Biomass fuel processing and forming device

A biomass fuel, processing and molding technology, which is applied in the direction of extrusion granulation of raw materials, solid separation, sieving, etc., can solve the problem of inability to achieve classification, collection and molding of straw particles, etc., and achieve the effect of improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

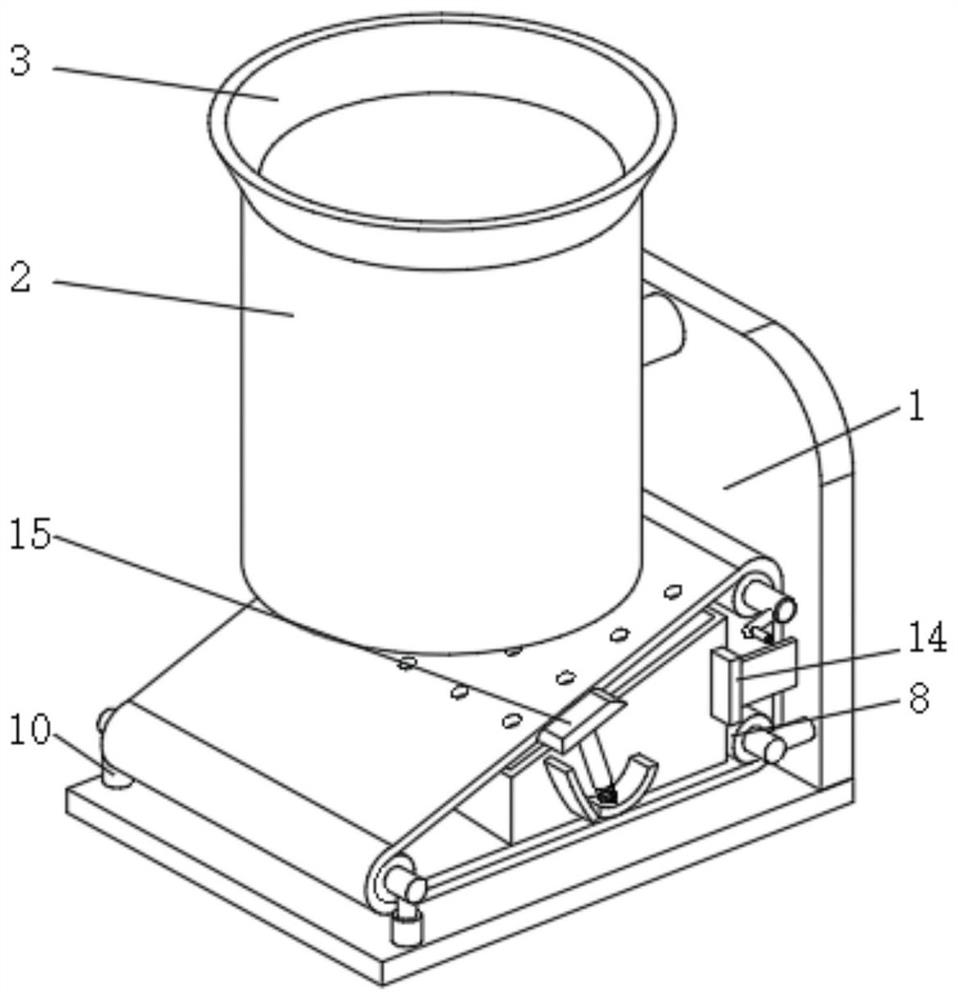

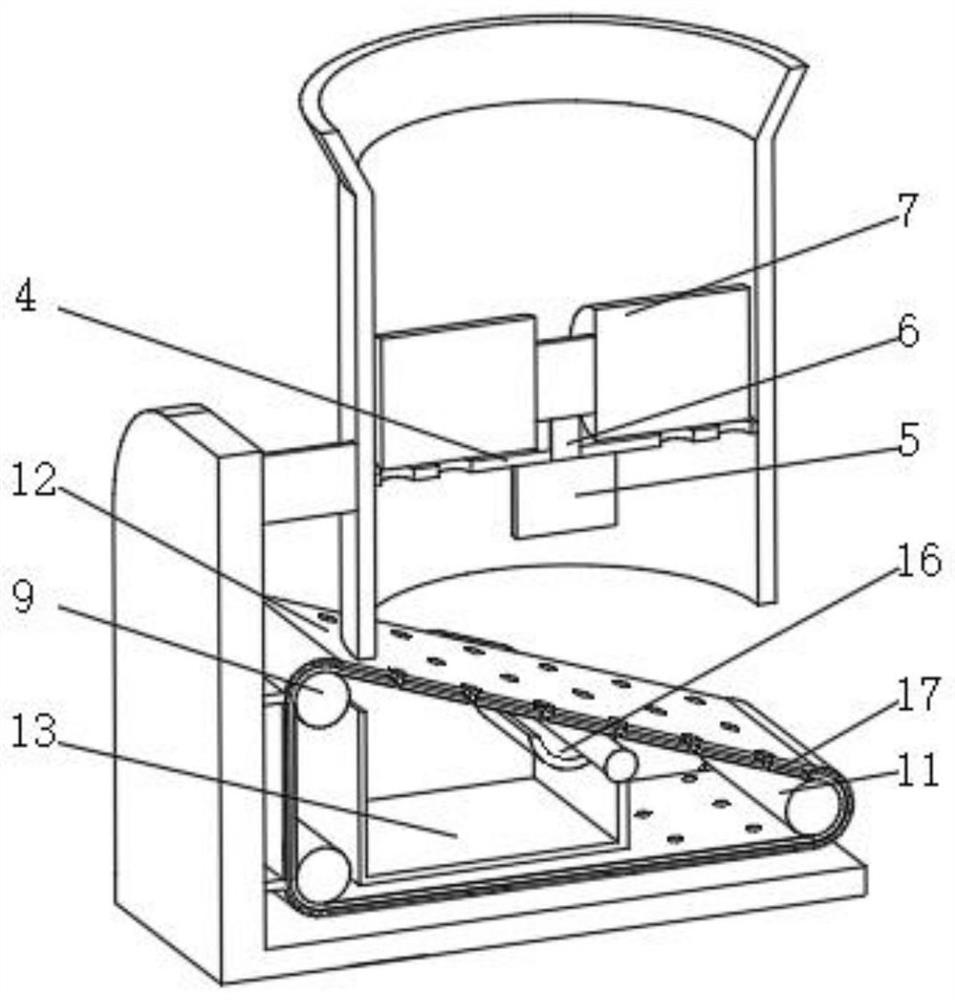

[0029] see Figure 1-5, the present invention provides a technical solution: a biomass fuel processing and molding device, including a base 1, one side of the base 1 is fixedly connected with a forming cylinder 2 through a fixed column, and the top of the forming cylinder 2 is connected with a feeding cylinder 3, forming The inner wall of the cylinder 2 is fixedly connected with a fixed plate 4, and one side of the fixed plate 4 is evenly opened with a forming hole, the fixed plate 4 is put into the bottom and fixedly connected with a driving motor 5, and the output shaft of the driving motor 5 is connected with a rotating rod 6 for rotation. One end of the rod 6 runs through the fixed plate 4 and is fixedly connected with the pressure wheel 7, one side of the base 1 is