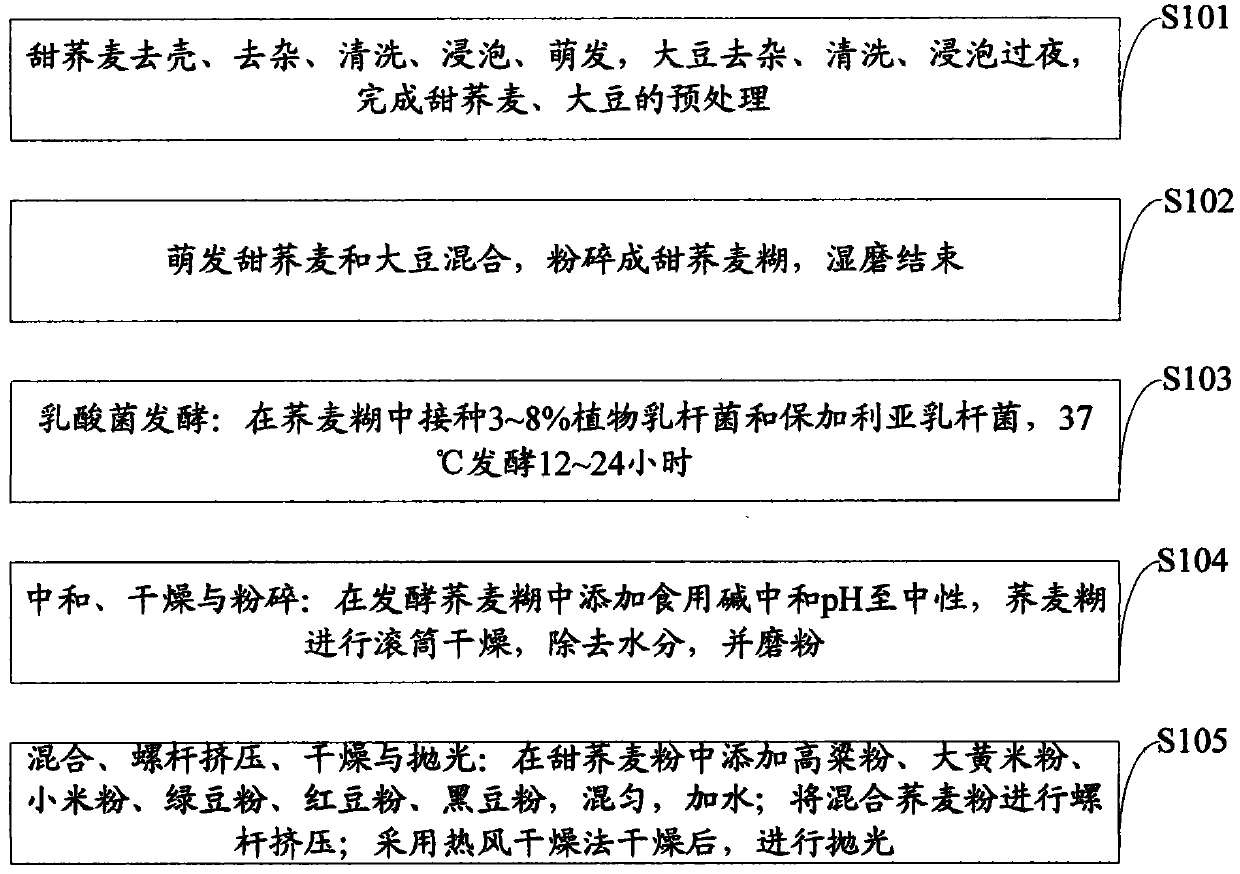

Method used

Image

Examples

Embodiment 1

[0047] 1. Example 1 Sweet buckwheat miscellaneous grain recombined rice:

[0048] 1), Lactobacillus plantarum and Lactobacillus bulgaricus are respectively activated to obtain a mother starter, which is mixed at 1:1 to prepare a working starter;

[0049] 2), remove impurities, wash and soak soybeans;

[0050] 3) The sweet buckwheat is peeled, removed, soaked, germinated, mixed with soaked soybeans and refined;

[0051] 4), sweet buckwheat soybean paste is inoculated with lactic acid bacteria working starter;

[0052] 5), ferment at 37°C for 12-24 hours, add edible alkali to neutralize the pH to neutral, drum-dry the buckwheat paste, remove water, and grind it into powder, with a particle size of 80-100 mesh;

[0053] 6) Add 20% to 40% of sorghum flour, rhubarb rice flour or millet flour, mix well, and add appropriate amount of water (the amount of water added to the material is 15% to 30%);

[0054] 7) Screw extrusion: The above mixed buckwheat flour is subjected to screw e...

Embodiment 2

[0056] Two, embodiment 2 sweet buckwheat miscellaneous beans recombinant rice:

[0057] 1), Lactobacillus plantarum and Lactobacillus bulgaricus are respectively activated to obtain a mother starter, which is mixed to prepare a working starter;

[0058] 2), remove impurities, wash and soak soybeans;

[0059] 3) The sweet buckwheat is peeled, removed, soaked, germinated, mixed with soaked soybeans and refined;

[0060] 4), sweet buckwheat soybean paste is inoculated with working starter;

[0061] 5), ferment at 37°C for 12-24 hours, add edible alkali to neutralize the pH to neutral, drum-dry the buckwheat paste, remove water, and grind it into powder, with a particle size of 80-100 mesh;

[0062] 6), add mung bean powder, red bean powder or black bean powder, gluten powder and egg white powder, the weight ratio is 5-25%, fully mix, add appropriate amount of water, the amount of water added to the material is 15%-30%;

[0063] 7) Screw extrusion: The above mixed buckwheat flo...

Embodiment 3

[0065] Three. Embodiment 3 Sweet buckwheat miscellaneous grains miscellaneous beans recombined rice:

[0066] 1), Lactobacillus plantarum and Lactobacillus bulgaricus are respectively activated to obtain a mother starter, which is mixed at 1:1 to prepare a working starter;

[0067] 2), remove impurities, wash and soak soybeans;

[0068] 3) The sweet buckwheat is peeled, removed, soaked, germinated, mixed with soaked soybeans and refined;

[0069] 4), sweet buckwheat soybean paste is inoculated with working starter;

[0070] 5) Ferment at 37°C for 12-24 hours, add edible alkali to neutralize the pH to neutral, drum-dry the buckwheat paste, remove water, and grind to a particle size of 80-100 mesh;

[0071] 6) Add 10-30% of sorghum flour, rhubarb rice flour or millet flour and 5-25% of mung bean flour, red bean flour or black bean flour, mix well, add appropriate amount of water, the amount of water added to the material is 15%-30%;

[0072] 7) Screw extrusion: The above mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com