Continuous production processing system for clean coal

A processing system and clean technology, applied in the field of continuous production processing system, can solve the problems of increasing processing cost, not too high processing and molding integrity, jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

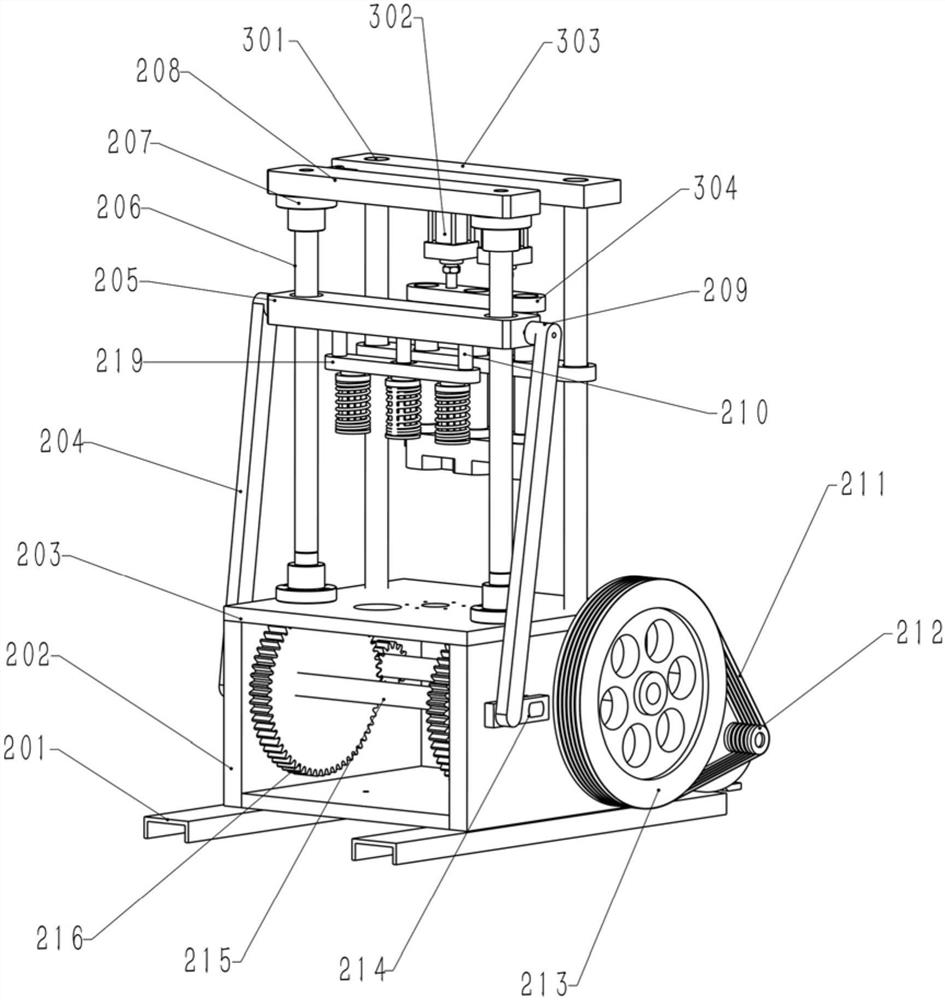

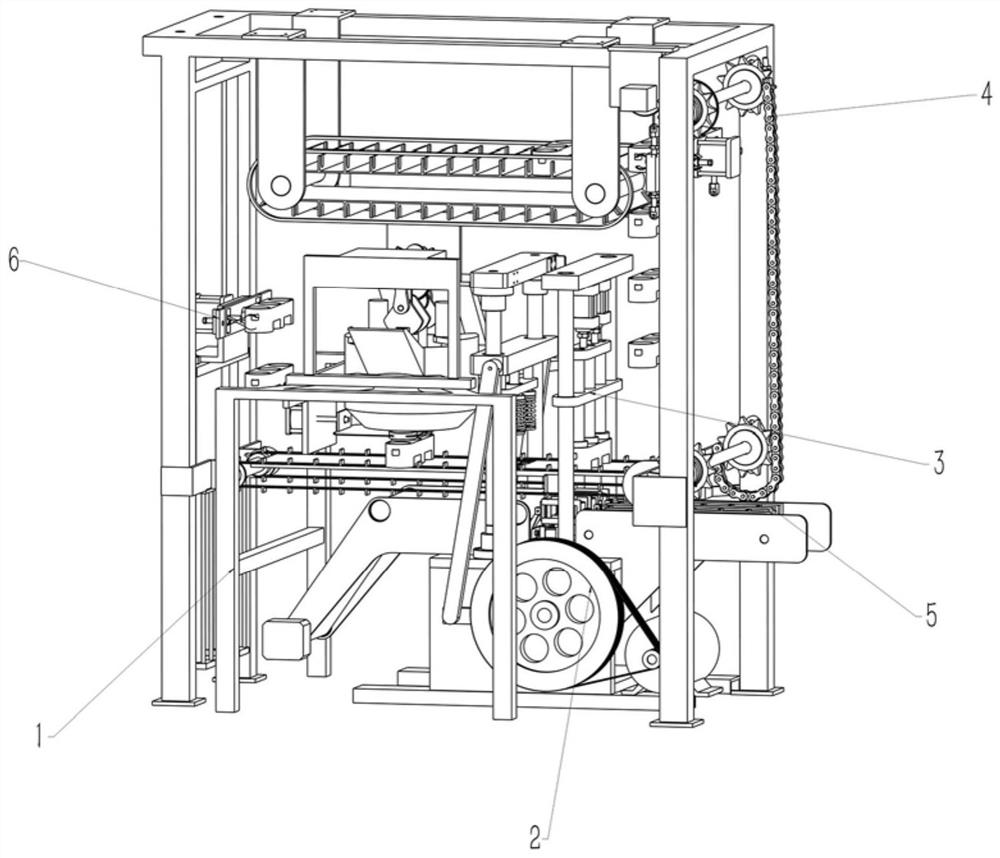

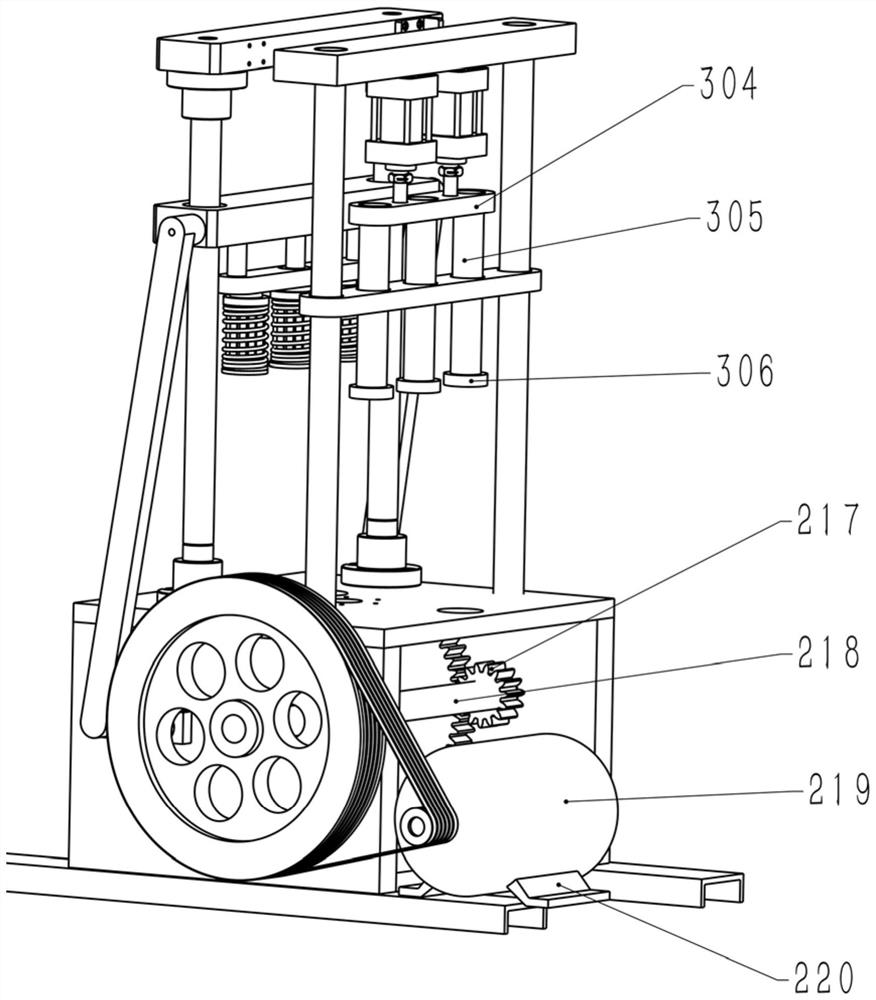

[0035] Specific implementation mode one: combine Figure 1-13As shown: it includes a tamping assembly, a forming assembly 2, a demoulding assembly 3, a mold transmission assembly 1 4, a transmission assembly 5 and a mold transmission assembly 2 6; the tamping assembly is provided with a first supporting vertical column 101, a first connecting horizontal Column 102 and the second connecting horizontal column 103; Wherein the first supporting vertical column 101 and the second connecting horizontal column 103 are welded together; The upper end surface of the first supporting vertical column 101 is horizontally aligned with the upper end surface of the second connecting horizontal column 103; A connection horizontal column 102 is welded between the two first support vertical columns 101; the vertical plane of the first connection horizontal column 102 is aligned with the vertical plane of the first support vertical column 101 outside; and the first connection horizontal column 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com