Fertilizer processing system

A fertilizer processing and feeding device technology, applied in manure drying, lighting and heating equipment, separating solids from solids with airflow, etc., can solve the inconvenience of cleaning process, unfavorable material dust reuse, increase construction height and Construction costs and other issues to achieve the effect of ensuring air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

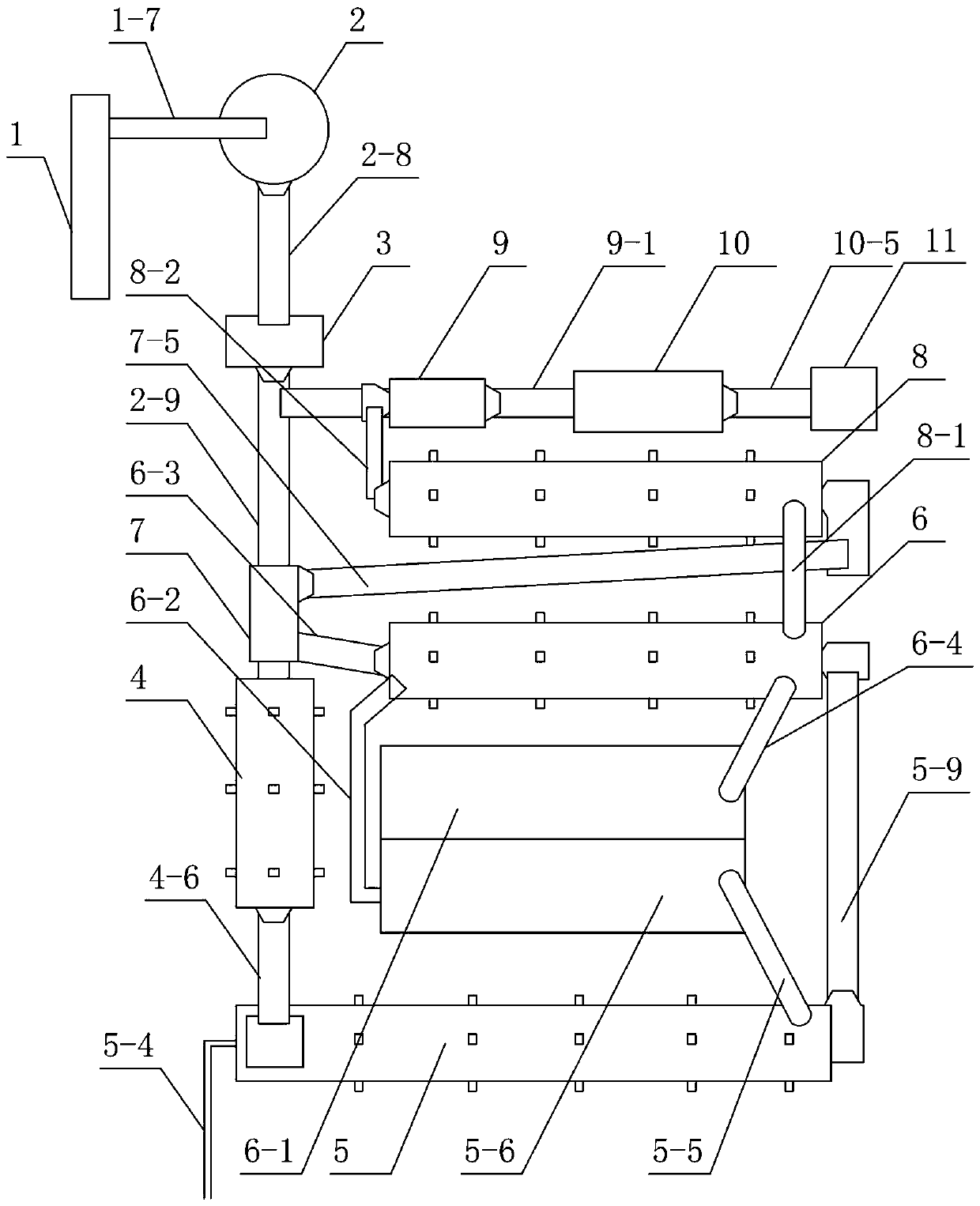

