Method for improving gel strength and boiling fastness of minced fillet product

A technology for gel strength and surimi products, applied in the field of improving the gel strength and cooking resistance of surimi products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

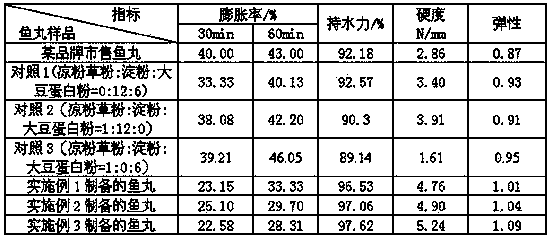

Examples

preparation example Construction

[0015] 1. Preparation of jelly grass powder: take dried jelly grass or fresh jelly grass stems and leaves, and prepare jelly jelly powder according to the conventional extraction process of jelly grass powder. The process includes: adding water to mash, boiling, filtering, concentrating, decolorizing, cooling and filtering , drying, crushing, etc. That is, soak the fresh jelly grass or jelly grass hay in 20-30 times the weight of water, mash it with a masher, heat it to boiling and cook for about 1 hour, and filter it with a filter cloth to obtain the filtrate. Concentrate the filtrate with a vacuum concentrator to evaporate 80%-90% of the water to obtain a concentrate. Add absolute ethanol that is 4 times the weight of the concentrated liquid to the concentrated liquid, place it in a decolorizing tank equipped with a condensation reflux device, decolorize at 60°C for 5-6 hours, and filter after cooling to obtain a shallow gelatin rich in jelly jelly. color precipitate. Dry ...

Embodiment 1

[0019] 1. Preparation of jelly grass powder: take dried jelly grass or fresh jelly grass stems and leaves, and prepare jelly jelly powder according to the conventional extraction process of jelly jelly powder. The process includes: adding water to mash, boiling, filtering, decolorization, concentration, drying, Smash etc.

[0020] 2. Thawing: Thaw the surimi naturally at room temperature until it can be chopped into pieces, but it is advisable to have a semi-thawed state where there is still some crushed ice in the center.

[0021] 3. Beating: Put the semi-thawed frozen miscellaneous surimi in the hollow of the beating equipment for 3 minutes, add salt with 3% of the weight of the surimi to the fish after the empty beating, and carry out salt beating for 10 minutes. Finally, add edible starch accounting for 15% of the weight of the surimi and appropriate amount of sugar, monosodium glutamate, pepper and other seasonings to make it fully even with the surimi, and finally add 1....

Embodiment 2

[0026] 1. Preparation of jelly grass powder: take dried jelly grass or fresh jelly grass stems and leaves, and prepare jelly jelly powder according to the conventional extraction process of jelly grass powder. The process includes: adding water to mash, boiling, filtering, decolorization, concentration, drying, Smash etc.

[0027] 2. Thawing: Thaw the surimi naturally at room temperature until it can be chopped into pieces, but it is advisable to have a semi-thawed state where there is still some crushed ice in the center.

[0028] 3. Beating: Put the semi-thawed frozen miscellaneous surimi in the hollow of the beating equipment for 5 minutes, add salt with 2% of the weight of the surimi to the fish meat after the empty beating, and carry out salt beating for 15 minutes. Finally, add edible starch accounting for 12% of the weight of the surimi and appropriate amount of sugar, monosodium glutamate, pepper and other seasonings to make it fully even with the surimi, and finally a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com