rotatably connected with the first driven roller 8 through the rotating seat, and the side of the base 1 close to the driven roller 8 is rotatably connected with the driving roller 8 through the rotating seat. ...

Embodiment 2

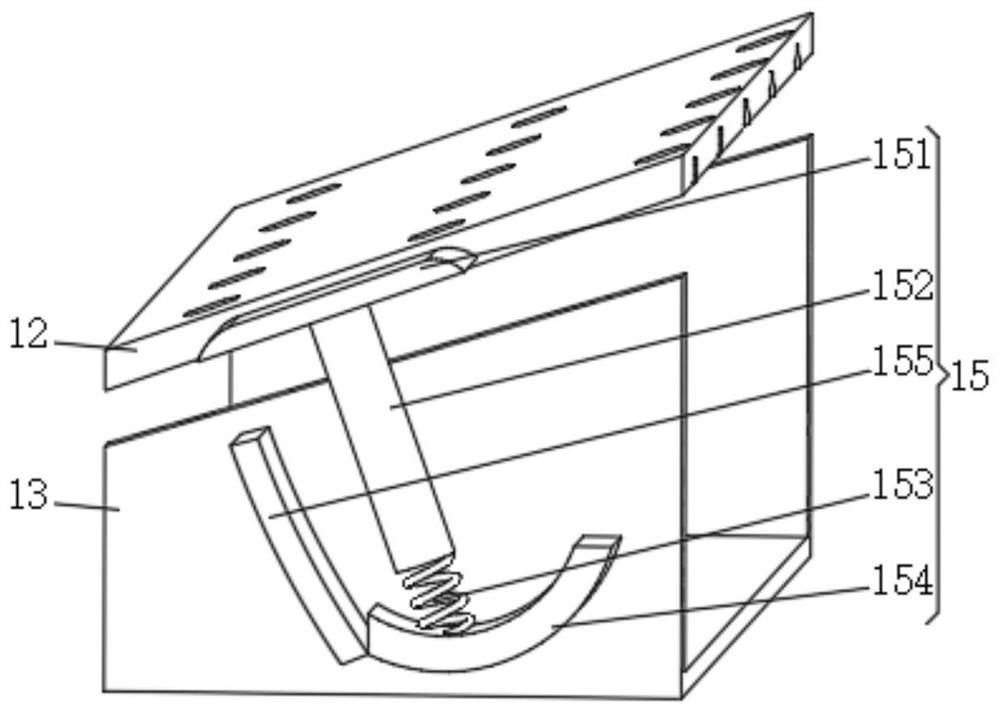

[0037] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, an impact device 16 is installed on the top of the collection frame 13

[0038] The impact device 16 includes an arc-shaped plate 161, one end of the arc-shaped plate 161 penetrates and is fixedly connected with a rotating rod 162, one end of the rotating rod 162 is rotatably connected with a fixed rod 163 through a bearing, and a Clockwork spring 164, one side of arc-shaped plate 161 is evenly equipped with elastic impact block 165.

[0039] When in use, straw scraps fall from one side of the first annular screen 12, and part of the scraps accumulate on the arc-shaped plate 161. When the scraps accumulated on the arc-shaped plate 161 gradually increase, the gravity on the arc-shaped plate 161 increases Larger and drives the rotating rod 162 to rotate, the elastic impact block 165 at the other end of the arc plate 161 rotates and hits the second annular screen 17, throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com