Inoculation device special for silage lactic acid bacteria

An inoculation device and a technology for lactic acid bacteria, which are used in biochemical cleaning devices, enzymology/microbiology devices, applications, etc., can solve problems such as low production efficiency, lack of lactic acid bacteria liquid dilution, culture, storage and spraying, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

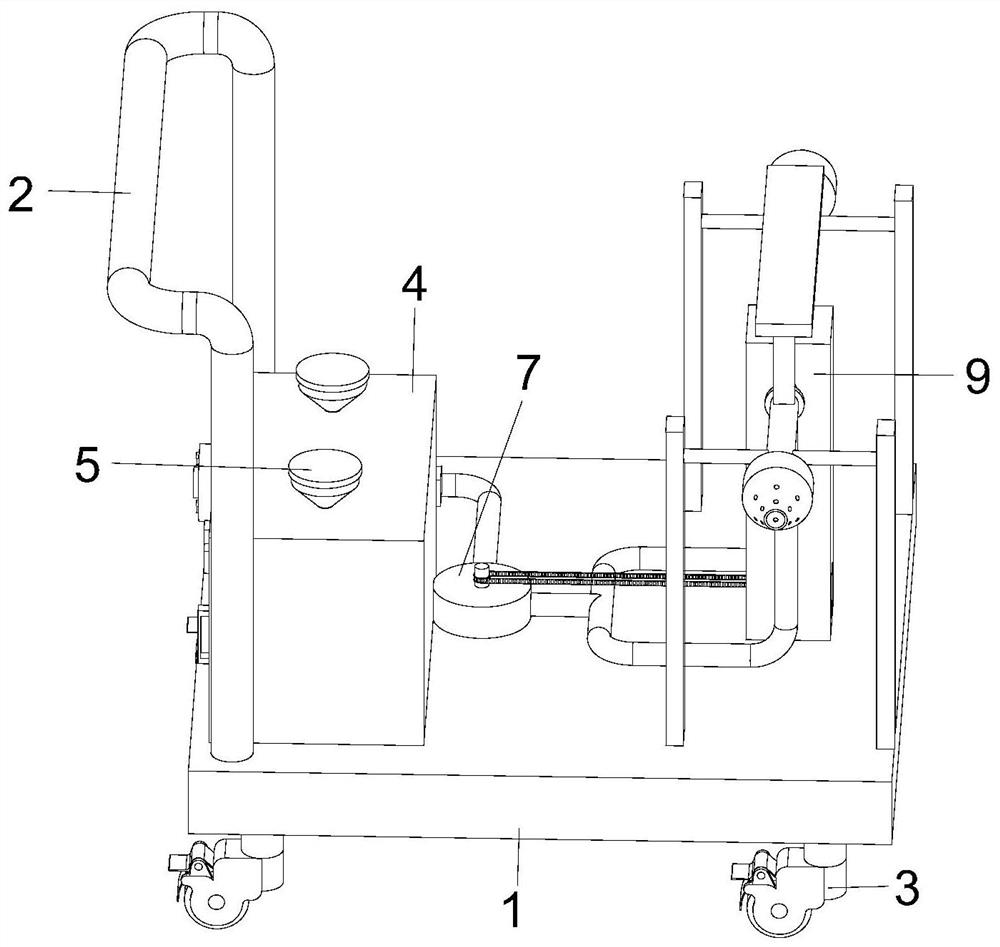

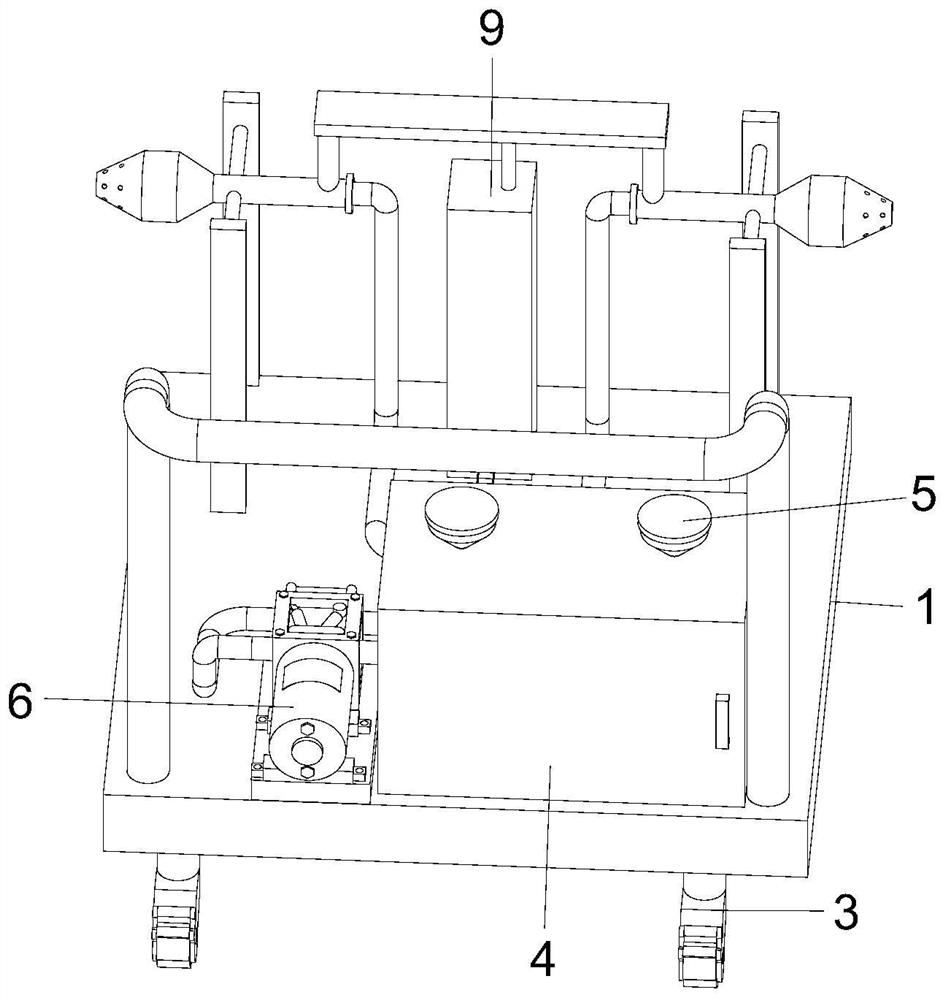

[0032] see Figure 1-4, a kind of inoculation device specially used for silage lactic acid bacteria, comprising a car body 1, a handrail 2 is provided on the top of the left end of the car body 1, brake wheels 3 are fixed on the four corners of the bottom surface of the car body 1, and an inoculation box 4 is fixed on the top surface of the right end of the car body 1 , the inoculation box 4 is provided with an inoculation assembly 5, the rear side of the inoculation box 4 is provided with a booster pump 6, the end of the outlet pipe of the booster pump 6 is provided with a drive box 7, and the front end of the drive box 7 is provided with a sprinkling pipe 8, and the sprinkling pipe The 8 right end is connected with sprinkling assembly 9.

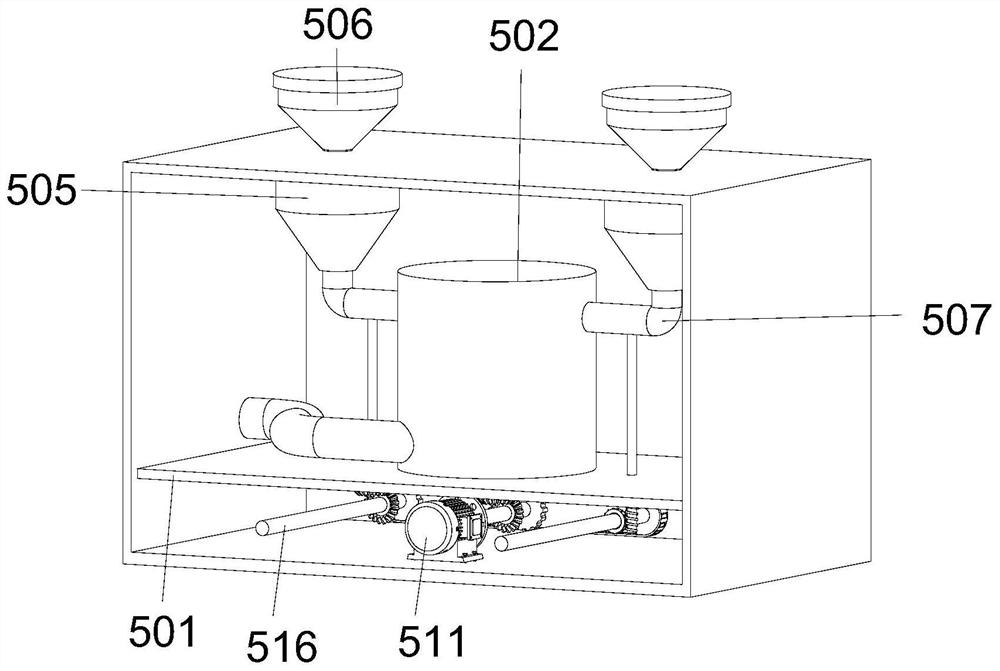

[0033] The inoculation assembly 5 comprises a partition 501, the partition 501 is fixed at the position near the bottom of the inoculation box 4, the middle part of the top surface of the partition 501 is fixed with a mixing bucket 502, an...

Embodiment 2

[0037] see Figure 5-6 The difference in connection with the basis of Embodiment 1 is that the end of the booster pump 6 inlet pipe passes through the inoculation box 4 inner wall and the bottom inner wall of the mixing bucket 502 to communicate with the inside.

