Mould capable of demoulding keycap through short oblique pins

A keycap and demoulding technology, which is applied in the mold field of short oblique pin demoulding keycaps, can solve the problems of damaging the keycap, affecting the finished product of the mold, and affecting the ejection of the keycap, so as to achieve the effect of increasing the straight line and reducing waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

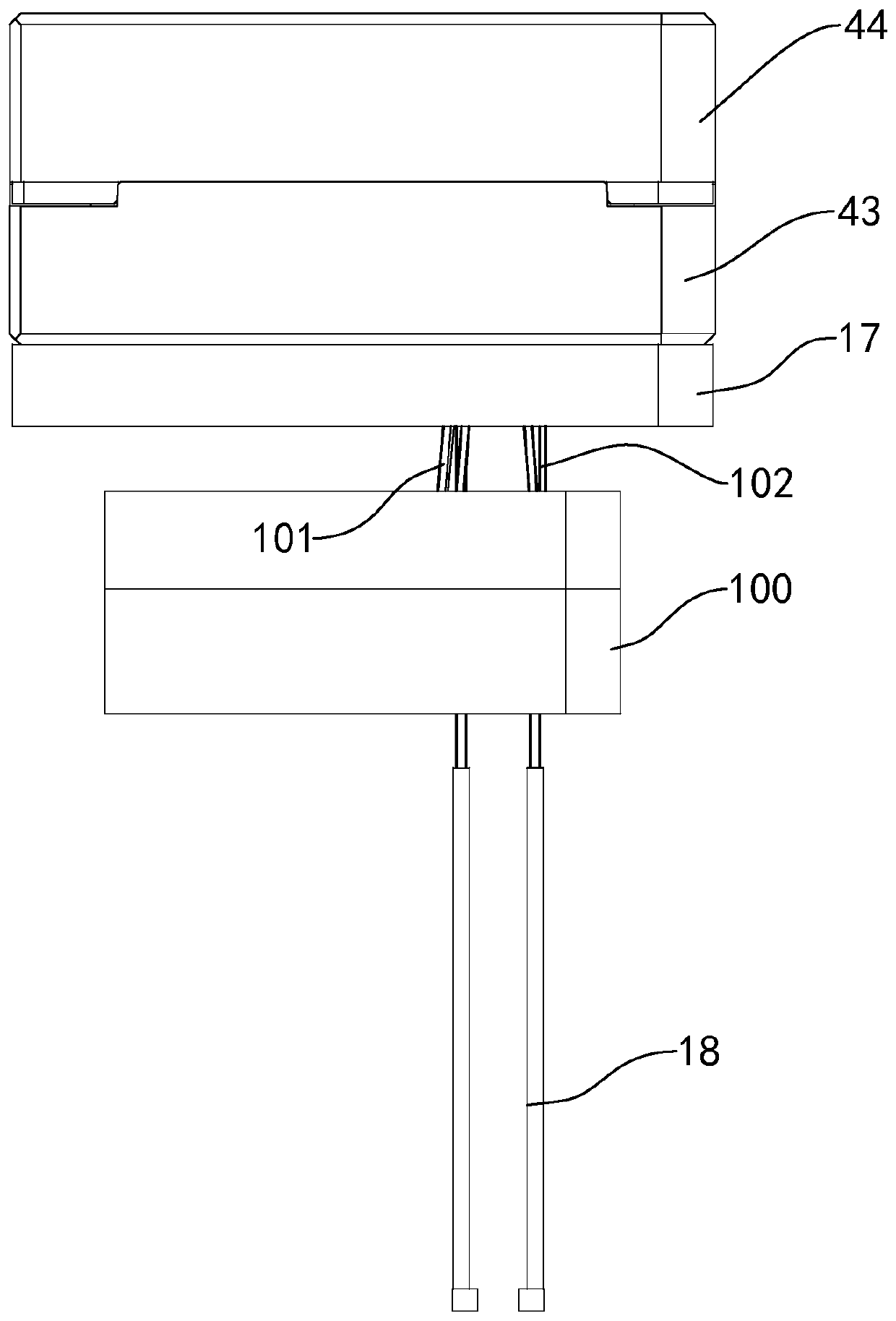

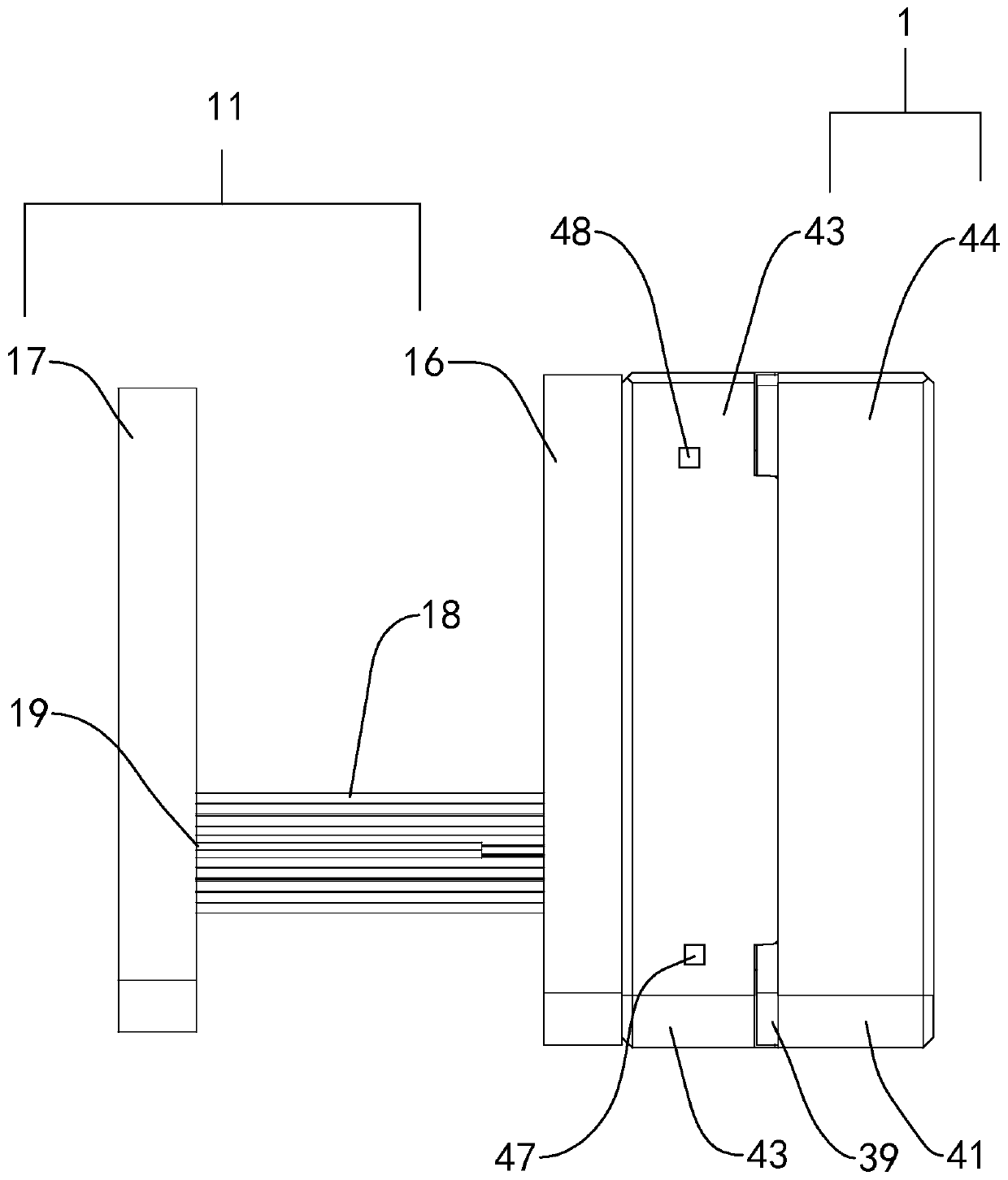

