Room-changing belt-type binding machine

A baler and front cabin technology, applied in the field of mechanical design and manufacturing, can solve the problems of loose forming core, low compression rate, uneven straw entering the compression chamber, etc., achieve large compression force, improve compression rate, and reduce costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

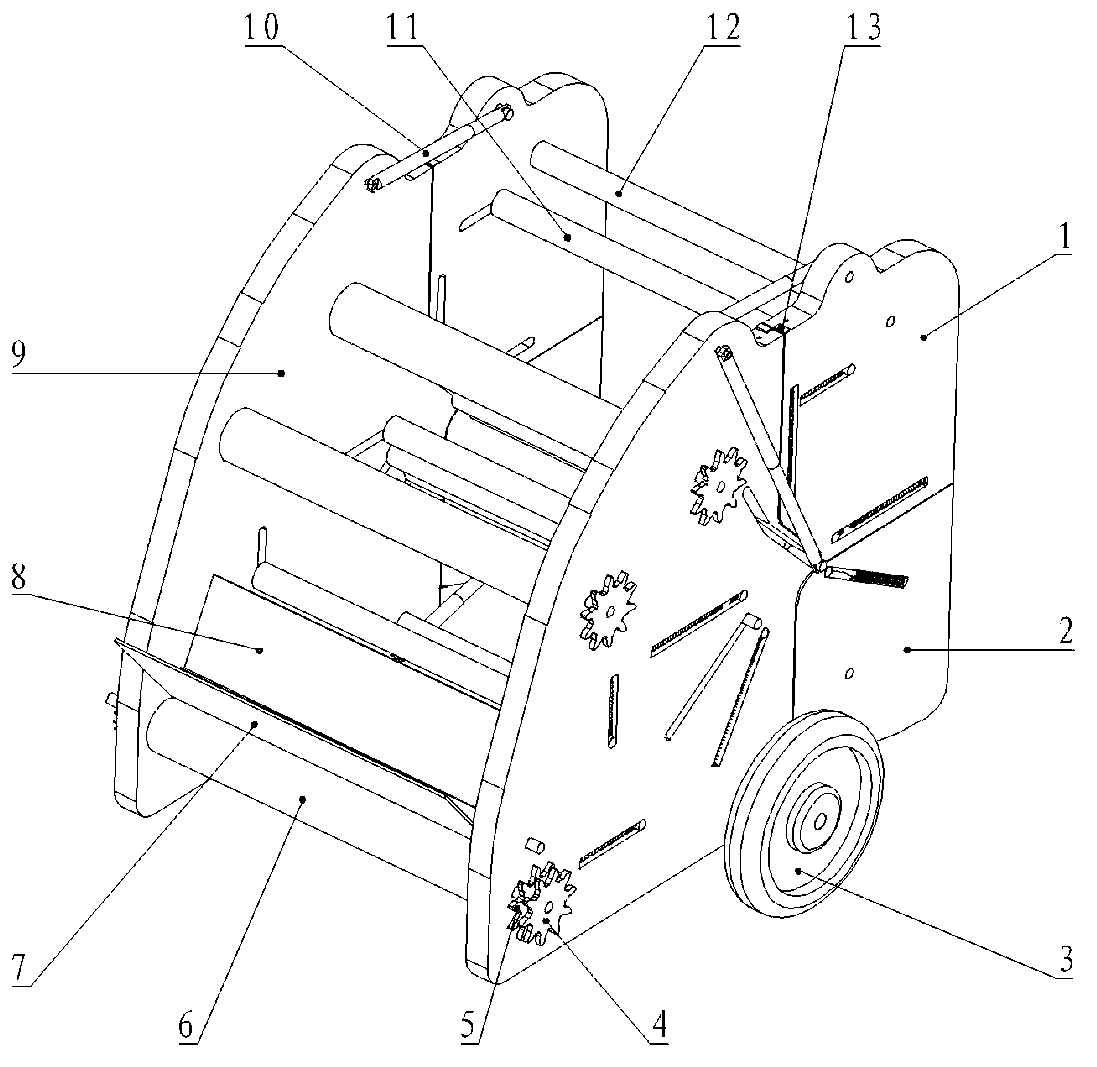

[0025] The present embodiment is a belt-type strapping machine with changing cabins.

