Method and device for producing fresh-keeping instant wet noodles

A wet noodle and convenient technology, which is applied in the production of fresh-keeping instant wet noodles, vermicelli preservation, and production of convenient wet noodles stored at room temperature. It can solve the problems of long sterilization time, unsuitable Chinese noodle taste, and high acidity of noodles, and achieve high-temperature sterilization time. Short, strong production controllability, and complete production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

[0047] The experimental methods without specific conditions indicated in the following examples are usually carried out according to conventional conditions or the conditions provided by the manufacturer.

[0048] (1) Device for producing fresh-keeping instant wet noodles

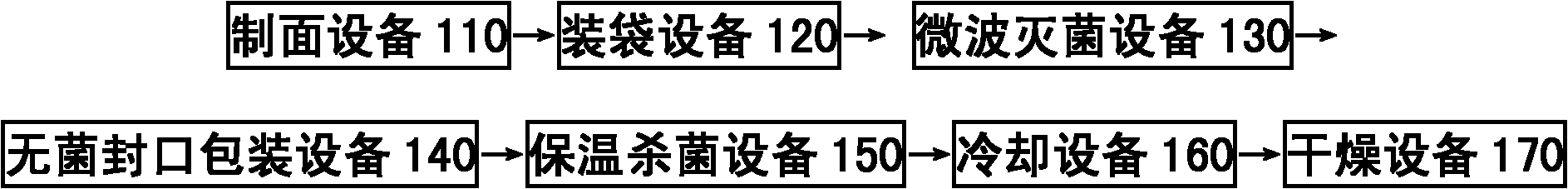

[0049] Such as figure 1 As shown, a device for producing fresh-keeping instant wet noodles includes: noodle making equipment 110 → bagging equipment 120 → microwave sterilization equipment 130 → aseptic sealing packaging equipment 140 → heat preservation and sterilization equipment 150 → cooling equipment 160 → drying equipment 170 .

[0050] The noodle making equipment 110 includes general equipment for noodle making, (with wheat flour as the main ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com