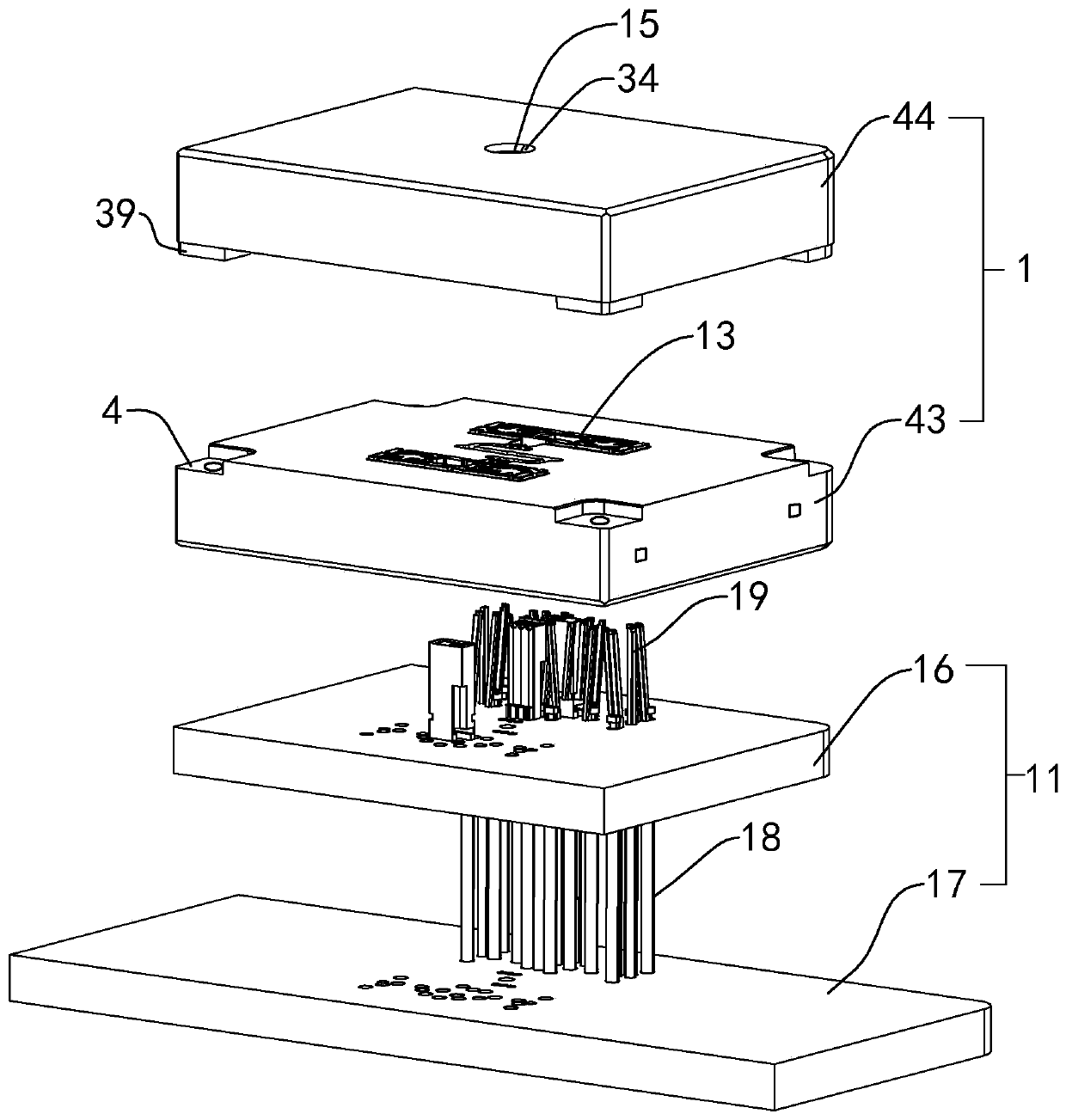

[0048] refer to figure 2 , a mold for demoulding keycaps with short oblique pins disclosed in the present invention, comprising an injection molding assembly 1 and a jacking assembly 11, the injection molding assembly 1 includes a fixed mold 44 and a moving mold 43 for forming a keycap, and the jacking assembly 11 includes Close to the top plate 16 of the movable mold 43 and the bottom plate 17 away from the top plate 16, the bottom plate 17 is provided with a plurality of ejector rods 18 and resisting rods 19 fixed on the bottom plate 17. The function of the ejector rods 18 and the resisting rods 19 is to help Keycap molding and automatic return of formed keycaps.

[0049] refer to image 3 and Figure 4 The upper molding cavity 12 is provided on the opposite surface of the fixed mold 44 and the movable mold 43, and the lower molding cavity 13 corresponding to the upper molding cavity 12 is provided on the movable mold 43. After the movable mold 43 and the fixed mold 44 ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com