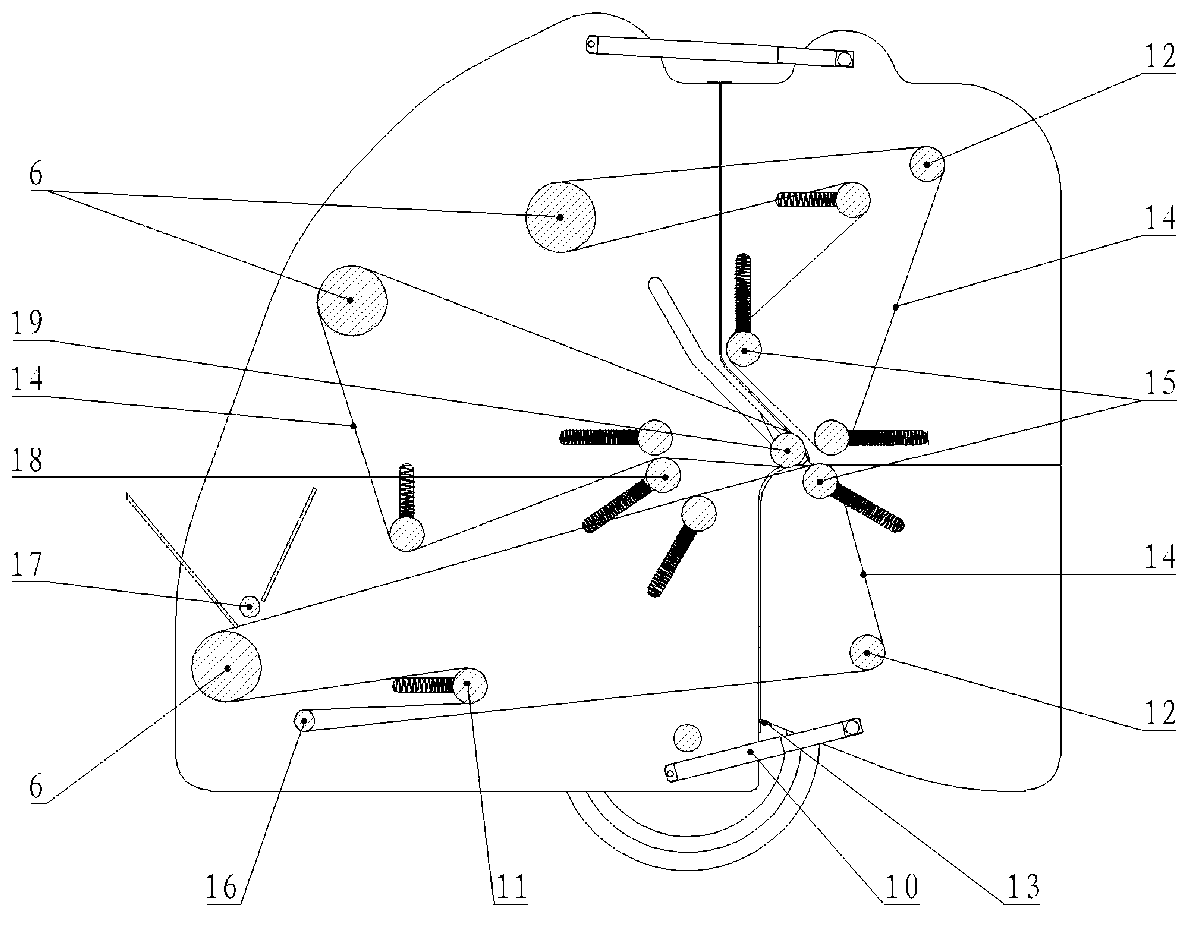

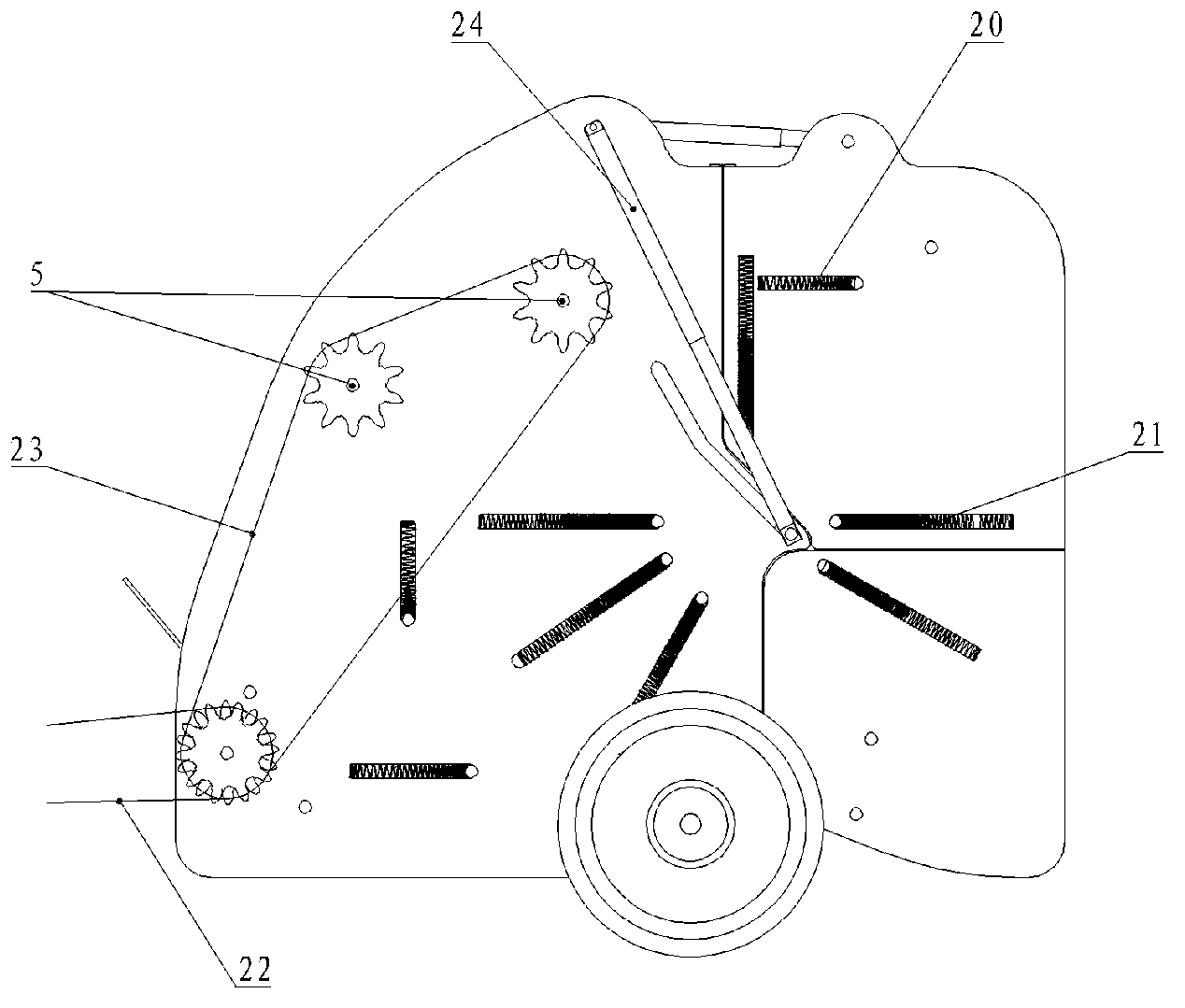

[0026] refer to Figure 1-Figure 4 , The variable cabin belt baler is composed of a mounting plate, a feeding trough, a chain mechanism, a compression device, and a wheel. The mounting plate is two parallel and symmetrically installed plates with the same structure. The feeding trough is located under the front part between the two mounting plates. The side is connected to the output port of the harvester, the compression device is located in the middle part between the mounting plates, the chain mechanism is set on the outer front of the mounting plate, and the two wheels are fixedly installed on the lower part of the two mounting plates. The mounting plate comprises a front deck 9, a rear cabin upper panel 1 and a rear cabin lower panel 2, a cabin opening hydraulic cylinder 10, and a hinge 13. A cabin opening hydraulic cylinder 10 is provided on the inside upper part of the board 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com