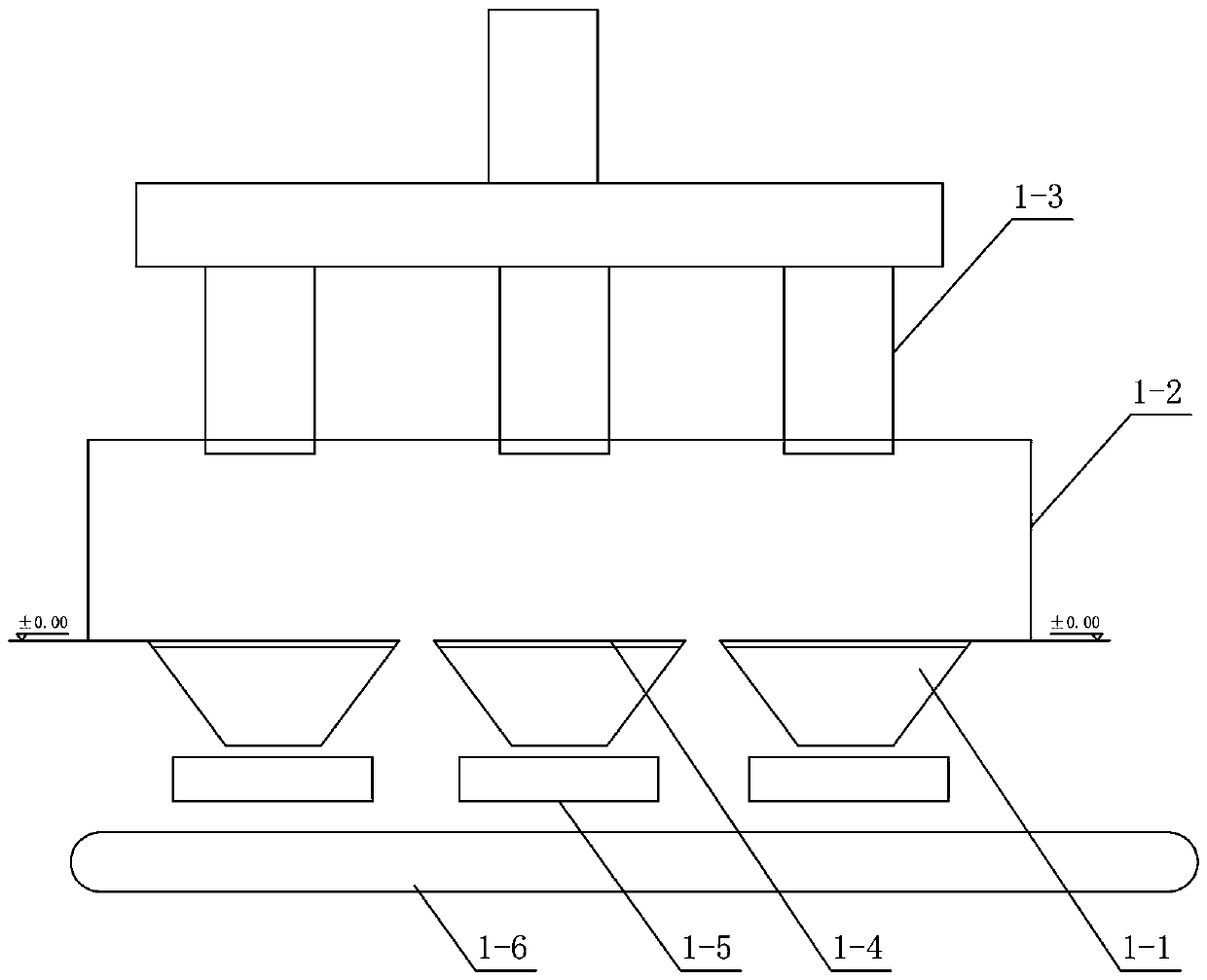

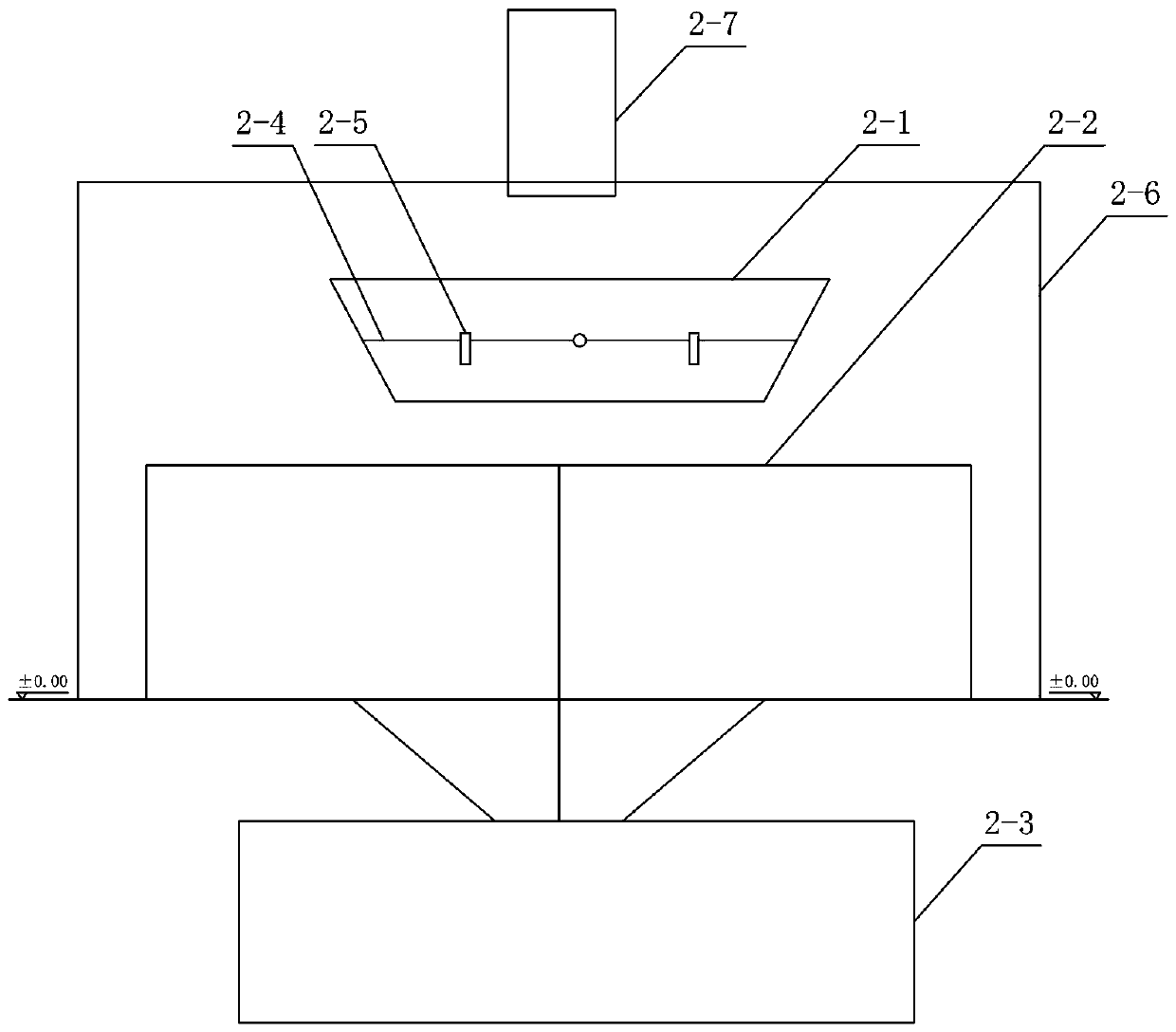

[0046] Such as figure 1 As shown, the present invention includes feeding device 1, stirring device 2, crushing device 3, primary granulation device 4, secondary granulation device 5, primary cooling device 6, primary screening device 7, secondary cooling device from front to rear. Device 8, secondary screening device 9, coating device 10, weighing bagging device 11, such as figure 2 As shown, the feeding device 1 includes a plurality of (three as an example in the figure) below the ground feeding hopper 1-1, the top of the feeding hopper 1-1 is surrounded by a first ash baffle 1-2, the second A dust baffle 1-2 is provided with a first dust removal pipeline 1-3, a feed mesh screen 1-4 is provided at the upper end of the feed hopper 1-1, and a weighing metering control is provided below each feed hopper 1-1 System 1-5, a first belt conveyor 1-6 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com