[0038] The inside of the drive box 7 includes a rotating seat 701. The outer wall of the rotating seat 701 is circular and equidistantly fixed with a plurality of water baffles 702. The top of the rotating seat 701 is fixed with a connecting rod 703, and the top of the connecting rod 703 extends through the top surface of the driving box 7. To the top thereof and to be rotationally connected with it, a gear C704 is sleeved on the outer wall of the top end of the connecting rod 703, and a chain B705 is sleeved on the outer wall of the gear C704.

[0039] In the present invention, the inoculated fermented liquid inside the mixing tank 502 is used to spray on the feed, and the feed is sealed and stored. The spraying pro...

Embodiment 3

[0041] see Figure 7-9 , and the basis of Embodiment 1 is different in that the sprinkling assembly 9 includes a support rod 901, and the bottom end of the support rod 901 is provided with a limit hole 902, and the inside of the limit hole 902 is vertically provided with a rotating shaft C903, and the outer wall of the bottom end of the rotating shaft C903 A gear D904 is socketed, and the gear C704 and the gear D904 are meshed and connected by a chain B705. A cavity 905 is opened inside the support rod 901 near the top, and the top of the rotating shaft C903 passes through the middle of the supporting rod 901 and extends to the inside of the cavity 905. The bevel gear E906 is socketed, and the middle part of the bevel gear E906 is longitudinally provided with a rotating shaft D907. The outer wall of the rotating shaft D907 is socketed with a bevel gear F908 that meshes vertically with the bevel gear E906. The outer wall of the rotating shaft D907 is socketed with a cam relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com